Patents

Literature

158results about How to "Not prone to gaps" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

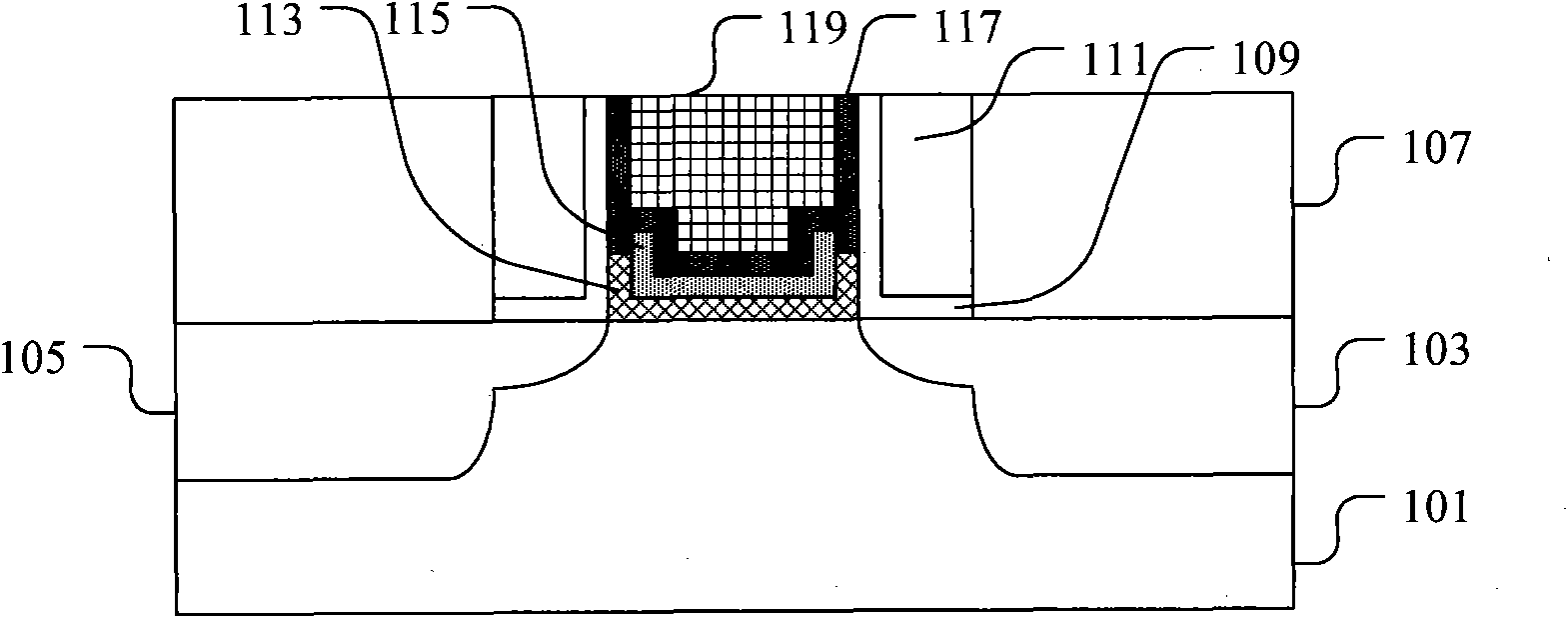

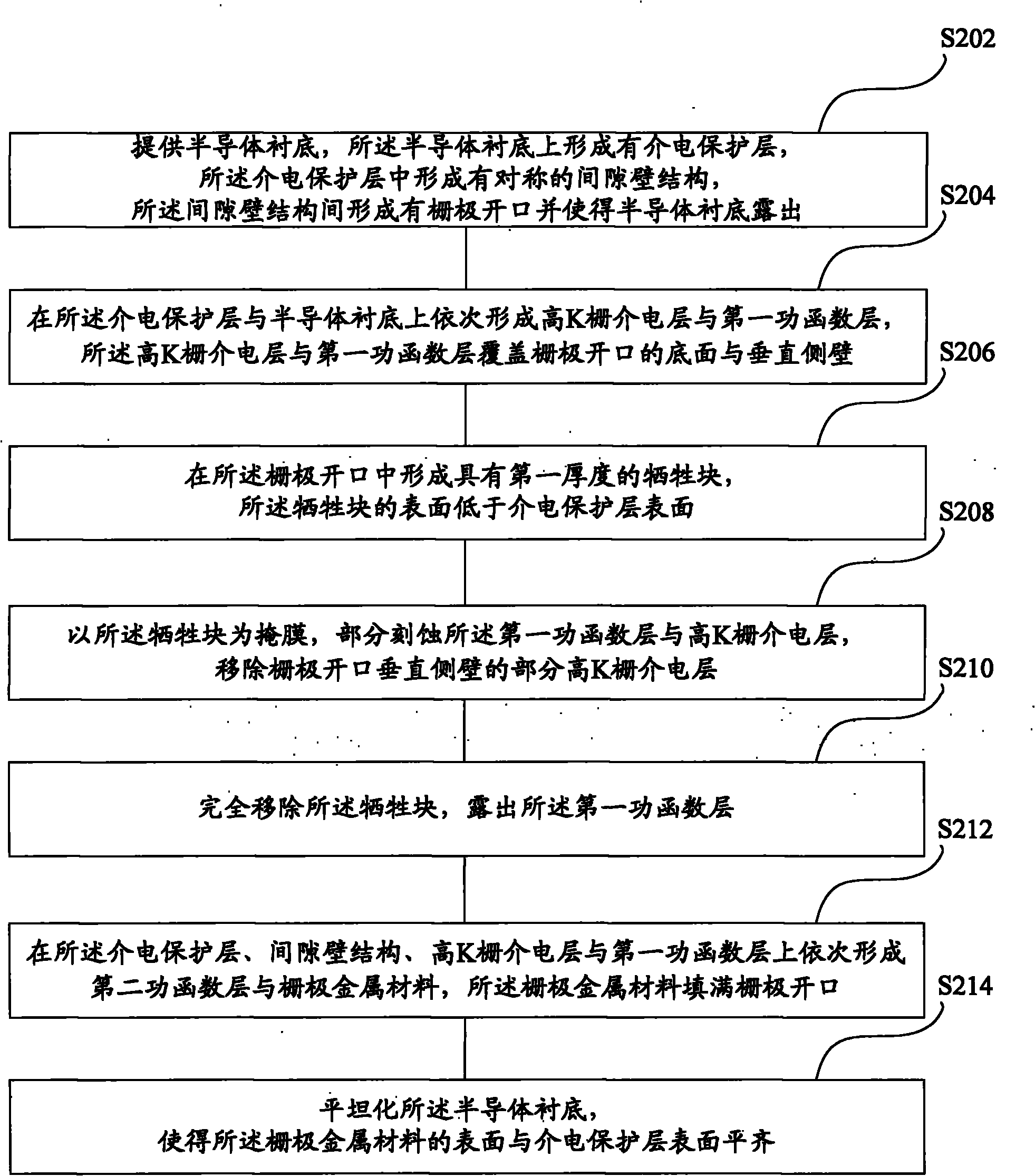

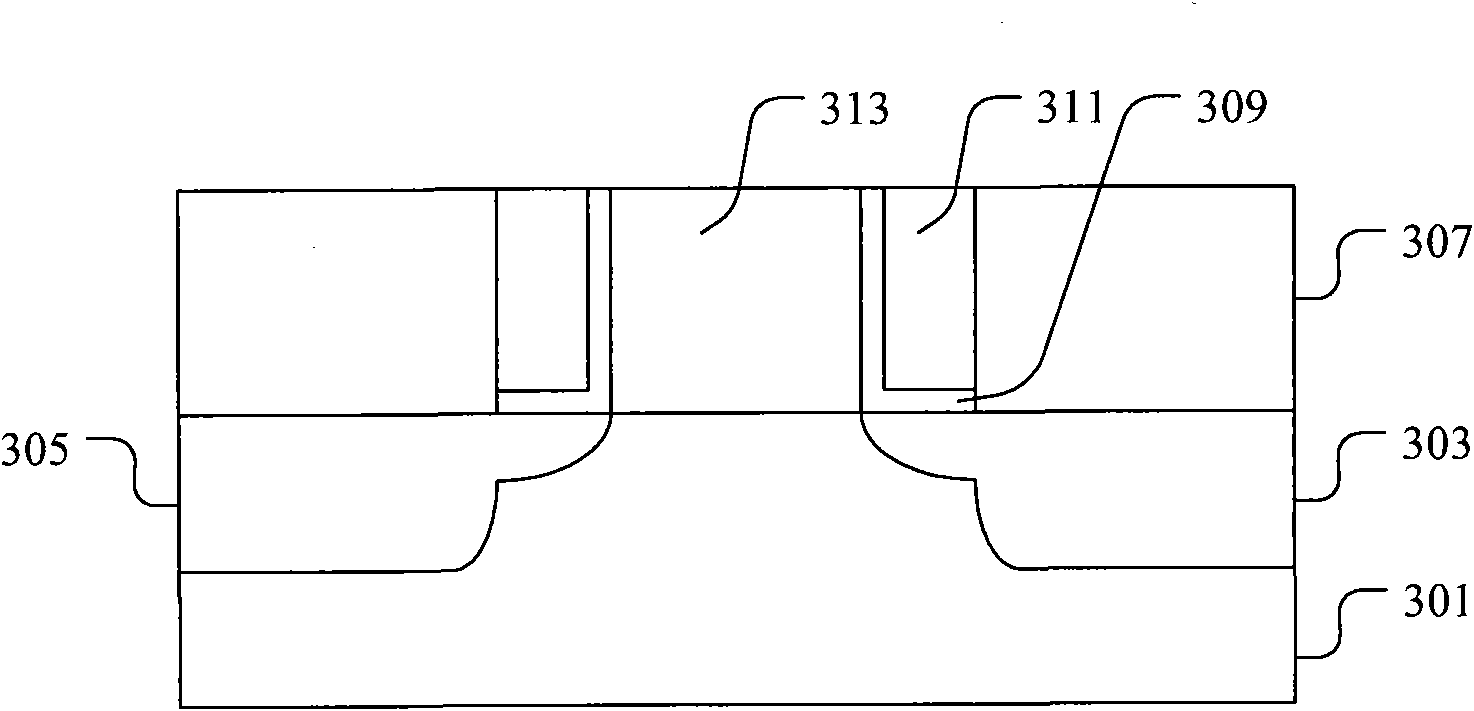

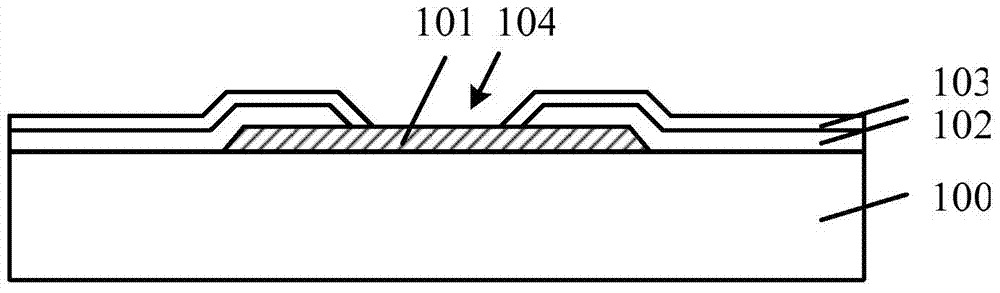

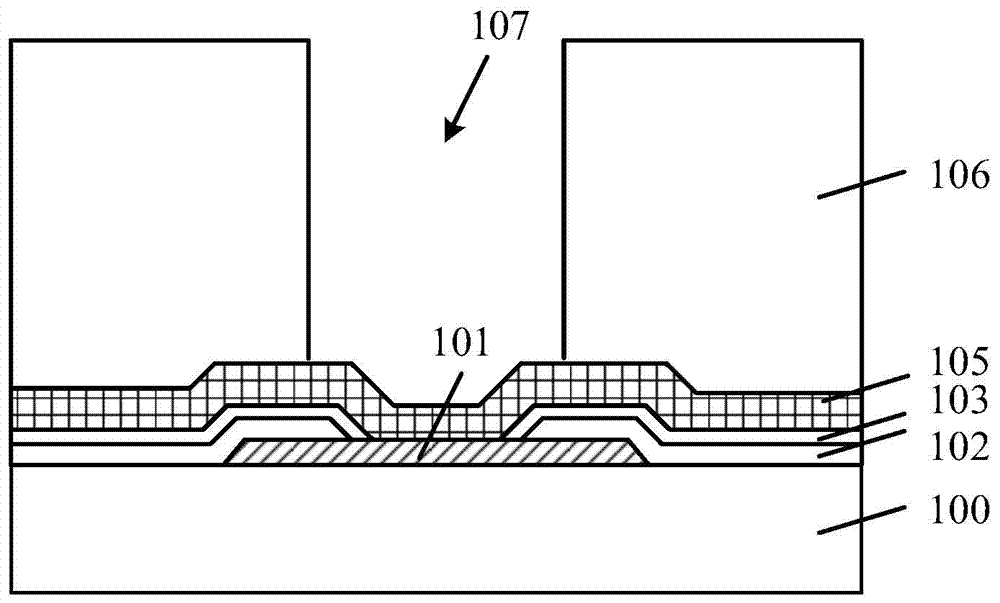

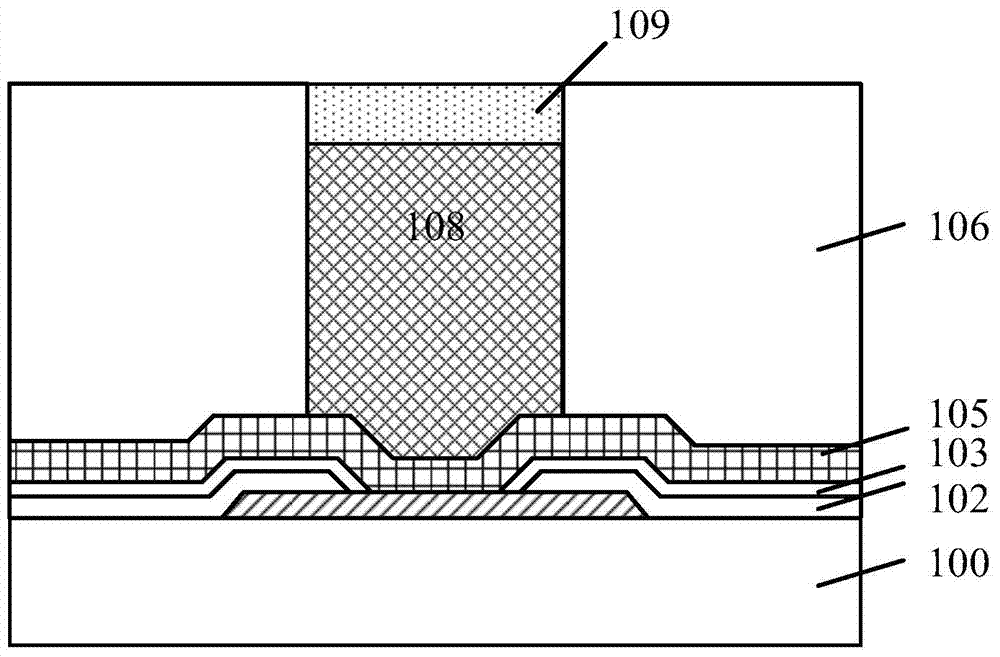

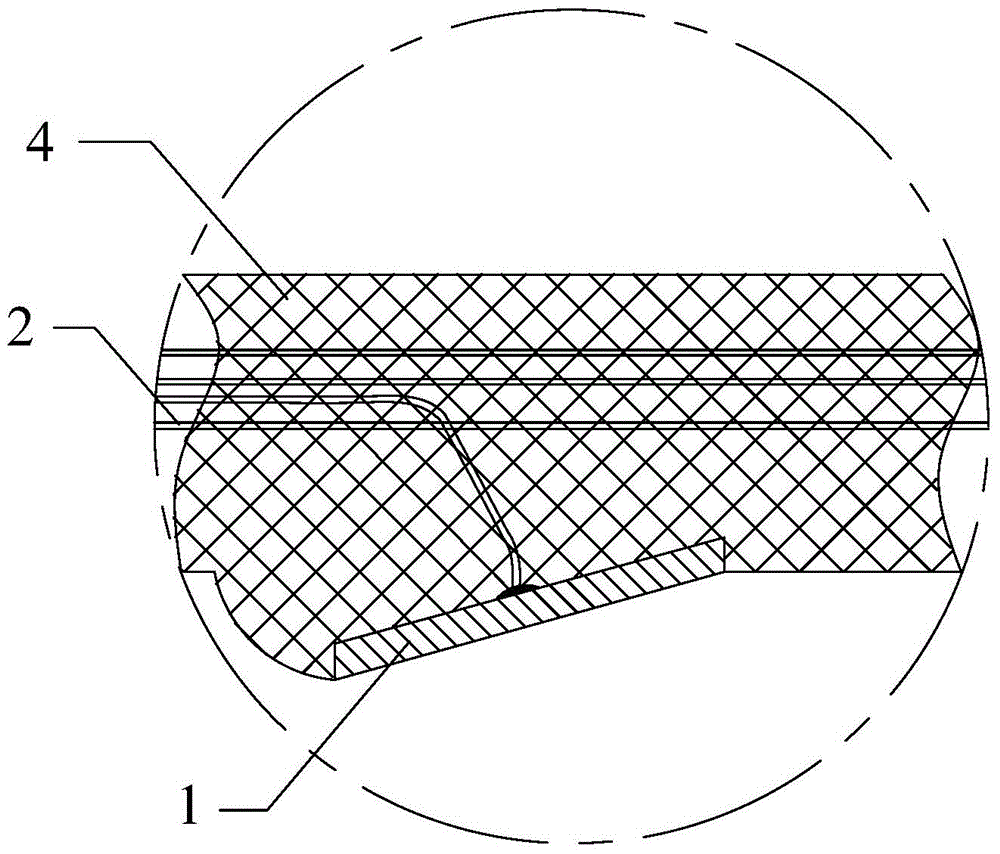

Grid stack structure and manufacturing method thereof

ActiveCN102386217ANot prone to gapsSemiconductor/solid-state device manufacturingSemiconductor devicesParasitic capacitanceWork function

The invention relates to a grid stack structure and a manufacturing method of the grid stack structure; the grid stack structure is formed on a semiconductor substrate which also comprises symmetrical gap wall structures; the grid stack structure comprises a high K-grid dielectric layer and a first work function layer which are formed between the gap wall structures and sequentially positioned on the semiconductor substrate; the high K-grid dielectric layer is contacted with vertical side walls of the gap wall structures; a metal gate electrode is also formed on the first work function layer; and the top of the metal gate electrode is parallel and level to the tops of the gap wall structures. The problem that a gap appears in the metal gate electrode can be avoided by the grid stack structure, and the parasitic capacitance of a grid can be reduced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

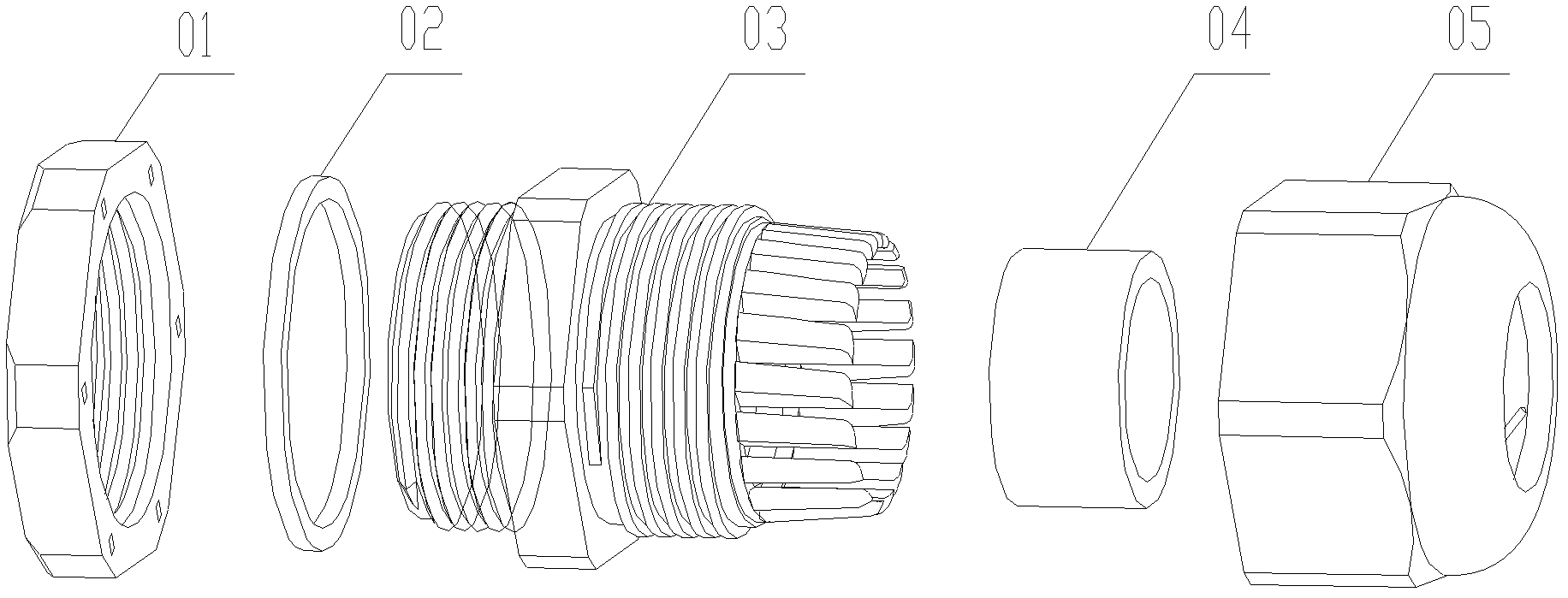

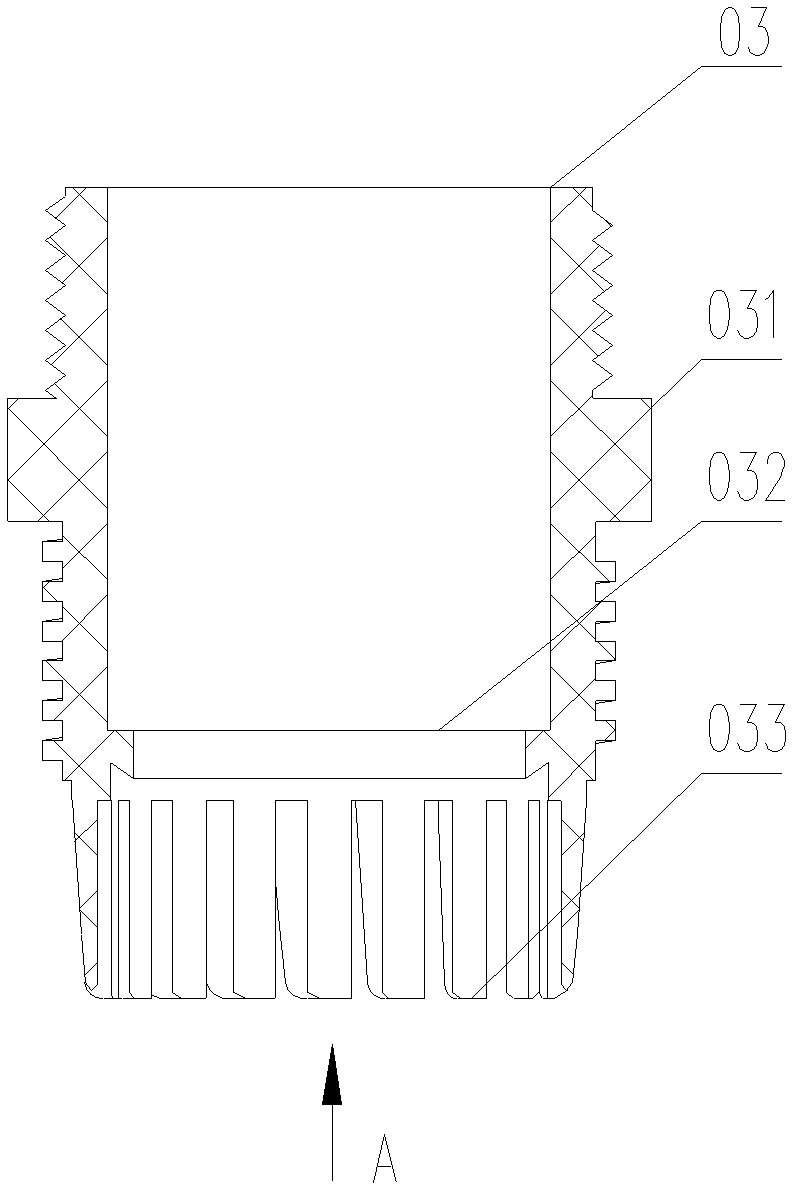

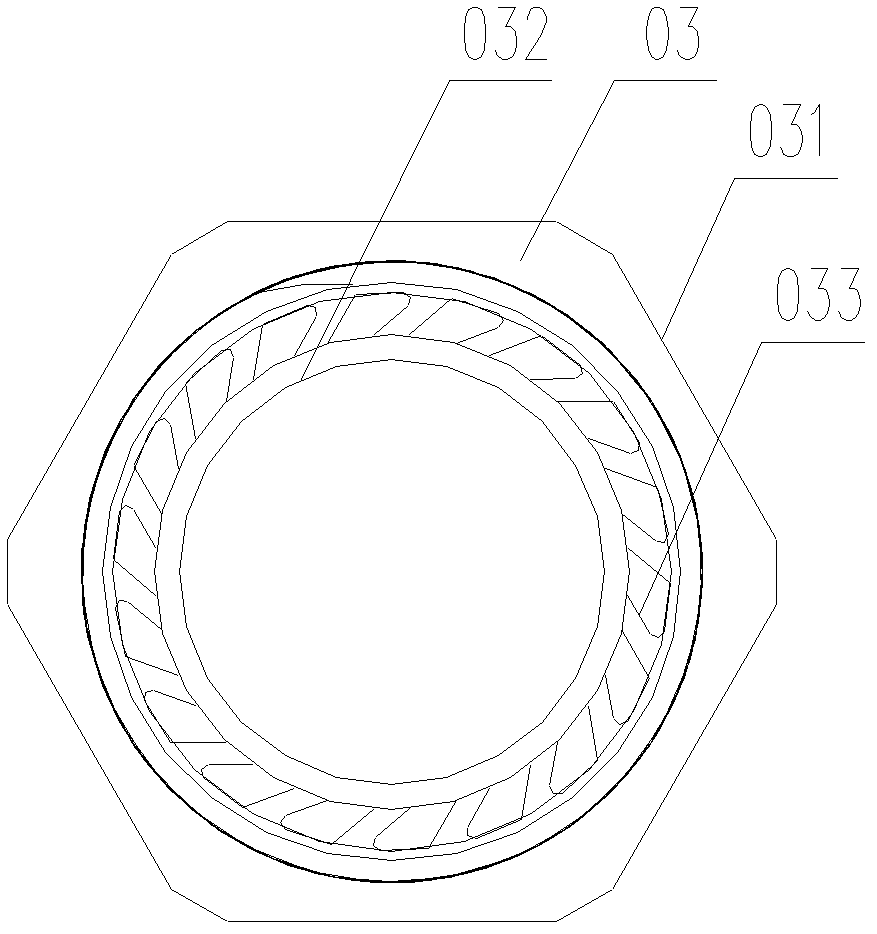

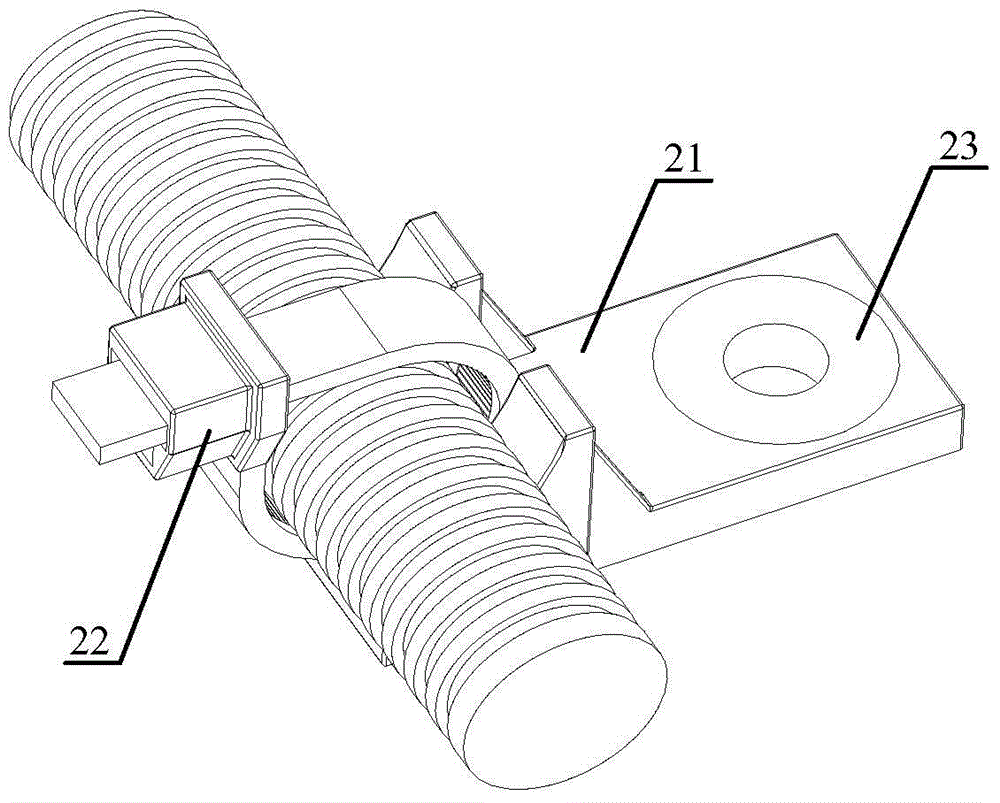

Cable fixing head

ActiveCN102856857AImprove the ability to resist external pullPrevent ejectionElectrical apparatusPipesCable glandPush out

The invention relates to the field of electric equipment, in particular to a cable fixing head. The cable fixing head comprises a nut, a waterproof ring, a tightening nut and a tubular body with outer threads. A clamping claw with gaps, which extends along the axial direction of the body, is disposed at a clamp end of the body. A fixed protrusion extending outwards is disposed on the outer periphery of the body. The nut is matched with a fixed end of the body. Positioning protrusions are disposed on the inner side of the clamping claw. A limit groove which opens towards the positioning protrusions is arranged on the inner wall of the body. Positioning grooves which are matched with the positioning protrusions are arranged at one end of the waterproof ring. The other end of the waterproof ring is inserted into the limit groove. The tightening nut is tightened at the clamp end of the body. The waterproof ring can be prevented from being pushed out by a cable, the water ring is less prone to deformation, and accordingly spacing between the waterproof ring and the body is avoided so as to improve airtightness between the waterproof ring and the body, dust, moisture and the like are prevented from entering a box, and stability of electric equipment elements in the box is improved.

