Patents

Literature

35results about How to "Achieve opposite motion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

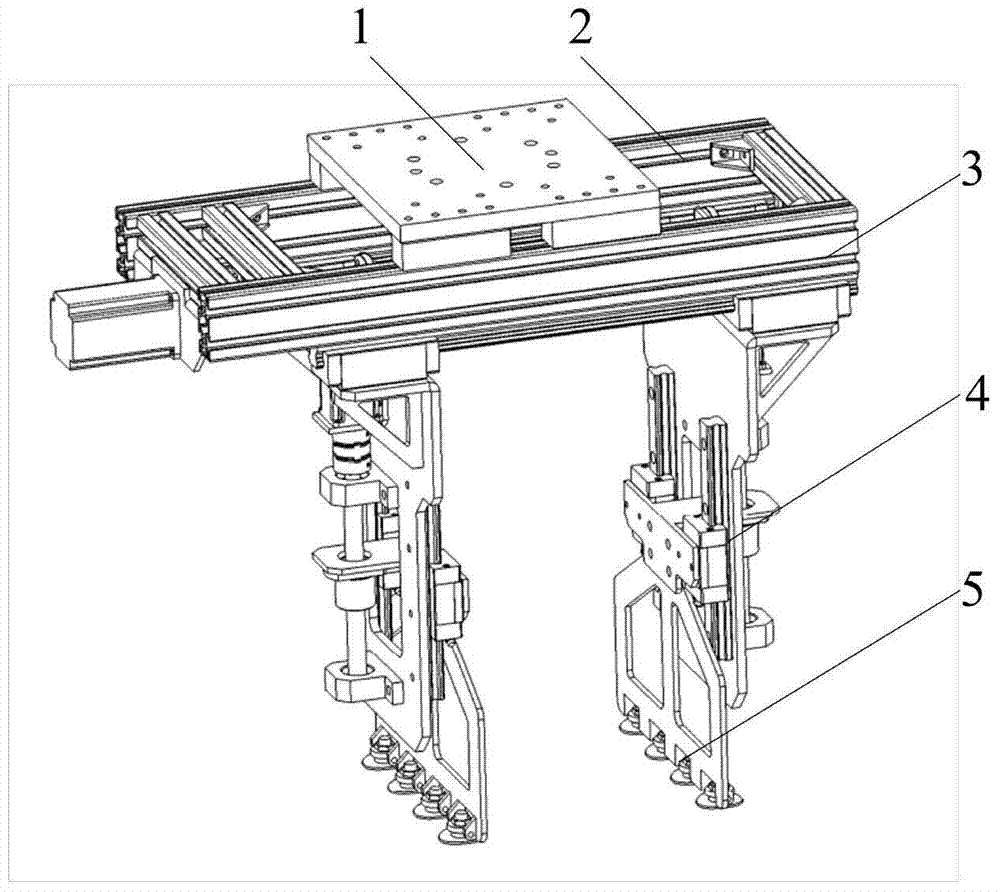

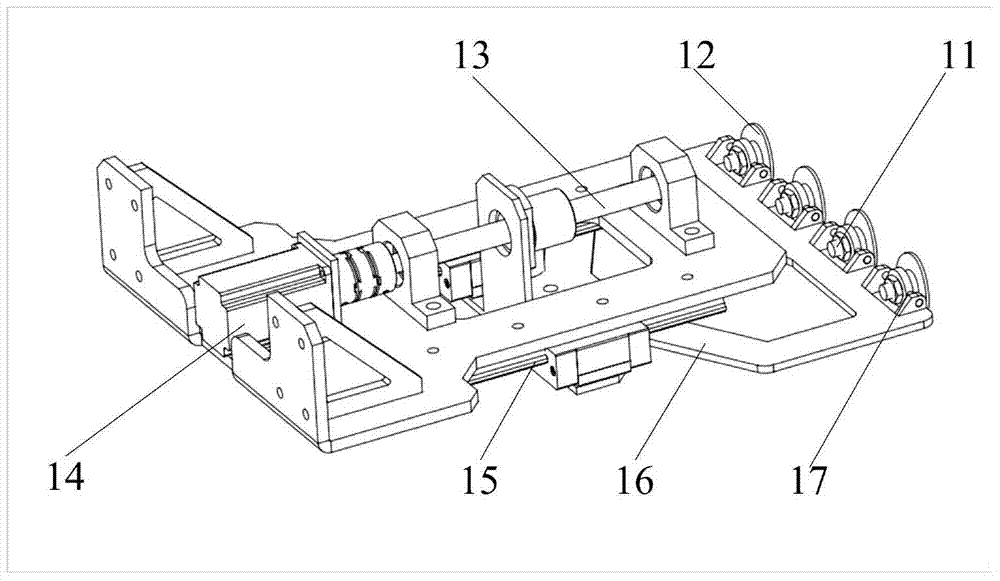

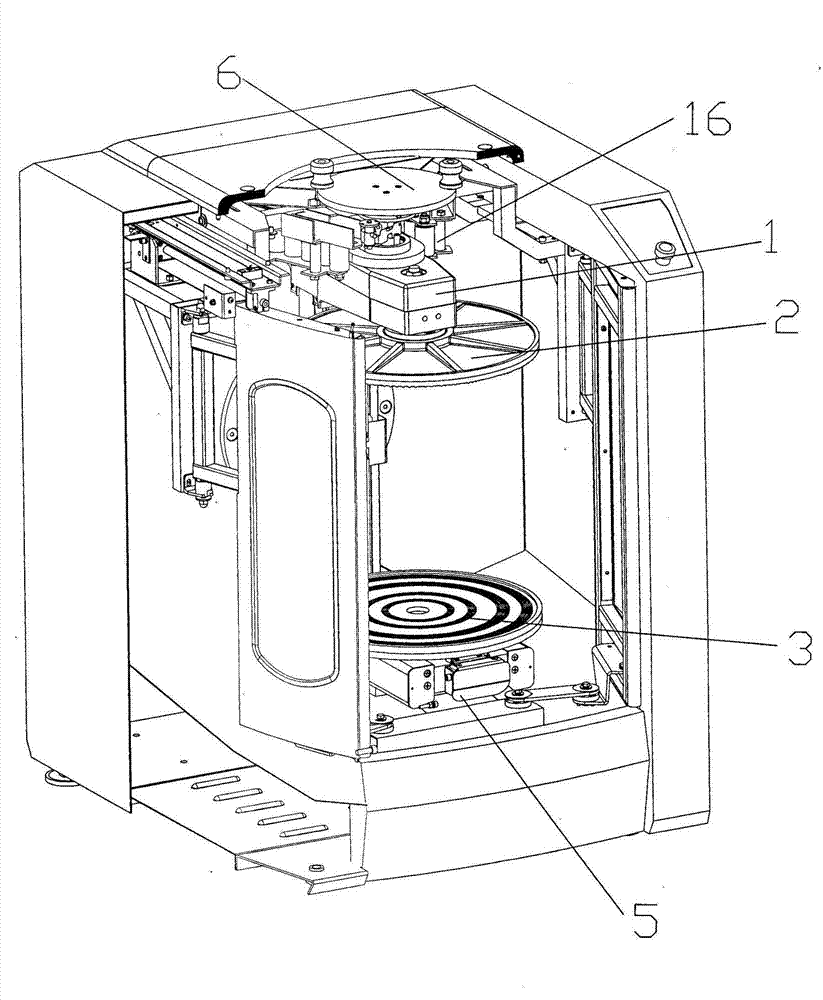

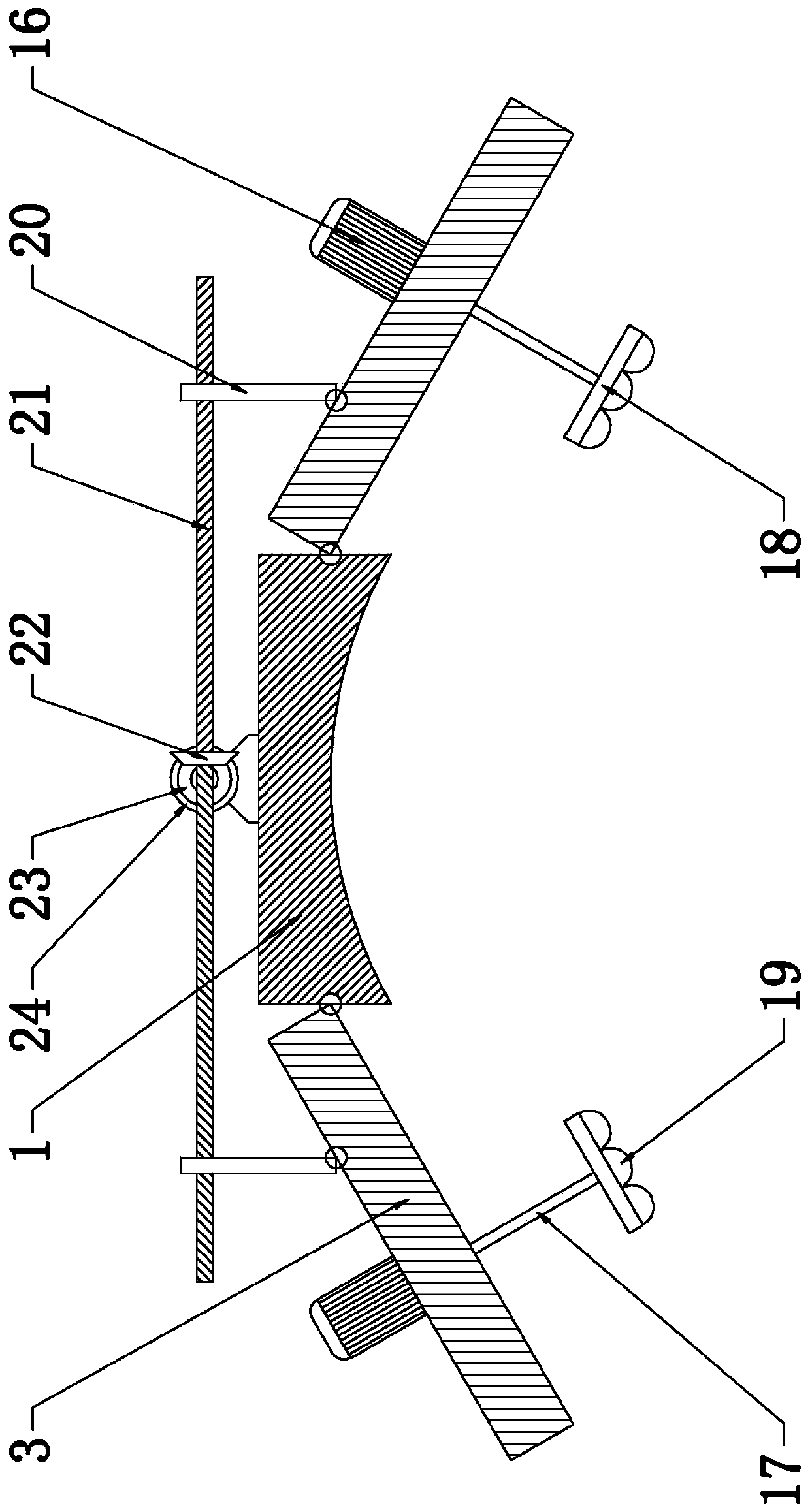

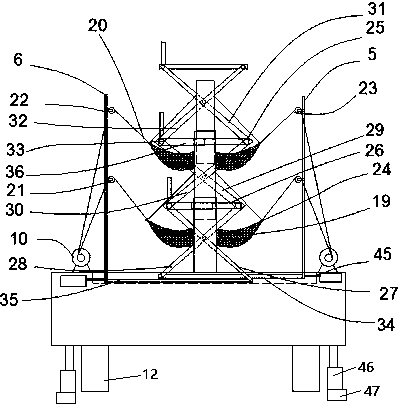

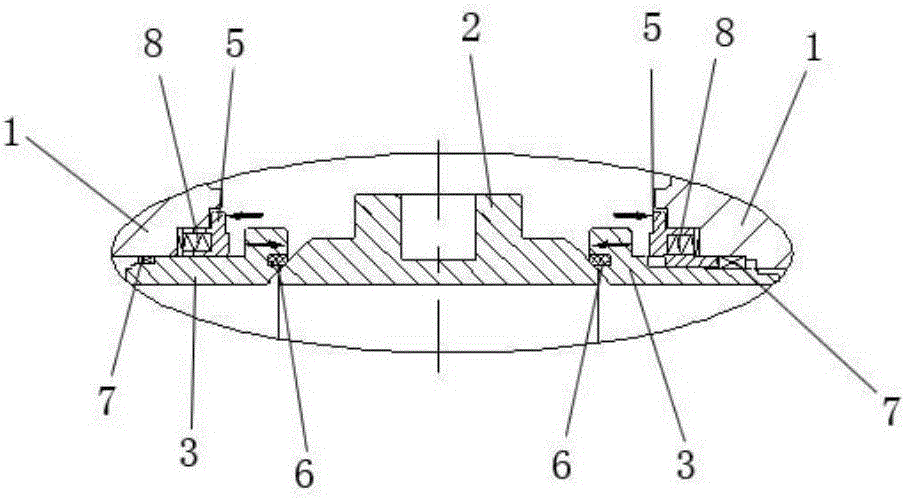

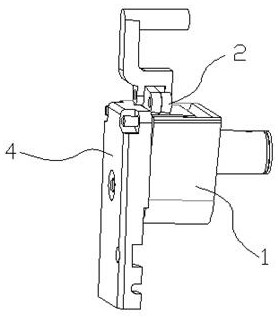

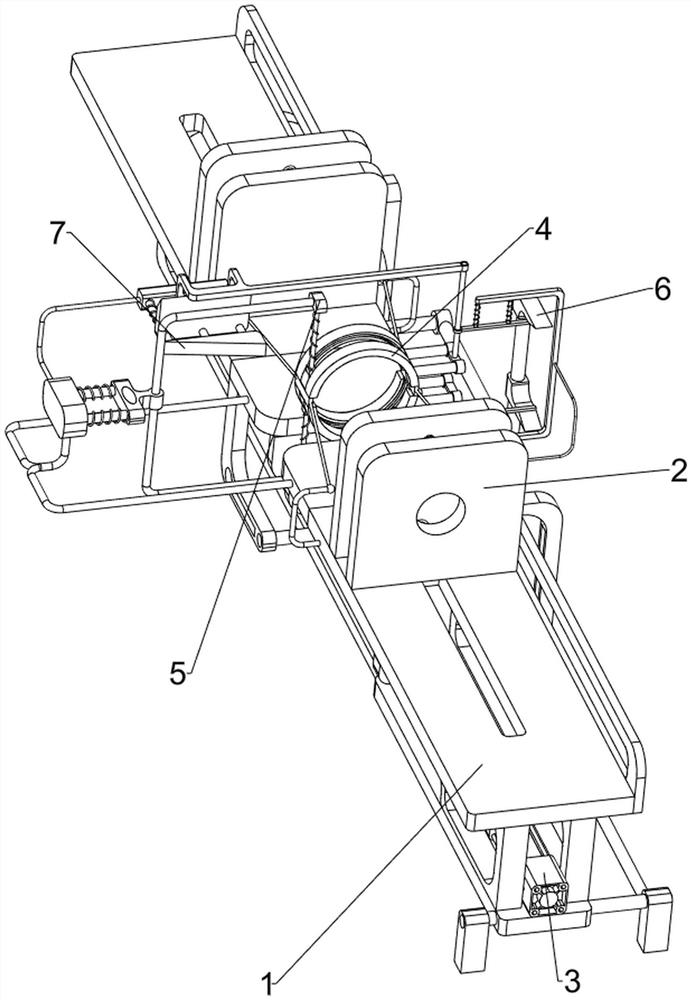

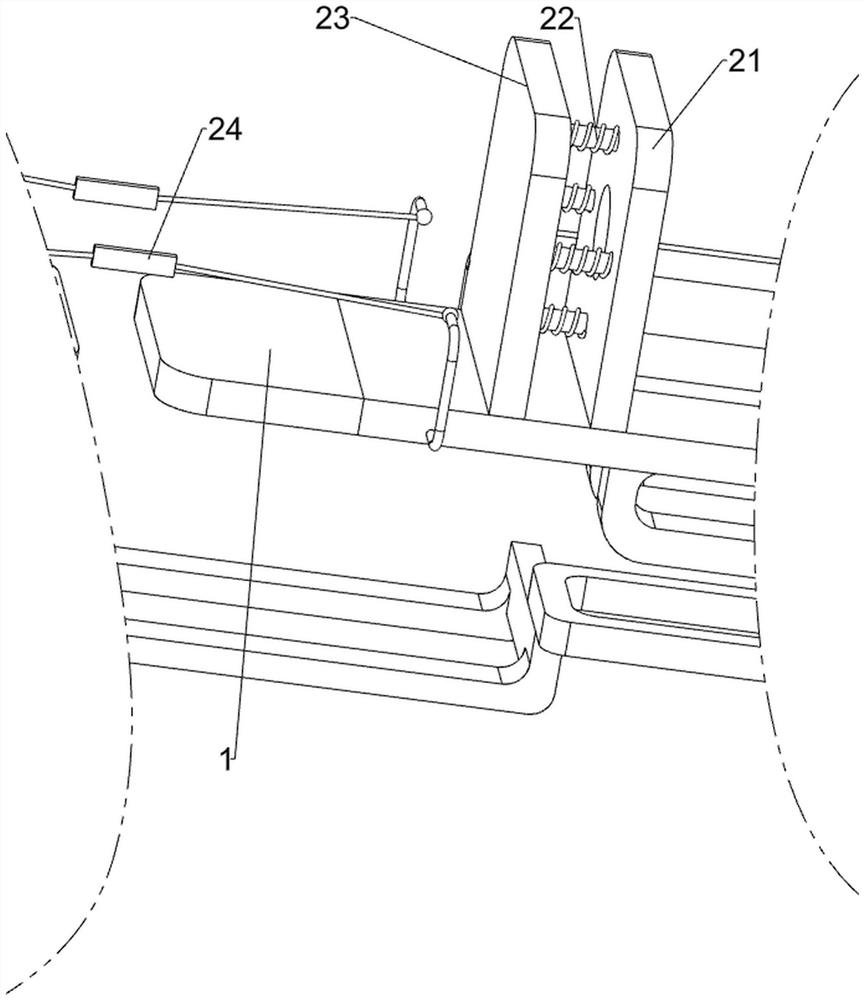

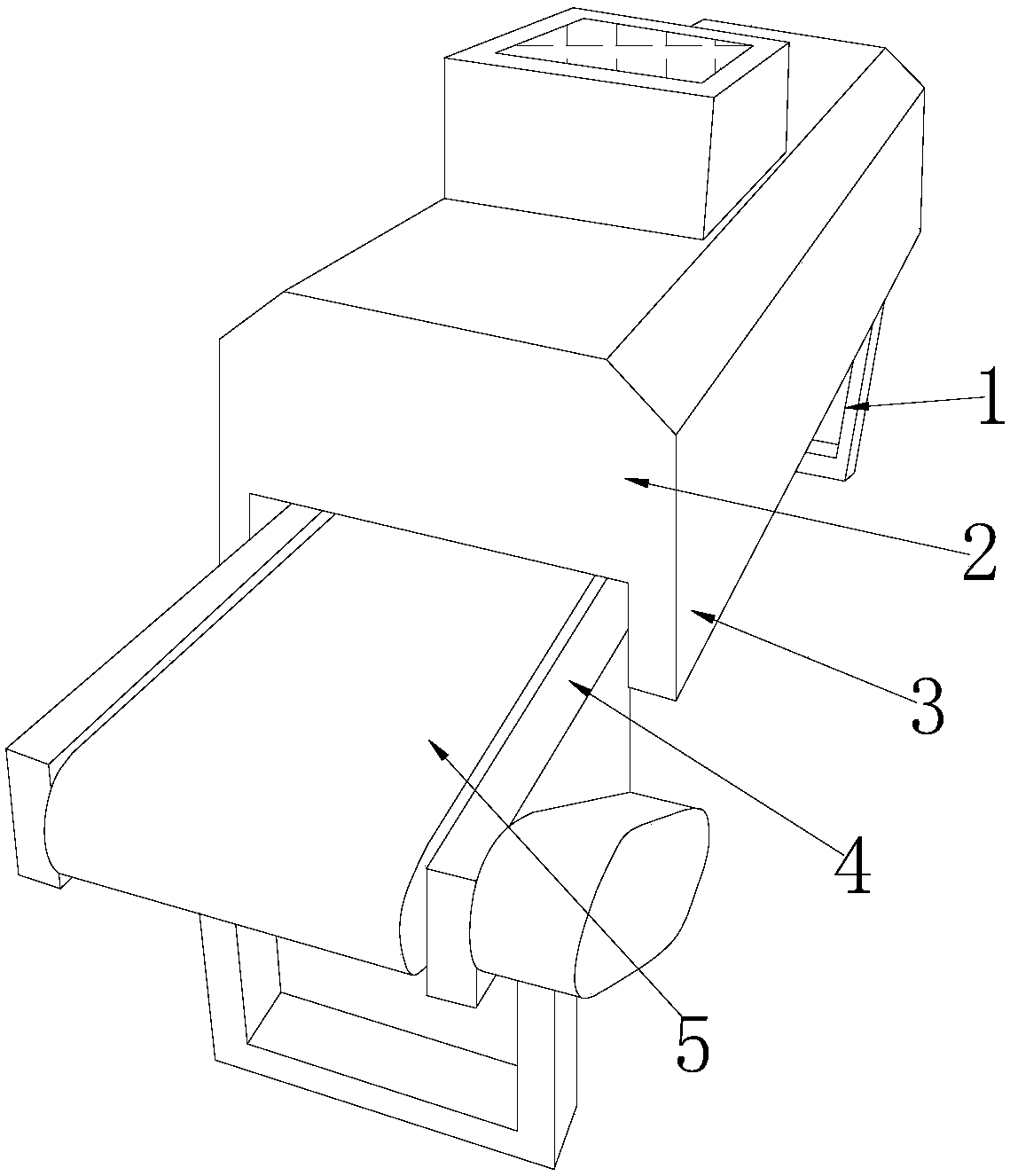

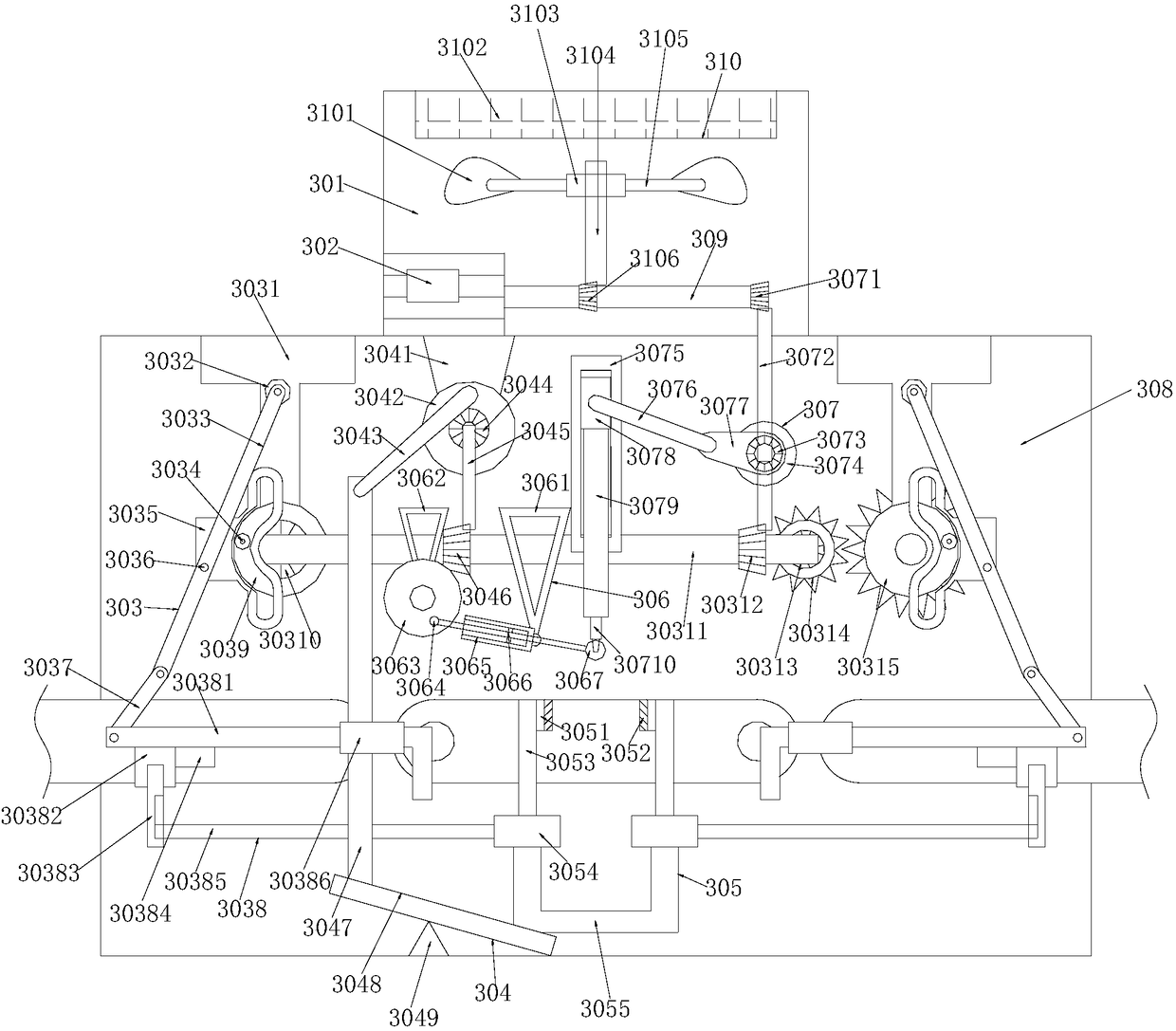

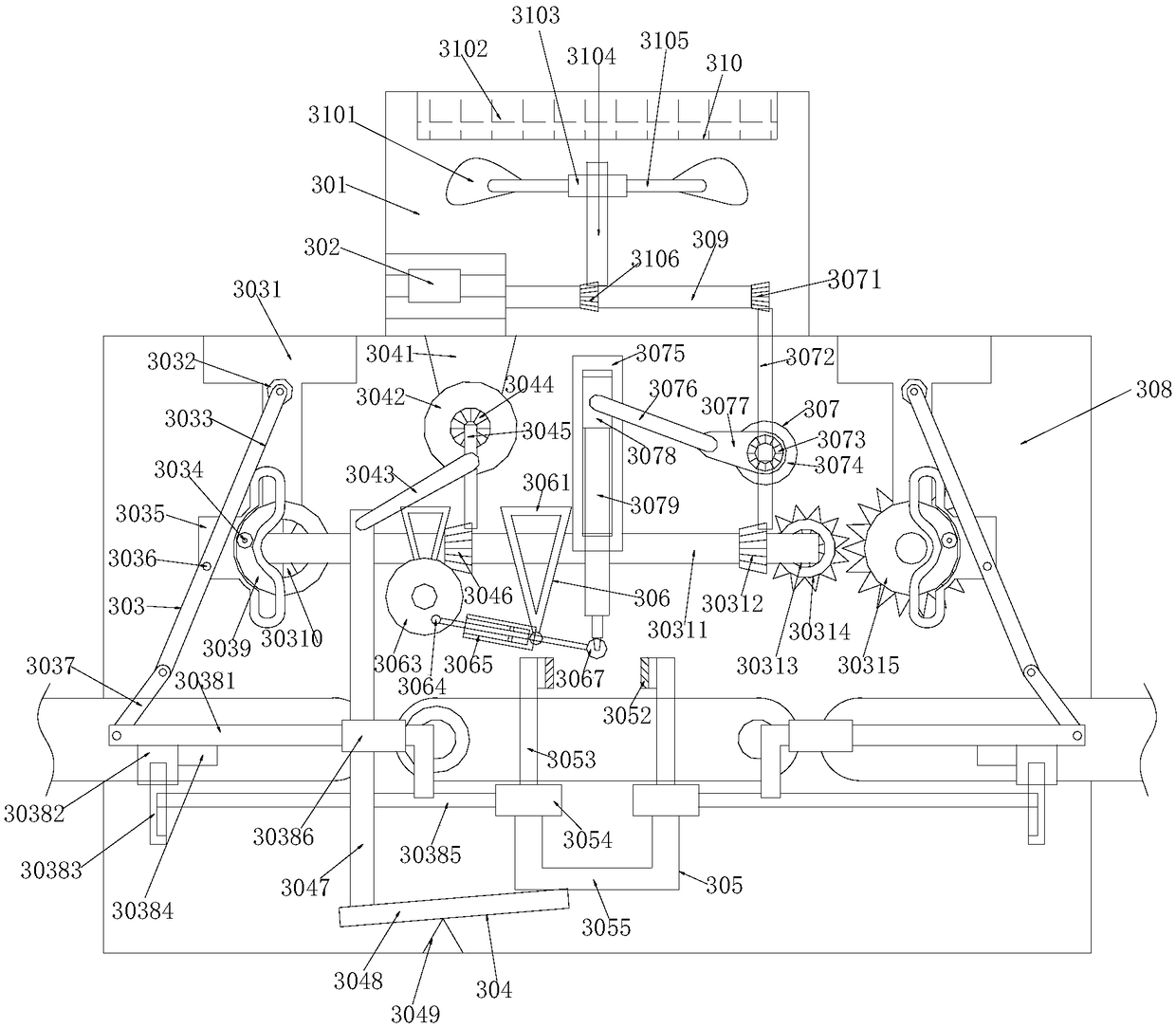

Chuck gripper device of stacking robot for complex surface

InactiveCN104493822AAchieve opposite motionGuaranteed gripping stabilityProgramme-controlled manipulatorGripping headsSymmetric designMotor drive

The invention provides a chuck gripper device of a stacking robot for a complex surface. The device comprises a connecting flange, a mounting frame, a transverse adjusting mechanism, longitudinal adjusting mechanisms, an absorbing mechanism, a human-computer control interface and an electrical protection device; the transverse adjusting device is used for adjusting the width of the absorbing mechanism through a motor driving a bidirectional rotating lead screw; the longitudinal adjusting mechanisms are of a symmetric design and are respectively mounted at two sides of the bidirectional rotating lead screw to lift and lower down the absorbing mechanism; the absorbing mechanism is connected with a sponge chuck by a hinging manner, which effectively avoids the phenomenon of failure of absorbing on an uneven surface; the absorbing mechanism can be in match with the transverse and longitudinal moving mechanisms to adapt to the change on the size of materials. The device is suitably used for gripping objects with different size and surface forms and has the characteristics of being simple in structure, convenient to drive, steady and reliable, high in generality, and flexible to operate.

