Patents

Literature

32results about How to "Reduce the number of rolling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

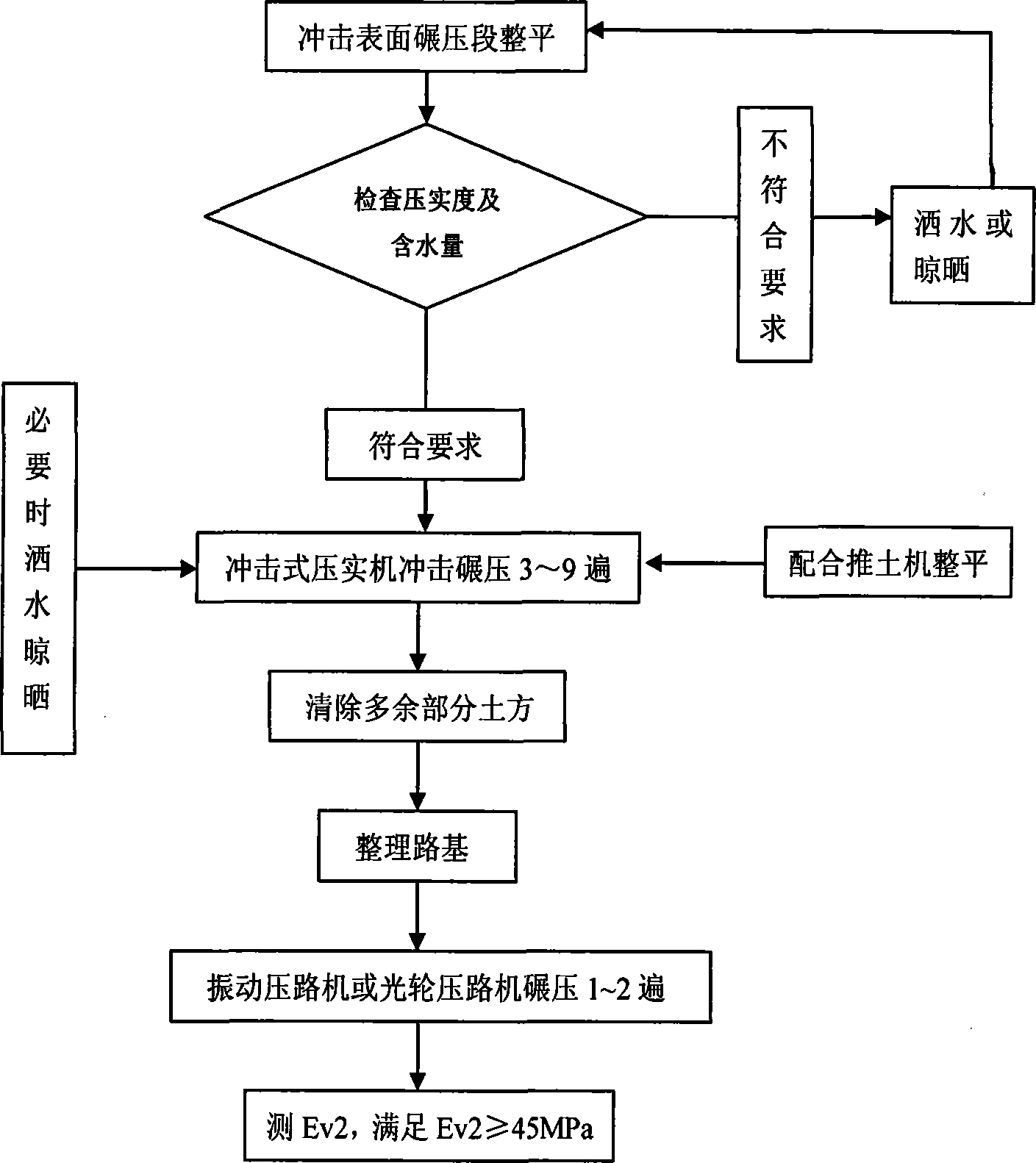

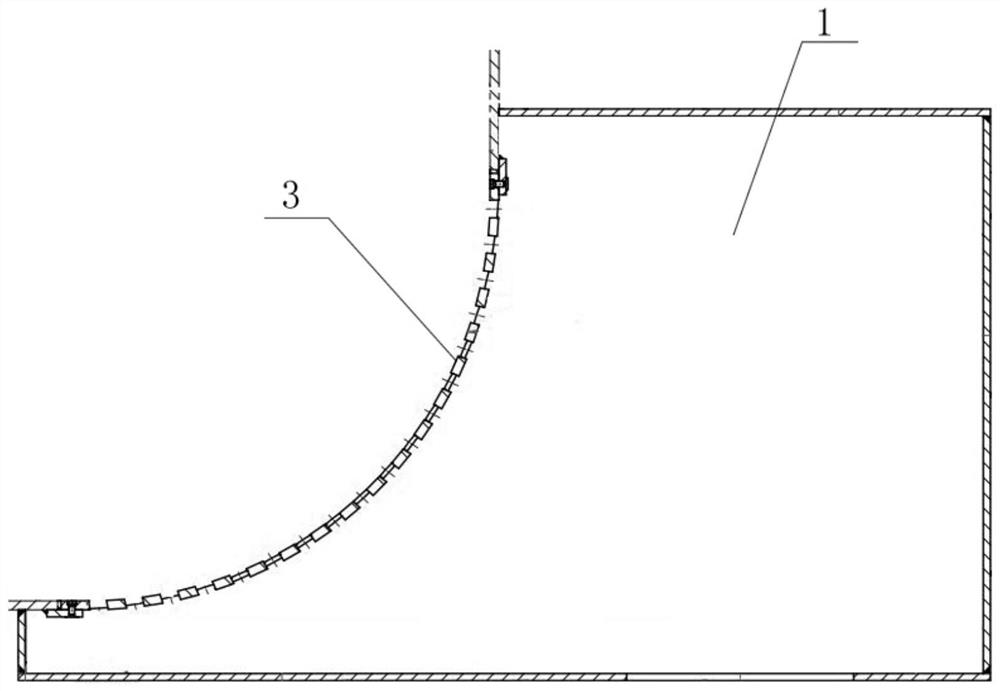

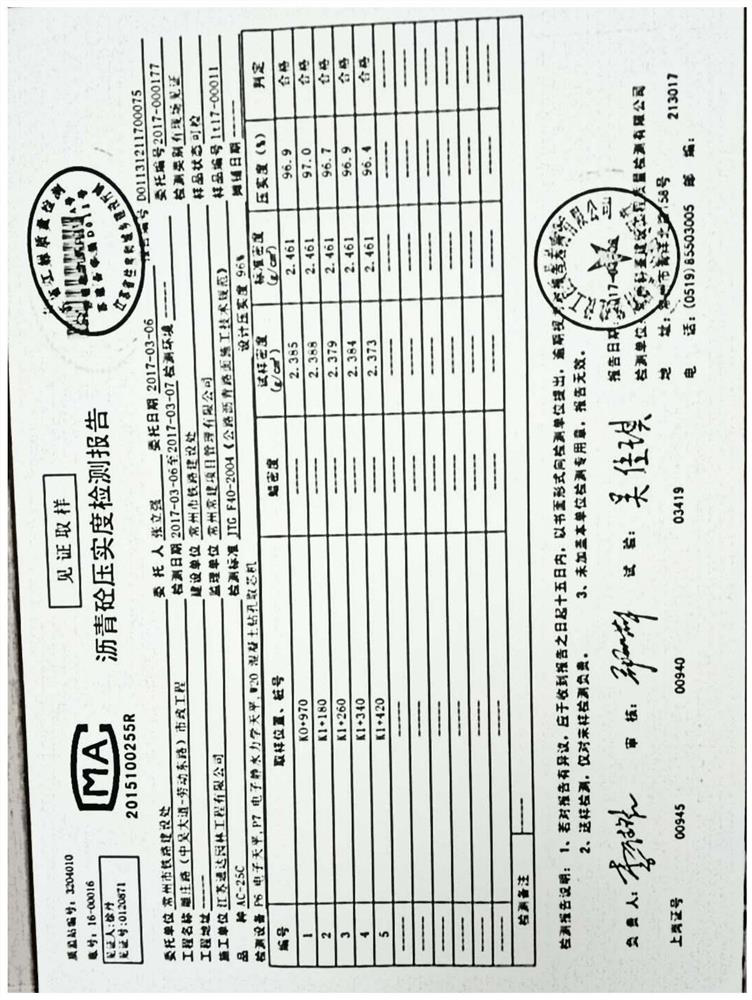

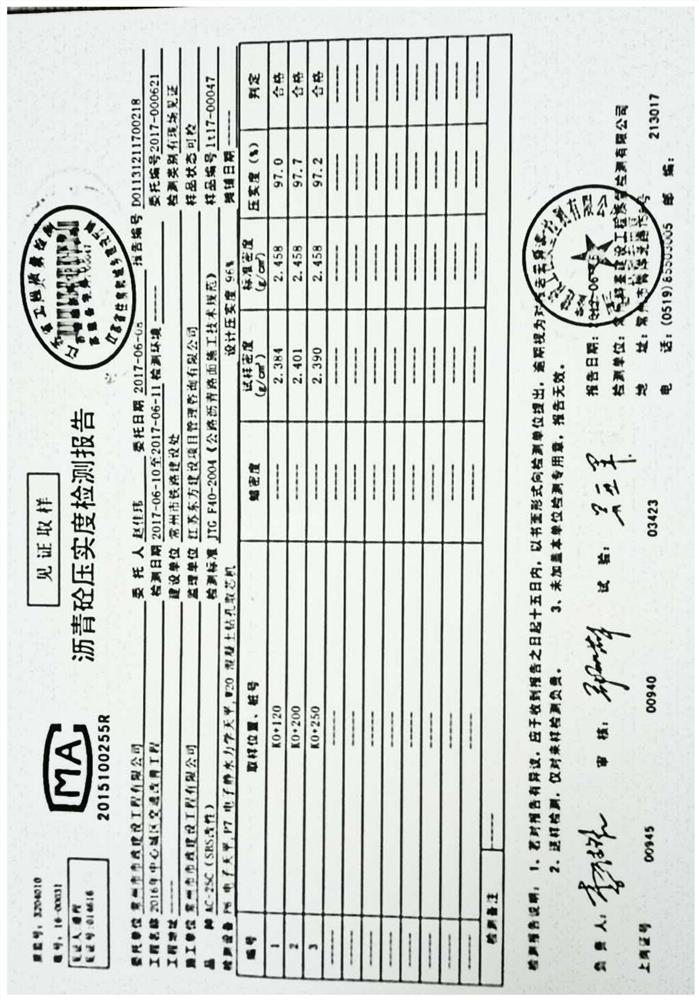

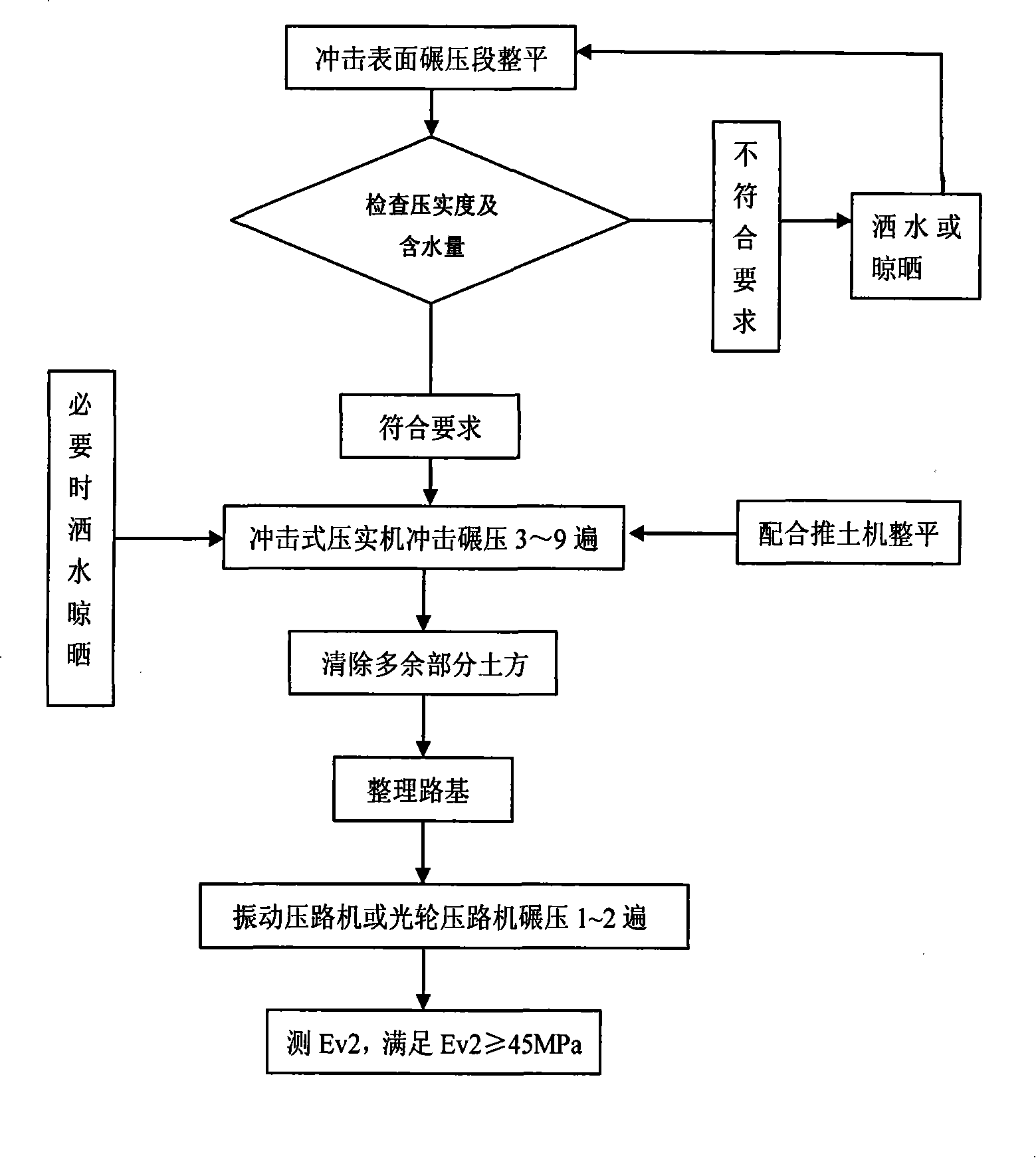

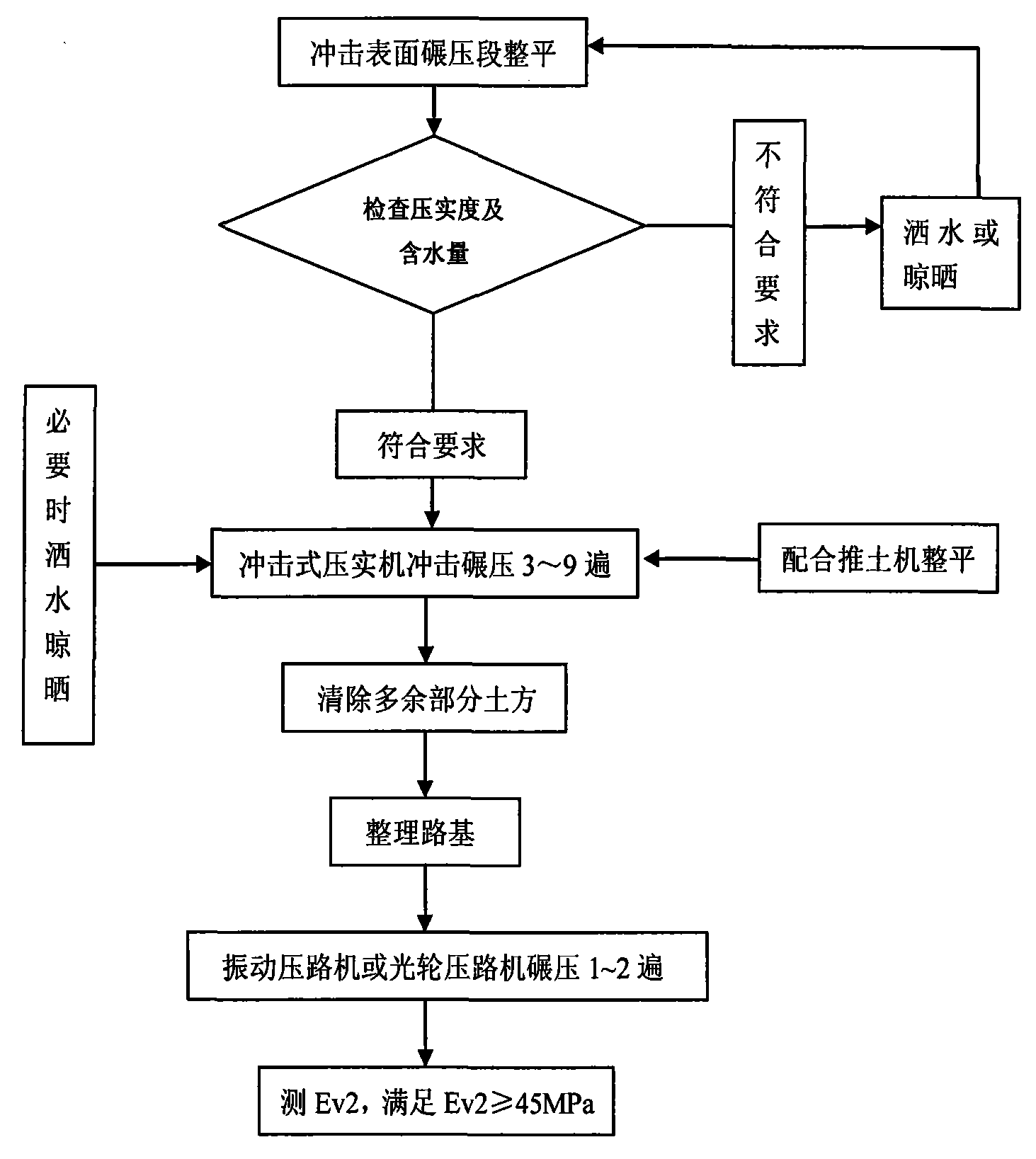

Construction method of impacting and rolling

The invention discloses an impact rolling construction method, belonging to the technical field of roadbed reinforcement construction, comprising the steps of leveling the surface of the impact rolling section, detecting the degree of compaction and water content, and when the degree of compaction and the water content of the surface of the impact rolling section are After the water content meets the design requirements, use an impact compactor to impact and roll 3 to 9 times, and at the same time use a bulldozer to level it, remove excess earthwork, arrange the roadbed, and use a vibratory roller or smooth wheel roller to roll 1 to 2 times. The secondary deformation modulus Ev2 value of the foundation soil after impact rolling; the present invention accurately limits which geological conditions are suitable for the impact rolling reinforcement construction method, more fully exerts the effect of impact rolling, and greatly reduces the impact of rolling. The number of times of rolling is generally 3 to 9 times. The detection index after rolling reaches the German high-speed railway foundation standard, which reduces the project cost and speeds up the project progress. The present invention is especially suitable for the foundation reinforcement construction of high-speed railways and highways.

