Pole piece conveying deviation rectification compound manipulator device and implementation method

A manipulator and sheet feeding technology, which is applied in the field of pole piece feeding and deflection rectification composite manipulator devices, can solve the problem that the alignment accuracy cannot be effectively and accurately controlled, and can shorten the effective distance, reduce the number of rollers, and improve the control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

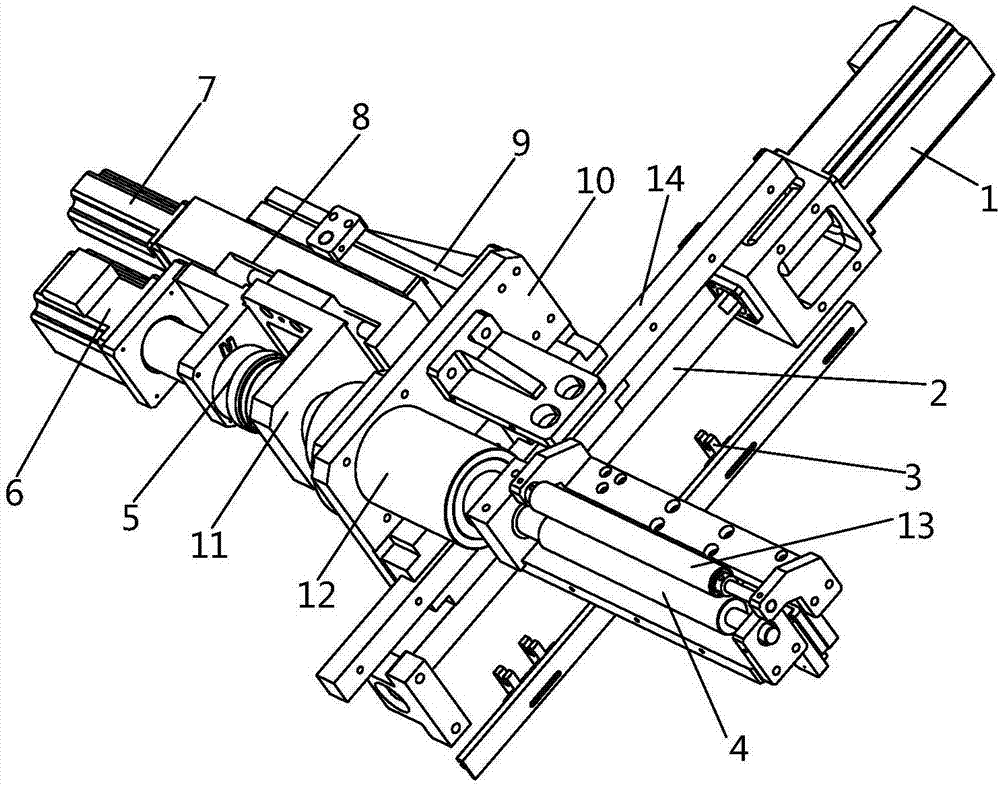

[0041] Such as figure 1 As shown, the composite manipulator device for pole piece feeding and deviation correction described in Embodiment 1 of the present invention, the manipulator device is composed of a compensation unit driven by servo motor I1, a film feeding unit driven by servo motor II6, and a deviation correction unit driven by servo motor III7;

[0042] The setting of the above compensation unit includes but not limited to the following means of implementation:

[0043] Some parts of the compensation unit are installed on the corresponding equipment frame, the compensation unit includes the servo motor I1, the screw mandrel 2, the sensor 3, the guide rail 14 and the workpiece, the screw mandrel 2 and the guide rail 14 pass through the connecting plate II10 To connect, the guide rail 14 and the screw mandrel 2 are kept parallel to each other in the positional relationship, and the connecting plate II10 matched with the guide rail 10 has a sliding clamp perpendicular ...