Owner:BEISIT ELECTRIC TECH HANGZHOU CO LTD

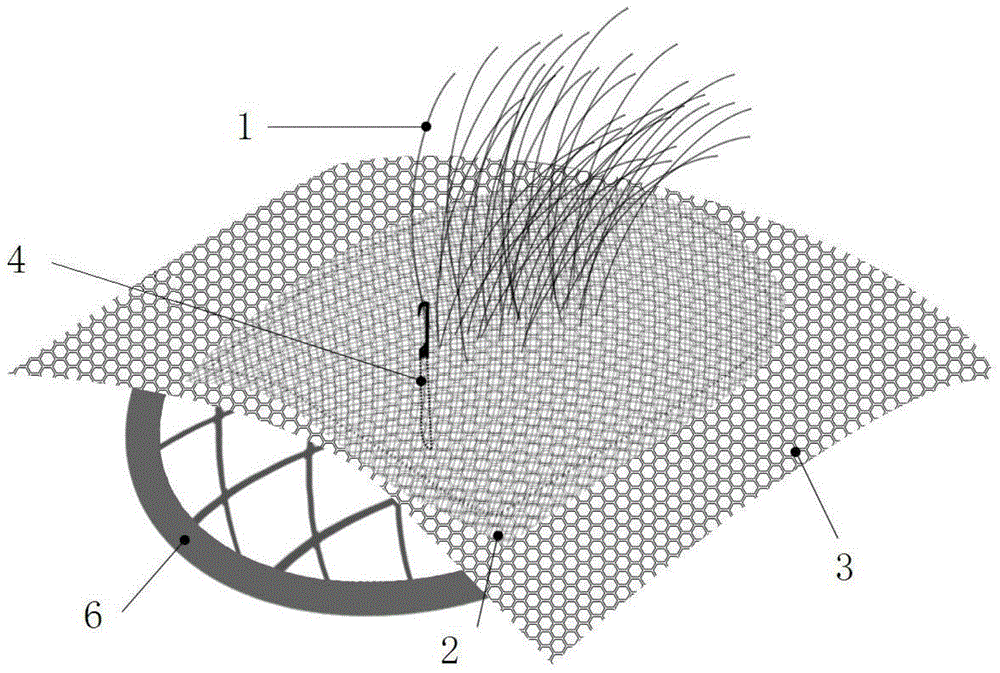

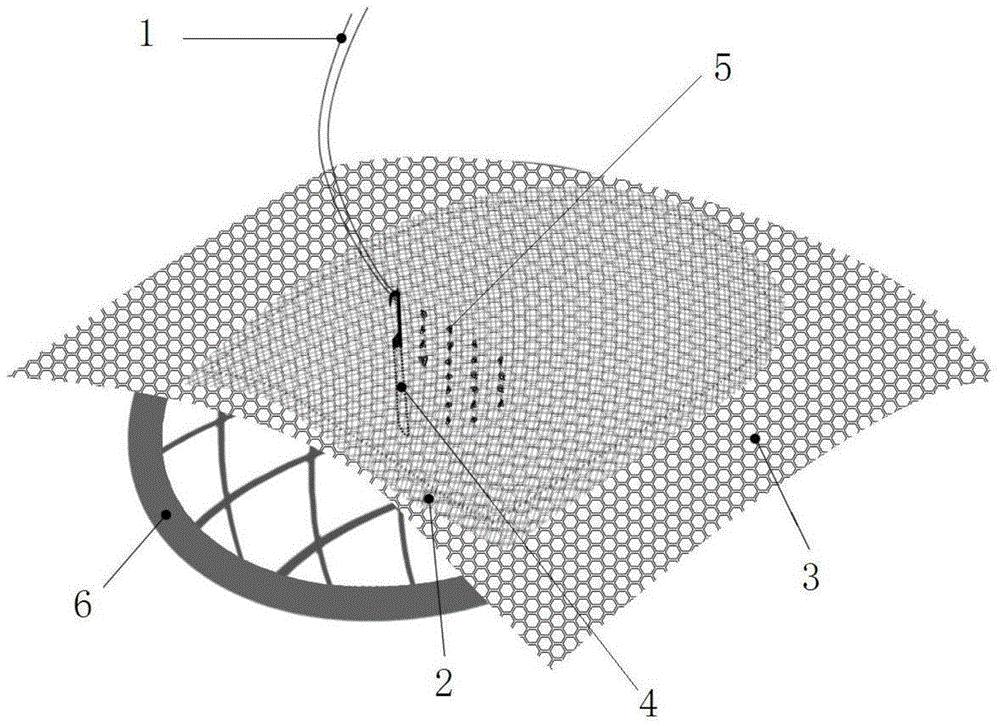

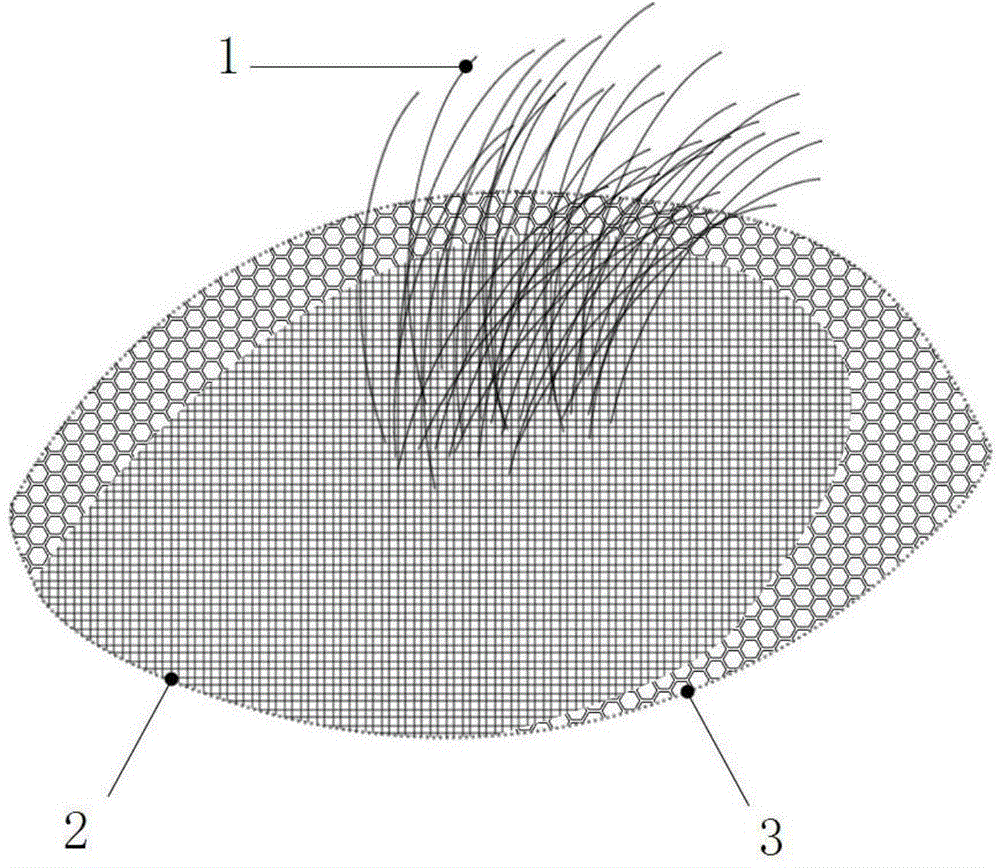

Wig production process

InactiveCN104905456ALess likely to cause unevennessVisually beautifulWigsHairpiece/toupeeSurface layer

The invention discloses a wig production process. The process comprises the following steps of fixing a wig base body composed of a surface layer hairnet and a bottom layer hairnet on a wig model with radian similar with the head radian of the human body; planning a hair flow direction on the wig base body, crocheting the wig hairline on the bottom hairnet by using a hooked bearded needle, when the wig hairline is exposed below the bottom layer hairnet and a hair knot is positioned at the back side of the bottom layer hairnet; crocheting the wig hairline exposed below the bottom layer hairnet above the surface layer hairnet after passing through the bottom layer hairnet and the surface layer hairnet in sequence; rotating the hair knot of the wig hairline on the other side of the bottom layer hairnet, wherein when the wig hairline penetrates out above the surface layer hairnet from the space between the bottom layer hairnet and the surface layer hairnet, the hair angle is set according to the preplanned hair flow direction. The wig made by using the method is light in texture, beautiful in visual sense, high in reality degree, small in clearance degree and good in ventilation effect, and can be worn all the year in a labor-saving and material-saving mode.

Owner:LYRICAL HAIR CORP

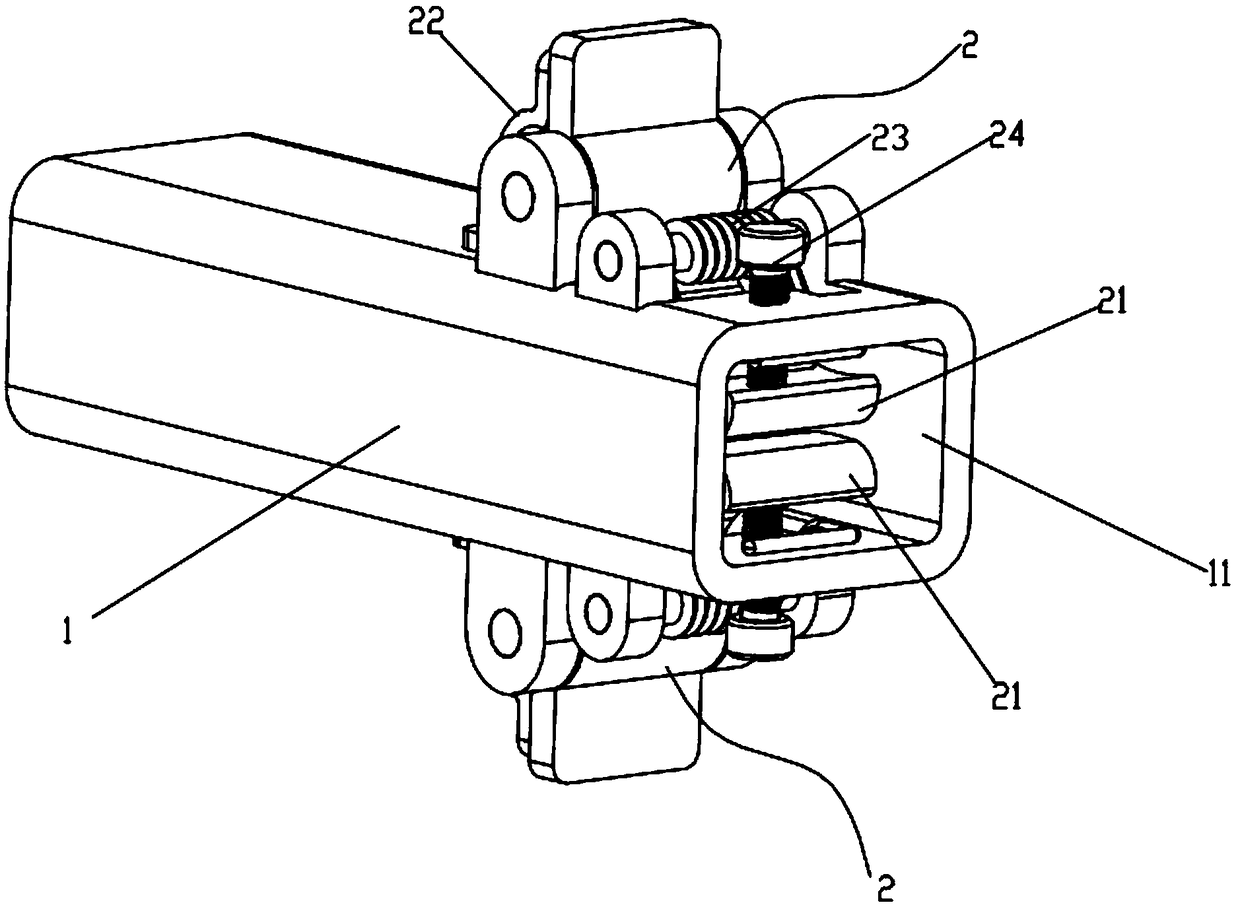

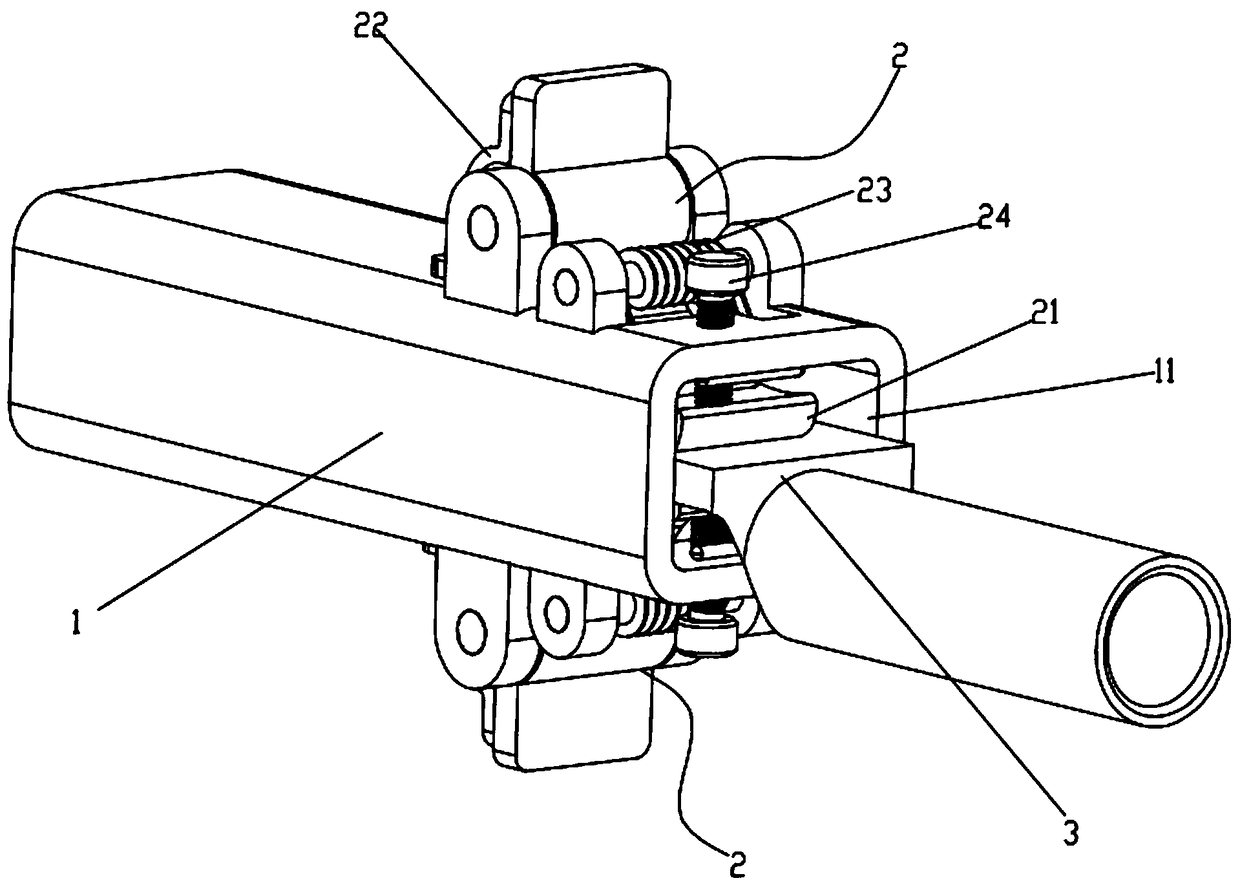

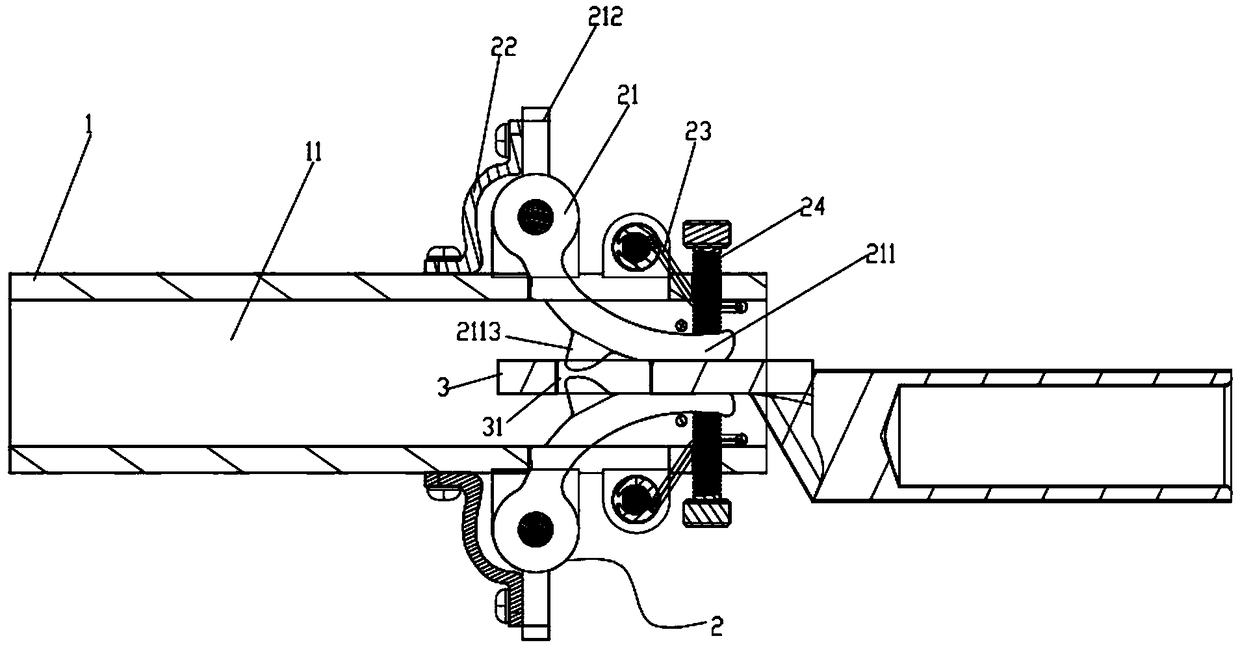

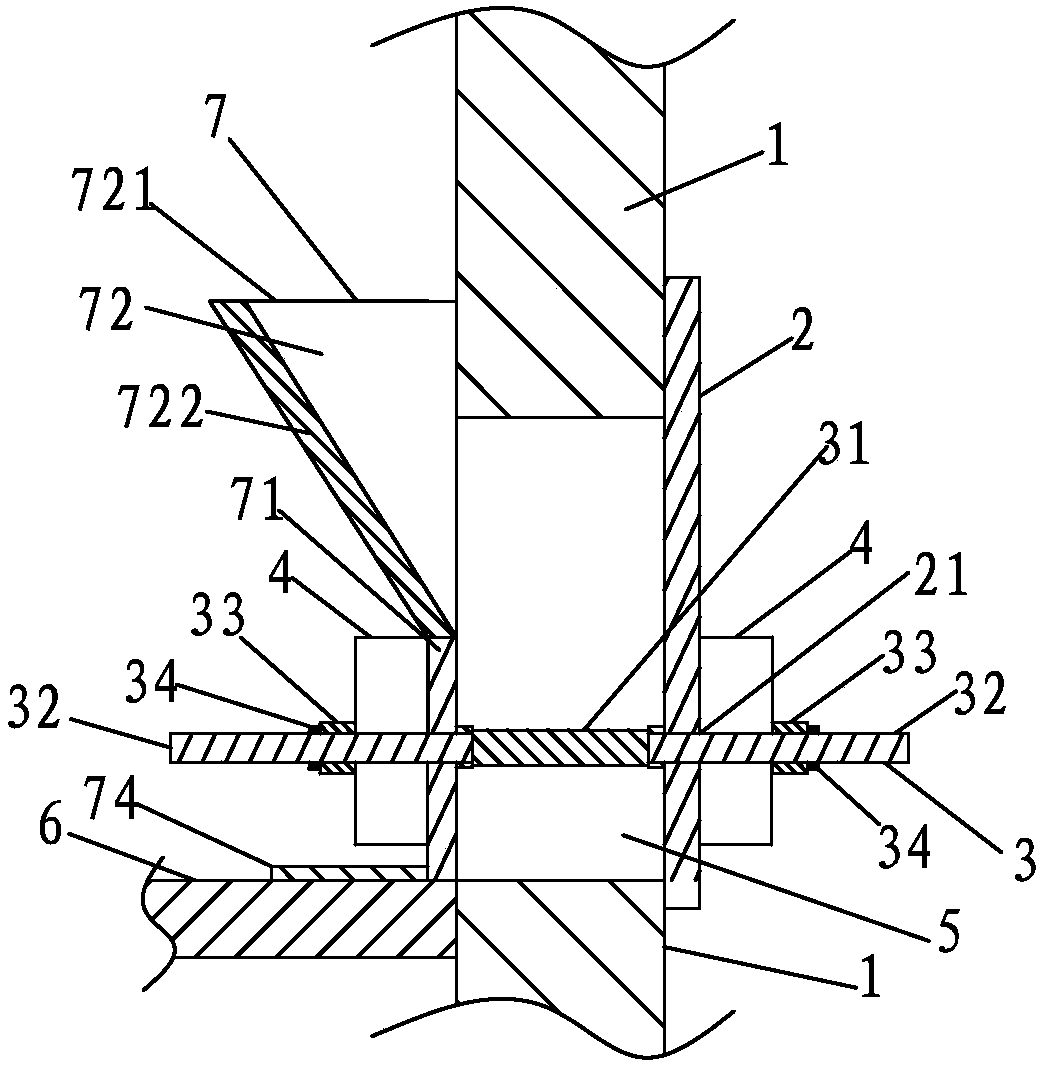

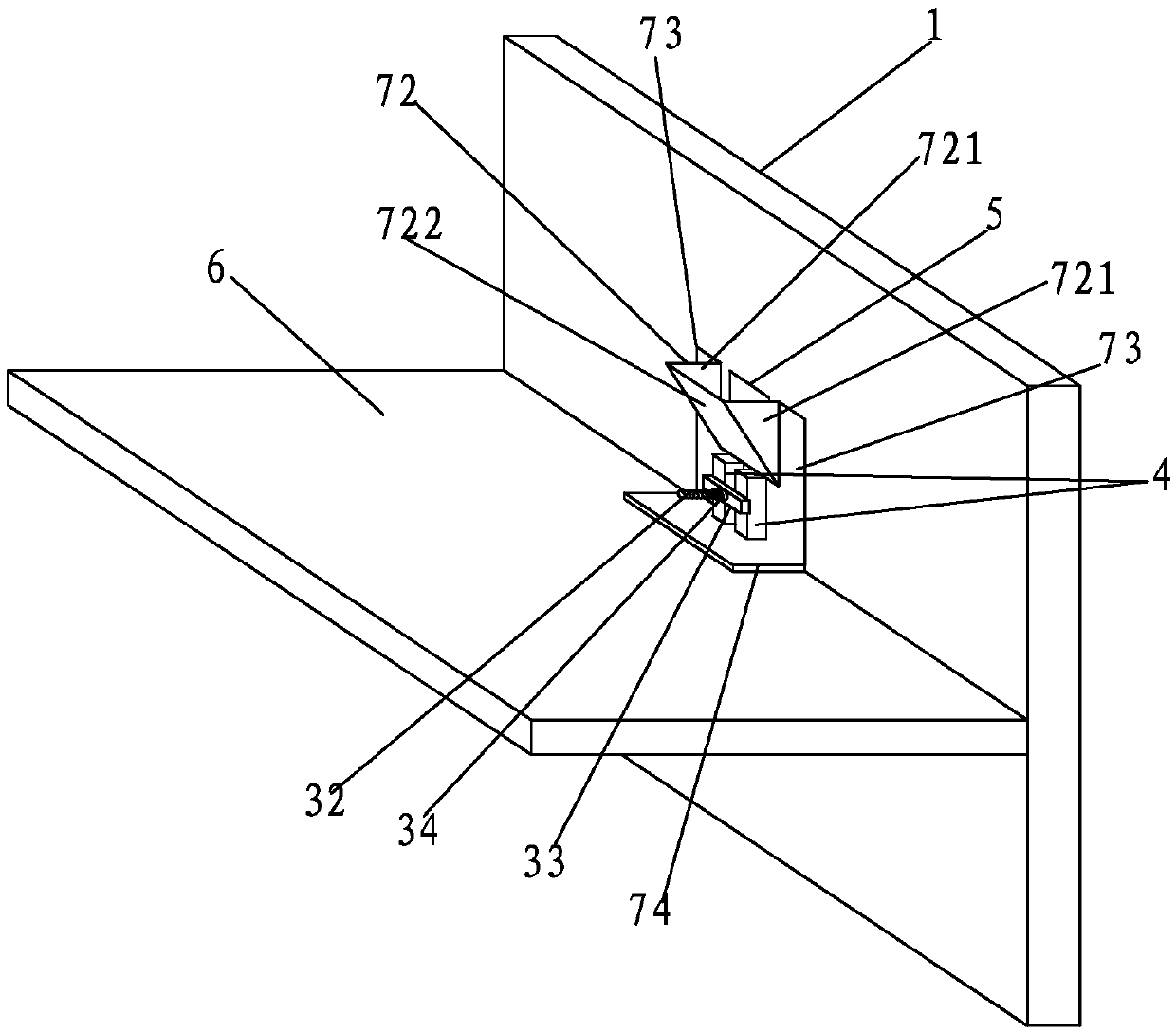

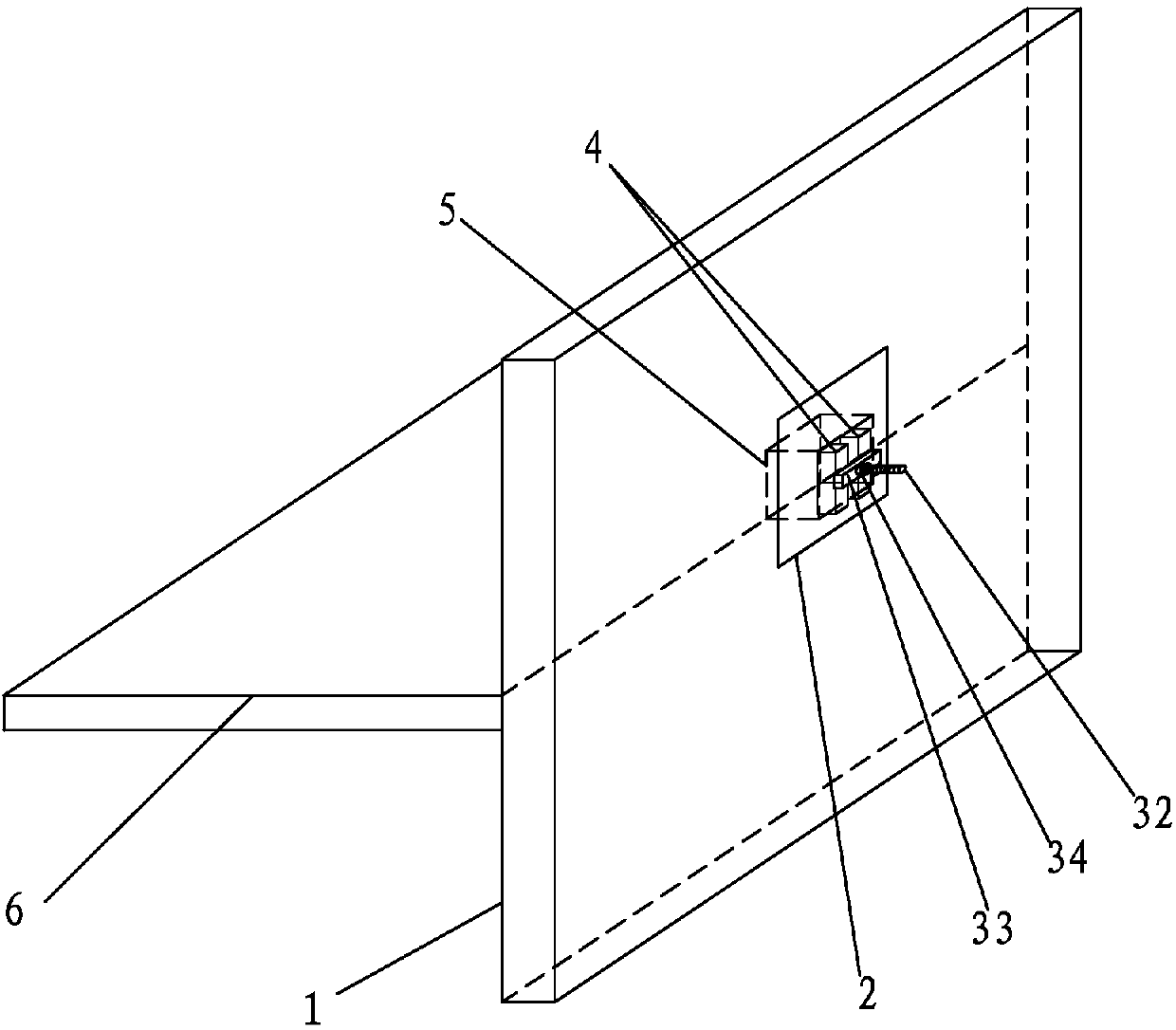

A terminal connection structure

The present invention relate to the field of power tool, in particular to a terminal connection structure, comprises a connecting seat and a two-action chuck, A plug hole is arranged on the connectingseat, A movable chuck comprises a splint and an elastic pressing member, the splints of the two moving chucks are respectively articulated with the connecting seat, As that two end of the two elasticpressing member abut on the connecting seat and the corresponding splint respectively, the clam ends of the two splints are pressed against each other to clamp the terminal, the clamping end includessuccessively arranged inlet segments, a flat pressure section and an anti-disengagement section, wherein the inlet section is raised in the opposite direction to the pressing direction so as to facilitate insertion of the terminal, the flat pressure section is a planar structure capable of abutting against the pressing of the terminal and forming an electrically conductive contact surface with the terminal, and the anti-disengagement section is provided with barbs inclined in the insertion direction of the terminal for hooking the terminal to prevent disengagement of the terminal; The terminal connection structure has the advantages of convenient operation, firm connection, tight contact of the conductive contact surface and no gap.

