A ball valve disassembly tooling and installation and disassembly method

A tooling and ball valve technology, applied in the direction of manufacturing tools, hand-held tools, etc., can solve the problems of labor, damage, and the installation tooling of the ball valve cannot be tightened and stretched at the same time, so as to achieve the effect of saving manpower and reliable process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a ball valve disassembly tooling, such as Figure 4 As shown, it includes: a tensioning device for tightening the fixture 3 and a stretching device for stretching the spring seat 5, and the tensioning device and the stretching device cooperate to realize the spring seat 5 and the spring seat 5. opposite movement of the holder 3,

[0046] The tensioning device includes a rotating device 30, a screw 12 connected to the rotating device 30 and driven to rotate by the rotating device 30, and a moving part 11 that cooperates with the screw 12 through a first matching structure. The moving part 11 is connected with the fixer 3 through the second matching structure, and the moving part 11 drives the fixer 3 away from the spring seat 5 under the drive of the rotation of the screw 12;

[0047] The spreading device includes a power device 60 , a push rod 15 connected to the power device 60 and driven by the power device 60 , and an abutting portion 14 , o...

Embodiment 2

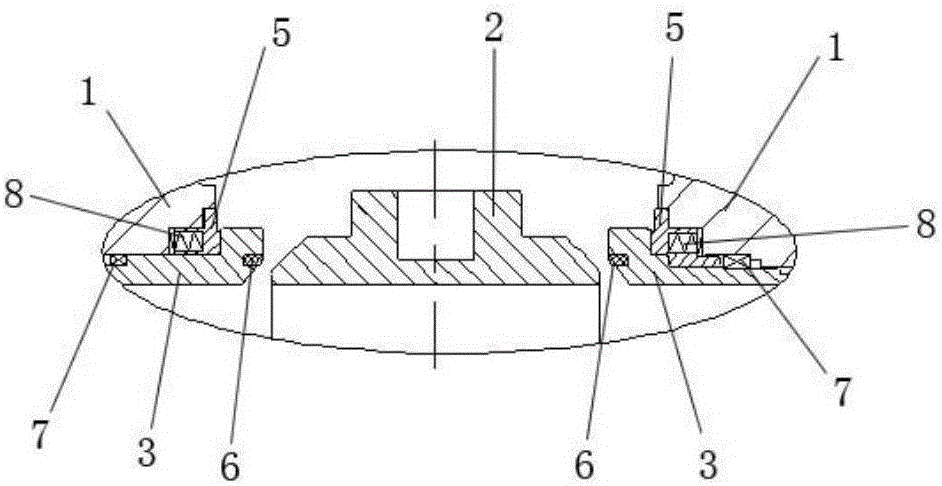

[0056] This embodiment provides a method for installing a top-mounted ball valve using the disassembly tooling described in Embodiment 1, which includes the following steps:

[0057] S1: Put the first seal 7, spring 8, spring seat 5, retainer 3, second seal 6, and ball 2 into the valve, according to figure 2 The state shown is installed;