Owner:CHANGZHOU INST OF ADVANCED MFG TECH +1

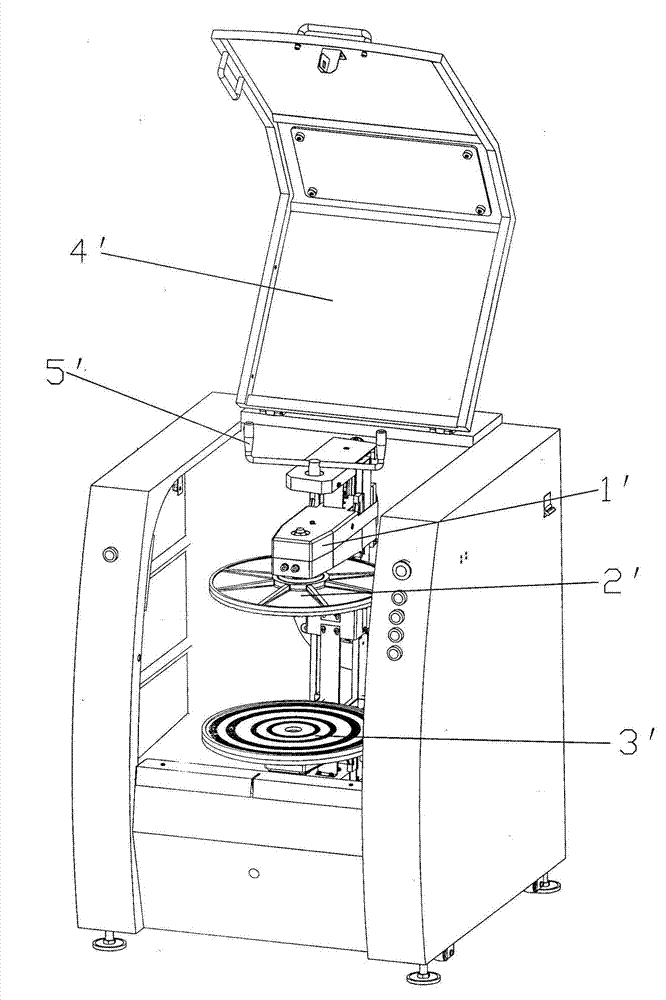

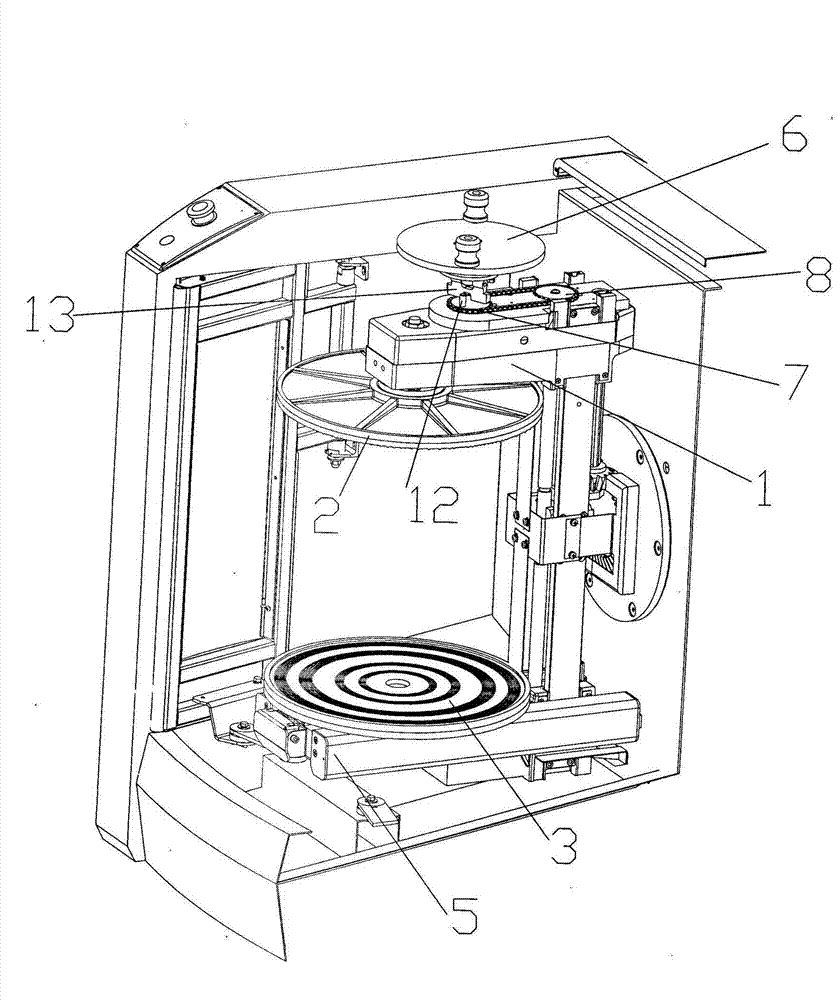

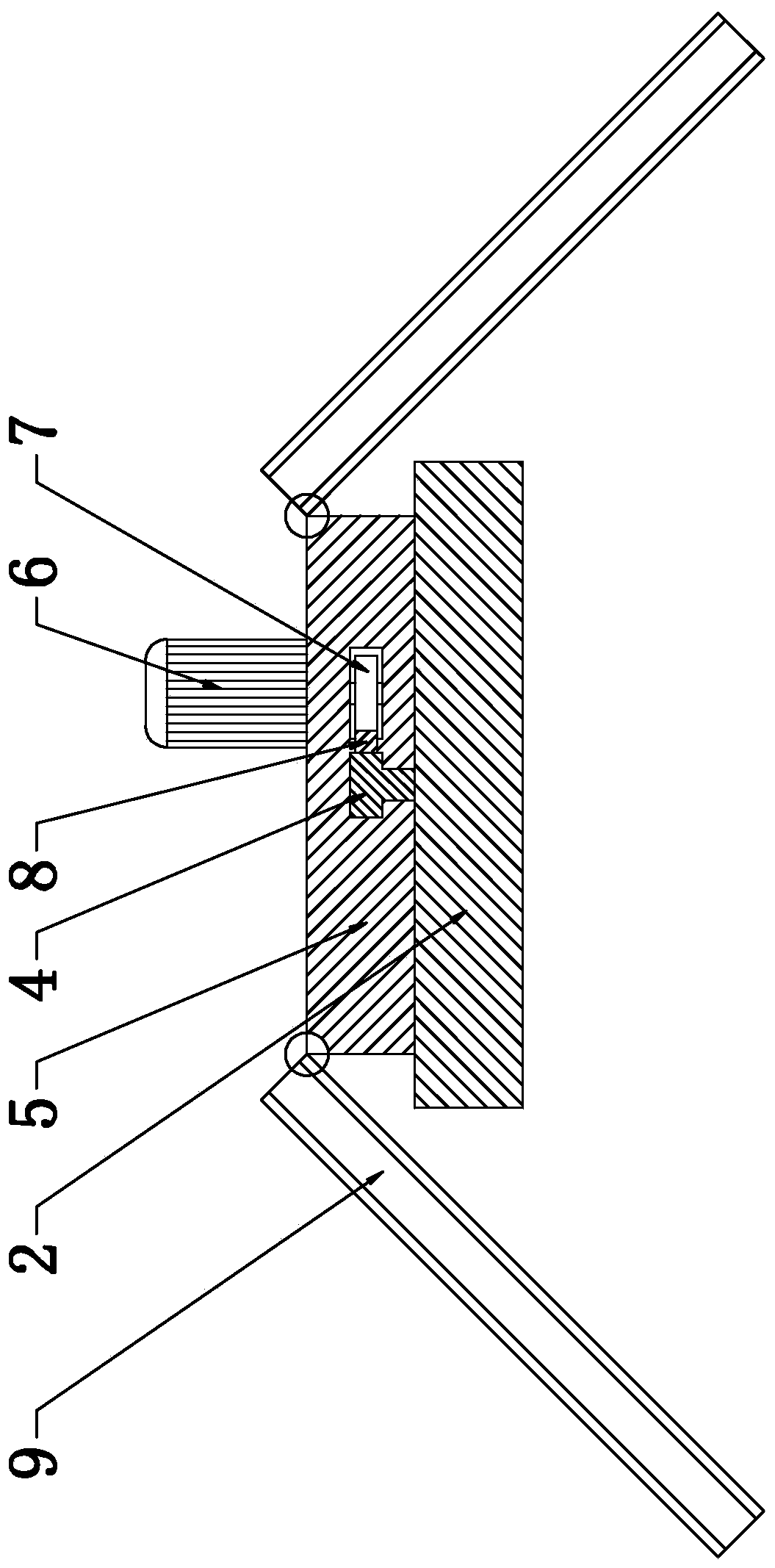

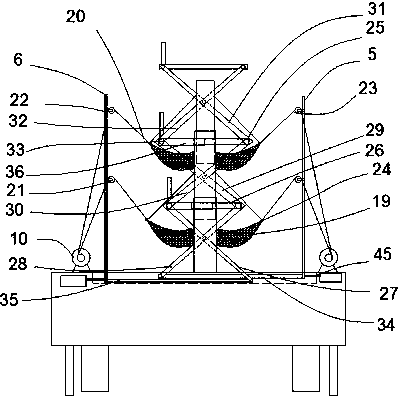

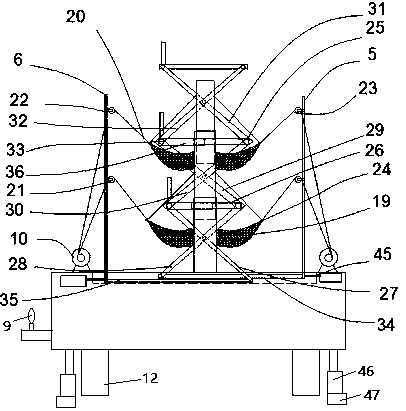

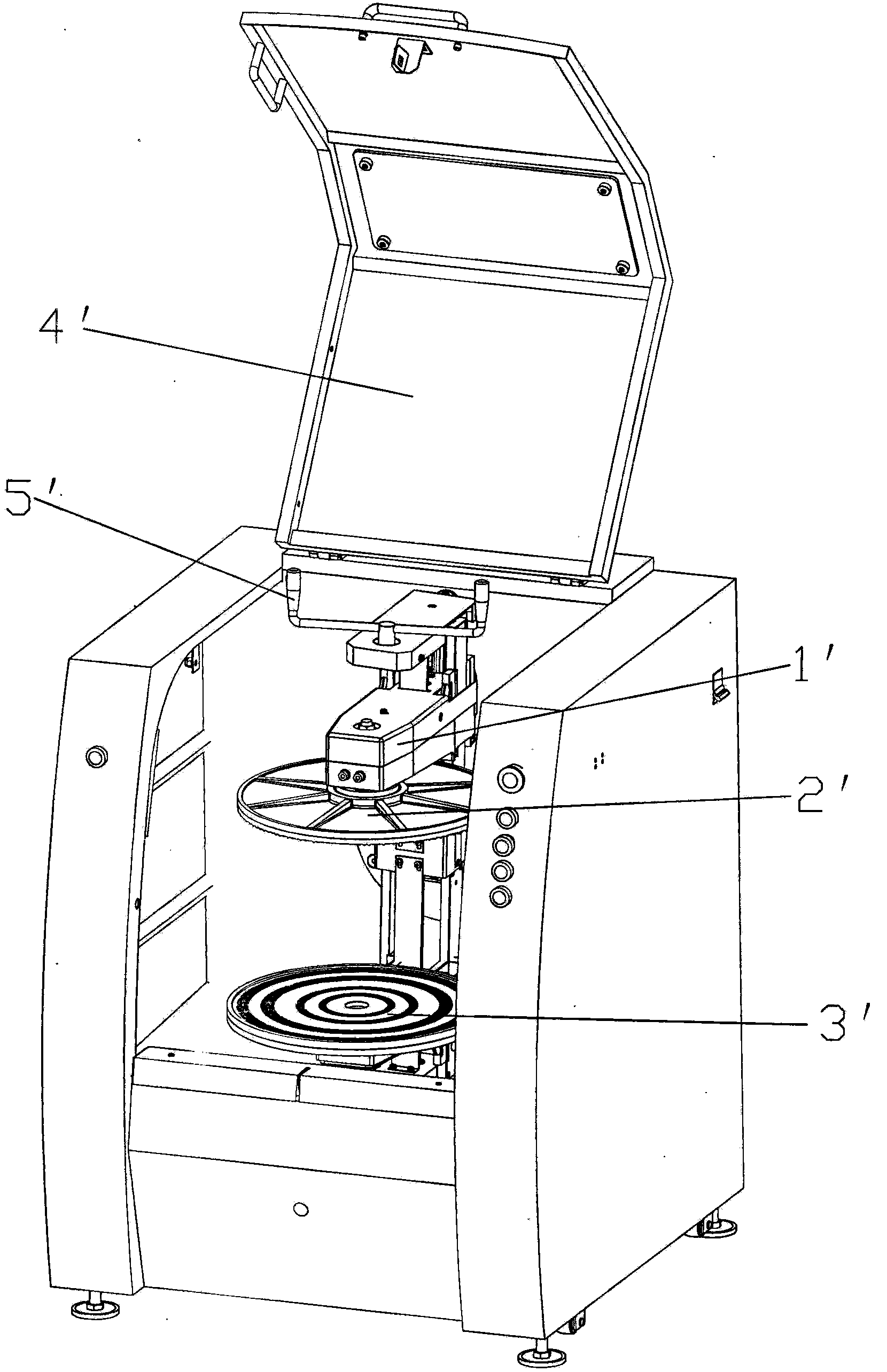

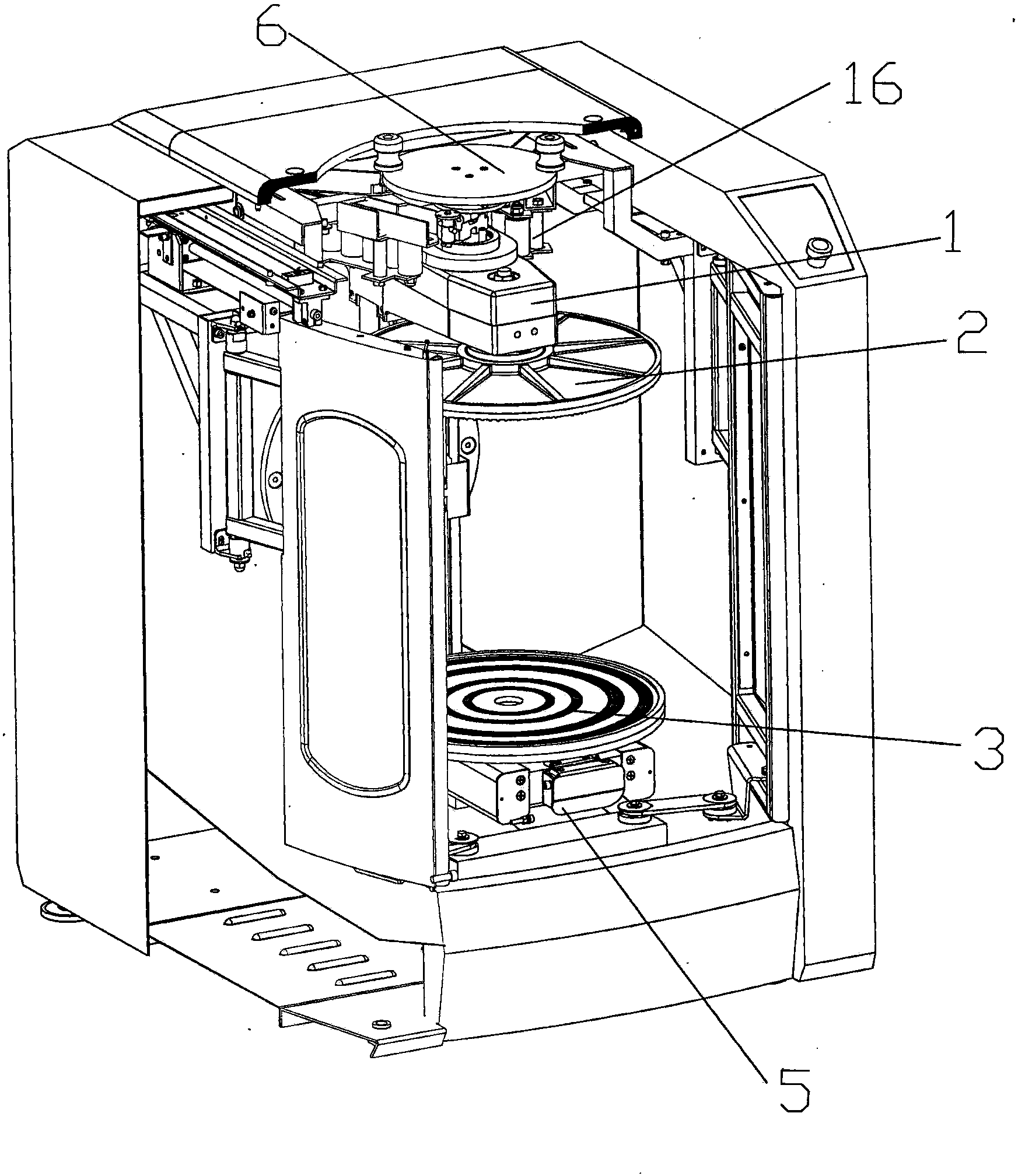

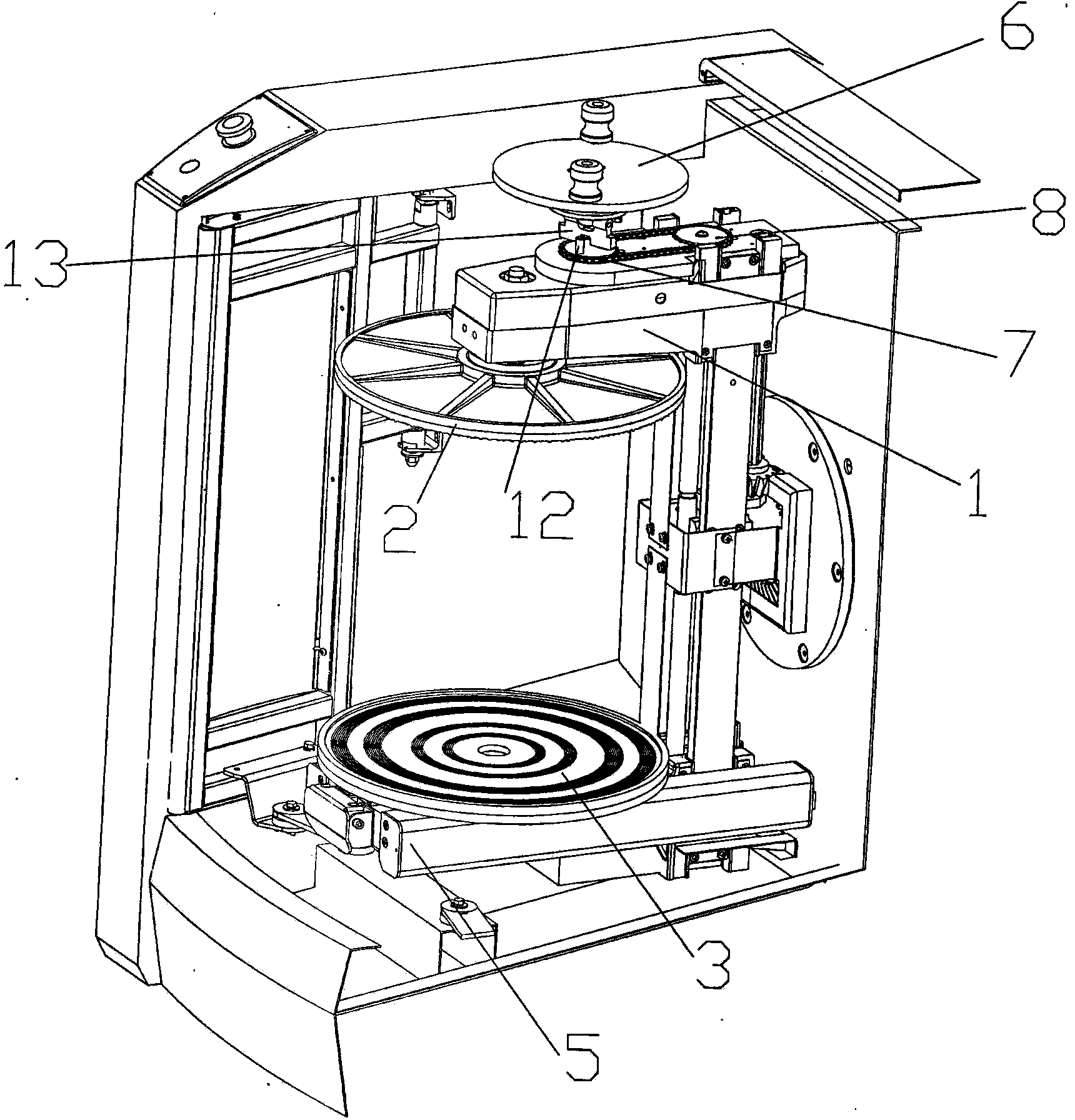

Manual pressing structure for double-rotation paint mixing machine

ActiveCN102764606AEasy to operateSafe and reliable structureRotating receptacle mixersMixer accessoriesDouble rotationPush and pull

The invention relates to a manual pressing structure for a double-rotation paint mixing machine, which is characterized in that: the upper top cover of the mixing machine is internally provided with a manual rotating pressing component, the pressing component comprises pressing discs, a rotating shaft base, rotating shafts of the pressing discs, the rotating shafts of the pressing discs penetrate through the rotating shaft base, the top ends of the rotating shafts of the pressing discs are fixedly connected with the pressing discs, the lower ends of the rotating shafts of the pressing discs are provided with pressing shifting components, pressing driving wheels are provided with shifted components which are in overlap joint with the shifting components, and when the upper top cover is fully opened, the pressing driving wheels match with the rotating shafts of the pressing discs coaxially. By pushing and pulling the upper top cover, the shifting connecting matching structures can be combined and separated smoothly, and by rotating the pressing discs to drive the pressing driving belt wheels to rotate, the upper pressing disc and the lower pressing disc can move oppositely, thus a colored paint barrel can be pressed and opened without using a special separable pressing wrench. The manual pressing structure is convenient to use and is safe and reliable in structure.