Owner:GUANGZHOU PANYU CABLE WORKS

Method for forming semiconductor packaging structure

ActiveCN103489804AImprove stability and reliabilityImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesEngineeringMask layer

A method for forming a semiconductor packaging structure comprises the steps of providing a semiconductor substrate and enabling a welding pad layer to be formed on the semiconductor substrate; forming a passivation layer covering the semiconductor substrate and part of the surface of the welding pad layer and enabling the passivation layer to be provided with a first opening which exposes part of the surface of the welding pad layer; forming concave metal layers on a side wall and the bottom of the first opening and the passivation layer; forming a first mask layer covering the concave metal layers and enabling the first mask layer to be provided with a second opening exposing part of the concave metal layers on the first opening; forming a metal column in the second opening; removing the first mask layer; forming a bottom layer metal layer on a side wall of the bottom of the metal column and part of the surfaces of the concave metal layers; removing second mask layers; and enabling the metal column and the bottom layer metal layer to serve as masks to remove the concave metal layers on two sides of the metal column by etching. According to the method, undercutting defects of the concave metal layers below the metal column are avoided.

Owner:NANTONG FUJITSU MICROELECTRONICS

Weather-resistant paint and preparation method thereof

PendingCN105670437AShort drying timeStrong weather resistanceFireproof paintsAntifouling/underwater paintsCellulosePolymer science

The invention provides weather-resistant paint and a preparation method thereof. The weather-resistant paint is prepared from the following ingredients in parts by weight: 30 to 42 parts of pure acrylic emulsion, 13 to 21 parts of pigment fillers, 8 to 12 parts of water glass, 0.5 to 1.2 parts of tea polyphenol, 0.05 to 0.15 part of antioxidant, 5 to 10 parts of sodium carboxymethylcellulose, 8 to 15 parts of diatomite, 1 to 5 parts of propylene glycol methyl ether acetate, 1 to 3 parts of rosin and 15 to 25 parts of water. The weather-resistant outer wall paint can be coated and brushed on an outer wall in modes of scraping coating, spray coating and the like; the paint drying time is short; the weather-resistant performance of the outer wall paint is high; the service life of the paint is prolonged; meanwhile, a good contamination resistant effect and a waterproof characteristic are realized; in addition, certain antiseptic and mildew proofing effects are also achieved; the weather-resistant paint belongs to paint with various functions; the application range is wide; the requirements of people on the outer wall paint are met.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

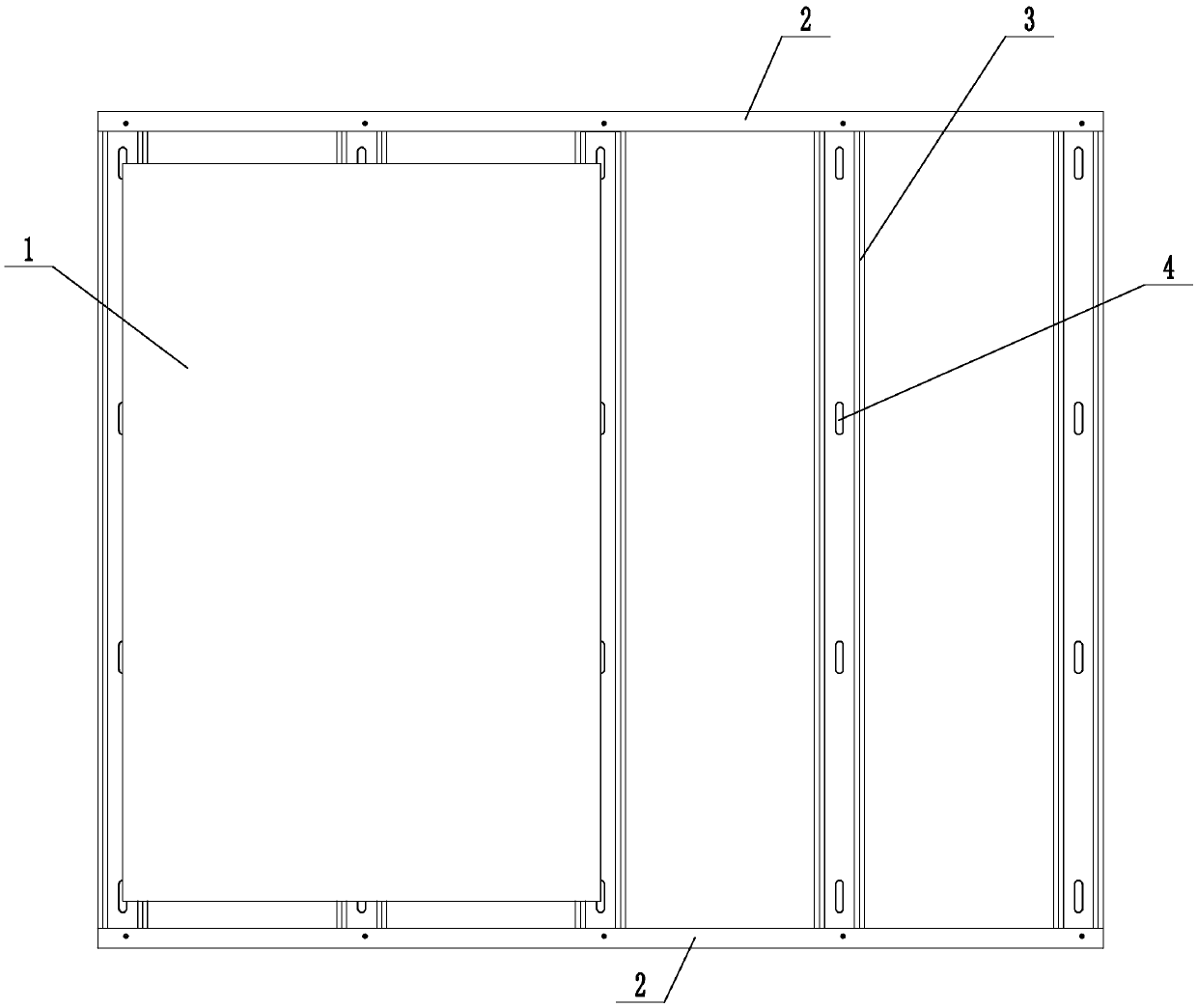

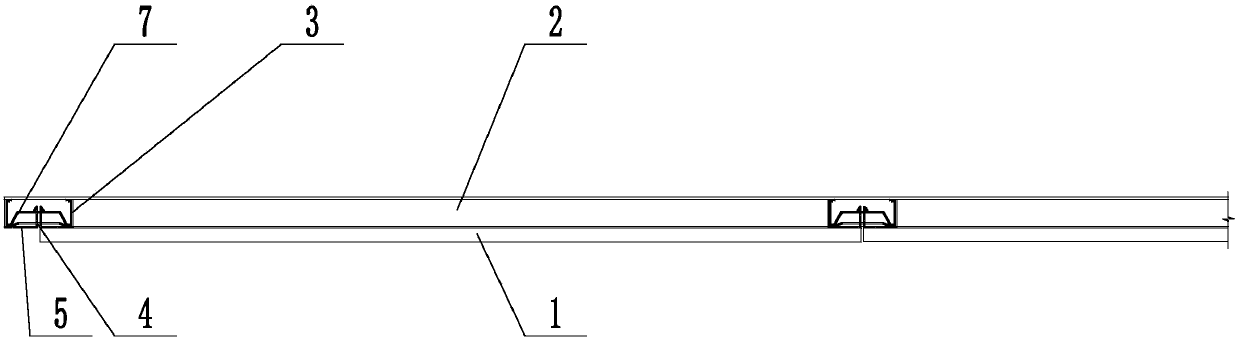

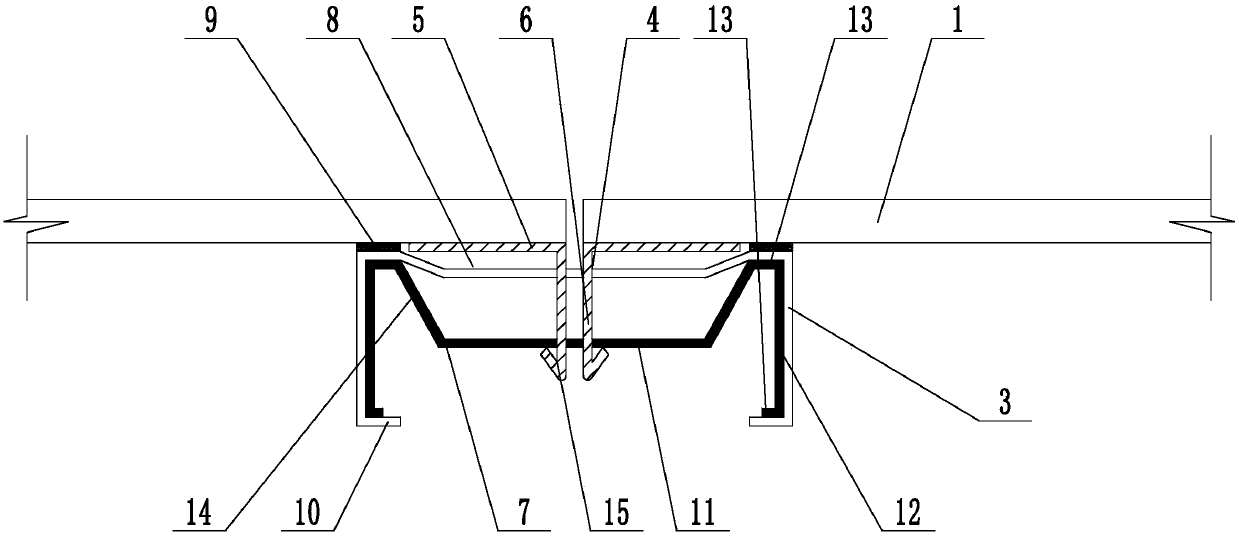

Assembled door pocket frame with adjustable width

InactiveCN103924867AAvoid deformationThe connection is tight and firmWindow/door framesConvex structureEngineering

The invention discloses an assembled door pocket frame with the adjustable width. The assembled door pocket frame comprises a main frame and an auxiliary frame capable of being assembled with the main frame. An auxiliary frame fixing groove is formed in one side of the main frame, and a plug matched with the auxiliary frame fixing groove is formed in one side of the auxiliary frame. The assembled door pocket frame is characterized in that a U-shaped connector is fixed in the auxiliary frame fixing groove, the opening direction of the U-shaped connector is the same as that of the auxiliary frame fixing groove, a concave-convex structure is formed in the inner edge of the side edge, close to the wall, of the U-shaped connector, an adjusting connector is fixed to the outer edge of the side, close to the wall, of the plug, and a convex-concave structure matched with the concave-convex structure is formed in the outer edge of the side, close to the wall, of the adjusting connector. According to the assembled door pocket frame with the adjustable width, the width of the door pocket frame can be adjusted according to the thickness of the wall, assembly is fast and convenient, the assembled door pocket frame is firm and stable, quantity production is suitable, and the problem that installation of an existing high-end wood door needs customization is solved.

Owner:黄仕哲

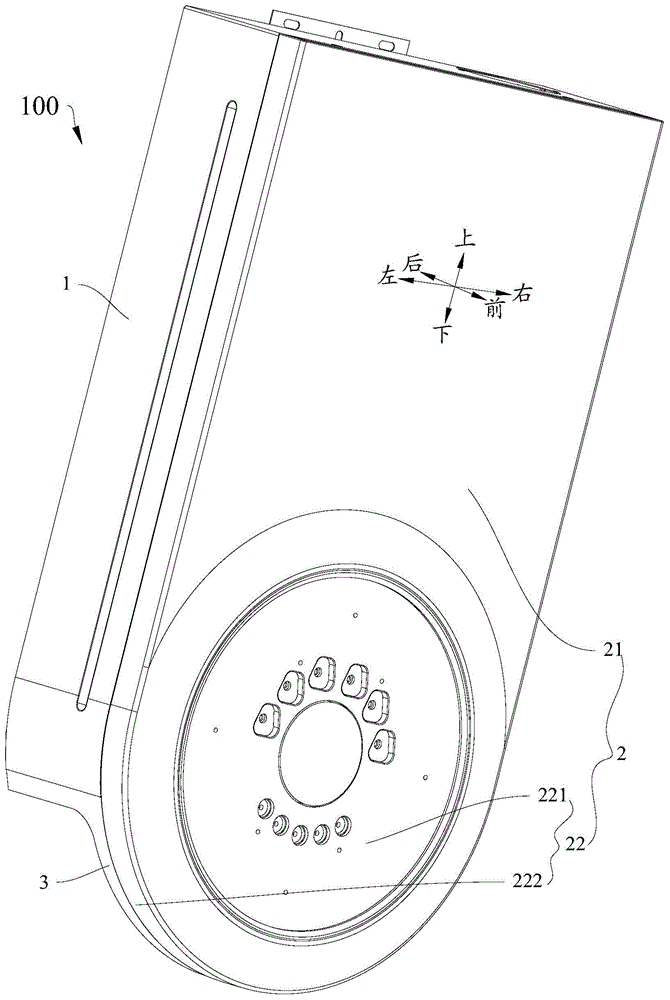

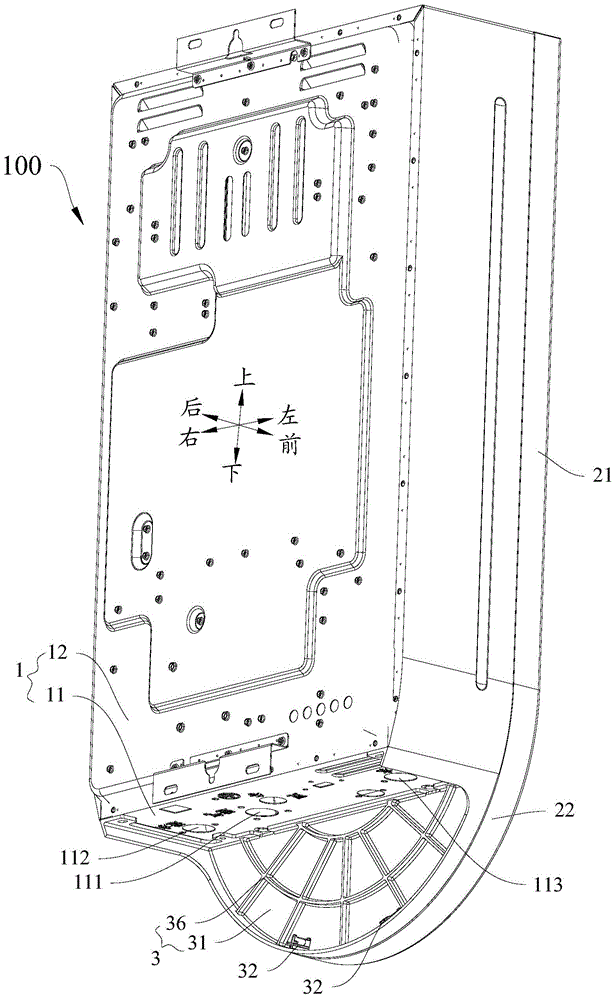

Gas water heater

ActiveCN104101093AGuaranteed aestheticsImprove assembly efficiencyFluid heatersEngineeringMechanical engineering

The invention discloses a gas water heater which comprises a shell, a face shell and a decorative sheet. The front side of the shell is open to form an opening. The face shell is arranged on the shell to close the shell; the face shell comprises a matching part and an extending part; the matching part is matched with the opening; the extending part extends downwards out of the lower surface of the matching part. The decorative sheet is buckled and connected to the rear surface of the extending part. According to the gas water heater disclosed by the embodiment of the invention, the decorative sheet is buckled and connected to the face shell, so that the decorative sheet is tightly connected with the face shell and a gap is not easy to generate, and thus, aesthetics of the gas water heater is ensured. Meanwhile, the decorative sheet is simple, rapid and convenient to install; moreover, the decorative sheet is arranged on the extending part in a detachable manner, so that assembling efficiency and maintainability of the gas water heater are improved and the service life of the gas water heater is prolonged.

Owner:WUHU MIDEA SMART KITCHEN APPLIANCE MFG CO LTD

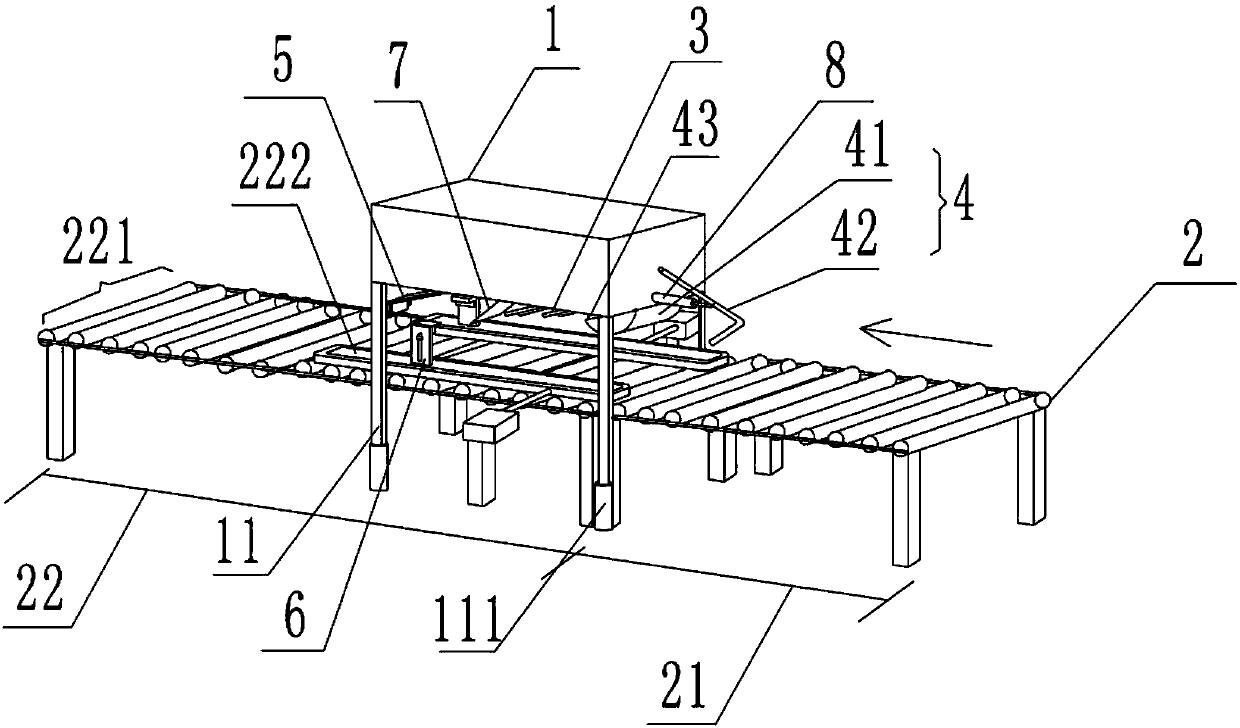

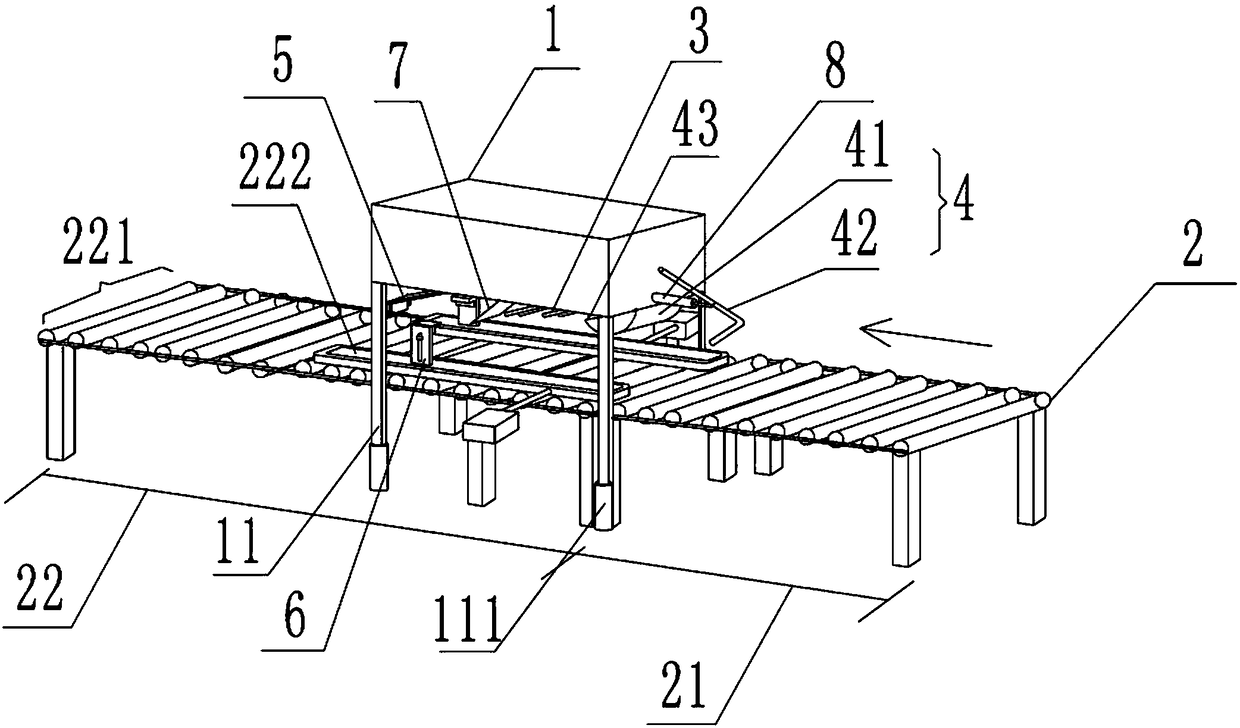

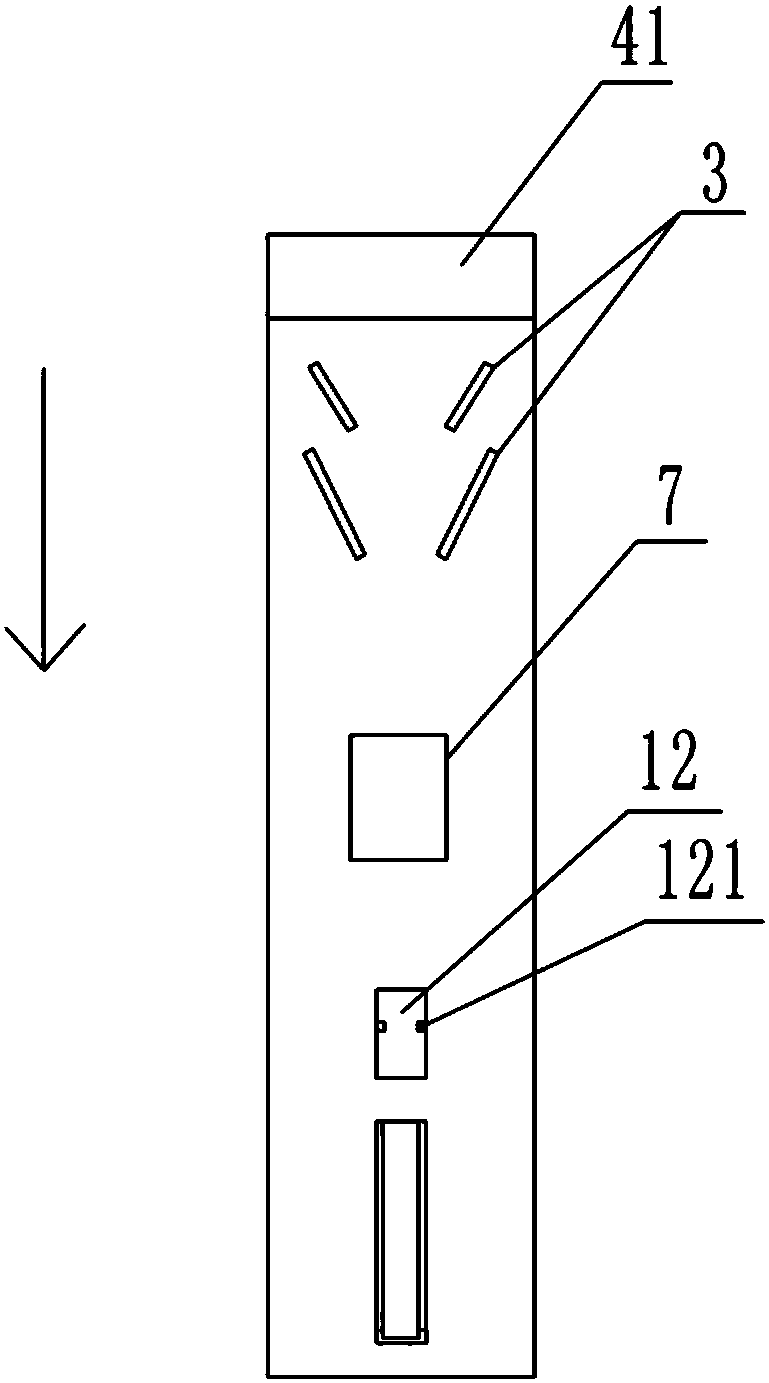

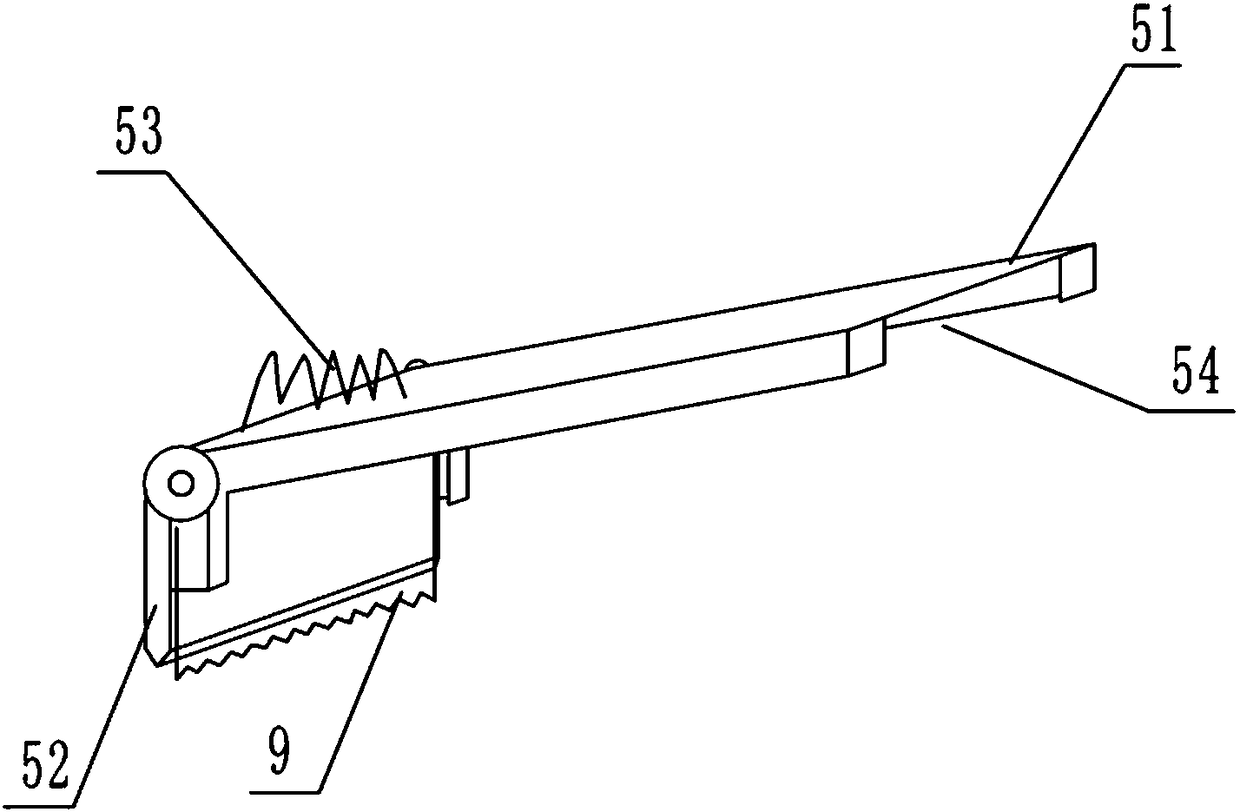

Electronic product carton sealing machine

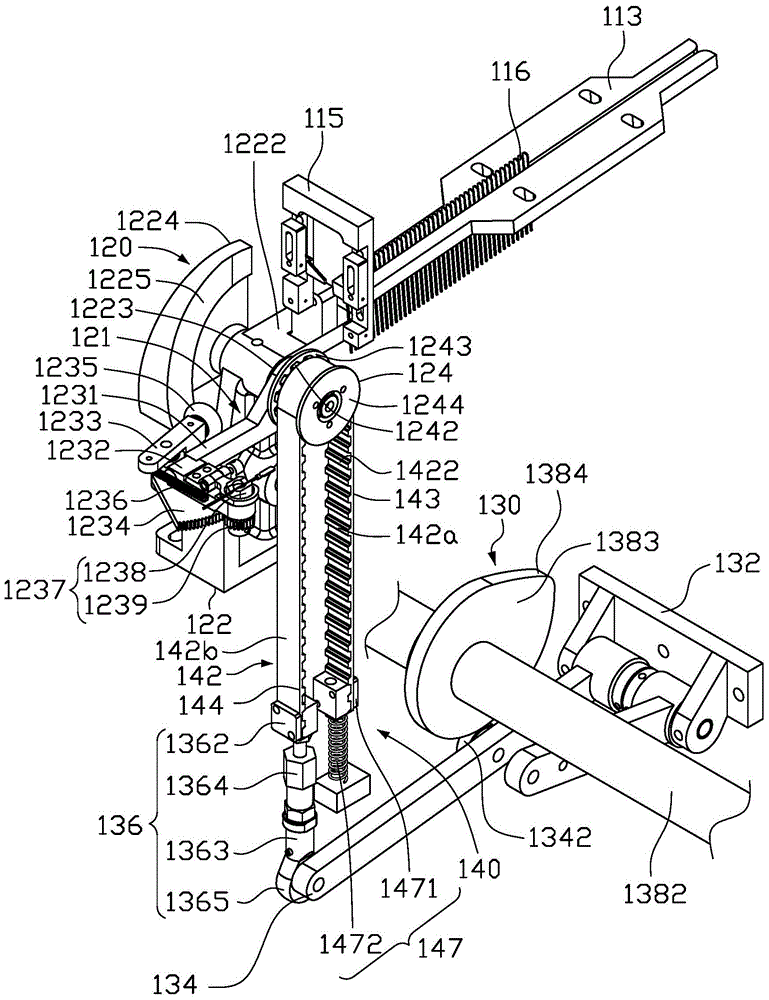

InactiveCN108045655AImprove sealing efficiencyQuality assuranceWrapper twisting/gatheringCartonEngineering

The invention relates to the technical field of forward movement mechanisms, in particular to an electronic product carton sealing machine. The electronic product carton sealing machine comprises a machine frame body, a conveying part, a side plate flattening part, an end plate flattening part and an adhesive tape sticking part. The end plate flattening part, the side plate flattening part and theadhesive tape sticking part are all sequentially arranged in the conveying direction of the conveying part. Telescoping parts are arranged at the bottom of the machine frame body. The conveying partcomprises a rear conveying part body and a front conveying part body which is formed by a chain drive roller bed. The rear conveying part body comprises a conveying rack. The upper surface of the conveying rack is provided with a conveying plane which is composed of a plurality of cylinders, and the two sides of the cylinders are connected with the two sides of the conveying rack separately. The conveying plane is provided with sliding bars which can move oppositely along the conveying plane and are used for clamping packing boxes. A conveying belt is arranged on the side faces of the slidingbars. The sliding bars are further provided with squeezing parts used for squeezing the upper portions of the packing boxes. A limiting part used for preventing flattened side plates and end plates ofthe packing boxes from being warped upwards is further arranged at the bottom of the machine frame body. According to the scheme, the packing boxes of various specifications can be sealed and gaps inthe sealed positions can be prevented.