Embodiment 2

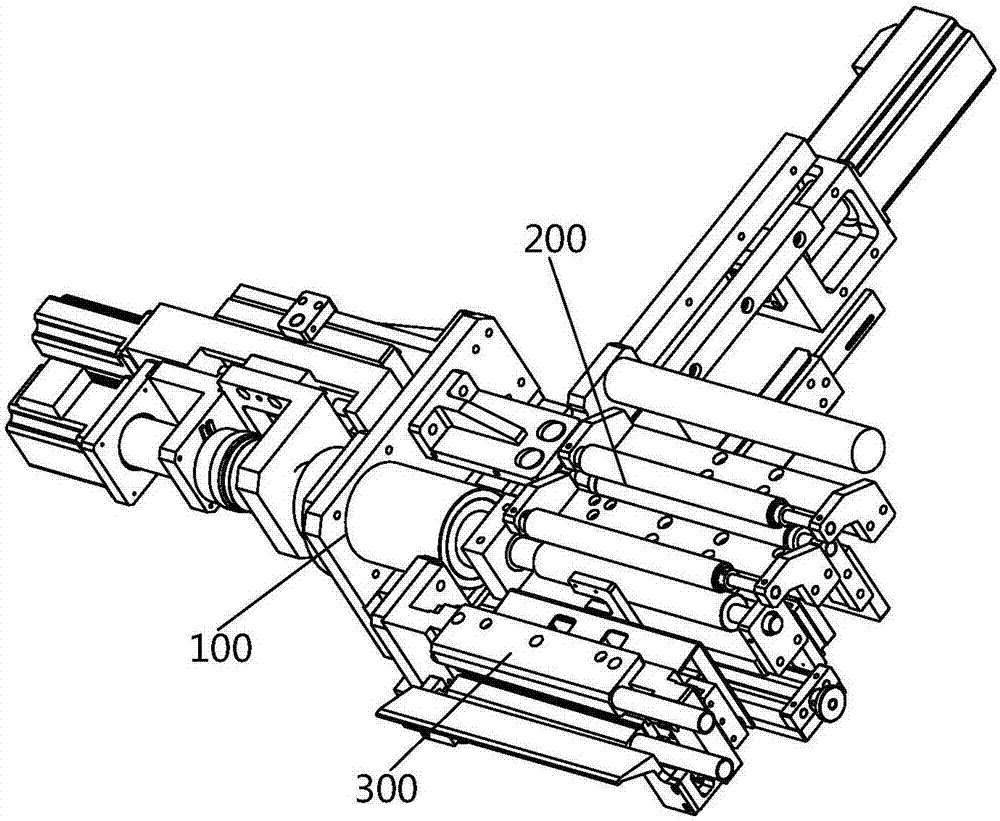

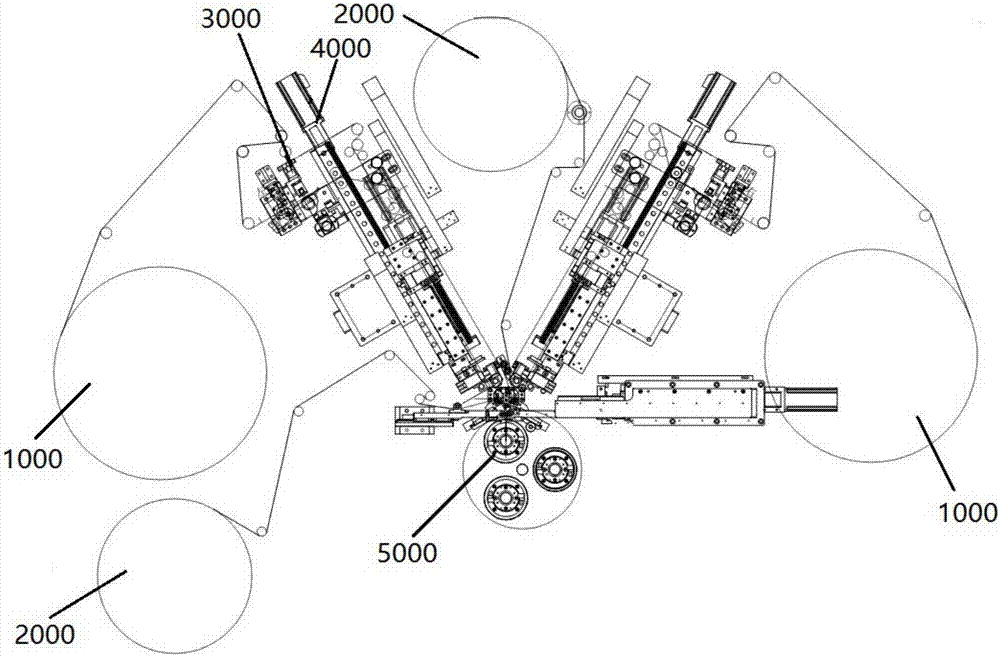

[0058] Such as Figure 2-3 As shown, what is described in Embodiment 2 of the present invention is a manipulator device, which is composed of three parts, namely, the drive feeding and deviation correction mechanism 100, the clamping mechanism 200, and the pole piece cutter mechanism 300. The film and deviation correction mechanism 100 includes the film feeding unit and deviation correction unit as described in the first embodiment, wherein the film feeding unit is driven by the servo motor II6, and the deviation correction unit is driven by the servo motor III7, and the clamping mechanism 200 is installed on the drive On the periphery of the sheet feeding and deflection correction mechanism 100, the clamping mechanism 200 is perpendicular to the compensating unit driven by the servo motor I1 and the clamping mechanism 200 includes several pinch rollers 13, and the adjacent parts below each pinch roller 13 have corresponding The driving roller 4, the connection relationship an...

Embodiment 3

[0063] Such as Figure 1-2 As shown, what is described in Embodiment 3 of the present invention is a method for implementing a composite manipulator device to send and rectify pole pieces, which mainly consists of the following steps:

[0064] (1) At first, three basic units are set on the same manipulator device with components in the prior art, namely, the compensation unit formed by driving the screw mandrel 2 driven by the servo motor I1, and the sheet feeding unit formed by driving the driving roller 4 to rotate by the servo motor II6 unit, a deviation correction unit composed of a servo motor III7 driving a linear module 8;

[0065] (2) Then, carry out detailed arrangement in each of the above units, that is, a number of sensors 3 are arranged on the periphery of the compensation unit, a clutch 5 is arranged inside the sheet feeding unit, and a pinch roller 13 is arranged under the driving roller 4 of the sheet feeding unit. At the same time, in the three The connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com