Owner:ZHENGZHOU SANHUA TECH & IND

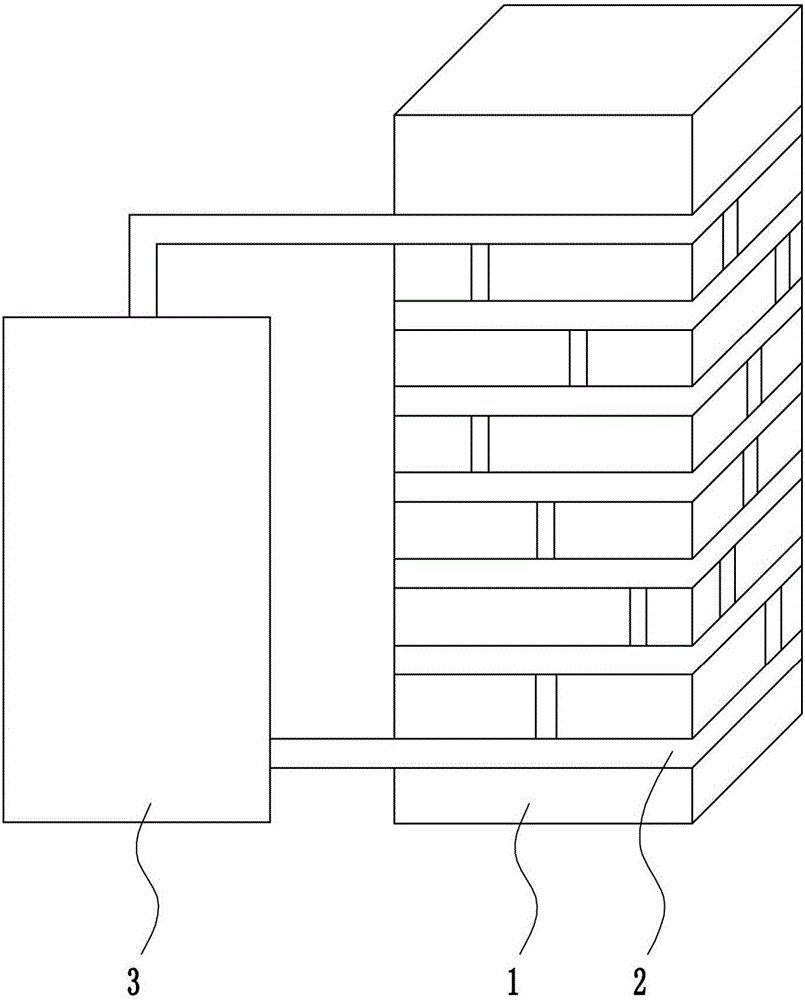

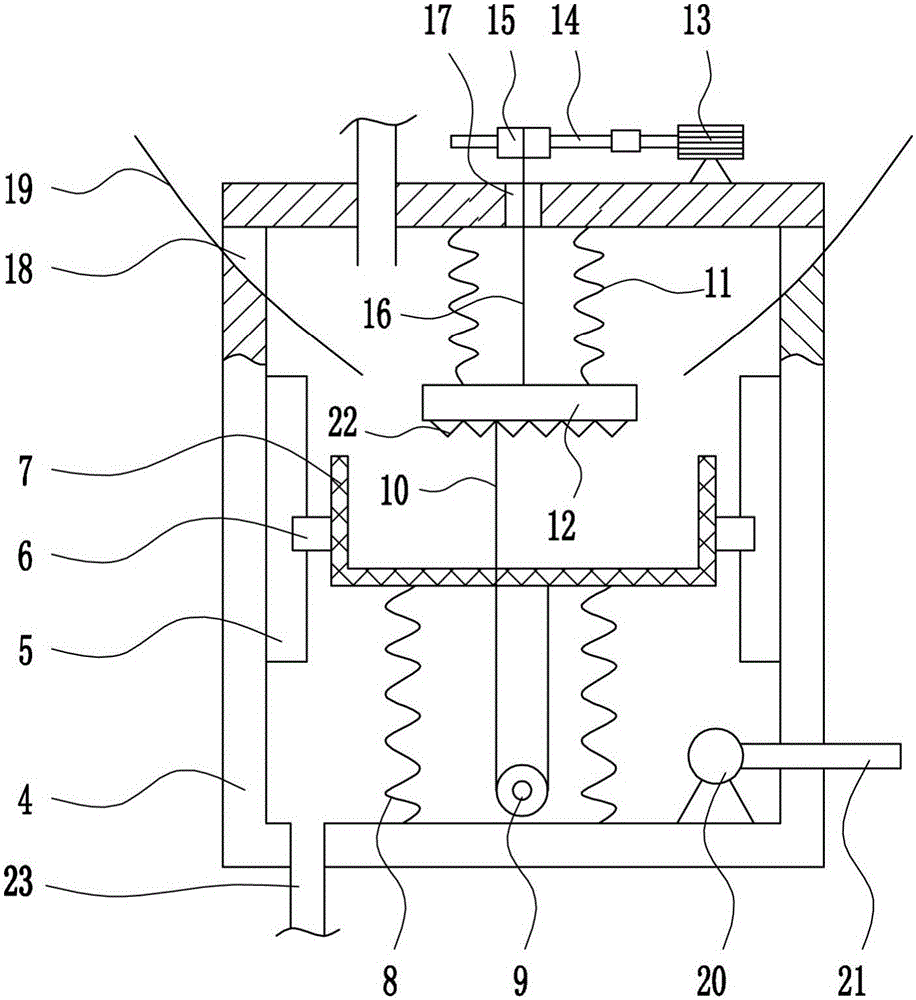

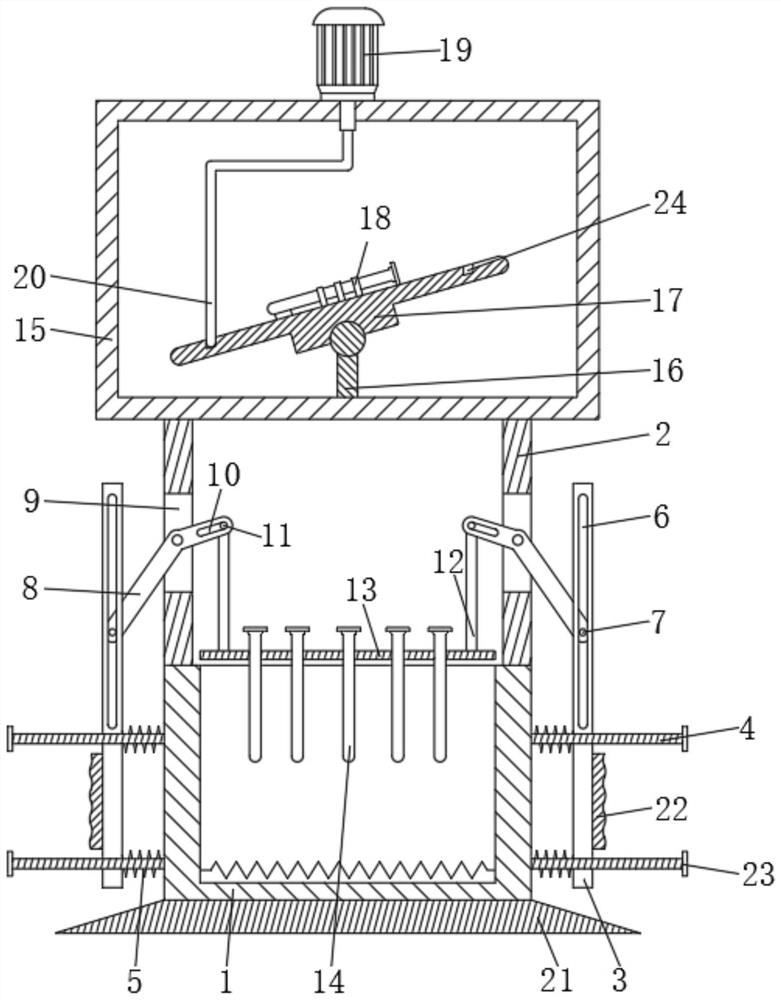

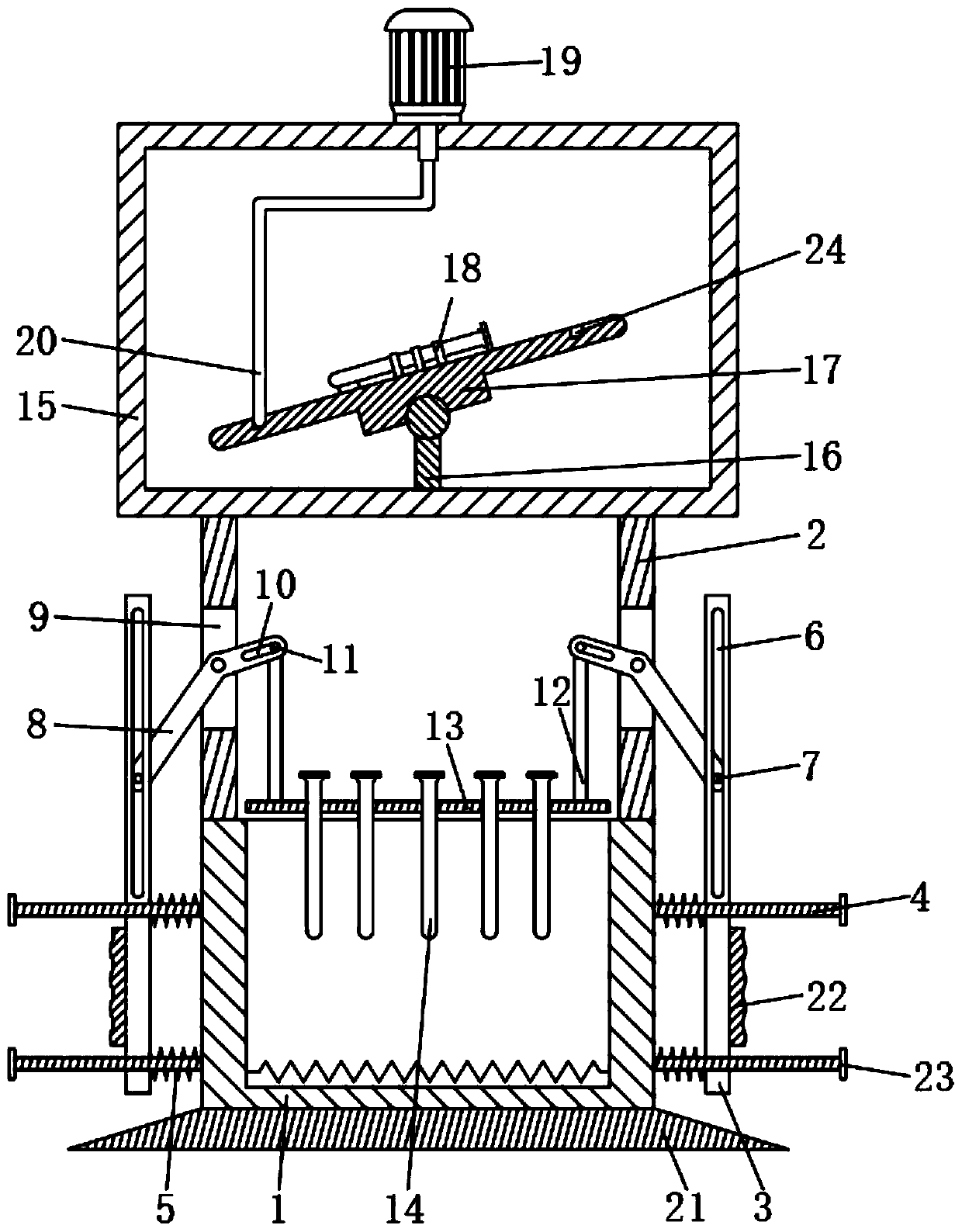

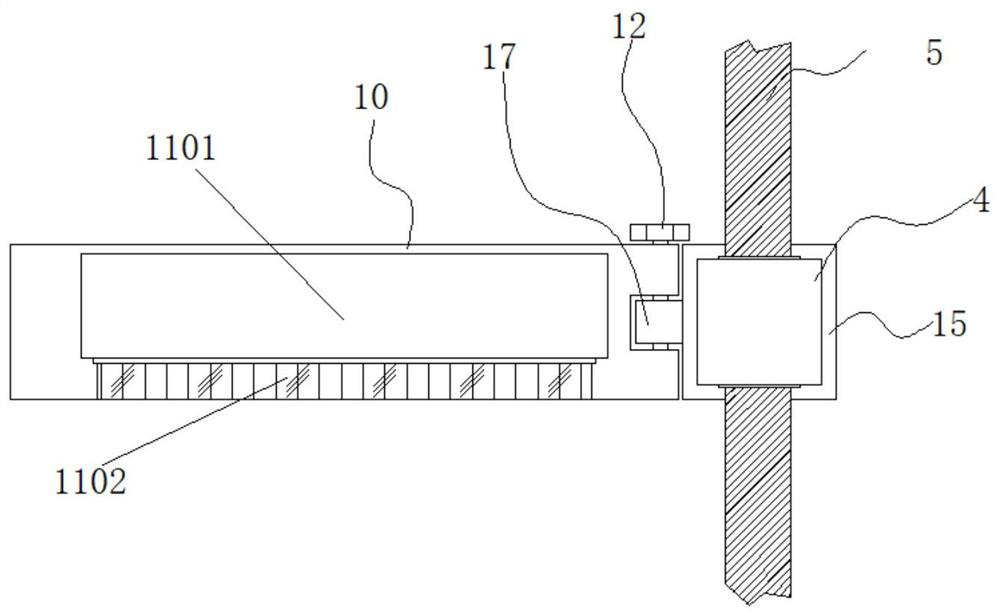

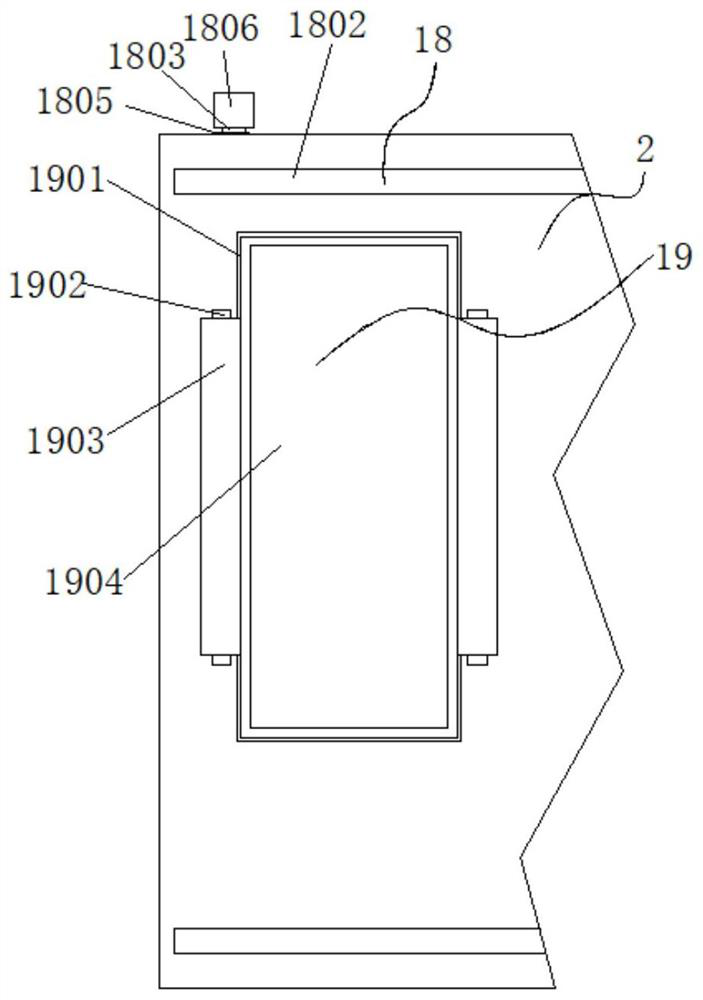

Heat dissipation device of big data human-computer machine

InactiveCN106406475AAchieve opposite motionSave resourcesDigital data processing detailsEngineeringBig data

The invention relates to a big data human-computer machine, in particular relates to a heat dissipation device of a big data human-computer machine. The invention provides the heat dissipation device, which is good in heat dissipation effect and fast in heat dissipation speed and is environmental-friendly, of the big data human-computer machine. In order to solve the technical problem, the heat dissipation device of the big data human-computer machine comprises the big data human-computer machine, water inlet pipes are connected with the periphery of the big data human-computer machine by a paste connection mode, a temperature reduction device is arranged at a left side of the big data human-computer machine, and an upper end of a lower end of the water inlet pipe are both connected with the temperature reduction device. The heat dissipated from the big data human-computer machine is absorbed by means of the temperature of water, the water can be recycled, resources are saved, and a press plate and a filter screen frame can move relative to each other.

