Plate-and-frame filter for chondroitin sulfate processing

A chondroitin sulfate, plate and frame filter technology, applied in the direction of filtration separation, separation methods, chemical instruments and methods, etc., to achieve the effect of not easy to crack, high clarity, and thorough filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

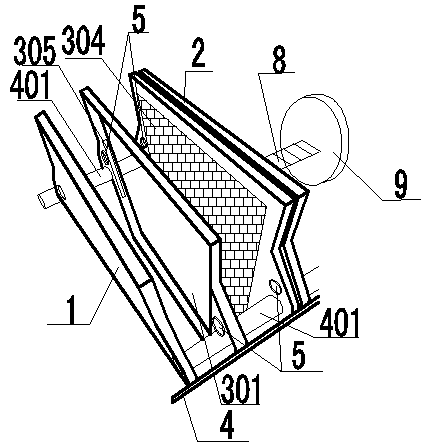

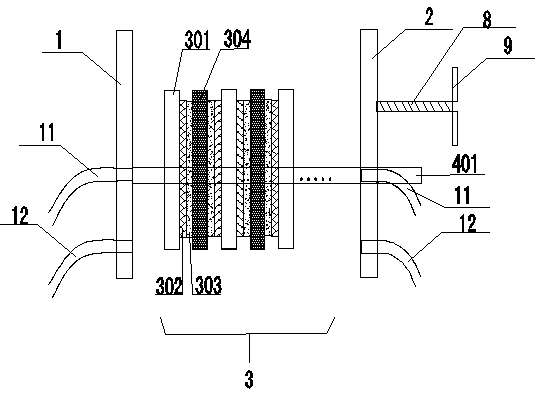

[0030] The invention relates to the technical field of filtration equipment, and discloses a plate-and-frame filter for processing chondroitin sulfate. The plate-and-frame filter can realize multiple filtrations from rough filtration to fine filtration in one piece of equipment, and greatly reduce impurities in the filtrate. When entering the subsequent sterile filter, the occurrence of equipment blockage is reduced and the clarity is high.

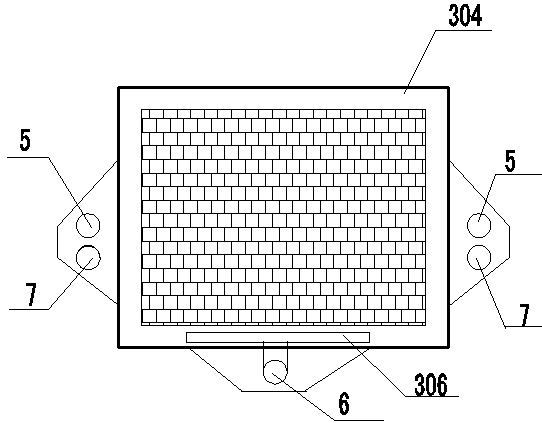

[0031] The plate-and-frame filtering device includes a frame 4, a thrust plate 1 fixed on the frame 4, a plurality of filter units 3 that are slidably connected to the frame 4 and can be compressed, and a compression unit that is slidably connected to the frame 4 through a compression mechanism. Tightening plate 2, each filter unit 3 includes plate frame 301, clarification plate 302, PP film 303 and screen plate 304, the two sides of screen plate 304 are respectively provided with PP film 303, clarification plate 302, plate Frame 301 , cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com