Ceiling putty painting device

A ceiling and putty technology, applied in the direction of construction and building structure, can solve the problems of uneven coating, low work efficiency of workers, and a lot of labor, so as to avoid the effect of continuous discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

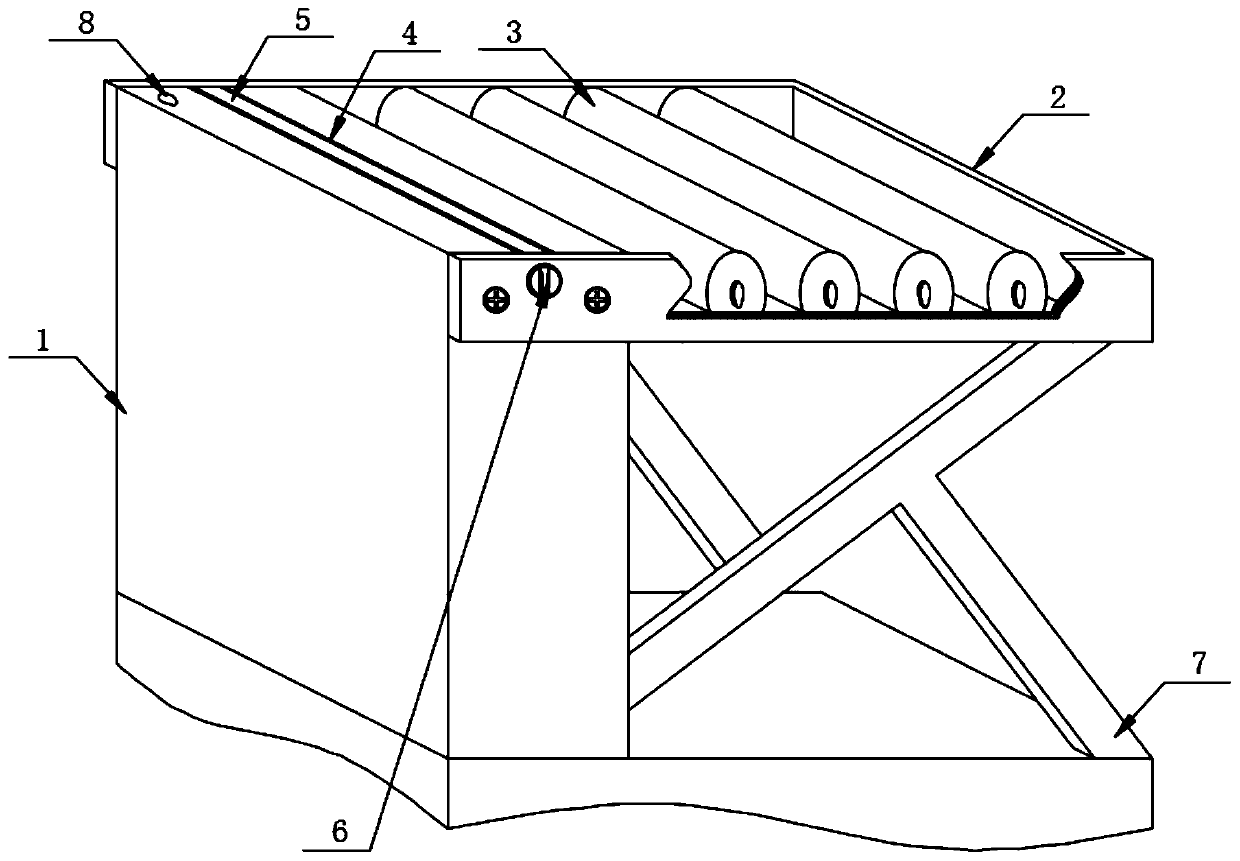

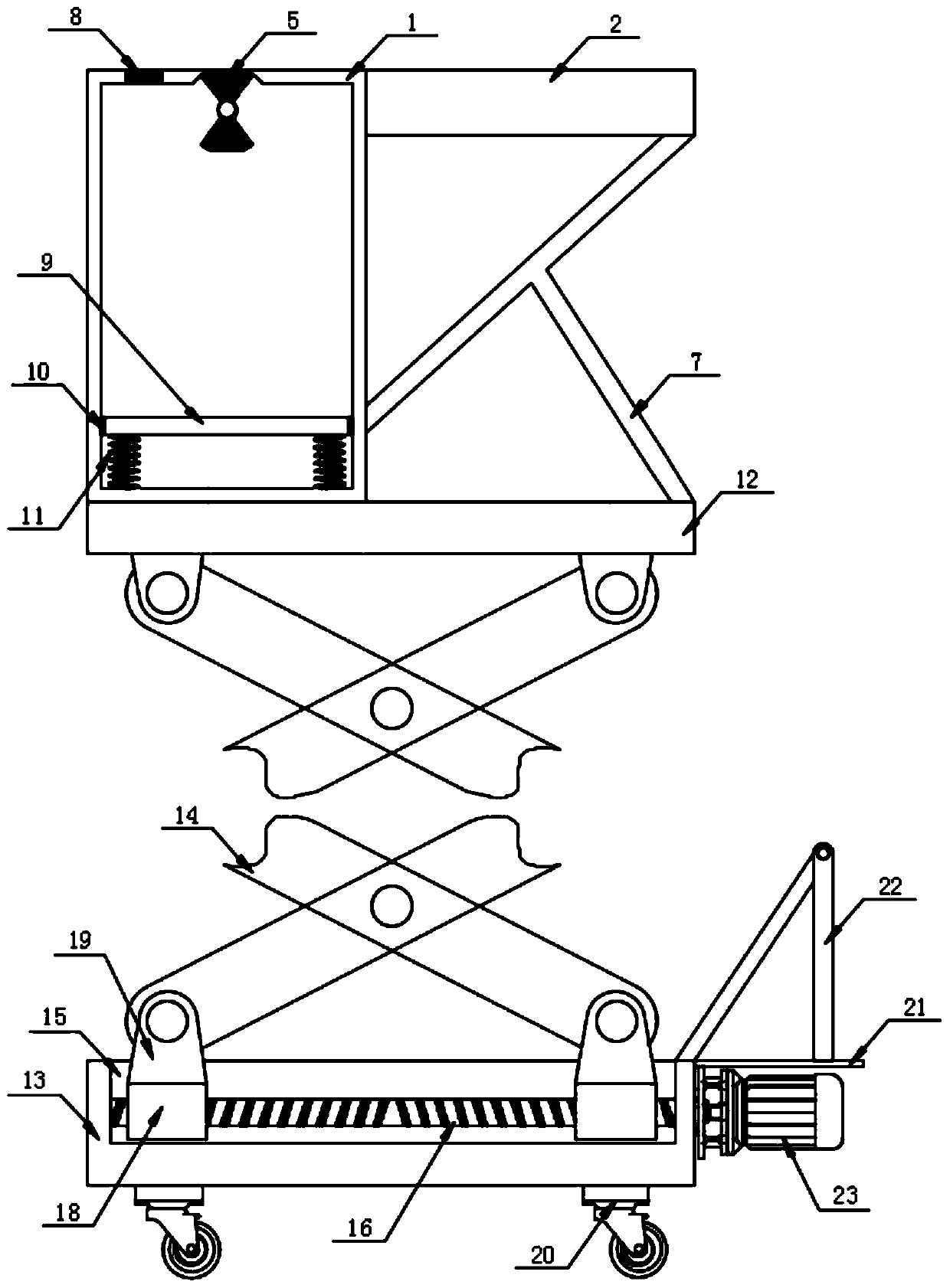

[0028] Such as Figure 1-2 and Figure 5 As shown, the present invention provides a ceiling smearing putty device, including a smearing device, a base plate 13, a traveling wheel 20 and a lifting device, the bottom four corners of the base plate 13 are equipped with a traveling wheel 20, and the top of the base plate 13 is provided with a lifting device , A smearing device is installed on the lifting device.

[0029] The smearing device includes a material box 1, a fixed frame 2, a cylinder 3, a sealing plate 5, a knob 6, a support 7, a movable plate 9, a sealing ring 10 and a spring 11, and the top left side of the lifting device is provided with a material box 1, and the material There is a feeding port 8 on the left side of the top of the box 1. There is a sliding movable plate 9 in the material box 1 that can push the putty to move. The side wall of the movable plate 9 is equipped with a sealing ring 10, which can effectively prevent the movable plate in the material box ...