Owner:吴秦

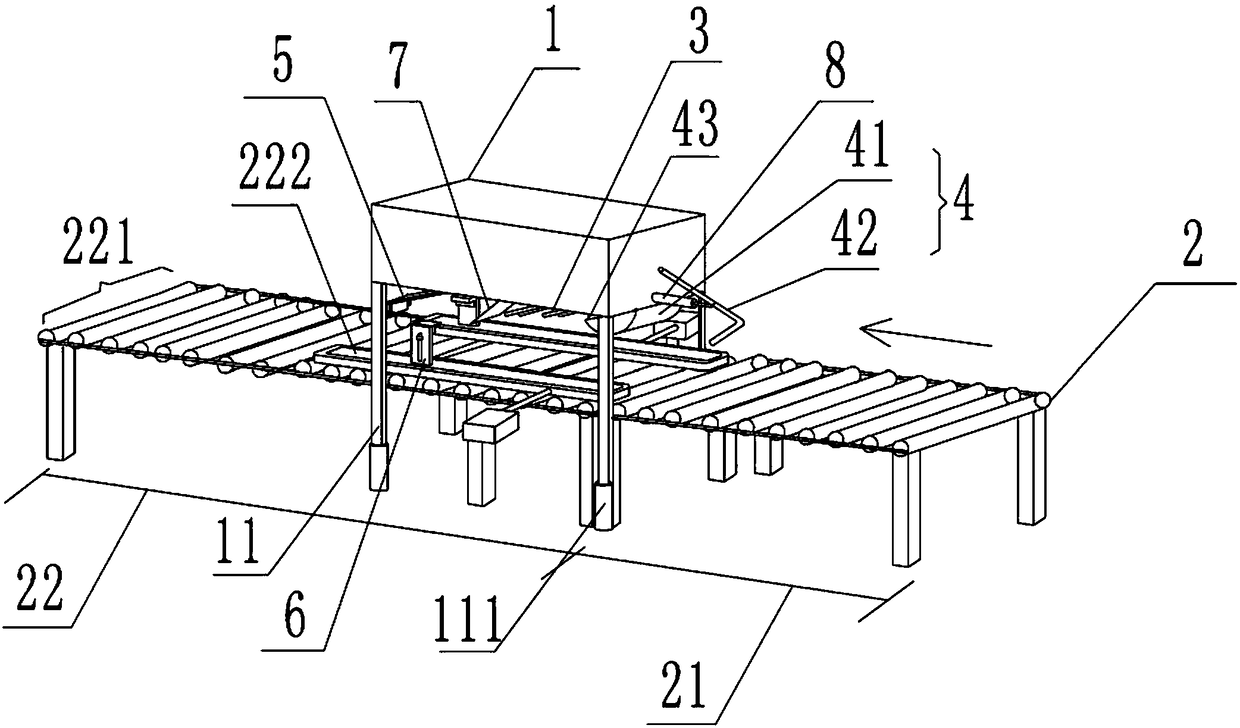

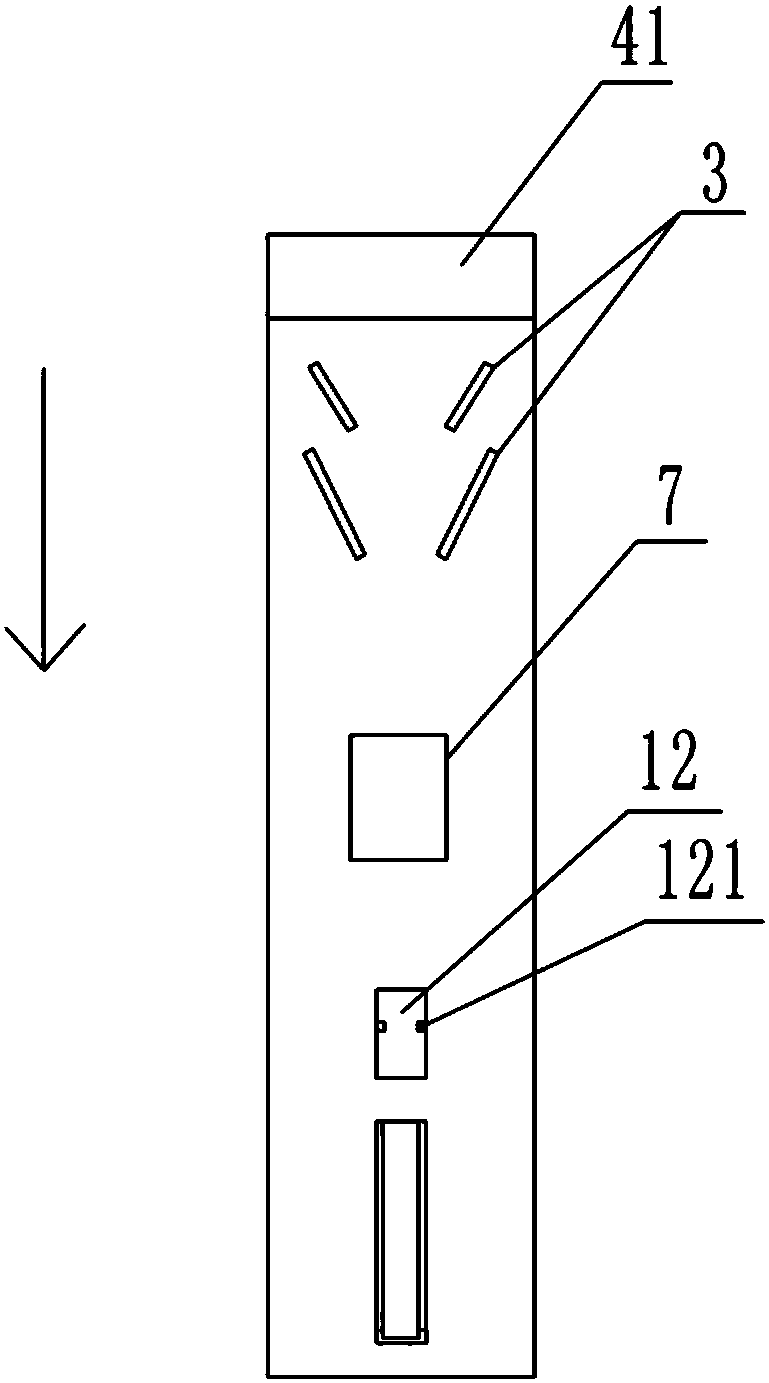

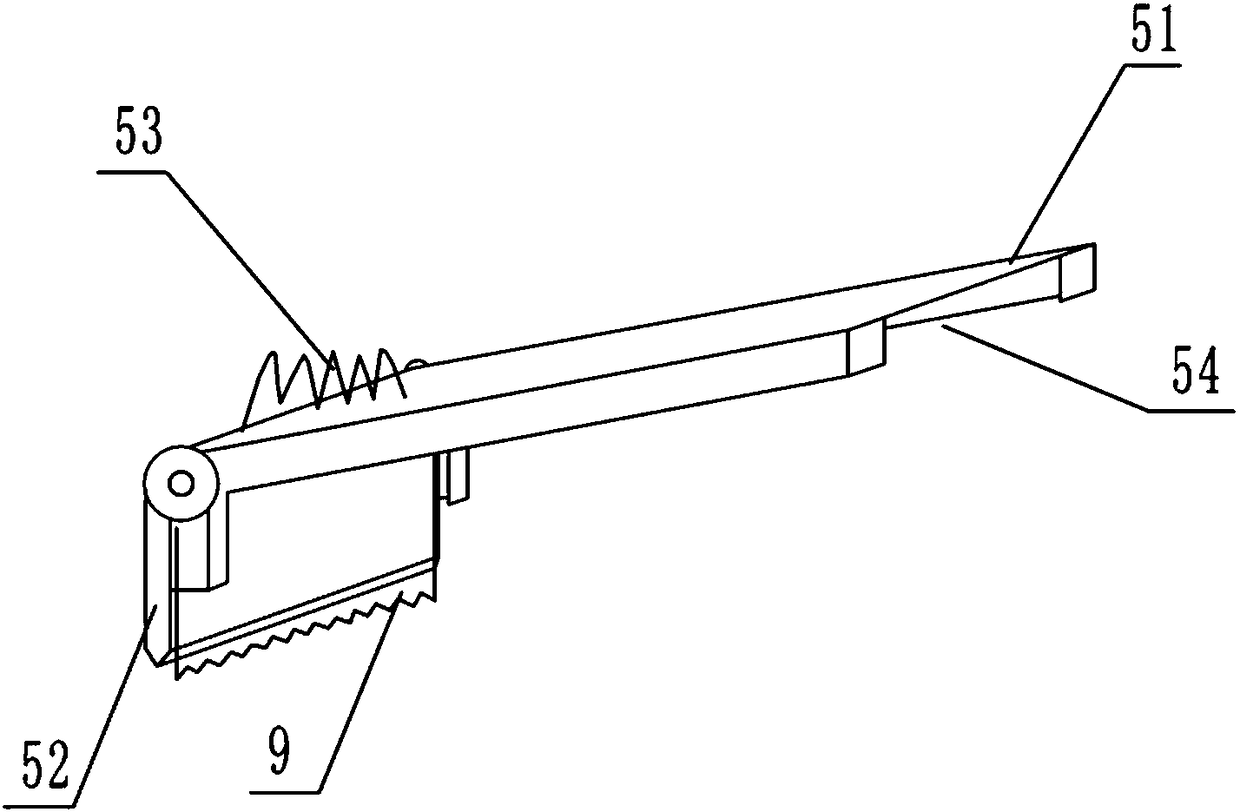

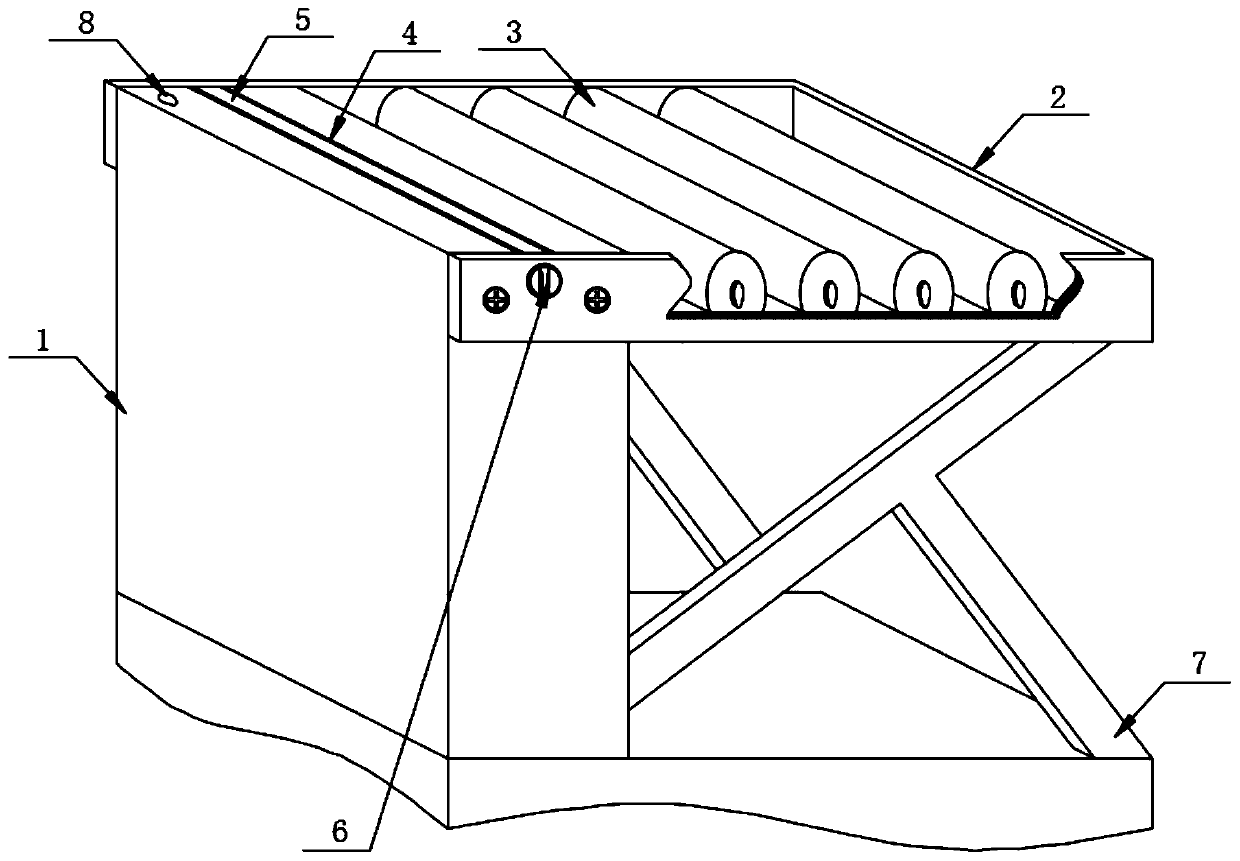

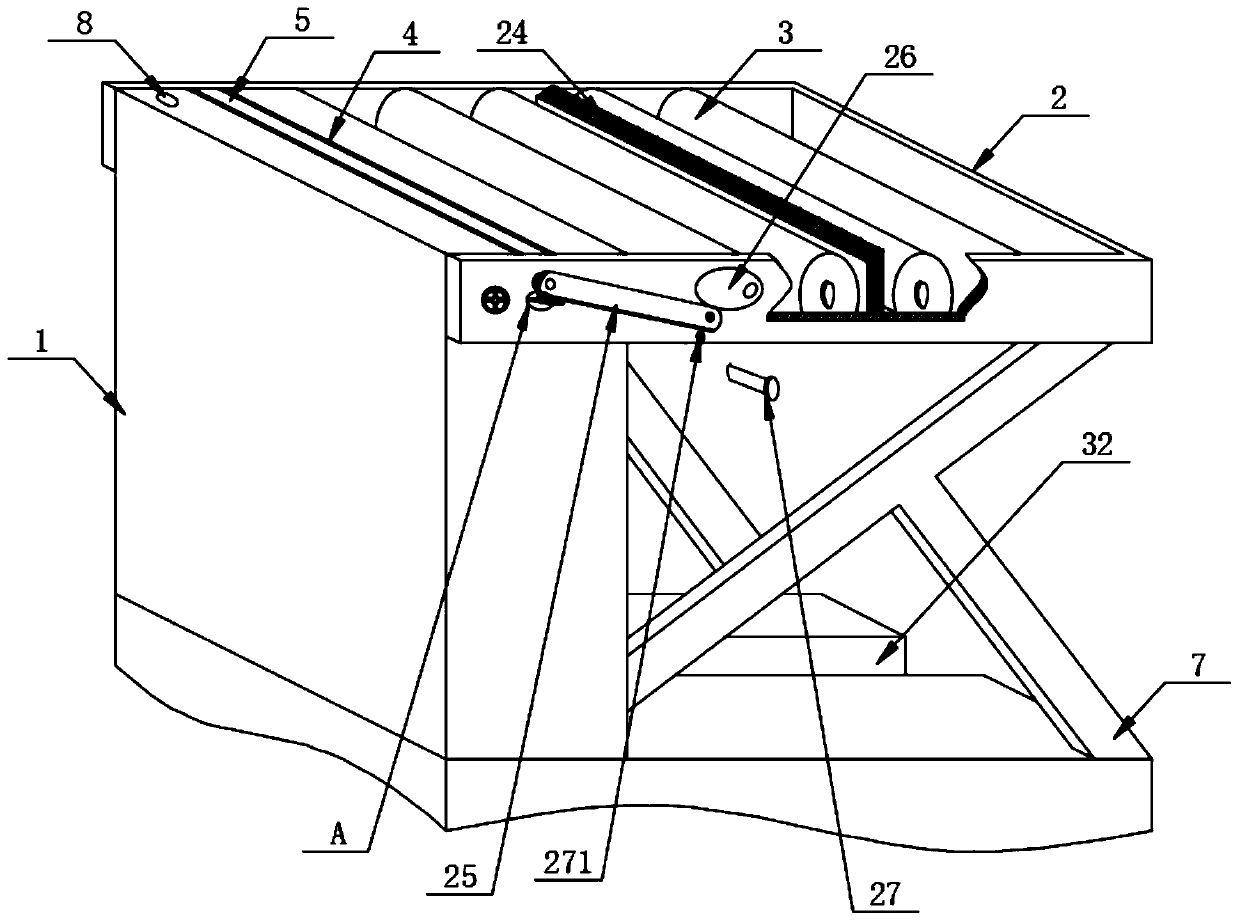

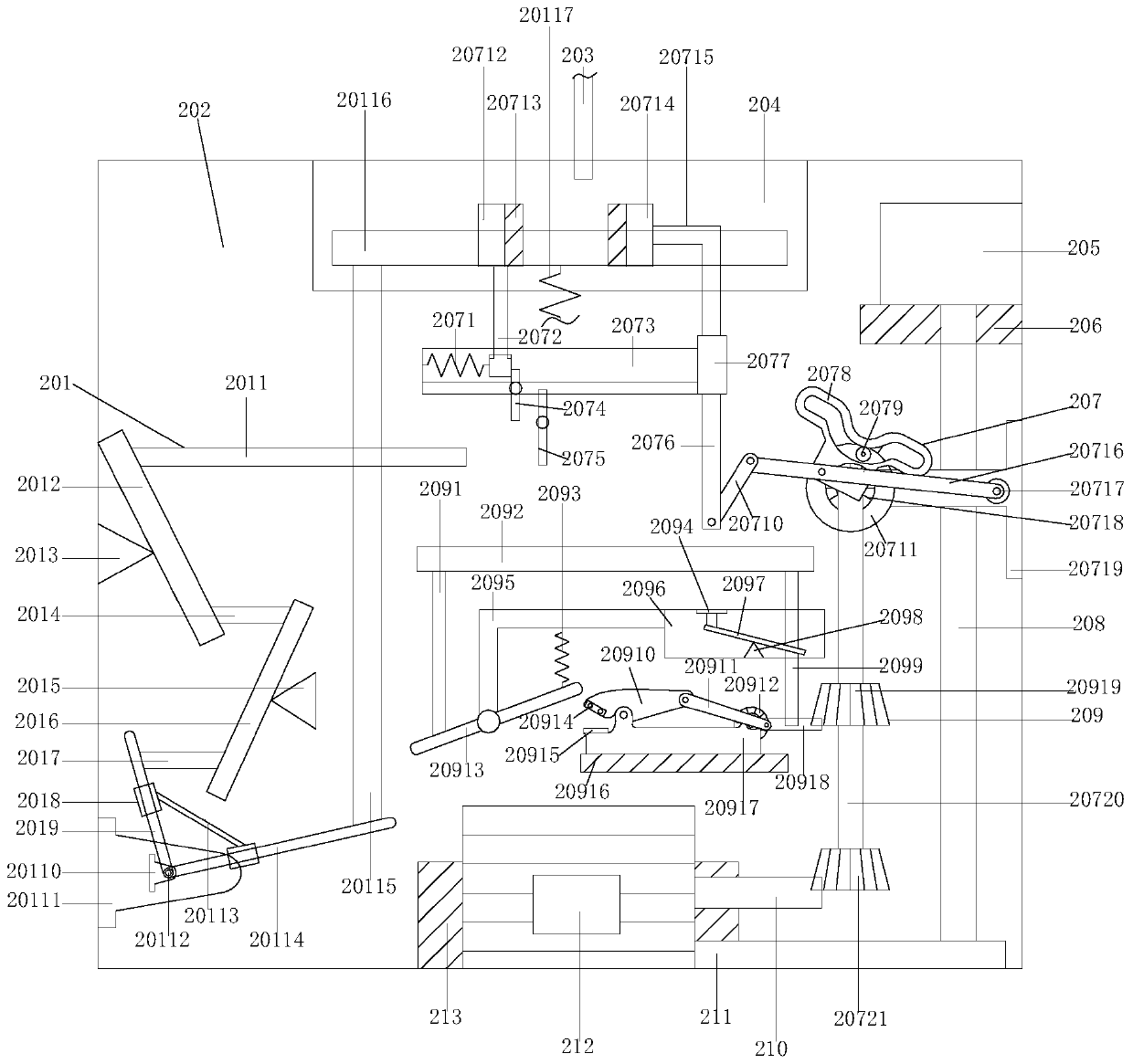

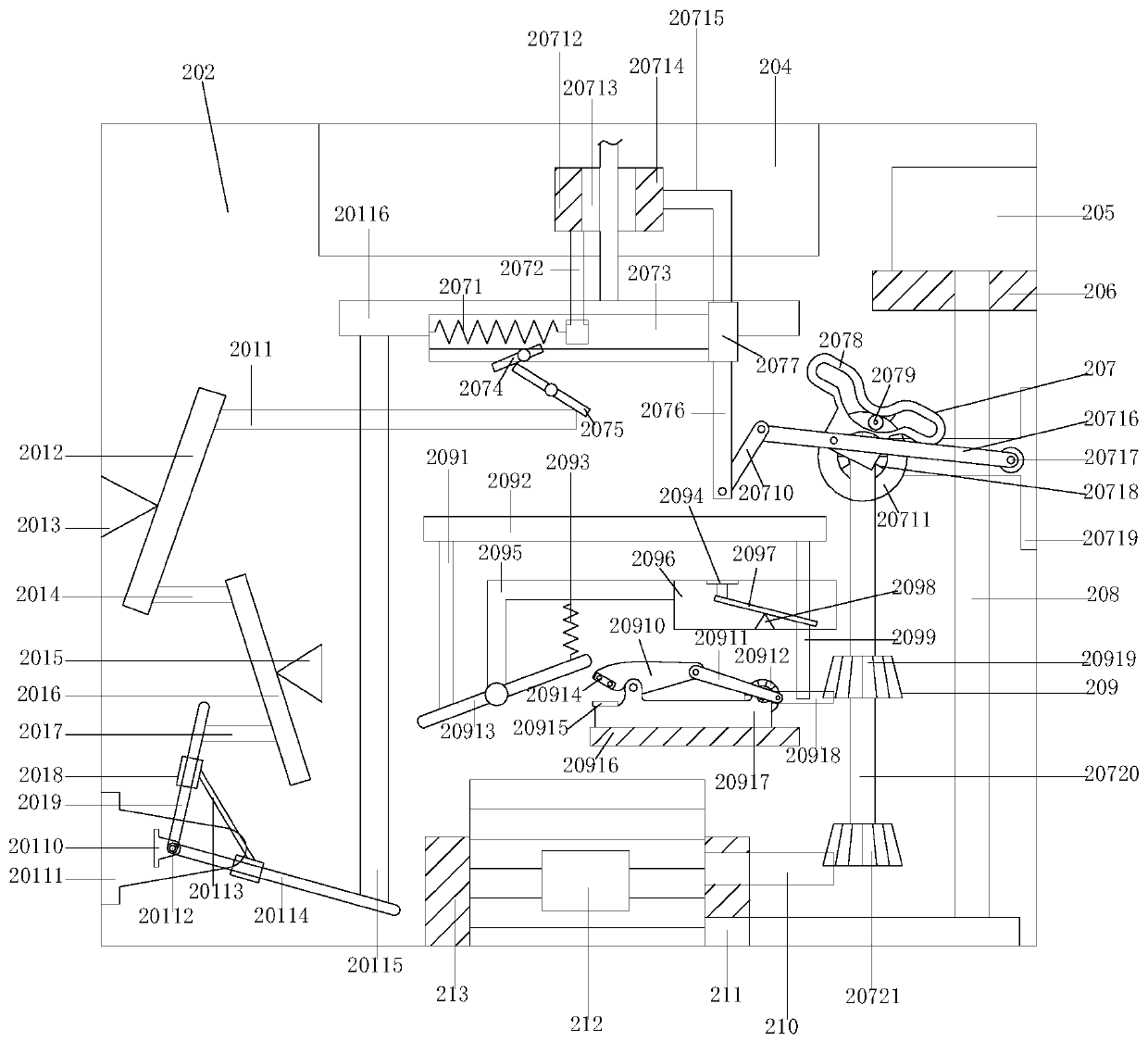

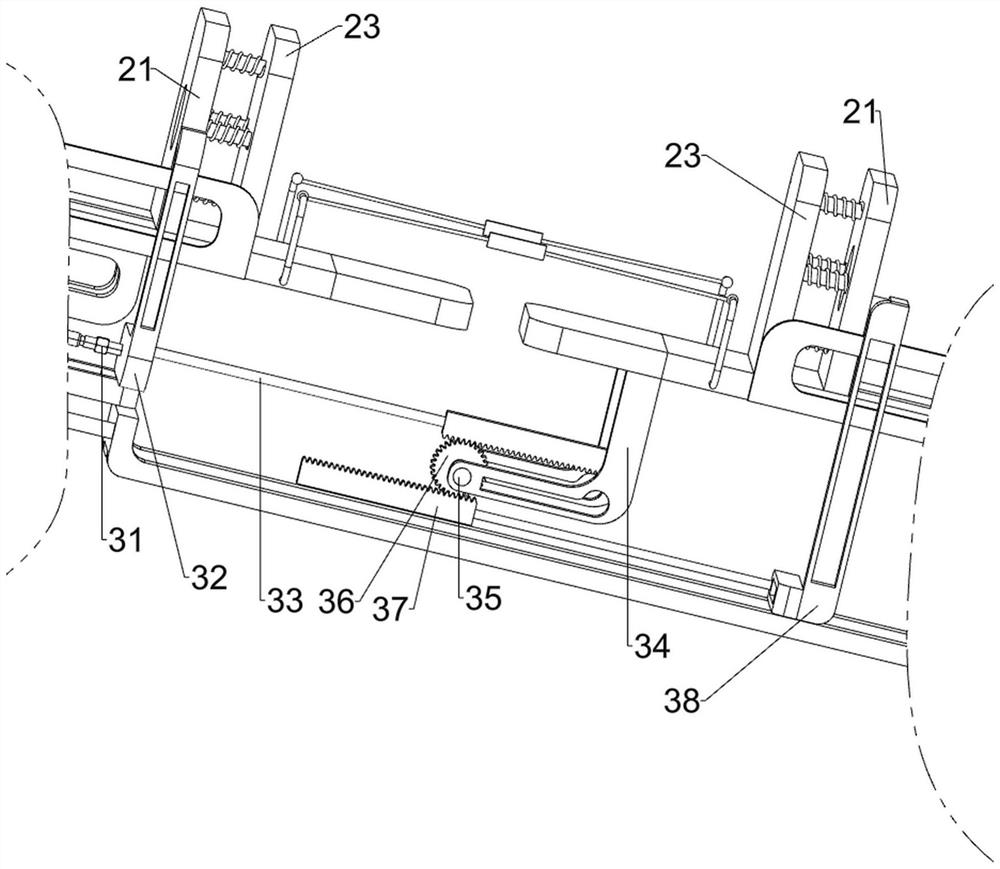

Electronic product container packing method

InactiveCN108100330AImprove sealing efficiencyQuality assuranceWrapper twisting/gatheringEngineeringPacking method

The invention relates to the technical field of shifting mechanisms, in particular to an electronic product container packing method. The electronic product container packing method comprises a framebody, a conveying part, a side plate leveling part, an end plate leveling part and an adhesive tape bonding part; the end plate leveling part, the side plate leveling part and the adhesive tape bonding part are arranged in a conveying direction of the conveying part in sequence; an extension part is arranged at the bottom of the frame body; the conveying part comprises a back conveying part, and afront conveying part consisting of a chain transmission roller way; the back conveying part comprises a conveying frame; the upper surface of the conveying frame is a conveying plane consisting of multiple cylinders; the two sides of the cylinders are connected with the two sides of the conveying frame; the conveying plane is provided with slide bars capable of oppositely moving along the conveying plane and clamping packing containers; conveying belts are arranged on the side surfaces of the slide bars; the slide bars are provided with extrusion parts for extruding the upper parts of the packing containers; and limiting parts for preventing side plates and end plates of the leveled packing containers from upwards turning are arranged at the bottom of the frame body. The electronic product container packing method not only can seal the packing containers with multiple specifications, but also can prevent generation of gaps in seals.

Owner:重庆市长寿区普爱网络科技有限公司

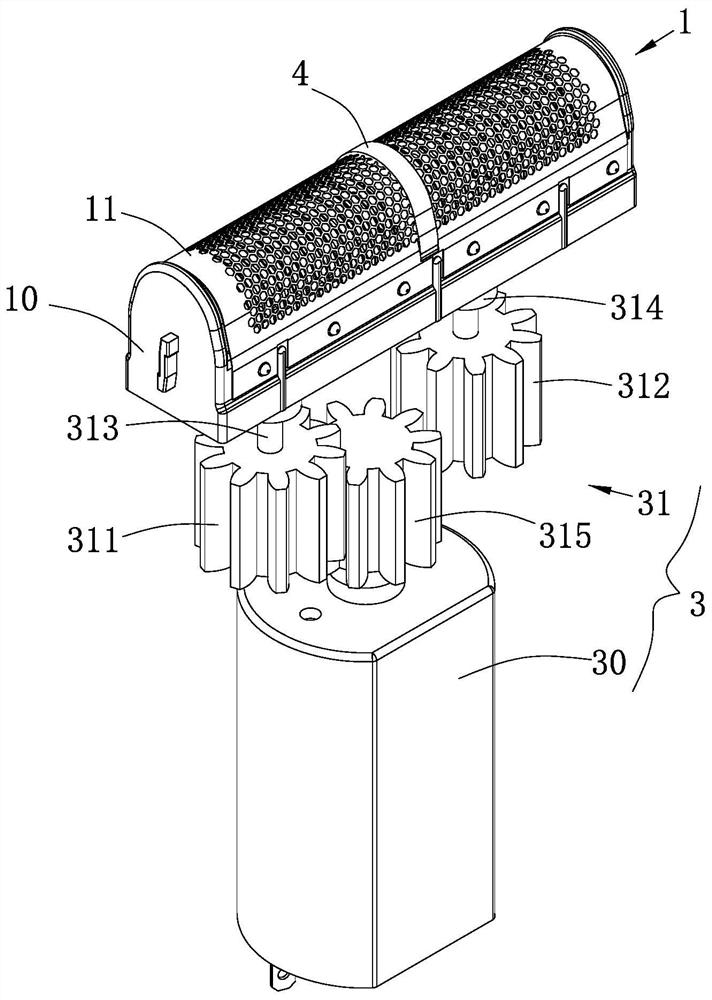

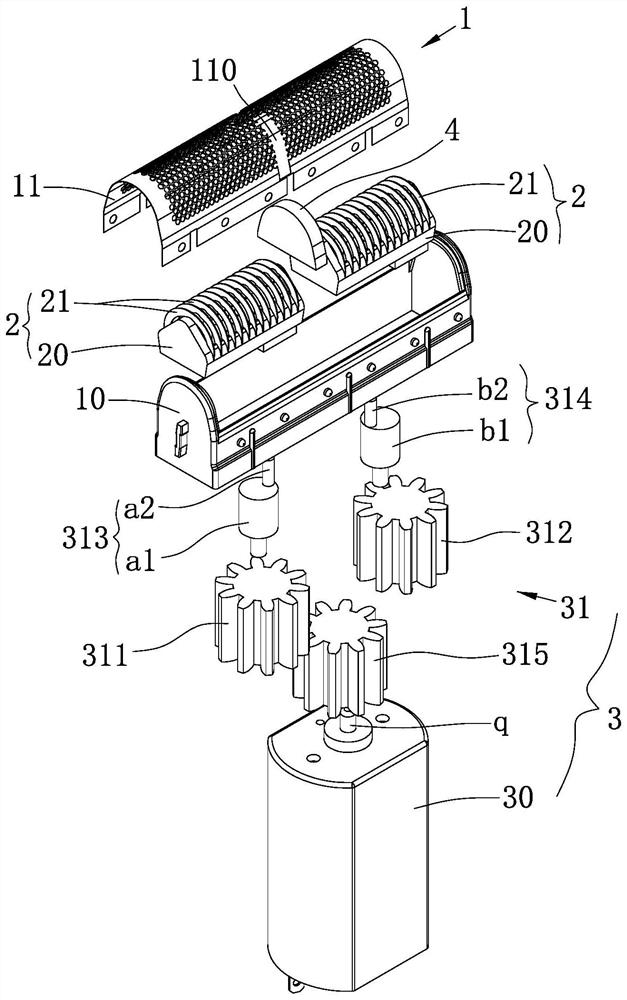

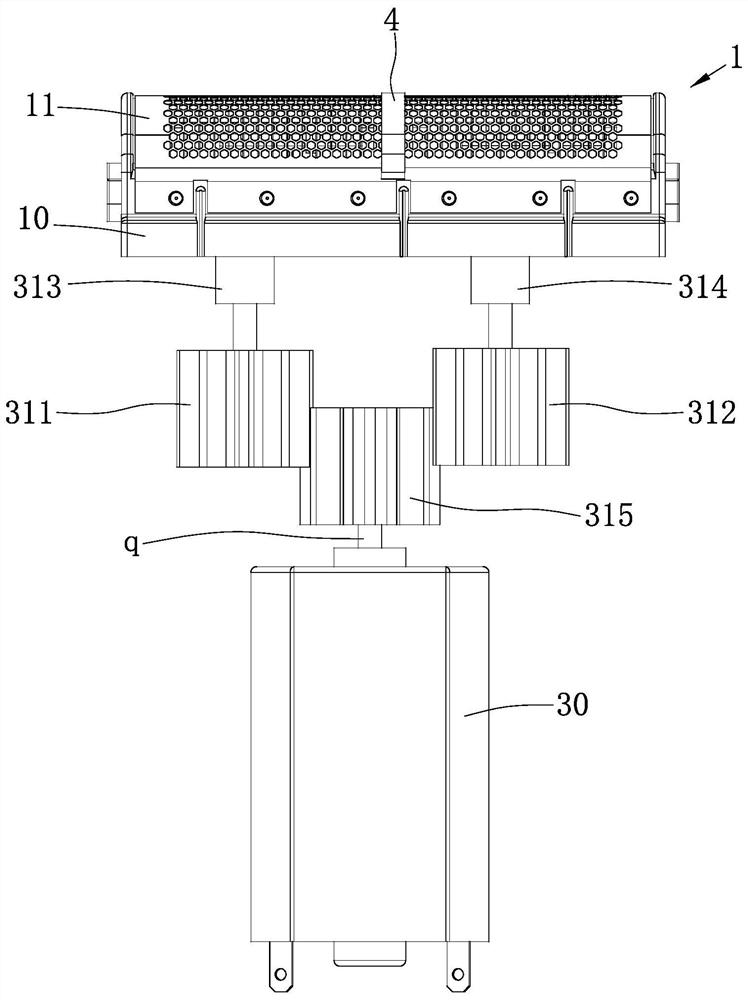

Reciprocating shaver

PendingCN113084876AImprove shaving effectAchieve synchronizationMetal working apparatusClassical mechanicsStructural engineering

The invention relates to a reciprocating shaver. The reciprocating shaver comprises a shaver holder, at least two shaver heads and a driver, wherein the shaver holder comprises a shaver rack and shaver nets, each shaver head comprises a movable shaver holder and a movable blade, the driver comprises a motor and a transmission part, particularly, the shaver rack is provided with at least one shaver groove extending in the length direction of the shaver rack, the shaver nets correspond to the shaver grooves in a one-to-one mode, the number of the shaver heads is at least two, the shaver heads are divided into two groups, one or two shaver heads are arranged in each shaver groove, the two group of shaver heads are arranged in a spaced mode, the movable shaver holders of each group of shaver heads are integrally arranged and form sliding bases, the two sliding bases are arranged in a staggered or spaced mode, an output shaft of the motor is in synchronous transmission connection with the two sliding bases through the transmission part, and under the driving of the motor, the two groups of shaver heads synchronously move in opposite directions. Under the same power output, synchronous and opposite movement of the shaver heads in the shaver grooves is achieved, vibration generated when the shaver heads swing is counteracted, and therefore the vibration amplitude is reduced, and noise generated by vibration is also reduced.

Owner:倍雅电子护理制品(苏州)有限公司

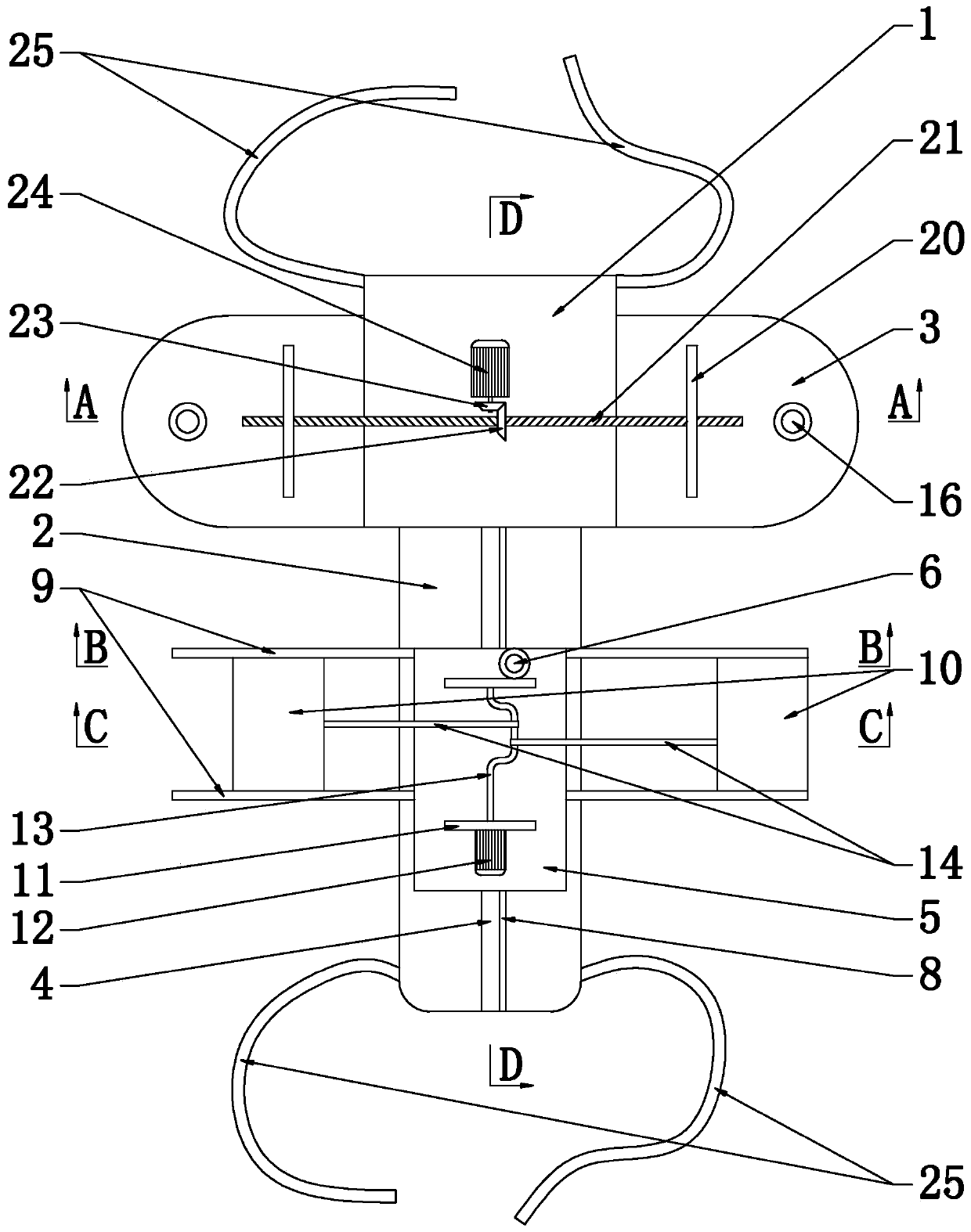

Knee joint relaxing massager

PendingCN110974650AImprove the effectPromote blood circulationRoller massageSuction-kneading massageMassager deviceKnee Joint

The invention provides a knee joint relaxing massager, which belongs to the field of massage health care, and solves the technical problem of how to relax quadriceps femoris muscles and massage knee joints in the prior art. The knee joint relaxing massager comprises knee covers, a base plate and a rotating plate, one end of the knee cover is connected with the base plate, a first sliding rail is arranged above the base plate, a moving seat is arranged on the first sliding rail in a sliding mode, a moving mechanism and a rubbing mechanism are arranged on the moving seat, movable plates are hinged to the two sides of the knee cover, a massaging mechanism is arranged on the movable plates, and an angle adjusting mechanism is further arranged on the knee cover. The massager has the advantagesthat the two legs horizontally extend during massage; the moving mechanism on the base plate drives the moving seat to slide on the first sliding rail, firstly, the quadriceps femoris muscles of thighs are rubbed and relaxed through the rubbing mechanism, pits in the two sides of knees are massaged through the massaging mechanism on the movable plate, the angle between the movable plates is adjusted through the angle adjusting mechanism, and therefore the massaging mechanism can adapt to the advantages of different users.

Owner:安徽伽马莱恩机器人有限公司

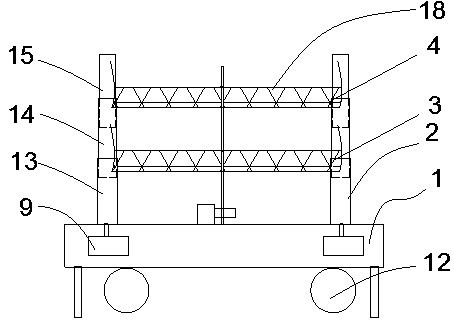

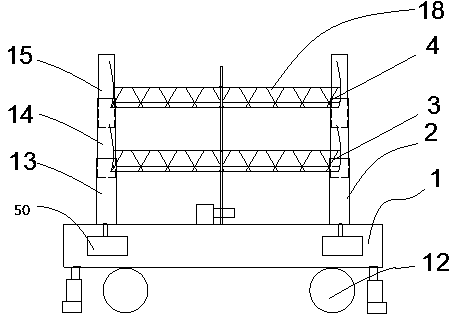

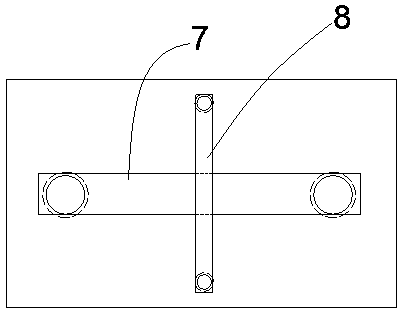

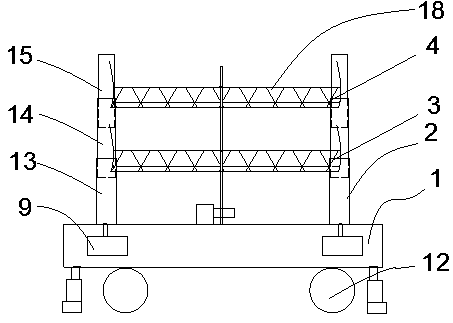

Temporary climbing frame system

InactiveCN108316631AEasy to operateGood security performanceScaffold accessoriesDrive motorNylon material

The invention discloses a temporary climbing frame system which comprises a movable standard base, two parallel hydraulic-driven telescopic rods, a first blocking net assembly, a second blocking net assembly, a first vertical rod and a second vertical rod. A transverse sliding groove and a longitudinal sliding groove are formed in the standard base; the standard base is provided with four hydraulic pumps and two driving motors; the telescopic rods are movably fixed into the transverse sliding groove and provided with first sleeves, second sleeves and third sleeves; the first blocking net assembly and the second blocking net assembly each comprise two blocking net structures which are located on the two sides of the transverse sliding groove; the blocking net structures comprise rectangularretractable nylon rope blocking nets, hanging belts and fixed rings located in the middles of the transverse side edges of the nylon rope blocking nets; and the vertical rods are each provided with two sets of vertically-distributed pulley systems. The hydraulic pumps drive the telescopic rods to rise, rising of the telescopic rods is matched with outward moving of the movable vertical rods, thenylon rope blocking nets are quickly unfolded, and the temporary climbing frame system is convenient to operate, quick in operation, and good in safety protection performance.

Owner:CCCC SHEC FOURTH ENG

Cotton guiding device and cotton guiding method of cotton carding machine leather ring

PendingCN111235706ADoes not increase footprintLow modification costCarding machinesFiberMechanical engineering

The invention discloses a cotton guiding device and a cotton guiding method of a cotton carding machine leather ring, and belongs to the technical field of textile machinery. The cotton guiding devicecomprises a cross beam, a driving unit, a left leather ring, a right leather ring and an air suction system, wherein the driving unit is arranged at one end of the cross beam; the left leather ring is in transmission connection with the driving unit, and the setting direction of the left leather ring is the same as the length direction of the beam; the right leather ring is in transmission connection with the left leather ring, and the right leather ring is arranged on the extension line in the length direction of the left leather ring; the rotating directions of the left leather ring and theright leather ring are opposite; mesh holes are formed in the middle parts of the left leather ring and the right leather ring, and the mesh holes are arranged in the rotating direction of the corresponding leather ring; and the air suction system can form negative pressure on the outer surface of the leather ring mesh hole area. The cotton guiding device provided by the invention has the advantages that the air suction system is arranged, the mesh holes in the surfaces of the left and right leather rings are matched, the cotton net on an upper roller and a lower roller can be better stripped, the cotton guiding efficiency is improved, the straightening degree and the parallelism of the cotton net fibers are not affected, and finally the cotton net fibers are folded into bundles, and thecotton guiding quality is high.