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD

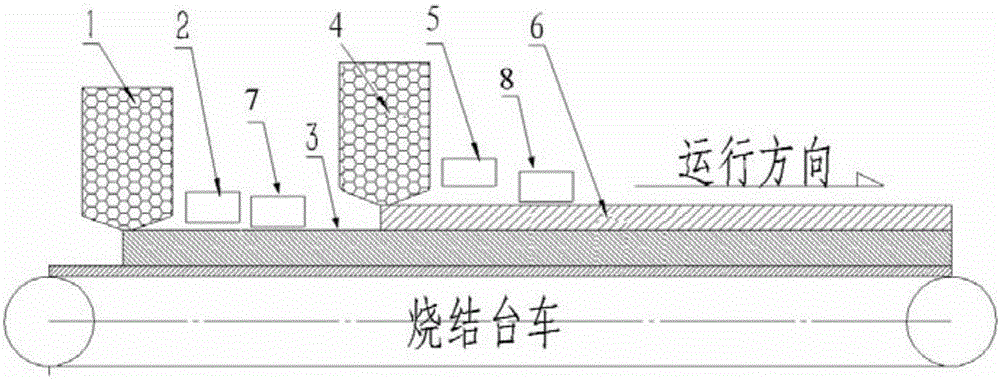

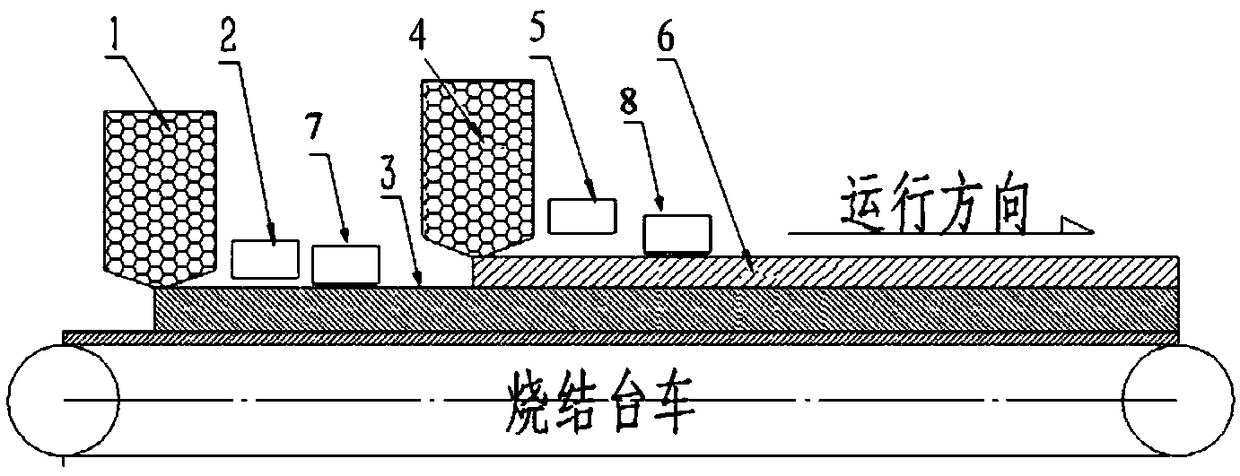

Ultra-thick bed sintering method for reducing sinter return ratio and employing presintering

The invention discloses an ultra-thick bed sintering method for reducing sinter return ratio and employing presintering; ignition temperature is optimized, a suitable amount of insulation covers are provided, high-oxygen hot air is introduced, surface ignition quality of upper and lower beds of sinter can be effectively improved, mineralizing time of surface sinter can be extended, and cold brittleness of the sinter is reduced; through reasonable coal allocation and water regulation for the upper bed of sinter mixture and reducing the amount of rolls of a distributor, better breathability is provided for the upper bed of sinter mixture; according to the features of the upper bed of mixture, bed combustion and particle size deviating is inhibited, and the bed never combusts too fast; through comprehensive technical means, it is possible to effectively decrease the return ratio of the upper bed of sinter and the whole bed of sinter.

