Patents

Literature

52results about How to "Achieve suppression" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

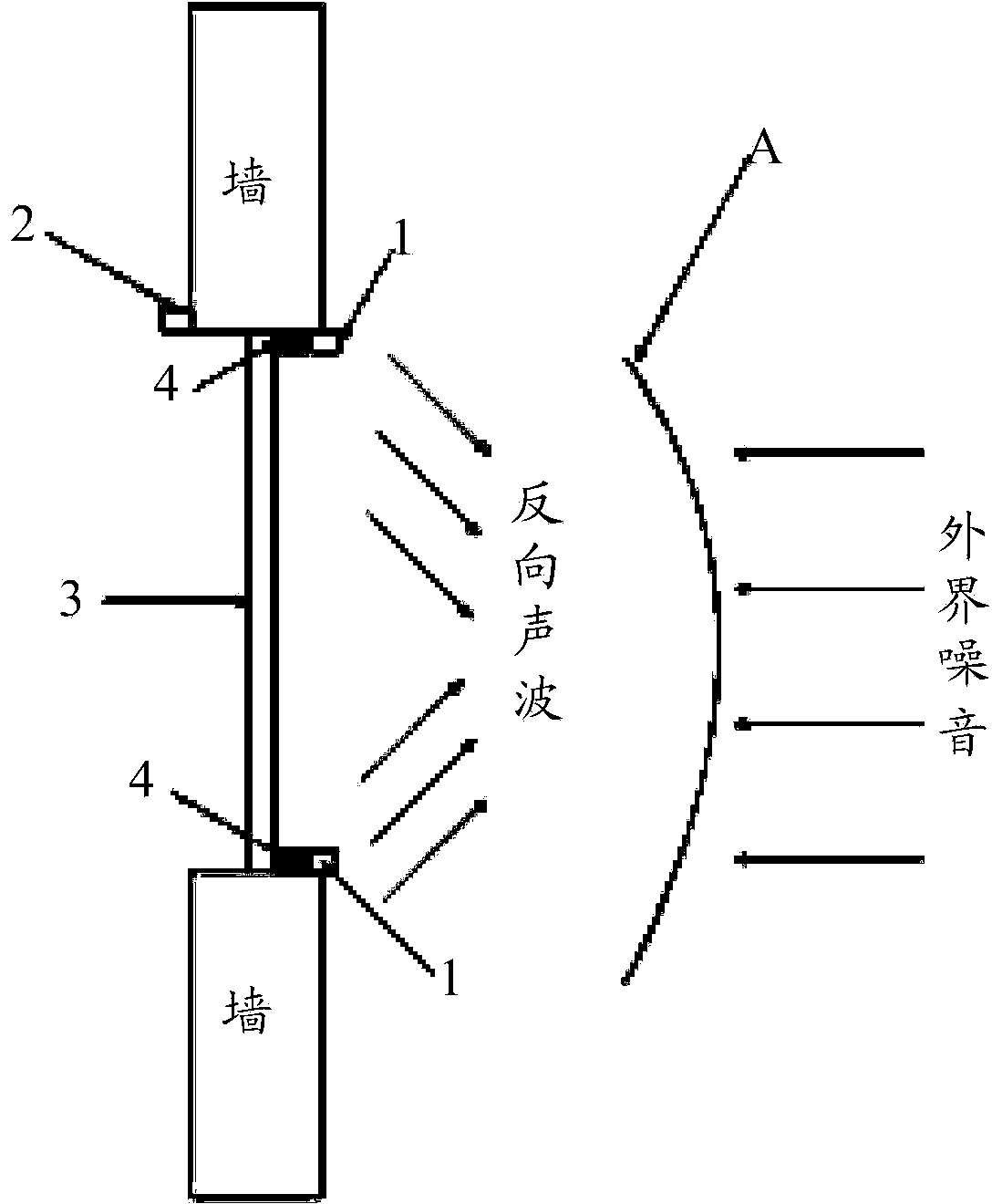

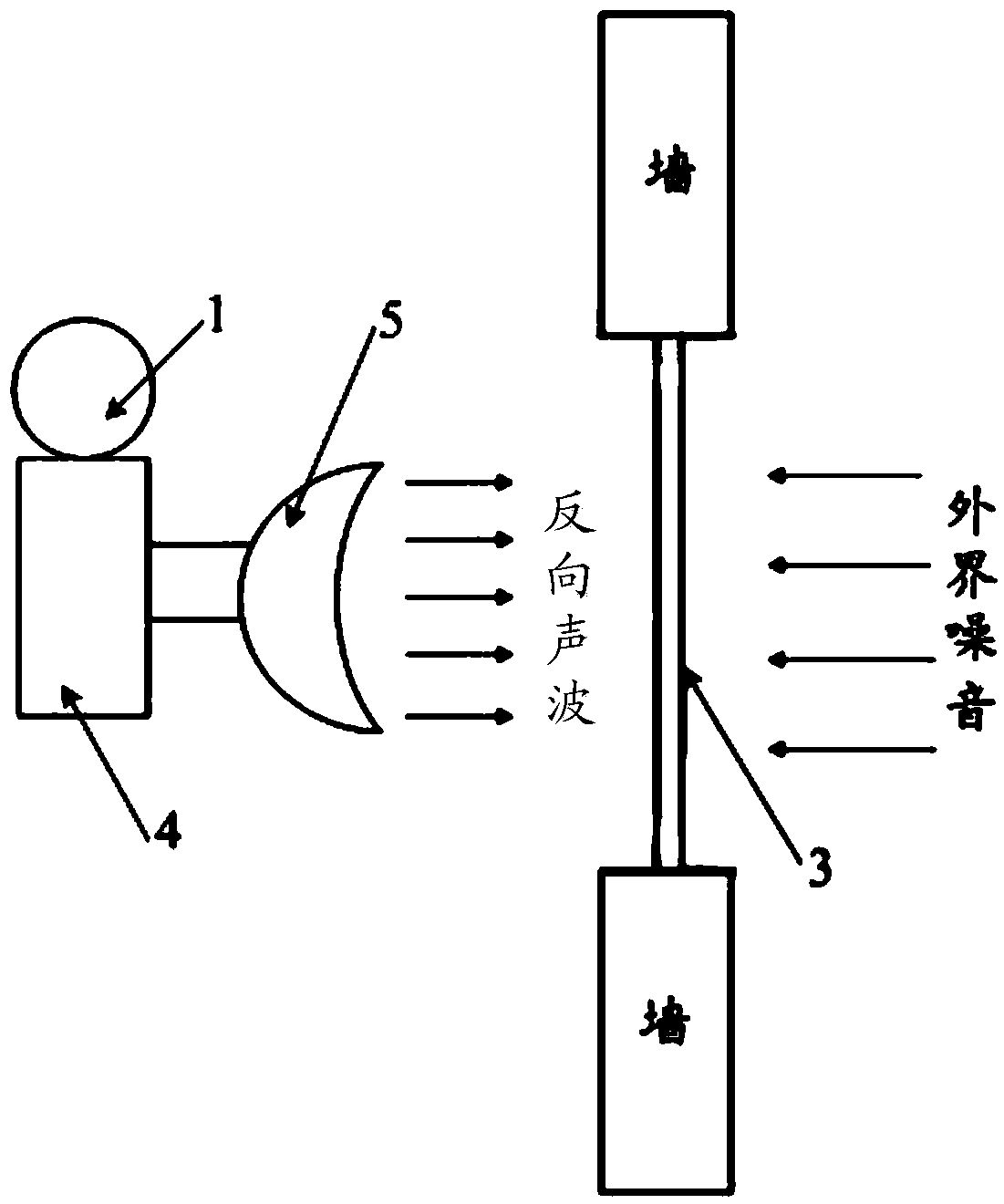

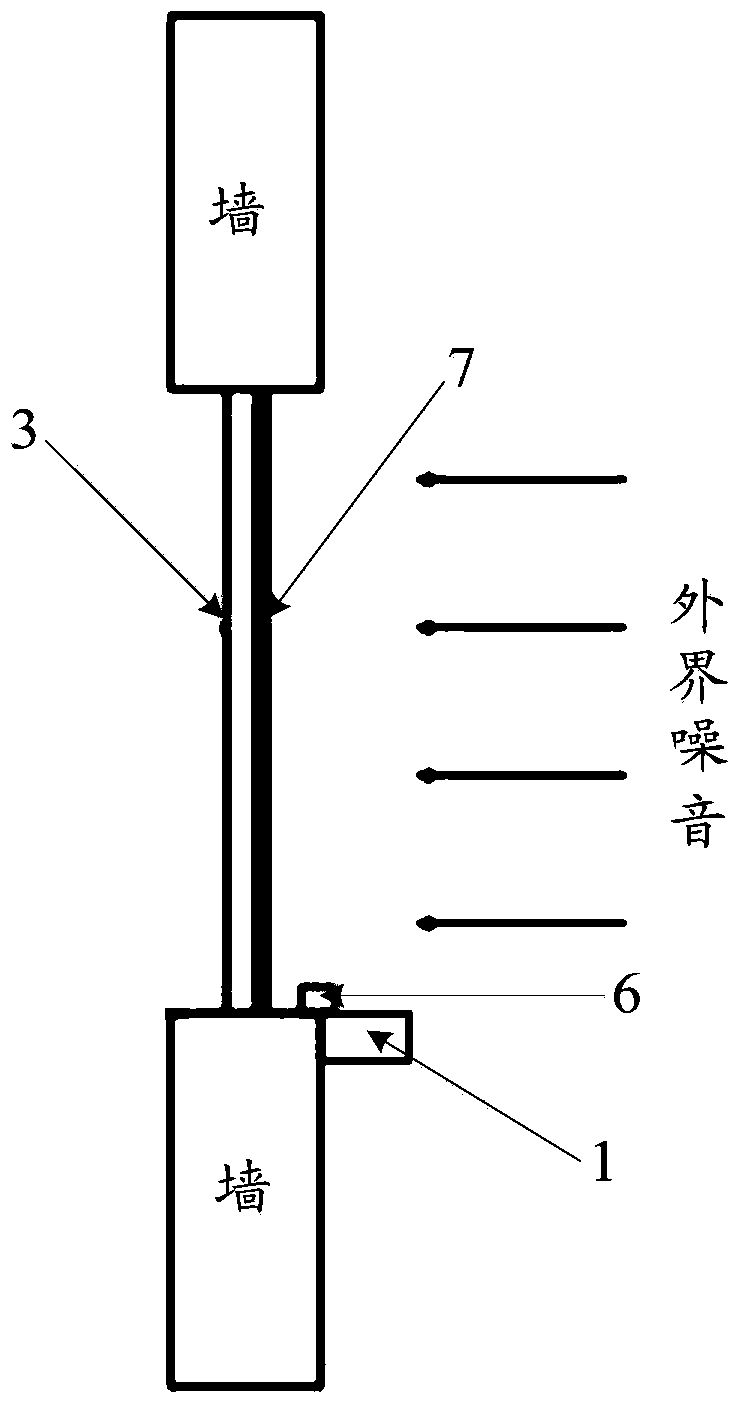

Indoor noise elimination device

InactiveCN104064176AAvoid enteringImprove elimination effectSound producing devicesTransmission channelSound wave

The invention provides an indoor noise elimination device. The indoor noise elimination device comprises a noise collector, a backward wave frequency transmitter and a controller. The noise collector is used for measuring the waveform and frequency of external noise in a preset direction and transmitting external noise collection signals. The backward wave frequency transmitter is used for attenuating or offsetting noise energy and can emit backward sound waves with the same frequency as the external noise in the direction opposite to the direction of the external noise, or can form a wave attenuating energy field region on a noise transmission channel, wherein the wave attenuating energy field region can prevent the external noise from entering a room. The controller is used for receiving the external noise collection signals and controlling the working status of the backward wave frequency transmitter according to the external noise waveform and frequency corresponding to the external noise collection signals. According to the indoor noise elimination device, the noise collector is used for measuring the external noise, and the controller is used for controlling the backward wave frequency transmitter to eliminate the noise, so that active elimination of the noise is achieved, the effect of noise elimination is improved, and the noise pollution is reduced.

