Preparation method of environment-friendly modified waterproof asphalt

An asphalt and modification technology, applied in building thermal insulation materials, building components, buildings, etc., can solve problems such as environmental and human injury, and achieve the effect of improving mechanical properties, good fluidity, and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

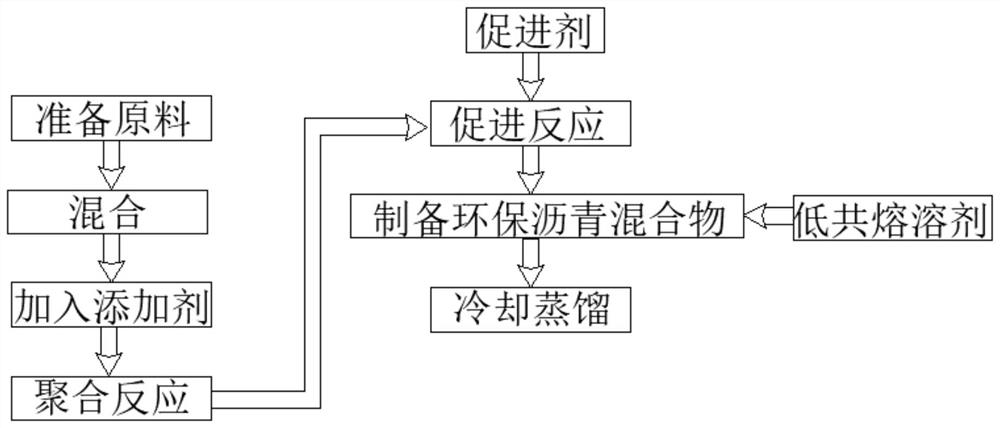

[0035] refer to figure 1 , an environment-friendly preparation method of modified waterproof asphalt, comprising the following steps:

[0036] S1: Prepare raw materials, 16 parts of base asphalt, 36 parts of vegetable asphalt, 24 parts of rock asphalt, 2 parts of anti-aging agent, 1 part of petroleum resin, 8 parts of rubber powder, 3 parts of modifier, 9 parts of accelerator, 6 parts of oxidant , 11 parts of deep eutectic solvent;

[0037] S2: Mixing, pour the matrix asphalt, vegetable asphalt and rock asphalt into the mixing tank for heating and stirring. The mass ratio of raw materials is: vegetable asphalt 40%, rock asphalt 36%, matrix asphalt 24%, vegetable asphalt contains Zibo, Vitamin E and a large amount of higher fatty acids, which are added to the base asphalt, can have the same viscosity reduction effect as the warm mix agent, which can fully coat the asphalt binder and the mineral material, which can not only improve the mechanical properties of the mixture, but ...

Embodiment 2

[0046] refer to figure 1 , an environment-friendly preparation method of modified waterproof asphalt, comprising the following steps:

[0047] S1: Prepare raw materials, 25 parts of base asphalt, 42 parts of vegetable asphalt, 36 parts of rock asphalt, 8 parts of anti-aging agent, 2 parts of petroleum resin, 12 parts of rubber powder, 4 parts of modifier, 18 parts of accelerator, 11 parts of oxidant , 13 parts of deep eutectic solvent;

[0048] S2: Mixing, pour the matrix asphalt, vegetable asphalt and rock asphalt into the mixing tank for heating and stirring. The mass ratio of raw materials is: vegetable asphalt 48%, rock asphalt 30%, matrix asphalt 22%, vegetable asphalt contains Zibo, Vitamin E and a large amount of higher fatty acids, which are added to the base asphalt, can have the same viscosity reduction effect as the warm mix agent, which can fully coat the asphalt binder and the mineral material, which can not only improve the mechanical properties of the mixture, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com