Owner:ANGANG STEEL CO LTD

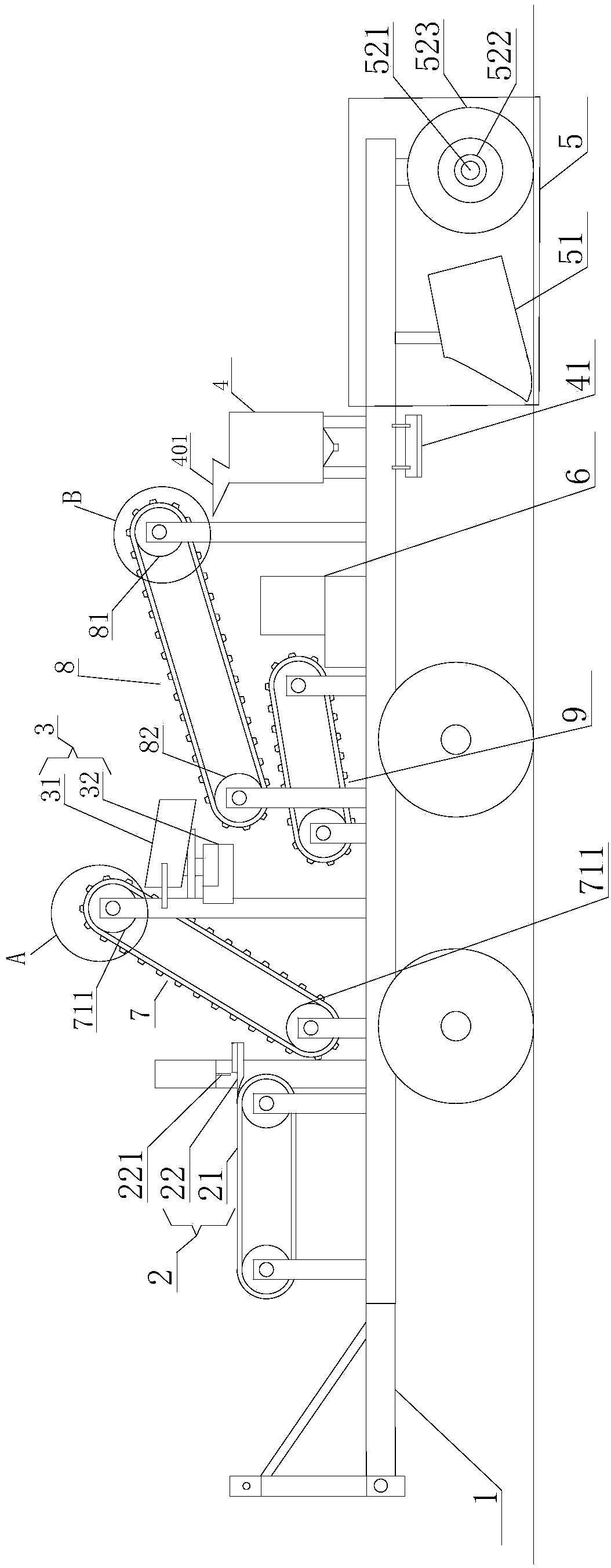

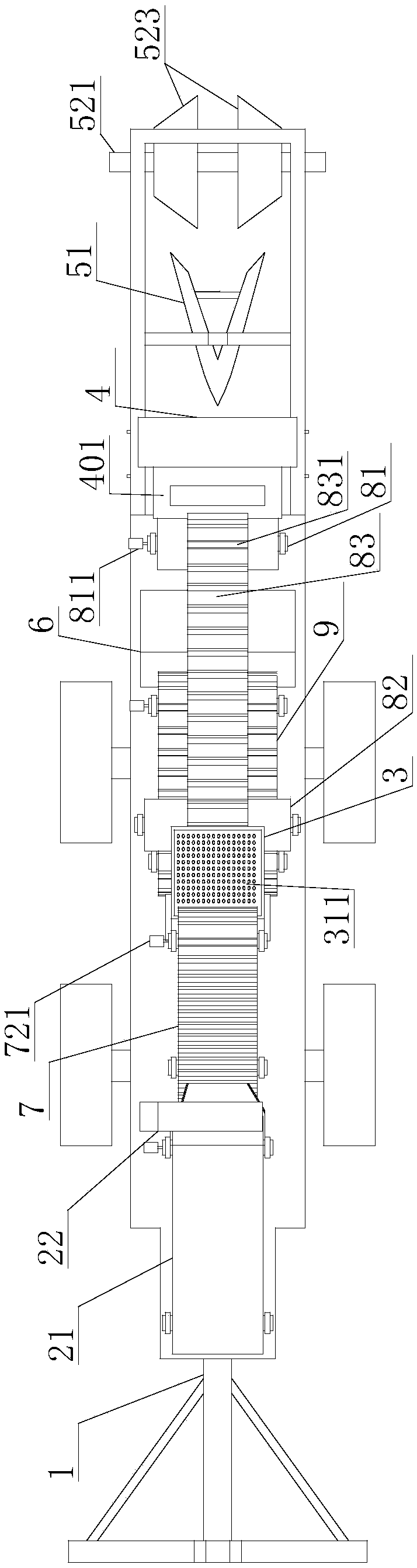

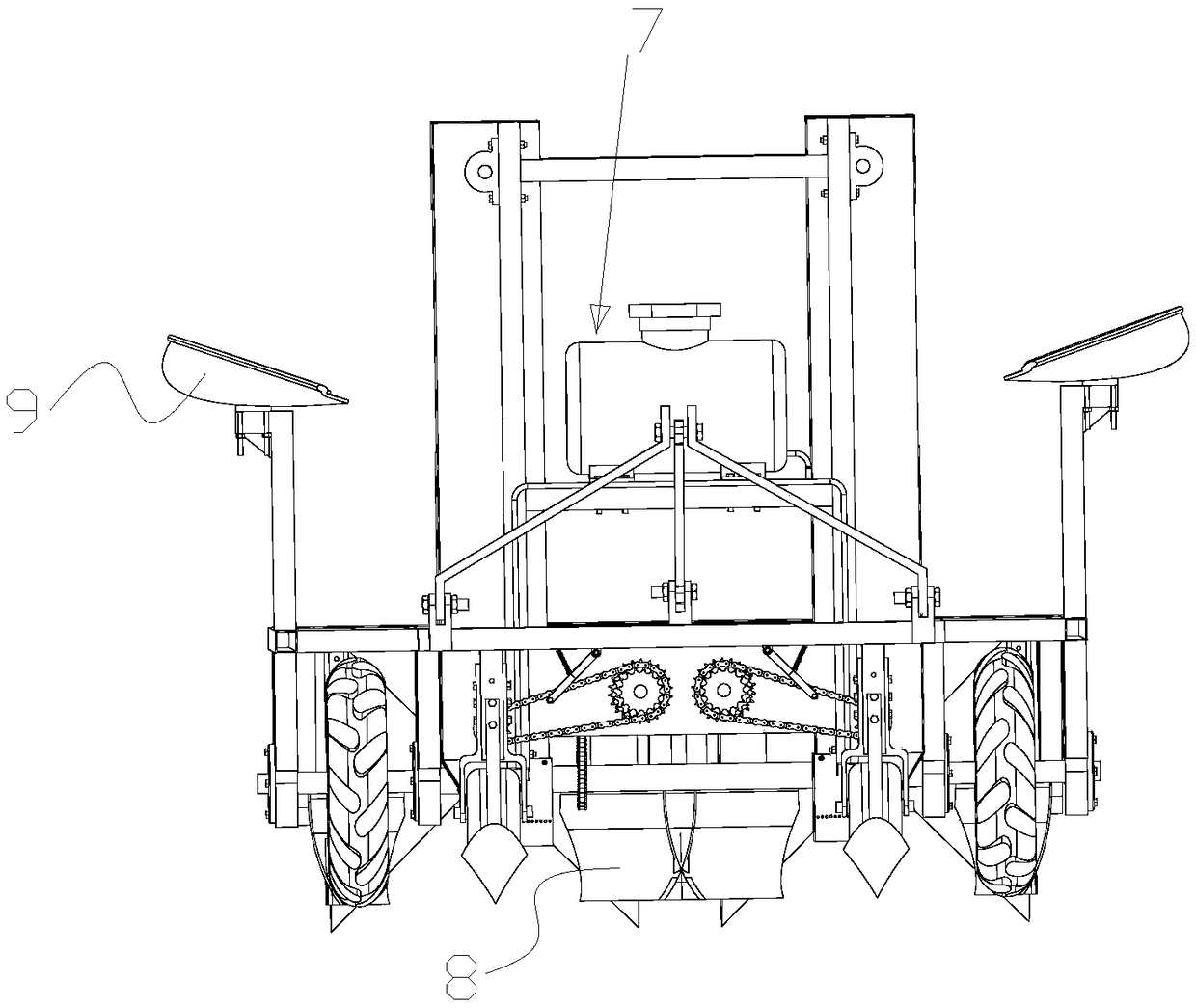

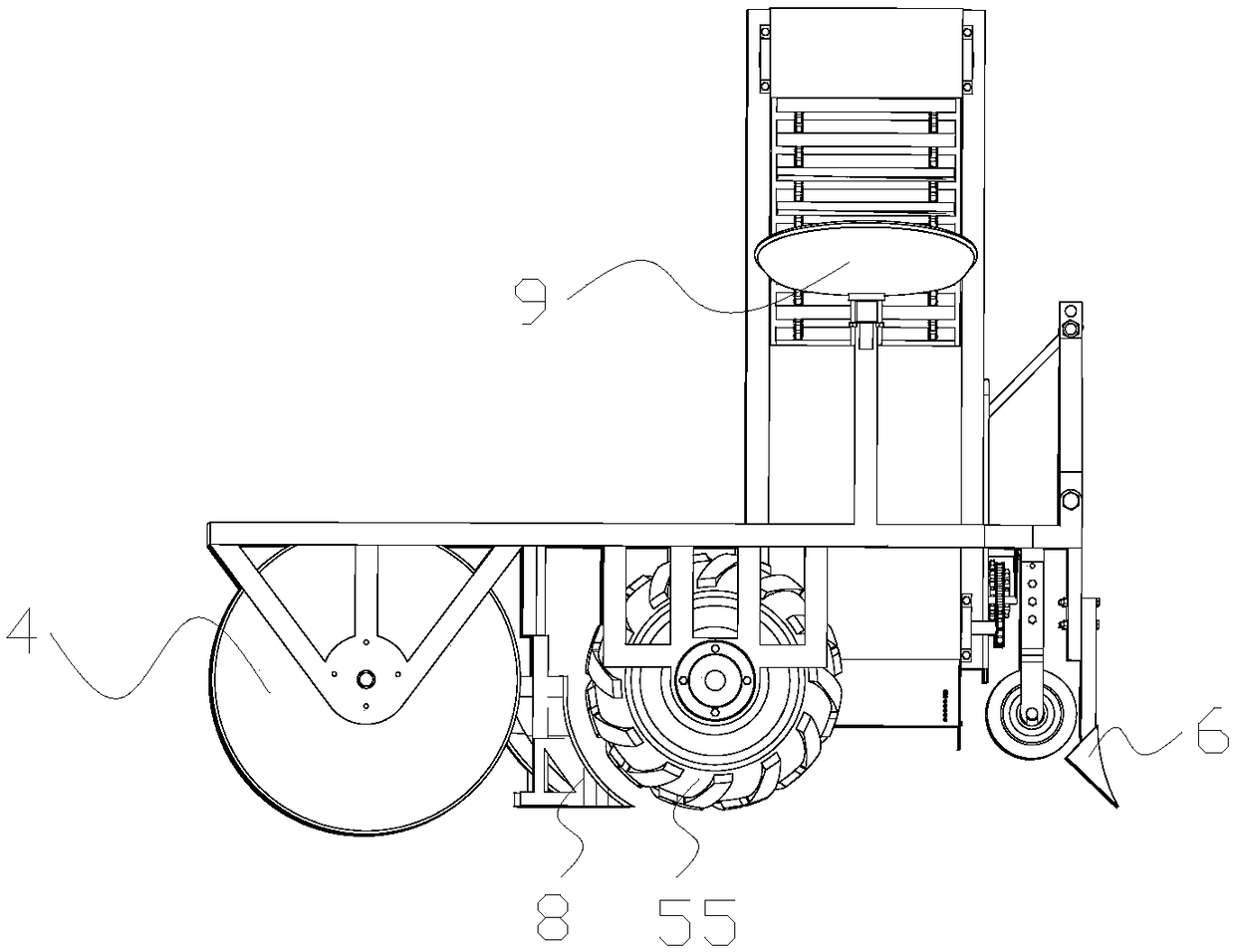

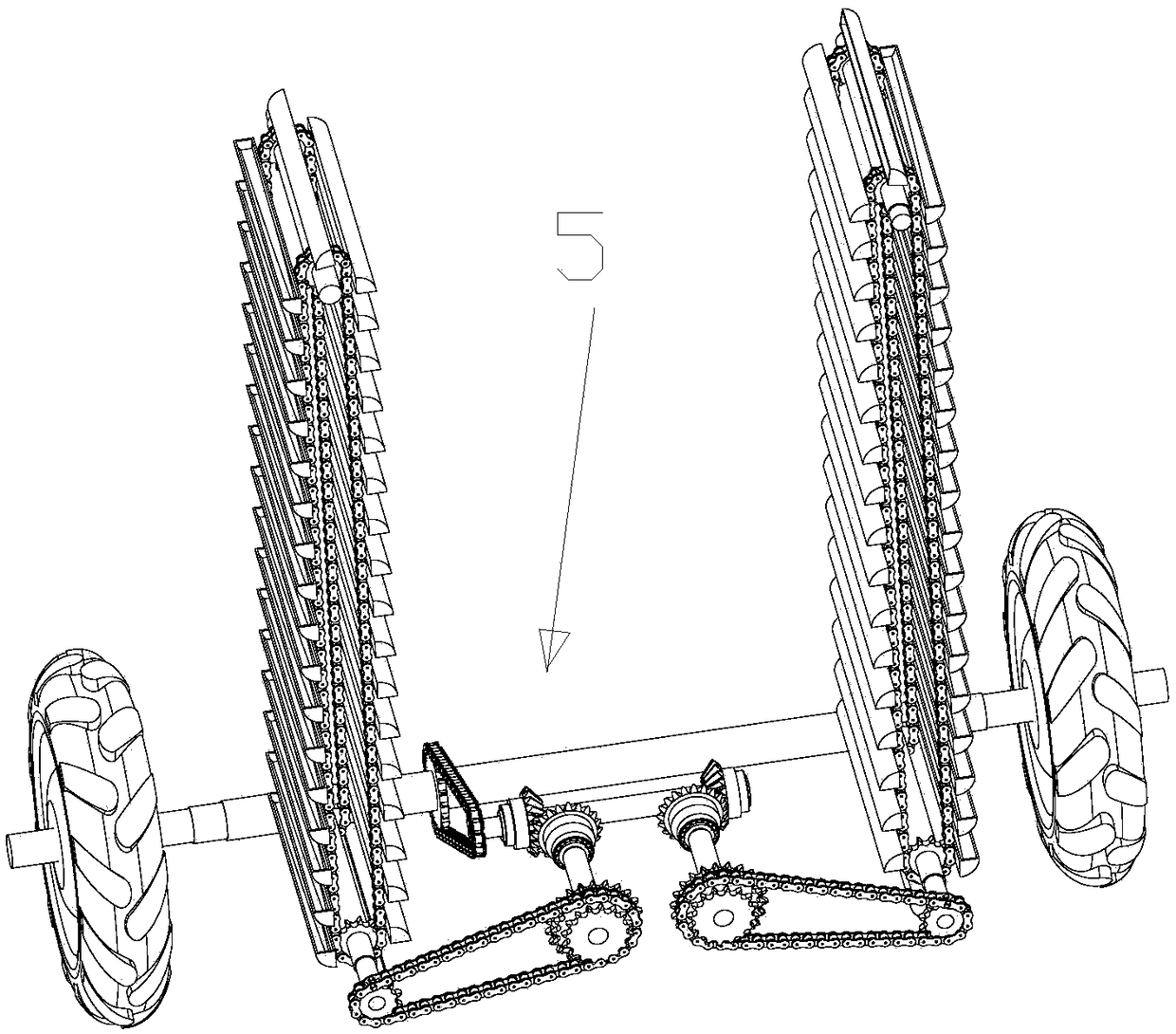

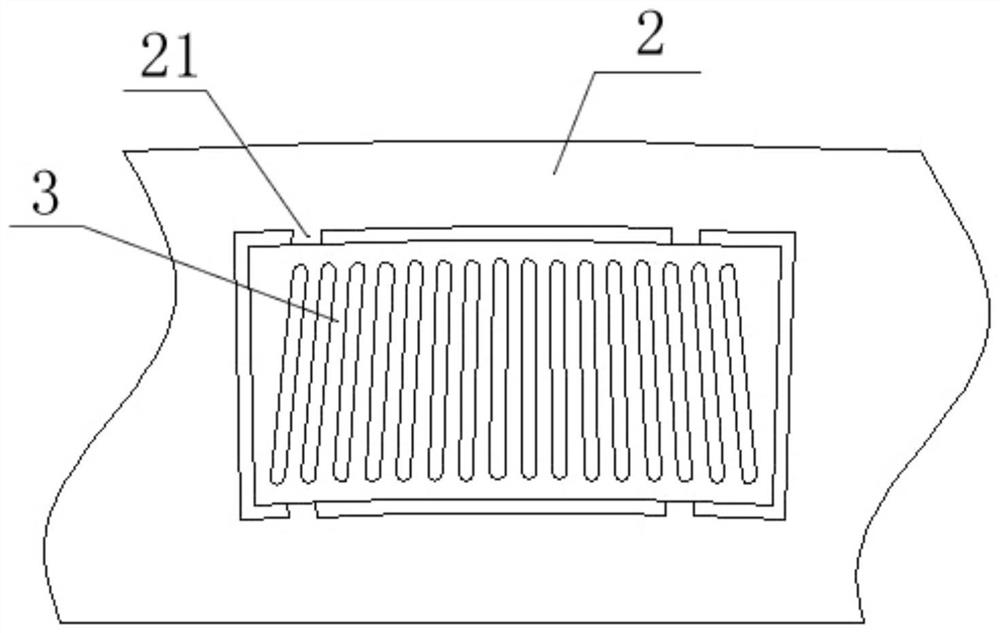

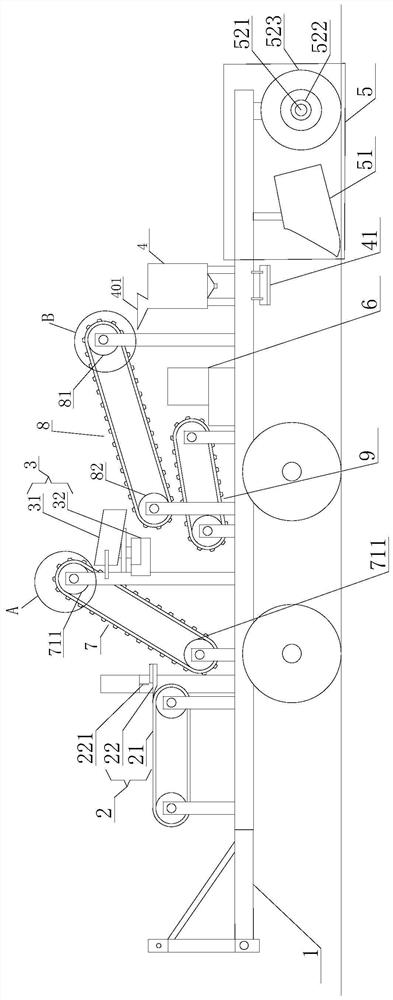

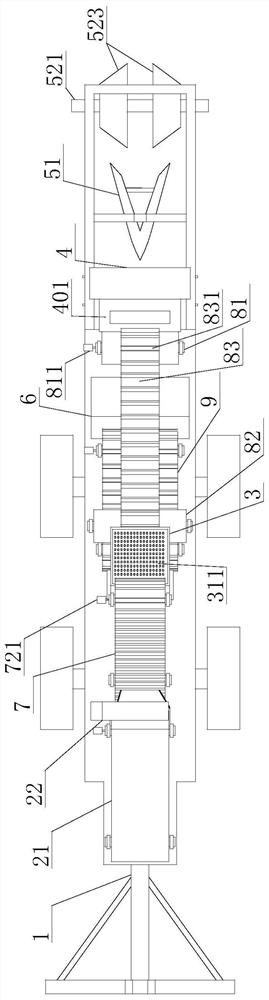

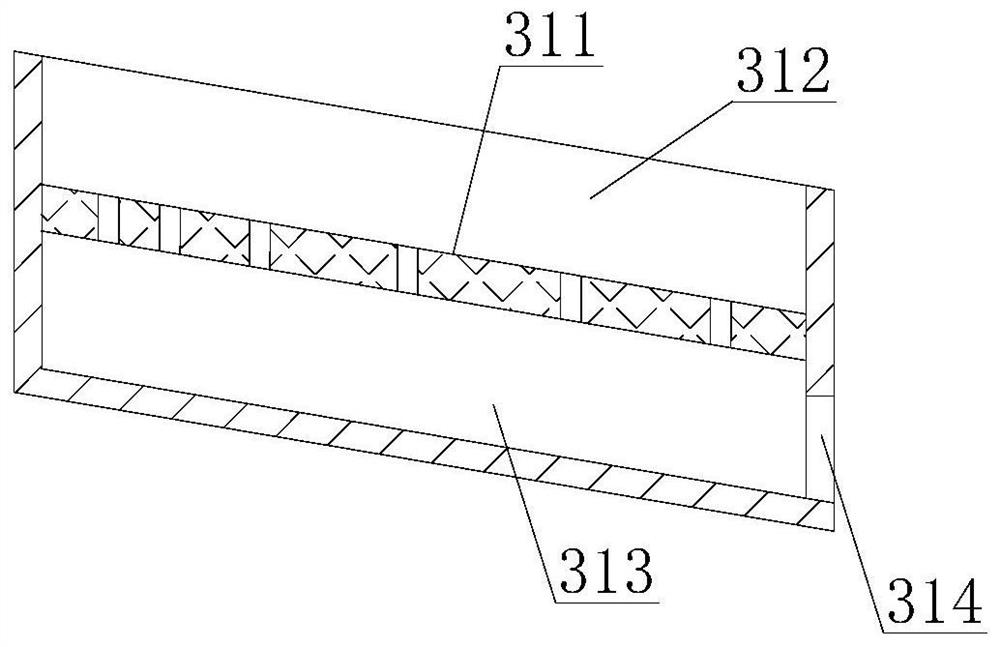

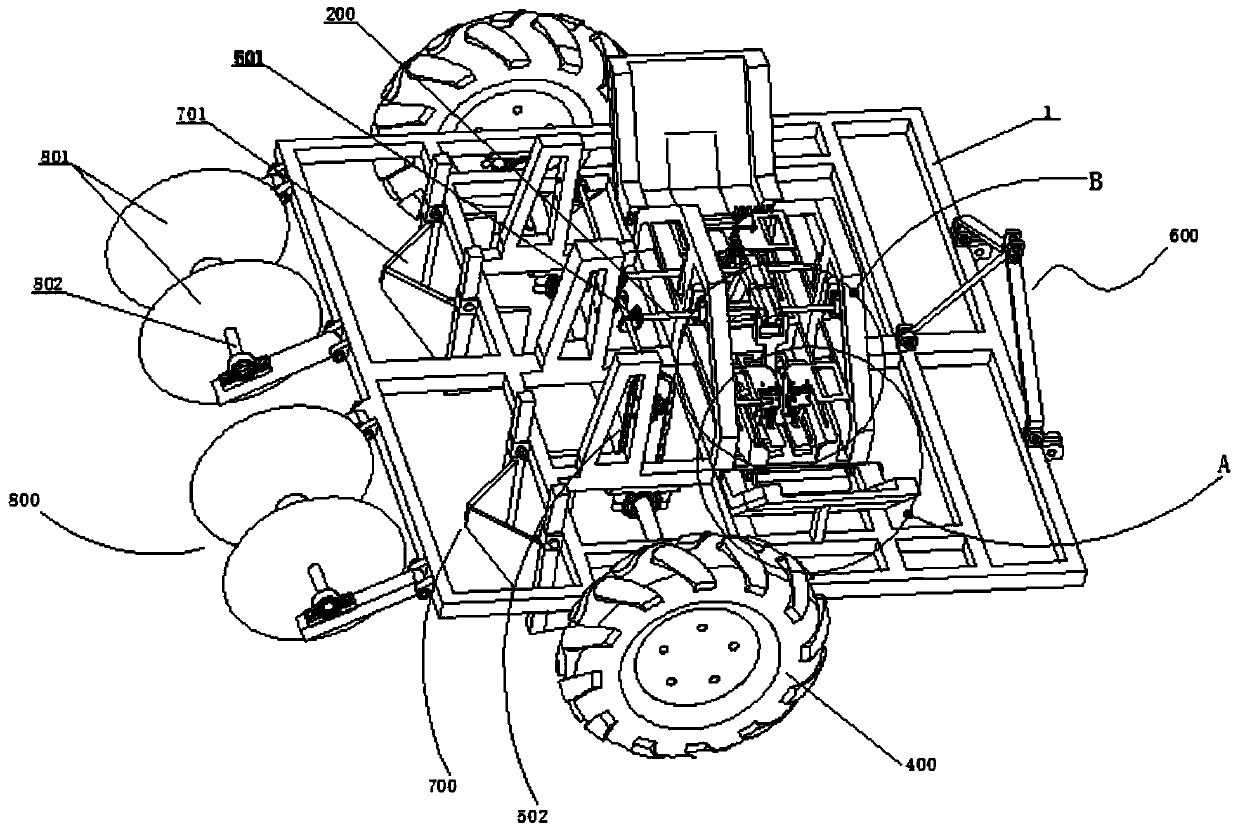

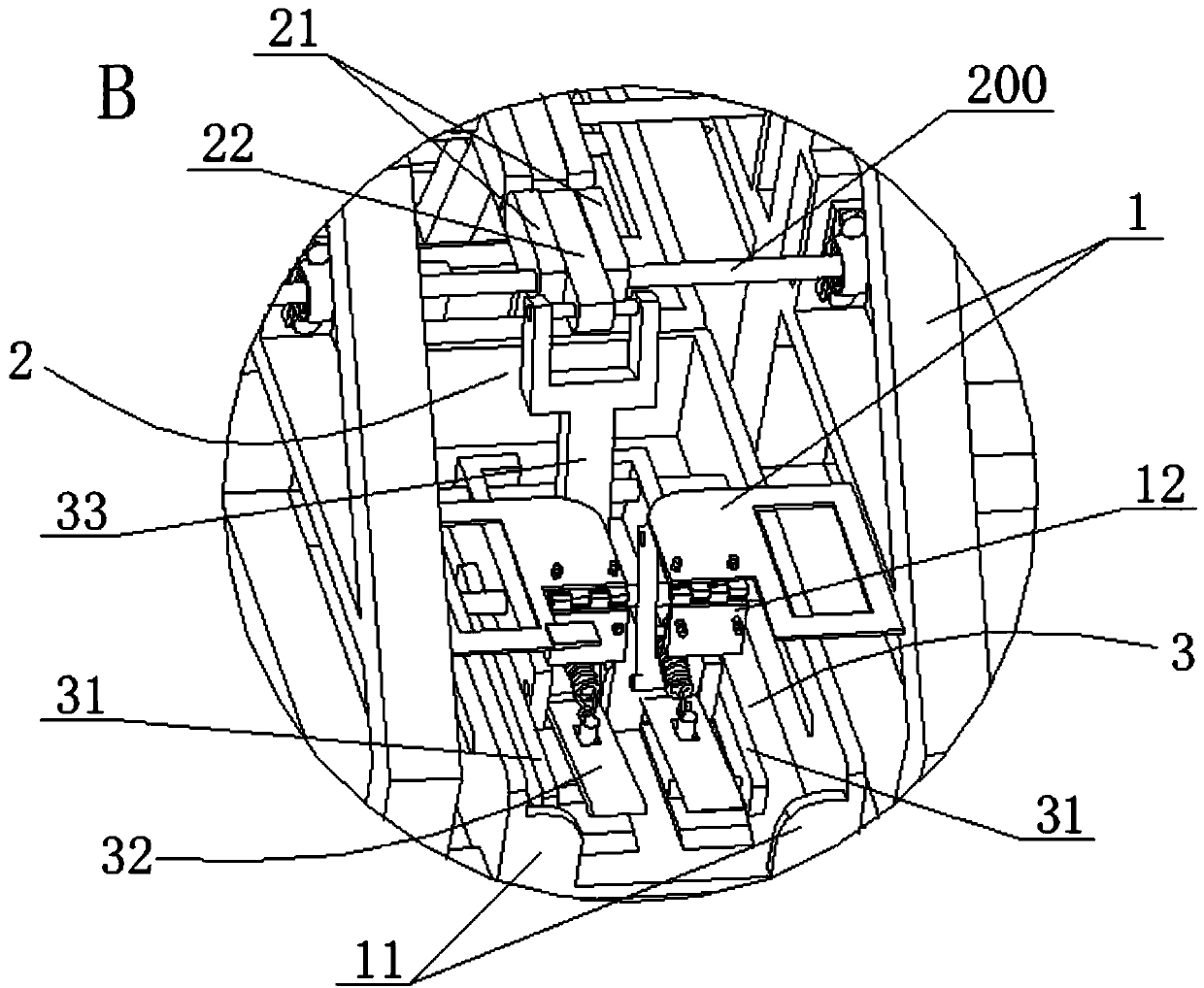

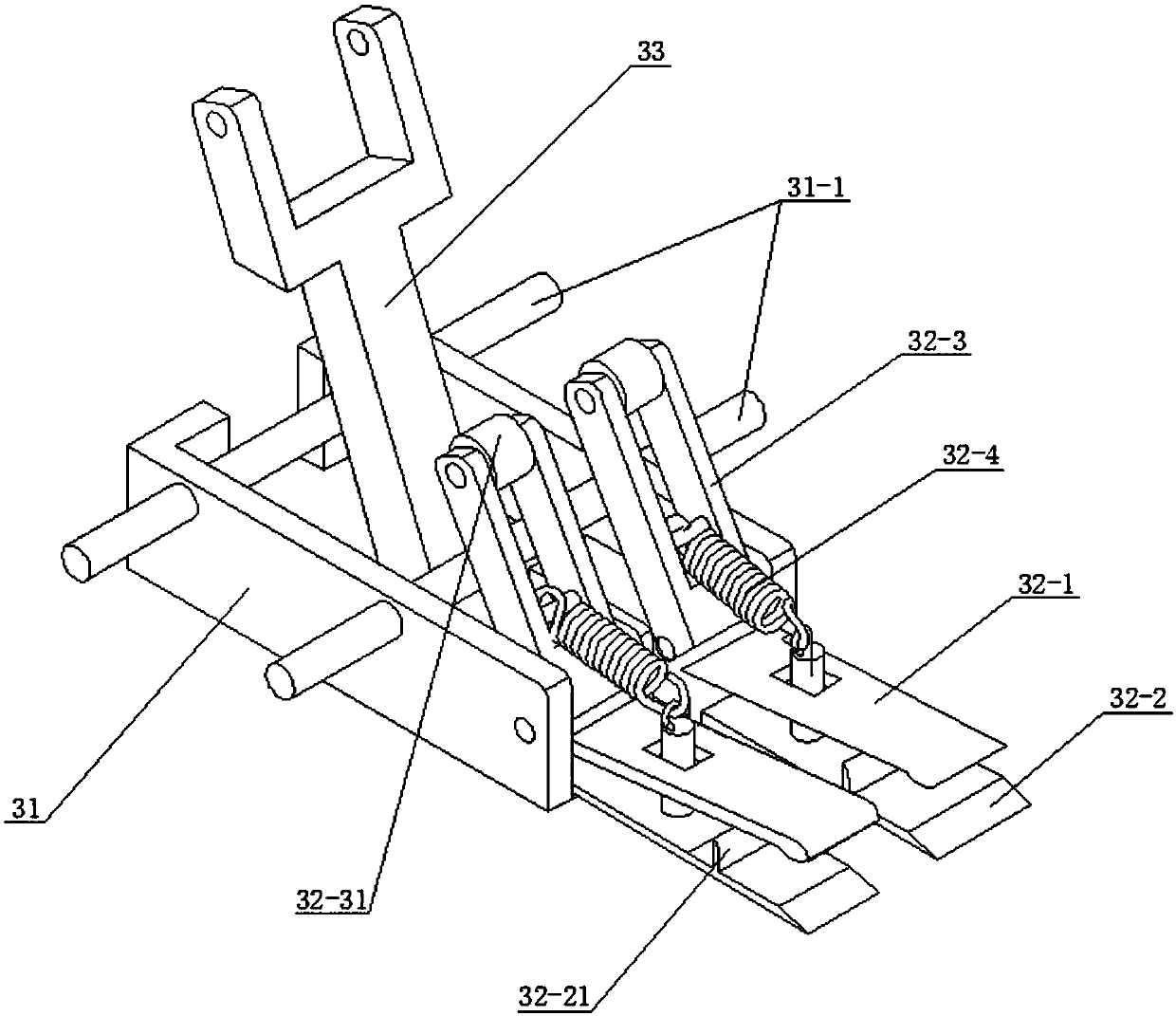

Corn stalk treatment device and method

ActiveCN108617268AReduce the number of rollingShorten the timeSpadesSievingEngineeringMechanical Treatments

The invention relates to the technical field of mechanical treatment of corn stalks and in particular relates to a corn stalk treatment device and method. The corn stalk treatment device comprises a moving chassis moving in a farmland as well as a cutting mechanism, a screening mechanism, a smashing mechanism, a returning mechanism and a briquetting mechanism which are mounted on the moving chassis. Corn stalks in the farmland are smashed and screened by the cutting mechanism, the screening mechanism, the returning mechanism and the like are arranged on the moving chassis, and then, corn sections are returned and packaged, so that the technical problem that no devices for collecting and returning the corn stalks at one time are provided in the prior art is solved.