Owner:曾斌

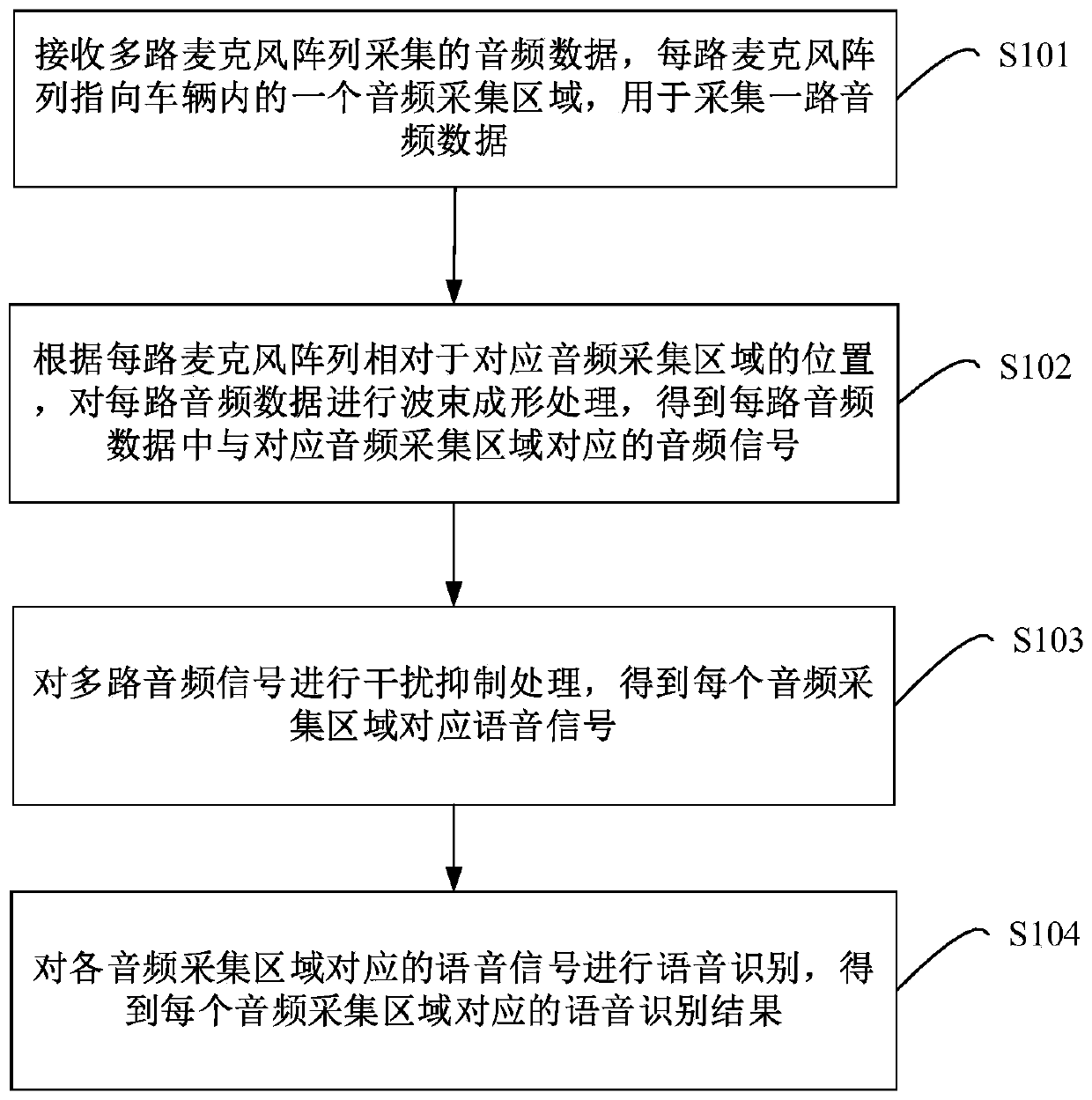

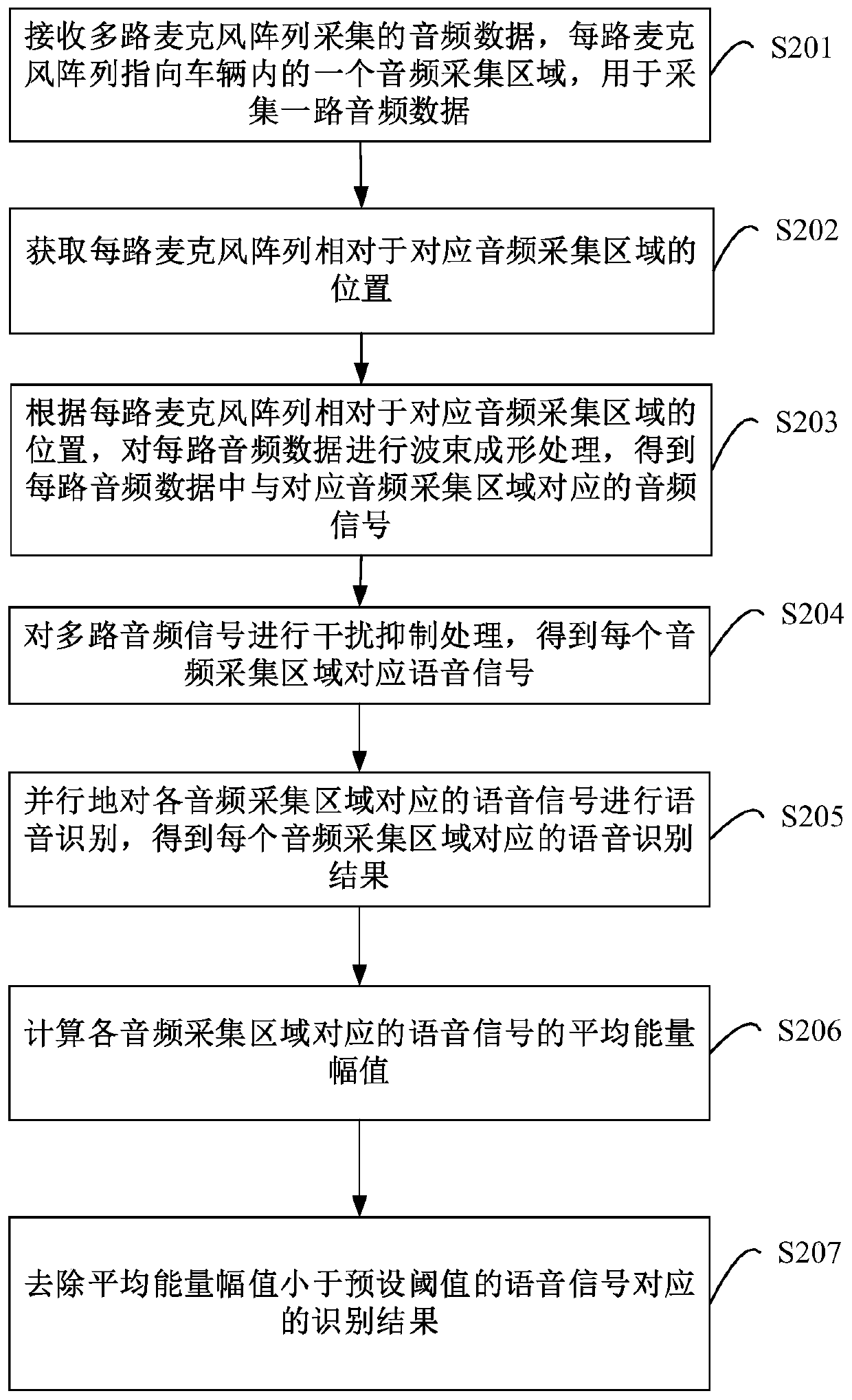

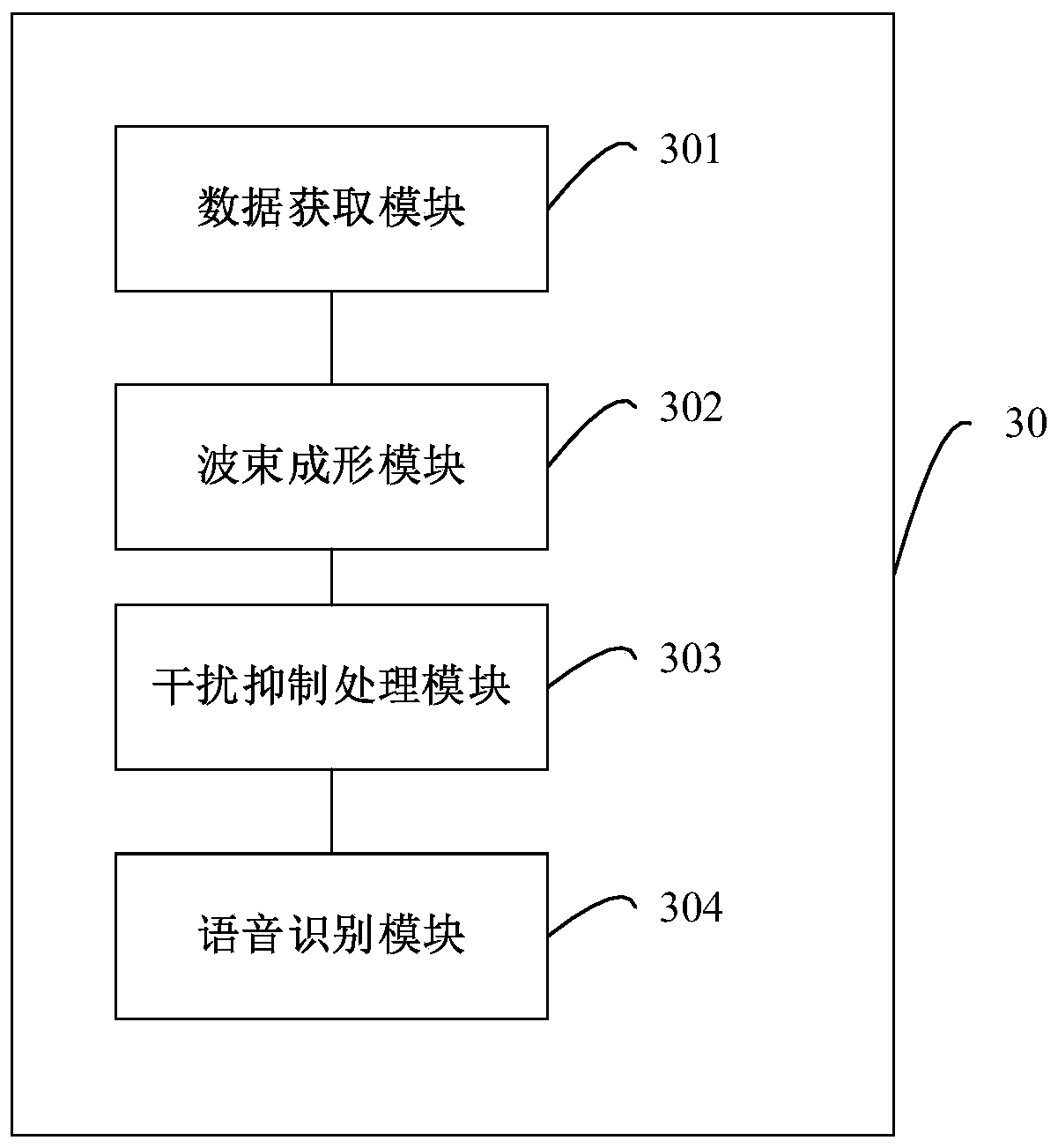

Method, device and equipment for identifying multiple paths of voice as well as readable storage medium

PendingCN109920405AAchieve suppressionSuppress mutual interferenceSpeech recognitionIdentification rateSpeech identification

The embodiment of the invention provides a method, a device and equipment for identifying multiple paths of voice as well as a readable storage medium. The method comprises the following steps: receiving audio data collected by multiple paths of microphone arrays, carrying out wave beam formation treatment on each path of audio data to obtain audio signals corresponding to audio collection areas in each path of audio data, and weakening audio signals in other directions of the path of audio data; carrying out interference inhibition treatment on multiple paths of audio signals to obtain voicesignals corresponding to each audio collection area, reducing interference of noise signals of other audio collection areas on the path of voice signals, carrying out voice identification of the voicesignals to obtain a voice identification result corresponding to each audio collection area, and improving identification rate of the voice identification; inhibiting mutual interference among the multiple paths of voice signals when multiple people talk at the same time to obtain a voice identification result corresponding to each audio collection position, and improving the efficiency and accuracy of voice identification.

Owner:APOLLO INTELLIGENT CONNECTIVITY (BEIJING) TECH CO LTD

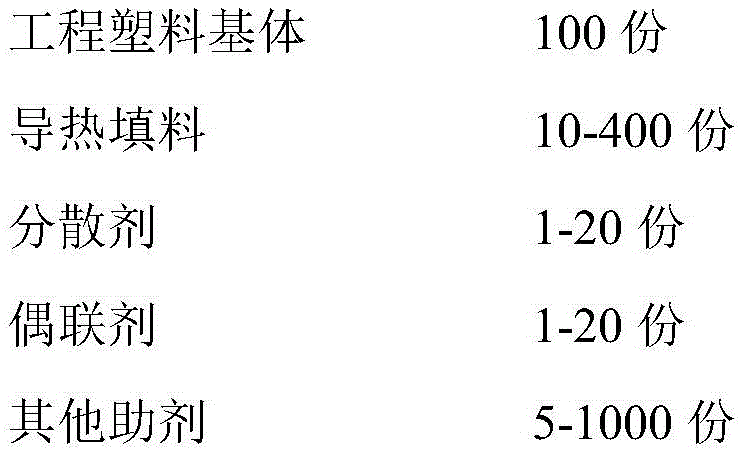

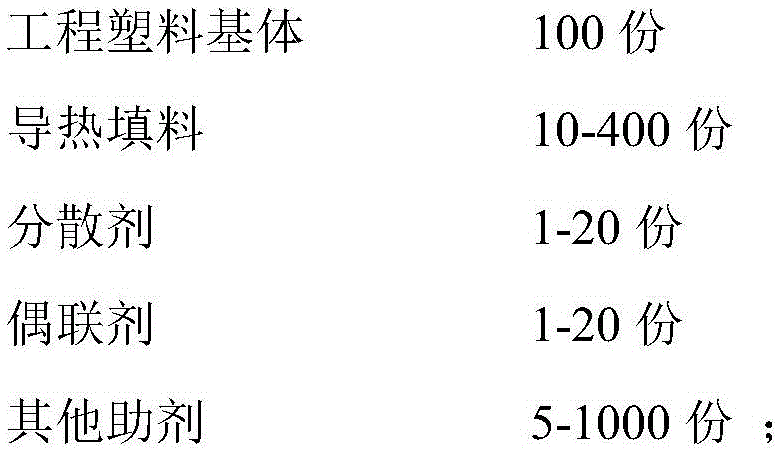

High-thermal-conductivity engineering plastic and preparation method thereof

The invention discloses high-thermal-conductivity engineering plastic and a preparation method thereof. The high-thermal-conductivity engineering plastic is prepared from raw materials as follows: in parts by mass, 100 parts of an engineering plastic matrix, 10-400 parts of thermal-conductive filler, 1-20 parts of a dispersant, 1-20 parts of a coupling agent and 5-1000 parts of other additives. The thermal-conductive filler of the engineering plastic evenly disperses in a plastic matrix solution, and is smashed after film formation and drying or spray drying to obtain granular materials. The engineering plastic prepared with the preparation method has relatively high thermal conductivity and good mechanical and machining performance.

Owner:ANHUI UNIVERSITY

Pharmaceutical composition treating ringworm of the nails, extremity tinea and method of manufacturing the same

InactiveCN101108162AStrong bactericidal anti-relapse effectStrong penetrationHydroxy compound active ingredientsAerosol deliveryUreaSource area

The invention discloses a medicine combination for curing onychomycosis and tinea manuum and pedis, which comprises an ointment and a liquid medicine that are prepared and applied independently. Wherein, the ointment comprises the following components with relevant weight shares: Vaseline of 50-70 shares, urea of 30-50 shares and resorcinol of 25-30 shares; the liquid medicine comprises the following components with relevant weight shares: distilled water of 80 to 120 shares and glacial acetic acid of 20 to 40 shares. The ointment in the invention has outstanding effects of eliminating true fungus and softening the affected nail; the liquid medicine has the effects of sterilizing and preventing the relapse, ensuring strong penetration and realizing double effects for curing and promoting the growth of new nail. With the coordination of the two medicines, the fungus can be eliminated and the affected disease source area can be completely sterilized, thus thoroughly curing the onychomycosis, realizing outstanding treatment effect for tinea manuum and pedis. Besides, in clinical medication, the invention results in no adverse reaction and ensures reliable treatment effect.

