Polyester film-coated filter cartridge for industrial dust collection

A polyester film-coated filter cartridge and industrial dust collection technology, applied in the direction of dispersed particle filtration, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of inconvenient cleaning of dust, affecting filtration efficiency, affecting service life, etc., and achieve improvement efficiency, improve cleaning efficiency, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

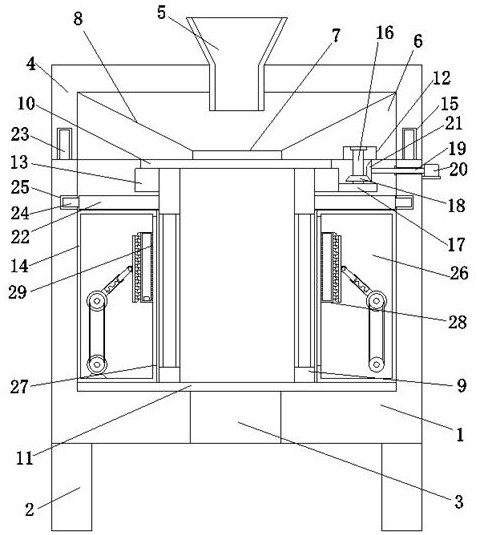

[0031] Embodiment one, by Figure 1 to Figure 6 Given, the present invention comprises box body 1, box cover 4 and polyester film filter cartridge body 9, and the top of box body 1 is provided with box cover 4, and polyester film filter cartridge body 9 is positioned at box body 1 and box cover 4 Inside, the bottom end of the box body 1 is symmetrically provided with a support column 2, the middle position of the bottom end of the box body 1 is provided with an air outlet 3, the top middle position of the box cover 4 is provided with an air inlet 5, and the inside of the box cover 4 is provided with There is a stop plate 6, and the middle position of the stop plate 6 is provided with a port 7, and the bottom end of the stop plate 6 is provided with a filter membrane-10 positioned at the top of the polyester film-coated filter cartridge body 9, and the polyester film-coated filter cartridge The bottom of the body 9 is provided with a filter membrane two 11 located at the inner ...

Embodiment 2

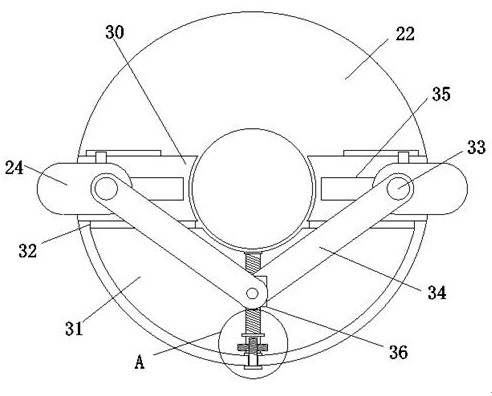

[0034] Embodiment two, on the basis of embodiment one, by figure 1 , figure 2 and Figure 6 Given, the inner wall of accommodating groove one 30 is provided with a connecting groove 35 that is slidably connected with the connecting shaft 33, and the driving member includes an internally threaded cylinder 36, a screw 37, a worm gear 38 and a worm 39, and the two ends of the connecting rod 34 are passed through the inner Threaded cylinder 36 is connected, and screw mandrel 37 is installed on the inwall of holding groove two 31, and internally threaded cylinder 36 is threadedly connected with screw mandrel 37, and screw mandrel 37 is provided with worm gear 38, is connected with worm screw 39 in rotation on fixed ring 22, and worm screw 39 and Turbine 38 meshing connection;

[0035] By rotating the worm 39, the worm 39 and the worm gear 38 will be meshed to make the worm gear 38 rotate, and the worm gear 38 will drive the screw 37 to rotate, and the threaded connection between...

Embodiment 3

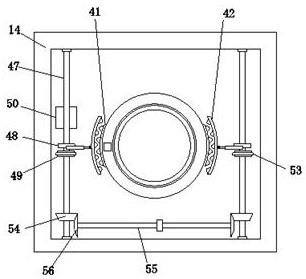

[0036] Embodiment three, on the basis of embodiment one, by figure 1 Given, the bottom end of the case cover 4 is provided with a slot 15, and the top of the box body 1 is provided with a plunger 23 that is snapped into the slot 15, and through the snap-fit design of the slot 15 and the plunger 23, the case cover is improved. 4 The tightness of the connection with the box body 1, thereby reducing the possibility of gas outflow, thereby improving the sealed connection between the box body 1 and the box cover 4, and the top end of the stop plate 6 is provided with a polymerization groove 8 communicating with the port 7, The cross-section of the polymerization tank 8 is an inverted trapezoidal structure, and a groove 12 is provided on one side of the bottom end of the stopper plate 6. The rotating mechanism includes a rotating shaft 16, a gear 2 17, a bevel gear 18, a rotating shaft 19 and Motor one 20, the inner top end of groove 12 is equipped with rotating shaft one 16, is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com