Owner:重庆市长寿区普爱网络科技有限公司

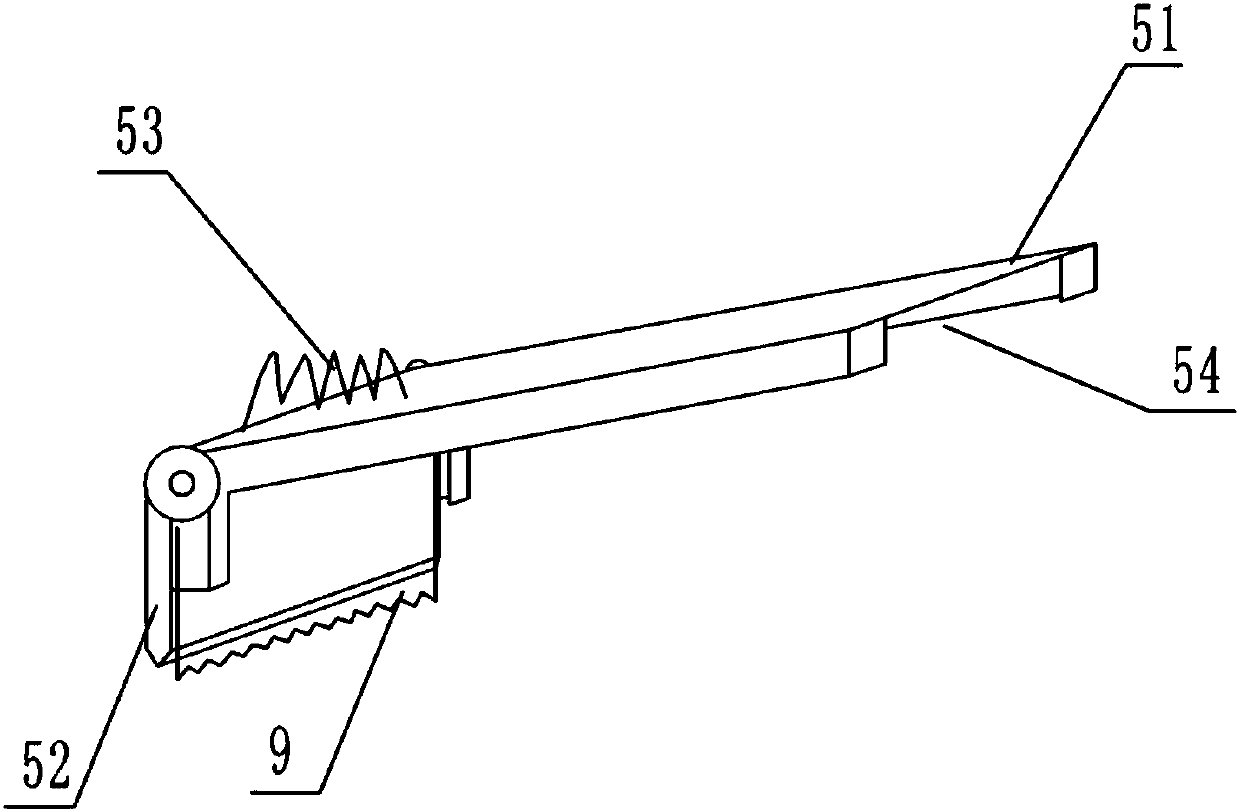

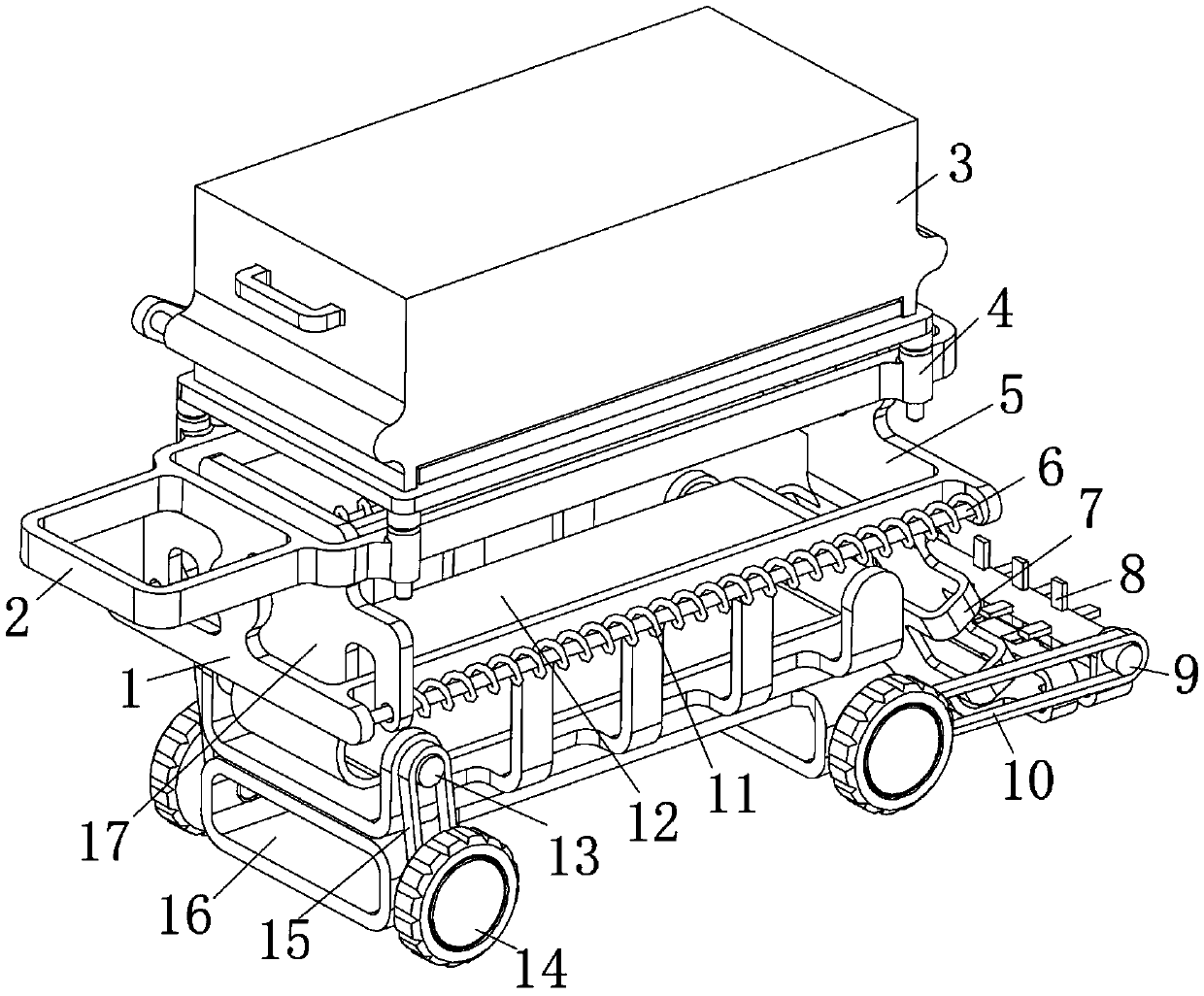

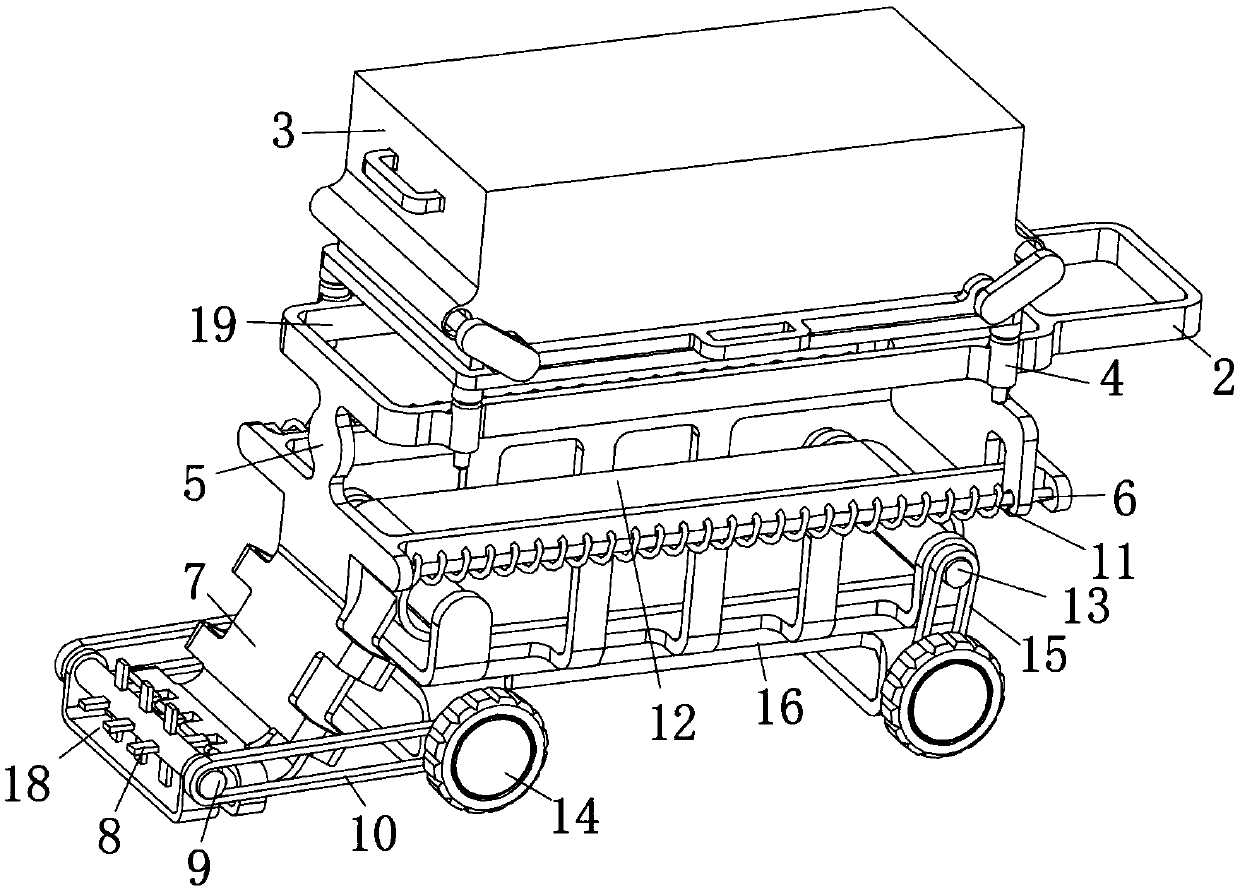

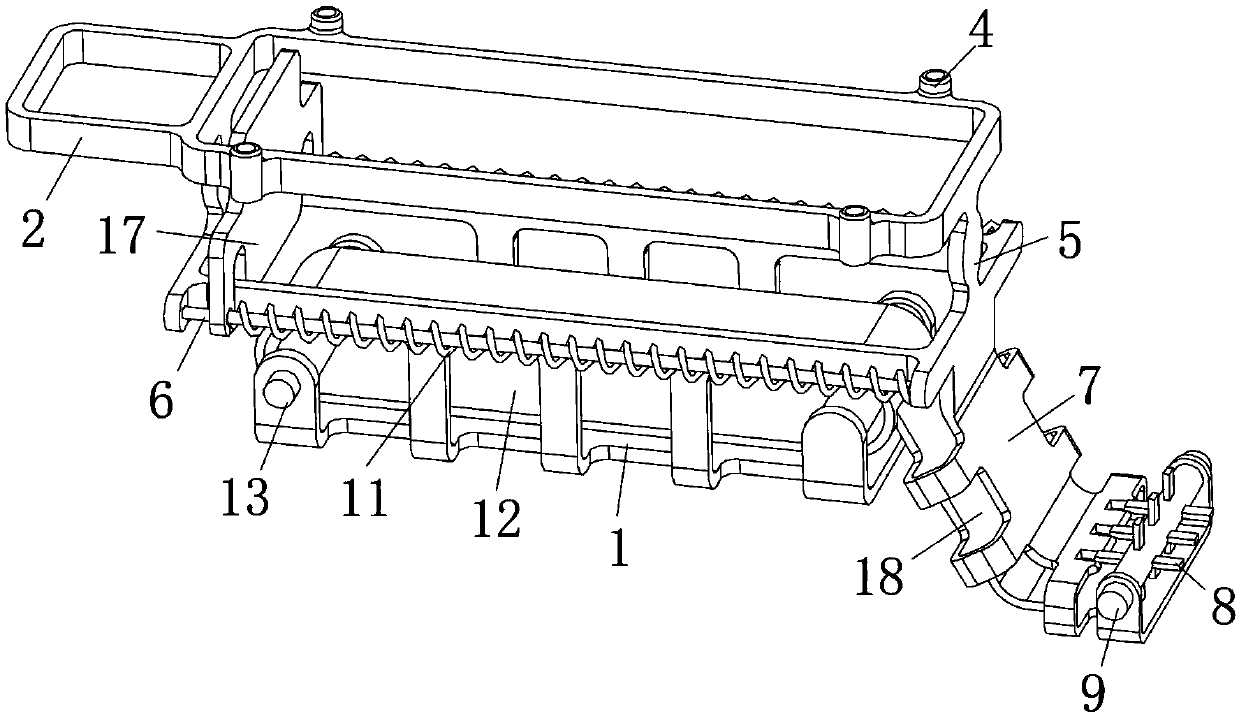

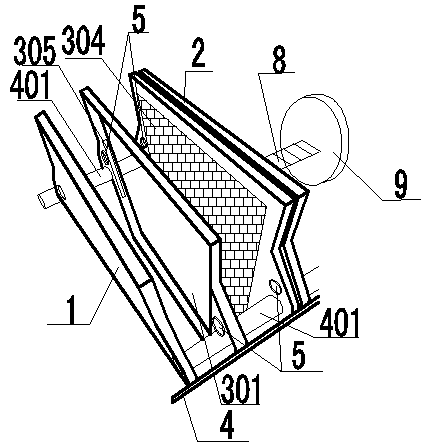

Hand-held turf paving machine

ActiveCN109526591AImprove continuityReduce occupancyHops/wine cultivationTurf growingHand heldEngineering

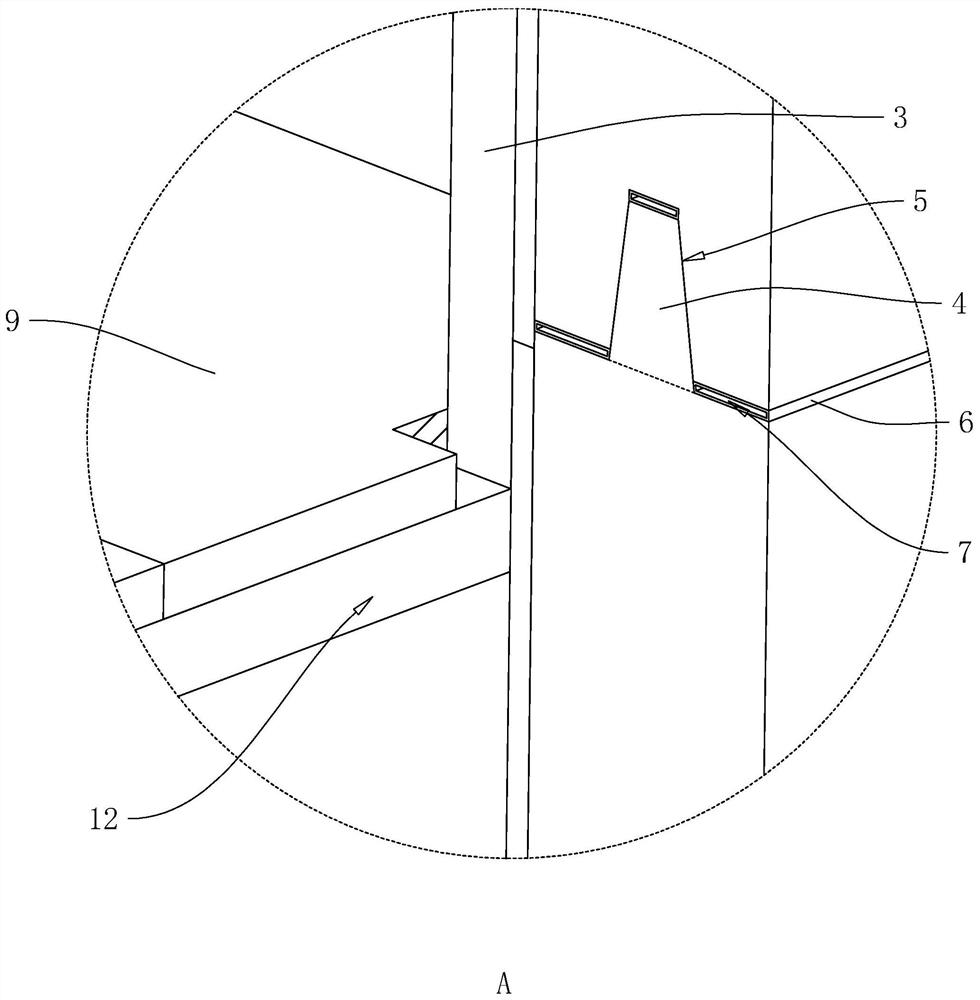

The invention relates to the field of garden building machinery, and discloses a hand-held turf paving machine. The turf paving machine comprises a connection rack. A pair of baffle plates is welded above the connection rack. A support rack is welded above the baffle plates. The front side and rear side of the connection rack are both fixedly provided with a guide rod. A push plate is slidingly arranged on the guide rods. The push plate and the tail ends of the guide rods are connected by reset springs. A conveyor belt is fixedly arranged on the connection rack. The provided turf paving machine can be used by one person or two persons, the paving is carried out by the turf paving machine, people do not need to deliver the turfs one by one manually, the labor is greatly reduced, the pavingspeed is automatically matched with the moving speed of the rollers of the turf paving machine by two synchronous belts, during the paving process, the turfs are continuously paved, and the physical output of an operator during the paving process is lower.

Owner:THE SECOND INSULATING MATERIAL FACTORY OF WENLING

Electronic product container packing method

InactiveCN108100330AImprove sealing efficiencyQuality assuranceWrapper twisting/gatheringEngineeringPacking method

The invention relates to the technical field of shifting mechanisms, in particular to an electronic product container packing method. The electronic product container packing method comprises a framebody, a conveying part, a side plate leveling part, an end plate leveling part and an adhesive tape bonding part; the end plate leveling part, the side plate leveling part and the adhesive tape bonding part are arranged in a conveying direction of the conveying part in sequence; an extension part is arranged at the bottom of the frame body; the conveying part comprises a back conveying part, and afront conveying part consisting of a chain transmission roller way; the back conveying part comprises a conveying frame; the upper surface of the conveying frame is a conveying plane consisting of multiple cylinders; the two sides of the cylinders are connected with the two sides of the conveying frame; the conveying plane is provided with slide bars capable of oppositely moving along the conveying plane and clamping packing containers; conveying belts are arranged on the side surfaces of the slide bars; the slide bars are provided with extrusion parts for extruding the upper parts of the packing containers; and limiting parts for preventing side plates and end plates of the leveled packing containers from upwards turning are arranged at the bottom of the frame body. The electronic product container packing method not only can seal the packing containers with multiple specifications, but also can prevent generation of gaps in seals.

Owner:重庆市长寿区普爱网络科技有限公司

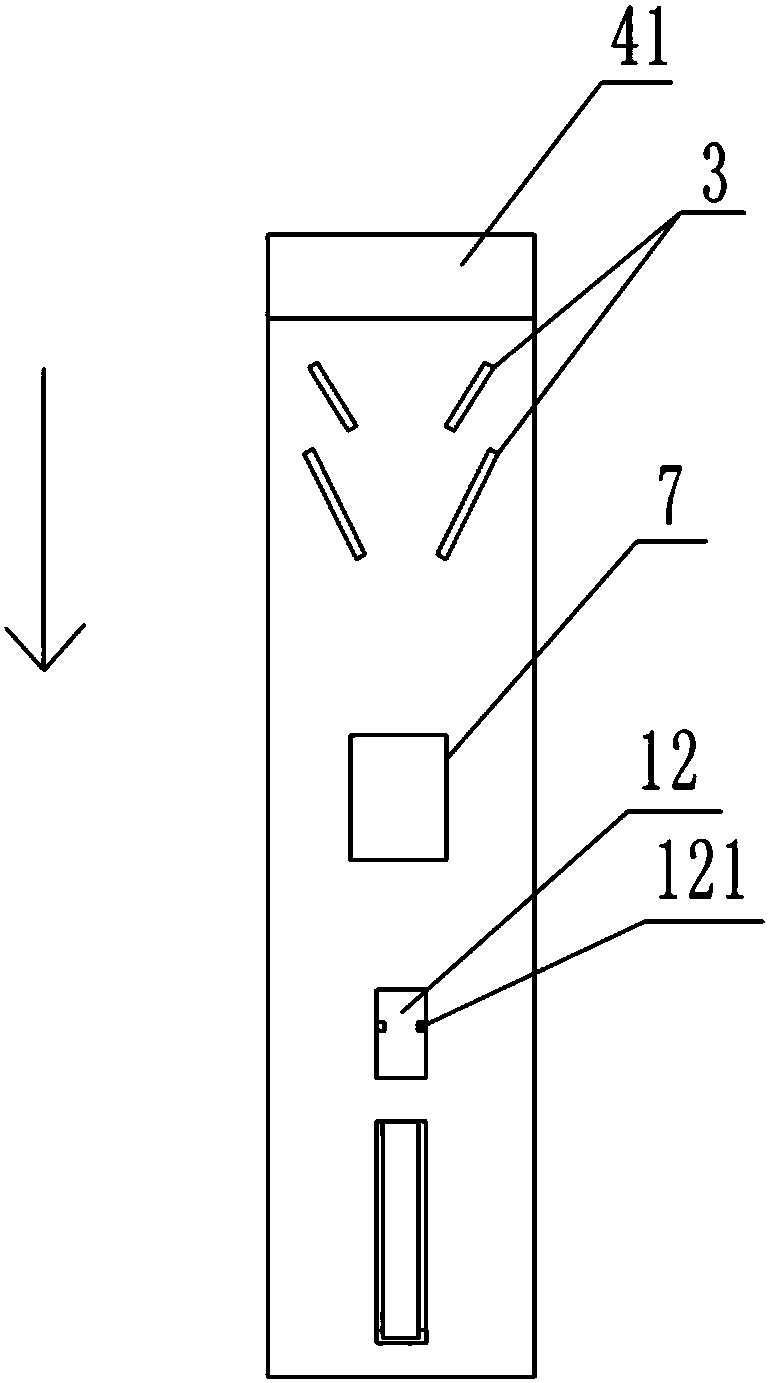

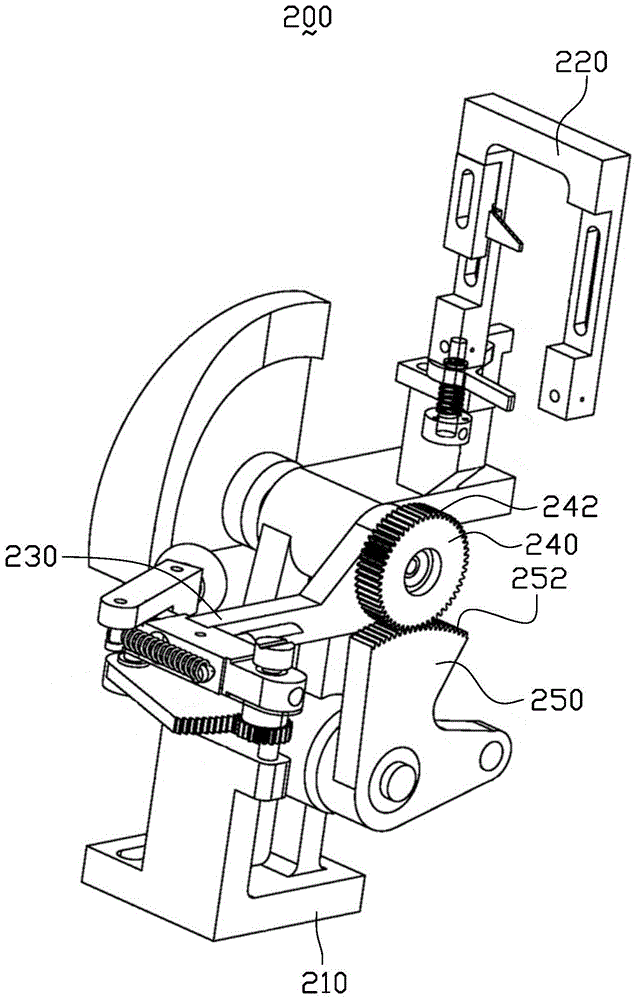

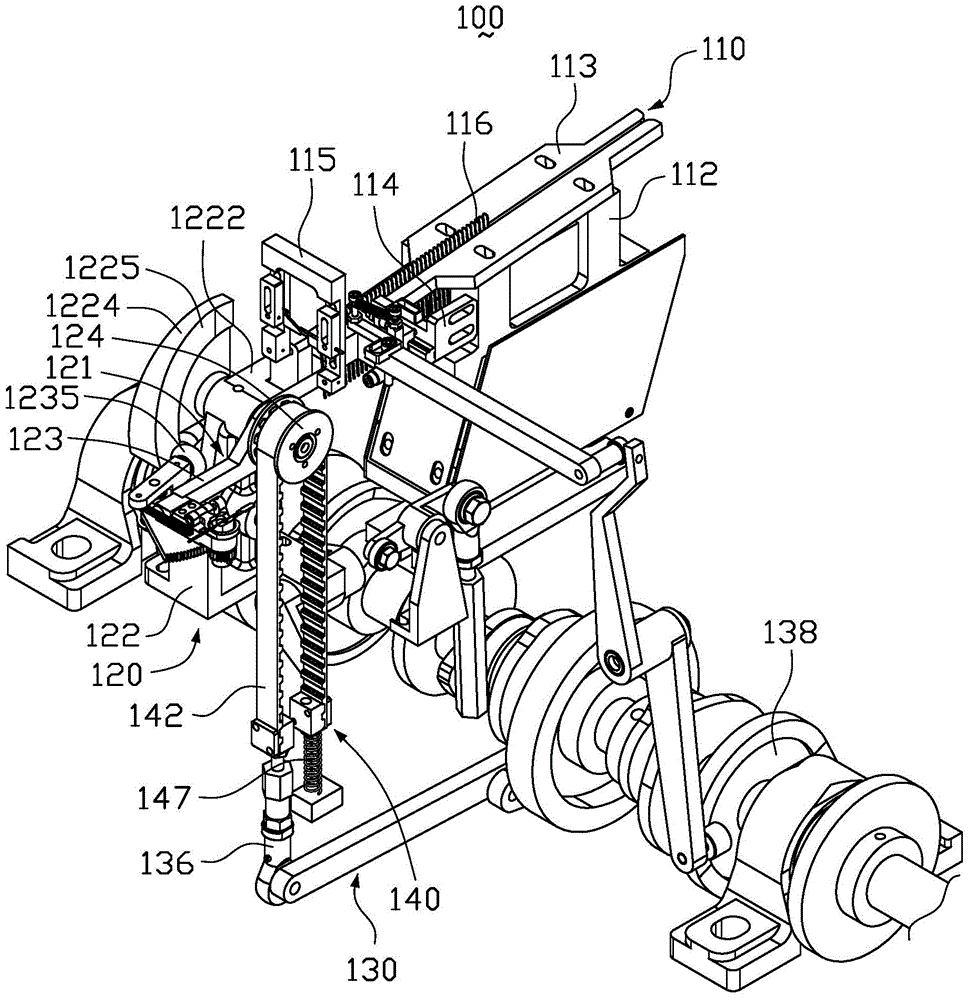

Capacitor nailing machine discharge device

A capacitor nailing machine discharge device comprises a needle guide and collection mechanism. The needle guide and collection mechanism comprises a machine base and a turning mechanism arranged on the machine base in a rotating mode. The turning mechanism comprises a drive wheel and a turning arm fixed to the drive wheel. The capacitor nailing machine discharge device further comprises a turning drive mechanism and a transmission mechanism. The transmission mechanism comprises a synchronous belt and an elastic assembly connected to one end of the synchronous belt. The turning drive mechanism is connected to the other end of the synchronous belt and drives the synchronous belt to drive the drive wheel, and the turning arm is driven to rotate and reset. Overall structural shaking of the capacitor nailing machine discharge device can be avoided, and the capacitor nailing machine discharge device can normally conduct needle collection and discharge.