Owner:郭华岩

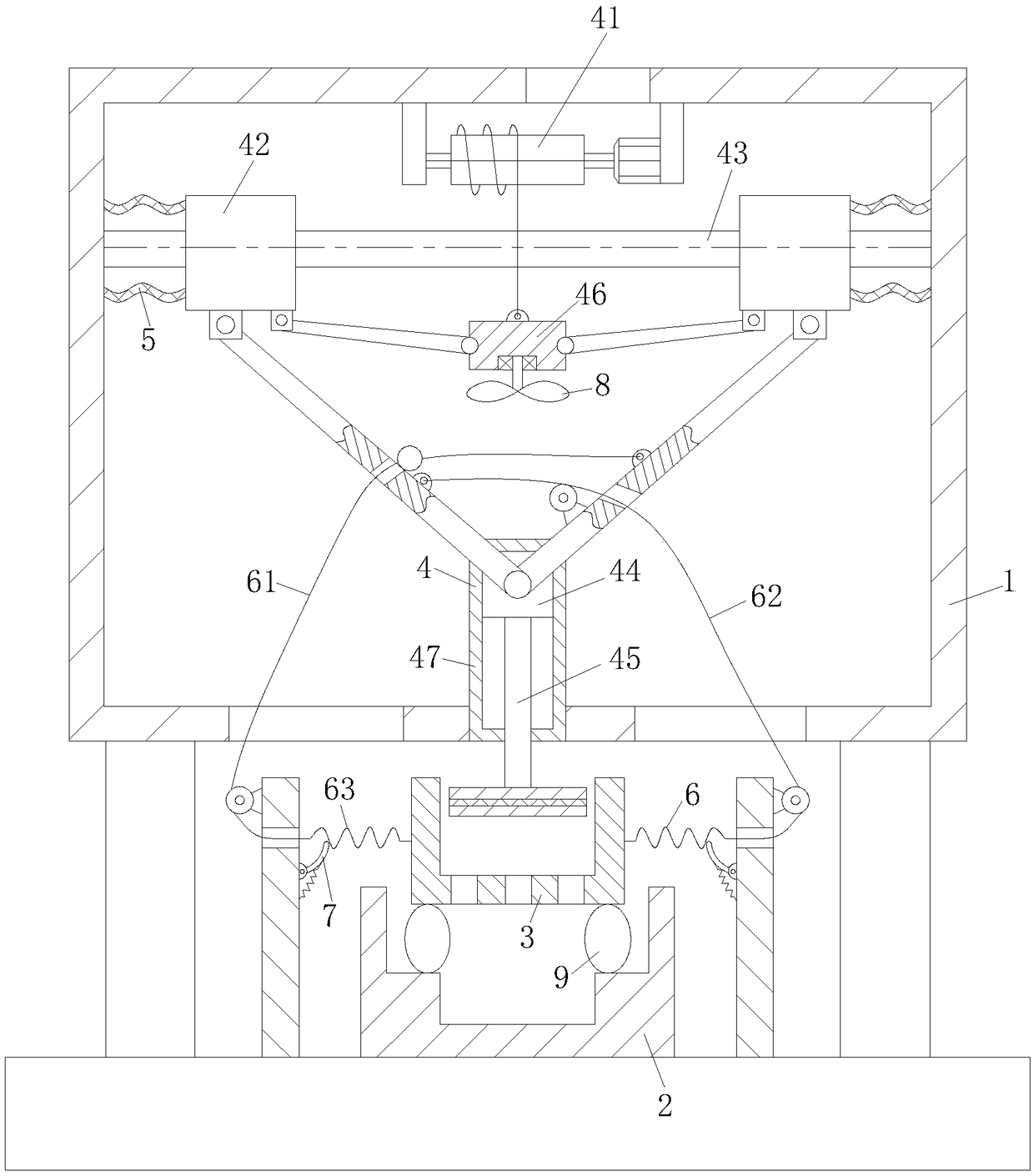

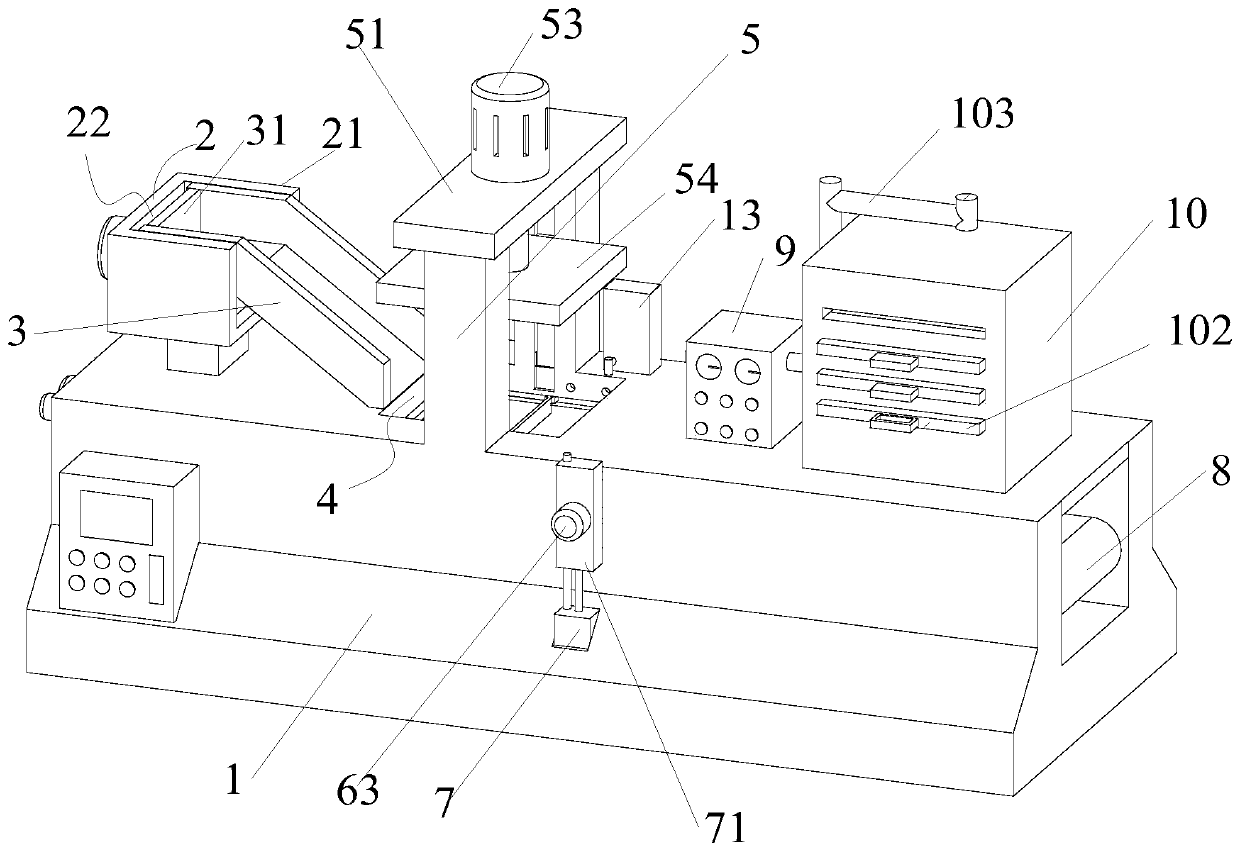

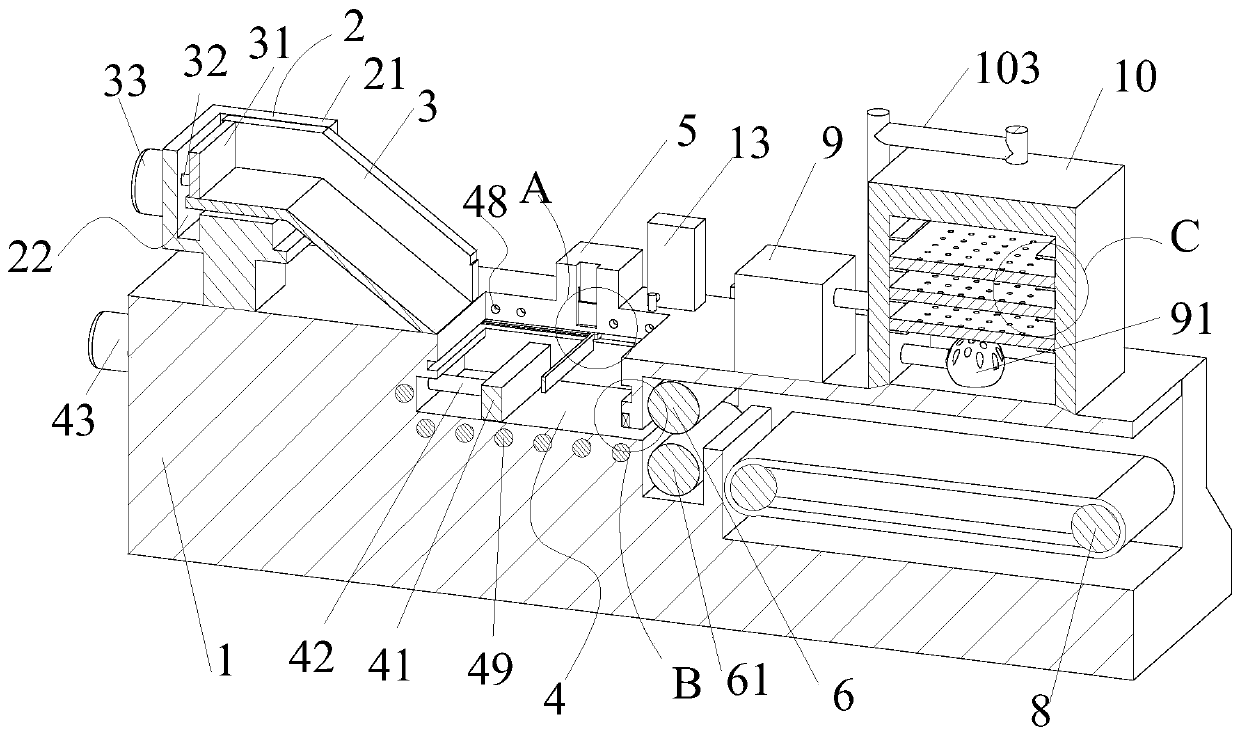

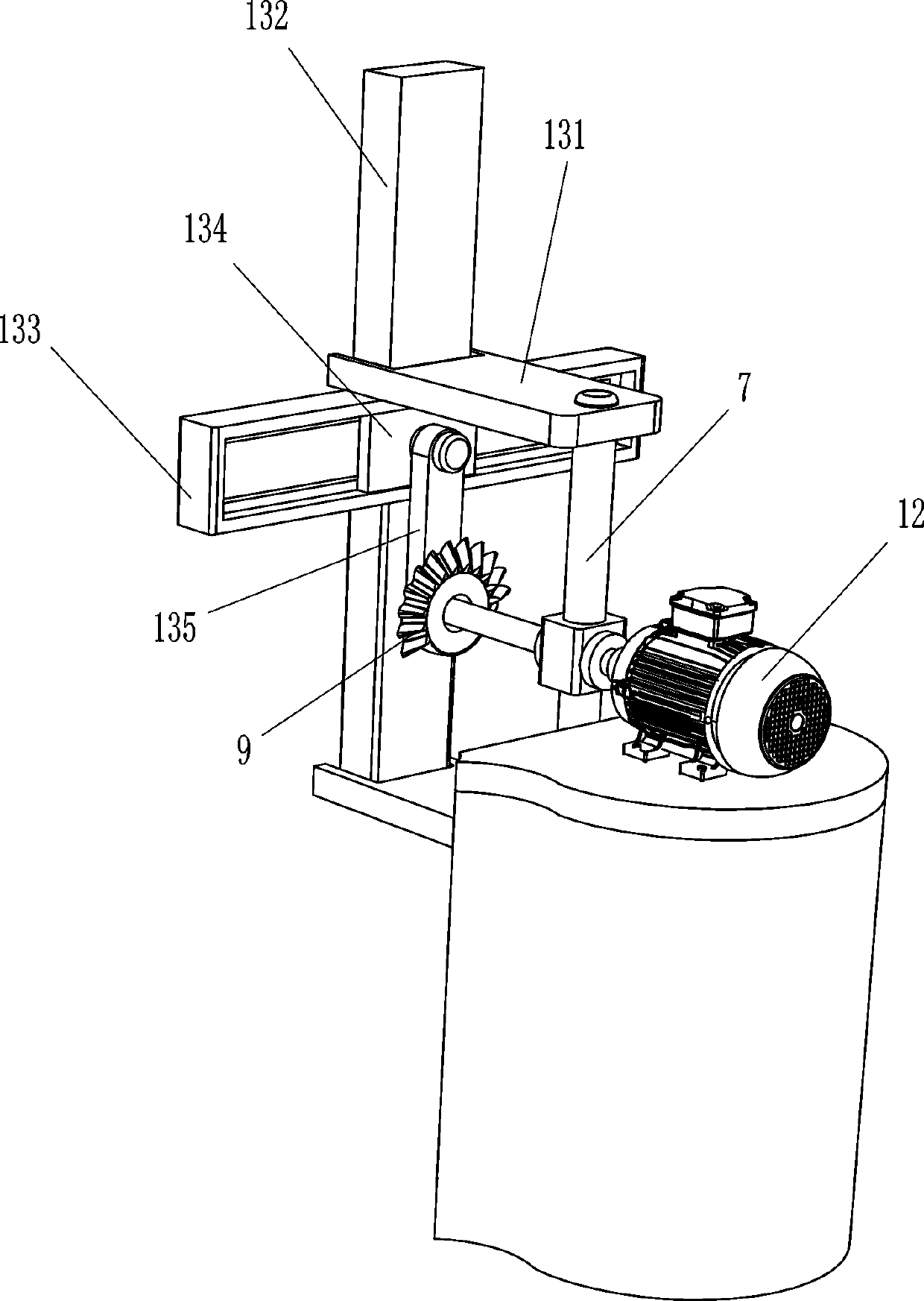

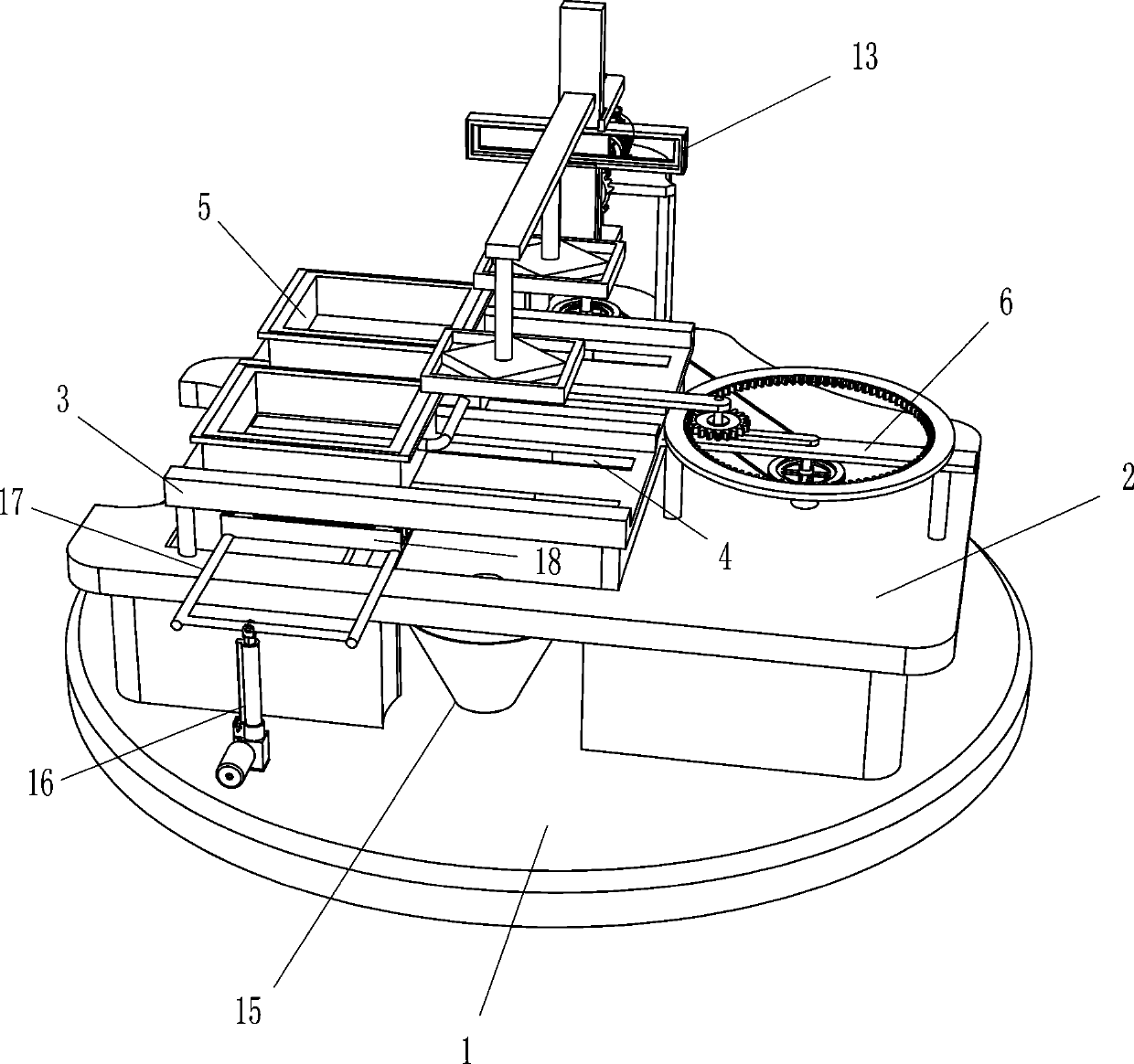

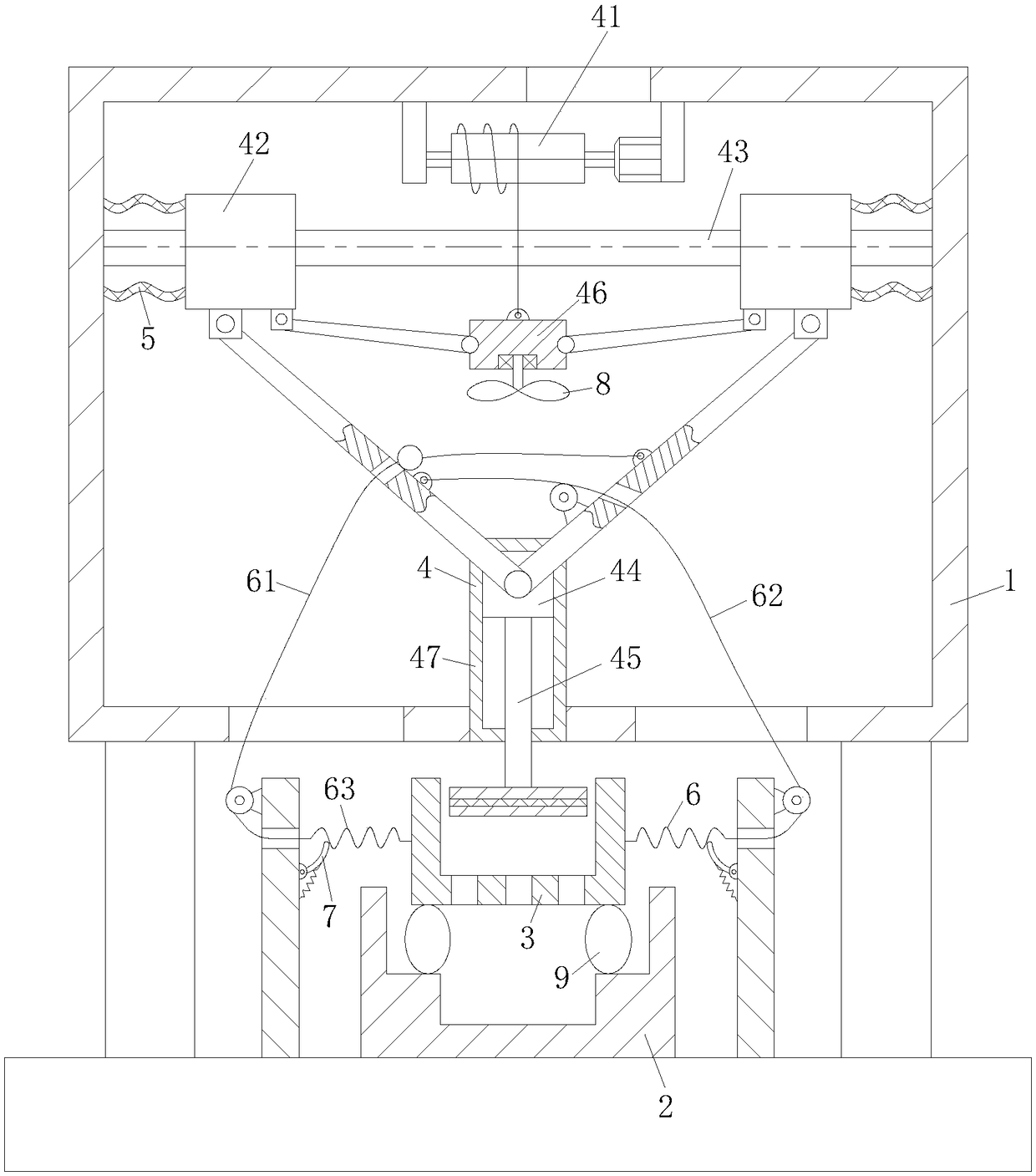

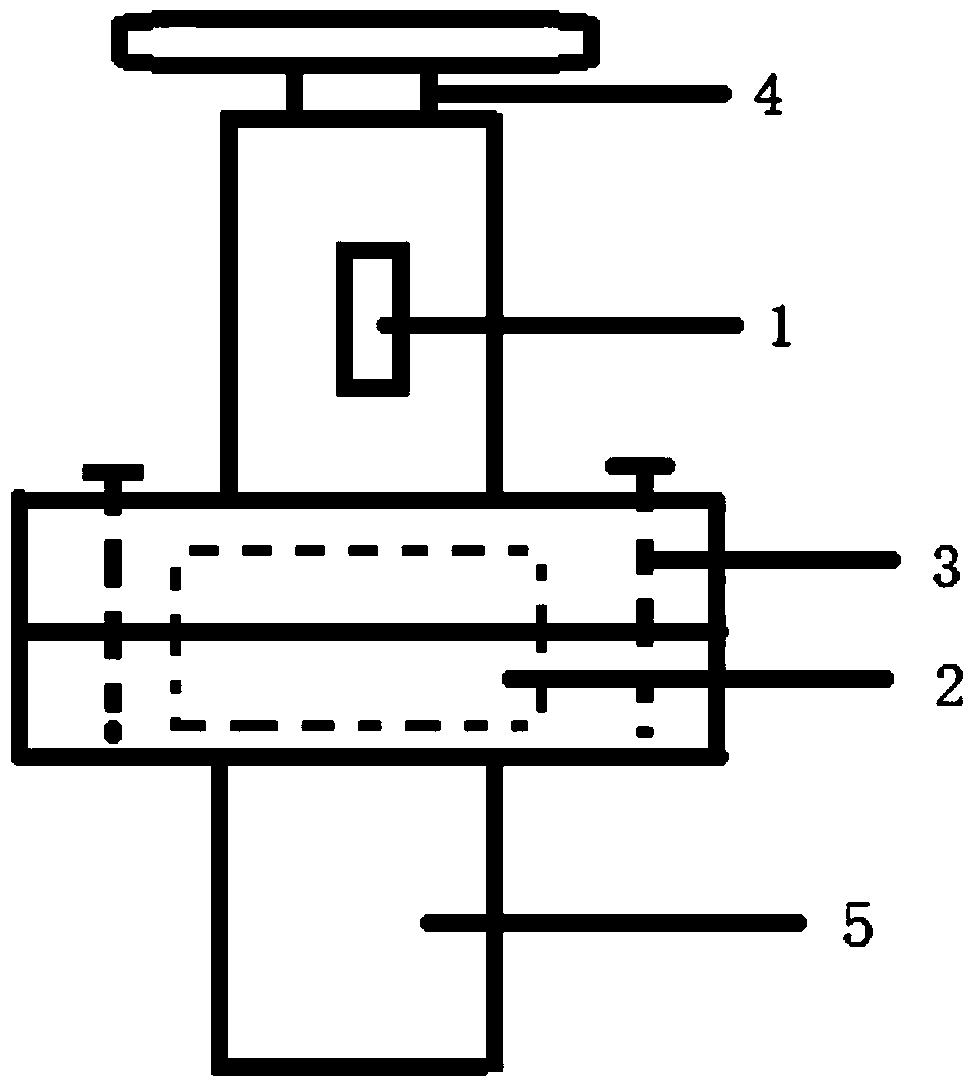

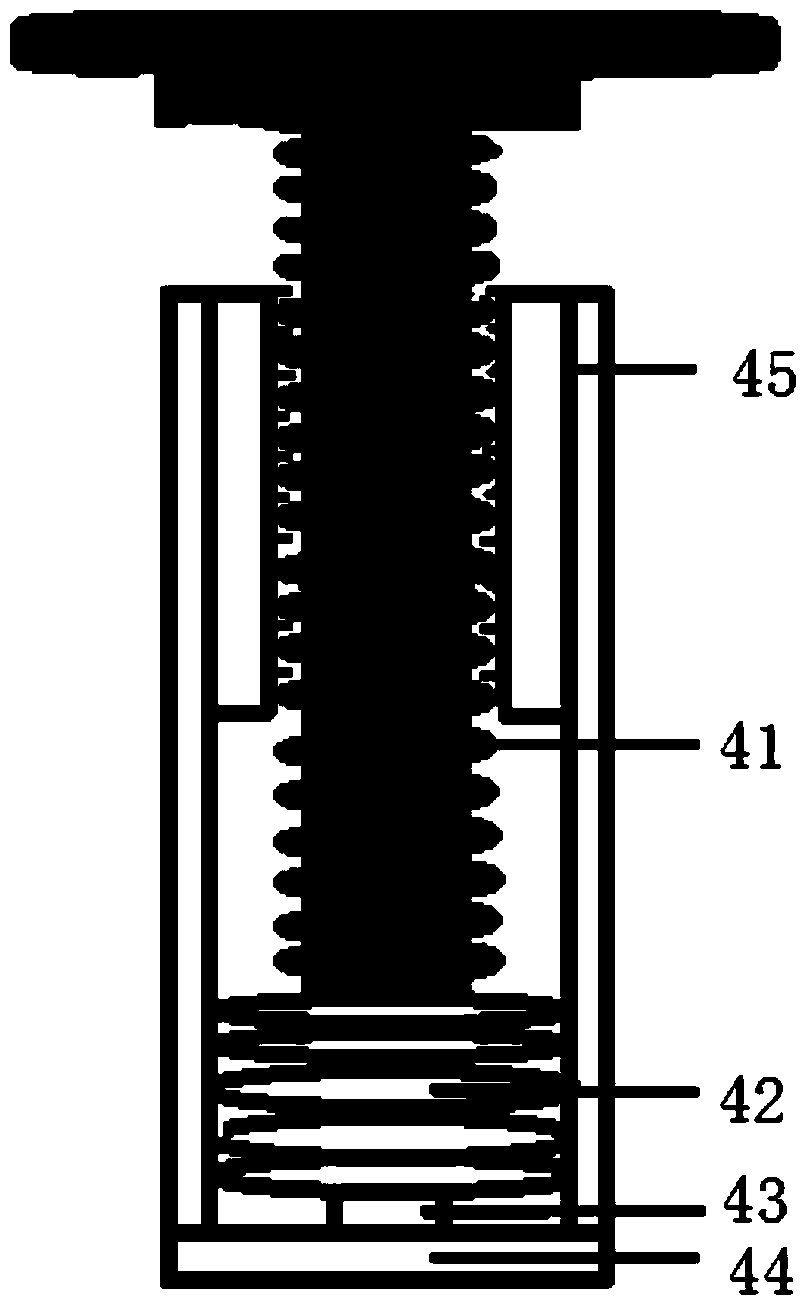

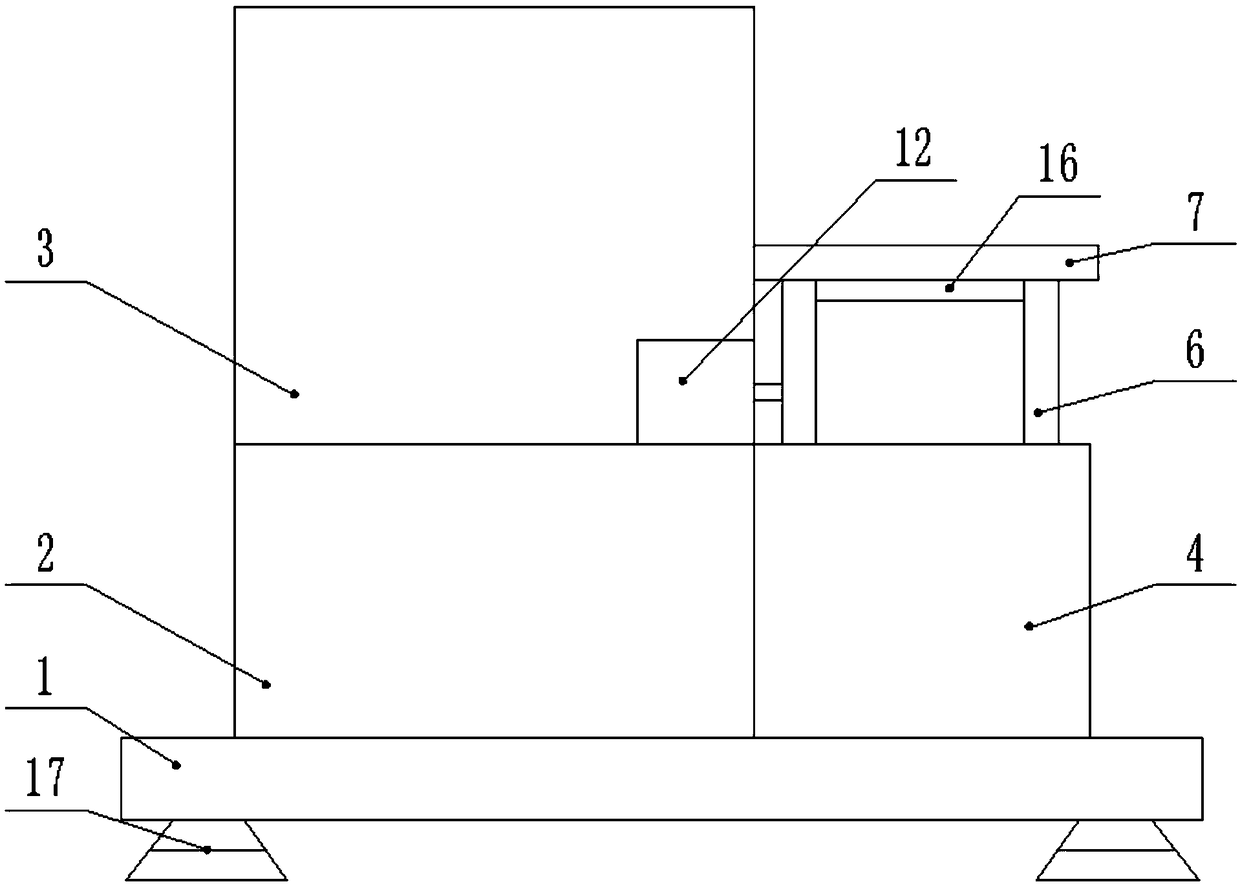

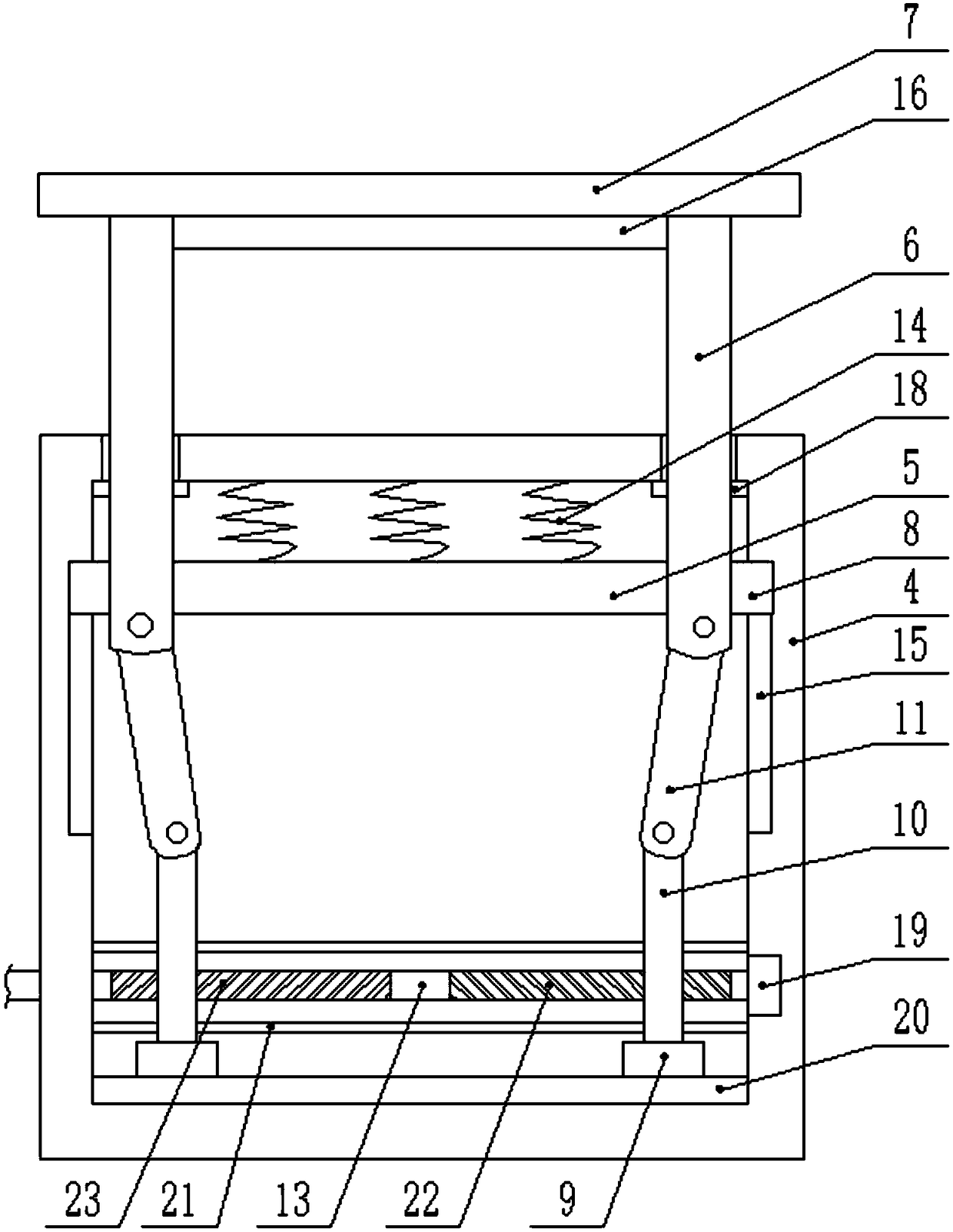

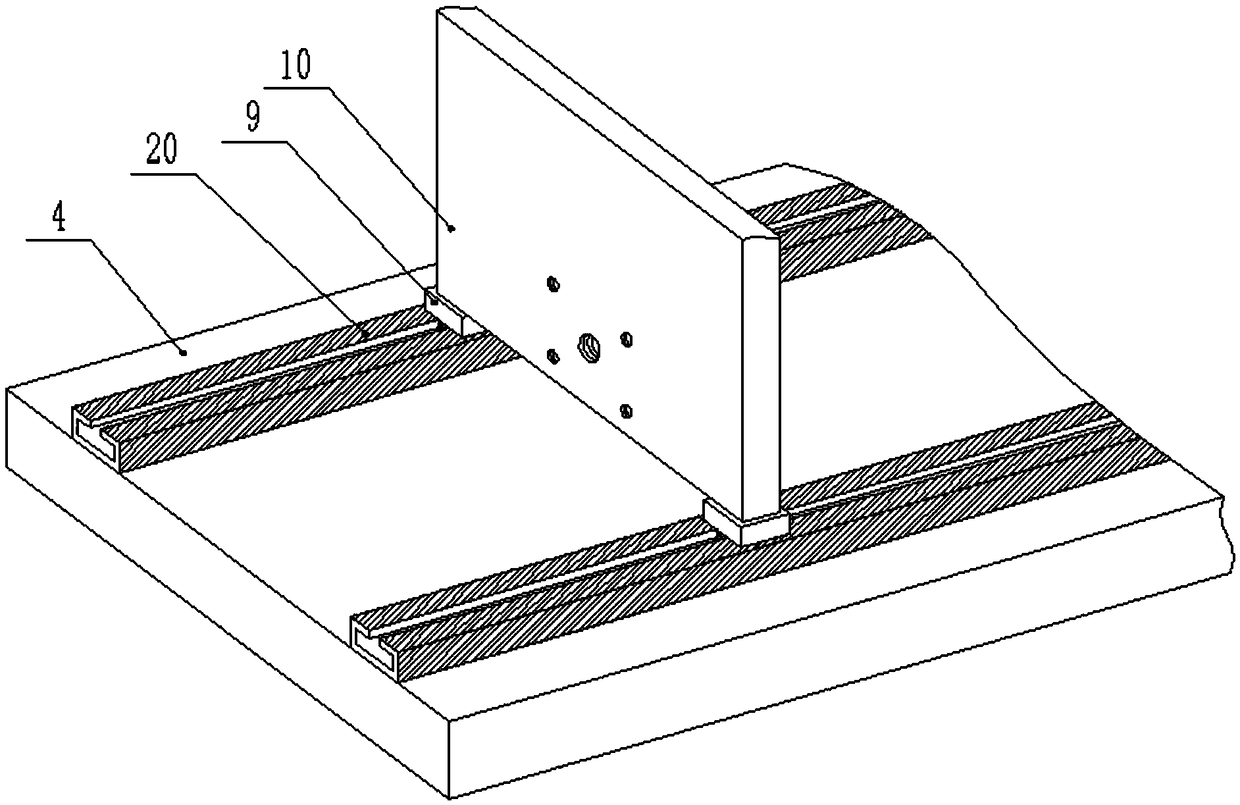

Energy-saving fertilizer granulator

PendingCN109173930AAchieve suppressionExtended service lifeDrying gas arrangementsGranulation by material expressionEngineeringEnergy conservation

The invention belongs to the field of chemical fertilizer production equipment, and in particular relates to an energy-saving fertilizer granulator, which comprises a work box, a base, a controller and a pillar. The controller controls the automatic operation of the granulator. An extrusion module is disposed in the work box. The extrusion module comprises a motor, a rotating roller, No. 1 slidingblocks, a sliding shaft, a No. 2 sliding block, a pressing rod, a balancing weight and a guide rail, wherein the sliding shaft is horizontally mounted on the inner roof of the work box; two No.1 sliding blocks are slidably connected to the sliding shaft; the No. 2 sliding blocks are both hinged to the No.2 sliding block through a connecting rod; the No.2 sliding block is slidably installed in theguide rail, which is fixedly installed on the bottom of the work box; and the balancing weight is hinged between the two No.1 sliding blocks through two struts. According to the invention, a materialis extruded through the extrusion module, and the chemical fertilizer granules are dried by using heat generated by the motor. Thereby, energy is saved, and production efficiency of the chemical fertilizer granules is improved.