Owner:XUZHOU UNIV OF TECH

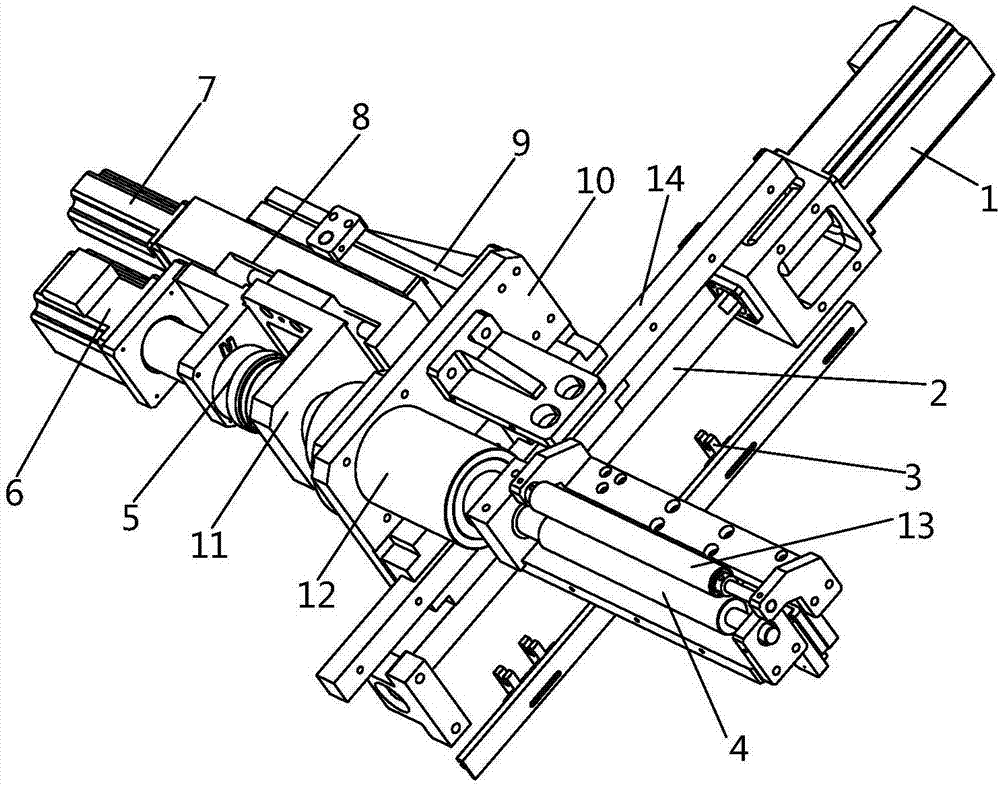

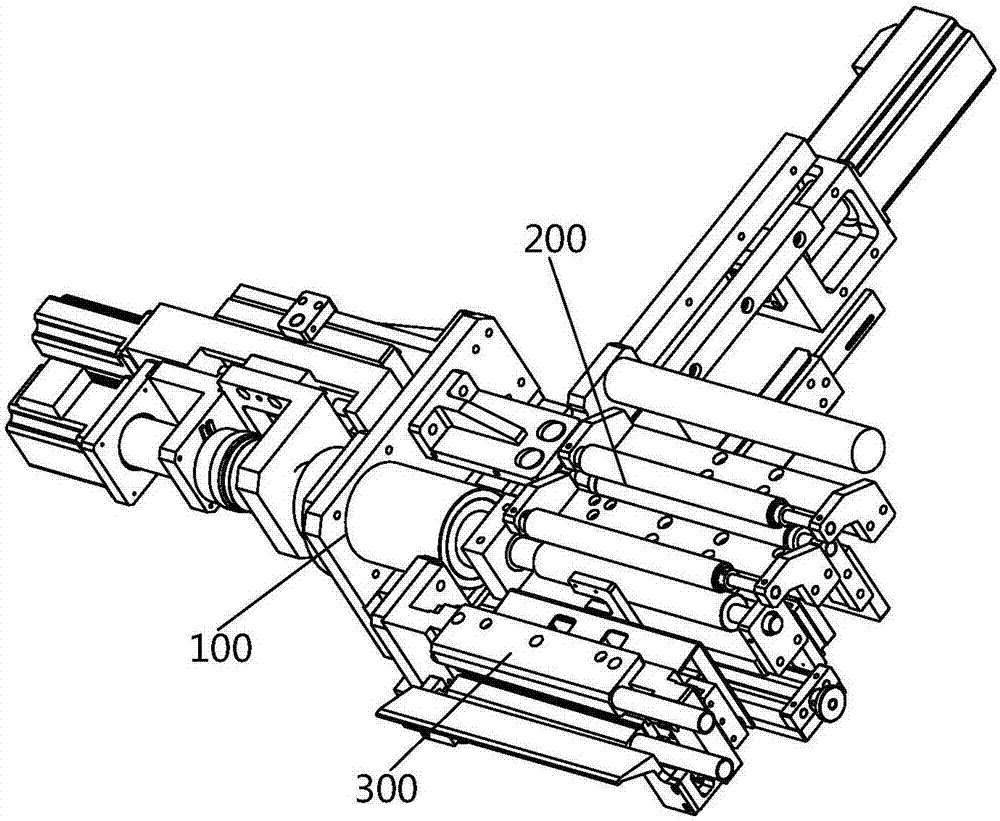

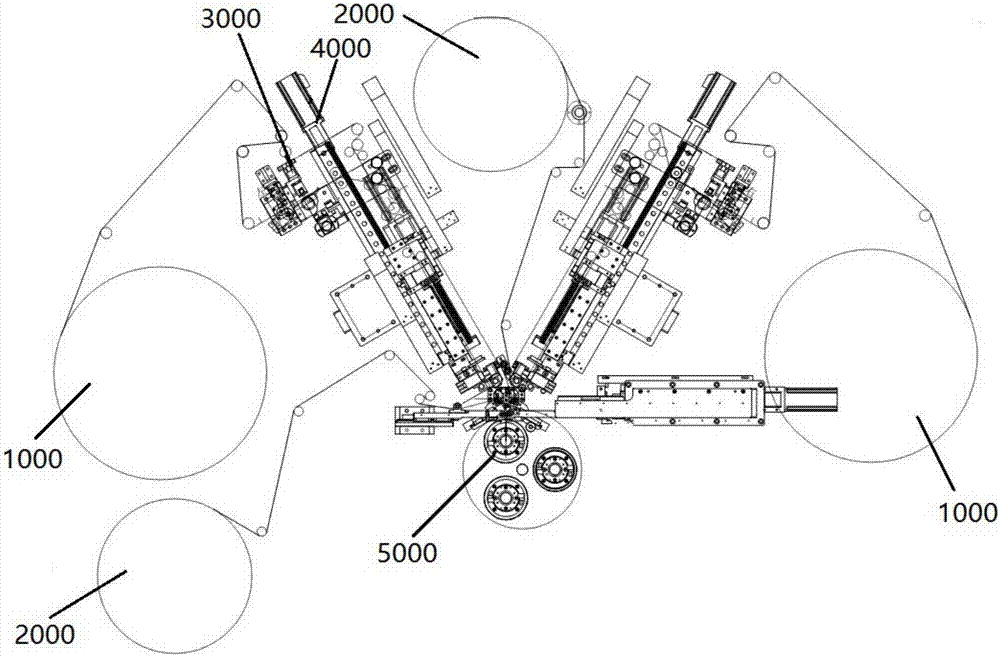

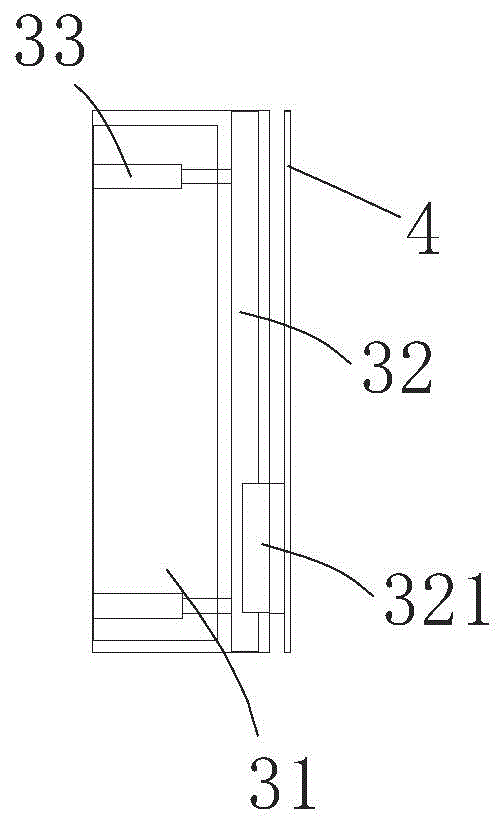

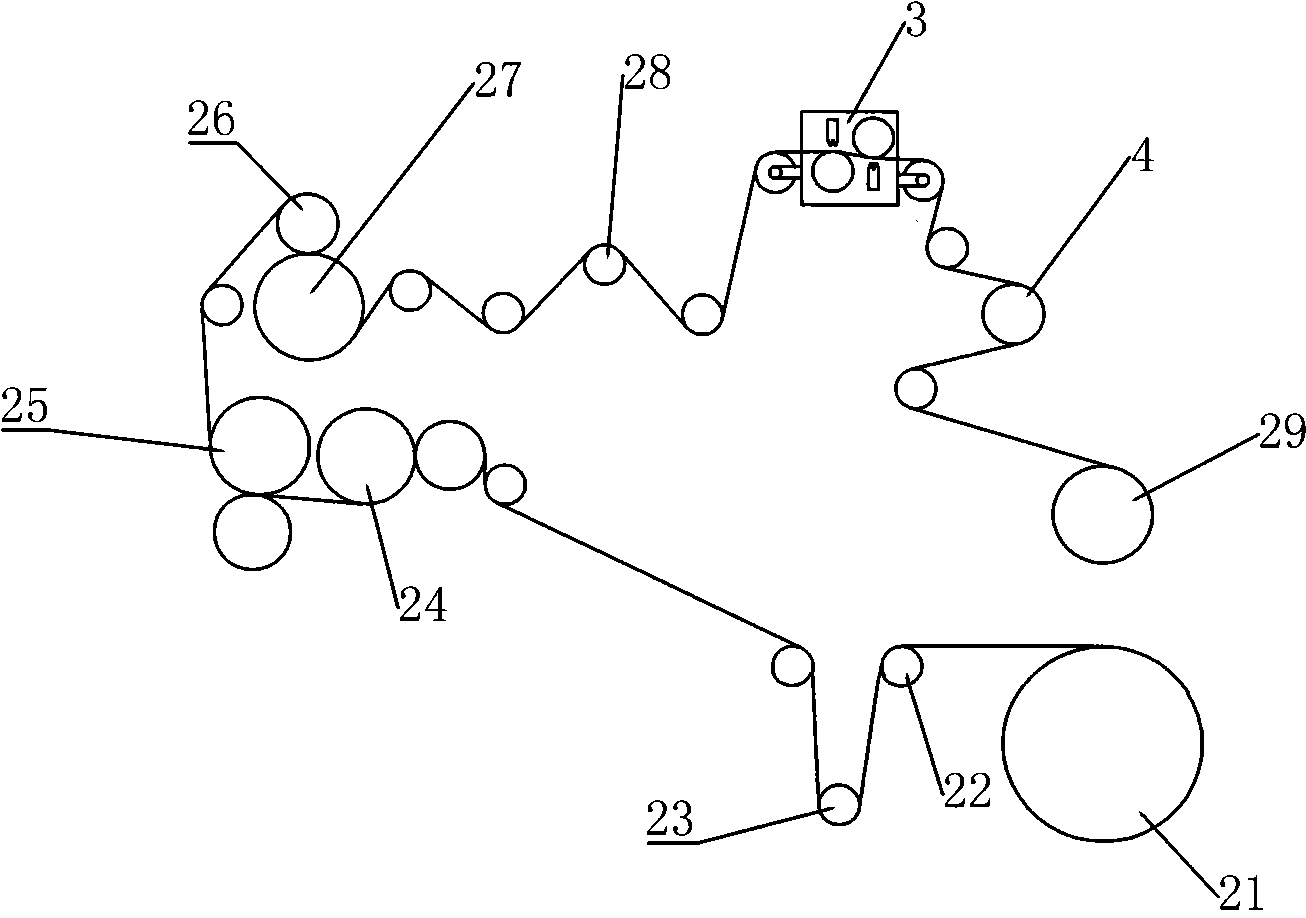

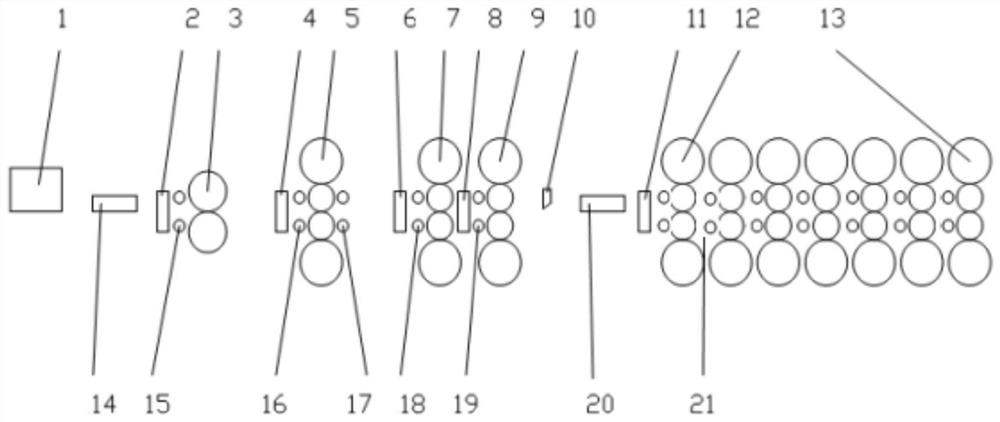

Pole piece conveying deviation rectification compound manipulator device and implementation method

PendingCN107123826AReduce the number of rollsReduced effective distanceAssembling battery machinesFinal product manufactureWinding machinePole piece

The invention relates to a pole piece conveying deviation rectification compound manipulator device. The manipulator device consists of a compensation unit driven by a servo motor I, a pole piece conveying unit driven by a servo motor II and a deviation rectification unit driven by a servo motor III, wherein the servo motor I drives a screw rod to rotate to drive the deviation rectification unit and the pole piece conveying unit to move towards the lower forward direction to a limiting position of a sensor; the servo motor III drives a linear module to drive the pole piece conveying unit to move forwards and backwards, so as to pull a pole piece to move forwards and backwards to keep the edge of the pole piece at a value range set by a program. The pole piece conveying deviation rectification compound manipulator device has the beneficial effects that by recombination of pole piece conveying and pole piece deviation rectification, an effective distance between a winding mechanism in winding machine equipment and a deviation rectification mechanism is shortened as much as possible; moreover, the quantity of rollers through which the pole piece passes from the deviation rectification mechanism to the winding mechanism is reduced, so that control over the pole piece alignment degree is further increased.

Owner:东莞市联德企业管理有限公司

Construction method of highway asphalt pavement

ActiveCN102011360AIncreased durabilityPrevent intrusionIn situ pavingsRoads maintainenceEngineeringRoad surface

The invention relates to a construction method of a highway asphalt pavement with long service life, which is suitable for ensuring highway quality. The construction method comprises the following steps: carrying out initial rolling by using a tyre roller: the tyre roller rolls 2-3 times after a spreading machine, and the temperature of the pavement is 120-150 DEG C in the rolling process; and finishing final rolling by using the steel roller. In order to prevent the material from attaching to the tyres, the temperature of the pavement is kept above 100 DEG C when the tyre roller is used for finishing initial rolling. Since the temperature of the pavement during initial rolling is high and the kneading amplitude of the tyres is high, the weight of the tyre roller can be properly reduced, and the design requirement for pavement compactness can be satisfied only by rolling 2-3 times. The rolling quality of the pavement is determined by temperature. Asphalt in the materials can easily form a thick seal oil film layer on the pavement, thereby preventing the invasion of water, mud and air, being beneficial to preventing the pavement from being damaged by water and enhancing the durability of the pavement.

Owner:宗焕清

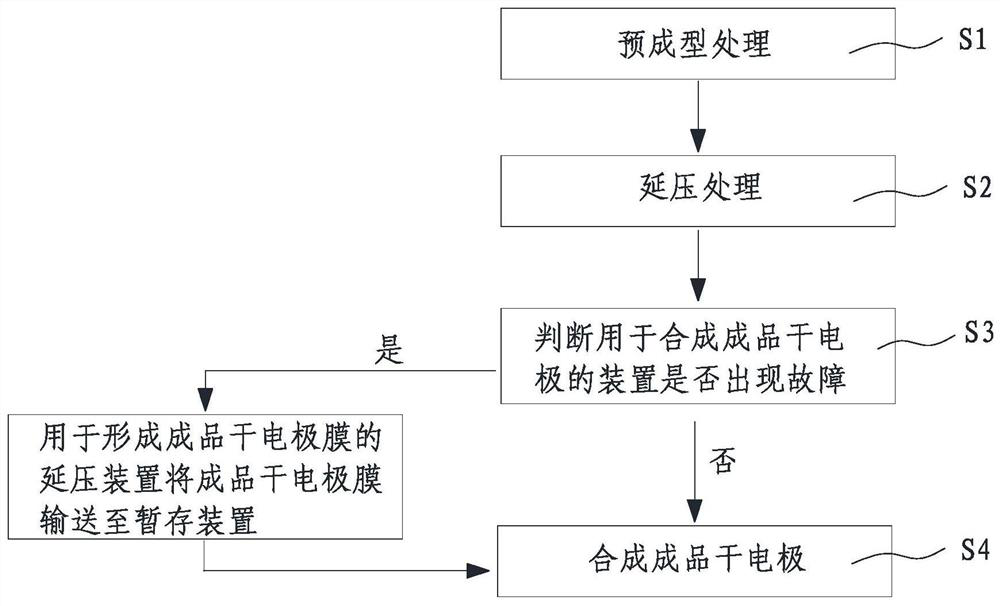

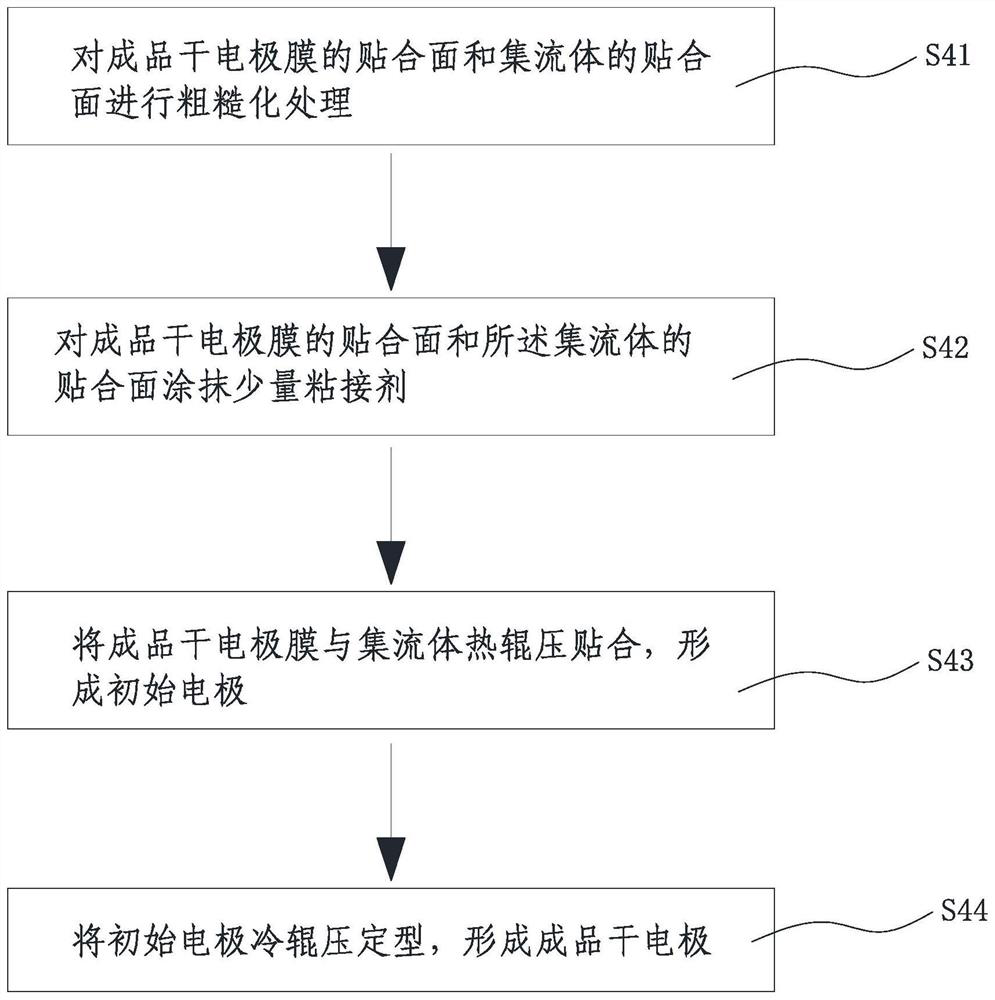

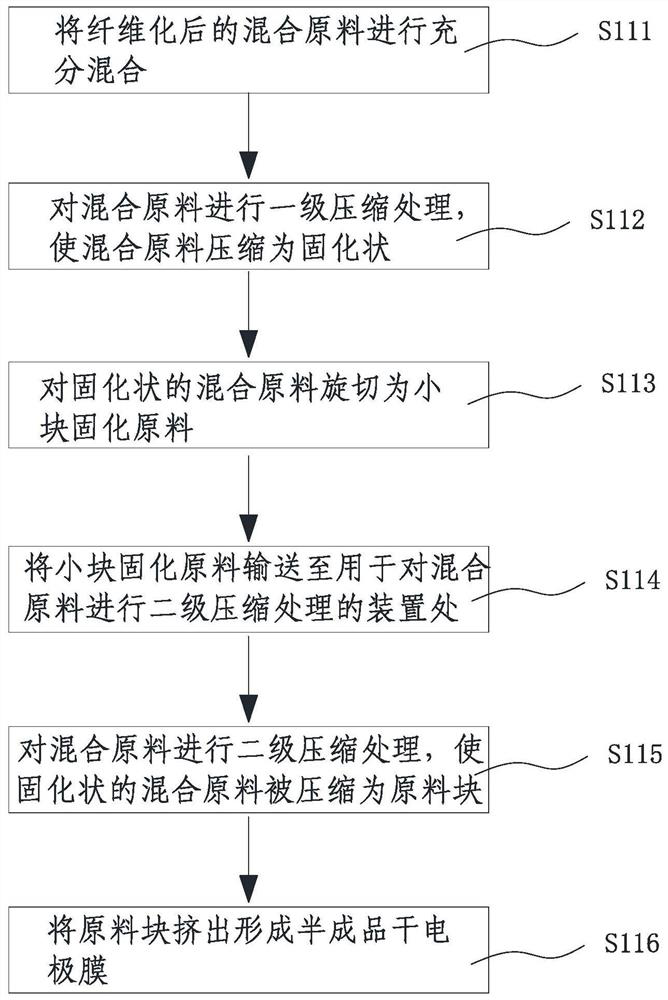

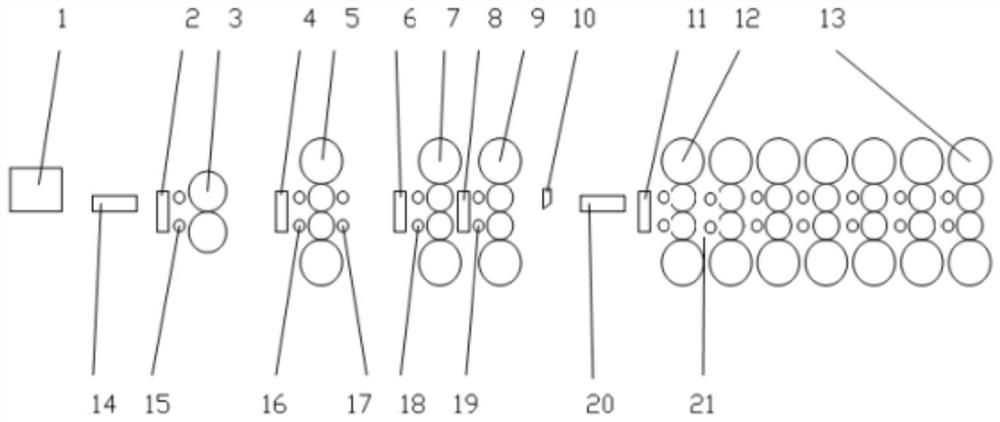

Dry-method electrode preparation method and battery production line

PendingCN114122309AAvoid breakingImprove production efficiencyElectrode manufacturing processesProduction lineElectrical battery

The invention provides a dry-method electrode preparation method and a battery production line, and the method comprises the steps: carrying out pre-forming treatment: carrying out pre-forming treatment on a mixed raw material, and enabling the mixed raw material to form a semi-finished product dry electrode film with self-supporting performance; calendering treatment: carrying out calendering treatment on the semi-finished dry electrode film to enable the semi-finished dry electrode film to form a finished dry electrode film; and synthesizing a finished product dry electrode, and laminating the finished product dry electrode film and a current collector in a rolling manner to form the finished product dry electrode. A semi-finished dry electrode film with self-supporting property is formed by performing pre-forming treatment on a mixed raw material, then a finished dry electrode film is formed by rolling treatment, and the finished dry electrode film and a current collector are synthesized into a finished dry electrode by rolling, so that the problem that the electrode film is easy to break in the preparation process is effectively solved; and the semi-finished dry electrode film does not need to be rolled for multiple times, so that the rolling times are reduced, and the manufacturing efficiency of the dry electrode is improved.