Owner:SHENZHEN CHENGJIE INTELLIGENT EQUIP CO LTD

Prefabricated segment assembling concrete bridge pier and assembling method

InactiveCN110029570AIncreased shear capacityNot easy to slipBridge structural detailsBridge erection/assemblyShear capacityBearing capacity

The invention discloses a prefabricated segment assembling concrete bridge pier and an assembling method. Top mounting grooves for mounting shear keys and bottom mounting grooves for mounting the shear keys are correspondingly formed in the upper end surface and the lower end surface of a bridge pier prefabricated section, the upper end surface of a lower part bridge pier fabricated section is connected with the lower end surface of an upper part bridge pier prefabricated section in an abutting-against mode, thus the notches of the top mounting grooves of the lower part bridge pier prefabricated section are opposite to those of the bottom mounting grooves of the upper part bridge pier prefabricated section, the top mounting grooves and the bottom mounting grooves are matched with each other to form containing cavities for containing the shear keys, grouting holes communicating with the containing cavities and slurry discharging holes communicating with the containing cavities are formed in the surface of the bridge pier prefabricated section, grouting materials are solidified to form the shear keys, and the shear keys are arranged through the method. The bridge pier has large shearcapacity, thus seamless assembling between the bridge pier prefabricated sections is actually achieved, the two bridge pier prefabricated sections are not prone to sliding, water is prevented from entering the inner part of a bridge pier to erode the internal structure of the bridge pier, and thus the shear capacity is further improved.

Owner:段海涛

Blocking method of outer wall hole and blocking filling hopper

The invention provides a blocking method of an outer wall hole and meanwhile further provides a blocking filling hopper of the outer wall hole. The inner wall of the hole is roughened and cleaned completely, then the filling hopper is arranged on the inner side of the outer wall hole, a blocking piece is arranged on the outer side of the outer wall hole and connected and fixed through a three-section type water stop split bolt, and then concrete is poured from the filling hopper. The method is simple, operation is convenient, the outer wall hole can be effectively blocked, and the permeabilityresistance is improved. In filling, self-weight of the concrete can be utilized, filling is facilitated, operation is convenient, the structure is simple, and hollowing and cracks are not prone to occurring.

Owner:福建建工集团有限责任公司 +1

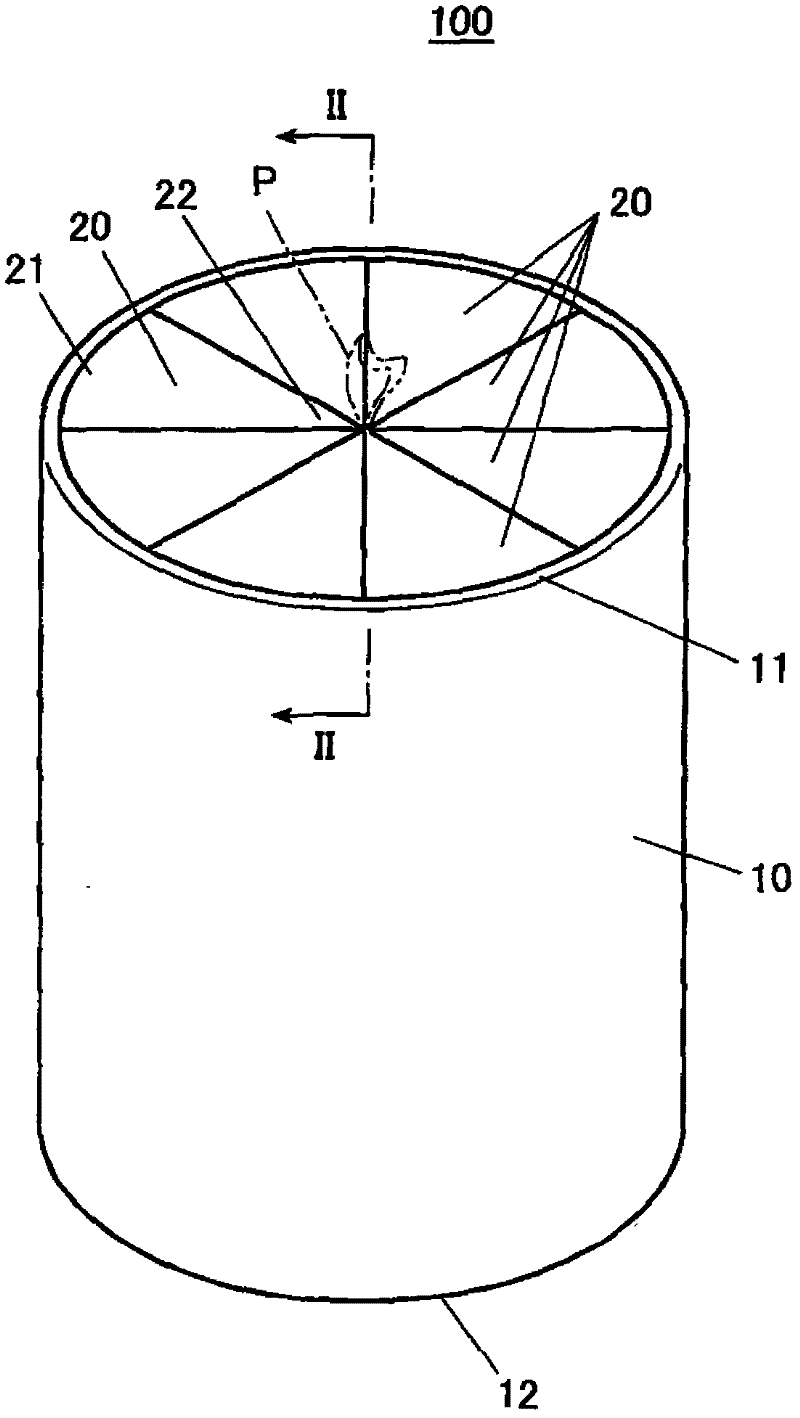

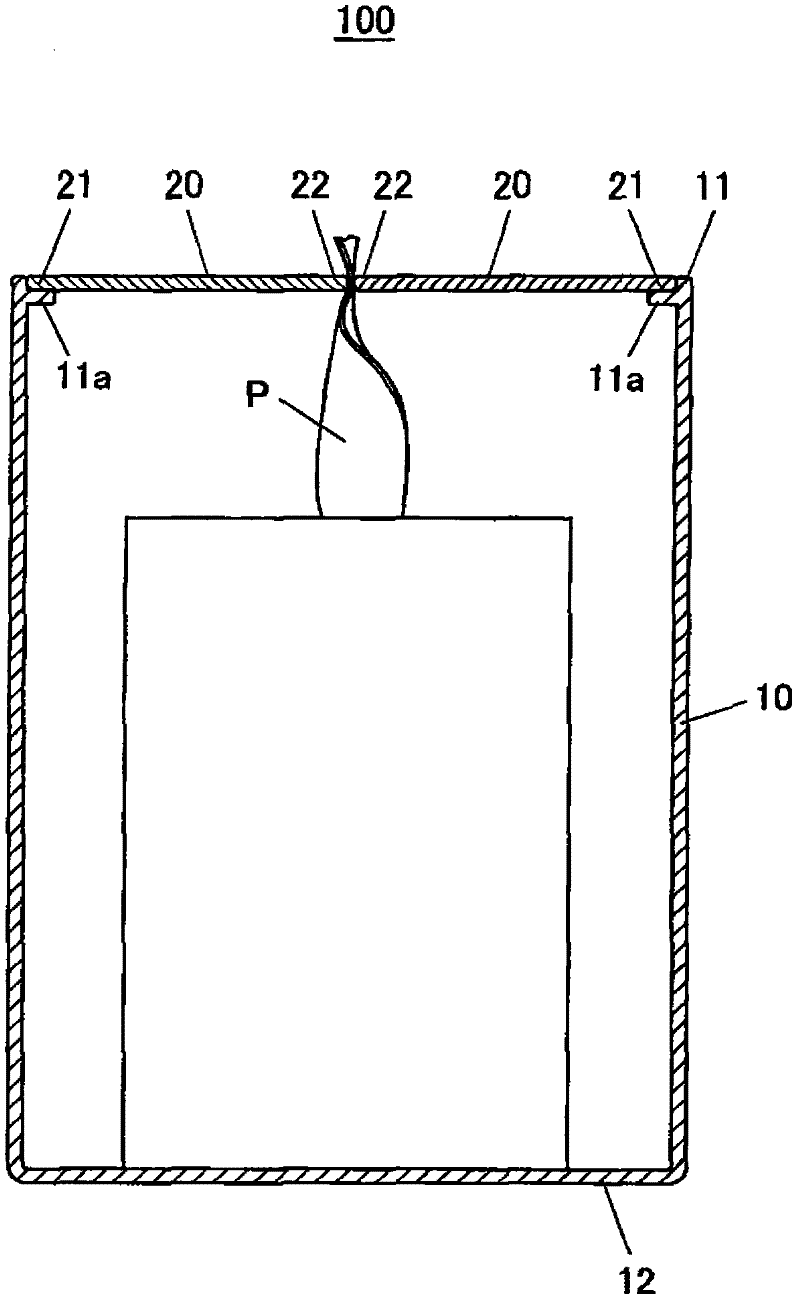

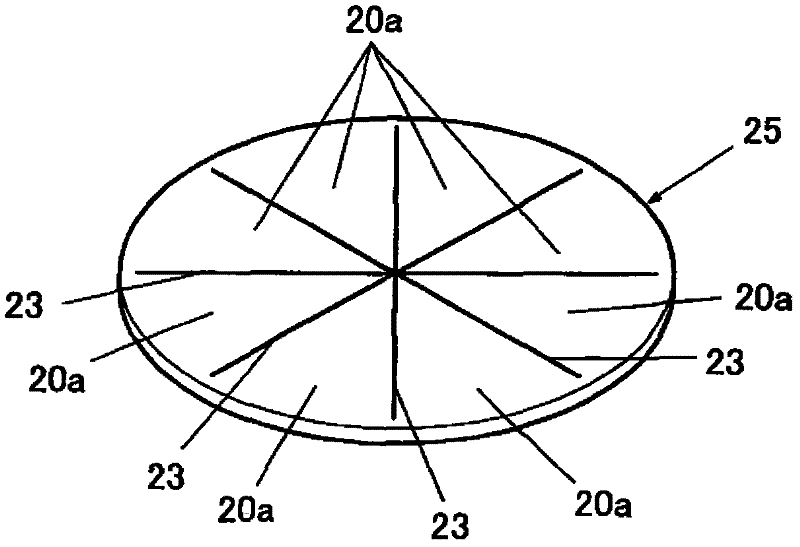

Container For Receiving Household Tissue Paper

A storage container for household tissue paper is provided to deform an end-unit of a bag piece toward the bottom of a container body for inserting the household tissue paper into the container body. A storage container for household tissue paper includes plural bag pieces (20) for covering and closing an opening of a container body(10). The bag pieces are formed with elastically transformable materials, to be restored to an original shape after a user pushes and opens the bag pieces for inserting the household tissue paper for replacing.

Owner:DAIO PAPER CORP

Wiring harness fixing device and automobile

InactiveCN105059211ANot easy to changeImprove fixed reliabilityElectric/fluid circuitThreaded fastenerEngineering

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

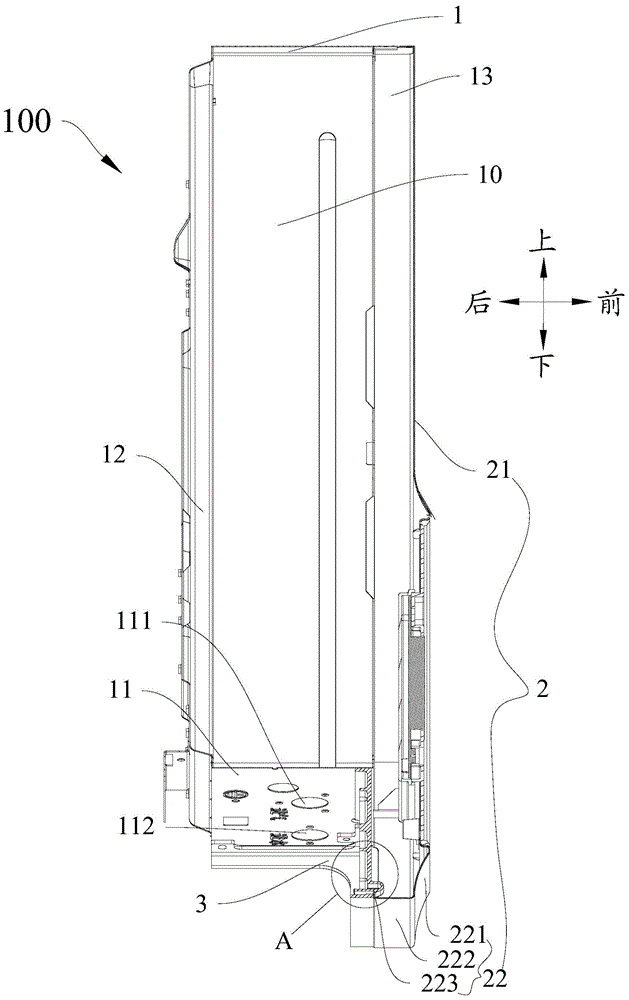

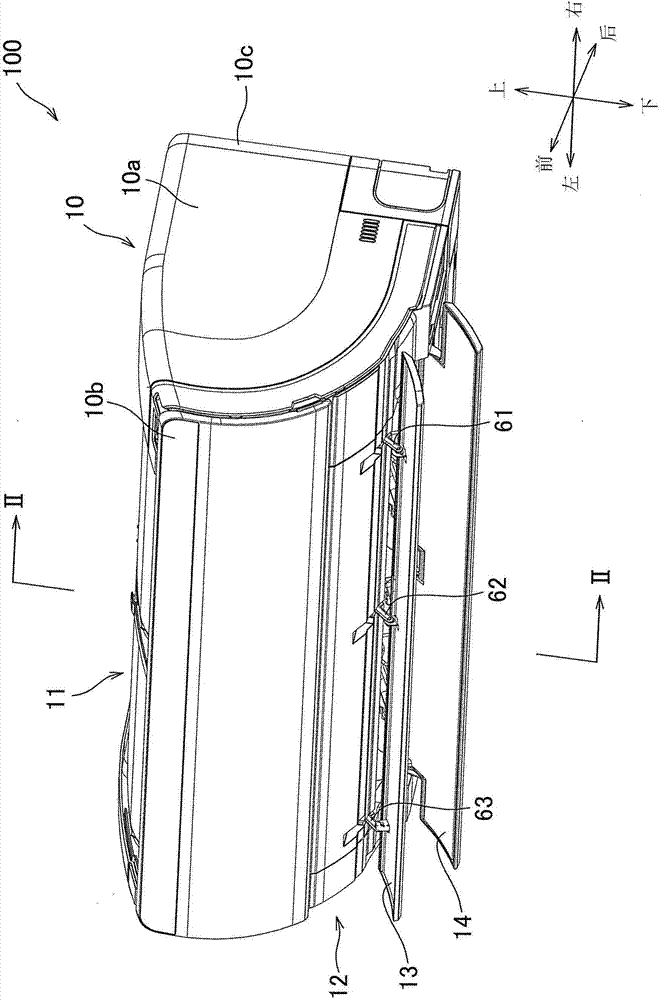

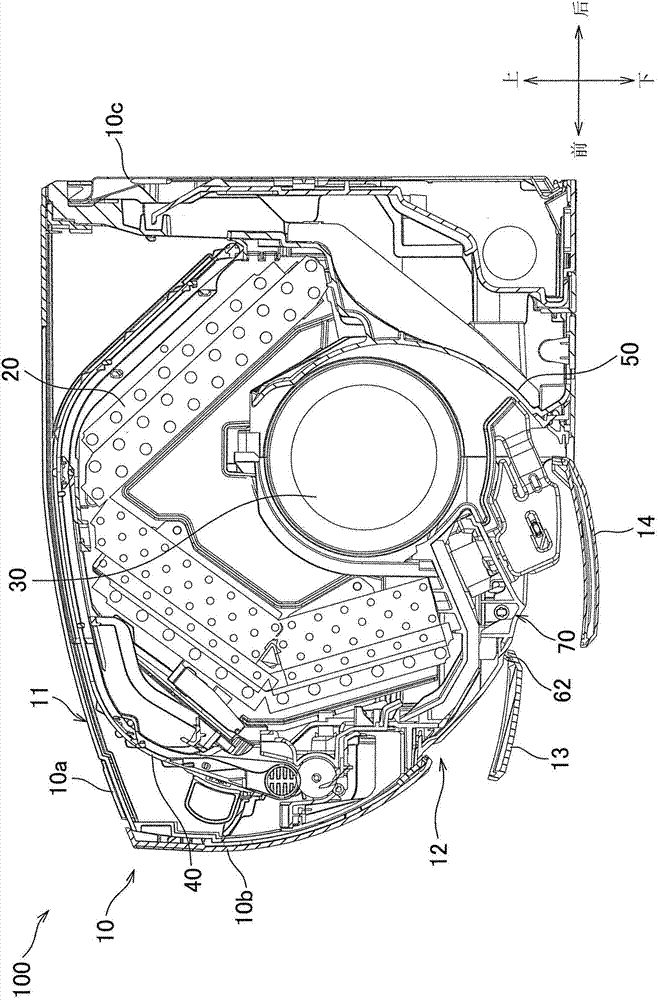

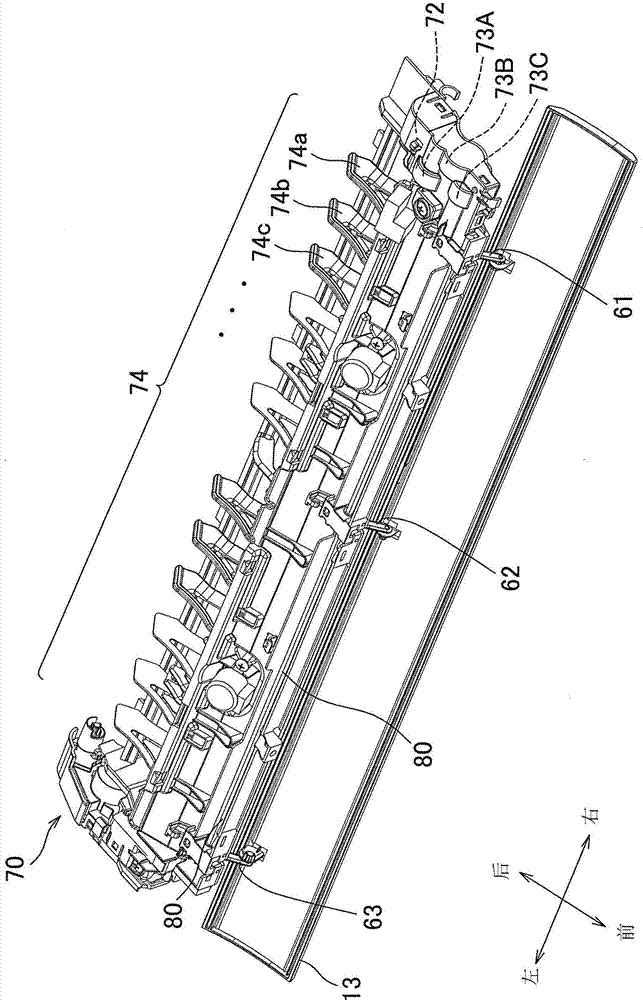

Air conditioner indoor unit

The invention discloses an air conditioner indoor unit capable of inhibiting a gap between a baffle plate and a housing under the closed state of the baffle plate. An exhaust opening of the air conditioner indoor unit is provided with a first baffle plate (13). The first baffle plate (13) is connected with a shaft (80) disposed on a rear side by arms (61,62,63). The right side of the shaft (80) is provided with a motor, and can rotate under the driving of the motor along with the first baffle plate (13). The arms (61,62,63) are respectively disposed on the right end part, the central part, and the left end part of the first baffle plate (13).The arms (61,62,63) are disposed on the shaft (80) in a staggered manner along the rotating direction of the closing motion of the first baffle plate (13).

Owner:DAIKIN IND LTD

Wall decoration board mounting structure

The invention discloses a wall decoration board mounting structure which aims to overcome the defects that wall decoration boards are not stable in dry hanging installation, low in strength and inconvenient to replace. The wall decoration board mounting structure comprises a mounting keel connected to a wall in a fastened mode and wall decoration boards connected to the mounting keel, wherein the mounting keel comprises top and bottom keels and a plurality of vertical keels, the vertical keels are connected between the two top and bottom keels located on the upper portion and the lower portion at intervals, the vertical keels are of a U-shaped structure opening to the wall, a plurality of inserting holes are formed in the outer surfaces of the bottoms of the U-shaped vertical keels, mounting clamping strips are connected to the edges of the left side and the right side of the surface, facing the mounting keel, of each wall decoration board and are provided with a plurality of buckles, the buckles penetrate through the inserting hole and are connected with elastic clamping seats in a clamped mode, and the elastic clamping seats are arranged in the vertical keels. According to the wall decoration board mounting structure, the wall decoration boards are firm in structure, high in strength and convenient to detach and replace in dry-hanging mounting.