Owner:ANHUI RIFA TEXTILE MACHINERY

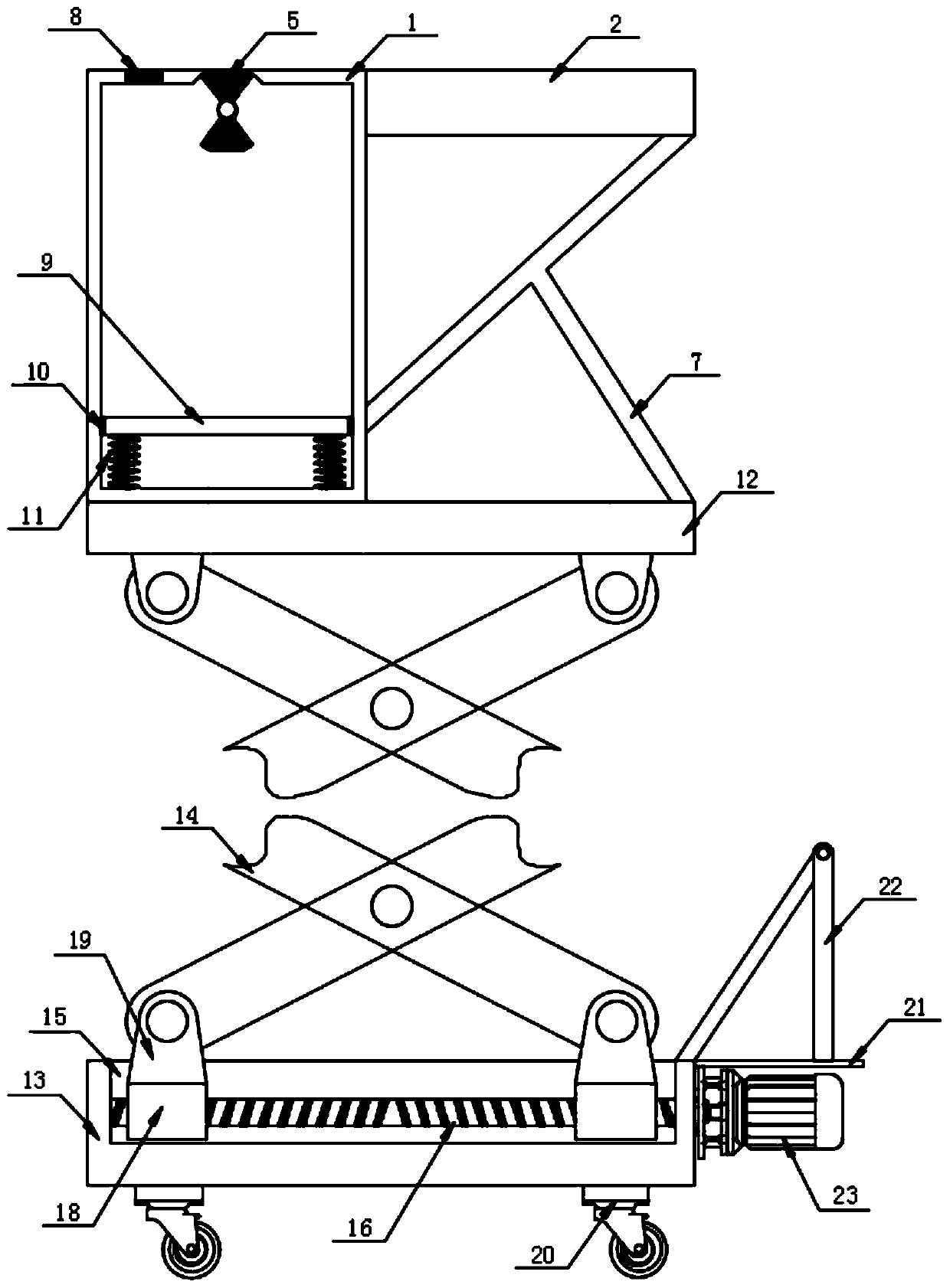

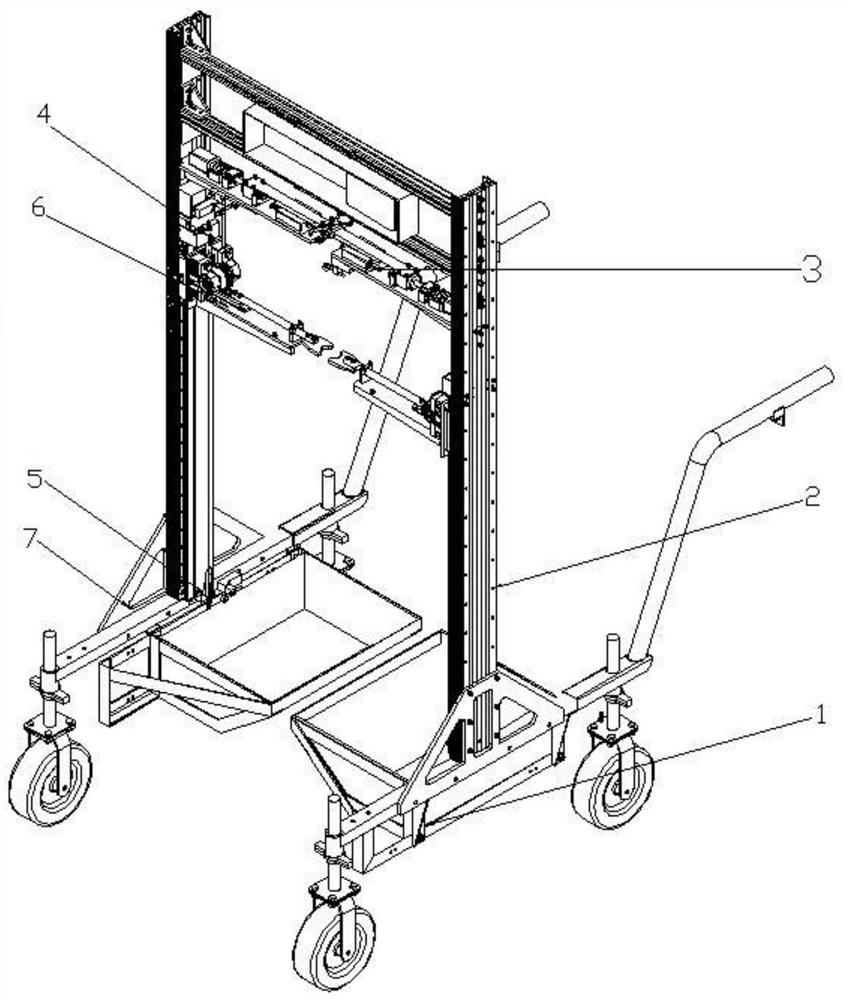

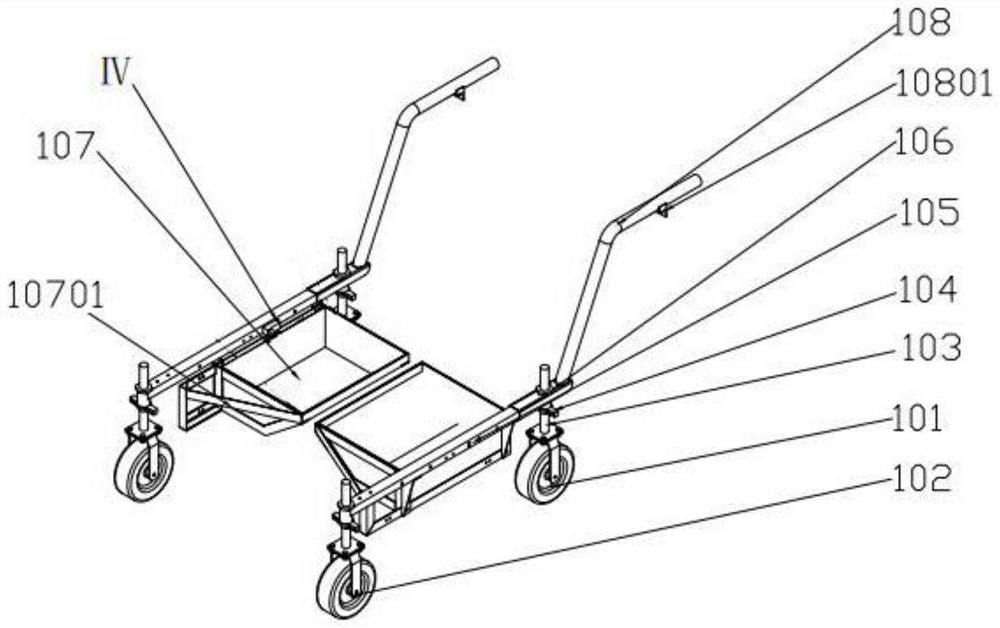

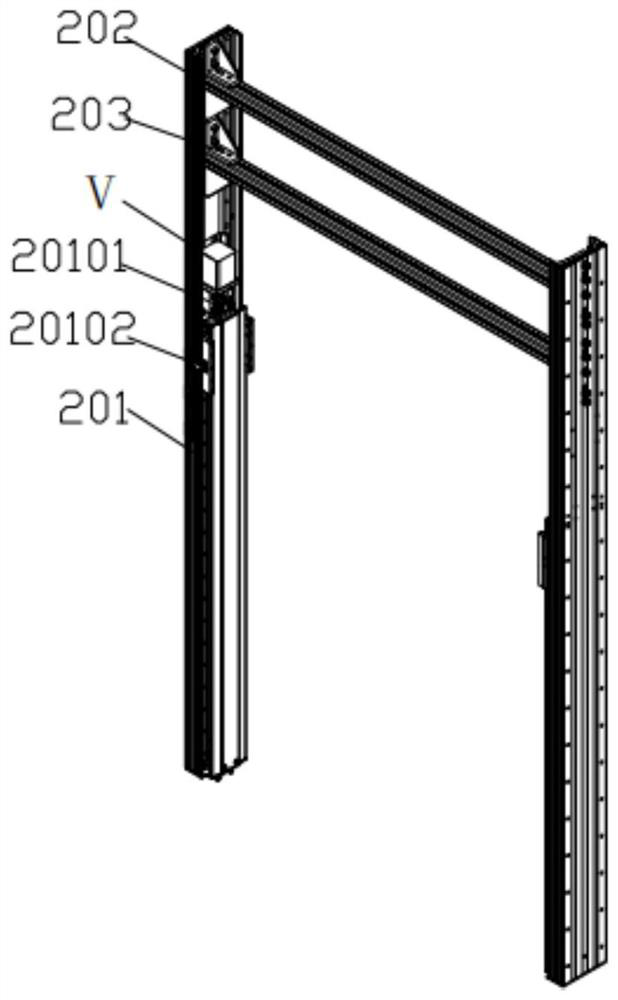

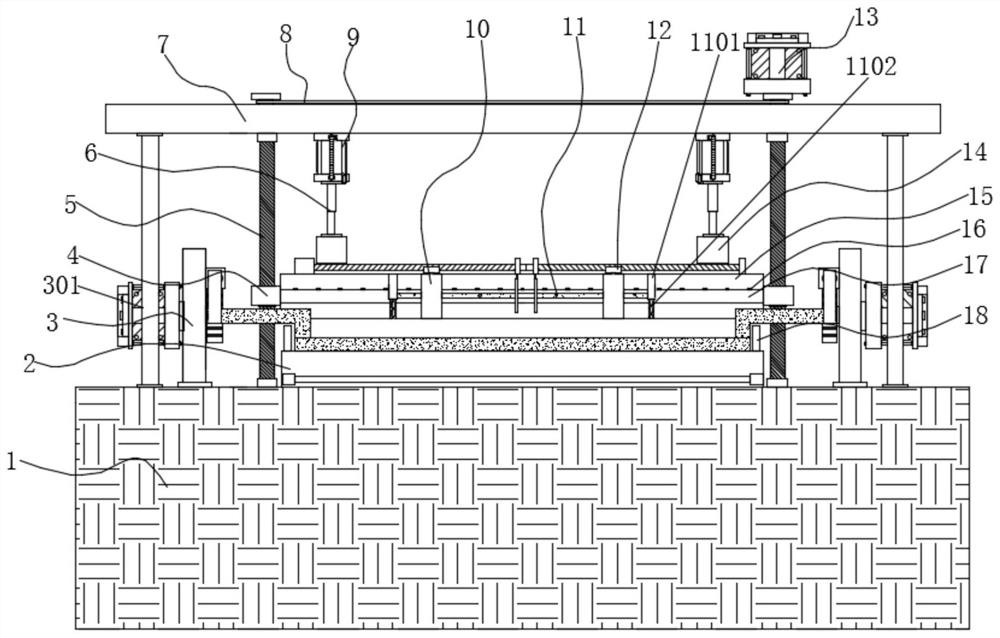

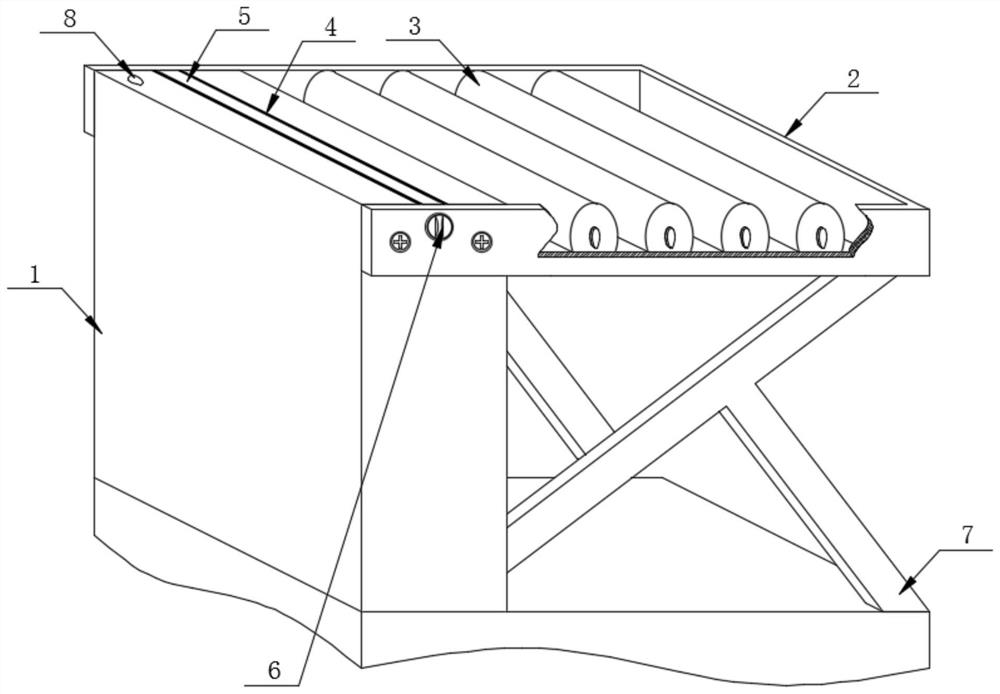

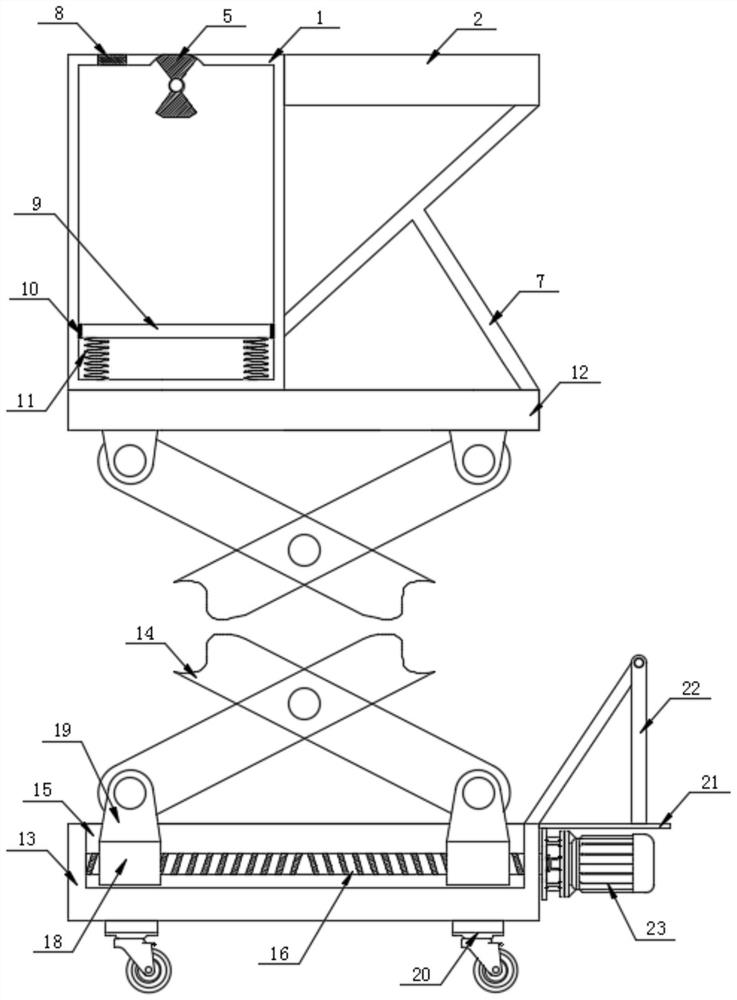

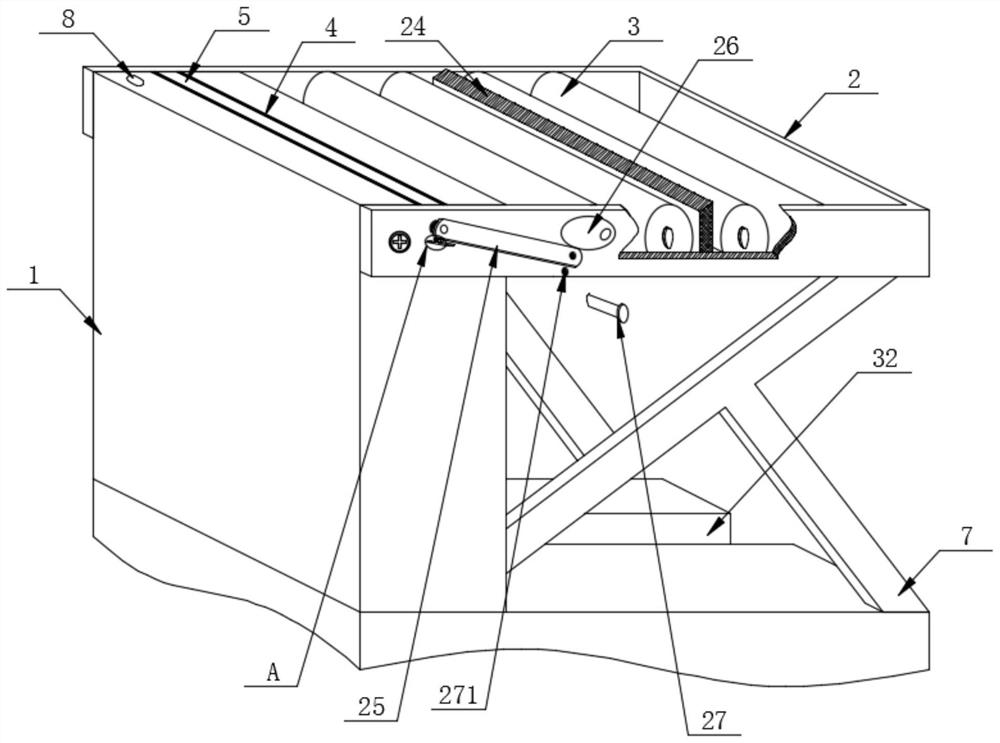

Ceiling putty painting device

ActiveCN110924643AAchieve opposite motionDecrease productivityBuilding constructionsFixed frameElectric machinery

The invention discloses a ceiling putty painting device, and particularly relates to the field of putty painting equipment. The ceiling putty painting device includes a painting device and a lifting device, wherein the painting device includes a material box, a fixed frame is fixedly installed on one side of the material box by bolts, the fixed frame is movably provided with a plurality of rollers, a discharge hole is formed in the middle of the material box top, the material box is internally provided with a discharge device, the discharge device includes springs, and the springs are fixedlyinstalled at the four corners of the bottom of an inner cavity of the material box. According to the ceiling putty painting device, a motor is used for driving a threaded rod to rotate so that slidingblocks at two ends of the threaded rod can move in the opposite direction, a telescopic frame is extended, then the painting device provided with the putty is lifted to be in contact with the top ofthe ceiling, then a rotary knob is opened, so that the putty in the material box is extruded out under the restoring force of the springs, and a staff only needs to push a push frame below, so that walking wheels at the bottom of a base plate rolls on the ground to realize the uniform painting of the putty.

Owner:广东粤冠建材有限公司

Climbing frame provided with hydraulic supporting foot indicator

InactiveCN108265964AGrow fastEasy to operateLighting elementsSemiconductor devices for light sourcesHydraulic pumpArchitectural engineering

The invention discloses a climbing frame provided with a hydraulic supporting foot indicator. The climbing frame comprises a movable base, two parallel hydraulically-driven telescopic rods, a first block net assembly, a second block net assembly, a first vertical rod and a second vertical rod. The base is provided with a transverse sliding groove and a longitudinal sliding groove. The base is provided with walking wheels, hydraulic supporting feet, hydraulic pumps and driving motors. The telescopic rods are movably fixed in the transverse sliding groove, and each telescopic rod is provided with a first sleeve, a second sleeve and a third sleeve. The first block net assembly and the second block net assembly comprise two block net structures. The two block net structures are located on thetwo sides of the transverse sliding groove. Each block net structure comprises a rectangular retractable nylon rope block net, a hanging belt and a fixed ring located in the middle of the transverse side edge of the nylon rope block net. The vertical rods are provided with two sets of vertically-distributed pulley systems. According to the climbing frame provided with the hydraulic supporting footindicator, the telescopic rods are driven by the hydraulic pumps to rise and are matched with the movable vertical rods in an outward-moving mode, the nylon rope block nets can be rapidly opened, operation is convenient and quick, and safety performance is good.

Owner:CCCC SHEC FOURTH ENG

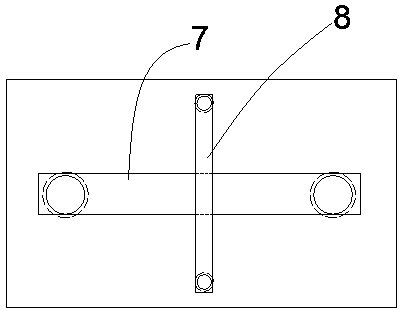

Semi-automatic mulberry twig supporting device

PendingCN111615928ARealize automatic controlImprove work efficiencyPicking devicesBall screwAgricultural engineering

The invention discloses a semi-automatic mulberry twig supporting device. The device comprises a left mulberry twig supporting mechanism and a right mulberry twig supporting mechanism which are symmetrical. Each mulberry twig supporting mechanism is composed of a transverse electric open type ball screw transmission assembly, a sliding guide rail assembly, a mulberry twig supporting clamp and a transverse supporting base; the ball screw transmission assemblies and the sliding guide rail assemblies are mounted on the transverse supporting bases; the mulberry twig supporting clamps are mounted on the sliding guide rail assemblies; mulberry twig supporting servo motors and drivers thereof are mounted on the ball screw transmission assemblies; and the mulberry twig supporting servo motors andthe drivers thereof drive the sliding guide rail assemblies to move horizontally through the ball screw transmission assemblies. The device can drive the mulberry twig supporting clamps to move oppositely to gather mulberry twigs, is relatively high in stability and provides guarantee for subsequent mulberry leaf picking.

Owner:GUANGXI NORMAL UNIV

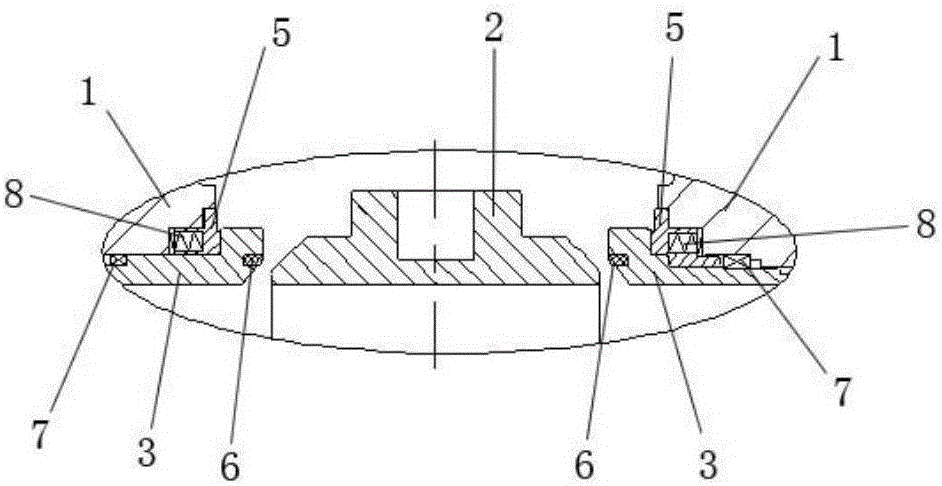

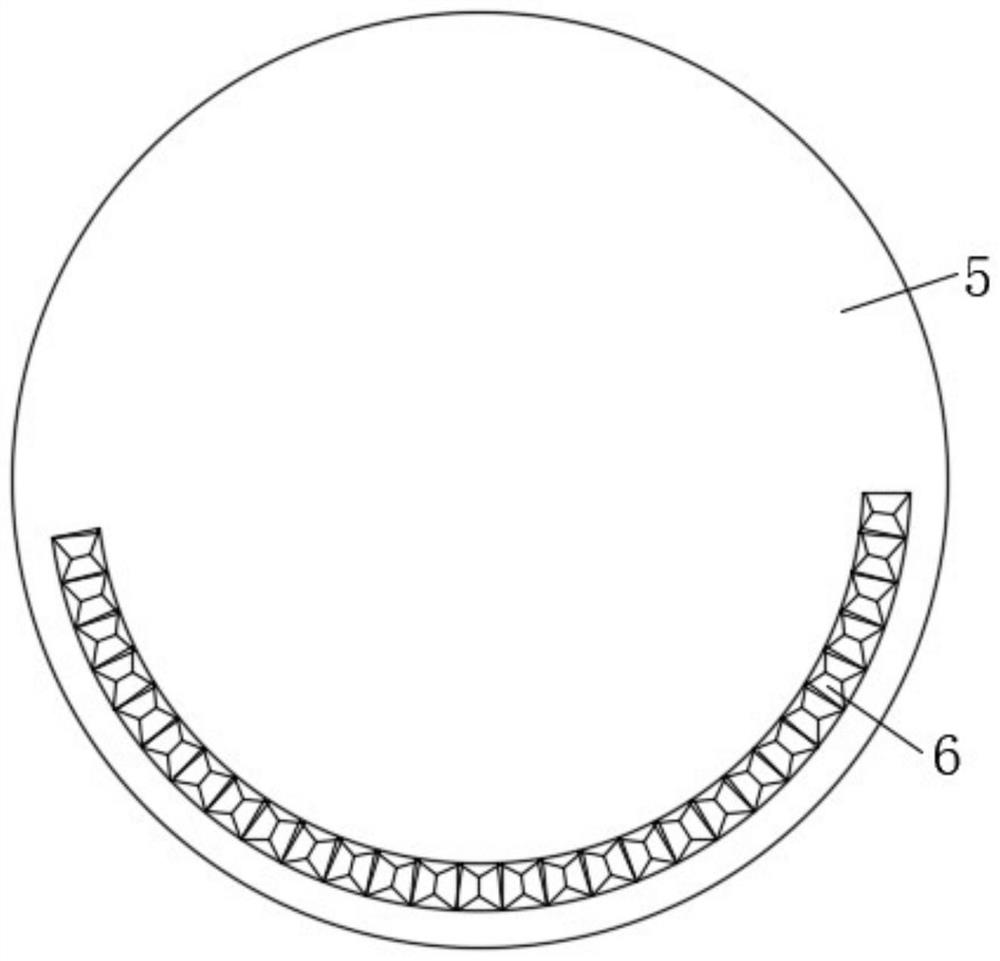

Rocker clamping type protective bearing device

ActiveCN111431328AAvoid damagePlay a protective effectWind energy generationMechanical energy handlingClassical mechanicsStructural engineering

The invention relates to the field of magnetic suspension bearing systems, in particular to a rocker clamping type protective bearing device. The rocker clamping type protective bearing device comprises a bearing arranged on a rotor; a rocker driving assembly which comprises a rocker, wherein the rocker is rotationally assembled at the axial outer side of the rotor and extends along the axis of the rotor, and two driving rings are in threaded fit with the rocker and are driven by the rocker to move face to face or back to back; a clamping assembly which comprises at least two clamping pieces,wherein the at least two clamping pieces are evenly distributed along the circumferential direction, the clamping end of each clamping piece extends to the periphery of the bearing, the other end of each clamping piece extends to the peripheries of the two driving rings and is hinged to the two driving rings, and when the two driving rings move back to back, all the clamping pieces can be driven to get close to and clamp the bearing; and when the two driving rings move oppositely, all the clamping pieces can be driven to be far away from the bearing. The rocker clamping type protective bearingdevice solves the technical problems that a gap cannot be manually eliminated through a bearing protection device in the prior art, and the safety is low, are solved.

Owner:JIANGSU UNIV OF TECH

Climbing frame provided with hydraulic supporting feet

InactiveCN108331323AEasy to operateGood security performanceScaffold accessoriesDrive motorHydraulic pump

The invention discloses a climbing frame provided with hydraulic supporting feet. The climbing frame comprises a movable base, two parallel hydraulic-driven telescopic rods, a first blocking net assembly, a second blocking net assembly, a first vertical rod and a second vertical rod. The base is provided with a transverse sliding groove and a longitudinal sliding groove, and the travelling wheels,the hydraulic supporting feet, hydraulic pumps and driving motors are arranged on the base. The telescopic rods are movably fixed into the transverse sliding groove and provided with first sleeves, second sleeves and third sleeves. The first blocking net assembly and the second blocking net assembly each comprise two blocking net structures which are located on the two sides of the transverse sliding groove. The blocking net structures comprise rectangular retractable nylon rope blocking nets, lifting belts and fixing rings located in the middles of the transverse side edges of the nylon ropeblocking nets. Each vertical rod is provided with two sets of vertically-distributed pulley systems. The telescopic rods are driven to rise by the hydraulic pumps, rising of the telescopic rods are matched with outward moving of the movable vertical rods, the nylon rope blocking nets are quickly expanded, and the climbing frame is convenient and rapid in operation and good in safety protection property.

Owner:CCCC SHEC FOURTH ENG

Manual pressing structure for double-rotation paint mixing machine

ActiveCN102764606BAchieve opposite motionSmooth opposite motionRotating receptacle mixersMixer accessoriesPush and pullDrive wheel

The invention relates to a manual pressing structure for a double-rotation paint mixing machine, which is characterized in that: the upper top cover of the mixing machine is internally provided with a manual rotating pressing component, the pressing component comprises pressing discs, a rotating shaft base, rotating shafts of the pressing discs, the rotating shafts of the pressing discs penetrate through the rotating shaft base, the top ends of the rotating shafts of the pressing discs are fixedly connected with the pressing discs, the lower ends of the rotating shafts of the pressing discs are provided with pressing shifting components, pressing driving wheels are provided with shifted components which are in overlap joint with the shifting components, and when the upper top cover is fully opened, the pressing driving wheels match with the rotating shafts of the pressing discs coaxially. By pushing and pulling the upper top cover, the shifting connecting matching structures can be combined and separated smoothly, and by rotating the pressing discs to drive the pressing driving belt wheels to rotate, the upper pressing disc and the lower pressing disc can move oppositely, thus a colored paint barrel can be pressed and opened without using a special separable pressing wrench. The manual pressing structure is convenient to use and is safe and reliable in structure.