Owner:三一技术装备有限公司

Environment-friendly type concrete modifier

The invention discloses an environment-friendly type concrete modifier, which is prepared by the following raw materials by weight: 2.5-3.8 parts of acrylic acid ester functional compound, 1.5-2.8 parts of polycarbonate, 2.5-3.2 parts of organic amine lignin; 2.5-3.3 parts of alkali lignin, 0.8-1.7 parts of benzenecarboxylic acid, 0.7-2.5 parts of carrageenan, and 2-4 parts of borax. Compared with the prior modifier, acrylic acid ester functional compound, benzenecarboxylic acid and carrageenan are added in an asphalt mixture production process, so as that a lubrication high-molecular chain-shaped structure is formed in a cementation material after addition, mixing and grinding temperature of a mixture is greatly reduced, and energy consumption is saved; pavement has good quality, and has a good high temperature rut resistant capability, a water damage resistant capability and an ageing resistance; and the raw materials have advantages of low cost, small smog and gas discharge amount, and environmental protection.

Owner:QINGDAO HUIERTONG TRADING

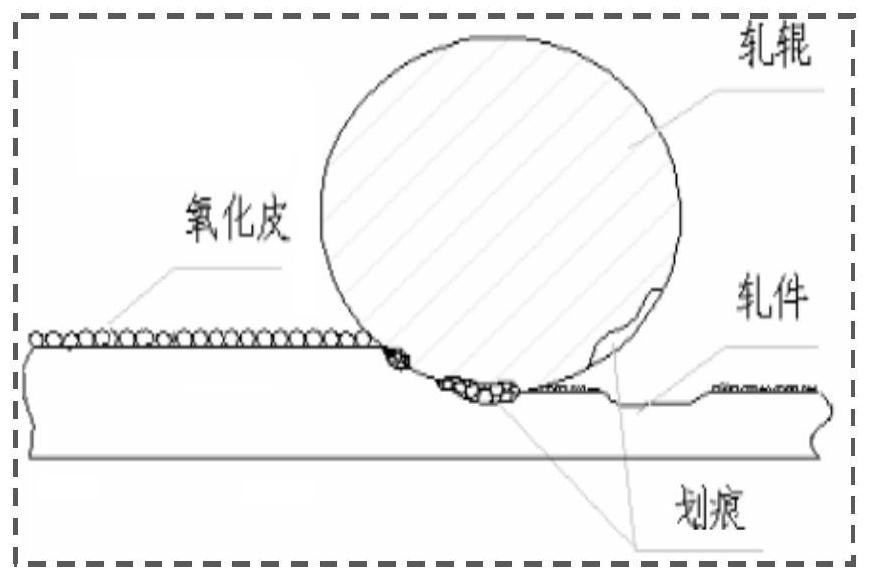

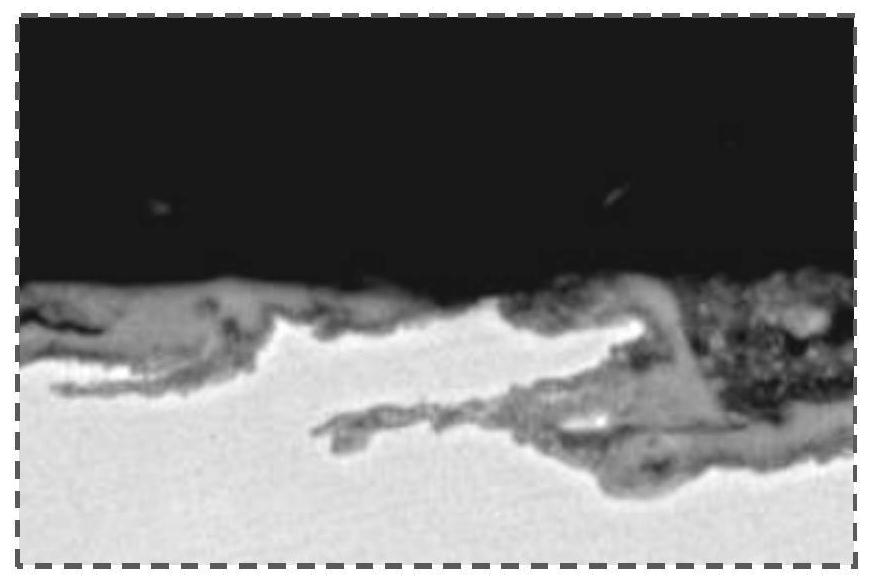

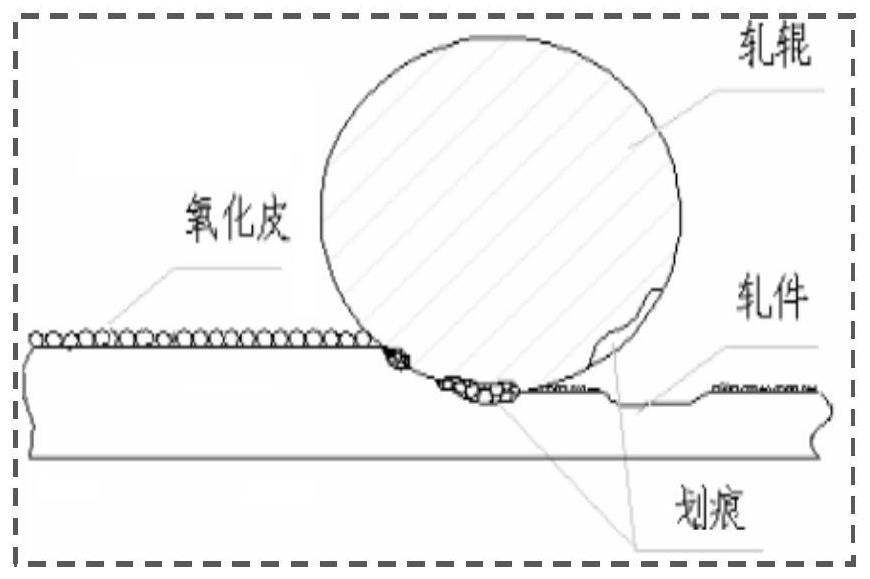

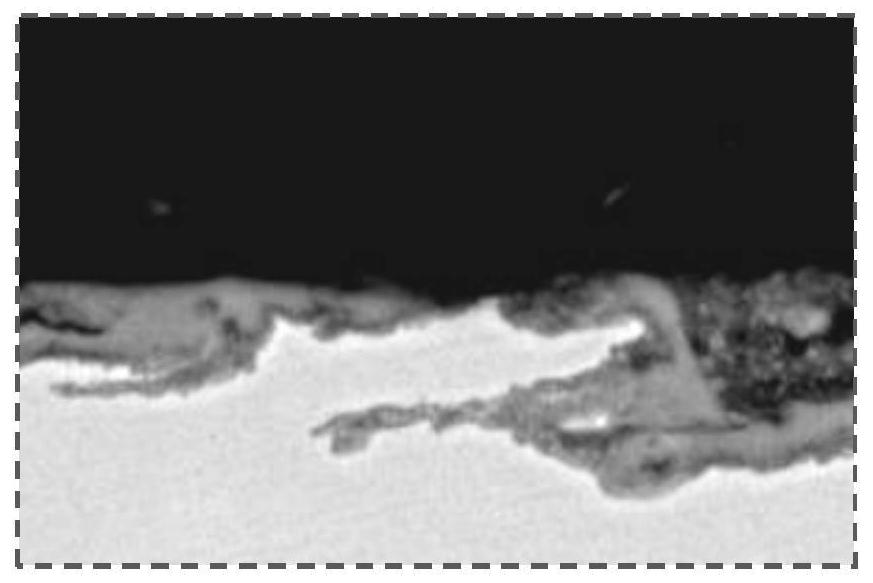

Rolling oil online adjustment method based on hot roller system iron sheet classification

ActiveCN112007954AReduce total usageReduce the number of rollsRoll mill control devicesMeasuring devicesOil canProcess engineering

The invention discloses a rolling oil on-line adjustment method based on hot roller system iron sheet classification, and relates to the technical field of hot rolling surface on-line detection, the method comprises rolling oil opening degree initial value setting, strip steel roller system iron sheet defect collection, rolling oil opening degree calculation logic, and rolling oil use strategy making according to the surface grade measured by a surface instrument. According to the invention, the use of the rolling oil is combined with the defects of the roller system iron sheet detected by thesurface instrument, and the rolling oil is put into use only when the roller system iron sheet appears and meets certain conditions, so that the roll number of the put rolling oil can be greatly reduced, and the consumption of the rolling oil is reduced; the defect grade is determined according to the grade of the strip steel surface roller system iron sheet and the number of defects, online dynamic adjustment of the rolling oil concentration is achieved, and the effect of rolling oil on improving the strip steel surface quality is further achieved. Rolling oil dynamic adjustment is conductedon the basis of the surface quality of a hot-rolled product, so that the rolling oil using efficiency in the hot rolling process is improved, the product quality is improved, and the rolling oil using efficiency is remarkably improved.

Owner:BAOSHAN IRON & STEEL CO LTD

Asphalt modifier

The invention relates to an asphalt modifier comprising the following components in parts by weight: 30-80 parts of asphalt mixtures, 5-20 parts of sodium dodecyl benzene sulfonate, 0.1-5 parts of furan resins and 40-80 parts of water. The invention has the advantages that the sodium dodecyl benzene sulfonate, the furan resin and the water are added in the producing process of the asphalt mixtures, and then a lubricating macromolecular chain structure is formed in a cementing material, thereby greatly reducing the mixing and grinding temperature of the asphalt mixtures and saving the energy consumption; in addition, the invention has the advantages of good compaction performance, reduced grinding times, good pavement quality, better high-temperature anti-rutting capacity, water damage resistant capacity, ageing resistant capacity, and the like, small discharge amount of smoke and gases, great environmental protection and wide application scope and can be used for paving tunnel pavements, steel bridge surfaces, heavy-load roads or airfield runways, and the like.

Owner:彭晓洁

System for reducing automobile turnover based on automobile external airbag

InactiveCN104691478AReduce the number of timesImprove securityPedestrian/occupant safety arrangementSafety coefficientEngineering

The invention discloses a system for reducing automobile turnover based on an automobile external airbag. The system comprises an external airbag device, a momentum early warning system and a pre-radar, wherein the momentum early warning system comprises a processing unit and a running state acquisition unit which is in communication connection with an automobile bus; the running state acquisition unit acquires the speed of the current automobile; the processing unit computes the momentum of the current automobile according to the running speed; and if the momentum reaches a certain value and the pre-radar obtains a certain distance between the current automobile and a front barrier, the processing unit controls the external airbag device to start in advance. With the adoption of the technical scheme, the system for reducing the automobile turnover based on the automobile external airbag monitors a posture of the automobile, forecasts a landing place and opens the external airbag in a relevant position, so that the times of the automobile turnover are reduced, and a safety coefficient of the automobile is increased.