Owner:ZHEJIANG YASHA DECORATION

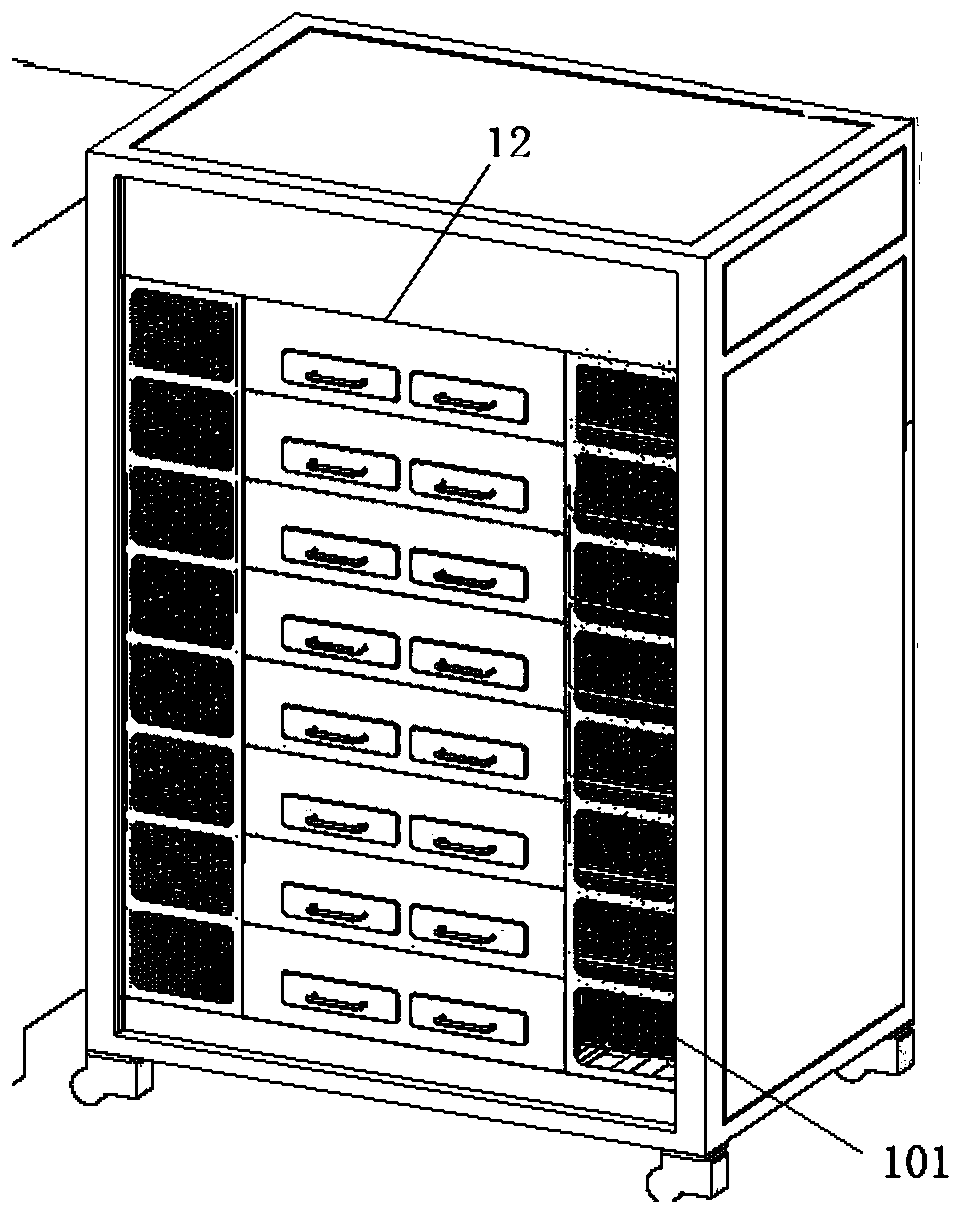

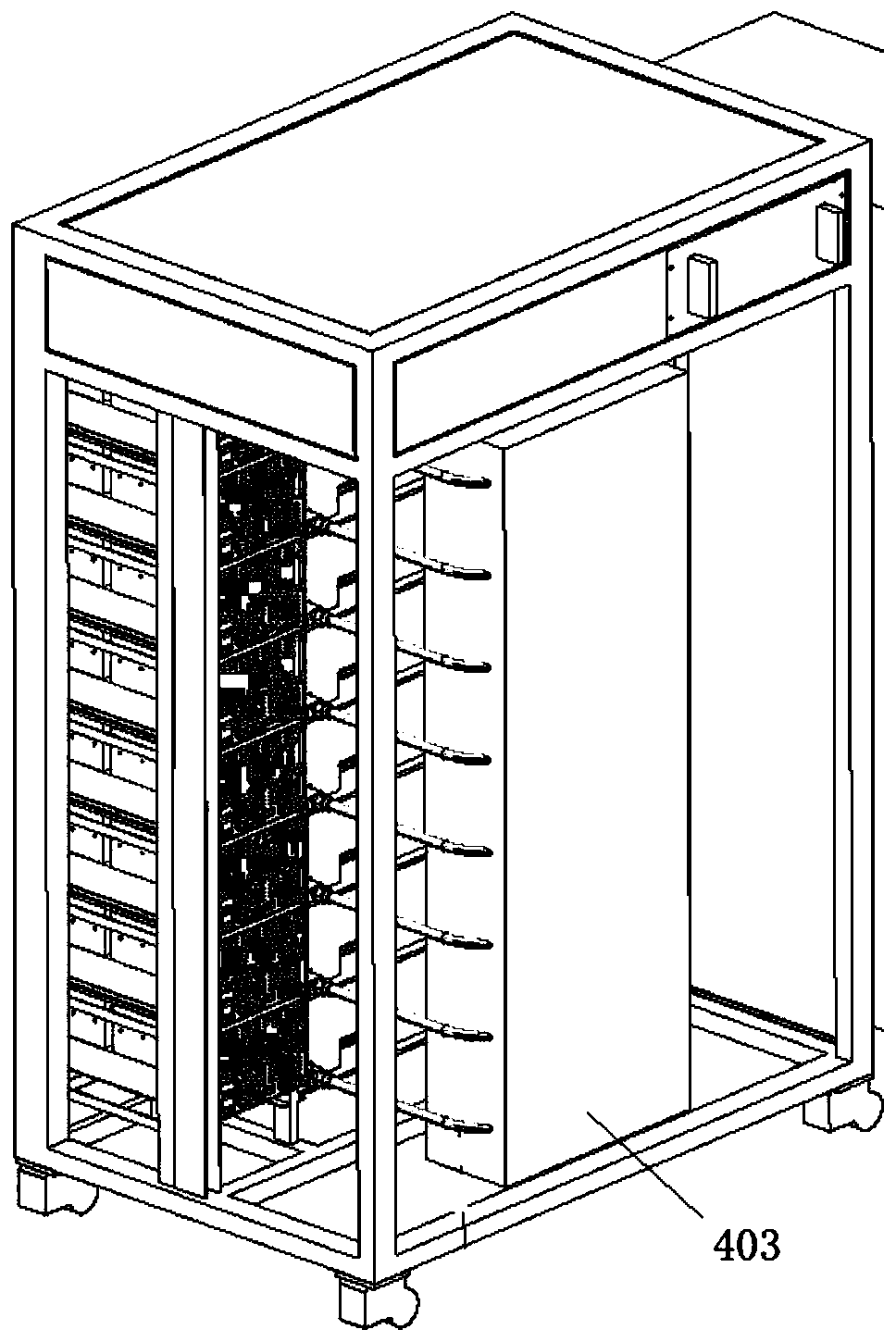

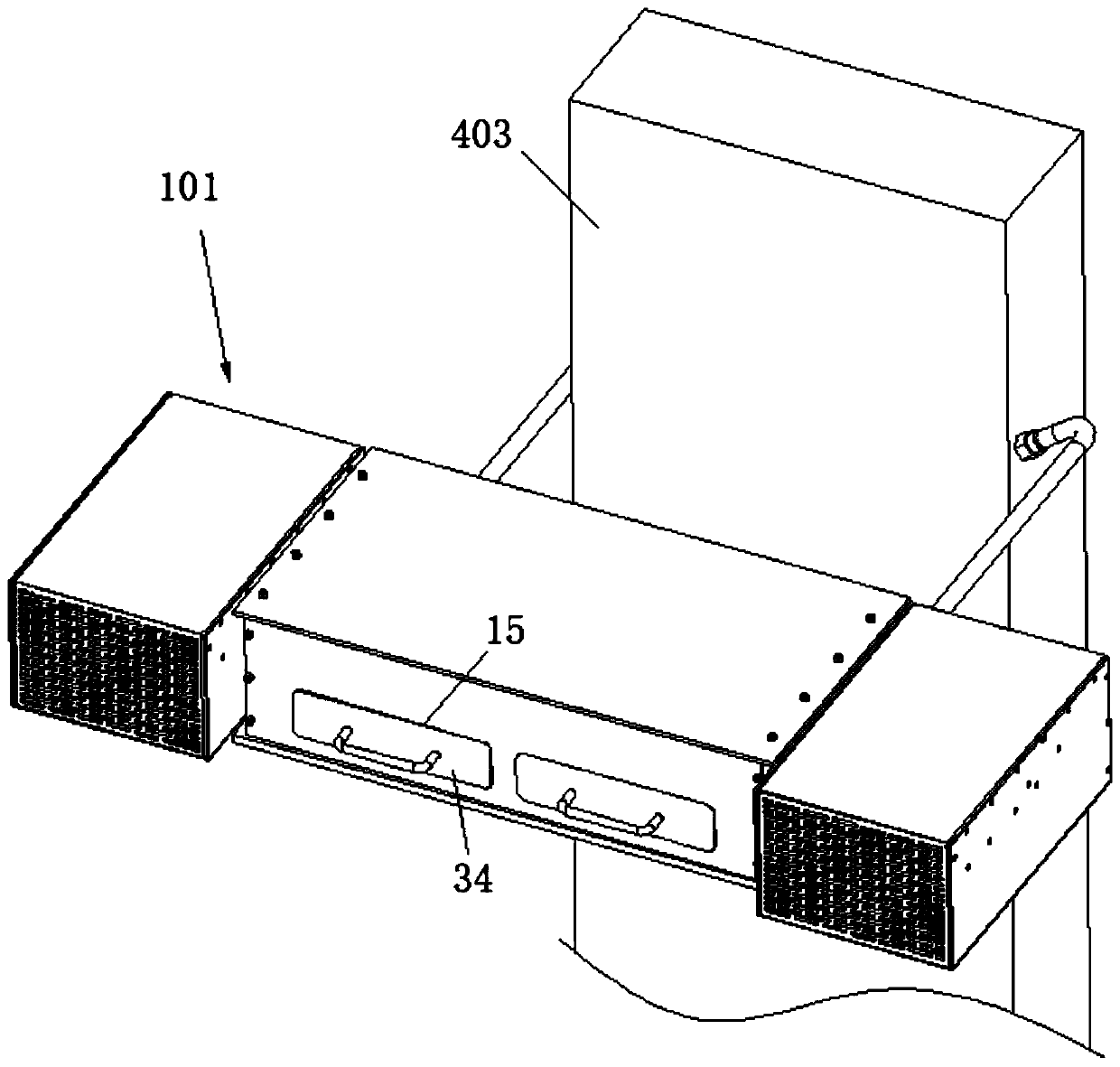

Reliability test device of high-power laser chip

PendingCN109870644AHigh densityEasy to assemble and disassembleElectronic circuit testingMeasurement instrument housingTest efficiencyElectricity

The invention discloses a reliability test device of a high-power laser chip. A carrying plate comprises a plurality of chip grooves for embedding of chips; the carrying plate is provided with a plurality of wires communicated with the chips; the wires form an electric connector at one end of the carrying plate; a connecting block is provided with a connector for insertion of the electric connector; the connecting block is electrically connected with a control assembly; a cooling box including a water inlet and a water outlet is arranged under the carrying plate; a cooling cavity communicatedwith the water inlet and the water outlet is formed in the cooling box; the water inlet and the water outlet are communicated with a cooling water circulation box; and a heat conduction plate used forbeing in contact connection with the upper surface of the cooling box is also arranged at the lower surface of the carrying plate. While realizing batch testing of chips, the reliability test deviceof the high-power laser chip can take away heat generated by the chip test in real time, can efficiently control the chip test temperature, can prevent temperature influence fluctuation from affectingthe chip test precision and can greatly improve the chip test efficiency.

Owner:STELIGHT INSTR CO LTD

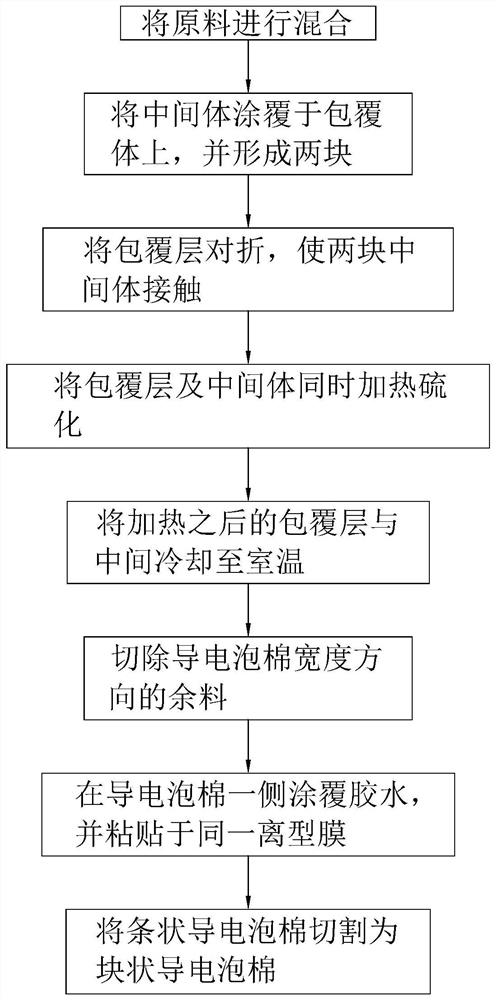

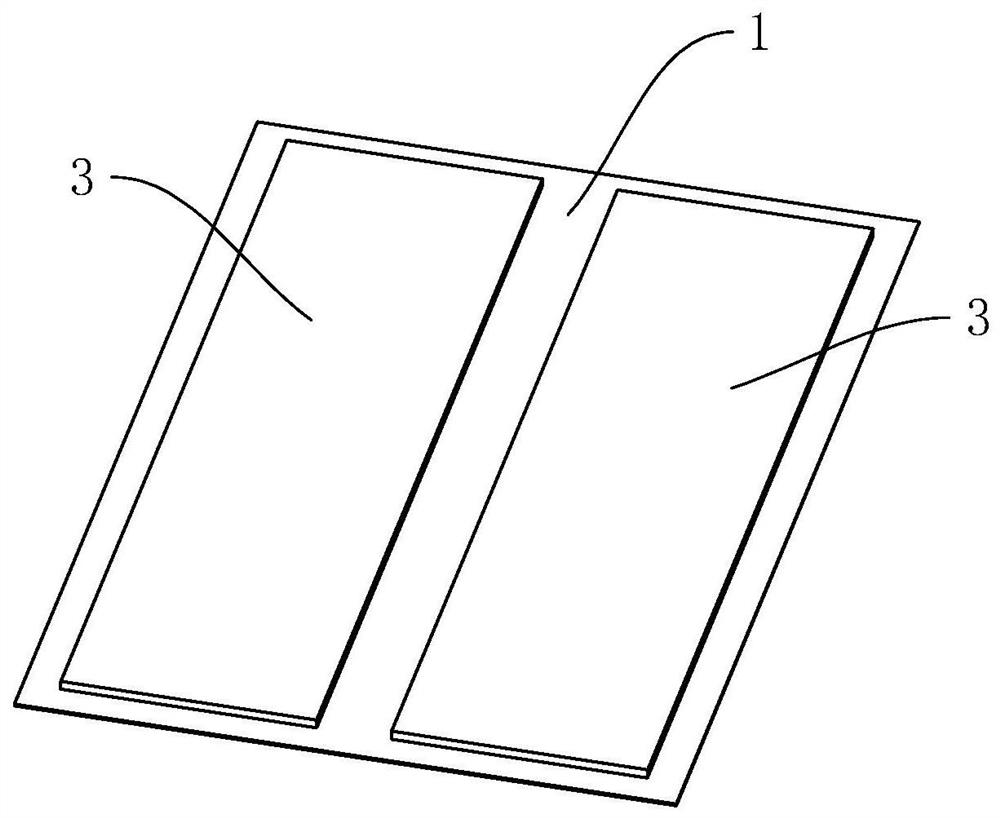

Processing technology of conductive foam and conductive foam

ActiveCN112029432AImprove foaming efficiencyReduce processing timeFilm/foil adhesivesPolymer sciencePolymer chemistry

The invention relates to a processing technology of conductive foam and conductive foam, and the technology comprises the steps: providing a coating layer and raw materials, mixing the raw materials,and stirring the raw materials to form an intermediate; flatly laying the coating layer, coating the upper end surface of the coating layer with two intermediates, reserving a gap between the two intermediates, and reserving a gap between the intermediates and the edge of the coating layer; folding the coating layer along the position between the two intermediates, so that the intermediates located on the two sides of the bent position of the coating layer make contact with each other; putting the folded coating layer into a jig, heating and vulcanizing the jig, the coating layer and the intermediate, heating the intermediate to form an elastic layer, and adhering the elastic layer to the coating layer to form conductive foam; and simultaneously cooling the elastic layer and the coating layer to room temperature. The intermediate is directly bonded with the coating layer in the process of foaming the intermediate into the elastic layer, and a gap is not easy to generate between the elastic layer and the coating layer, so that a conductive medium of the coating layer is not easy to break in the subsequent cutting process of the conductive foam.

Owner:SHENZHEN HFC SHIELDING PRODS CO LTD

Self-pressure sealing stop valve

The invention discloses a self-pressure sealing stop valve. The self-pressure sealing stop valve comprises a stop valve body, a valve deck is arranged at the upper end of the stop valve body, a valverod is rotationally arranged on the valve deck, the lower end of the valve rod penetrates through the valve deck and extends into the stop valve body, the lower end of the valve rod is connected witha valve plate, a water inlet cavity is formed in the left side of the stop valve body, a valve seat and a water outlet cavity are formed in the right side, an inner screw hole is formed in the lower surface of the valve plate, a first inner groove is formed in the inner top face of the inner screw hole, the inner diameter of the first inner groove is larger than that of the inner screw hole, an air bag mechanism is arranged in the first inner groove, a valve seat barrel is arranged on the valve seat, and an outer thread corresponding to the inner screw hole is arranged on the outer surface ofthe valve seat barrel. The valve plate is selectively connected with the valve seat cylinder in a sealed mode. According to the self-pressure sealing stop valve, the valve plate enables the valve seatcylinder to be connected in a threaded mode, so that the valve seat cylinder is sealed by the air bag mechanism in the first inner groove, cutting off of media is achieved, gaps are not prone to being generated at the sealing joint, and leakage is avoided.