Owner:ZHENGZHOU SANHUA TECH & IND

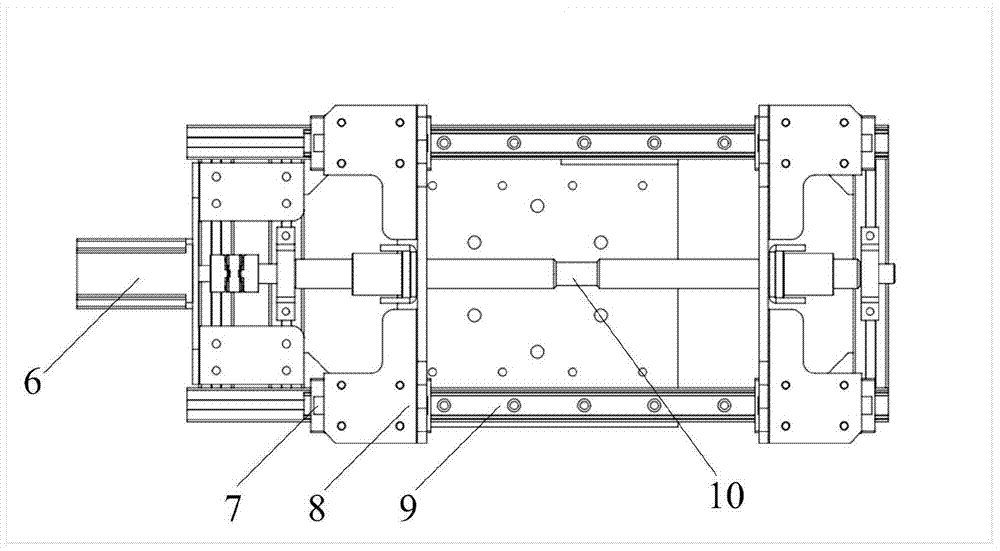

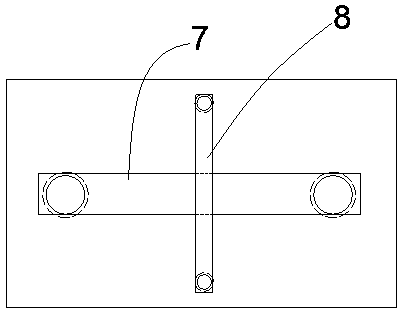

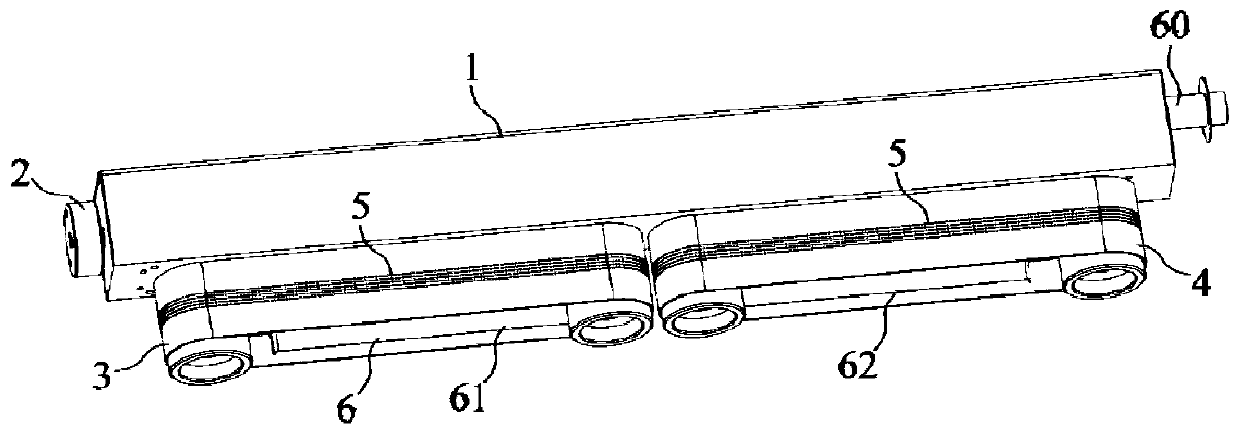

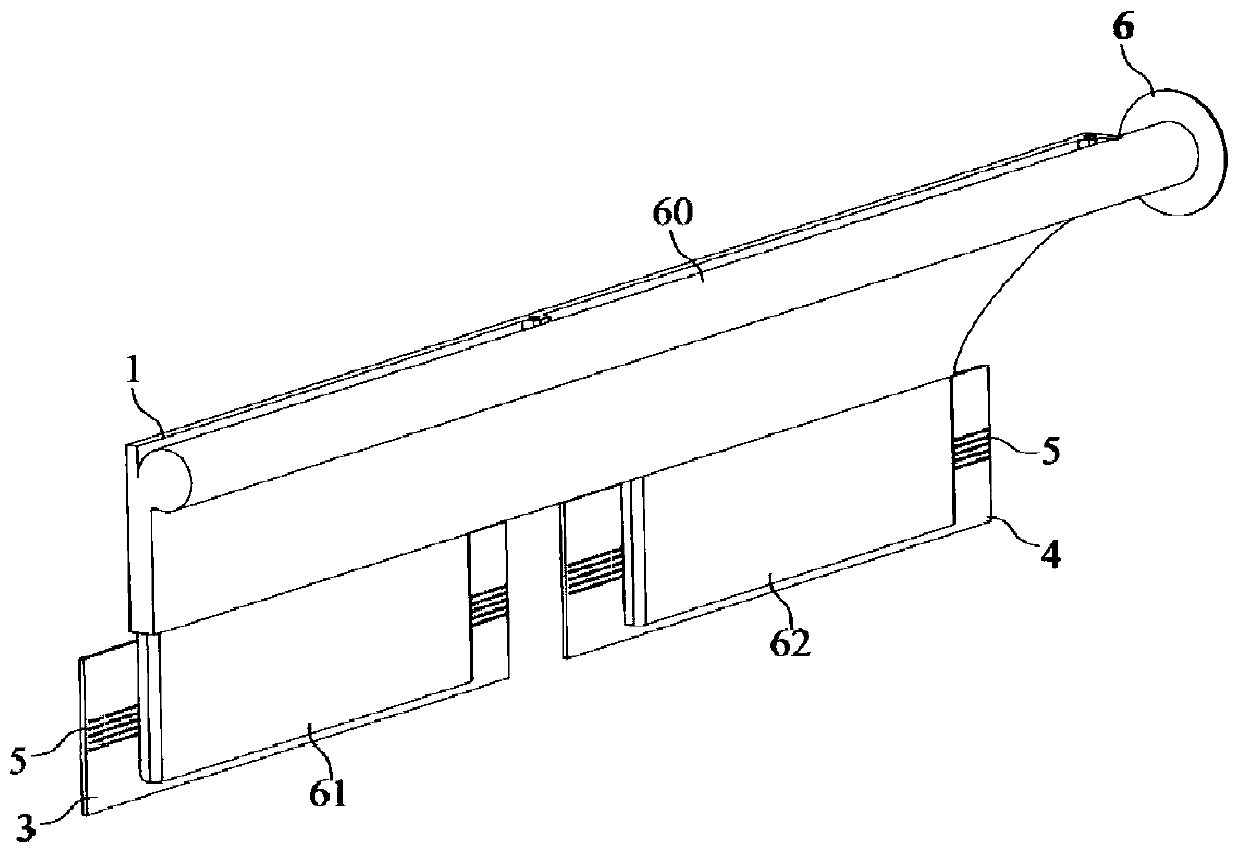

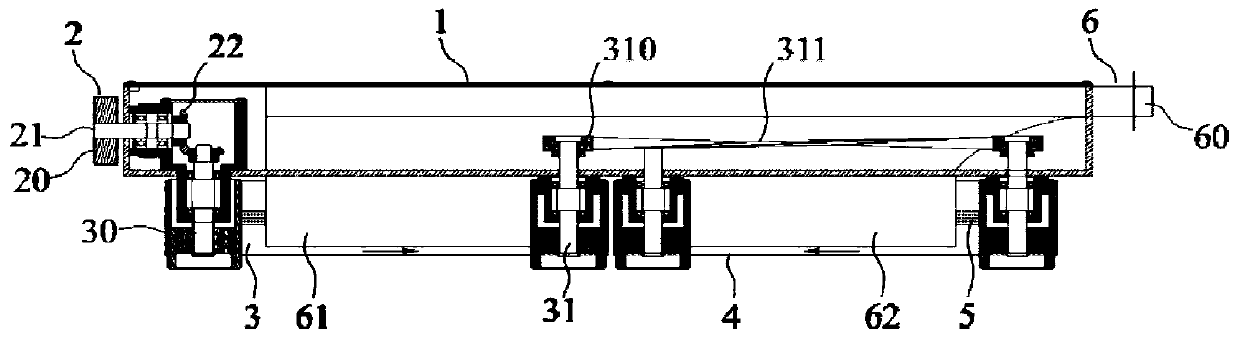

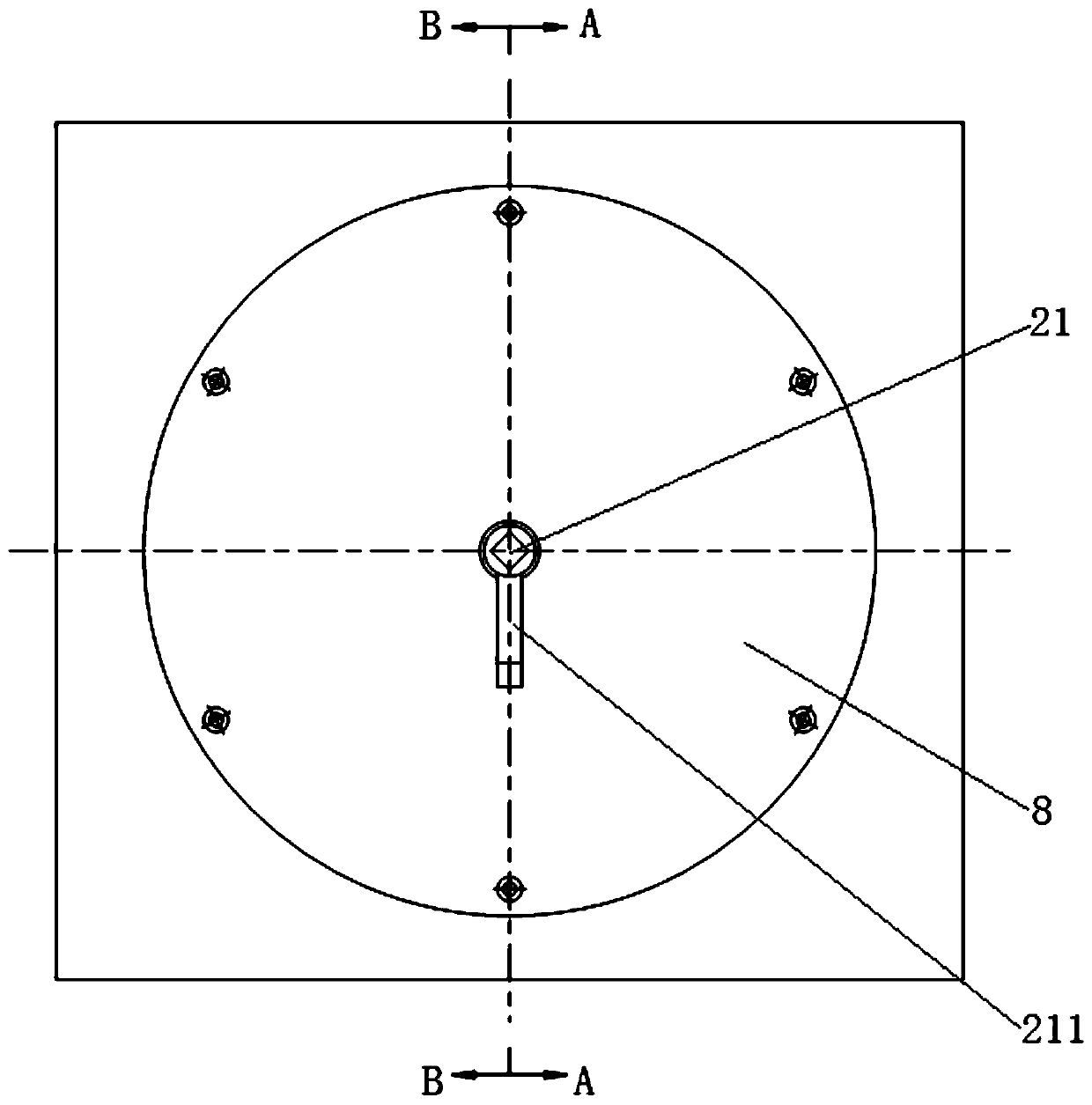

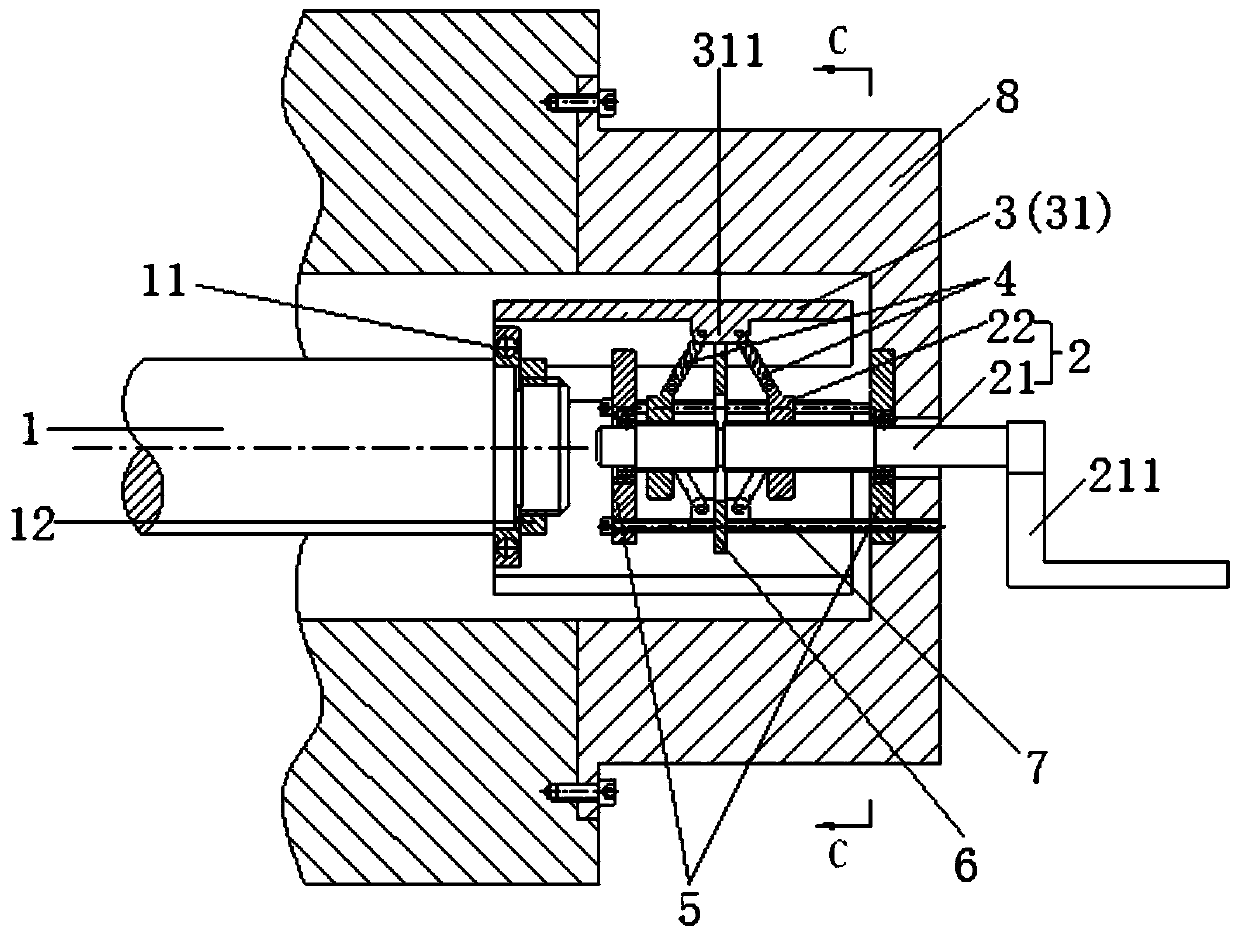

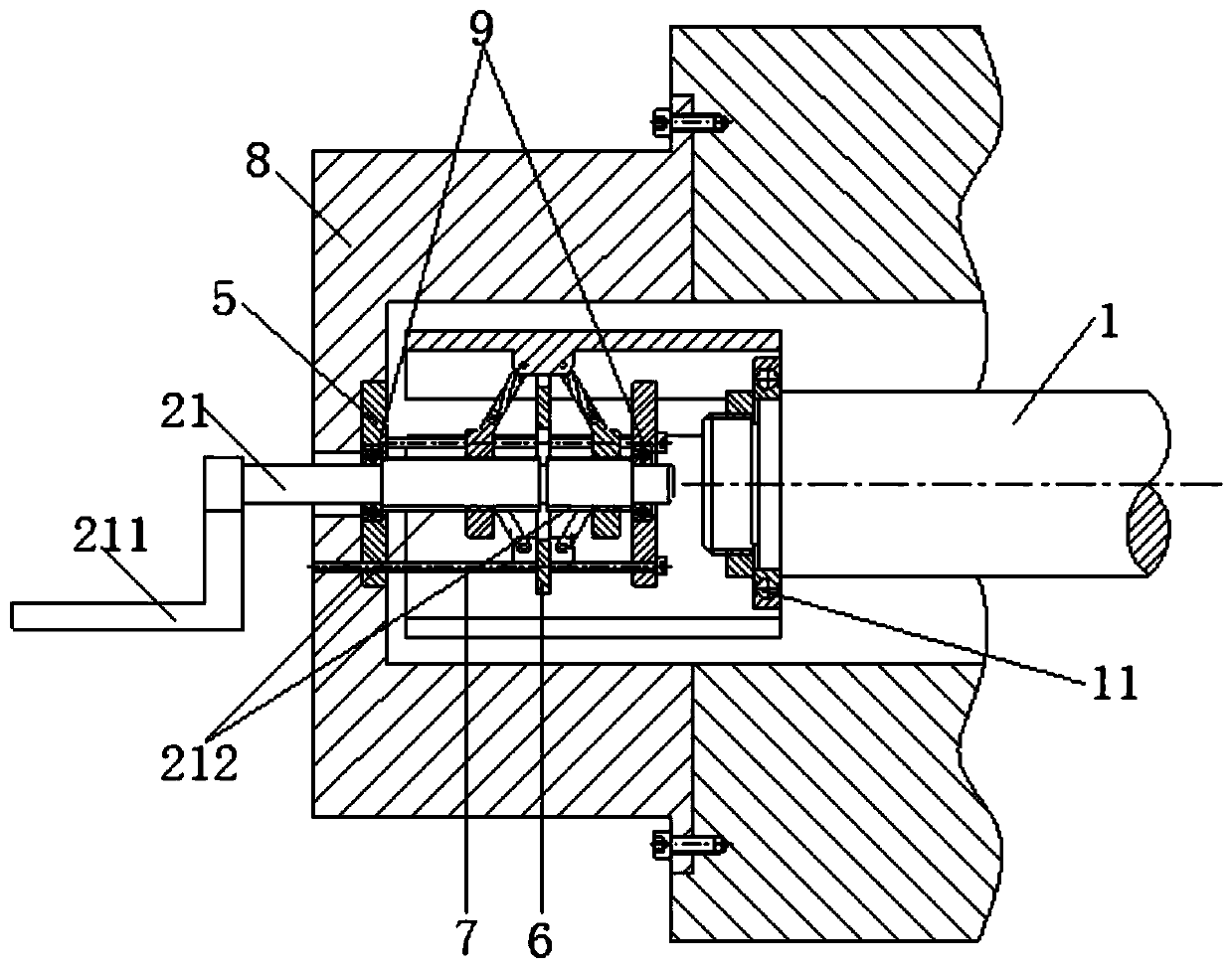

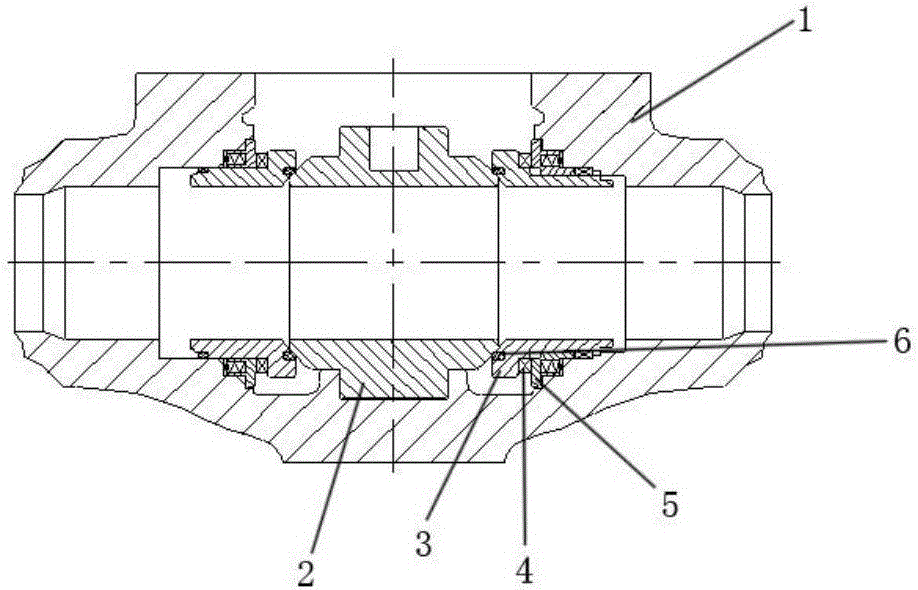

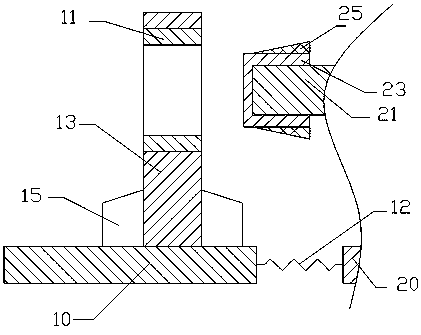

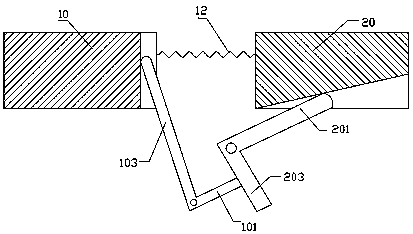

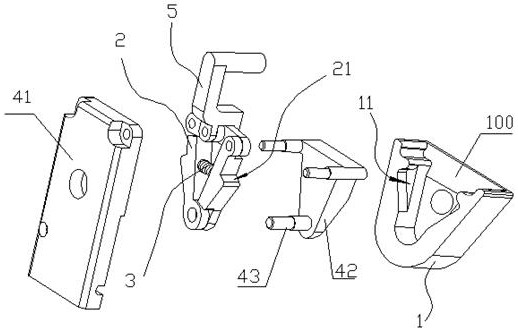

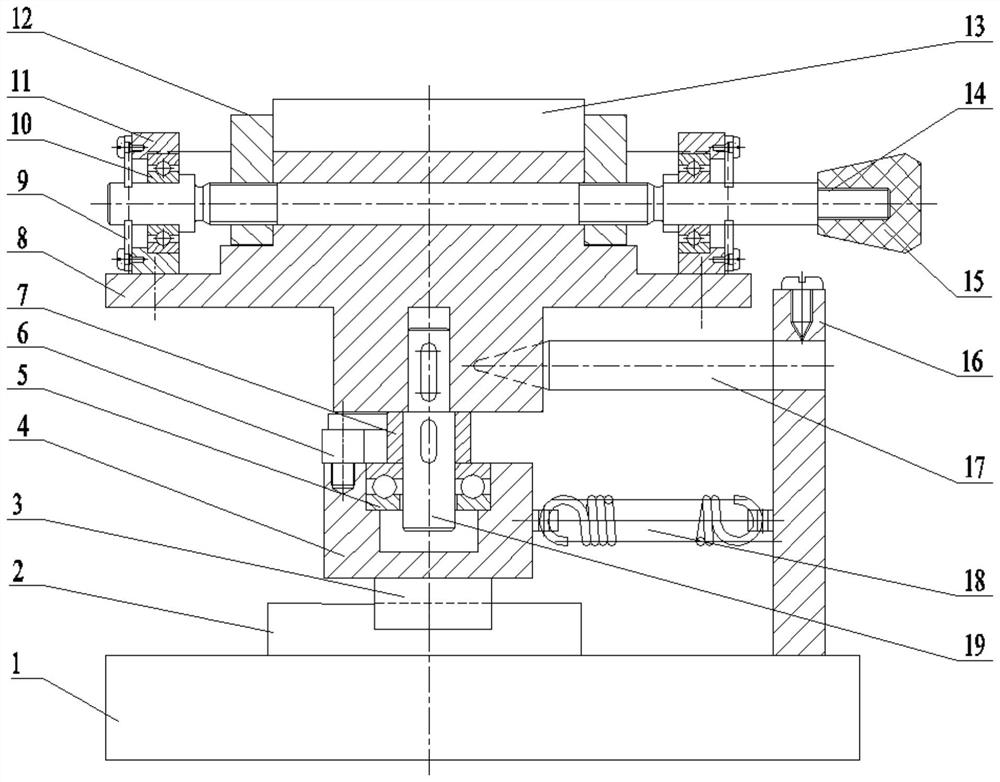

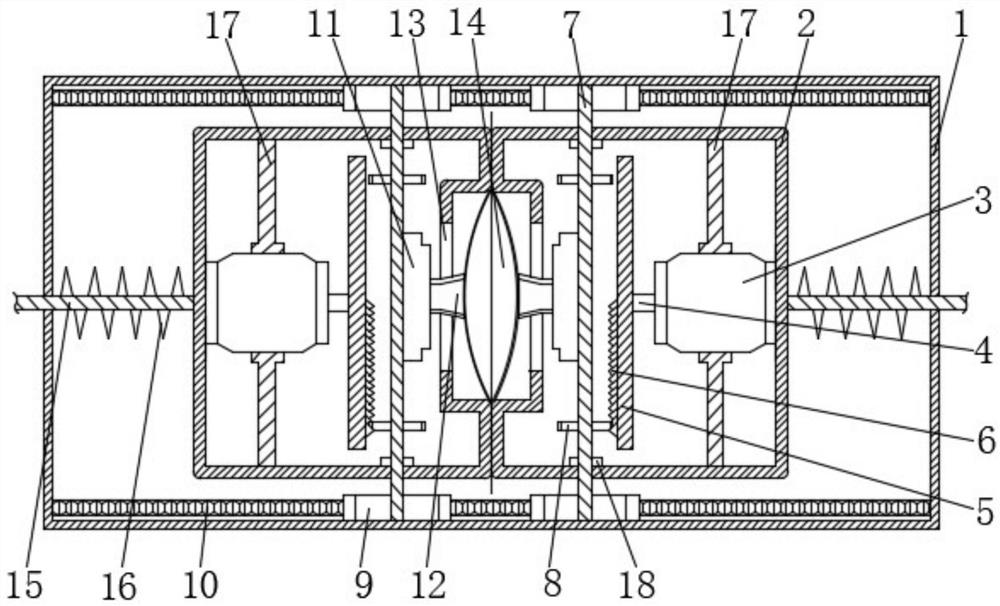

A ball valve disassembly tooling and installation and disassembly method

ActiveCN104084931BRealize disassemblyAchieve opposite motionMetal-working hand toolsEngineeringPower apparatus

The invention provides a ball valve installing and dismantling tool which comprises a tensioning device used for tensioning a fixer (3) and a stretching device used for stretching a spring seat (5) open, wherein the tensioning device and the stretching device cooperate to achieve opposite movement of the spring seat (5) and the fixer (3), the tensioning device comprises a rotating device (30), a screw (12) and a movable part (11), and the movable part (11) is connected with the fixer (3) through a second matching structure; the stretching device comprises a power device (60), an ejector rod (15) and an abutting part (14), one end of the abutting part (14) is connected with the ejector rod (15), and the other end of the abutting part abuts against the spring seat (5). The ball valve installing and dismantling tool can save labor, is convenient to use and can be used online. In addition, the invention provides a ball valve installing and dismantling method.

Owner:NEWAY VALVE SUZHOU

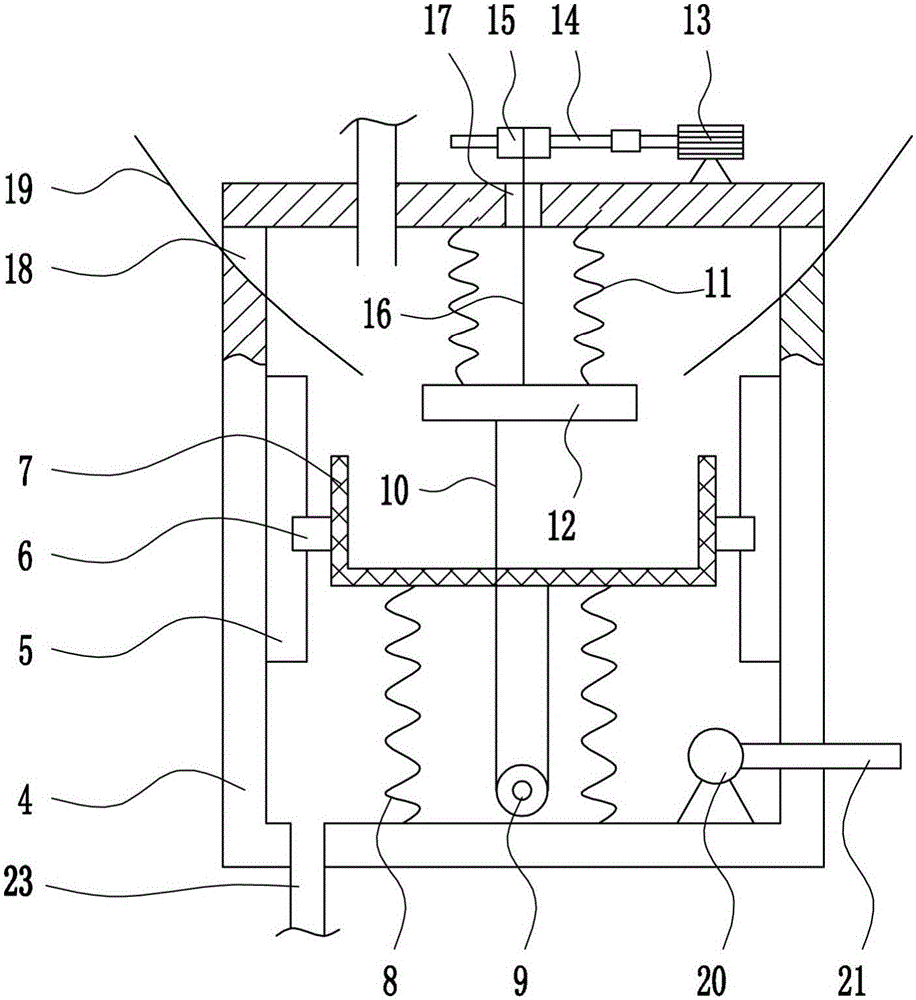

A detection reagent device for liver tumor marker enzyme in serum

ActiveCN109867001BGuaranteed stabilityAchieve opposite motionDomestic cooling apparatusLighting and heating apparatusHepatic tumorMarker enzymes

The invention discloses a detection reagent device for hepatic tumor marker enzymes in serum. The detection reagent device comprises an insulation can and two movable plates; the top part of the insulation can is fixedly connected with two symmetric side plates; through holes are formed in the side face, near the bottom part of the insulation can, of each movable plate, and a corresponding locating rod is glidingly connected through each through hole; the opposite ends of two of the locating rods are fixedly connected with the two sides of the insulation can; the surface of one end, near one end of the insulation can, of each locating rod is provided with a pressure spring in a sleeved manner; and the two ends of each pressure spring are fixedly connected with the opposite sides of the corresponding movable plate and the insulation can. By cooperatively using the structures of the detection reagent device disclosed by the invention, the problems that a reagent is liable to inactivate or the activity of the reagent is liable to decrease due to the fact that insulation operation on the detection reagent is hard to realize during actual use of a traditional reagent kit, and meanwhile,the labor quantity of a physician is increased, and inconvenience is brought to the use due to the fact that a reagent taken out from the reagent kit can be partially precipitated after being storedfor a long time in a standing state, and needs to be shaken up when in use are solved.