Owner:DALIAN DONGPU MECHANICAL & ELECTRICAL

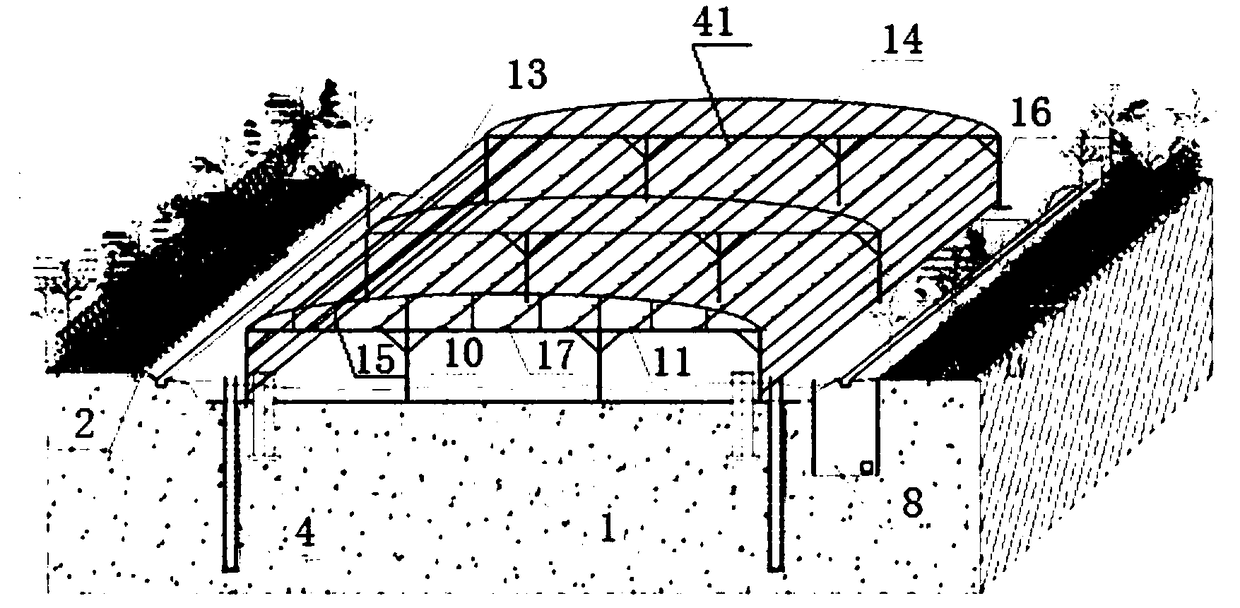

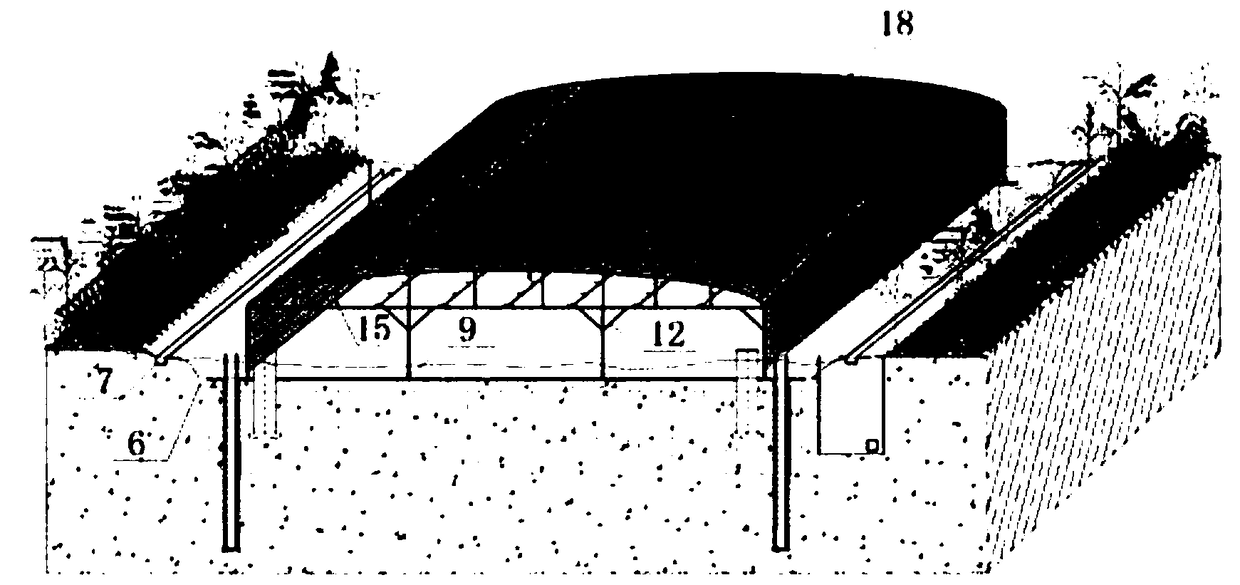

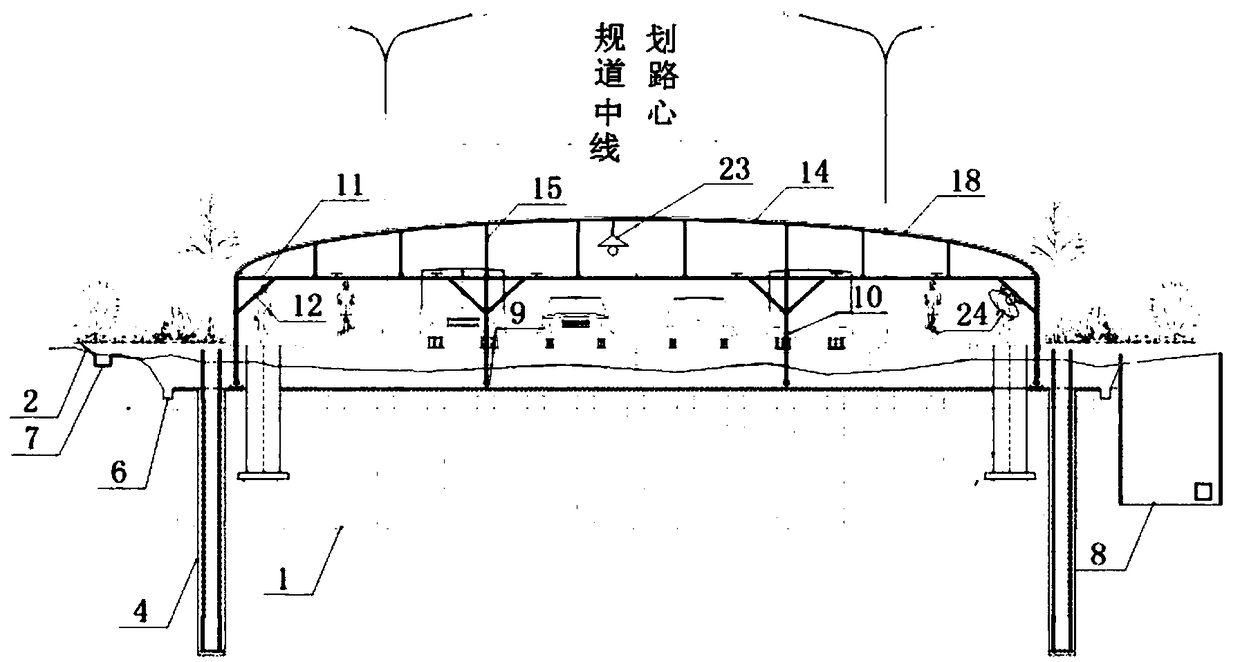

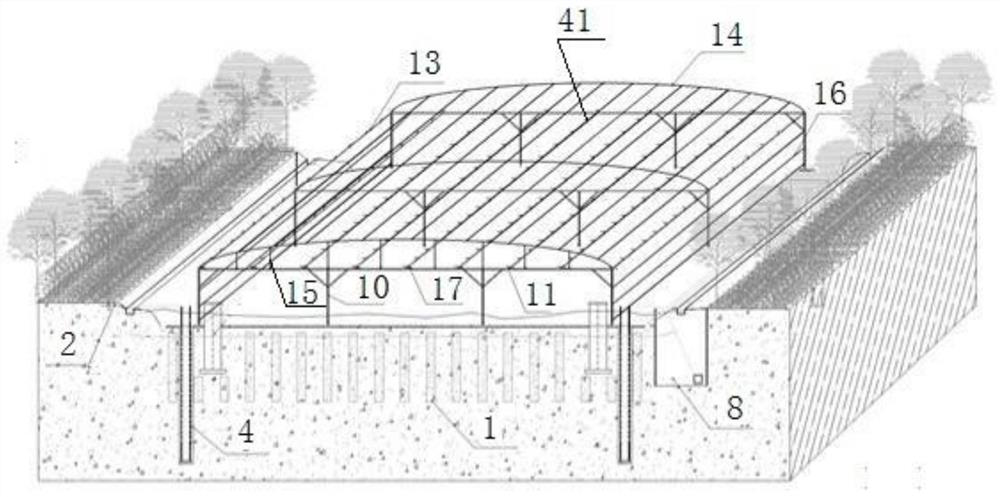

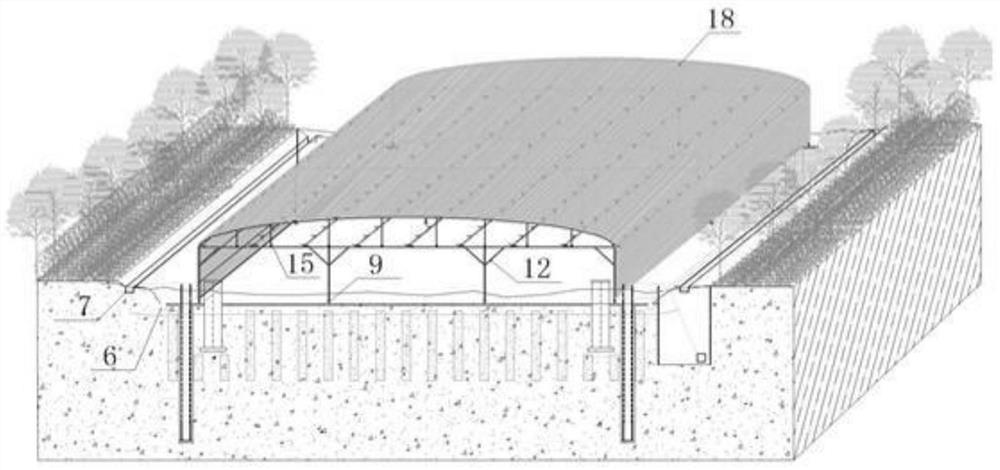

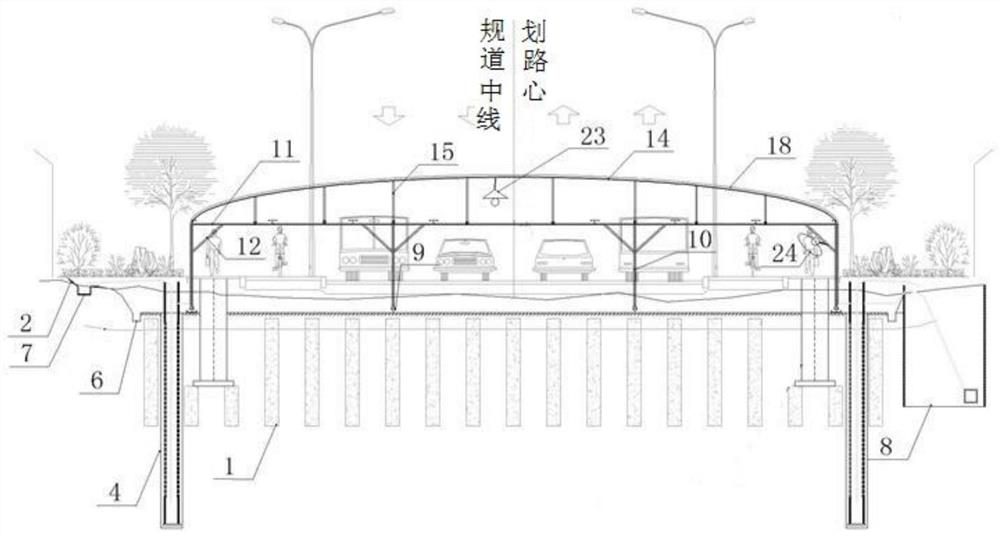

Sandbar water source comprehensive recycling system and construction method thereof

ActiveCN109024147AReduce construction impact by weatherGood water permeabilitySewerage structuresUsing liquid separation agentSprinkler systemCollection system

The invention discloses a sandbar water source comprehensive recycling system, which comprises a water resource collection system and a spraying construction shed system. The water resources collection system includes a side ditch, a dewatering well, a diversion ditch and a water collection purification tank. The side ditch drains the collected pavement water into the catchment purification tank;The water in the groove construction in the road construction flows into the dewatering well, and the dewatering well pumps the water into the diversion ditch, and the diversion ditch leads the waterinto the water collection and purification tank; The spray construction shed system comprises a sunshade shed and a spray system; The awning is located on the pavement and can slide along the slidewayof the road in the direction of road construction. The pump of the sprinkler system transfers the water in the water collecting purification tank to the sprinkler head of the sprinkler system; The sprinkler head of the sprinkler system has a plurality of sprinklers, which are evenly arranged on the sunshade awning and are sprayed in the sand foundation construction; The spray water flows into theside ditch for recycling. The invention can reasonably utilize water resources, realize energy conservation and environmental protection, and can harness the flying dust, and can avoid the influenceof sunshine, rain on the construction period, and improve the construction efficiency.

Owner:CHINA FIRST METALLURGICAL GROUP

Improved asphalt modifier

InactiveCN103602077AReduce stirringReduce the temperatureBuilding insulationsSodium lactateSilicic acid

The invention discloses an improved asphalt modifier, which is made by the following raw materials in parts by weight: 1.2-3.5 parts of nanometer silicon oxide, 2.5-3.7 parts of magnesium succinic acid dialkyl acid sulfonate, 1.5-2.3 parts of magnesium silicate, 2.5-4 parts of polyurethane, 0.5-1.6 parts of sodium lactate, 0.5-1.8 parts of soybean protein isolate, 0.5-0.8 parts of phenethyl phenol polypropylene-polyoxyethylene ether, and 0.5-1.7 parts of sodium butyl naphthalene. The magnesium succinic acid dialkyl acid sulfonate, the magnesium silicate and the soybean protein isolate are added into the production process of an asphalt mixture, and a lubricant high-polymer chain structure is formed in the bonding agent, the mixing and grinding temperatures of the mixture are greatly reduced, the energy consumption is reduced, the compactness performance is good, the grinding times are reduced, the road surface quality is good, and the high-temperature anti-rutting performance, the resistance to moisture damage, and the ageing resistance are good.

Owner:QINGDAO HIBOUND CHENGYUAN PLASTIC

Construction method for asphalt road surface of road

Owner:建发合诚工程咨询股份有限公司

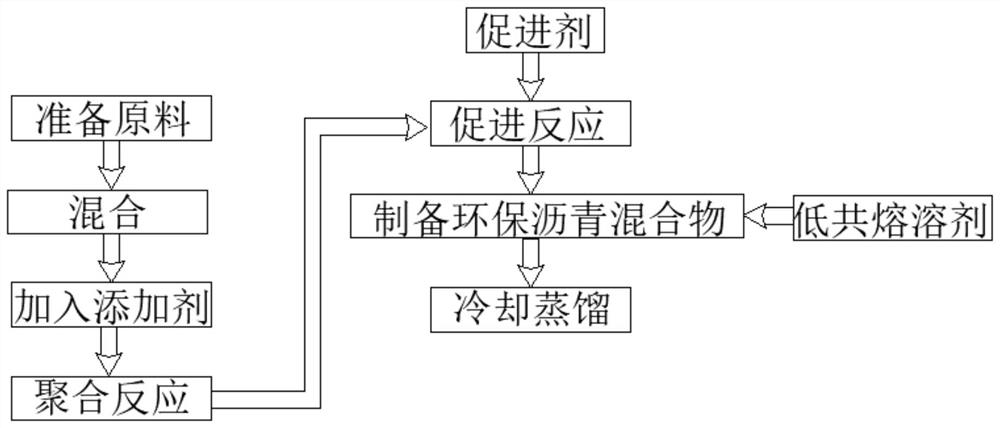

Environmentally friendly asphalt material and preparation method thereof

InactiveCN107986695AReduce benzo[a]pyrene (BaP) contentReduce the content of carcinogenic polycyclic aromatic hydrocarbonsActivated carbonCarcinogenic Polycyclic Aromatic Hydrocarbon

The invention discloses an environmentally friendly asphalt material and a preparation method of the environmentally friendly asphalt material. The process of the method is simple, the reaction condition is mild, the content of carcinogenic polycyclic aromatic hydrocarbons in the raw material is greatly reduced, no residues of a modifier and an accelerant are left, and the accelerant can be recycled. In order to fulfill the purpose, the invention provides the following technical scheme: the environmentally friendly asphalt material comprises the following parts: 15-20 parts of waste asphalt material, 120-150 parts of mineral aggregate, 1.5-5 parts of epoxy resin, 15-40 parts of cement, 3-5 parts of sodium sulphide, 0.5-10 parts of activated carbon, 0.5-3.0 parts of plant ash, 0.5-5 parts of magnetite, 0.5-3 parts of a coupling agent, 1-20 parts of a modifier and 1-20 parts of an accelerant.

Owner:南京化学工业园环保产业协同创新有限公司

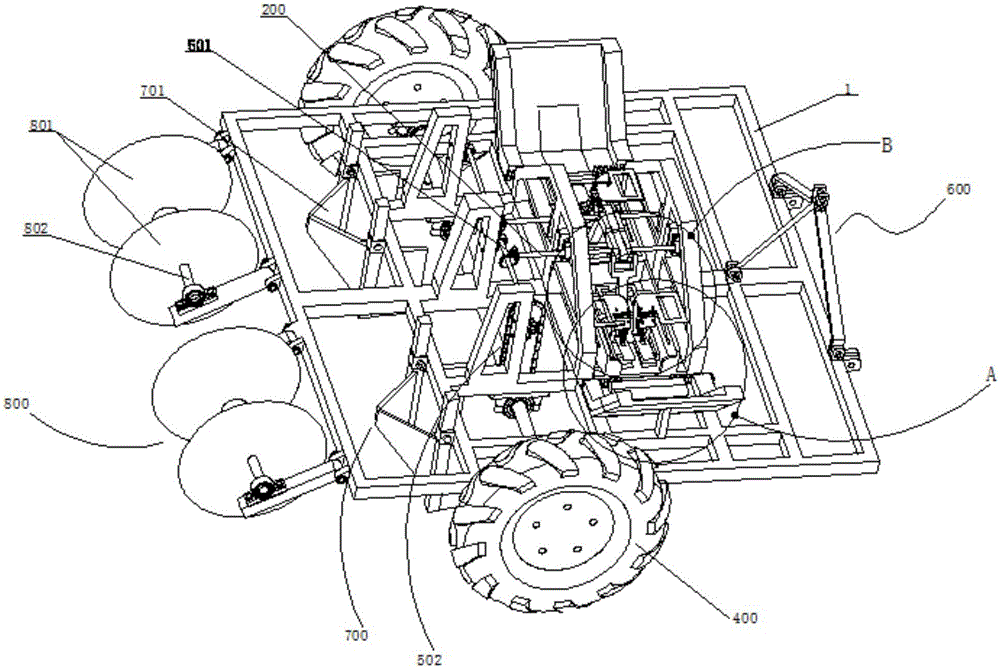

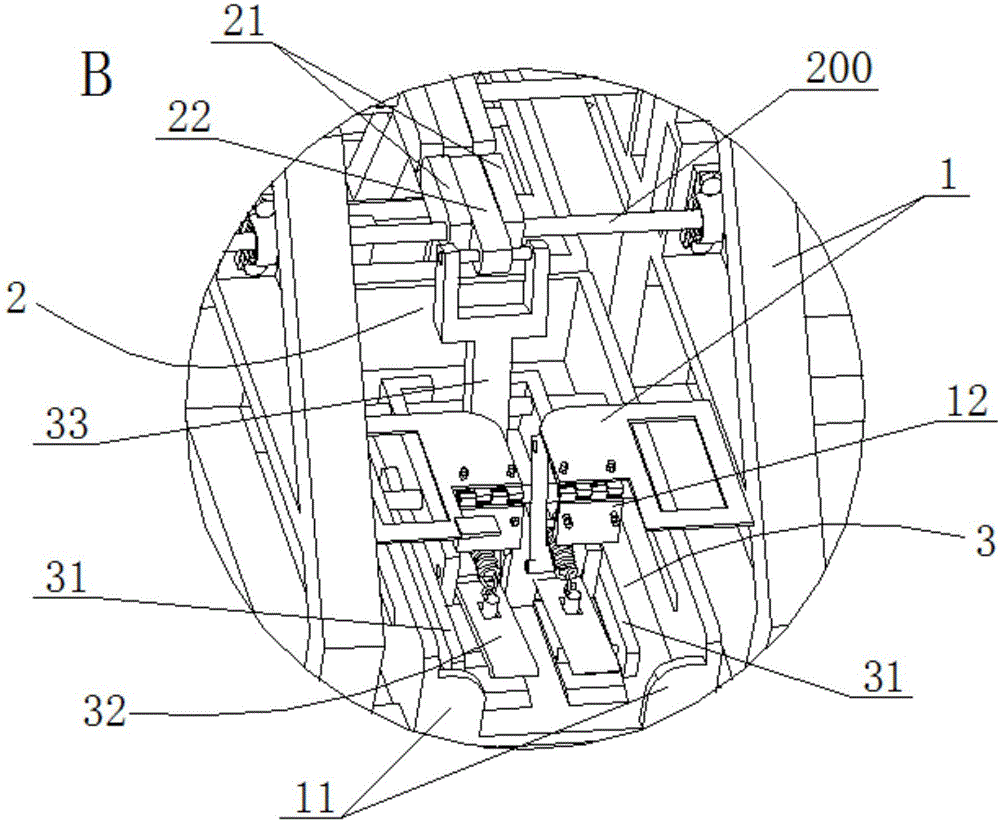

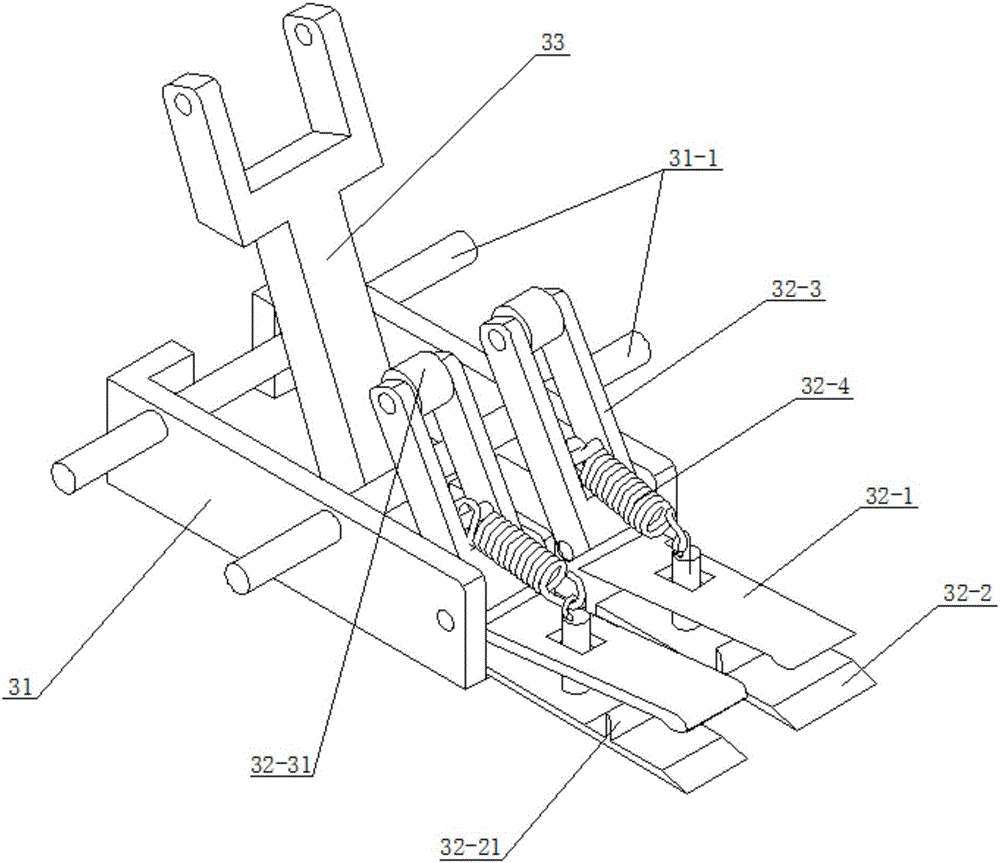

Chinese yam seeder

PendingCN109121593ASolve the inconvenience caused by replacing the seed tank mechanismControl the distance between plants evenlyFertiliser and seeding apparatusSeederPush pull

The invention discloses a Chinese yam seeder which comprises a furrowing device, a seed dropping device, a chemical spraying device, a ridging device and a compacting device which are integrally arranged, wherein the seed dropping device comprises a seed tank mechanism; the seed tank mechanism comprises an inner seed tank shell and an outer seed tank shell; the inner seed tank shell is mounted inside the outer seed tank shell in a push-pull manner. Due to adoption of the seed tank mechanism, the seed dropping device and the seeder disclosed by the invention, the inner seed tank shell is mounted inside the outer seed tank shell in the push-pull manner firstly, so that the Chinese yam seeder is applicable to Chinese yam seeds of different lengths, the inconvenience that seed tank mechanismsneed to be replaced to be adaptive to Chinese yam seeds of different lengths can be solved, meanwhile, mechanical operation of Chinese yam seeding is achieved, the ground grinding times can be reduced, the seeding efficiency can be greatly improved, the labor cost can be reduced, and meanwhile, a great deal of labor can be saved.

Owner:QINGDAO AGRI UNIV +1

Non-polar high polymer film laser moulding method and non-polar high polymer film integral machine for laser processing

InactiveCN101544153AReduce the amount of distortionReduce volatile componentsDecorative surface effectsEmbossing decorationsDistortionStop time

The invention discloses a non-polar high polymer film laser moulding method characterized as: laser moulding, corona treatment, then forced cooling for the non-polar high polymer film, then recoiling and aluminization. The method can effectively reduces deflection and distortion of laser pattern during corona treatment of non-polar high polymer laser film; the film surface diminishes volatile ingredient, while surface dyne value keeps long, which shortens stop time of half-product in conversion process, reduces operation difficulty of worker, substantially improves qualified rate of finished product and bring positive influence to combination of late period and printing procedure.

Owner:汕头市壮丽印刷有限公司

A super-thick material layer sintering method using pre-sintering to reduce the sintering return rate

The invention discloses an ultra-thick bed sintering method for reducing sinter return ratio and employing presintering; ignition temperature is optimized, a suitable amount of insulation covers are provided, high-oxygen hot air is introduced, surface ignition quality of upper and lower beds of sinter can be effectively improved, mineralizing time of surface sinter can be extended, and cold brittleness of the sinter is reduced; through reasonable coal allocation and water regulation for the upper bed of sinter mixture and reducing the amount of rolls of a distributor, better breathability is provided for the upper bed of sinter mixture; according to the features of the upper bed of mixture, bed combustion and particle size deviating is inhibited, and the bed never combusts too fast; through comprehensive technical means, it is possible to effectively decrease the return ratio of the upper bed of sinter and the whole bed of sinter.