Owner:NEWMAN (YANCHENG) VALVE MFG CO LTD

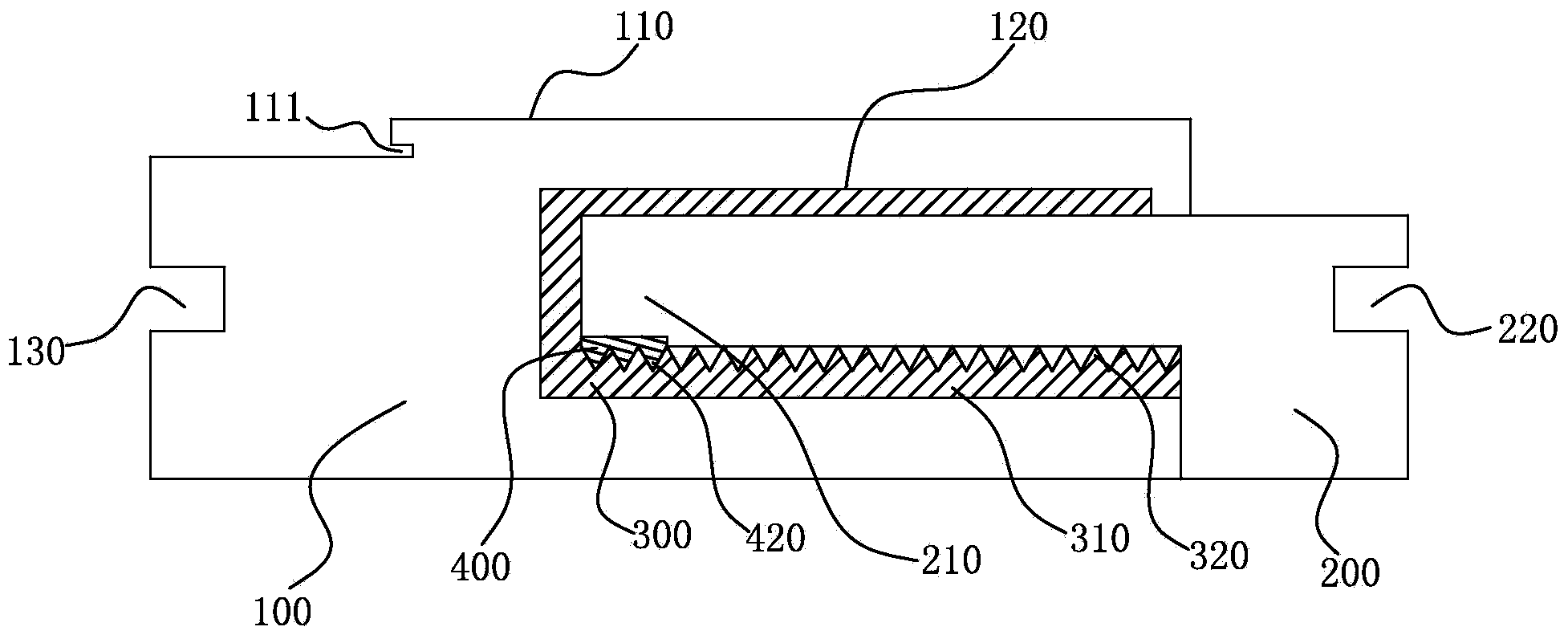

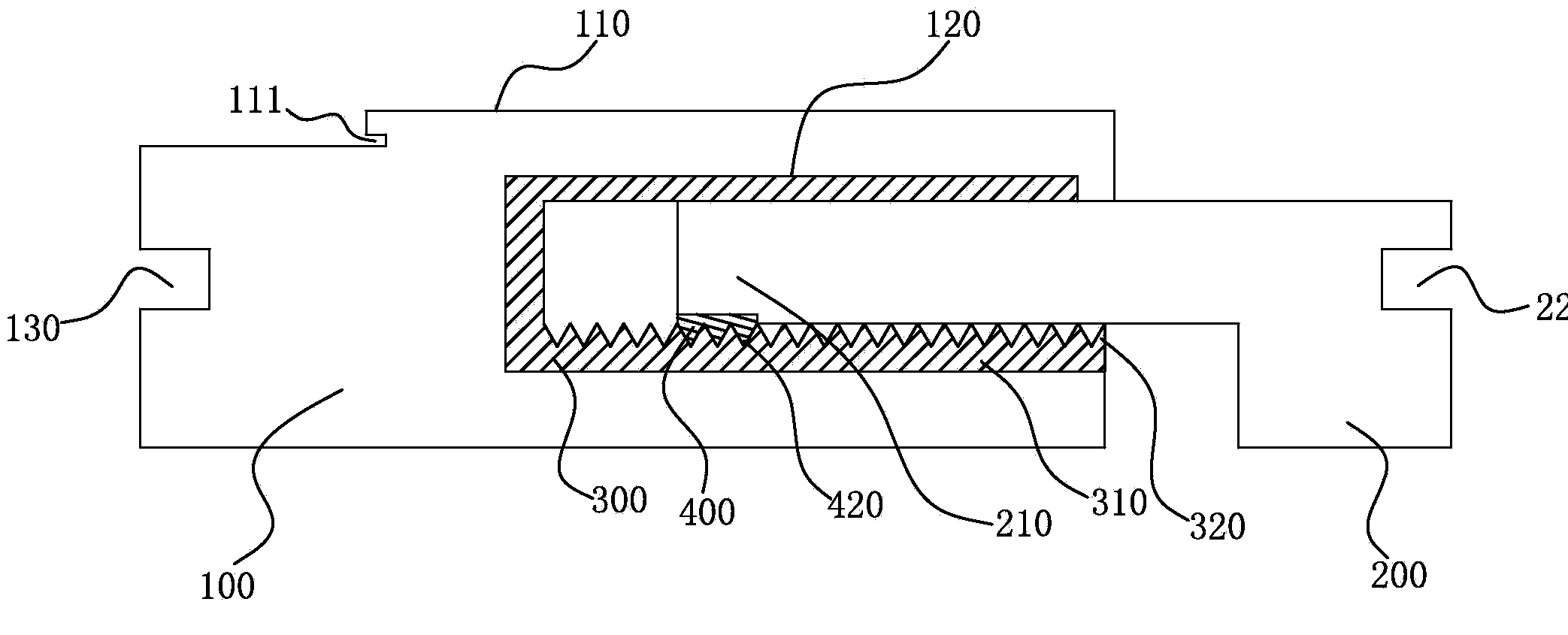

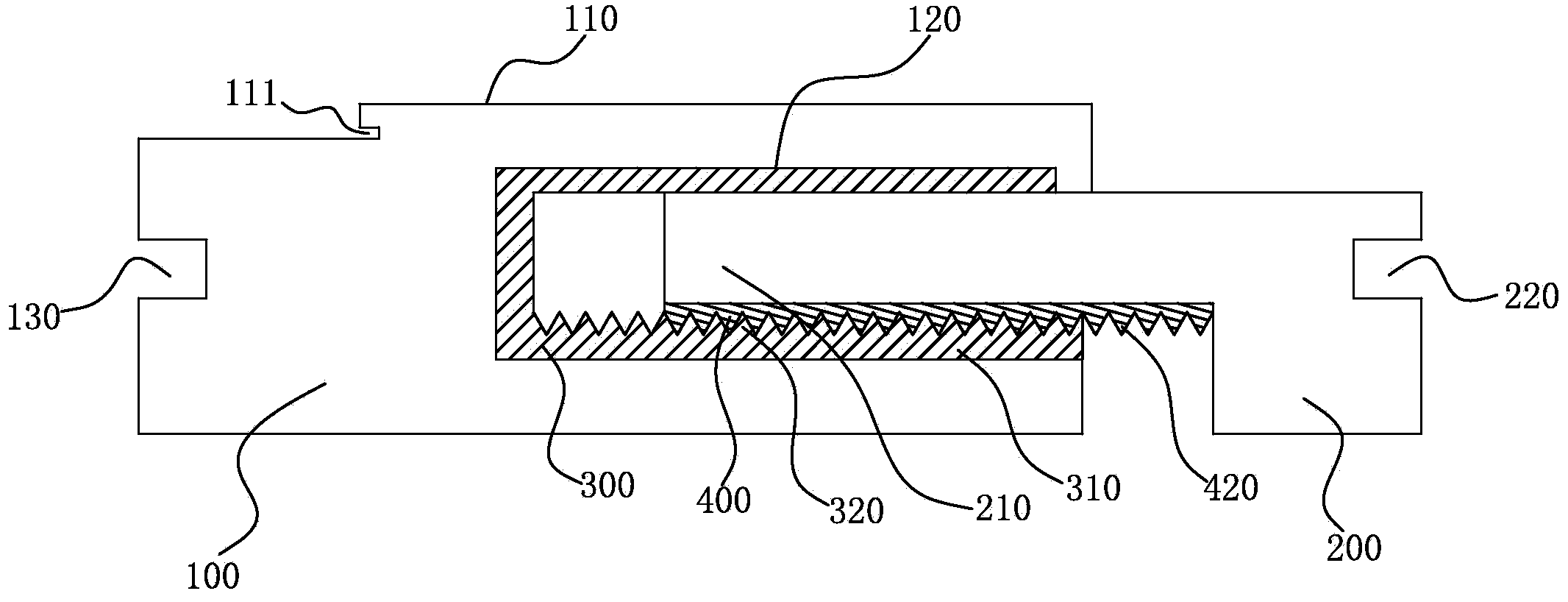

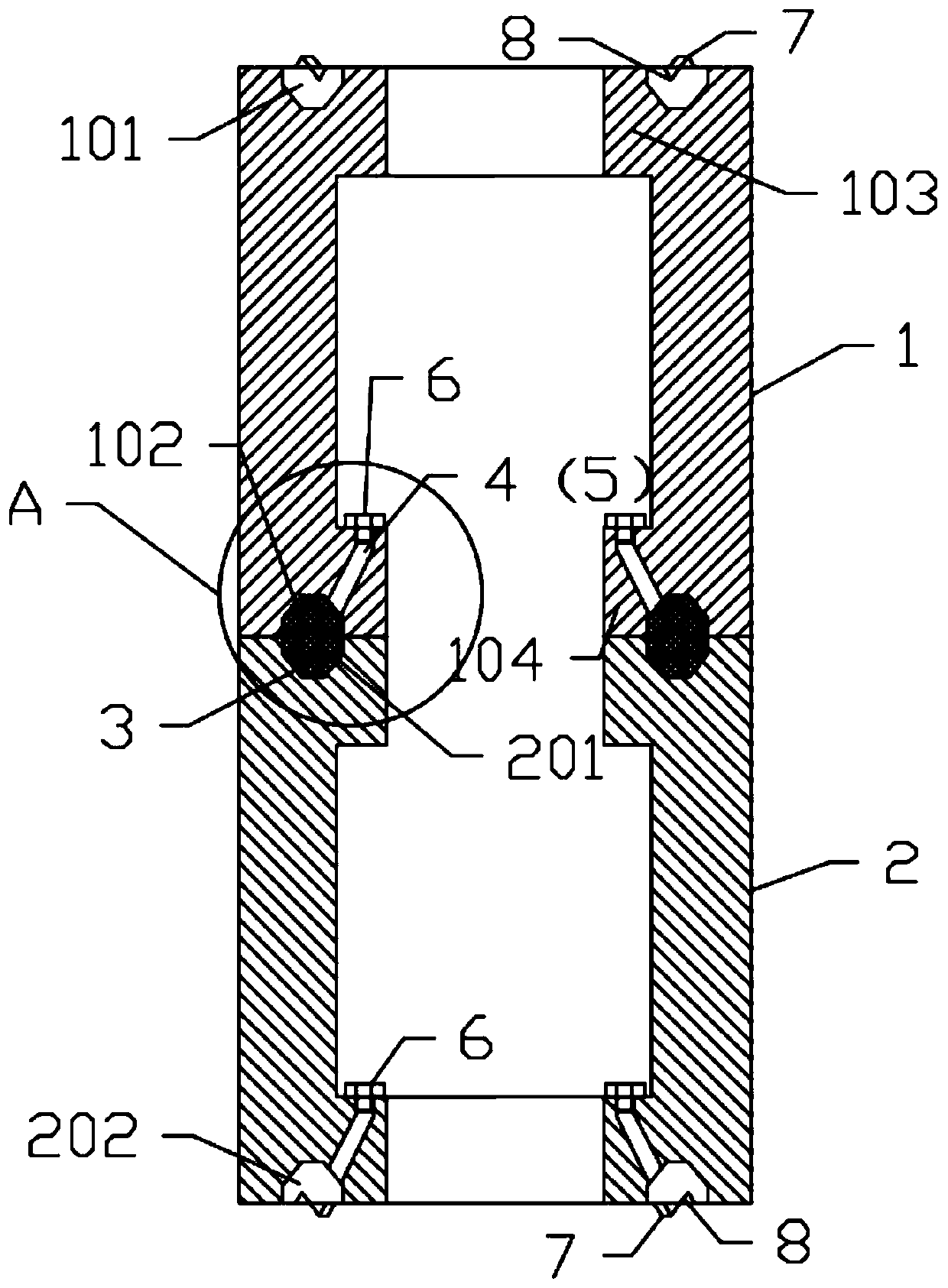

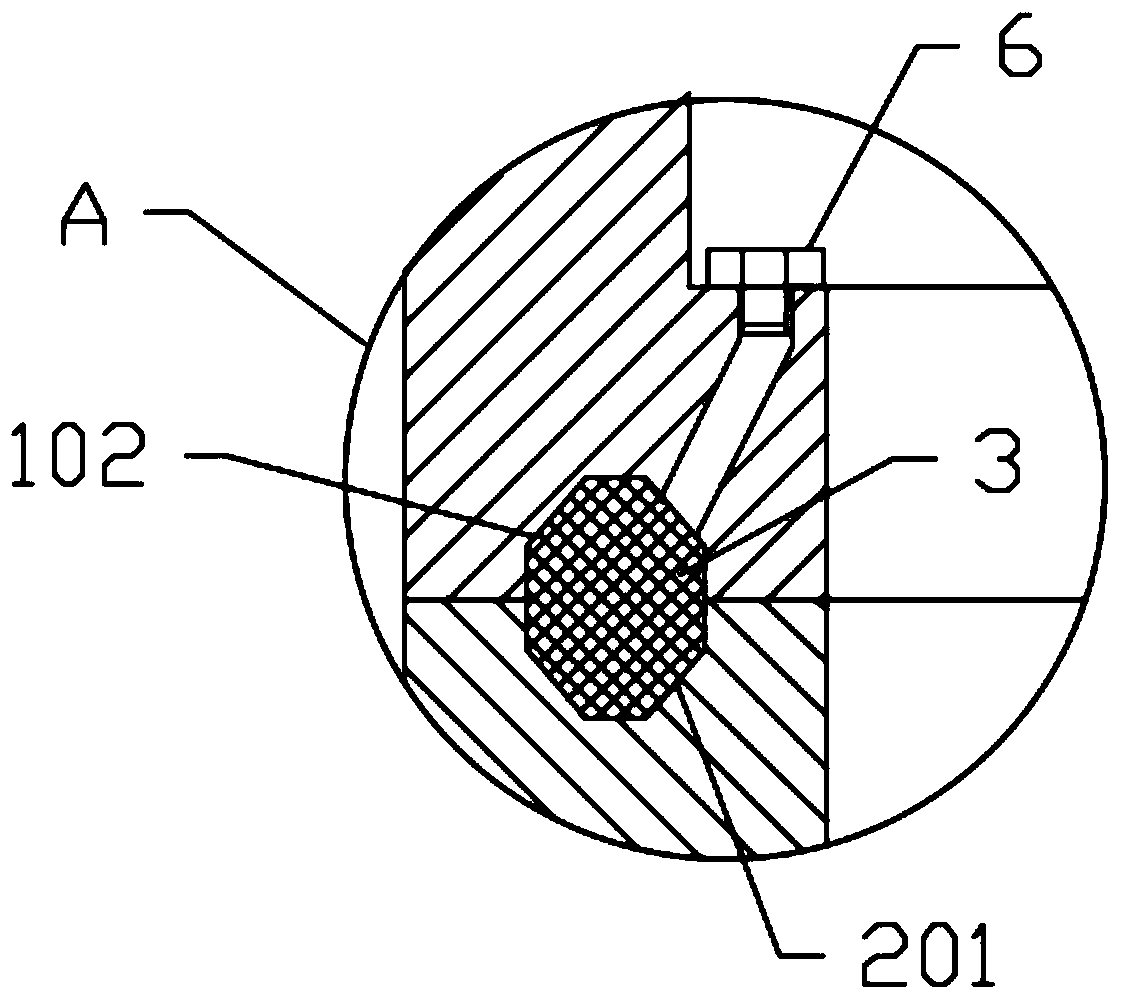

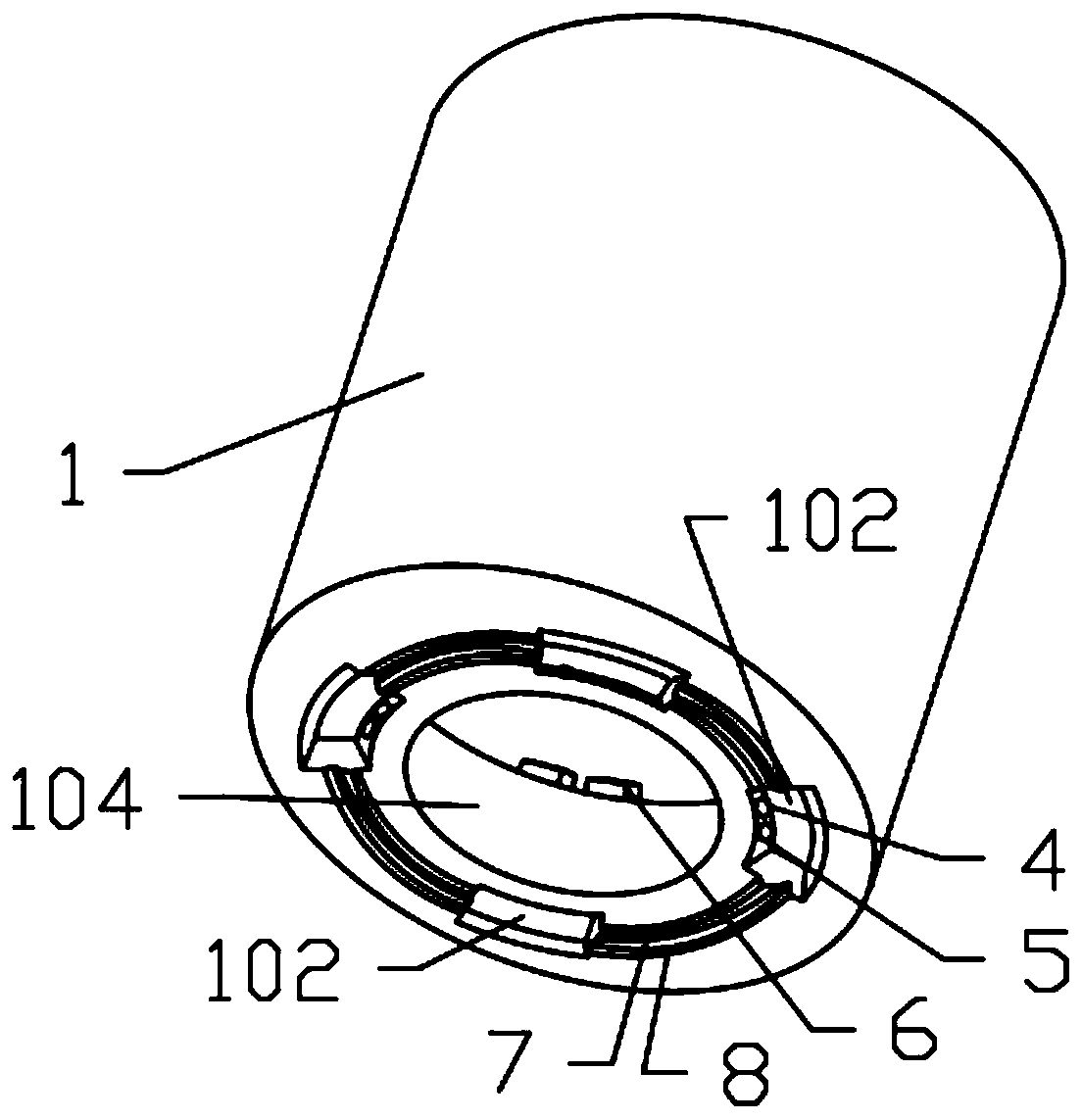

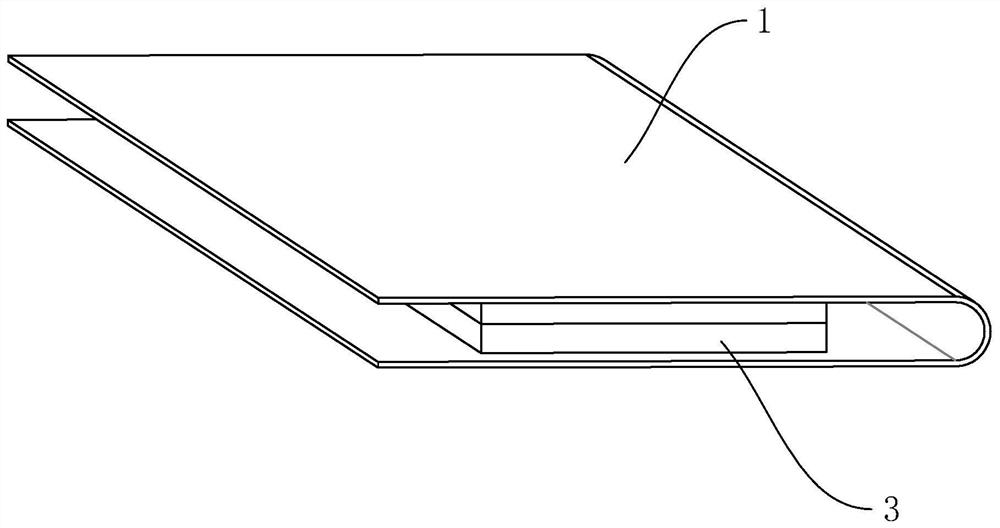

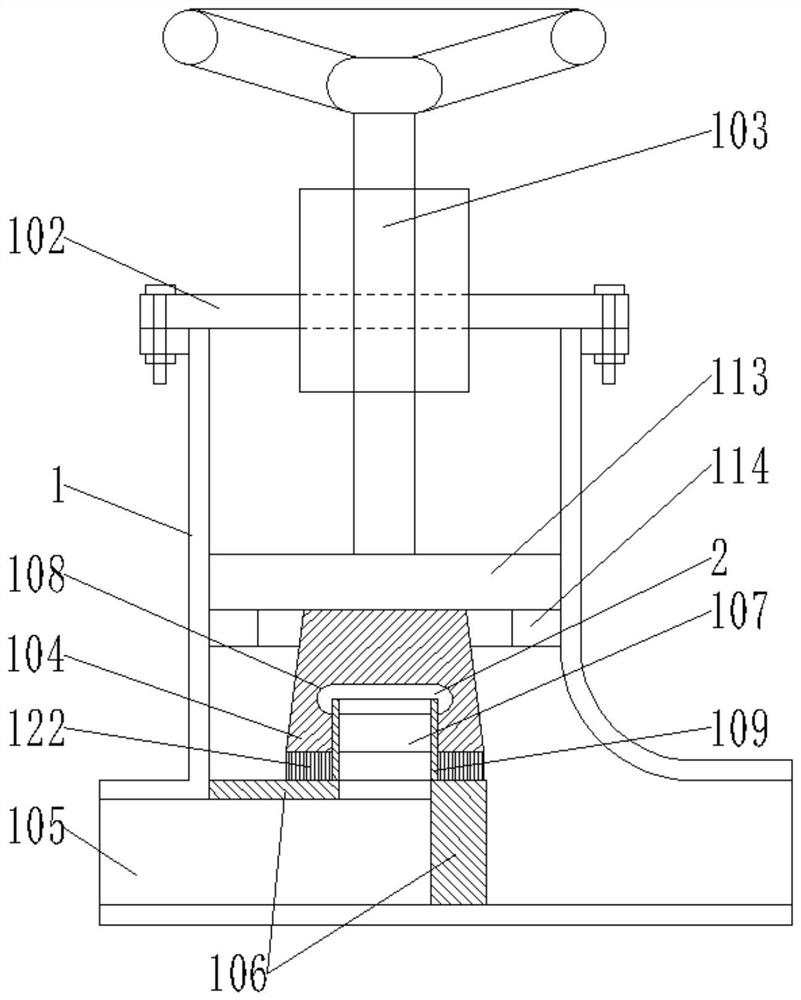

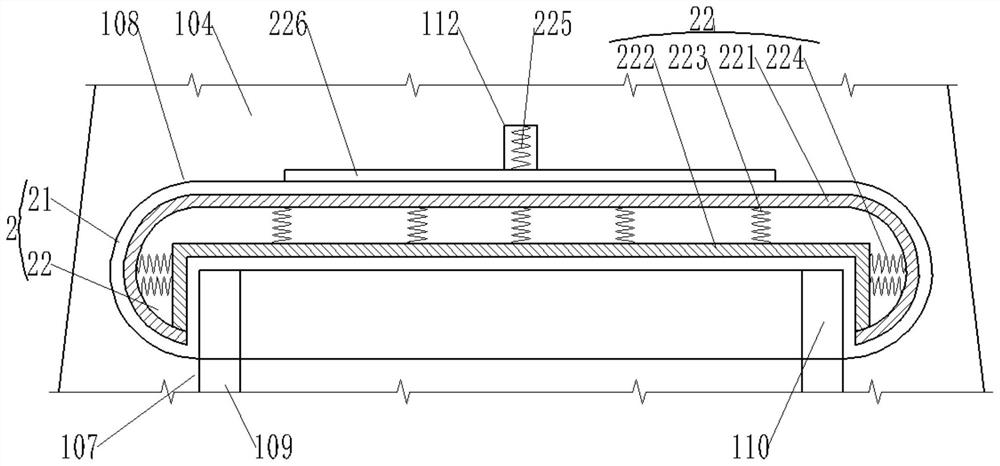

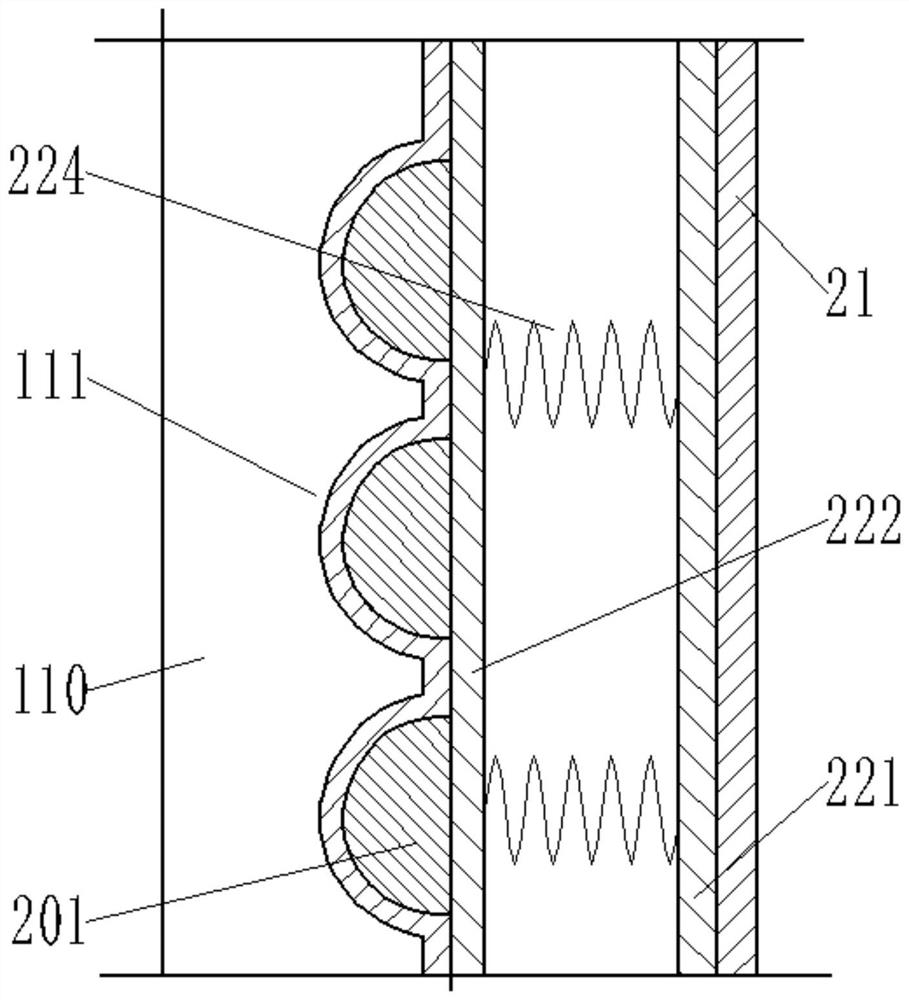

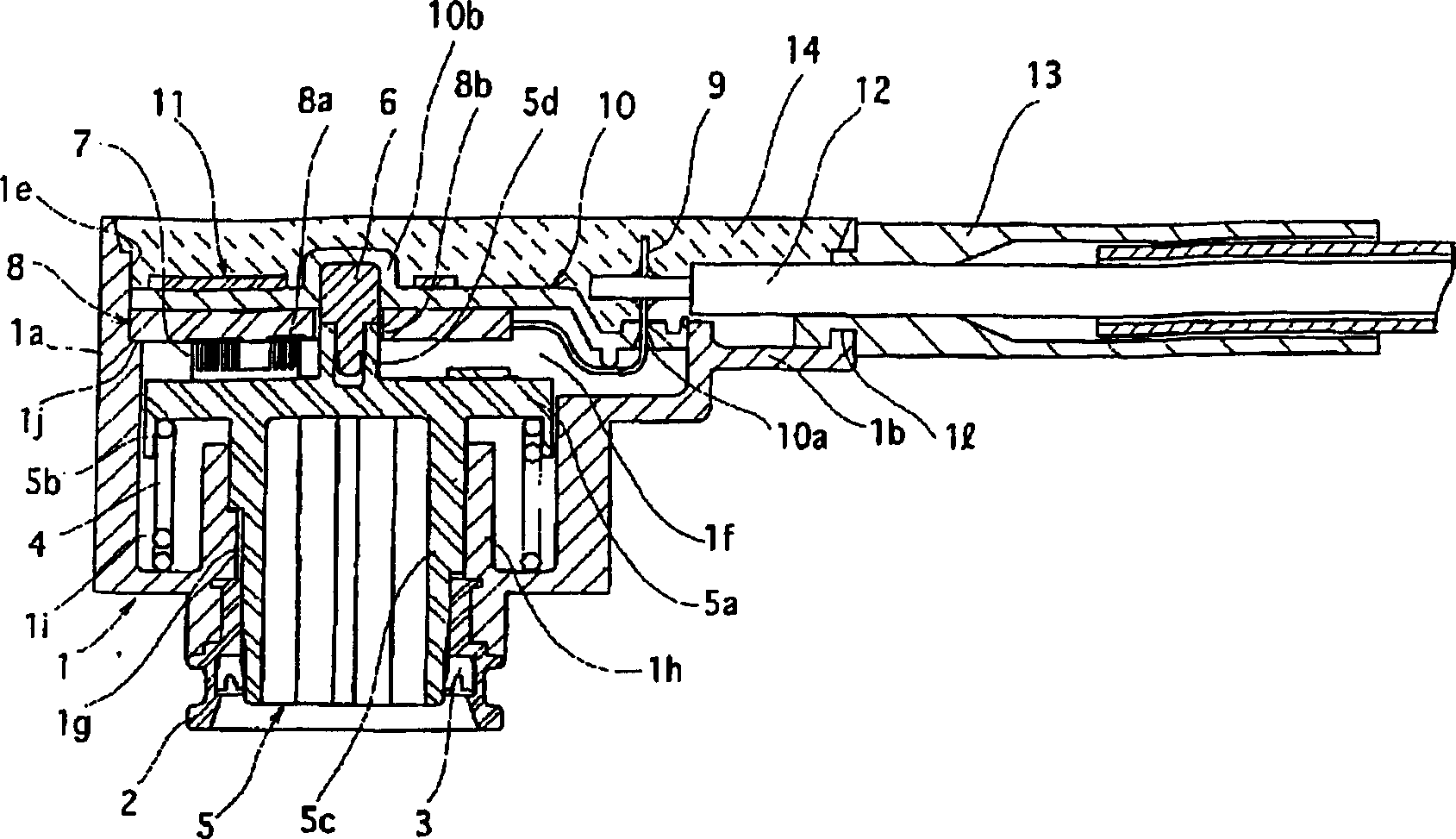

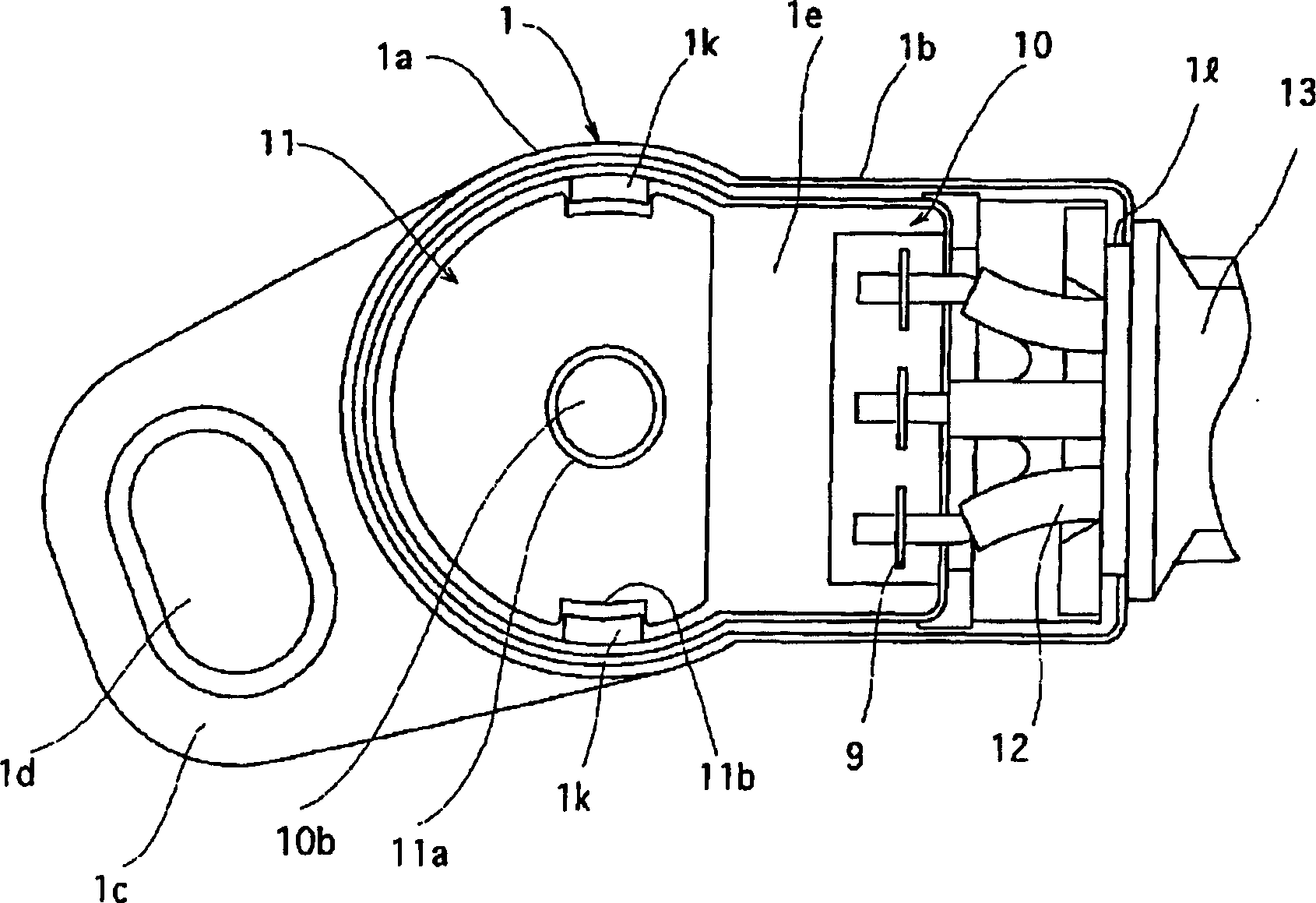

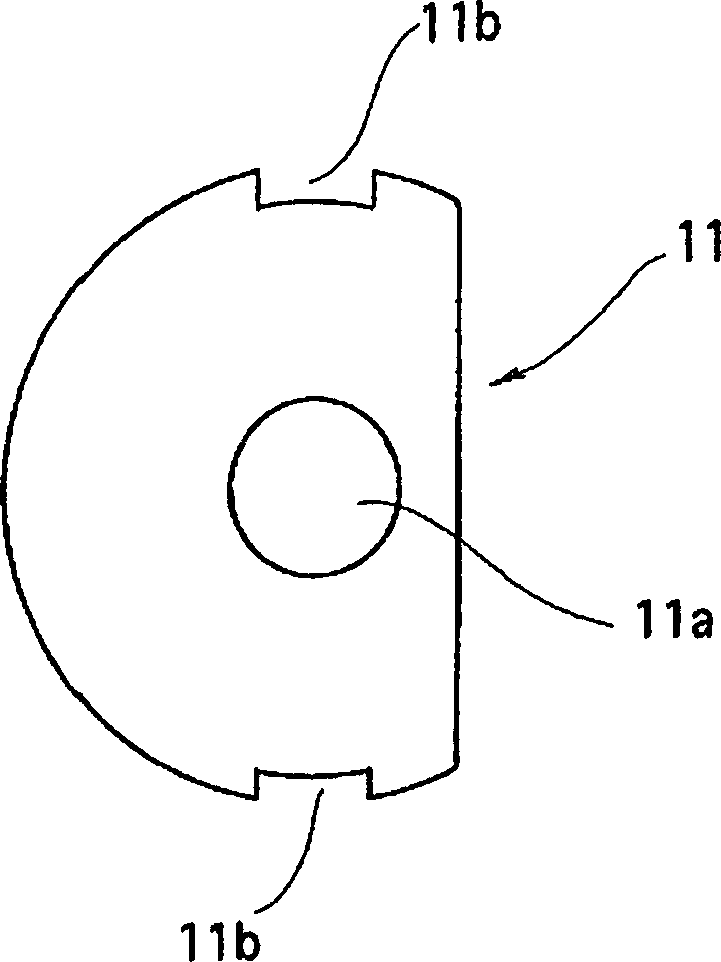

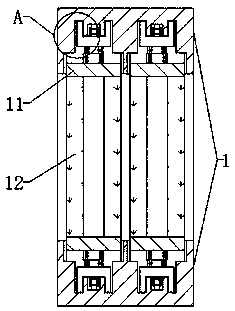

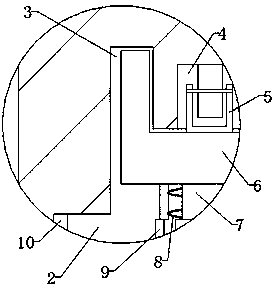

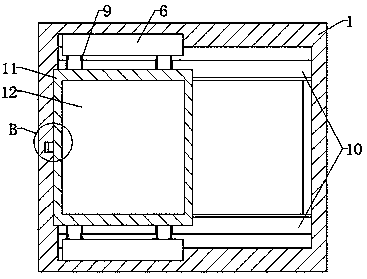

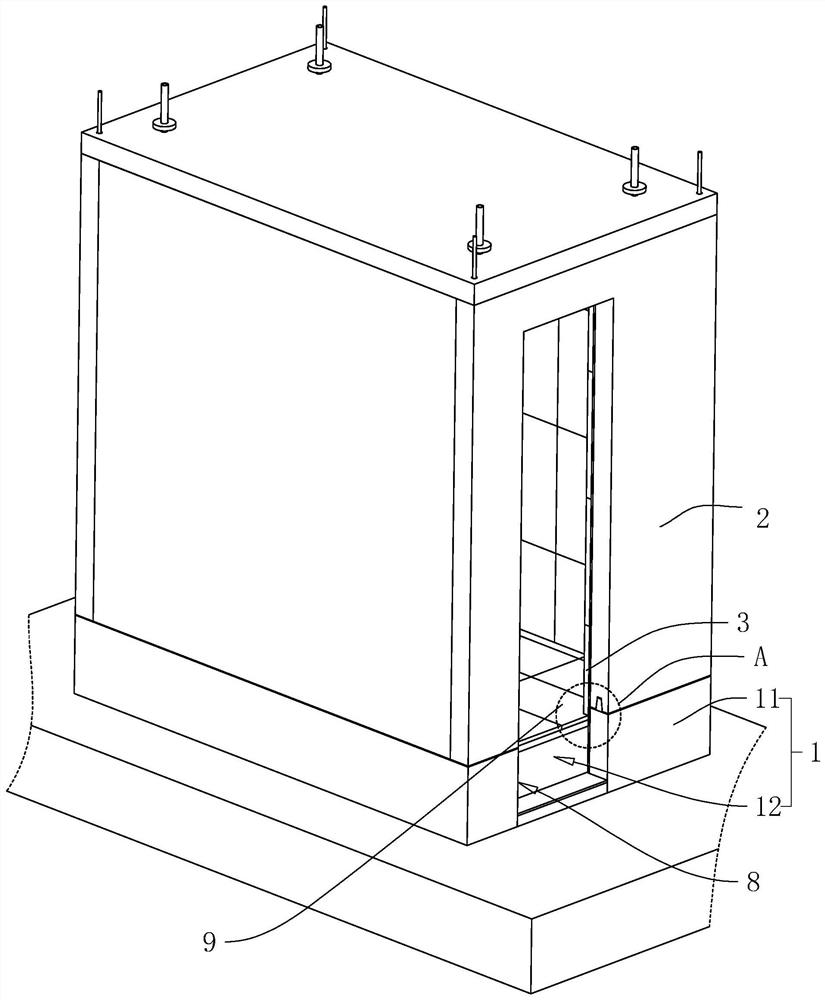

Sealed electric elements

InactiveCN1574116AFully bondedNot prone to gapsElectrically conductive connectionsResisitors with sliding contactThermal expansionAir tightness

The invention provides a seal electrical part, comprising a box body, a base plate, a cover body and adhesives, wherein, an opening is arranged on the box body; an external terminal extending toward the opening is arranged on the base plate; the cover body is embedded in the inner peripheral surface of the opening and is provided with a through hole for the external terminal to pass through; the adhesives is filled on the upper surface of the cover body to seal the inner peripheral surface of the opening and the embedded part of the cover body as well as the external terminal and the embedding part of the cover body; a plate-like partition is buried in the resin of the adhesives along the surface of the cover body; the partition is made of sheet materials; the physical parameter of the partition is between the coefficient of linear expansion of the box body and the adhesives, and is much closer to the coefficient of linear expansion of the box body. The seal electrical part has the advantage that the seal electrical part is not affected by the materials of the cover body even if the thermal expansion coefficients of the resin adhesives and the cover body are different; therefore, the gap is hard to be generated between the resin adhesives and the cover body and the tight contact is realized between the resin adhesives and the inner periphery of the box body, and the air tightness is enhanced.

Owner:ALPS ALPINE CO LTD

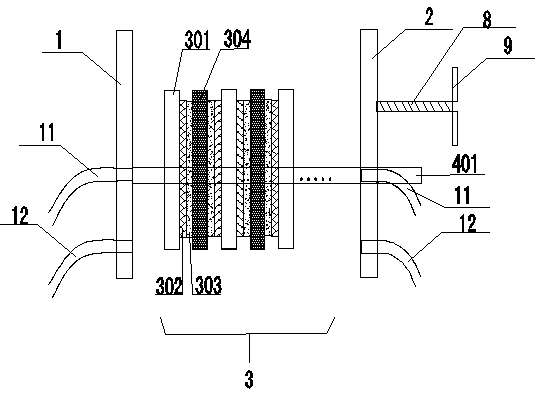

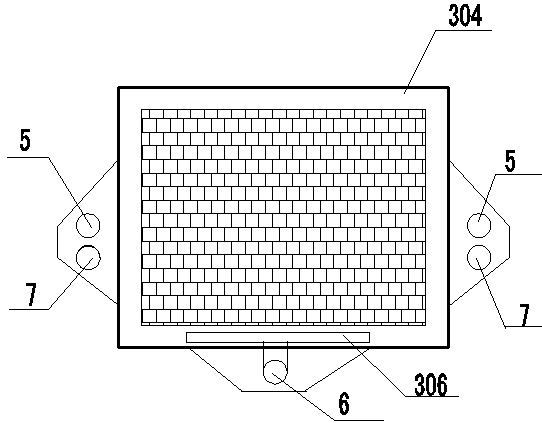

Plate-and-frame filter for chondroitin sulfate processing

InactiveCN111558242AImplement multiple filtersReduce congestionFiltration separationPhysical chemistryEngineering

The invention relates to the technical field of solution filtration. The invention discloses a plate-and-frame filter for chondroitin sulfate processing. The filter comprises a rack, a thrust plate fixed on the rack, a plurality of filter units which are connected to the rack in a sliding manner and can be pressed, and a pressing plate which is connected to the rack in a sliding manner through a compression mechanism. Each filter unit comprises a plate frame, a clarification plate, a PP (polypropylene) film and a screen plate. One PP film, one clarification plate and one plate frame are sequentially arranged on each of the two sides of each screen plate in the direction far away from the screen plate respectively. Each clarification plate is fixed on one side of the corresponding plate frame, and each PP film is attached to the corresponding clarification plate and is in close contact with the corresponding screen plate. Compared with the prior art, a layer of PP film is additionally arranged on each clarification plate of the plate frame, so that one piece of equipment achieves multiple filtration from rough filtration to fine filtration, the clarity is high, and the situation that the equipment is blocked when filtrate enters a subsequent sterile filter is avoided.