Owner:刘辉

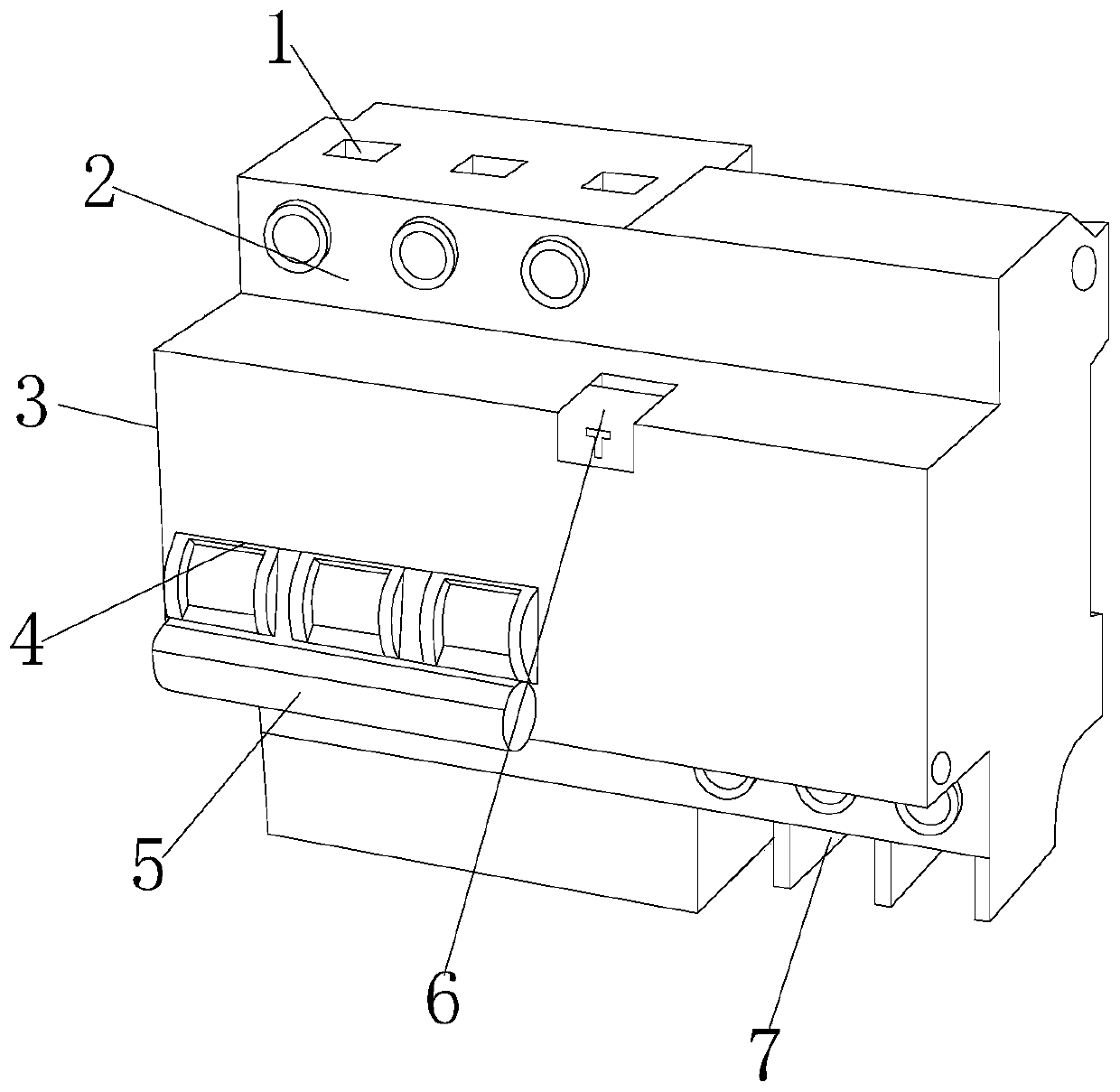

A circuit breaker for compact grounding circuits

ActiveCN108389761BAvoid displacementGuaranteed uptimeProtective switch terminals/connectionsCircuit breaker

The invention discloses a circuit breaker for a compact grounding circuit. The circuit breaker structurally comprises two or more incoming line connection ports, a connection fixing device, a housing,a manual switch tank, a manual switch, a reset switch and outgoing line connection ports, wherein the two or more incoming line connection ports are arranged at the left side of a top panel of the housing, and penetrate through the top panel of the housing; the number of the outgoing line connection ports is consistent with that of the incoming line connection ports; and the outgoing line connection ports and the incoming line connection ports are of a centrosymmetric structure and are arranged at the right side of the bottom of the housing. According to the circuit breaker for the compact grounding circuit, fixing of a connecting line is achieved through the combined action of a drive device, a clamping and pulling device and a fixing device, and fixing with manpower by using a screw driver is not needed, so that the human input is reduced while the fixing effect is ensured, and the time of manually fixing the connecting line is shortened.

Owner:广州孔孟科技有限公司

Permanent magnet drive support equipment for gear machining

ActiveCN106787602BReduce radial forceExtended service lifeDynamo-electric brakes/clutchesElectrical conductorGear wheel

The invention relates to the technical field of gear machining, and particularly relates to permanent magnet transmission support equipment for gear machining. The permanent magnet transmission support equipment comprises a support seat and an installation seat which can be mutually driven to reversely move at the same time, wherein the support seat comprises a base and a support rod; the support rod is fixed on the base; a connection hole is formed in the upper part of the support rod; a support bearing is arranged in the connection hole; a motor is arranged on the installation seat; a motor shaft of the motor is connected with a conductor plate; the conductor plate is sleeved with an outer sleeve capable of shrinking under the action force of the support bearing; the outer sleeve can slide into the support bearing and is provided with an inner cavity containing lubricating oil; and the outer sleeve is provided with a seal cover capable of being opened outwards. The invention aims at providing equipment capable of supporting a permanent magnet in a transmission mechanism.

Owner:CHONGQING SUTENG MACHINERY MFG

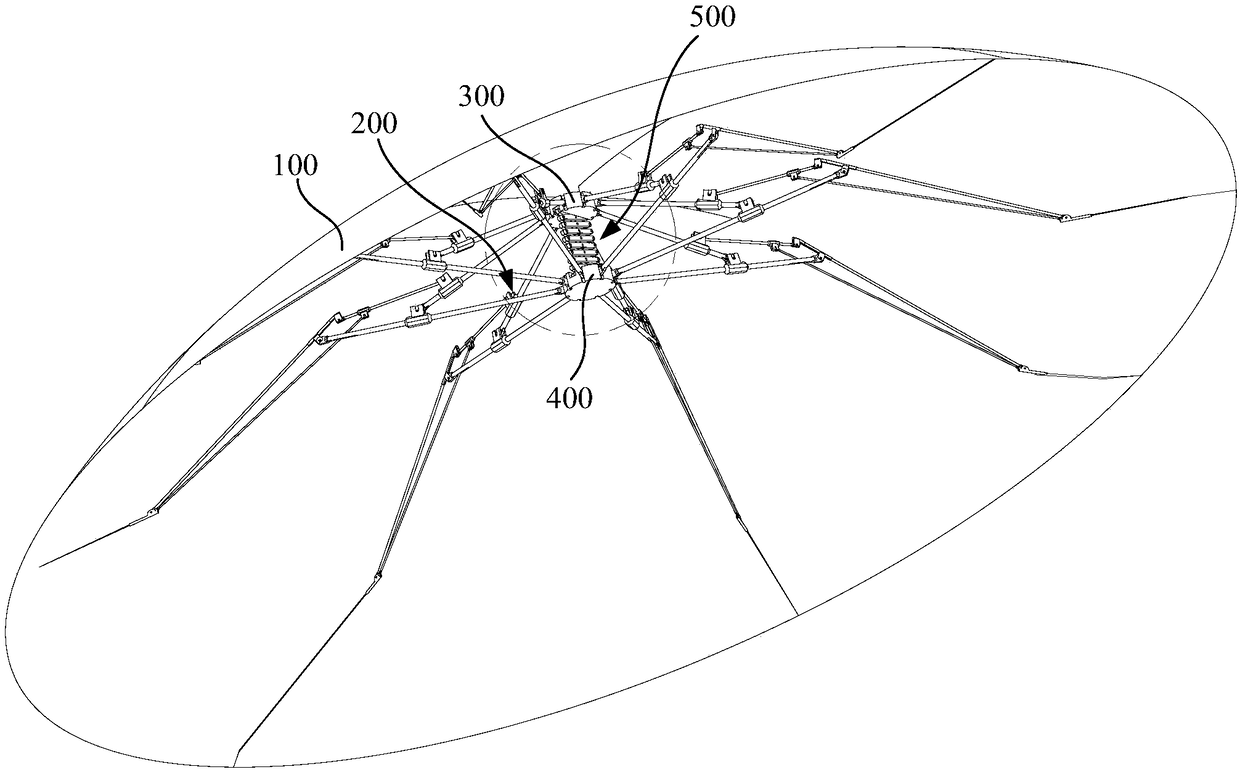

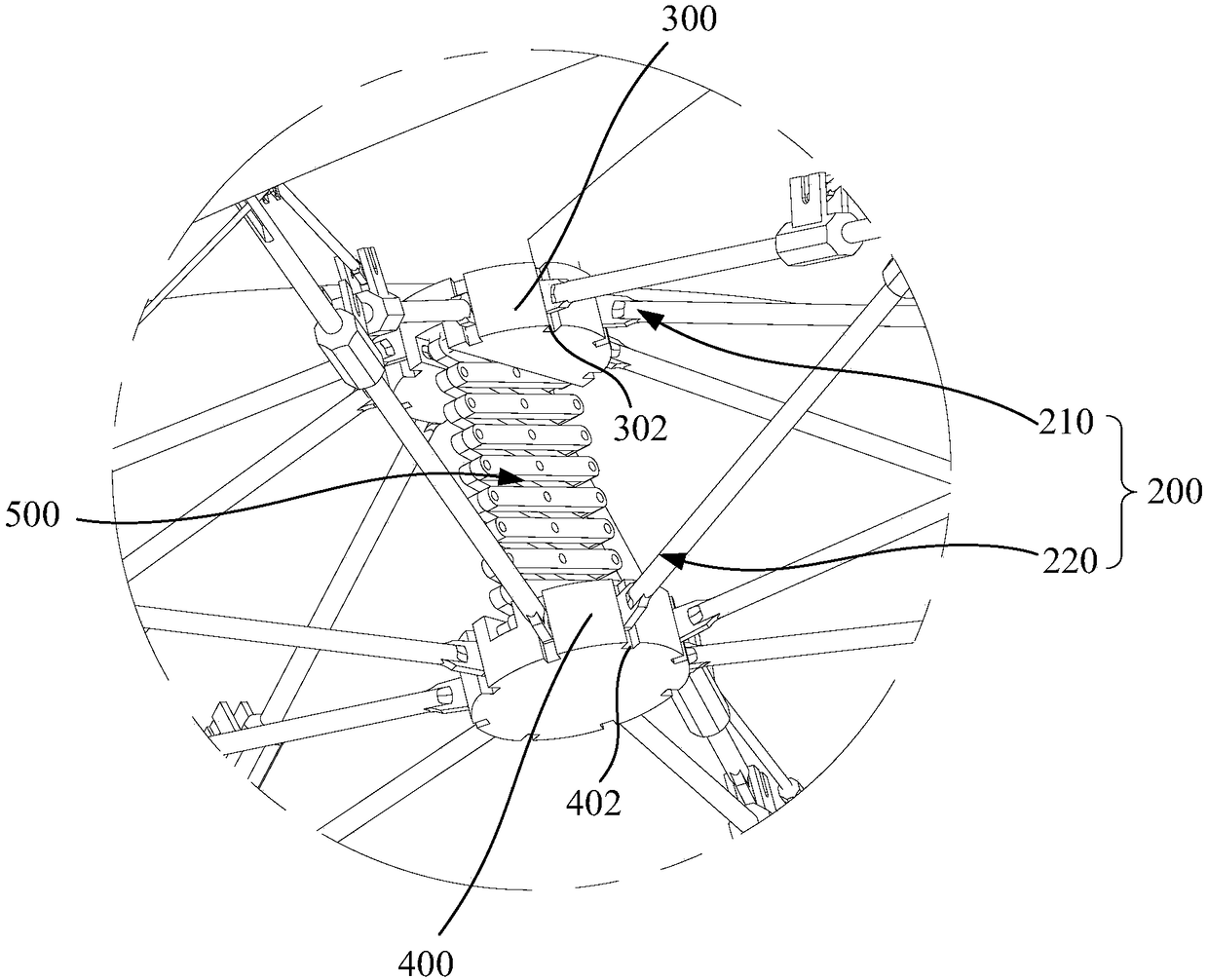

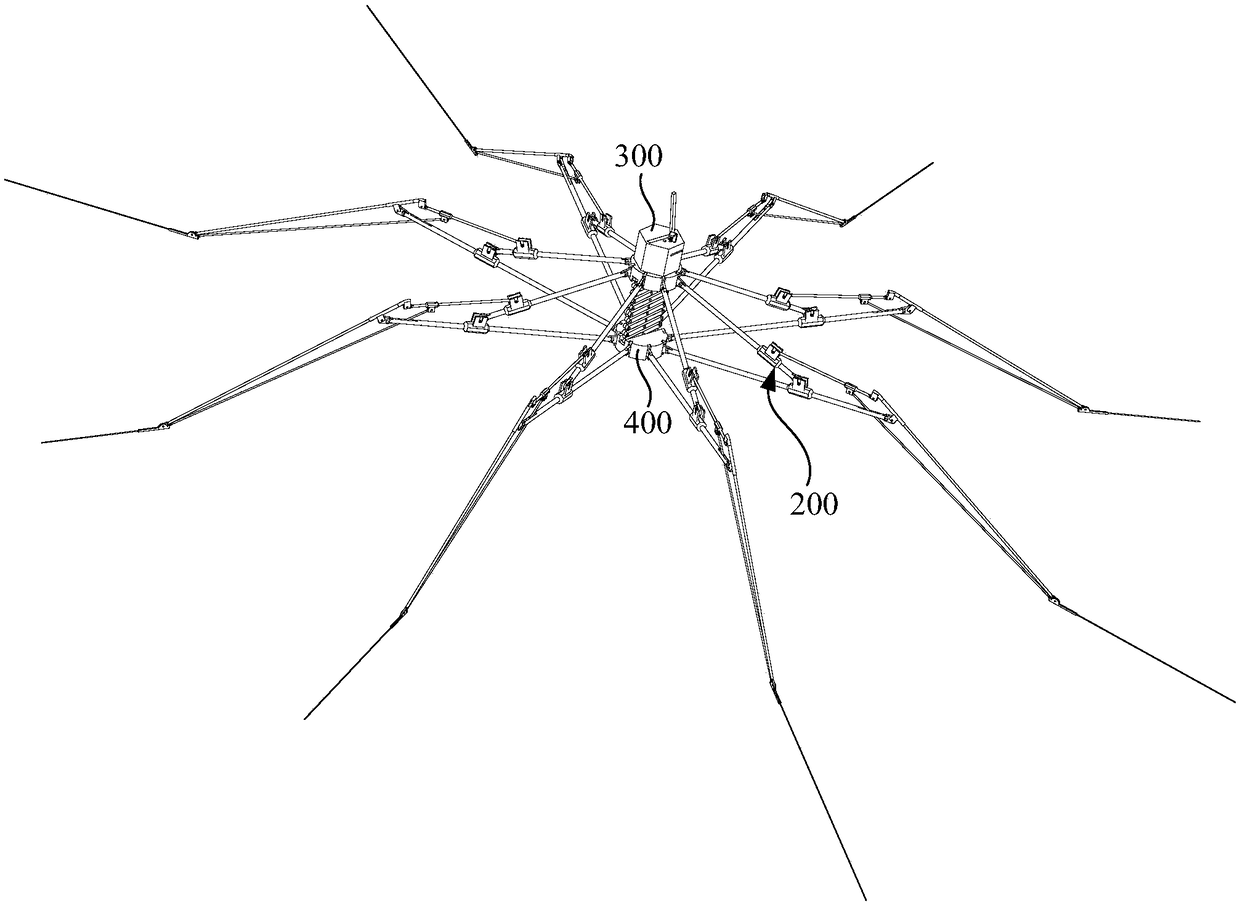

Umbrella

The invention relates to an umbrella. The umbrella comprises an umbrella surface, an umbrella rib assembly supporting the umbrella surface, a top base, an uplink base and a telescopic driving assembly, wherein the umbrella rib assembly is hinged to the top base and the uplink base in a circumferential direction; the telescopic driving assembly comprises a first hinge, a second hinge and a drivingpart; the first hinge comprises a plurality of first connecting rods which are hinged end to end, and the second hinge comprises a plurality of second connecting rods which are hinged end to end; thelengths of the first connecting rods and the lengths of the second connecting rods are equal; each first connecting rod is pivoted with the corresponding second connecting rod in a crossed mode to form a scissor fork type connecting rod mechanism; the two ends of each scissor fork type connecting rod mechanism are connected with the top base and the uplink base respectively so that the scissor fork type connecting rod mechanisms can stretch and retract under the action of the driving part, and the top base and the uplink base can be driven to be close to or away from each other to make the umbrella rib assembly unfolded or folded.

Owner:深圳市宝电工业技术有限公司

Detection reagent device for hepatic tumor marker enzymes in serum

ActiveCN109867001AGuaranteed stabilityAchieve opposite motionDomestic cooling apparatusLighting and heating apparatusSerum SGPTEngineering

The invention discloses a detection reagent device for hepatic tumor marker enzymes in serum. The detection reagent device comprises an insulation can and two movable plates; the top part of the insulation can is fixedly connected with two symmetric side plates; through holes are formed in the side face, near the bottom part of the insulation can, of each movable plate, and a corresponding locating rod is glidingly connected through each through hole; the opposite ends of two of the locating rods are fixedly connected with the two sides of the insulation can; the surface of one end, near one end of the insulation can, of each locating rod is provided with a pressure spring in a sleeved manner; and the two ends of each pressure spring are fixedly connected with the opposite sides of the corresponding movable plate and the insulation can. By cooperatively using the structures of the detection reagent device disclosed by the invention, the problems that a reagent is liable to inactivate or the activity of the reagent is liable to decrease due to the fact that insulation operation on the detection reagent is hard to realize during actual use of a traditional reagent kit, and meanwhile,the labor quantity of a physician is increased, and inconvenience is brought to the use due to the fact that a reagent taken out from the reagent kit can be partially precipitated after being storedfor a long time in a standing state, and needs to be shaken up when in use are solved.