Owner:ANGANG STEEL CO LTD

Processing method capable of improving performance of stainless steel

InactiveCN107497860AImprove work efficiencyReduce the number of rollsRollsMetal rolling arrangementsOil in waterOil film

The invention discloses a processing method capable of improving the performance of stainless steel, which comprises the steps of: conducting a hot rolling process on stainless steel, and coating a lubricant on the roll used in the hot rolling process, and the lubricant is a mixture of water and oil, and the coated During the process, the oil-in-water lubricant is spread on the roll surface of the roll, the stainless steel is placed on the roll, and it enters the deformation zone for heating and pressure, part of the oil is burned, and the other part of the oil is formed by the oil film The form exists between the rolls and the stainless steel, which is hot rolled. Through the above method, the processing method of the present invention that can improve the performance of stainless steel prevents the black surface on the roll from getting on the surface of the stainless steel by adding lubricating oil, can improve the working efficiency of the roll, reduce the number of rolls, and improve the various properties of stainless steel. performance.

Owner:SUZHOU DOUBLE GOLD IND

Preparation method of environment-friendly modified waterproof asphalt

InactiveCN114702833AFully coveredImprove mechanical propertiesBuilding insulationsSoil sciencePetroleum resin

The invention relates to the technical field of asphalt, and discloses a preparation method of environment-friendly modified waterproof asphalt, which comprises the following steps: S1, preparing the following raw materials in parts by weight: 15-30 parts of matrix asphalt, 35-45 parts of plant asphalt, 23-40 parts of rock asphalt, 0.5-10 parts of anti-aging agent and 0.5-3 parts of petroleum resin; s2, mixing: the matrix asphalt, the plant asphalt and the rock asphalt are poured into a stirring cylinder to be heated and stirred, and the mass ratio of the raw materials is as follows: 30-50% of the plant asphalt, 20-45% of the rock asphalt and 10-35% of the matrix asphalt; and S3, adding an additive. According to the present invention, the purposes of environmental protection and low pollution can be achieved through the cooperative use of the plant asphalt and the rock asphalt, the overall structure of the asphalt can be uniform and dense through the rubber powder so as not to easily crack in the actual application process, and the asphalt can have good high-temperature rut resistance and good water damage resistance through the modifier.

Owner:江西新越沥青有限公司

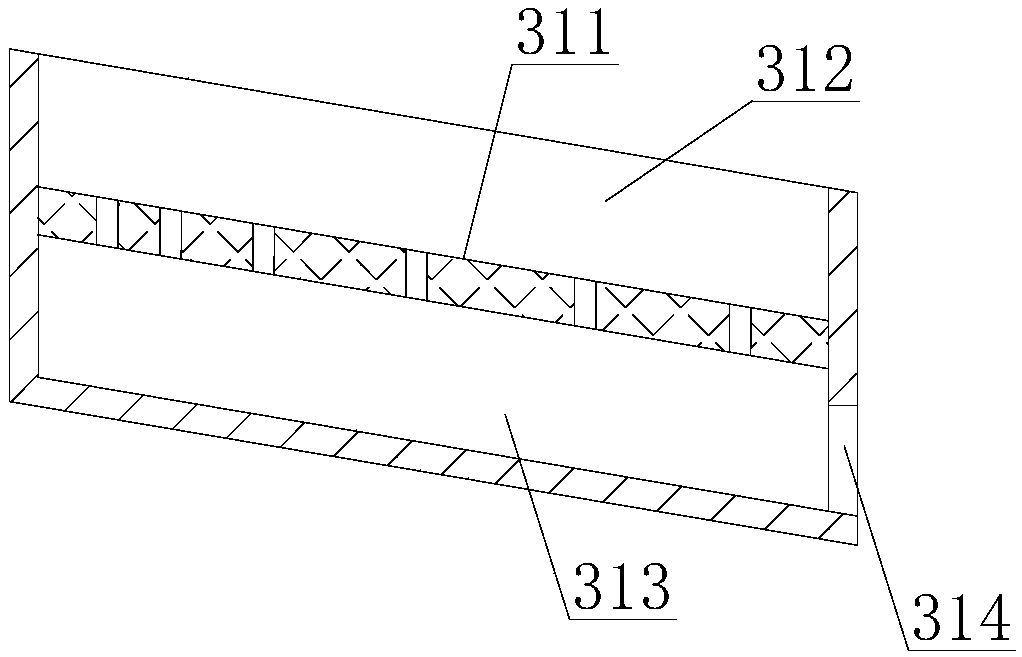

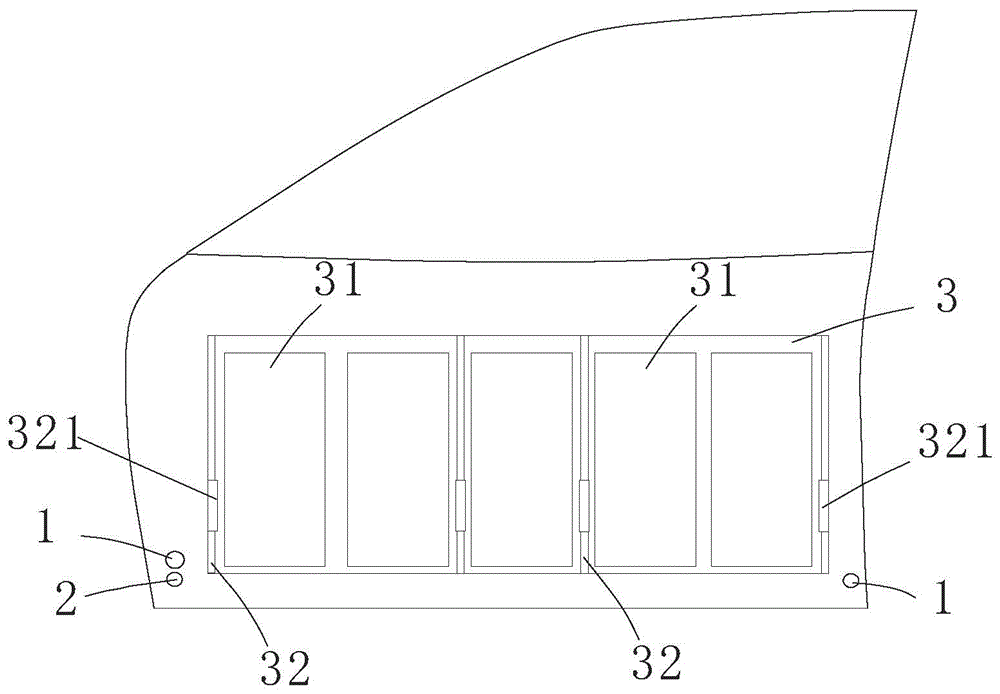

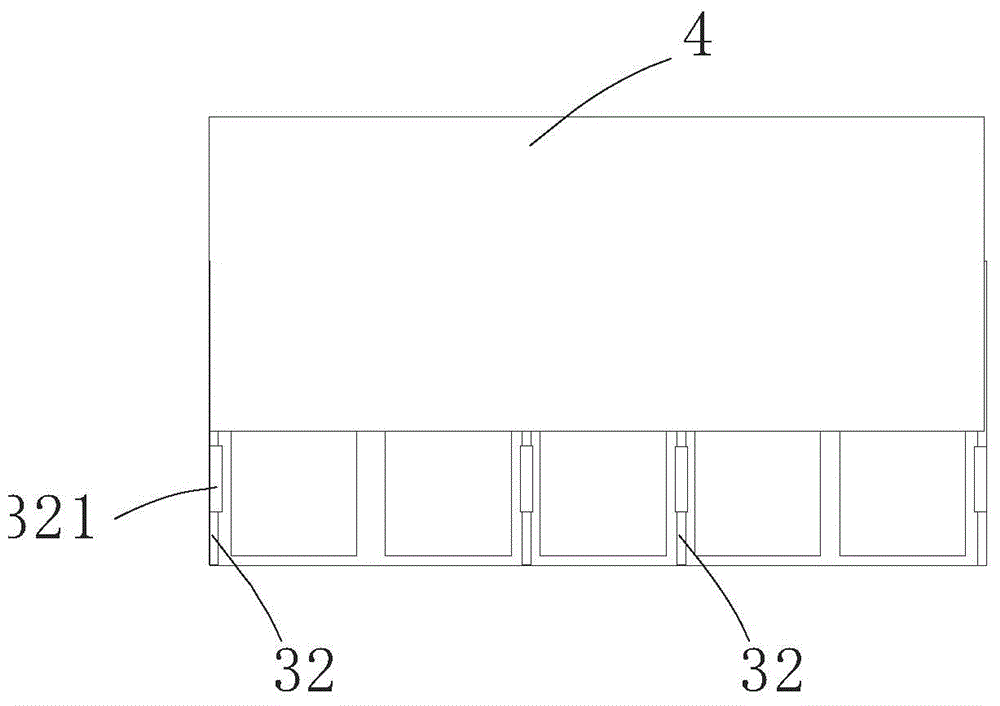

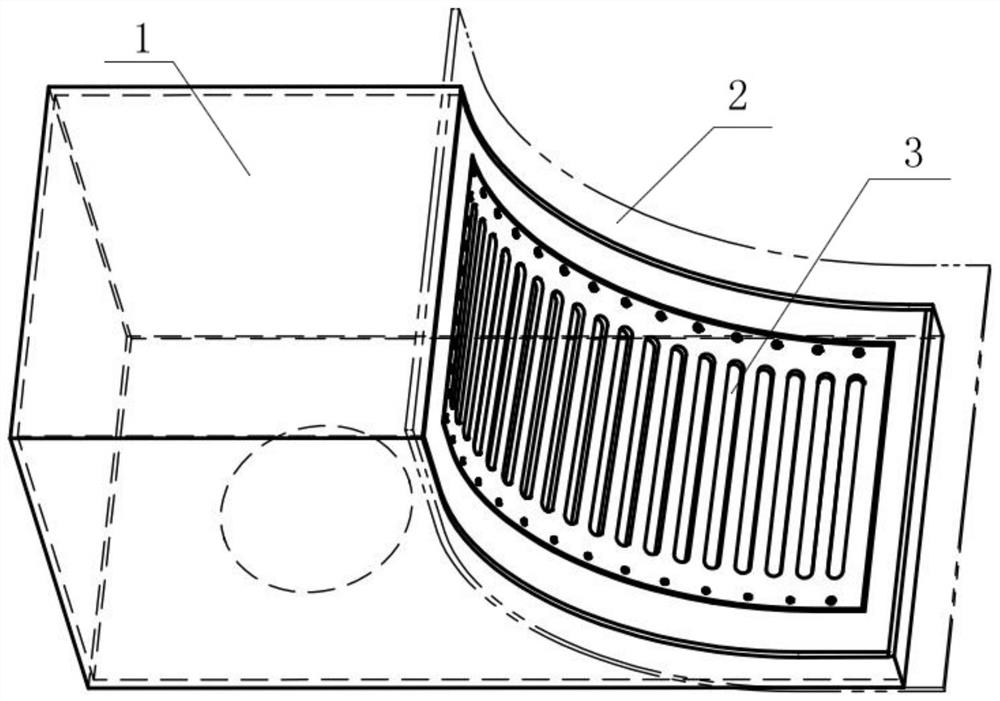

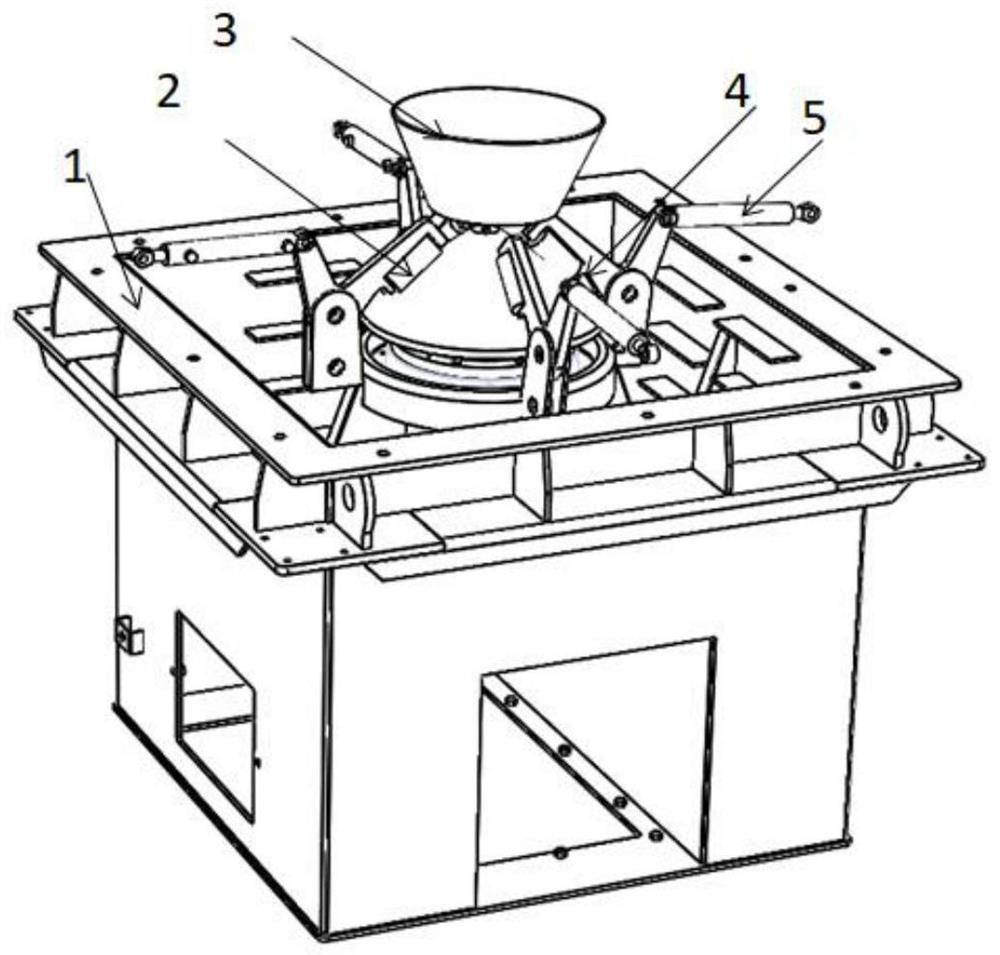

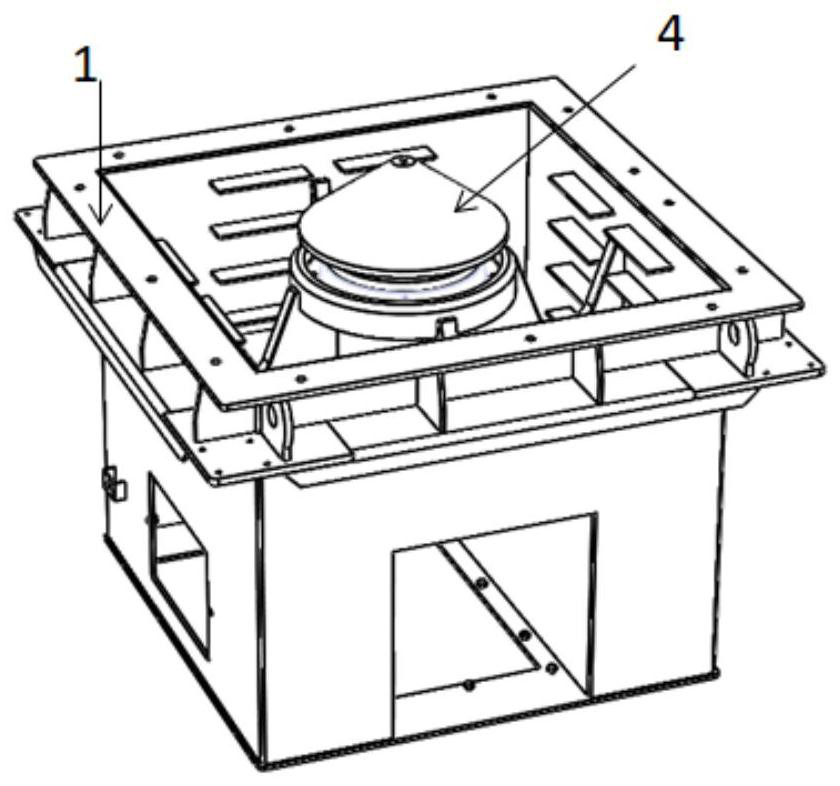

A method for integrally manufacturing trash rack panels in drainage chambers

ActiveCN109537543BReduce the number of rollingReduce difficultyFinal product manufactureWater-power plantsStructural engineeringMechanical engineering

An embodiment of the invention discloses a method of integrally manufacturing a trash rack plate of a drainage chamber. The method comprises the following steps that (1) the size of a water outlet ofthe drainage chamber is measured, a tile with arc-shaped structures on the top edge and the bottom edge is selected, and the size of the tile is larger than that of the water outlet of the drainage chamber; (2) the opening position is determined, specifically, the reserved position of the trash rack plate is determined according to the size of the water outlet of the drainage chamber; (3) cuttingis conducted, specifically, the tile is cut according to the reserved position, a reserved hole is formed, and at least two breakage points are reserved on the edge which needs to be bent and is located in the reserved hole in the rolling process; (4) the trash rack plate is installed, specifically, the trash rack plate is installed in the reserved hole, the trash rack plate and the tile are welded, and the welding positions are the positions of the breakage points; and (5) rolling is conducted, specifically, the tile where the trash rack plate is installed is rolled, so that the trash rack plate of the drainage chamber is obtained. By the adoption of the method, the frequency of rolling of the tile is effectively reduced, and the rolling quality is improved. Meanwhile, the difficulty andthe workload in the process of welding of the trash rack plate and the tile are reduced, the working efficiency is improved, and the cost is saved.