Owner:张振洋

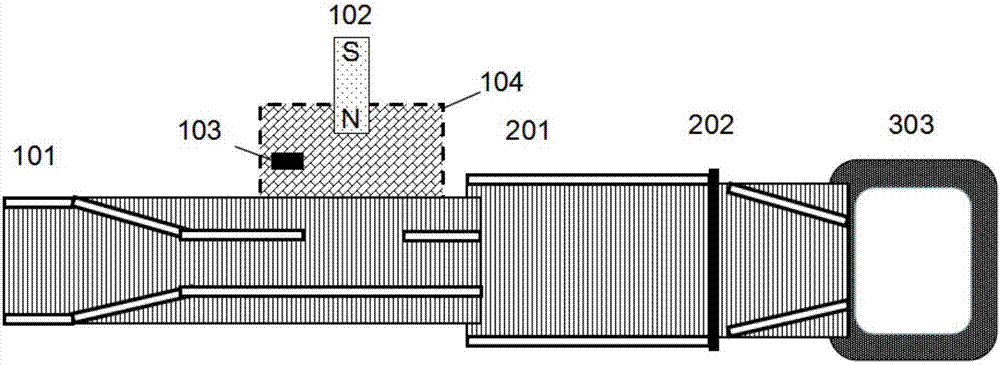

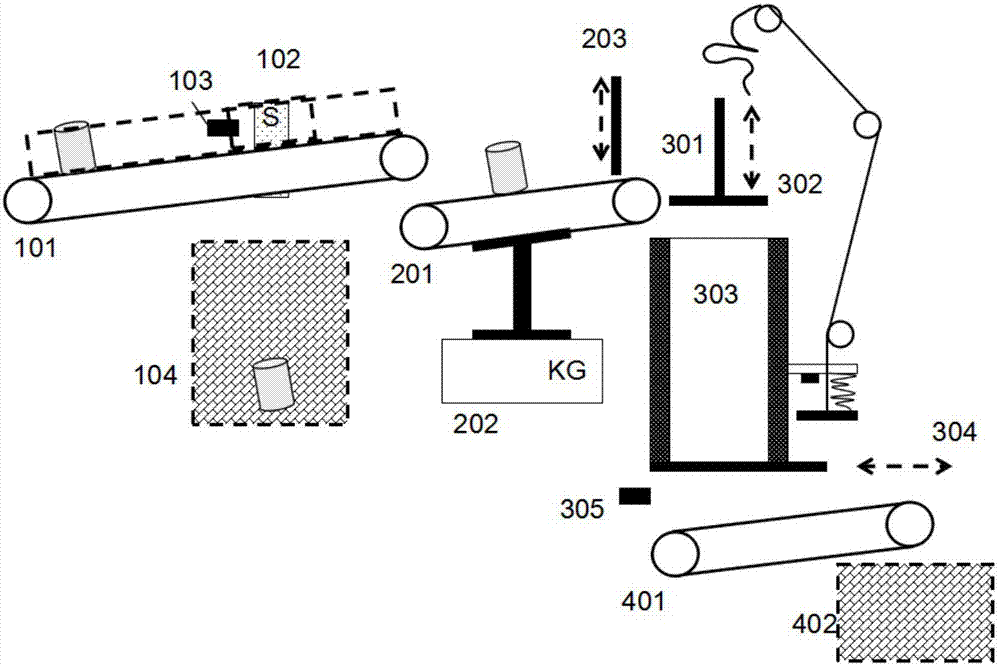

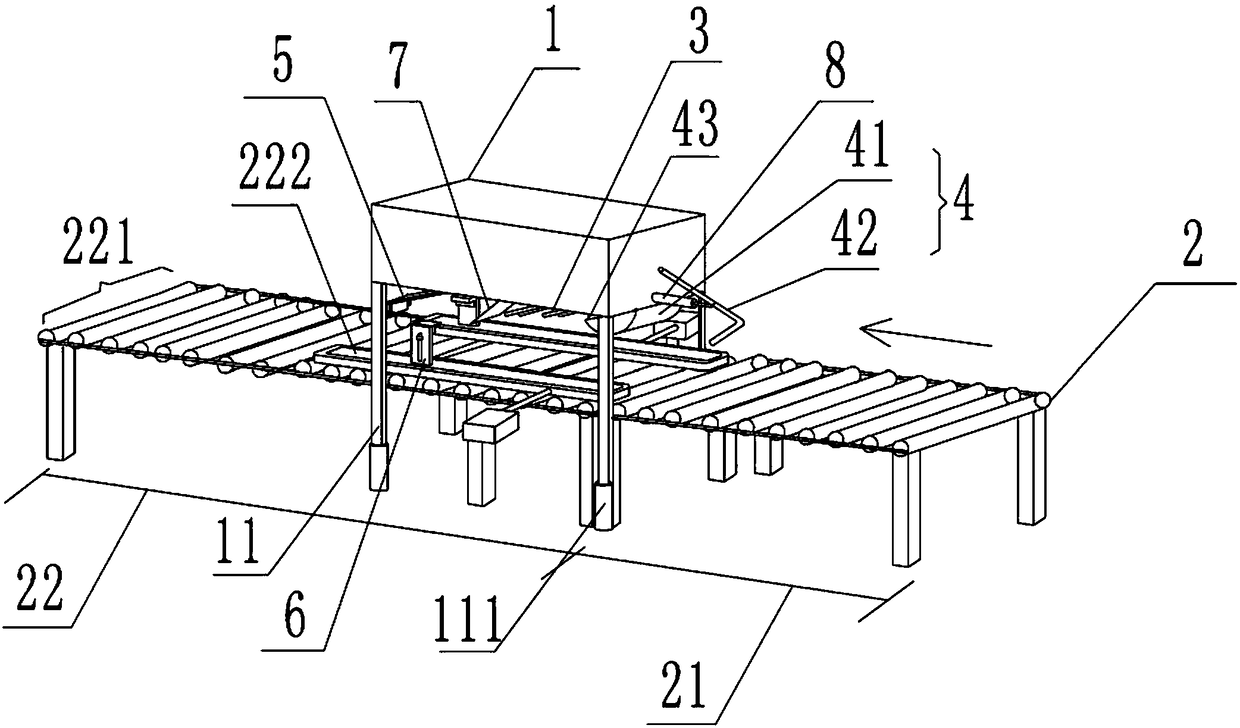

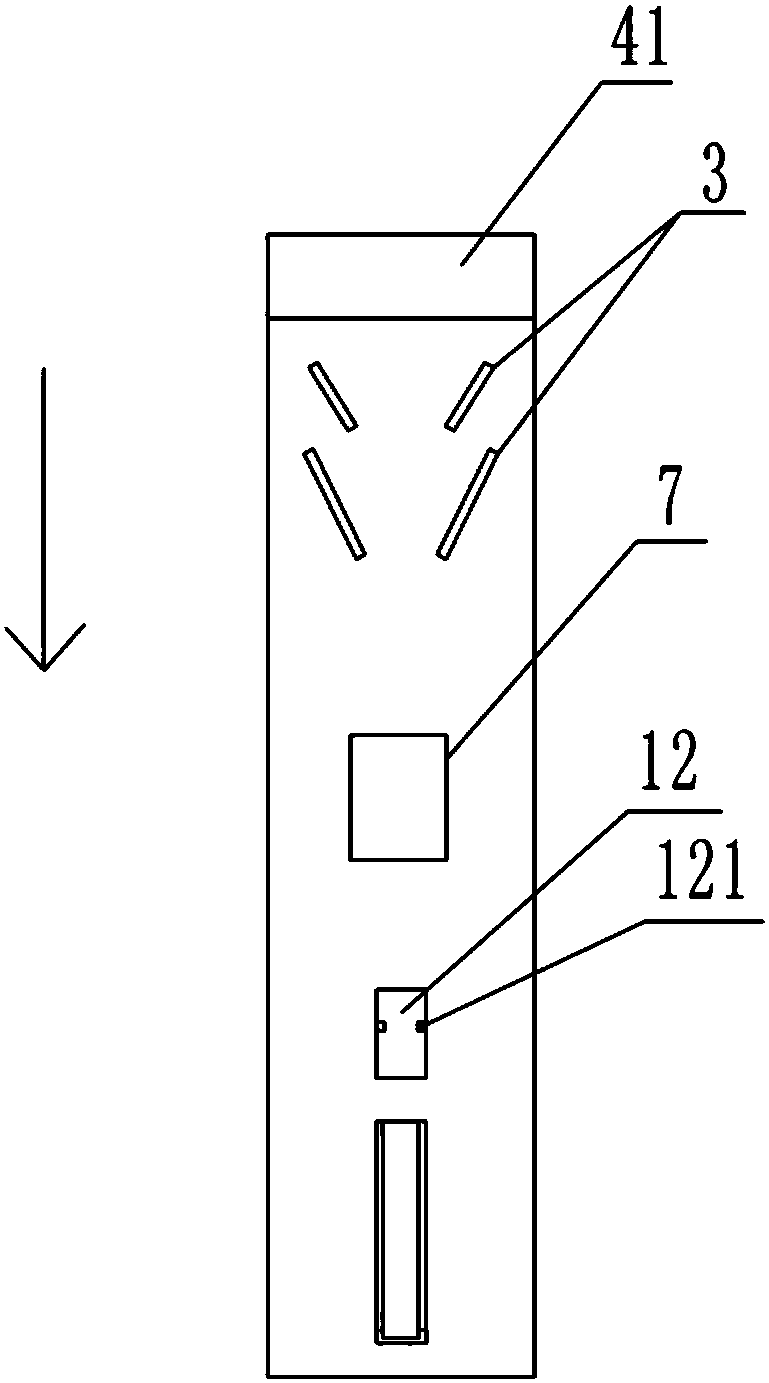

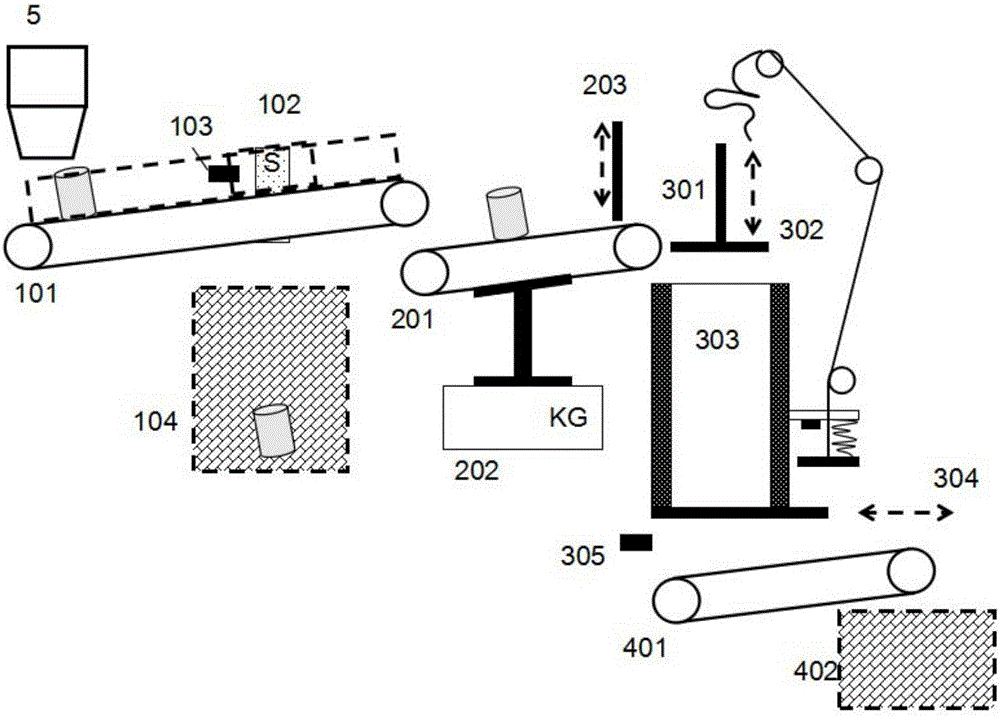

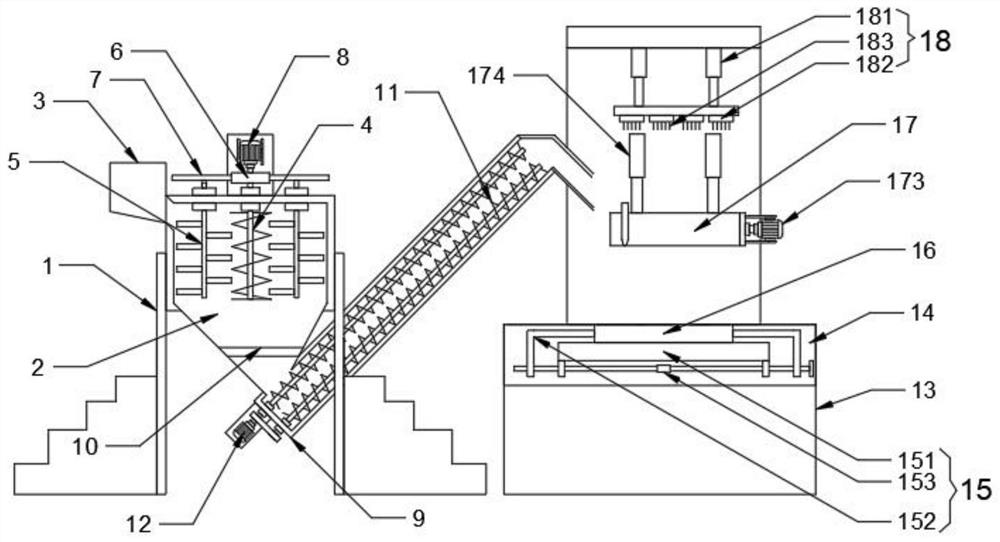

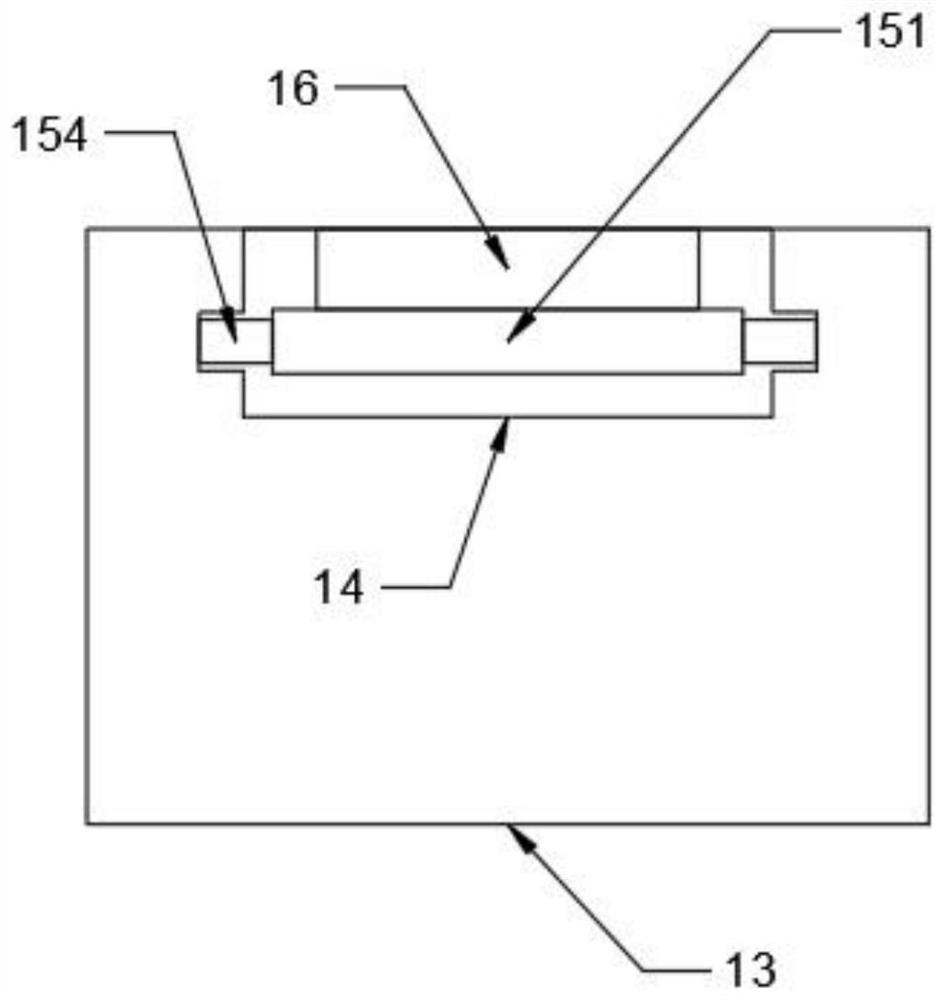

Ring-pull can packaging device removing iron ring-pull cans from waste ring-pull cans

ActiveCN106881900ARealize automatic identificationAchieve weighingMagnetic separationPressesMaterial resourcesMagnet

The invention discloses a ring-pull can packaging device removing iron ring-pull cans from waste ring-pull cans and belongs to the field of automatic packaging. The ring-pull can packaging device can remove the iron ring-pull cans in the process of packaging the aluminum ring-pull cans. The ring-pull can packaging device comprises a charging system (1), a feeding system (2), a ring-pull can packaging system (3), a discharging system (4) and a control host. The ring-pull can packaging device adopts a powerful magnet to remove the iron ring-pull cans in the conveying process and enables the ring-pull cans to become blanks, full-automatic ring-pull can pressing can be achieved, manual intervention is not needed in the whole process, and a large number of manpower and material resources are saved.

Owner:平湖市宸信机械有限责任公司

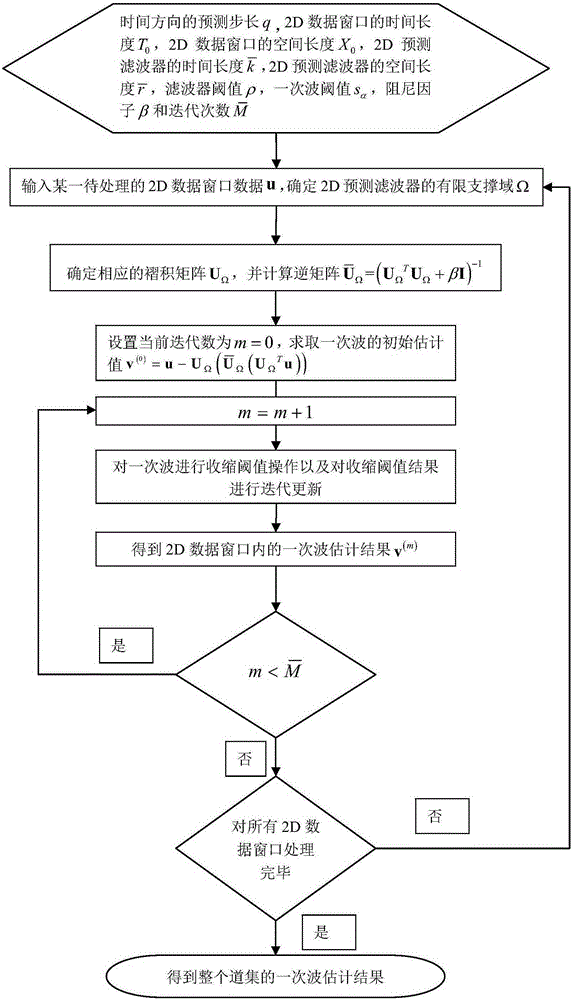

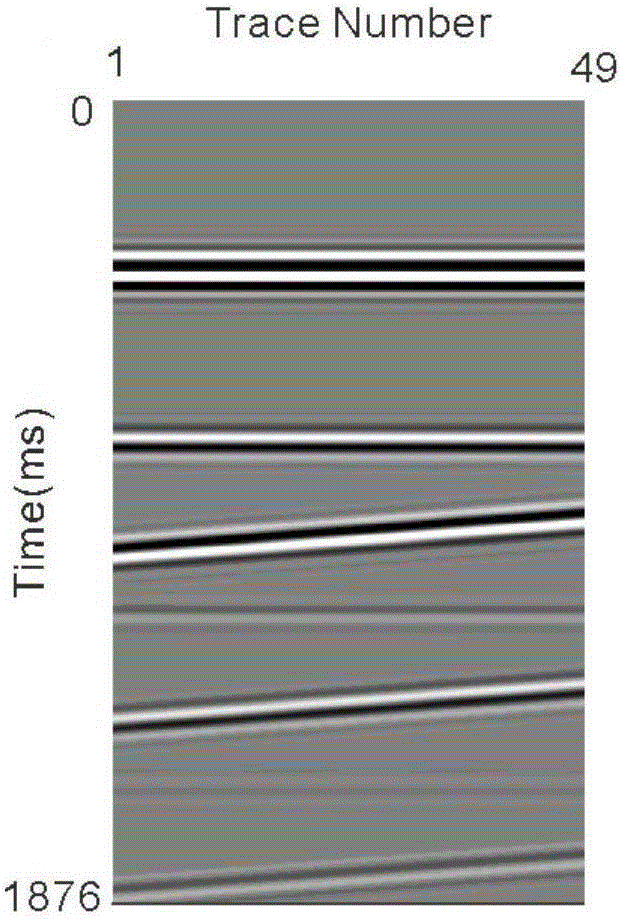

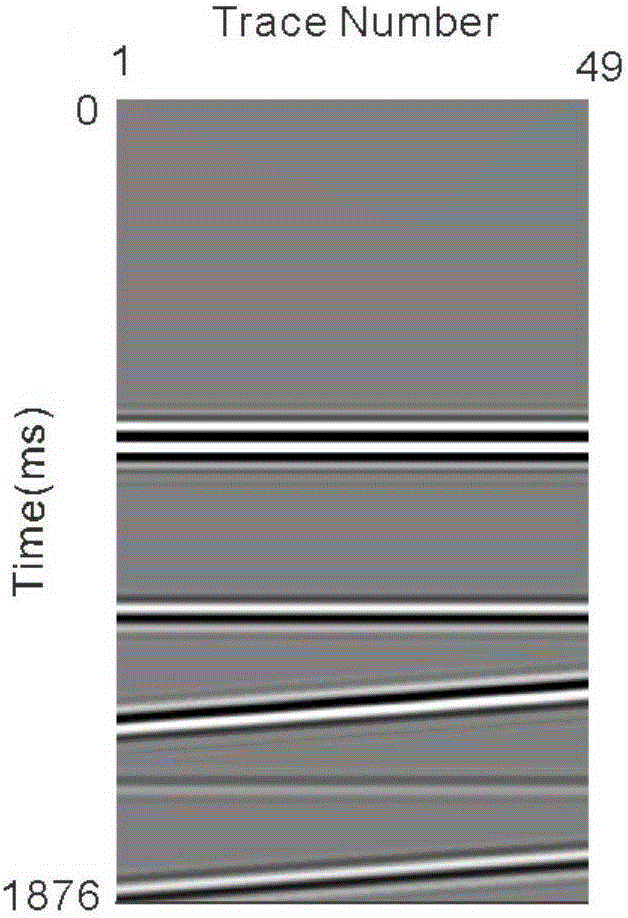

Multichannel prediction deconvolution method based on primary wave sparsity constraint

ActiveCN105259574AReduce the number of coefficientsAchieve suppressionSeismic signal processingComputation complexityEnergy minimization

The invention belongs to seismic signal processing field in seismic prospecting technology and specifically discloses a multichannel prediction deconvolution method based on primary wave sparsity constraint. The method comprises steps of: determining a limited support domain and a corresponding mathematic model of a 2D prediction filter in multichannel prediction deconvolution; decreasing the number of coefficients of the solved 2D prediction filter; constructing an optimization problem applying sparsity constraint to a primary wave and solving the 2D prediction filter by suing a fast iteration shrinkage threshold algorithm so as to achieve multiple suppression. Compared with a conventional multichannel prediction deconvolution method which needs to estimate all filter coefficients in a filter coefficient space and which applies energy minimization constraint to the primary wave to solve the 2D prediction filter, the method may decrease the number of coefficients of the solved 2D prediction filter, effectively balances primary wave protection and multiple suppression, and reduces the computation complexity of optimization problem solution.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

