Electronic product container packing method

A technology for electronic products and box sealing. It is used in packaging sealing/fastening, external support, transportation packaging, etc. It can solve the problems of different specifications of packaging boxes, non-deformation of the conveying part, and easy gaps in the sealing area, so as to improve the sealing efficiency. , Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below by means of specific embodiments:

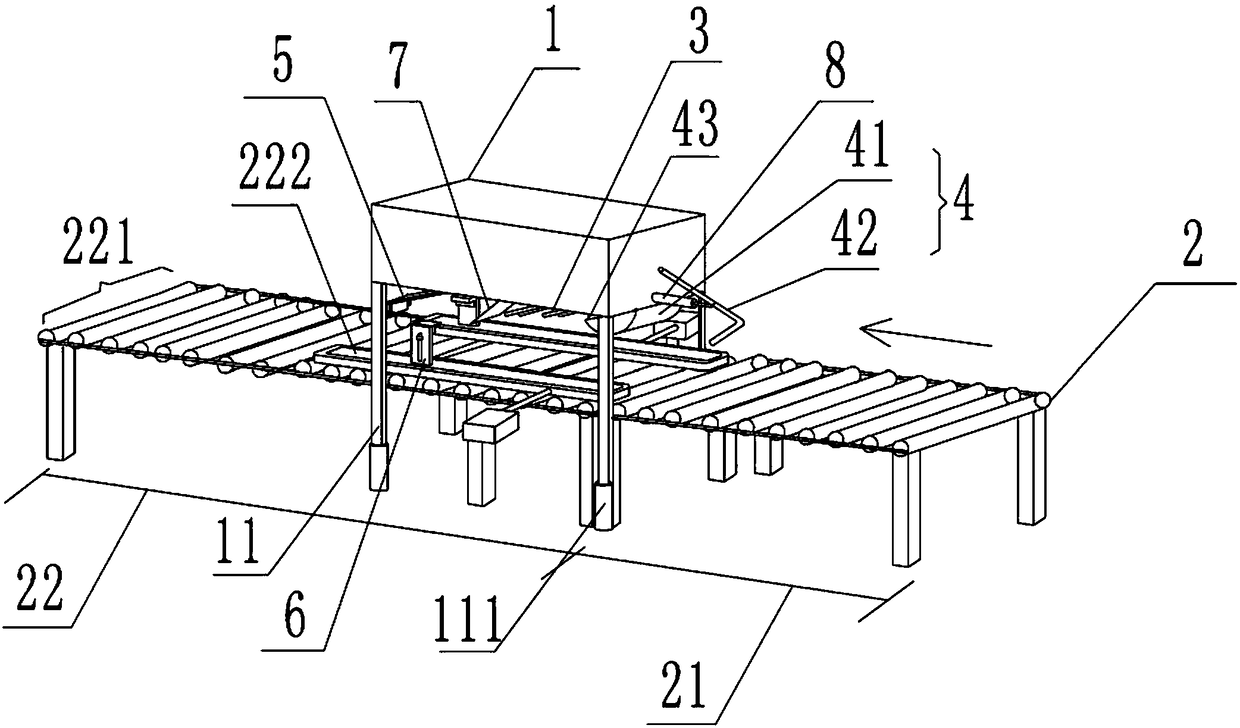

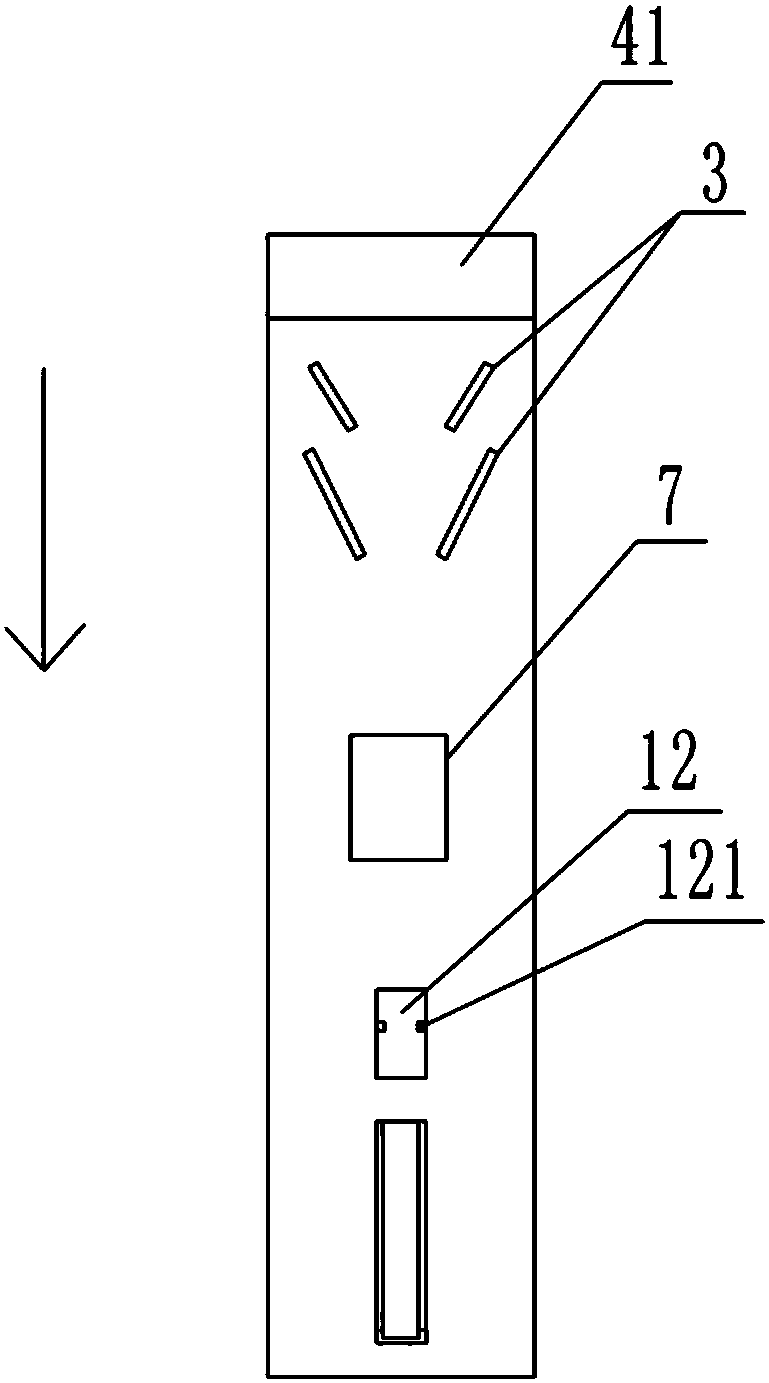

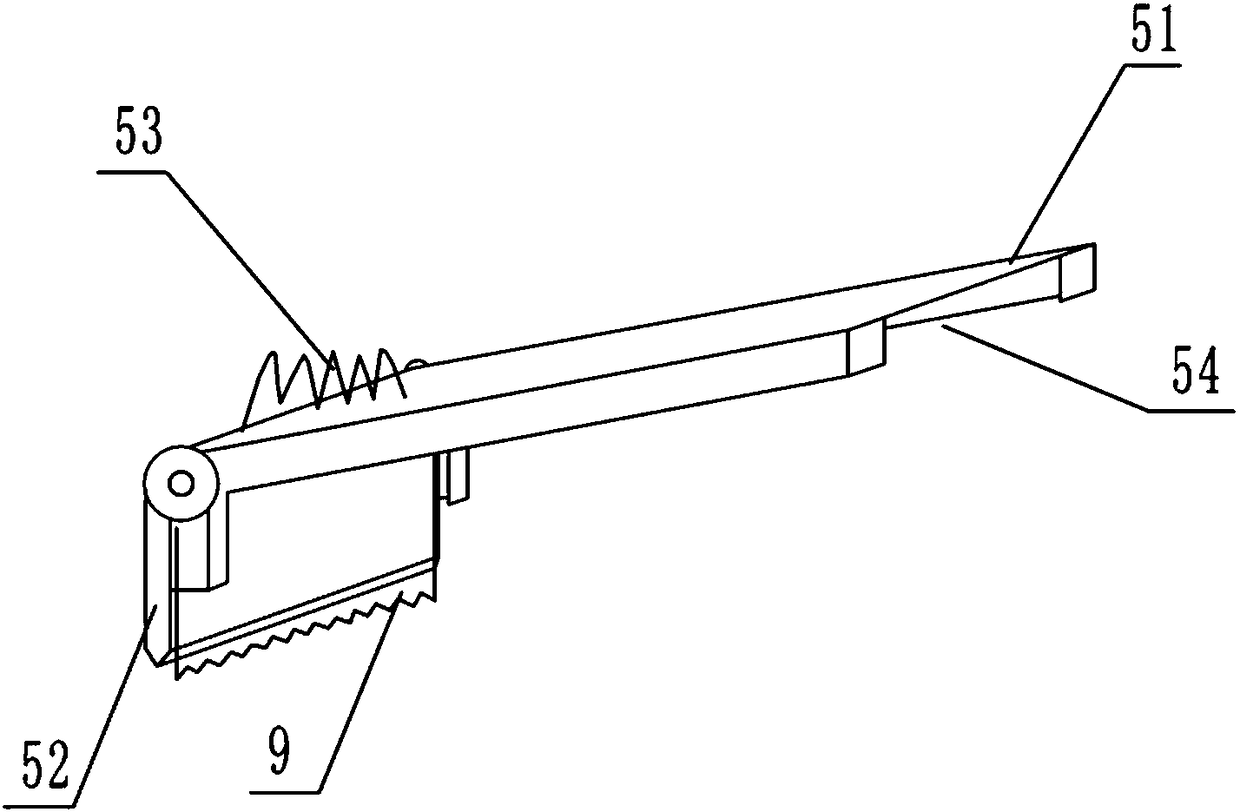

[0035] The reference signs in the drawings of the description include: frame body 1, telescopic rod 11, storage slot 12, support shaft 121, transmission part 2, front transmission part 21, rear transmission part 22, transmission plane 221, slide bar 222, eight Glyph smoothing rod 3, end plate smoothing part 4, front smoothing plate 41, rear folding rod 42, compression spring 43, adhesive tape sticking part 5, branch plate 51, scraper 52, elastic member 53, groove 54, extrusion Part 6, L-shaped extrusion plate 61, T-shaped convex strip 611, swivel 612, spring 613, pole 62, strip groove 621, limit groove 622, limit part 7, hydraulic cylinder 8, scotch tape 9 , Front end plate A, rear end plate B, left side plate C, right side plate D, corner 10, expansion part hydraulic cylinder 111.

[0036] A method for sealing electronic products, the steps are as follows:

[0037] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com