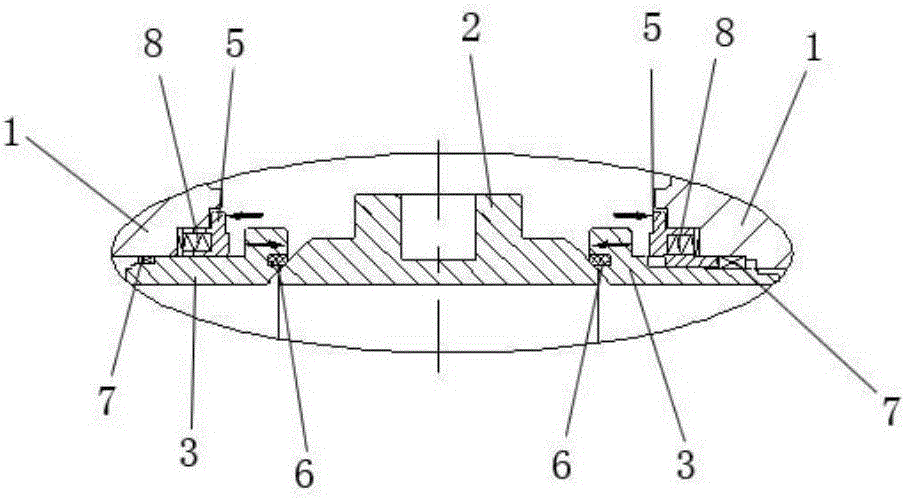

[0058] S2: Fix the moving part 11 on the holder 3 through the second matching structure, such as Figure 5 As shown, the screw rod 12 and the rotating device 30 are fixed through the third matching structure, and the abutting portion 14 is aligned with the spring seat 5, and the tensioning device fixer 3 is fixedly connected, such as connected by screws, and stretched apart. The device abuts against the spring seat 5 to complete the installation of disassembly tooling; it should be pointed out that at this time, the tensioning device and the spreading device can be placed at a certain angle along the circular inner cavity of the valve body...

Embodiment 3

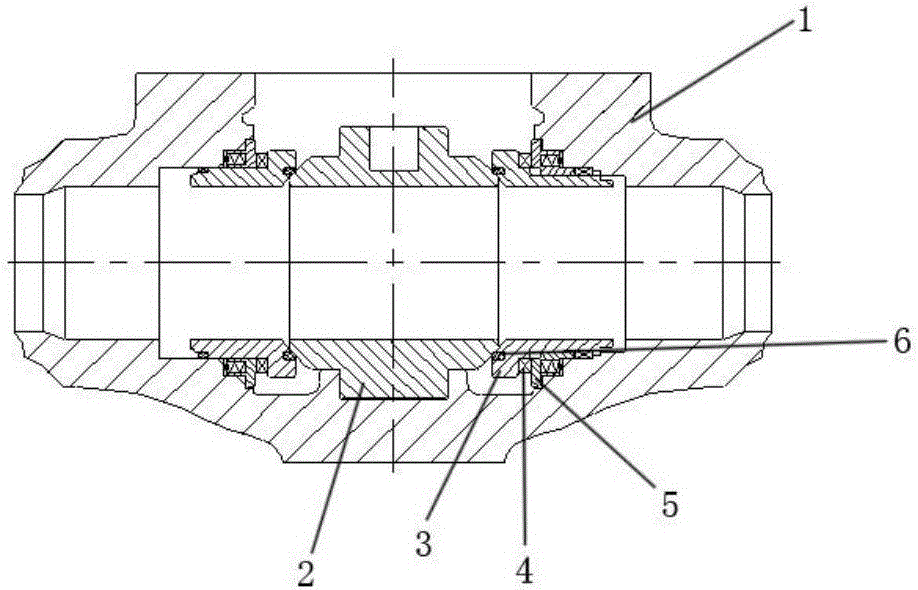

[0063] This embodiment provides a method for disassembling the top-mounted ball valve using the disassembly tooling described in Embodiment 1. The installed top-mounted ball valve is as follows: figure 1 shown, including the following steps:

[0064] S1: Fix the moving part 11 on the holder 3 through the second matching structure, such as Figure 5 As shown, the screw rod 12 and the rotating device 30 are fixed through the third matching structure, and the abutting portion 14 is aligned with the spring seat 5, and the tensioning device is fixedly connected with the fixer 3, such as by screw connection, supporting The opening device abuts against the spring seat 5 to complete the installation of the disassembly tooling;

[0065]S2: Start the rotating device 30 to drive the screw 12 to rotate, and drive the moving part 11 and the fixer 3 fixed with the moving part 11 away from the spring seat 5; at the same time start the power device 60 to drive the abutting part 14 Connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com