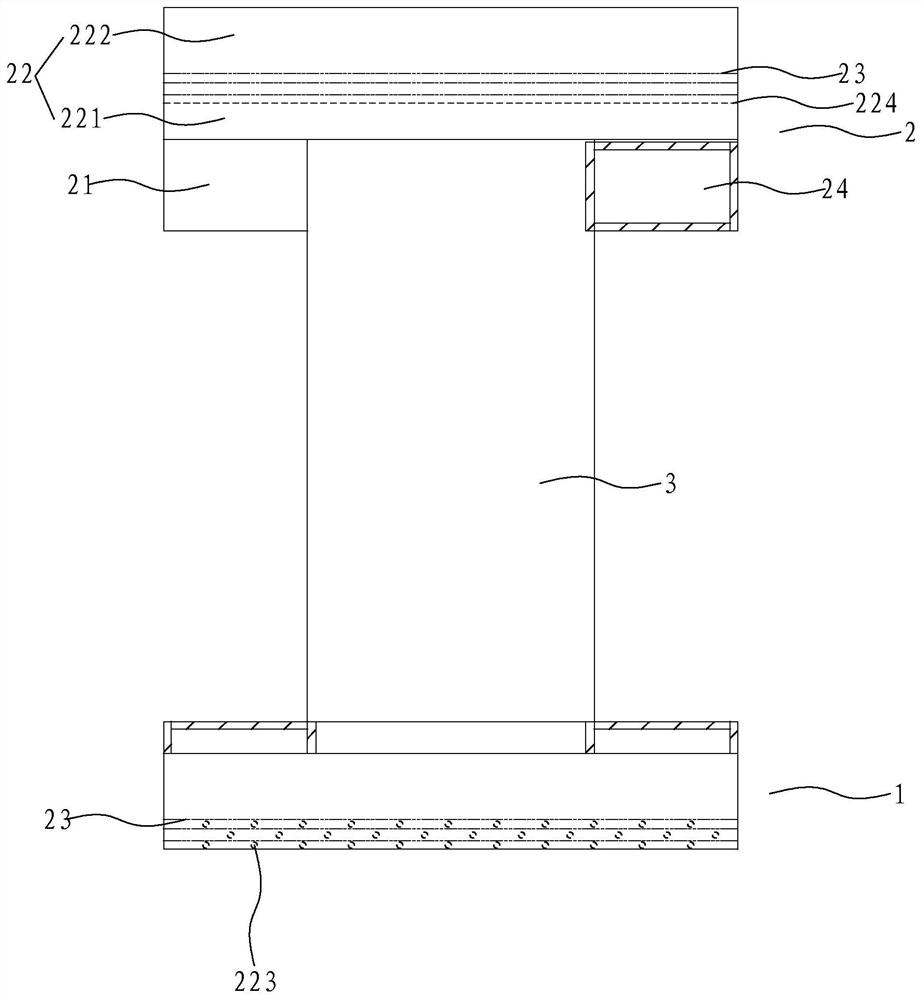

Hot-pressing device for PVC flame-retardant plastic-wood composite material

PendingCN110253905ASolve the problem of poor qualityAvoid pollutionFlat articlesEngineeringHeat press

The invention discloses a hot-pressing device for a PVC flame-retardant plastic-wood composite material, and relates to the technical field of material processing equipment. The hot-pressing device comprises a workbench, wherein the workbench is sequentially provided with a weighing table, a hot pressing groove, a hot pressing mechanism, a compression roller mechanism, a conveying mechanism and a cooling mechanism in the length direction of the workbench, the hot pressing groove is formed in the weighing table, electric heating tubes are embedded in the peripheral side wall of the hot pressing groove, the side wall, far away from the weighing table, of the hot pressing groove is provided with a material passing opening, and the cooling mechanism comprises a fan and a smoke removing box. According to the device, the weighing table, the hot pressing groove, the hot pressing mechanism, the pressing roller mechanism and the cooling mechanism are arranged, particles are weighed through the weighing table, preheating and leveling are performed in the hot pressing groove, and the particles are pressed into a plate with a certain thickness through the hot pressing mechanism, and then flattening and compacting are further carried out through the compression roller mechanism, so that the problem that the quality of the plate after hot pressing of an existing hot press is not too close is solved, the tail gas is reused, pollution is avoided, the operation is simple, and the device is suitable for popularization.

