Temporary climbing frame system

A temporary, vertical rod technology, applied in the attachment of scaffolding, construction, housing structure support, etc., can solve the problems of high safety hazard, laborious assembly, etc., and achieve the effect of fast process, convenient and fast operation, and good safety protection performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

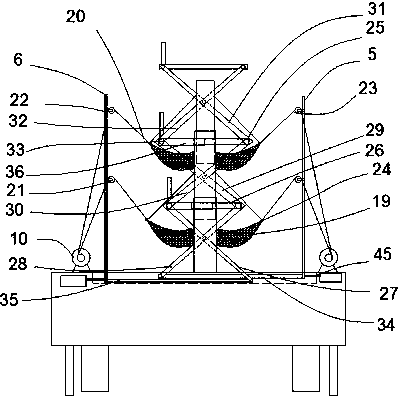

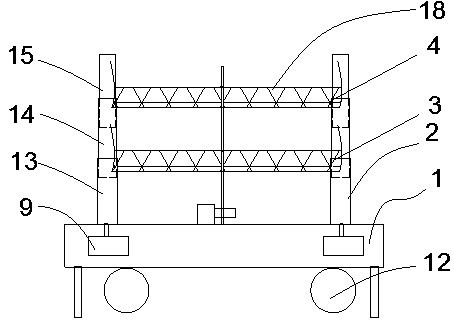

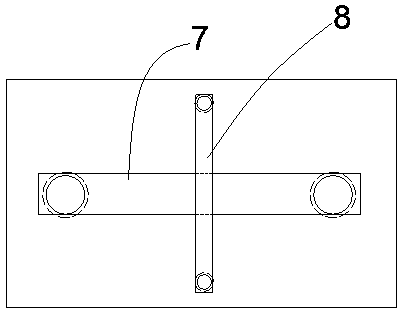

[0027] The invention discloses a temporary climbing frame system (see attached figure 1 , 2 . Two vertical bars 6, described standard base 1 is provided with transverse chute 7, has on the described transverse chute 7 the longitudinal chute 8 that is on the dividing line of transverse chute 7; Described longitudinal chute 8 is perpendicular to transverse The chute 7 is also located below the transverse chute 7; the standard base 1 is provided with four hydraulic pumps 9 and two drive motors 10; the telescopic rod 2 is movably fixed in the transverse chute 7; the The first vertical rod 5 is movably fixed in one longitudinal chute 8, and the second vertical rod 6 is movably fixed in the other longitudinal chute 8; wherein two hydraulic pumps 9 are used to drive a pair of telescopic rods 2 to raise or lower; the other two hydraulic pumps 9 connect the first vertical rod 5 and the second vertical rod 6 through two push rods 45, and then drive the first vertical rod 5 and the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com