Owner:刘辉

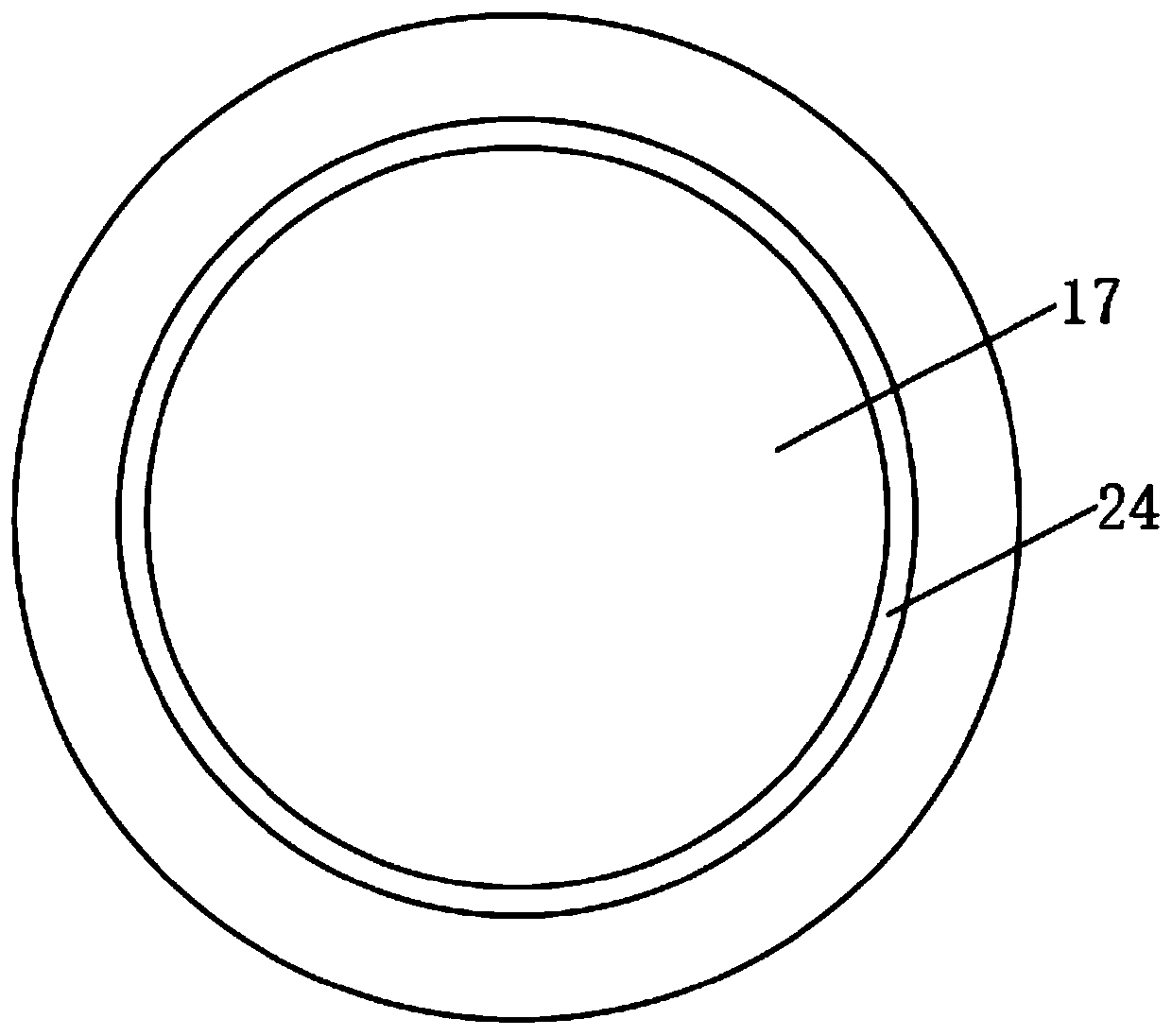

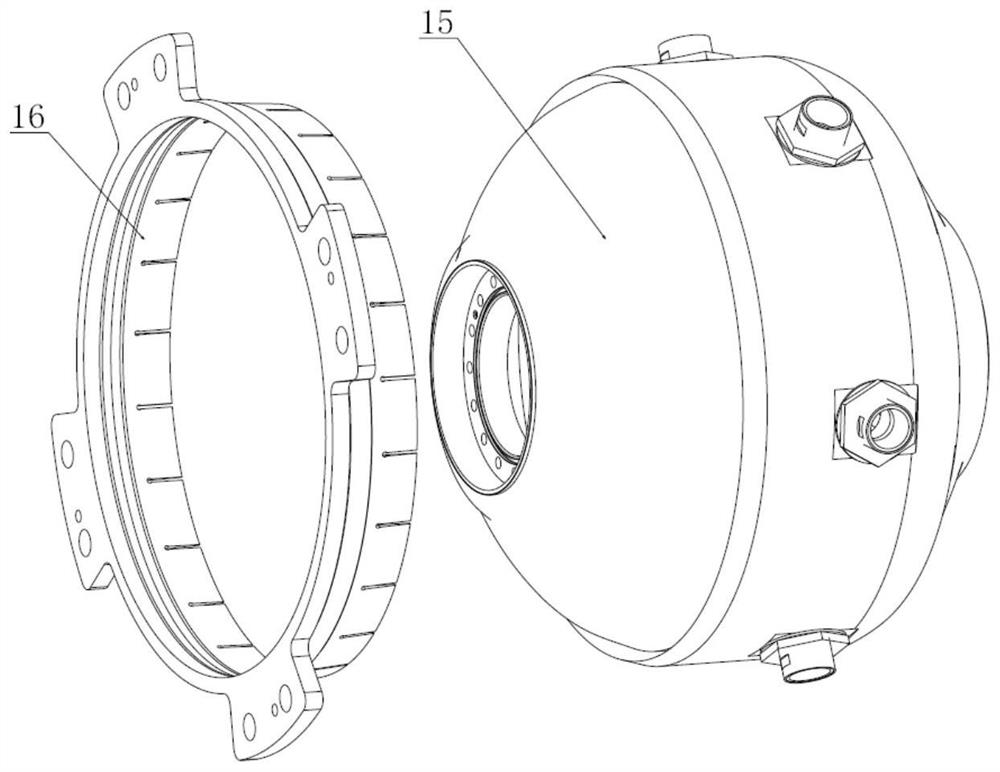

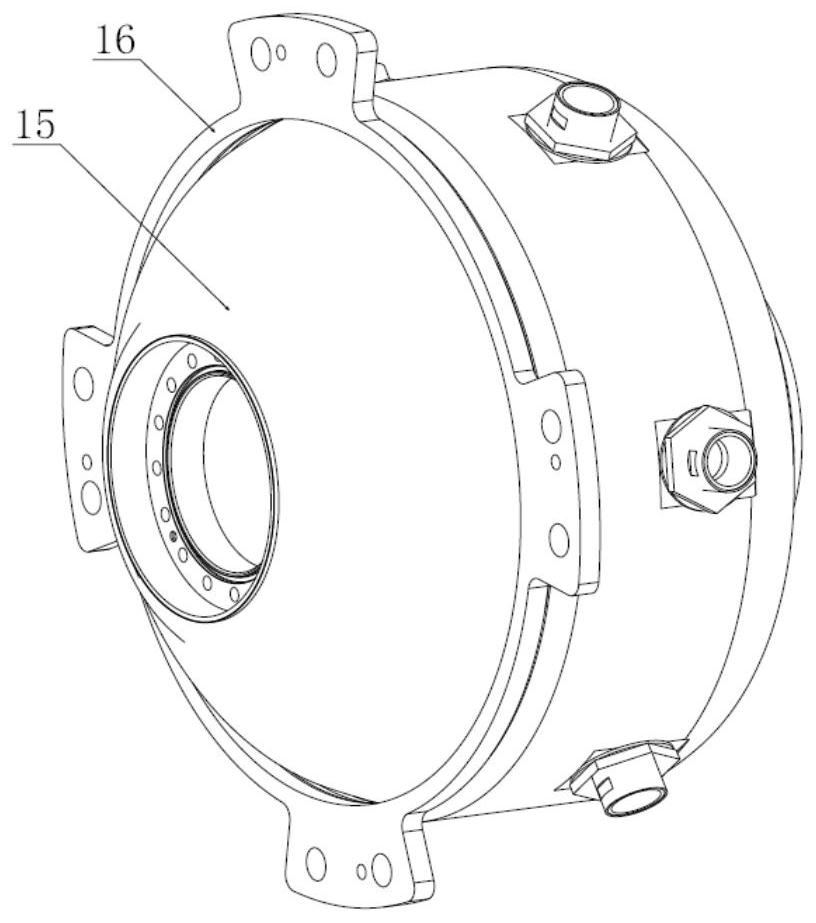

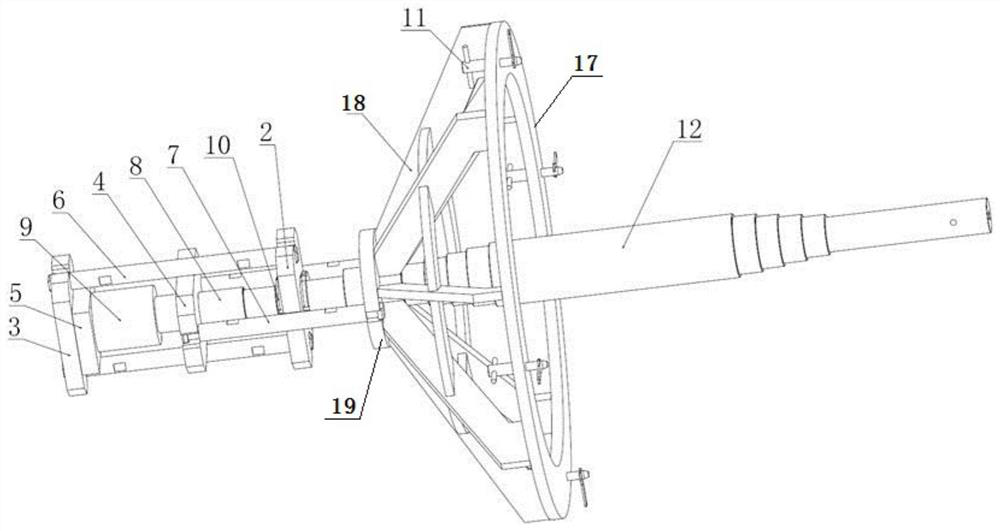

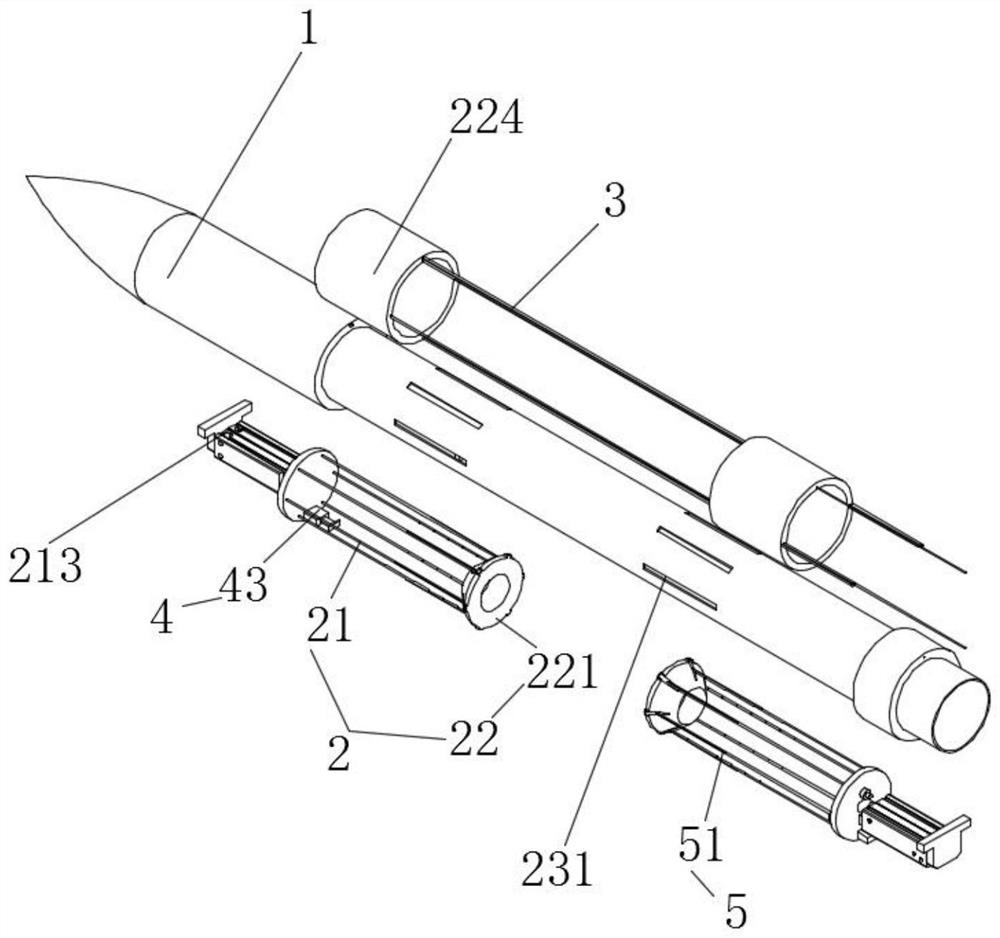

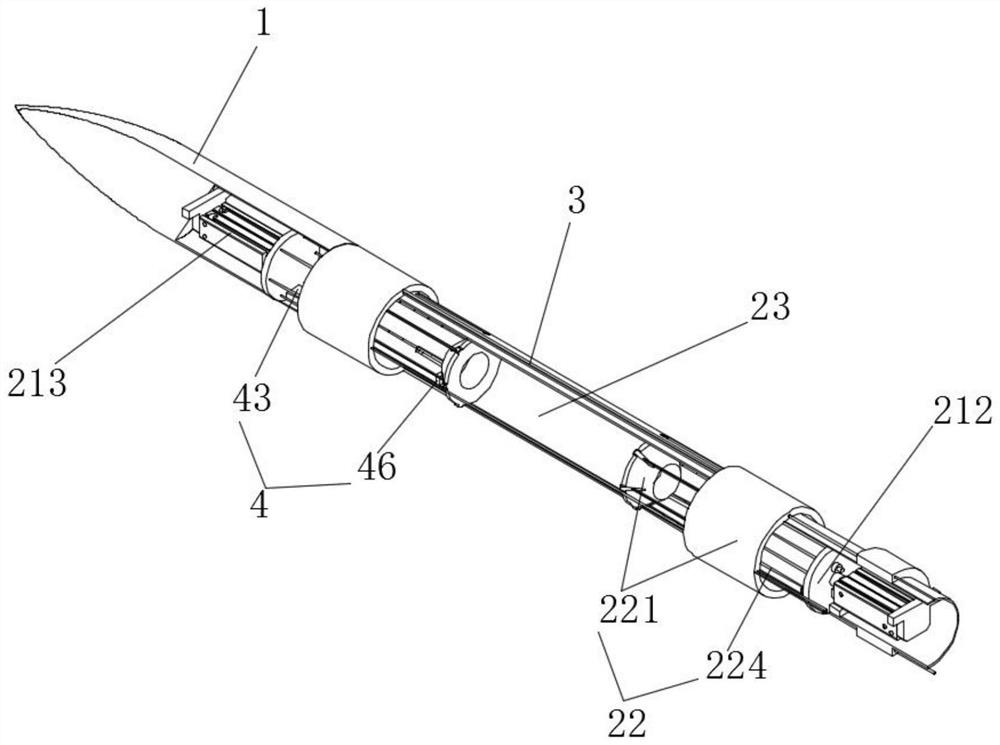

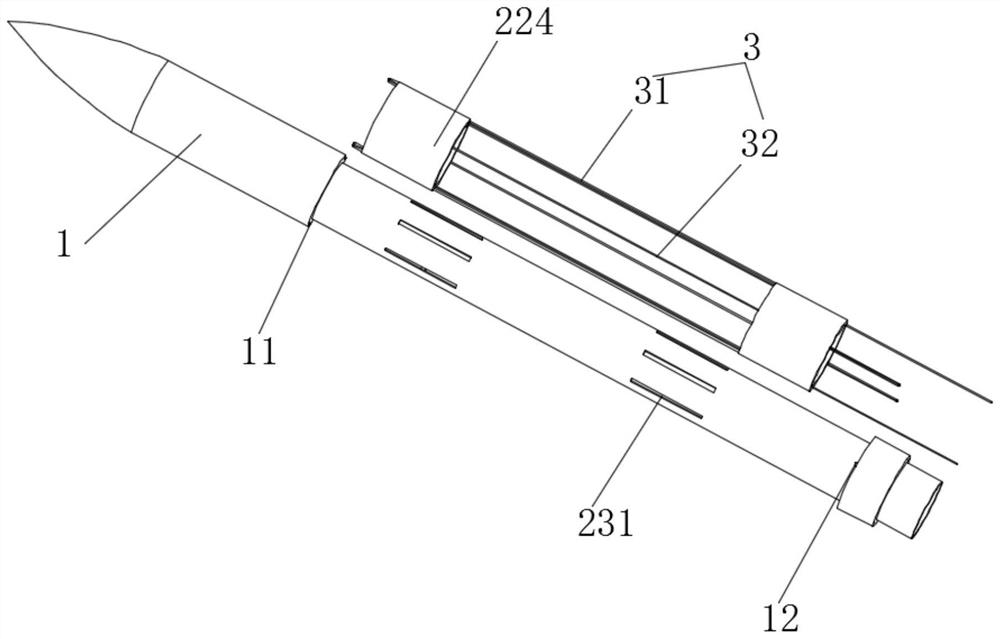

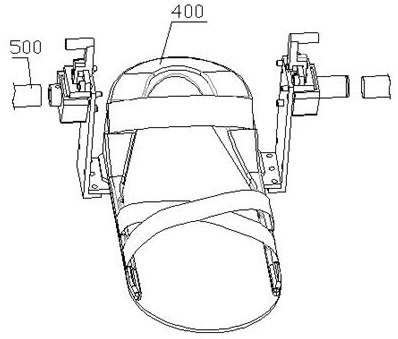

Assembly positioning device

The invention discloses an assembly positioning device which comprises a skirt sleeve positioning frame and a mandrel, the skirt sleeve positioning frame comprises a connecting main plate, a connecting frame and a sliding plate, the shape of the connecting main plate is matched with that of a connecting skirt sleeve, the connecting main plate is connected with the connecting skirt sleeve, and the connecting main plate is connected with the sliding plate through the connecting frame; one end of the mandrel is connected with the shell, the other end of the mandrel is connected with a driving device, and the sliding plate is connected to the mandrel in a sliding mode and located between the shell and the driving device; the driving device comprises a pulling mechanism and a jacking mechanism, and the jacking mechanism is connected with the sliding plate so that the connecting skirt sleeve can move towards the side close to the shell through the sliding plate. And the jacking mechanism is connected with the mandrel so as to drive the shell to move towards one side close to the connecting skirt sleeve through the mandrel. Accurate positioning is achieved for installation of the connecting skirt sleeve, and the connecting skirt sleeve has the advantages of being simple and labor-saving in installation.

Owner:HENGSHEN

Bundling multi-pole needle radiofrequency ablation device convenient to puncture

PendingCN114848134AFacilitate ablationAchieve opposite motionSurgical needlesSurgical instruments for heatingRf ablationExAblate

The invention relates to the technical field of radiofrequency ablation medical treatment, and discloses a bundling multi-pole needle radiofrequency ablation device convenient to puncture, which comprises a puncture end, the tail part of the puncture end is connected with an electrode needle assembly, and the electrode needle assembly comprises a bundling electrode needle. Two groups of bunched electrode needles move oppositely under the pushing of an electric push rod, so that each probe in each group of bunched electrode needles penetrates out of a needle outlet channel and pierces into the tissue of a patient, and meanwhile, when a carrier plate enables the probes to penetrate out of a supporting tube under the action of the electric push rod, a liquid storage tank and a piston push rod also move along with the carrier plate, so that the liquid storage tank and the piston push rod are driven by the electric push rod to penetrate into the tissue of the patient. When the piston push rod moves to the position of the check block, the piston push rod moves towards the interior of the liquid storage tank under the action of the check block, so that a solution in the liquid storage tank is compressed and injected into the middle of a lesion tissue through a liquid passing pipe on the probe and a liquid outlet, the progress degree of radiofrequency ablation is more uniform, and tumor tissue covering is conveniently completed; and in addition, in the ablation process, virus cells in the diseased tissue can be better ablated.

Owner:苏州凯克曼医疗科技有限公司

Separable foot dressing and fixing device for lower limb training device

PendingCN111616925ALess wear painAchieve lockingChiropractic devicesPhysical medicine and rehabilitationLinkage (mechanical)

The invention discloses a separable foot dressing and fixing device for a lower limb training device. The separable foot dressing and fixing device comprises a pedal and a driving shaft, wherein the pedal is detachably mounted on the driving shaft. The pedal is detachably mounted on the driving shaft, dressing pain of a patient is reduced, a quick inserting and drawing mechanism realizes locking and unlocking of a locking arm by a mechanical linkage principle, and the separable foot dressing and fixing device is reasonable in structural design, and simple to operate, can quickly realize actions of locking and unlocking, and is good in using effect.

Owner:南京瑞可赋机器人科技有限公司

Carton production stable grooving equipment facilitating scrap cleaning

PendingCN113478906AImprove work efficiencyEasy to cleanPaper-makingBox making operationsElectric machineryDrive motor

The invention discloses carton production stable grooving equipment facilitating scrap cleaning. The carton production stable grooving equipment comprises a workbench and a machining table. The top end of the workbench is fixedly connected with a top plate through a connecting piece. The top end of the workbench is fixedly connected with the machining table. A guide groove is transversely formed in the surface of a fixing block. A bearing pedestal is arranged at the left end of the guide groove. A third drive motor is arranged at the right end of the guide groove. A lead screw is arranged at the output end of the third drive motor. Through the arrangement of the lead screw, movable blocks, the third drive motor and other structures, when scraps on the workbench need to be cleaned, only the third drive motor needs to be started, the third drive motor drives the lead screw to rotate, accordingly, the movable blocks move in the opposite direction, a grip is driven to move in the opposite direction, finally, brush strips clean the scraps, and the automation degree is high.

Owner:陈子东

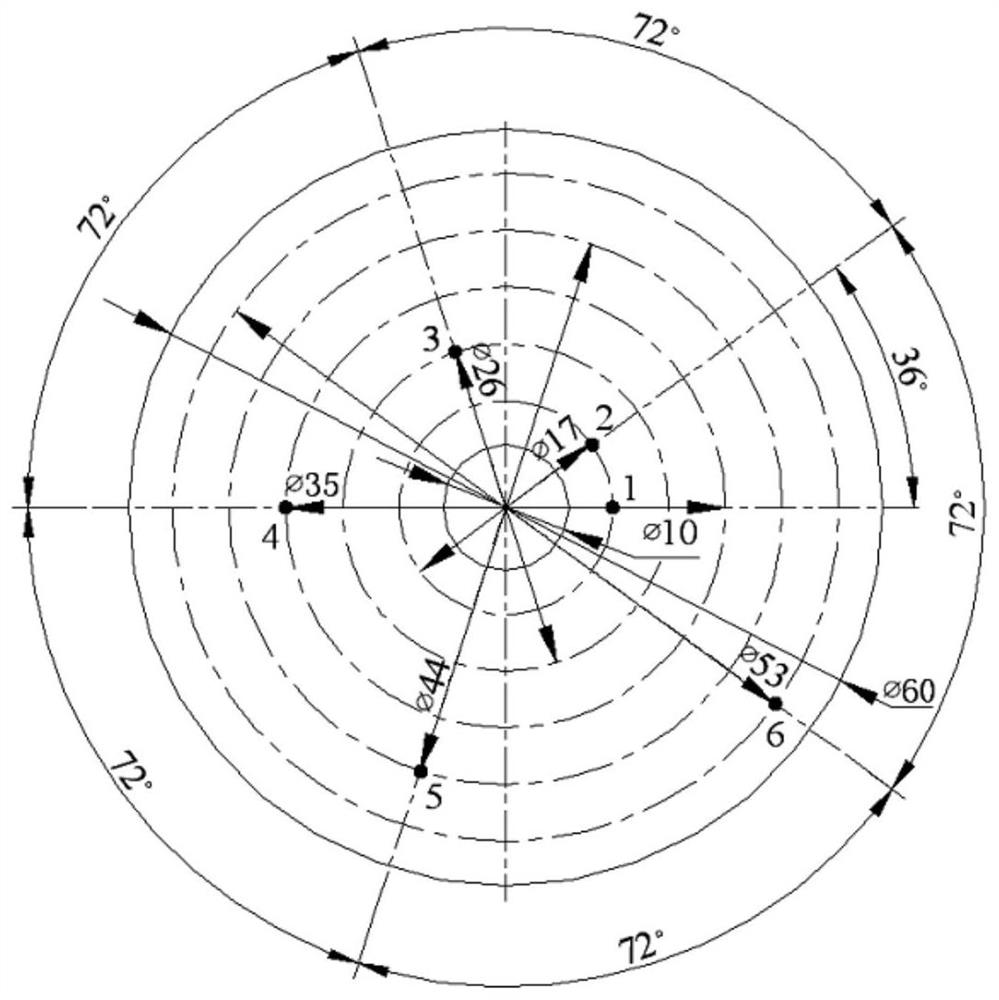

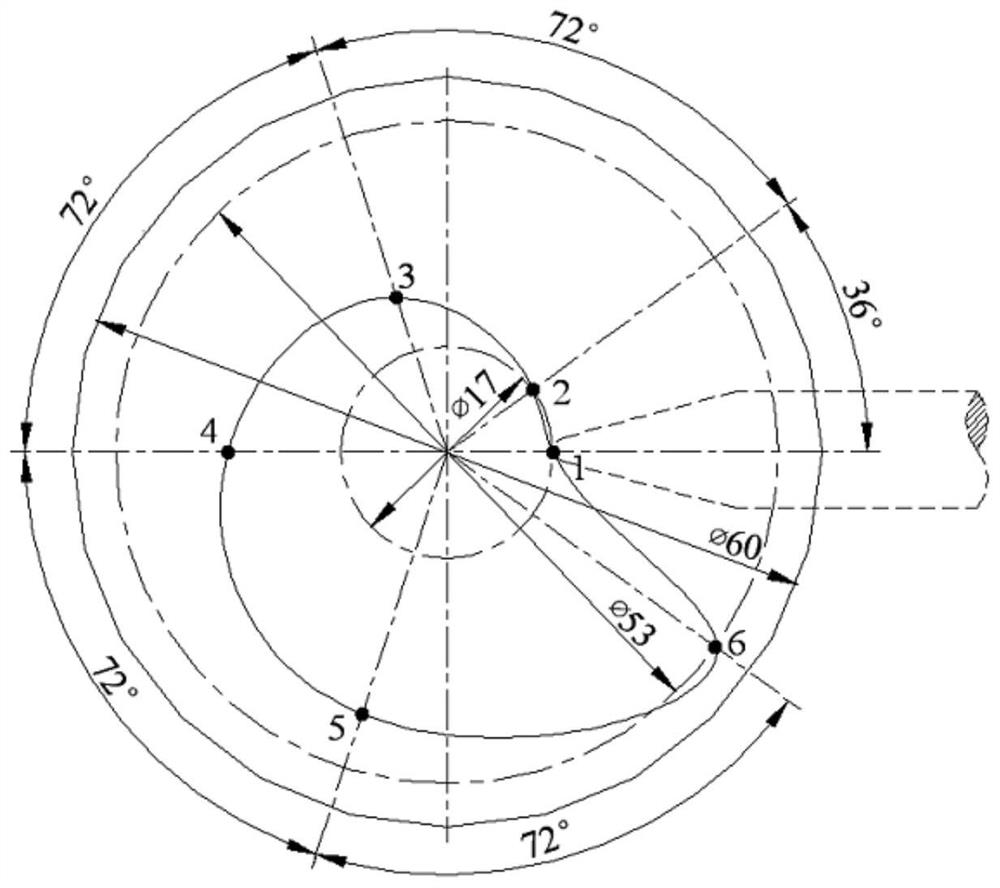

Workbench of fixed-degree hardness block and fixed-degree method of workbench

ActiveCN111751235AAchieve opposite motionPrevent movementInvestigating material hardnessRatchetLinear motion

The invention discloses a workbench of a fixed-degree hardness block and a fixed-degree method of the workbench, and belongs to the field of fixed-degree hardness blocks. According to the workbench ofthe fixed-degree hardness block, a working disc and a cam are of an integrated structure, the working disc for supporting the hardness block is arranged at the top, and the cam designed according todotting spline curves evenly distributed on the working face of the hardness block is arranged below the working disc; a linear guide rail and a support are fixed to the base, a first bearing pedestalis fixed to a sliding block of the linear guide rail and used for achieving linear motion of the working disc, and a thrust bearing is arranged on the first bearing pedestal. A ratchet wheel is arranged on the mandrel, and a limiting mechanism is arranged on the first bearing seat to realize one-way rotation; a spring is arranged between the bracket mechanism and the cam to ensure that the cam and the support rod are always in a tangent state; and when the scribed lines on the working disc are aligned with the scribed lines on the supporting rod, the working disc reaches the dotting position.According to the workbench of the fixed-degree hardness block, calibration errors caused by manual operation are avoided.

Owner:AECC AVIATION POWER CO LTD

Jinsihuangchrysanthemum eye patch preparation equipment and preparation process

ActiveCN111169717BRealize reciprocating rotationAchieve opposite motionPaper article packagingGear wheelElectric machinery

The invention discloses preparation equipment and a preparation process of a golden chrysanthemum eye mask. The preparation equipment includes a box body, wherein the inner wall of the box body is slidably connected with two shells, the inner walls of the shells are fixedly connected with motors, the end parts of output shafts on the motors are fixedly connected with first shafts, the ends, away from the motors, of the first shafts are fixedly connected with rotary tables, the sides of the rotary tables are fixedly connected with arc toothed plates, through holes are formed in the front sidesand the rear sides of the shells, and the shells rotate the second shafts in a limiting mode. The surfaces, close to the middle, of the second shafts are fixedly connected with two first gears, the surfaces of the first gears are meshed with teeth on the arc toothed plates, and the surfaces, close to the two ends, of the second shafts are fixedly connected with second gears. According to the preparation equipment and the preparation process of the golden chrysanthemum eye mask, through the combination use of the structures, the problem that in the actual use process, inconvenience is brought to the users due to the fact that a traditional bag opening and mask collecting mechanism is difficult to quickly open bag mouths of package bags, and the working efficiency is reduced is solved.

Owner:ANHUI AGRICULTURAL UNIVERSITY

Efficient welding equipment for connecting wires for automobile system

ActiveCN112756516ARealize the driving effectAchieve opposite motionAutomotive systemsStructural engineering

The invention relates to welding equipment, and particularly relates to efficient welding equipment for connecting wires for an automobile system. The efficient welding equipment for the connecting wires for the automobile system is easy and convenient to operate, high in welding quality and capable of achieving repeated welding. The efficient welding equipment for the connecting wires for the automobile system comprises a rack, a first auxiliary mechanism, a pressing mechanism and a welding mechanism, and a pushing mechanism is arranged on the rack; the first auxiliary mechanism is arranged at the upper middle part of the rack; the pressing mechanism is arranged at the upper middle part of the rack; and the welding mechanism is arranged on the upper left side of the rack. According to the efficient welding equipment, after a first push plate is pushed to the limit, a first elastic assembly is compressed, so that a second push plate is driven to move reversely, the second push plate pushes the connecting wires to the middle position of the rack, and the pushing effect is achieved.

Owner:赣州市硕祺电子科技有限公司

A ceiling smearing putty device

ActiveCN110924643BAchieve opposite motionDecrease productivityBuilding constructionsElectric machineryScrew thread

The invention discloses a ceiling smearing putty device, specifically relates to the field of putty smearing equipment, comprising a smearing device and a lifting device, the smearing device includes a material box, one side of the material box is fixed with a fixed frame by bolts, and the fixed The frame is movably equipped with a plurality of rollers, the top middle of the material box is provided with a discharge port, the inside of the material box is provided with a discharge device, and the discharge device includes a spring, and the spring is fixedly installed in the inner cavity of the material box bottom corners. The invention drives the threaded rod to rotate by using the motor, so that the sliders at both ends of the threaded rod move toward each other, so that the telescopic frame is extended, and then the putting device equipped with putty is raised to contact with the top of the ceiling, and then the knob is opened to make the material The putty inside the box is squeezed out under the restoring force of the spring, and the staff only need to push the push frame below to make the walking wheels at the bottom of the bottom plate roll on the ground to realize even application of putty.

Owner:广东粤冠建材有限公司

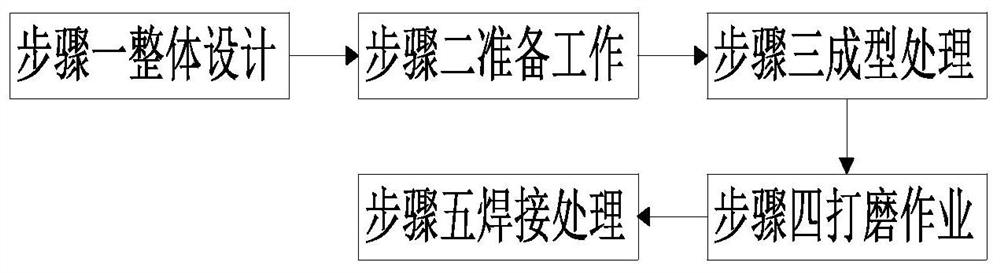

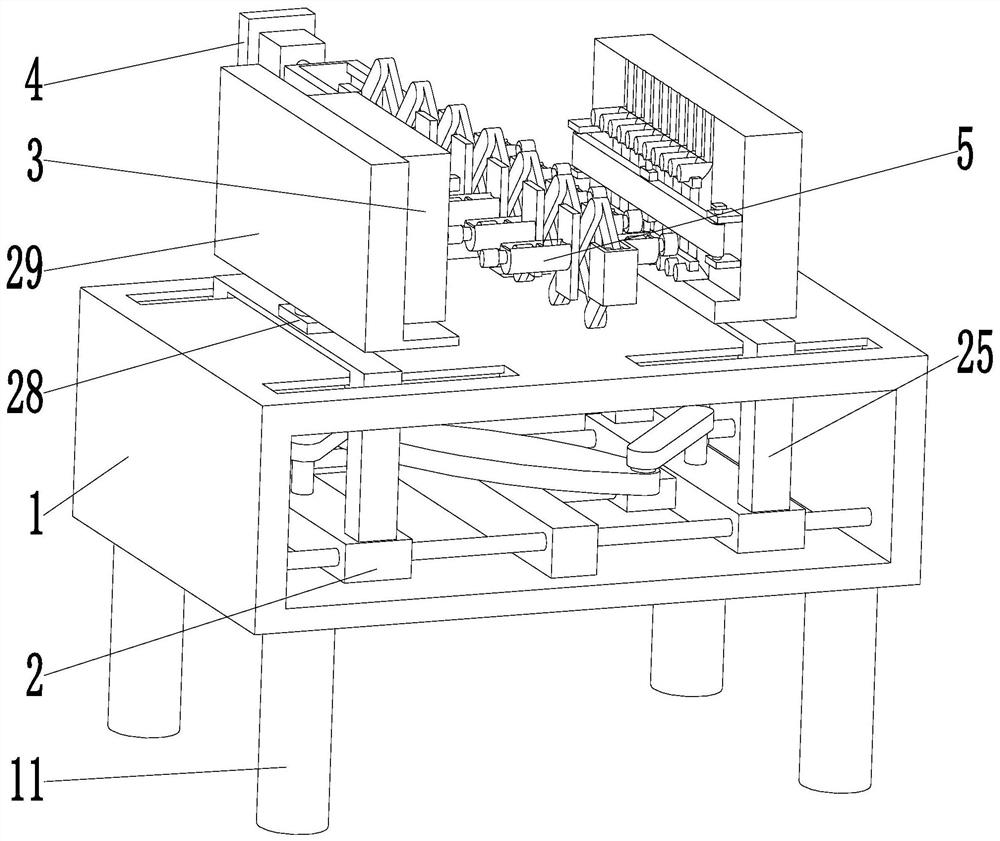

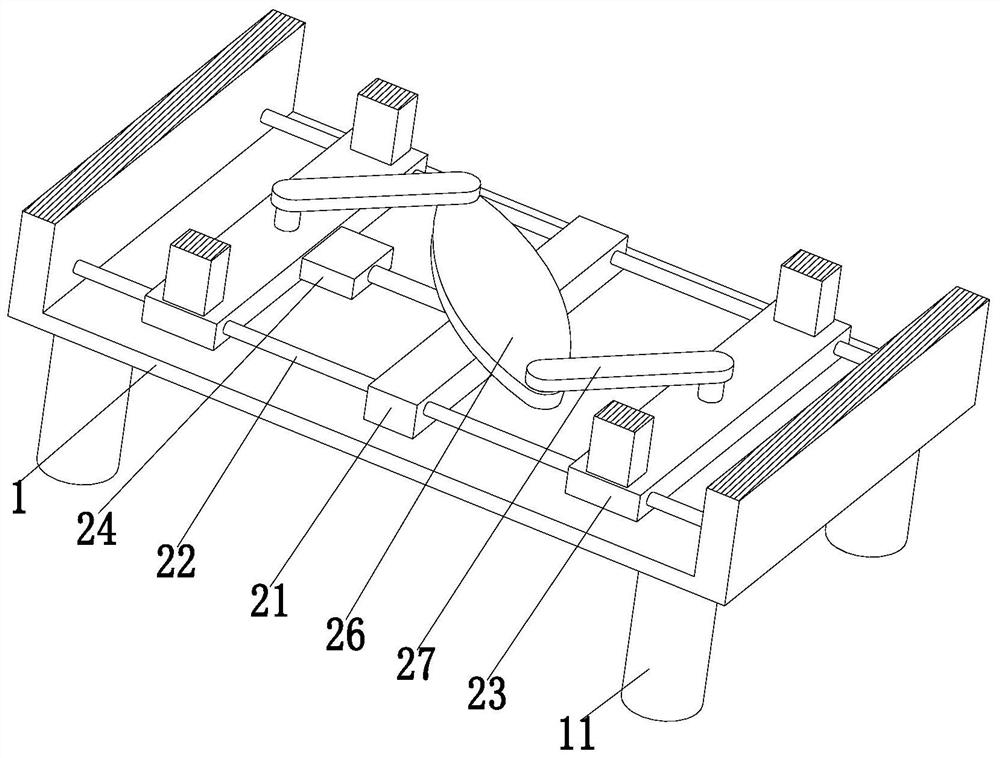

A method for manufacturing and processing a metal shell of a power transformer

ActiveCN111276325BAdjustable distanceAdapt to connection distanceTransformers/inductances casingsInductances/transformers/magnets manufactureTransformerProcess engineering

The invention relates to a method for manufacturing and processing a metal shell of a power transformer, which mainly includes the following steps: overall design, preparation work, forming treatment, grinding operation, welding treatment and other processes. The used shell grinding equipment includes a bottom plate and a docking device , positioning device, telescopic device and grinding device, the present invention can solve the following difficult problems existing in the grinding and welding of existing heat pipes and transformer boxes, a, traditional heat pipes and transformer boxes need to be manually held when grinding For the cooling pipe and the transformer box, use a grinding machine to grind the connection between the cooling pipe and the transformer box. The labor intensity of the workers is too high, the grinding time is long, and the installation efficiency is not high; b. The existing cooling pipe and the transformer box During welding, the welding machine is manually used to weld the connection between the heat dissipation pipe and the transformer box, and the connection between the heat dissipation pipe and the transformer box is unstable, which affects the heat dissipation function of the transformer.

Owner:WUHU JINNIU ELECTRIC

Socket assembling production equipment

InactiveCN108380998AAchieve opposite motionAvoid damageWelding/cutting auxillary devicesAuxillary welding devicesTransmission beltEngineering

The invention discloses socket assembling production equipment. The socket assembling production equipment structurally comprises two supporting feet, a shell, a welding device, a worktable and a transmission belt, the supporting feet are mounted at the bottom of the worktable, and the worktable is fixedly connected with the supporting feet; and the transmission belt is mounted in the worktable and connected with the worktable, the welding device is arranged in the shell, and the shell is arranged on the worktable and is fixedly connected with the worktable. According to the socket assemblingproduction equipment, through combined action of a mechanical driving device, a lever driving device, a fixture mechanism, a rosin feeding device, a welding driving mechanism, a heat dissipation mechanism and an auxiliary driving mechanism, steady and firm welding between a connecting wire and a copper plate is achieved, and the phenomenon that pseudo soldering exists and affects the quality of afinished product is avoided.

Owner:泉州市进光贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com