Owner:南京聚锋新材料有限公司 +1

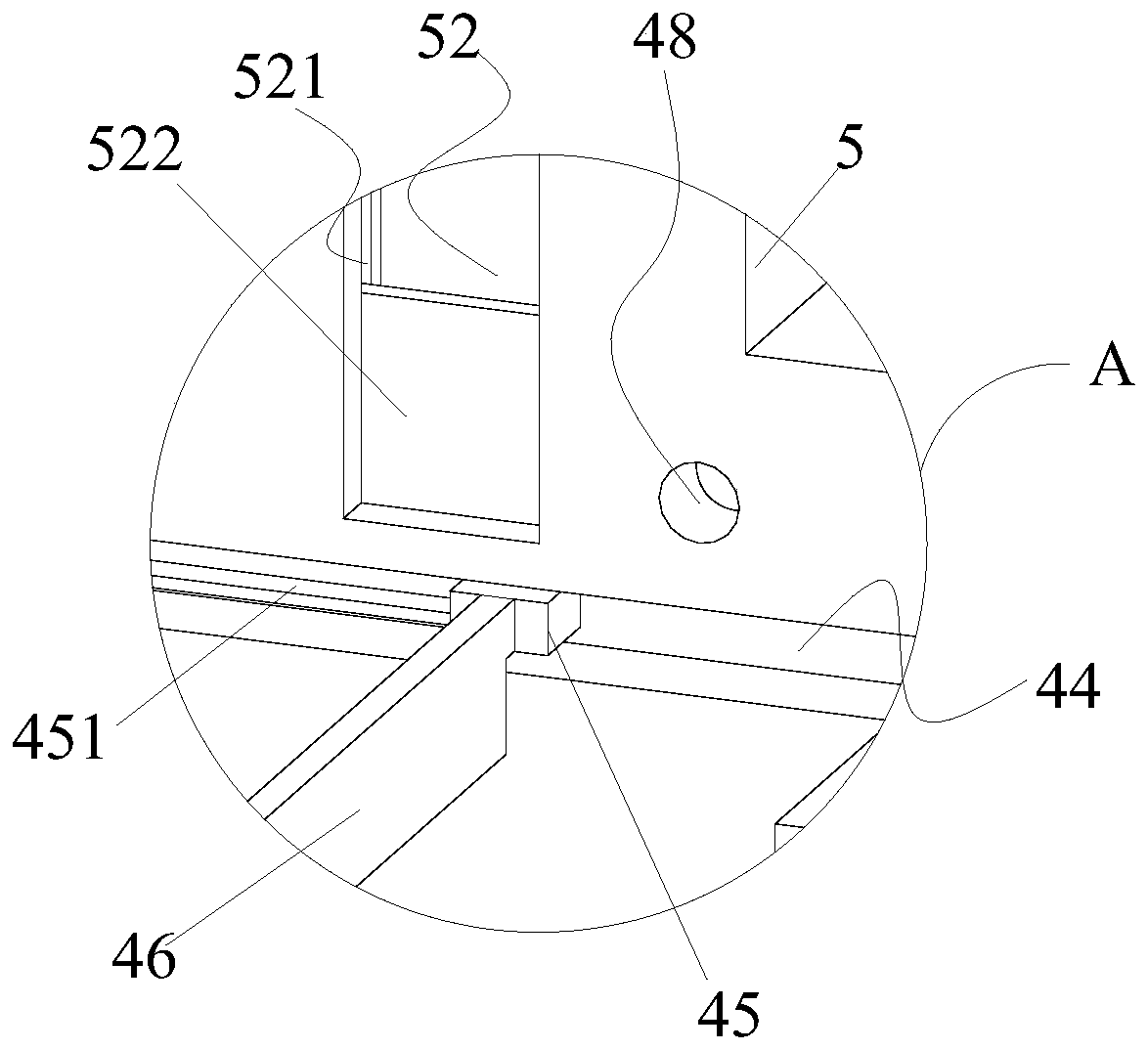

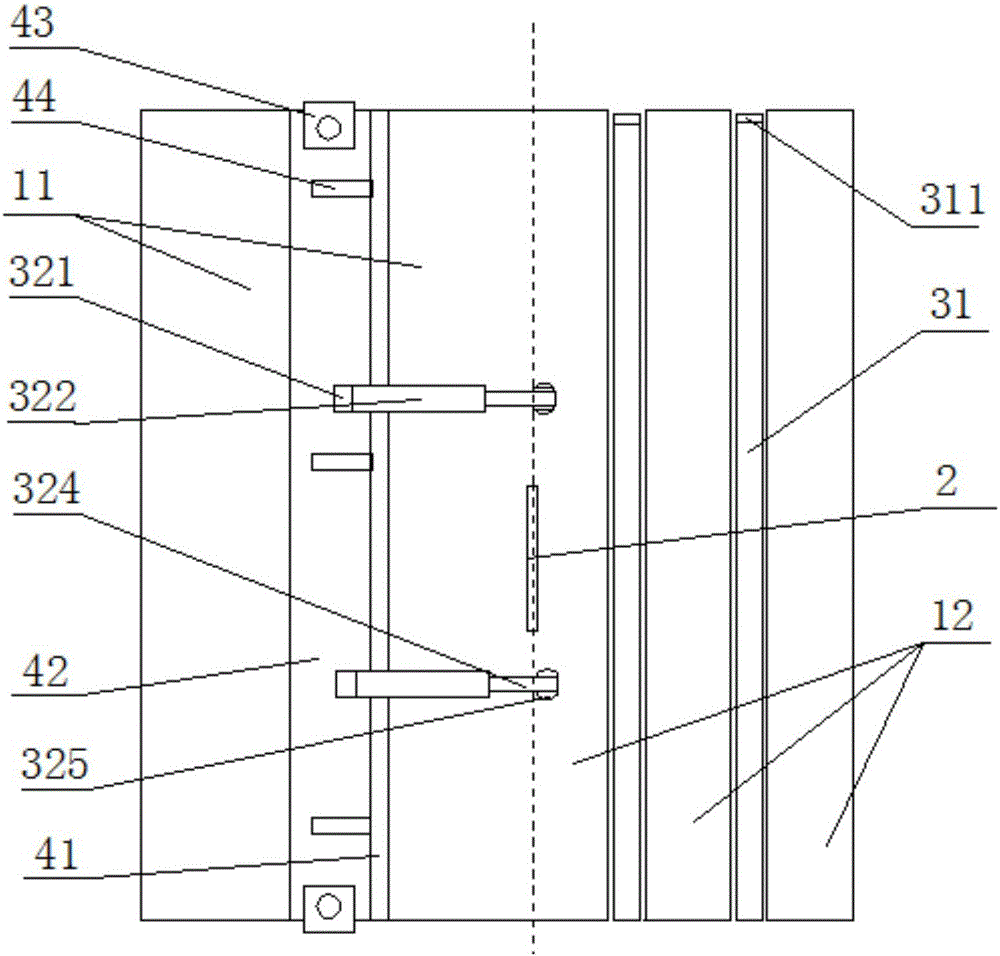

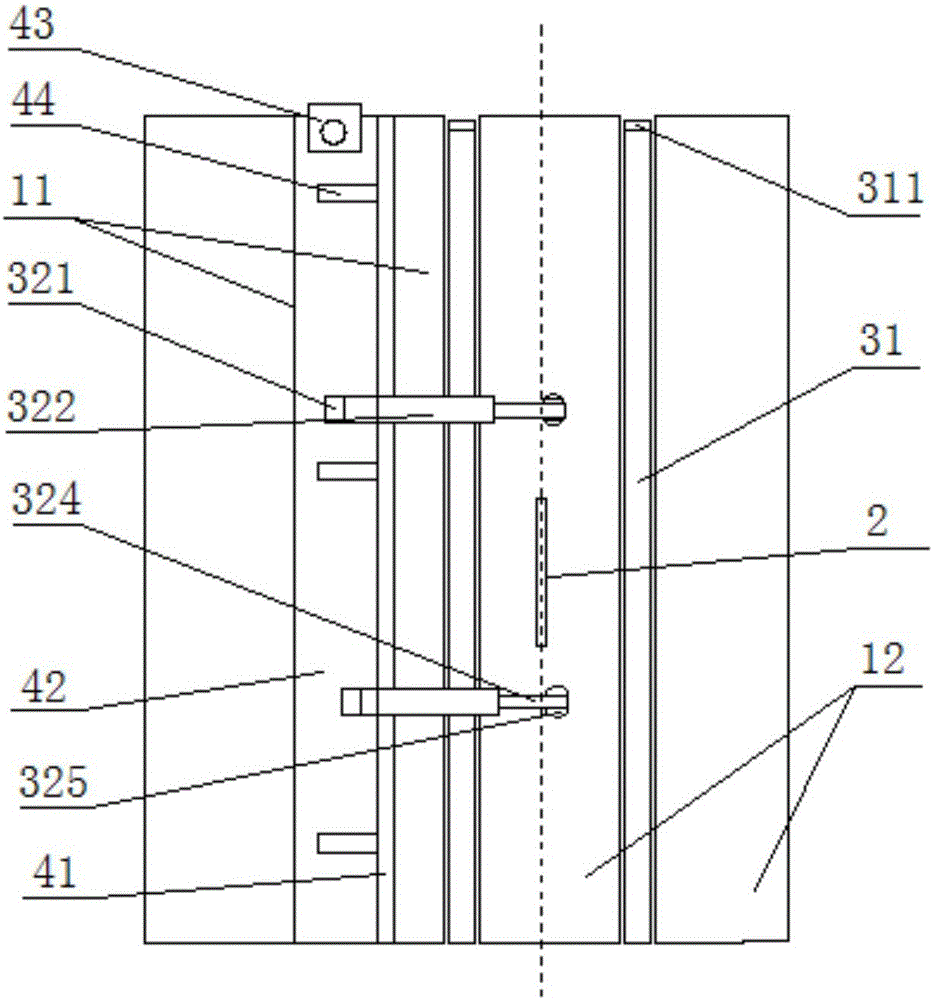

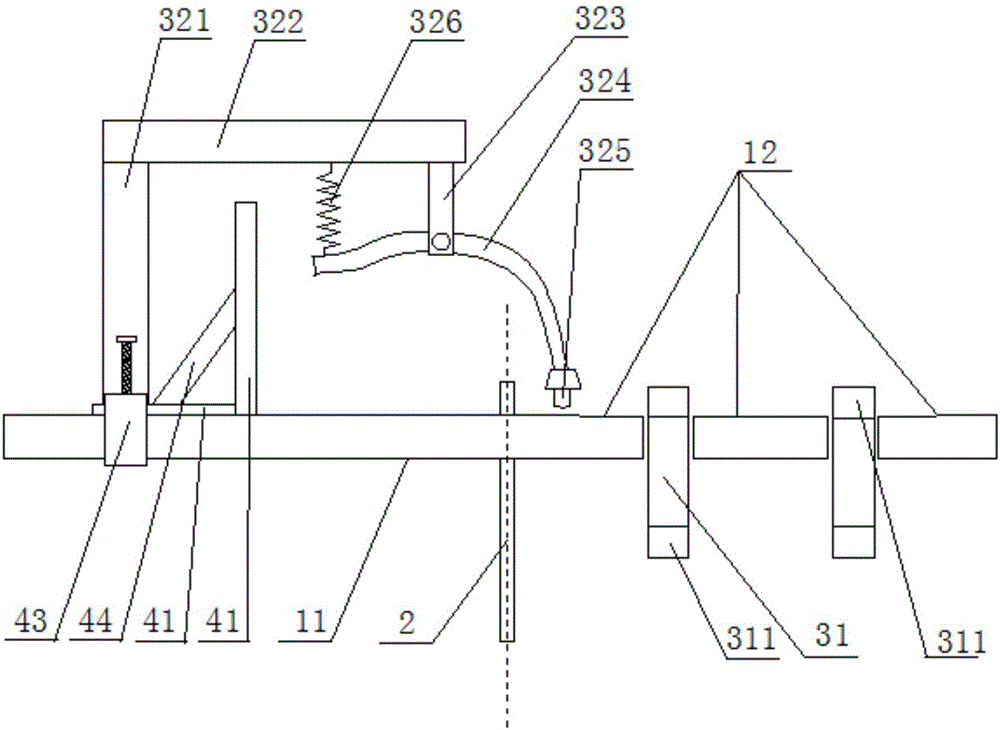

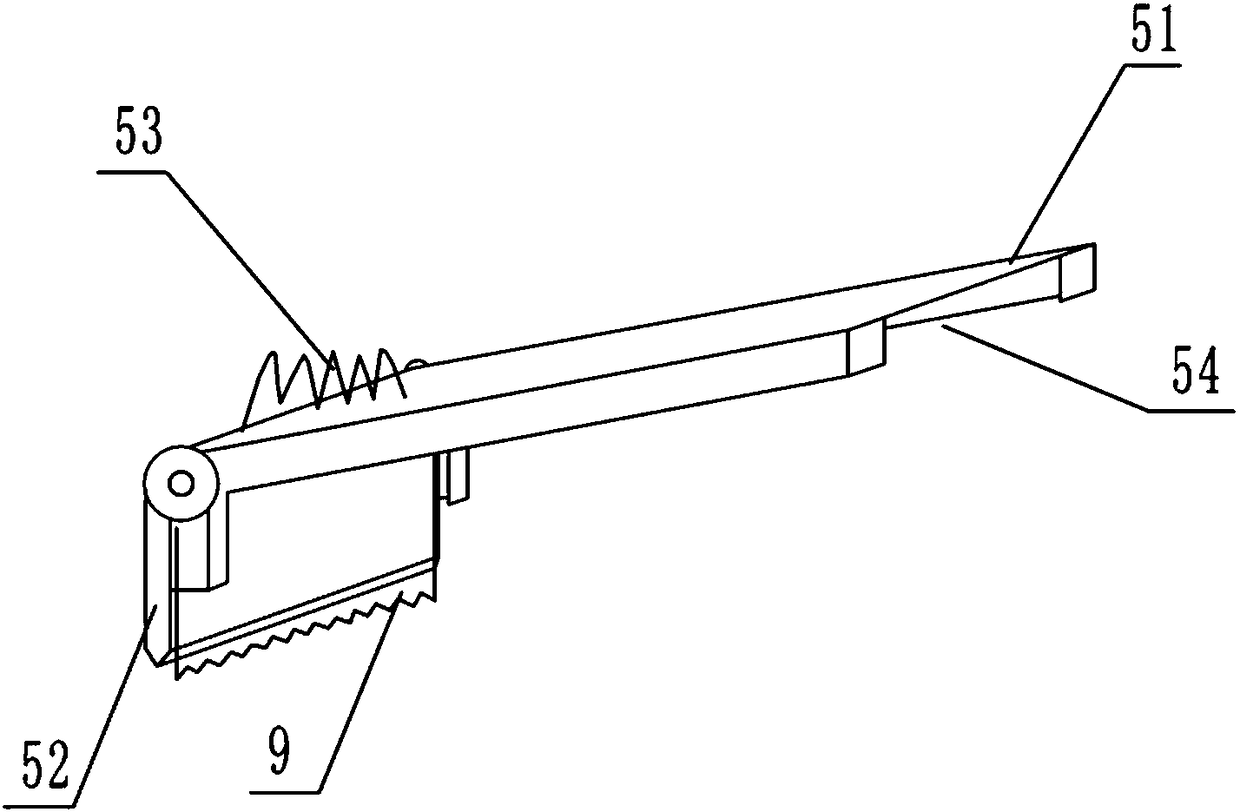

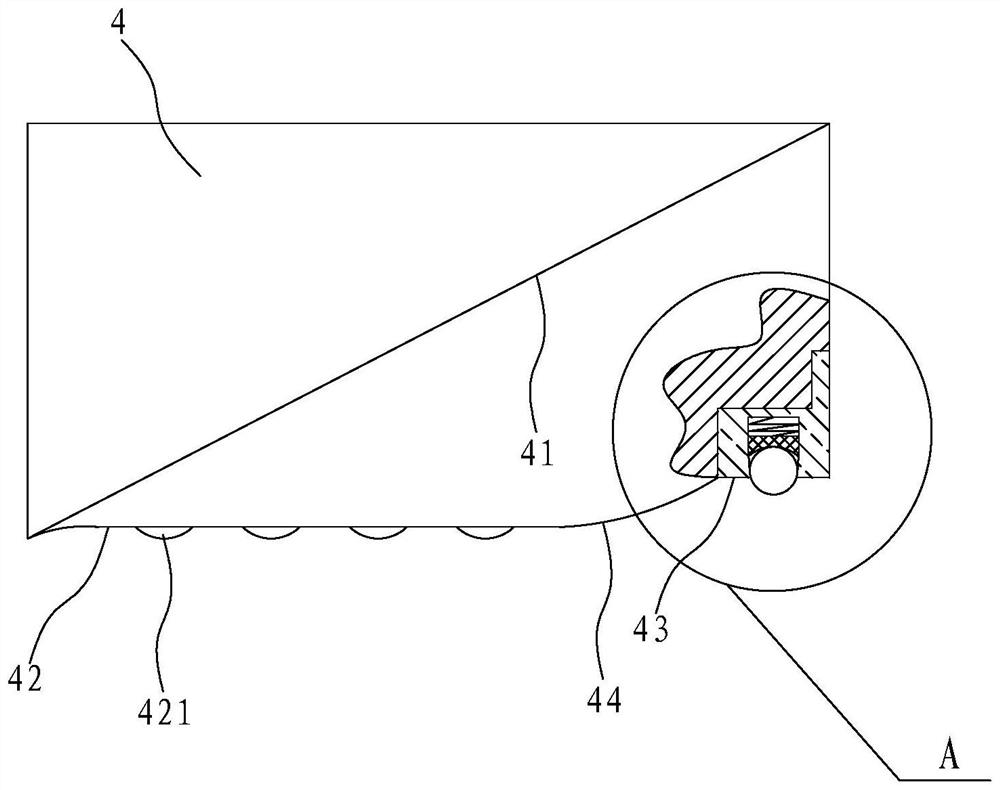

Cutter for automatically feeding and capable of machining plates with different sizes and machining method thereof

InactiveCN105946055ASimple structureEasy to assemble and disassembleGuide fencesFeeding devicesEngineeringGrinding wheel

The invention provides a cutter for automatically feeding and capable of machining plates with different sizes. The cutter comprises a pushing mechanism and a movable limiting mechanism. A worktable is sawed as a left worktable and a right worktable by a grinding wheel saw; the pushing mechanism includes at least one conveying part; a pushing part is at least arranged at an incoming end of the conveying part; the plates are put on the worktable, and are forwards pushed in the direction of the grinding wheel saw through matching between the pushing part and the conveying part; the grinding wheel saw is positioned between two ends of the conveying part; the pushing mechanism further includes at least one plate pressing device; the plate pressing device is fixed on the limiting mechanism, and includes a pressing wheel; and the height from the pressing wheel to the worktable is equal to or smaller than the height of the plates. The cutter can achieve the purposes of automatically pushing the plates and machining the plates with different sizes through the pushing mechanism and the movable limiting mechanism.

Owner:SUZHOU TIANYUAN FURNITURE CO LTD

Electronic product container packing method

InactiveCN108100330AImprove sealing efficiencyQuality assuranceWrapper twisting/gatheringEngineeringPacking method

The invention relates to the technical field of shifting mechanisms, in particular to an electronic product container packing method. The electronic product container packing method comprises a framebody, a conveying part, a side plate leveling part, an end plate leveling part and an adhesive tape bonding part; the end plate leveling part, the side plate leveling part and the adhesive tape bonding part are arranged in a conveying direction of the conveying part in sequence; an extension part is arranged at the bottom of the frame body; the conveying part comprises a back conveying part, and afront conveying part consisting of a chain transmission roller way; the back conveying part comprises a conveying frame; the upper surface of the conveying frame is a conveying plane consisting of multiple cylinders; the two sides of the cylinders are connected with the two sides of the conveying frame; the conveying plane is provided with slide bars capable of oppositely moving along the conveying plane and clamping packing containers; conveying belts are arranged on the side surfaces of the slide bars; the slide bars are provided with extrusion parts for extruding the upper parts of the packing containers; and limiting parts for preventing side plates and end plates of the leveled packing containers from upwards turning are arranged at the bottom of the frame body. The electronic product container packing method not only can seal the packing containers with multiple specifications, but also can prevent generation of gaps in seals.