Embodiment 2

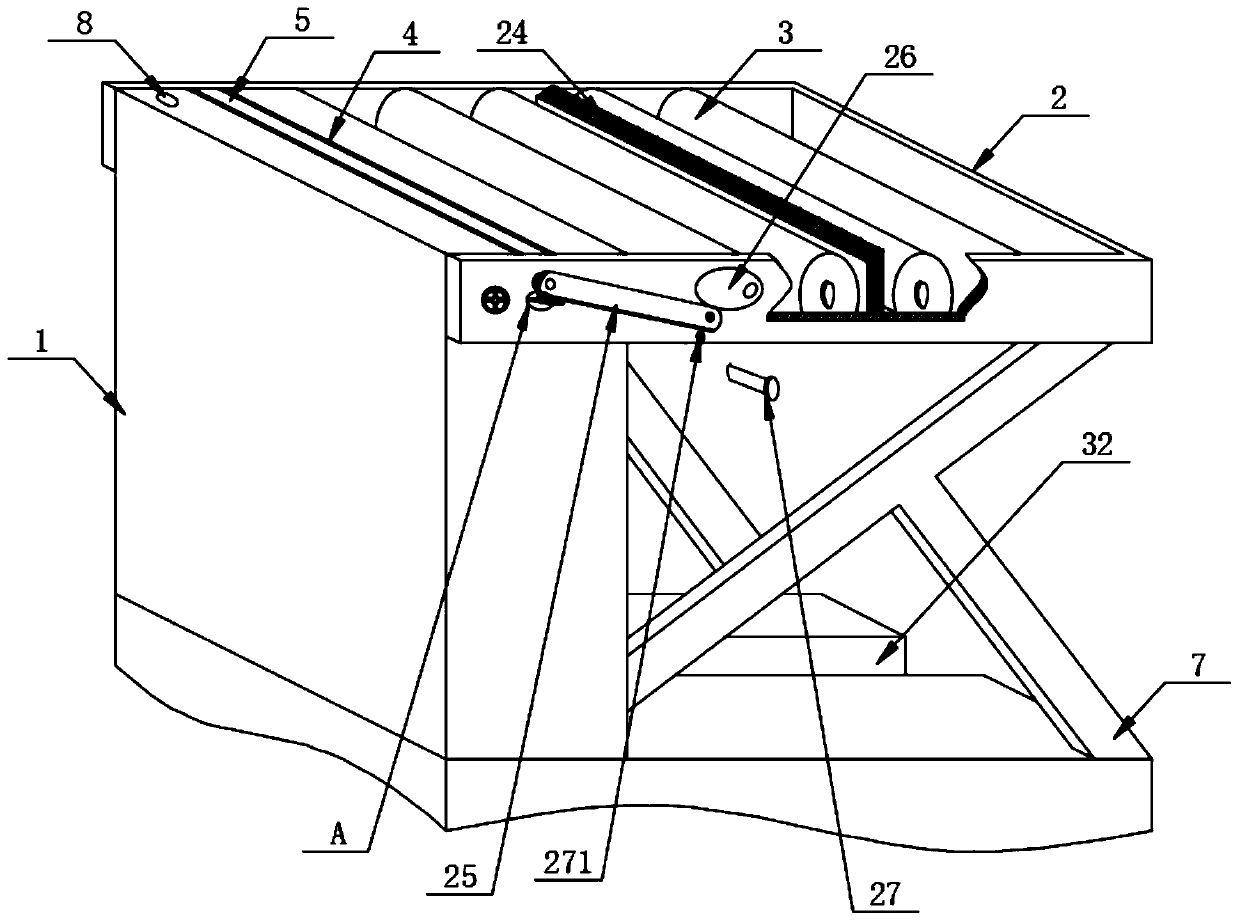

[0033] Such as Figure 3-4 and Figure 6-8 As shown, the difference from Embodiment 1 is that one side of the fixed frame 2 is provided with a linkage mechanism. , torsion spring 30, guide rod 33, seesaw 34, ejector rod 36, sleeve 37 and stay cord 38, described knob 6 front side is fixedly connected with turning plate 25, and the left side below turning plate 25 is provided with baffle plate 28, All have guide groove 31 in the middle of baffle plate 28 tops and baffle plate 28 bottom left sides, feed box 1 front side upper part is fixedly connected with fixed rod 29, is provided with torsion spring 30 on the fixed rod 29, and the two ends of torsion spring 30 and up and down The guide grooves 31 on both sides are fixedly connected, and the front end of the leftmost cylinder 3 is fixedly connected with an elliptical plate 26. The elliptical plate 26 is in contact with the flipping plate 25, and the middle of the right part of the flipping plate 25 and the left side of the fron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com