Owner:江苏麦德森制药有限公司

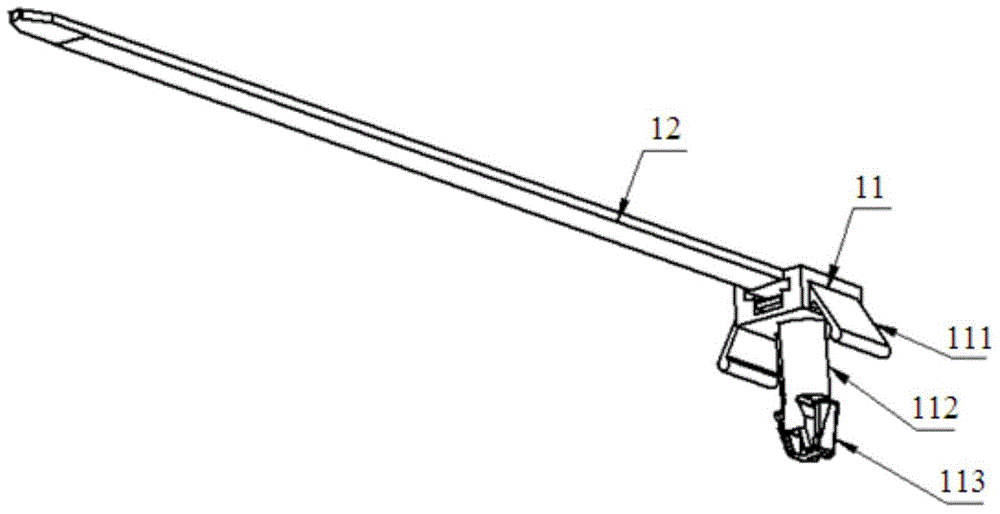

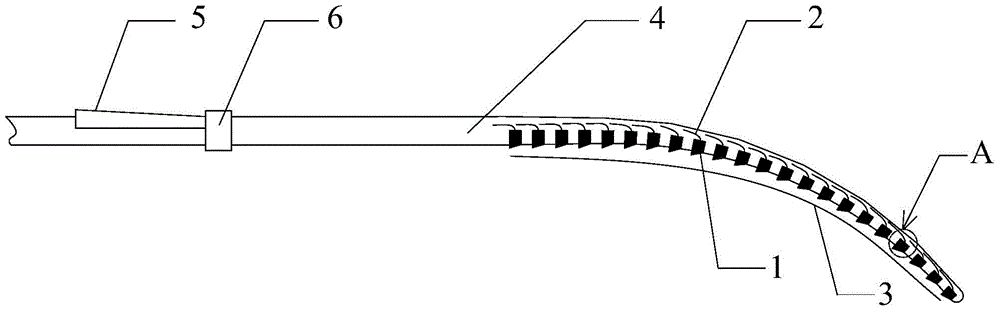

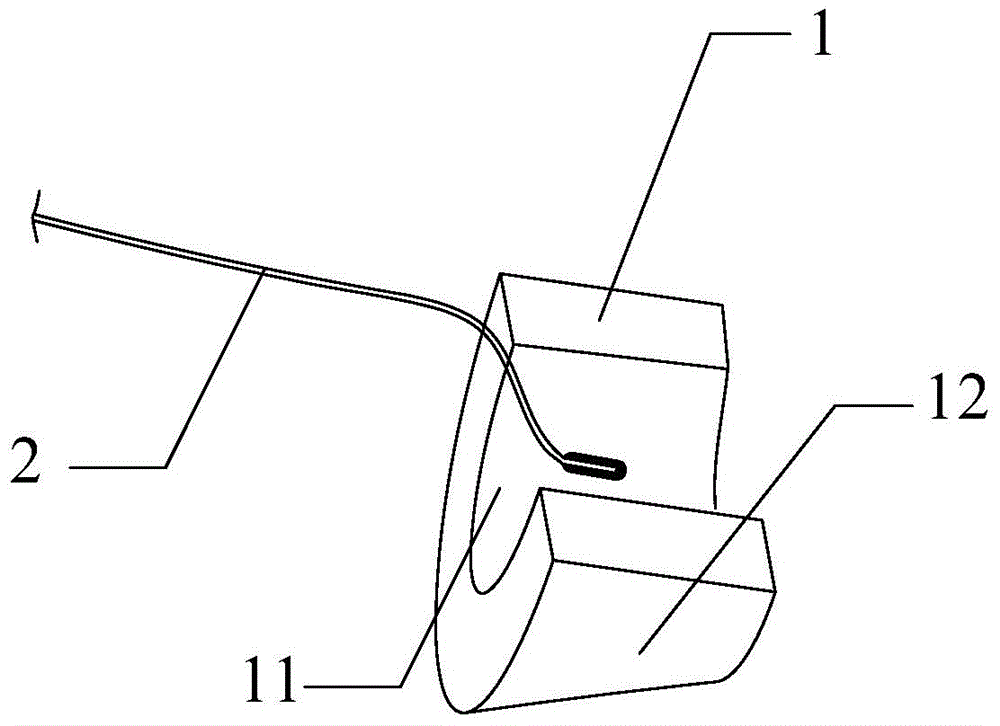

cochlear implant electrodes

The invention provides an artificial cochlear electrode. The artificial cochlear electrode comprises a plurality of electrode contacts which comprise tapered surfaces. The inner wall of each electrode contact is connected with an electrode wire, and the electrode contacts are arranged front and back successively along the artificial cochlear electrode implantation direction to form an electrode array which is packaged by silicone into a whole. The portions of the tapered surfaces of the electrode contacts exposed from the silicone are inclined, and the rear ends are more protruding than the front end. The electrode contacts and the electrode wires are insulated mutually. The electrode contacts are in semi-tapered-ring shapes and comprise grooves in semi-tapered-ring shapes. The electrode wires arranged in the front of the electrode contacts penetrate the grooves in semi-tapered-ring shapes of the electrode wires arranged behind, the electrode wires are converged to from an electrode beam, and the grooves in semi-tapered-ring shapes of the electrode contacts are communicated successively to from a channel for accommodating the electrode beam. The electrode array is in a micro bending shape. The stimulus of the artificial cochlear electrode to nervous tissues is centralized; electric field aliasing can be prevented effectively, and power consumption is reduced; resistance of the artificial cochlear electrode during implantation is reduced.

Owner:SHANGHAI LISTENT MEDICAL TECH CO LTD

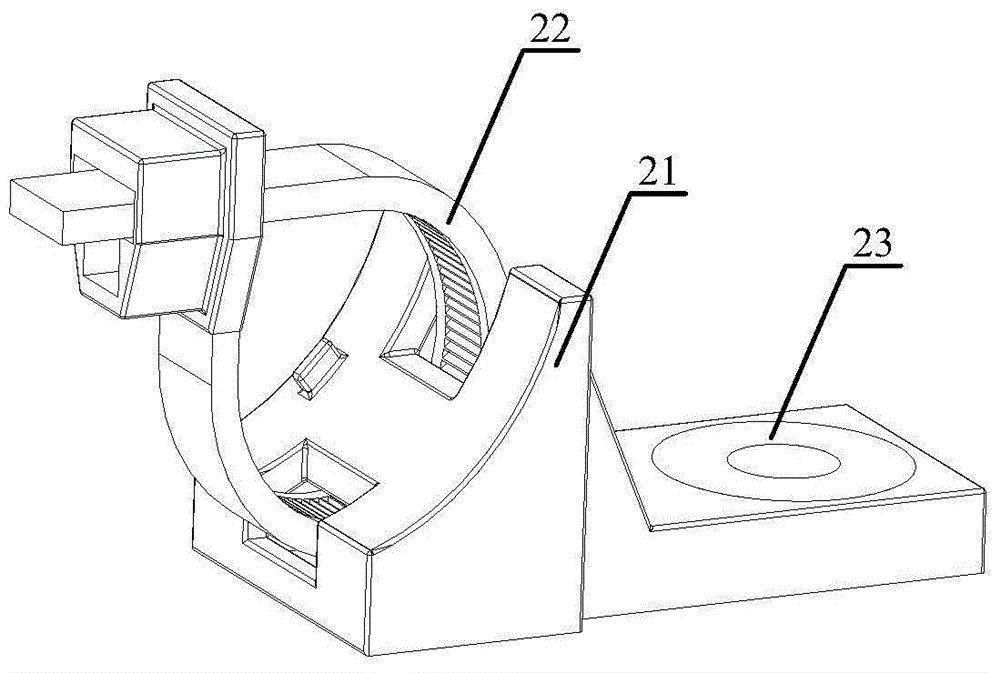

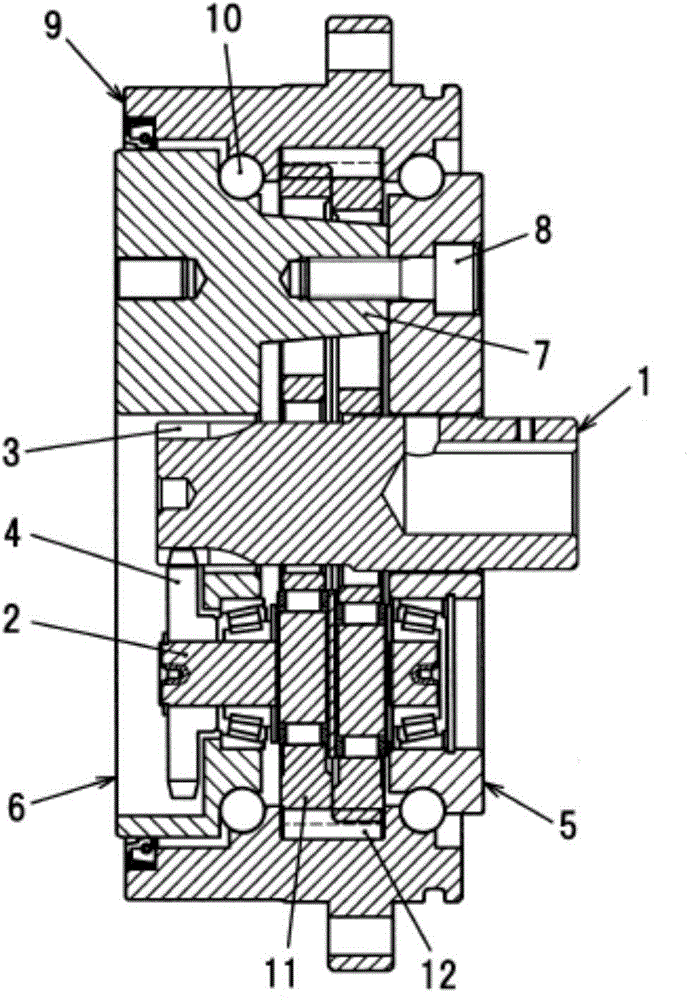

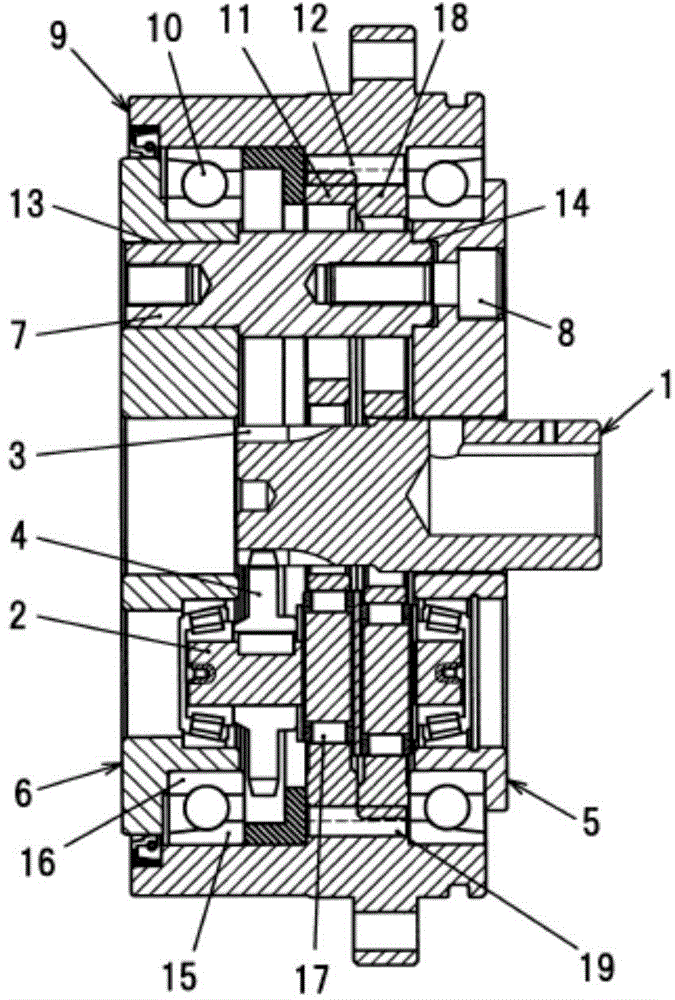

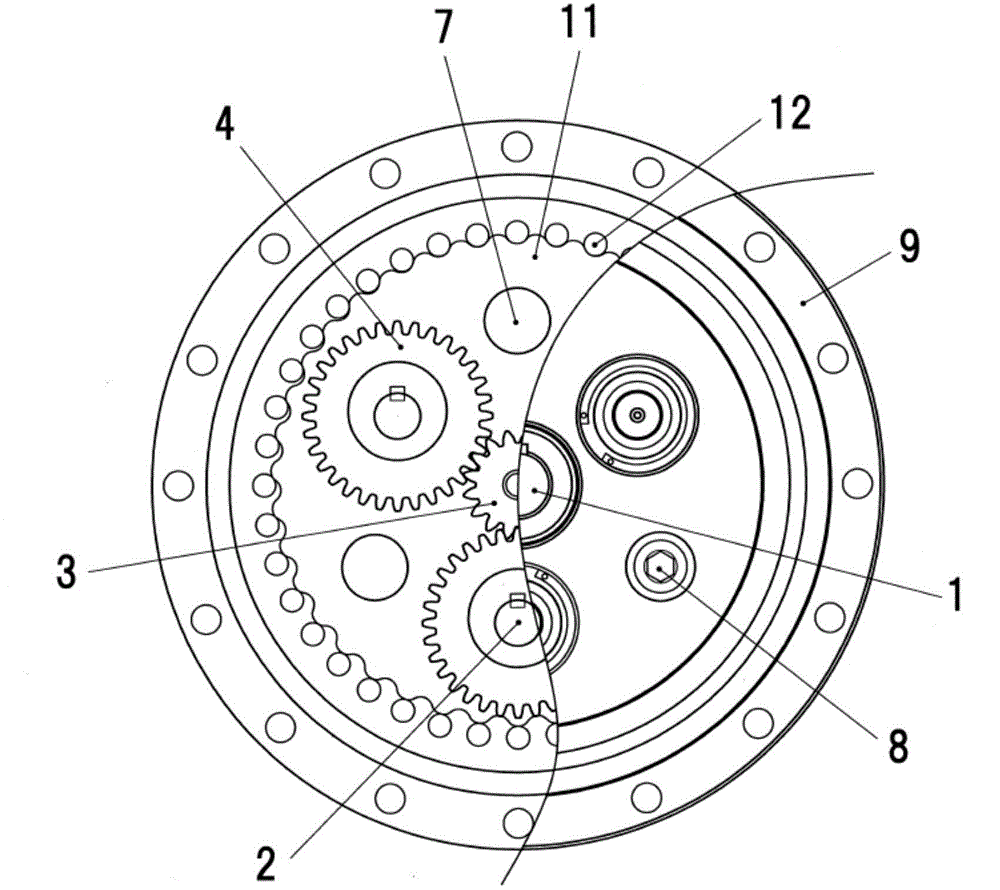

Inner-connection meshing type gear device

The invention provides an inner-connection meshing type gear device. The inner-connection meshing type gear device comprises an outer-tooth gear in a cycloidal tooth shape or a finished cycloidal tooth shape, an arc-tooth-profile inner-tooth gear and a plurality of eccentric crankshafts, wherein the number of teeth of the inner-tooth gear is larger than that of the outer-tooth gear; and the eccentric crankshafts are arranged to enable the outer-tooth gear to revolve in the inner-tooth gear, and the eccentric crankshafts can support swinging and rotating of the outer-tooth gear. An input shaft serves as an input side power source. A spur gear serving as a transmission gear is used for transmitting power to the eccentric crankshafts. The positions of the input shaft and a meshing part of the transmission gear deviate towards the input side relative to an output side supporting body and are adjacent to the outer-tooth gear. The inner-connection meshing type gear device can be applied to various industries such as a multi-link robot, an industrial machine, a positioning device of a machining tool and other inner-connection meshing type gear devices needing high precision, inclination of the input shaft and a gap of a speed reduction gear are reduced, and high durability is achieved.

Owner:亚杩拓精密机械(上海)有限公司

Thermal insulation aluminum alloy window with excellent leakproofness

InactiveCN111305708AIncreased friction and tightnessClosed tightlyClimate change adaptationWindows/door improvementThermal insulationStructural engineering

The invention relates to a thermal insulation aluminum alloy window with excellent leakproofness and belongs to the field of sealing aluminum alloy windows. The thermal insulation aluminum alloy window comprises an aluminum alloy window mounting frame, wherein sealing grooves are formed in the upper and lower ends of the aluminum alloy window mounting frame; a limiting groove is formed in a groovebottom plate of each of the two sealing grooves; an idler wheel sliding chute is formed in a groove bottom plate of each of the two limiting grooves; a pair of idler wheel bodies matched with the idler wheel sliding chutes are in sliding fit with the interior of each of the two idler wheel sliding chutes; a pair of connecting blocks matched with the limiting grooves are fixedly connected with theends, far away from groove bottom plates, of the idler wheel sliding chutes, of each of two pairs of idler wheel bodies; and telescopic rods are fixedly connected with the ends, far away from the idler wheel bodies, of the two pairs of connecting blocks. On the premise of facilitating installation of the thermal insulation aluminum alloy window, the leakproofness between the aluminum alloy windowand the mounting frame is improved, so that cold-blast air is unlikely to plunge into a gap between the aluminum alloy window and the mounting frame, and indoor thermal insulation is facilitated.

Owner:盐城市迪翔机械有限公司

Assembled toilet side bottom connecting structure

InactiveCN112878743AImpenetrableImprove waterproof performanceSpecial buildingBuilding insulationsStructural engineeringMechanical engineering

The invention relates to an assembled toilet side bottom connecting structure. The assembled toilet side bottom connecting structure comprises a prefabricated bottom plate, a side plate and a water baffle, wherein the bottom plate is horizontally arranged and comprises a reverse ridge; the side plate is vertically arranged on the reverse ridge, and the lower end of the side plate abuts against the upper surface of the reverse ridge; and the water baffle is vertically arranged on the surface of one side of the lower end of the side plate, the surface of one side of the lower end of the water baffle abuts against the surface of the inner ring of the reverse ridge, and the lower end of the water baffle is fixedly connected with the portion, located on the inner ring of the reverse ridge, of the bottom plate. The assembled toilet side bottom connecting structure has the advantage that water in a toilet is not prone to permeating out from the abutting portion between the bottom plate and the side plate.

Owner:CHINA STATE CONSTR HAILONG TECH CO LTD

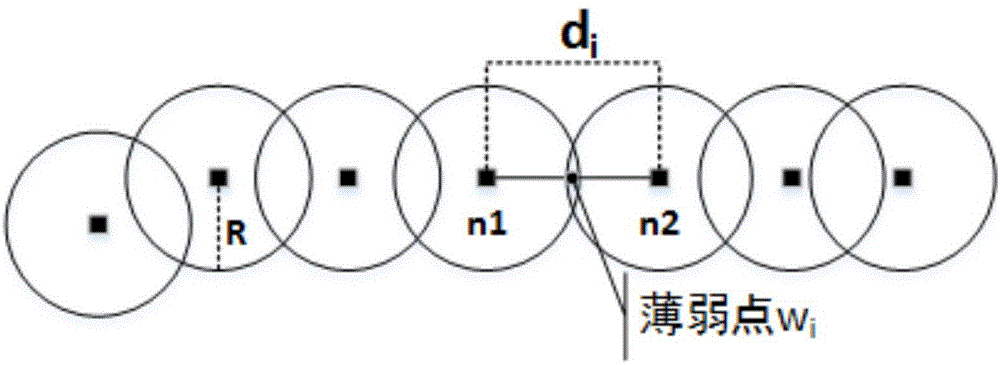

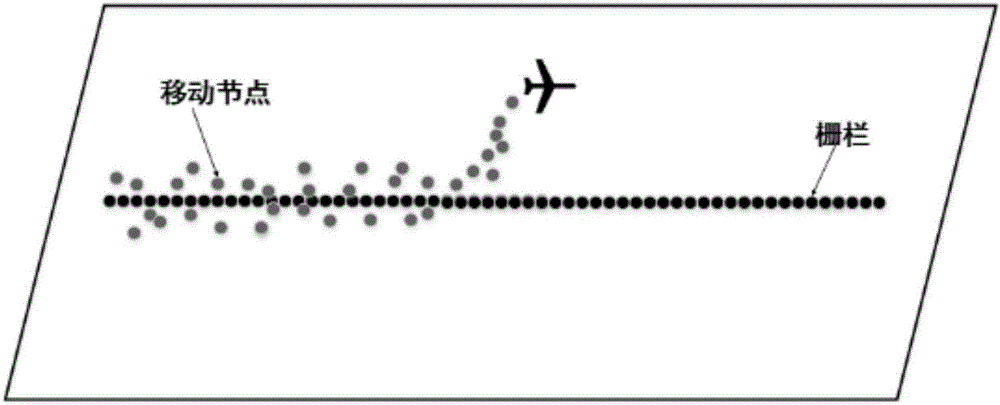

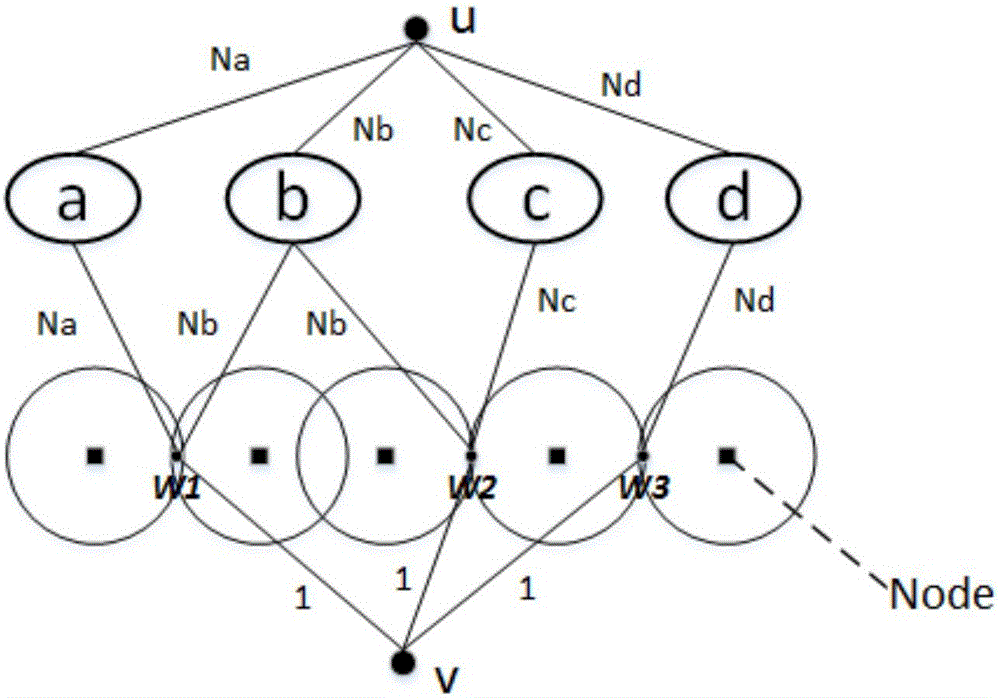

WSN (wireless sensor network) barrier enhancement method adopting secondary deployment

ActiveCN106507374AImprove survivabilityIncrease profitNetwork topologiesHigh level techniquesNODALMobile wireless sensor network

The invention relates to a WSN (wireless sensor network) barrier enhancement method adopting secondary deployment. The method includes the three steps of initial barrier analysis, secondary deployment and barrier enhancement. The initial barrier analysis further includes the following steps that: (1) robustness analysis is performed on initial barriers and enhanced barriers according to a node energy consumption sensing model; and (2) weak point search is carried out according to sensing radius decrease caused by energy consumption. According to secondary deployment, a secondary deployment is provided, static nodes are deployed primarily, the static nodes are utilized to construct barriers, mobile nodes are deployed along the constructed barriers again, and the mobile nodes are utilized to repair or enhance the barriers. According to barrier enhancement, a scheme enabling the sum of the movement distances of the mobile nodes to enhance the weak points of the barriers to be minimum is searched.

Owner:ZHEJIANG UNIV OF TECH

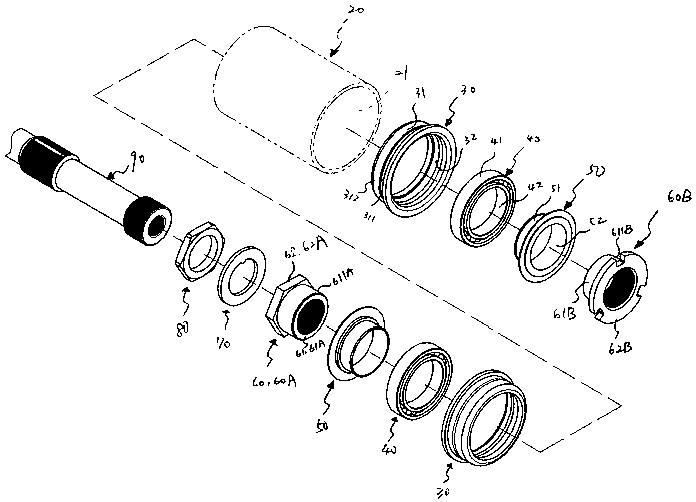

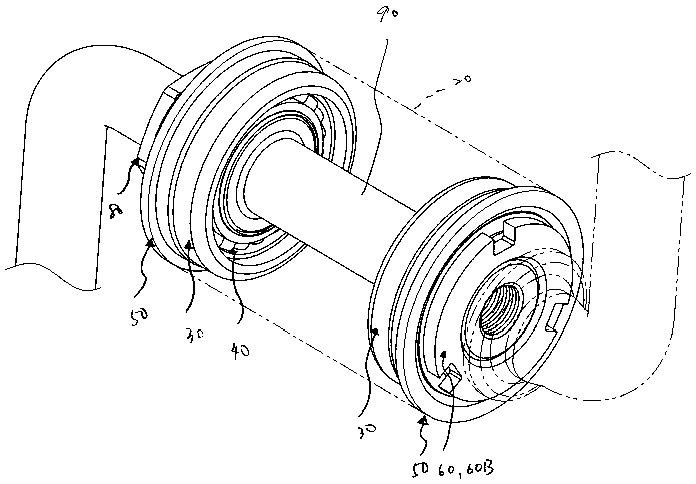

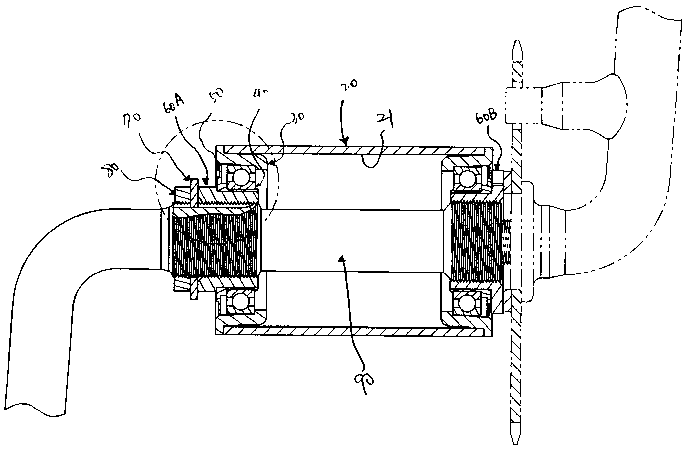

Bottom bracket cup and bicycle pedal crank component

The invention discloses a bottom bracket cup and a bicycle pedal crank component. The bicycle pedal crank component comprises a conjoined crank, a toothed disc and a hollow bottom bracket. The conjoined crank comprises a lower section, a mandrel and an upper section in sequential connection, the lower section and the mandrel are formed integrally, and two ends of the mandrel are provided with external threads. Each external thread is in threaded connection with a bottom bracket cup, and a fixing stop pin is arranged between the upper section and the toothed disc; preferably, a retaining part of the bottom bracket cup close to the lower section is a first retaining part, and a retaining part of the bottom bracket cup close to the upper section is a second retaining part. Bearings and the retaining parts can fit closely to enable close fit of wall surfaces, less proneness to gap generation is realized, an excellent orientation is obtained after assembly, and problems of shaking, deviation and the like of components are avoided. By an integrally formed structure of the lower section and the mandrel of the conjoined crank and a detachable connection structure of the upper section and the mandrel, convenience in assembly and high assembly efficiency are realized.

Owner:JURONG CHIIH SHIN PRECISION HARWARE PARTS CO LTD

Cover plate bottom foundation pit backfill construction method during cover-excavation construction

InactiveCN109695248AMeet operabilityMeet strength requirementsEmbankmentsExcavationsFoam concreteBasement

The invention discloses a cover plate bottom foundation pit backfill construction method during cover-excavation construction. The construction method comprises the following steps: S1, construction preparation; S2, survey mark; S3, retaining wall construction; S4, plain concrete construction; S5, foam concrete construction; S6, subsequent treatment. According to the construction method disclosedby the invention, backfilling is performed by adopting a construction method for taking plain concrete as basement and filling the cavity with the foam concrete, and due to combined use of the plain concrete and the foam concrete, the defects that the plain concrete is difficult in cover plate bottom backfill construction and the foam concrete is small in dead weight can be overcome; during construction, with the adoption of a construction manner of backfilling in separate warehouses on different layers, by matching with retaining walls, the construction method has the advantages of convenience in construction and excellent penetration resistance, filling compaction is realized, gaps are difficultly formed, and the cover plate bottom backfill construction quality is effectively ensured.

Owner:ZHONGYIFENG CONSTR GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com