Owner:SINOHYDRO ENG BUREAU 4 XIANGYUN MACHINERY ENERGY EQUIP CO LTD +1

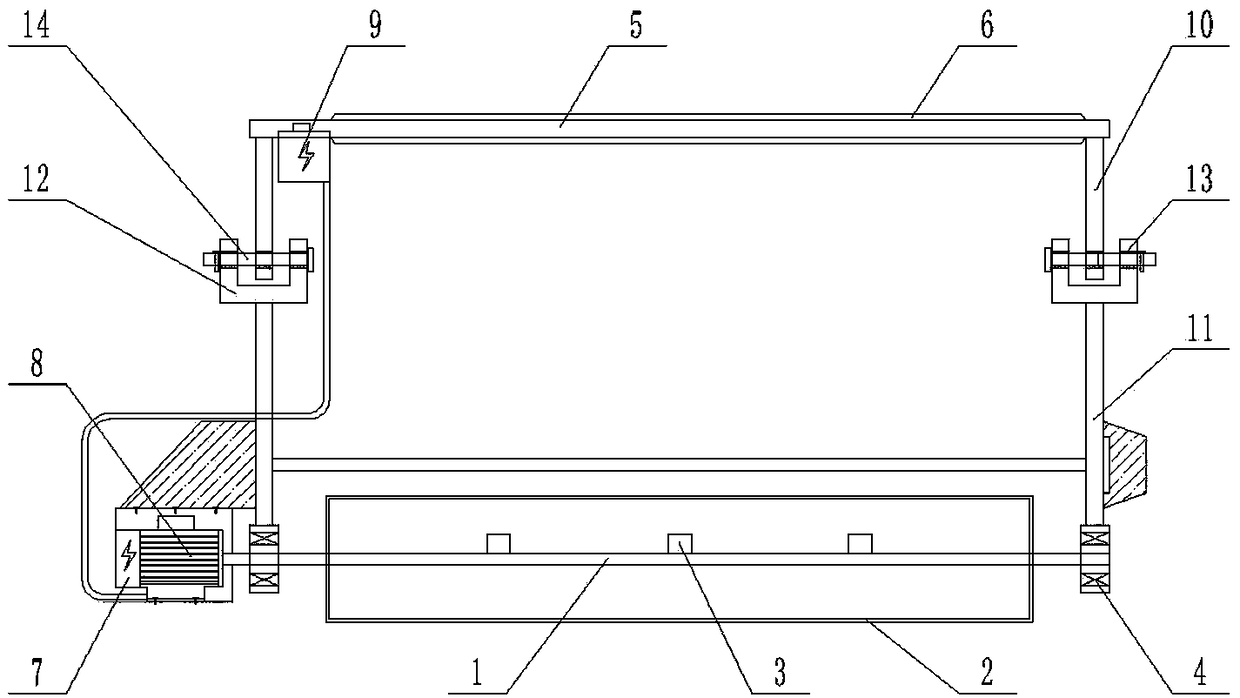

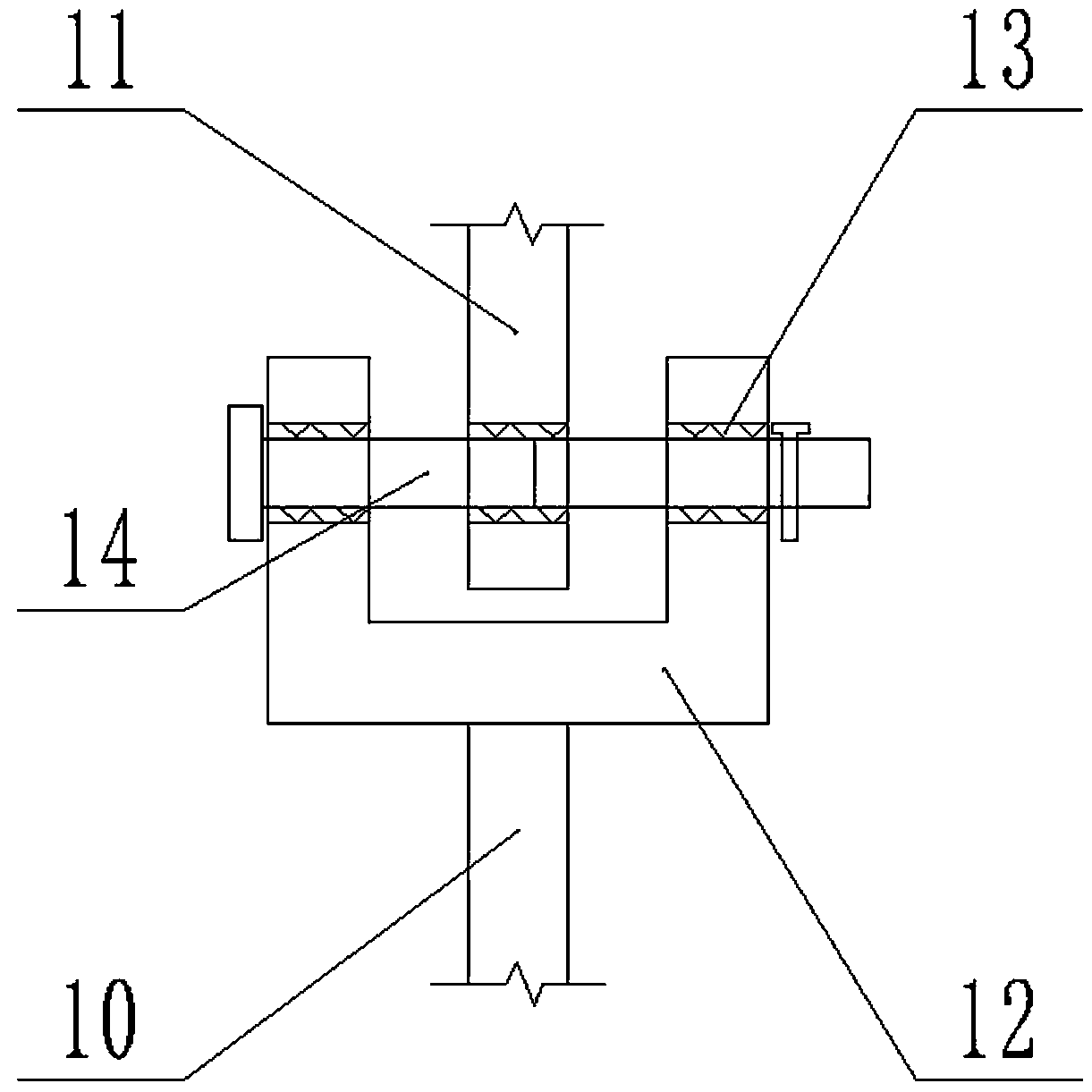

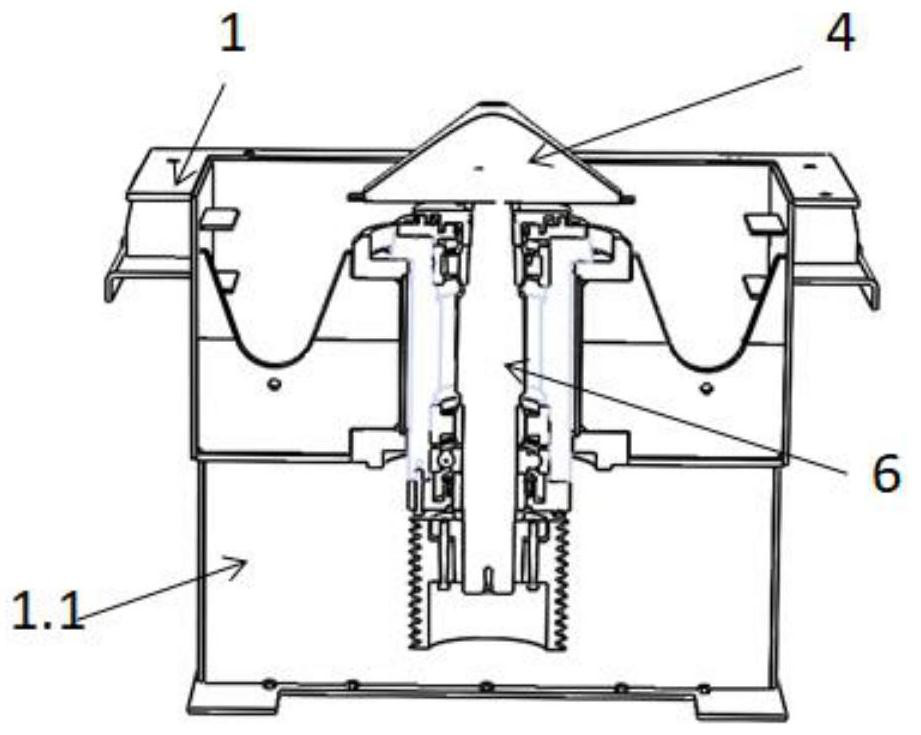

Terrazzo flooring vibration rolling device

PendingCN108412177AReasonable and reliable structural designUniform slurry stoneBuilding constructionsArtificial materialsTreatment need

The invention particularly relates to a terrazzo flooring vibration rolling device. The problems are solved that in existing terrazzo flooring rolling construction, the time and labor are consumed, the construction quality is poor, slurry supplement treatment needs to be conducted, and the labor is increased. A galvanization columnar cylinder sleeves a rolling shaft, semi-circular eccentric blocksare fixed to the rolling shaft, and bearings are arranged on the rolling shaft; supporting rods are fixed to the outer cylindrical surfaces of the bearings, a pull rod is arranged on the upper ends of the two supporting rods, and a rubber insulation sleeve is arranged on the outer cylindrical surface of the pull rod; a motor cover is fixed to the supporting rod at the left side, a vibration motoris arranged in the motor cover, and a reversible switch is connected to the vibration motor. According to the terrazzo flooring vibration rolling device, the terrazzo flooring is flat and dense, outlet slurry stone particles are even, gas in stirring materials is effectively removed, ground air holes are reduced, and the construction quality of the terrazzo flooring is improved; the working process of secondary slurry supplement is omitted, the input of artificial material machines and the cost of later flooring maintenance are lowered, the labor intensity of workers is lowered at the same time, and the rolling frequency is reduced.

Owner:DATONG TAIRUI GRP CONSTR

Corn stalk processing device and method for processing corn stalks

ActiveCN108617268BReduce the number of rollingShorten the timeSpadesSievingAgricultural scienceAgricultural engineering

Owner:XUZHOU UNIV OF TECH

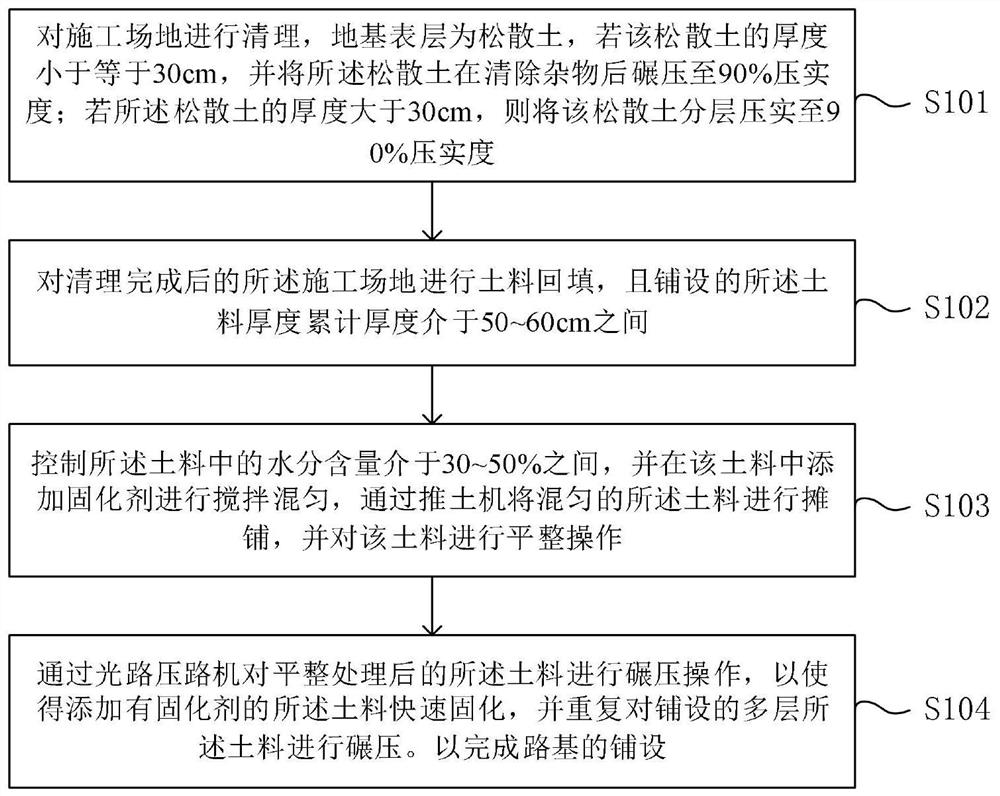

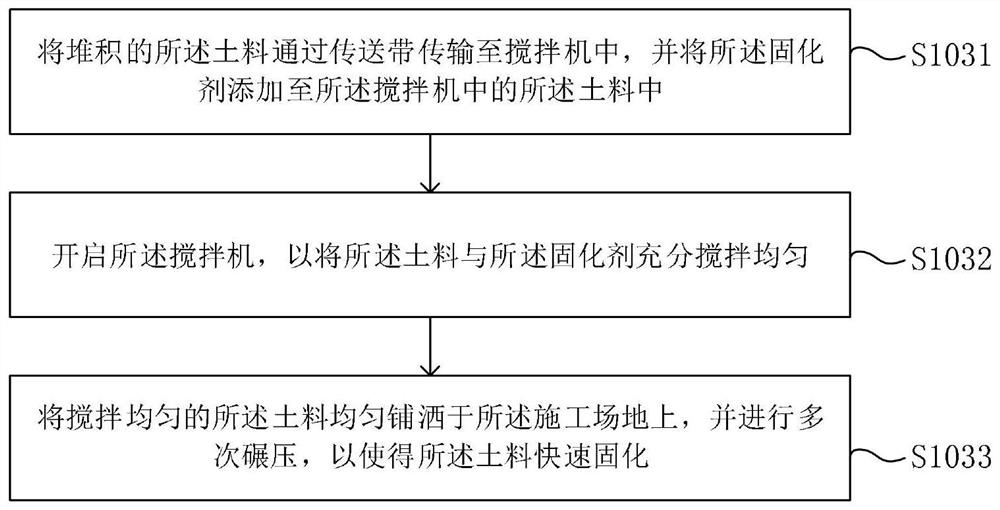

Municipal roadbed construction method

InactiveCN113047103AImprove laying efficiencyImprove compactionRoadwaysBuilding constructionsSoil scienceSoil material

The invention provides a municipal roadbed construction method which comprises the steps that a construction site is cleaned, the surface layer of a foundation is loose soil, and if the thickness of the loose soil is lower than than or equal to 30 cm, the loose soil is ground to the compactness of 90% after sundries are removed; if the thickness of the loose soil is larger than 30 cm, the loose soil is compacted in a layered mode till the compaction degree is 90%; the cleaned construction site is subjected to soil material backfilling, and the accumulated thickness of the laid soil material ranges from 50 cm to 60 cm; the moisture content in the soil material is controlled to be 30-50%, a curing agent is added into the soil material, uniformly stirring and mixing are implemented, the uniformly mixed soil material is paved through a bulldozer, and the soil material is flattened; and the flattened soil material is rolled through a light path road roller so as to quickly cure the soil material added with the curing agent, and the laid multiple layers of soil materials are repeatedly rolled . The roadbed is thus paved. Due to use of the curing agent, the compaction degree and the bearing capacity of the roadbed can be improved to a certain extent.

Owner:闫克智

Grab type yam seeder

ActiveCN106717382BReduce the number of rollingImprove work efficiencyPlantingFurrow making/coveringSeederEngineering

The invention relates to a grabbing Chinese yam seeder, which comprises a seeding mechanism, wherein the seeding mechanism comprises a crank-link mechanism and a mechanical arm; a crank in the crank-link mechanism is rotationally connected to an output shaft; the connecting rod is connected with the mechanical arm; the mechanical arm comprises a connecting rod, a slideway and a grabbing arm; one end of the connecting d is hinged to a connecting link in the crank-link mechanism and the other end is fixedly connected with the grabbing arm; and a baffle plate is formed on a rack. According to the grabbing Chinese yam seeder, through cooperation of the crank-link mechanism and the mechanical arm, the mechanical arm grabs Chinese yam circularly to seed and grabs one Chinese yam seed each time, the grabbing accuracy is high, the problems of seed blockage and leakage are solved. In addition, by using a tractor for traction, ditching, seed discharging, seeding, earthing and tapping are completed at one time, so that the number of grinding times for soil is reduced, the work efficiency of a machine is improved, conversion from manual seeding to automatic seeding is achieved and the labor burden is reduced.

Owner:QINGDAO AGRI UNIV

Shazhou water source comprehensive recycling system and its construction method

ActiveCN109024147BShorten the construction periodImprove work efficiencySewerage structuresPaving gutters/kerbsSprinkler systemWater source

The invention discloses a sandbar water source comprehensive recycling system, which comprises a water resource collection system and a spraying construction shed system. The water resources collection system includes a side ditch, a dewatering well, a diversion ditch and a water collection purification tank. The side ditch drains the collected pavement water into the catchment purification tank;The water in the groove construction in the road construction flows into the dewatering well, and the dewatering well pumps the water into the diversion ditch, and the diversion ditch leads the waterinto the water collection and purification tank; The spray construction shed system comprises a sunshade shed and a spray system; The awning is located on the pavement and can slide along the slidewayof the road in the direction of road construction. The pump of the sprinkler system transfers the water in the water collecting purification tank to the sprinkler head of the sprinkler system; The sprinkler head of the sprinkler system has a plurality of sprinklers, which are evenly arranged on the sunshade awning and are sprayed in the sand foundation construction; The spray water flows into theside ditch for recycling. The invention can reasonably utilize water resources, realize energy conservation and environmental protection, and can harness the flying dust, and can avoid the influenceof sunshine, rain on the construction period, and improve the construction efficiency.

Owner:CHINA FIRST METALLURGICAL GROUP

Construction method of highway asphalt pavement by adopting tire initial pressing process

PendingCN112127230AHigh hardnessHigh pressure strengthIn situ pavingsRoads maintainenceStructural engineeringRoad surface

The invention relates to a construction method of a highway asphalt pavement by adopting a tire initial pressing process. The method comprises the following steps that A, an adopted asphalt mixture comprises coarse aggregate, fine aggregate and asphalt, and the particle size of coarse aggregated rock in the coarse aggregate corresponds to the thickness of the asphalt pavement after construction; and B, a pneumatic tyred roller is adopted for initial pressing, that is, a paver paves the asphalt mixture on the roadbed, and the pneumatic tyred roller rolls after following the paver. After initialpressing is completed 2-3 times in a reciprocating manner, a steel cylinder road roller is adopted for final pressing. The top surfaces of the coarse aggregated rock directly form a road surface, andgaps between the adjacent coarse aggregated rock are filled with the fine aggregate. In the highway use process, the top surface of the coarse aggregated rock is directly rubbed with vehicle tires, and the aggregated rock hardness is far higher than that of the tires, so that the pavement is durable and wear-resistant; and meanwhile, the coarse aggregated rock is fixed on the hard roadbed and does not have a space for moving up and down, so that the compaction force and the bearing capacity of the whole pavement are relatively high and are far higher than those of an asphalt pavement in the prior art.

Owner:宗焕清

Construction method of impacting and rolling

ActiveCN101122128BMeet the requirements of Ev2≥45MPaLow costSoil preservationDeformation modulusEngineering

Owner:CHINA RAILWAY NO 8 ENG GRP CO LTD

An Online Adjustment Method of Rolling Oil Based on Iron Sheet Classification of Hot Roll System

ActiveCN112007954BReduce total usageReduce the number of rollingRoll mill control devicesMeasuring devicesThermodynamicsOil concentration

The invention discloses an on-line adjustment method for rolling oil based on the classification of hot-roller iron sheets, and relates to the technical field of hot-rolled surface on-line detection, including the setting of the initial value of rolling oil opening, the collection of steel sheet defects in strip steel rolls, and the rolling oil According to the calculation logic of the opening degree and the surface grade measured by the surface meter, the rolling oil application strategy is formulated. The invention combines the use of rolling oil with the defects of roll iron sheets detected by the surface instrument, and is put into use only when the roll iron sheets appear and meet certain conditions, which can greatly reduce the number of rolling oil coils to be used and reduce the rolling loss. Oil consumption; Defect grades are confirmed according to the steel sheet grade and the number of defects on the surface of the strip steel, and the online dynamic adjustment of the rolling oil concentration is realized, which further plays the role of rolling oil in improving the surface quality of the strip steel. The present invention dynamically adjusts the rolling oil based on the surface quality of hot-rolled products, so as to improve the use efficiency of the rolling oil in the hot-rolling process and improve product quality, and significantly improves the use efficiency of the rolling oil.

Owner:BAOSHAN IRON & STEEL CO LTD

Vertical sand mill and sand making method

PendingCN113198592AImprove passabilityIncrease crushing ratioGrain treatmentsEngineeringRotating disc

The invention provides a vertical sand mill. The vertical sand mill comprises a conical rotating disc with a vertical center and a plurality of grinding disc rollers mounted above the conical rotating disc, a gap exists between the grinding disc rollers and the conical rotating disc, the vertical sand mill further comprises a sand milling outer cover mounted on the peripheries of the conical rotating disc and the grinding disc rollers, and a grinding cavity is formed between the sand milling outer cover and the conical rotating disc; and the edge of the conical rotating disc is tooth-shaped and is matched with a peripheral wear-resistant ring. According to the sand mill and a sand making method, through the conical rotating disc, the passing capacity is increased, and the grinding times are reduced; materials are ground multiple times through the grinding disc rollers; and through extrusion and crushing of the edge tooth shape of the conical rotating disc and the wear-resisting ring, the passing capacity of the sand mill is improved, the crushing ratio is increased, the grain shape is optimized, and the powder amount is reduced.

Owner:南昌矿机集团股份有限公司

Grabbing Chinese yam seeder

ActiveCN106717382AReduce the number of rollingImprove work efficiencyPlantingFurrow making/coveringEngineeringTractor

The invention relates to a grabbing Chinese yam seeder, which comprises a seeding mechanism, wherein the seeding mechanism comprises a crank-link mechanism and a mechanical arm; a crank in the crank-link mechanism is rotationally connected to an output shaft; the connecting rod is connected with the mechanical arm; the mechanical arm comprises a connecting rod, a slideway and a grabbing arm; one end of the connecting d is hinged to a connecting link in the crank-link mechanism and the other end is fixedly connected with the grabbing arm; and a baffle plate is formed on a rack. According to the grabbing Chinese yam seeder, through cooperation of the crank-link mechanism and the mechanical arm, the mechanical arm grabs Chinese yam circularly to seed and grabs one Chinese yam seed each time, the grabbing accuracy is high, the problems of seed blockage and leakage are solved. In addition, by using a tractor for traction, ditching, seed discharging, seeding, earthing and tapping are completed at one time, so that the number of grinding times for soil is reduced, the work efficiency of a machine is improved, conversion from manual seeding to automatic seeding is achieved and the labor burden is reduced.

Owner:QINGDAO AGRI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com