Owner:重庆市长寿区普爱网络科技有限公司

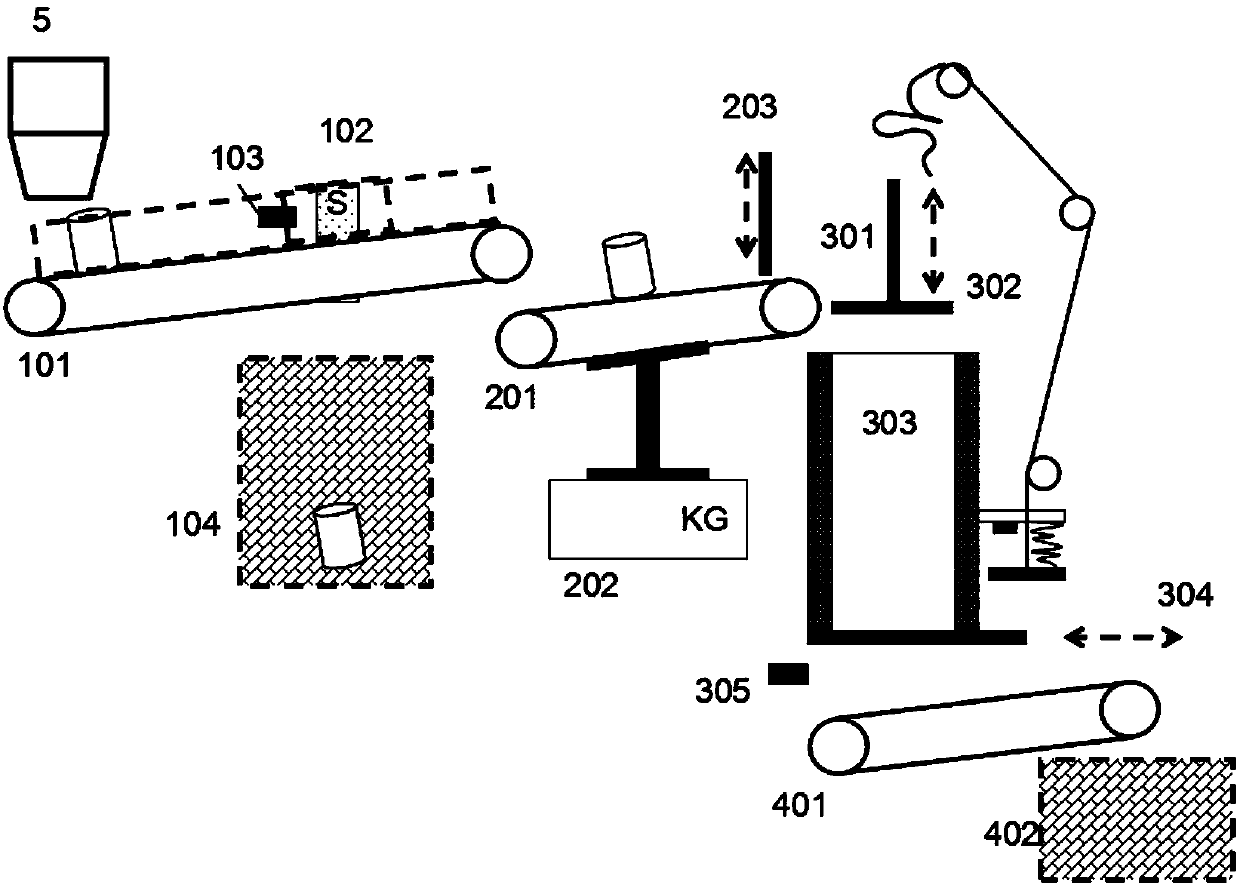

Pre-treatment type zip-top can packaging method for removing iron zip-top cans from waste zip-top cans

ActiveCN106827629ARealize automatic identificationAchieve weighingMagnetic separationPressesMaterial resourcesPre treatment

The invention discloses a pre-treatment type zip-top can packaging method for removing iron zip-top cans from waste zip-top cans, belongs to the field of automatic packaging and can be used for removing iron zip-top cans in the aluminum zip-top can packaging process. Adopted equipment comprises a loading system (1), a feeding system (2), a zip-top can packaging system (3), a discharging system (4), a pretreatment funnel (5) and a control main unit. The method works in the principle that the iron zip-top cans are removed through powerful magnets in the conveying process, the zip-top cans are pressed to blanks, automatic pressing of the zip-top cans can be realized, manual intervention is not required in the whole process, and a large quantity of labor and material resources are saved.

Owner:平湖市宸信机械有限责任公司

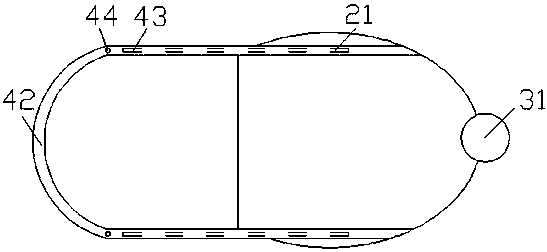

Anti-tightening pull-ups and manufacturing process thereof

ActiveCN111603314ANot easy to produce large areas of strangulationHigh expressionAbsorbent padsBaby linensMechanical engineeringRubber band

The invention relates to the field of disposable hygienic products, in particular to anti-tightening pull-ups. The anti-tightening pull-ups comprise a front waistline, a rear waistline and an absorption main body. The rear waistline comprises a base material layer; the upper end of the base material layer extends out of the absorption main body to form an extension part; the extension part is provided with a plurality of rubber bands along the width direction; elastic sheets are arranged at the left end and the right end of the absorption main body on the base material layer respectively; theelastic sheets extend to cover the two sides of the absorption main body and are bonded with the absorption main body; the portions, covering the absorption main body, of the elastic sheets achieve elasticity loss in a spot breaking mode, spot breaking areas are formed at the spot breaking portions; and the sides, away from the absorption main body, of the elastic sheets are bonded with the base material layer. The technical problems that in the prior art, the waistline of a pair of three-piece pull-ups needs to be subjected to rubber band breaking, consequently, perforation and wrinkling areirregular, and the appearance presentation degree is poor are solved. Correspondingly, the invention further provides a manufacturing process of the anti-tightening pull-ups.

Owner:FUJIAN HENGAN HLDG CO LTD +2

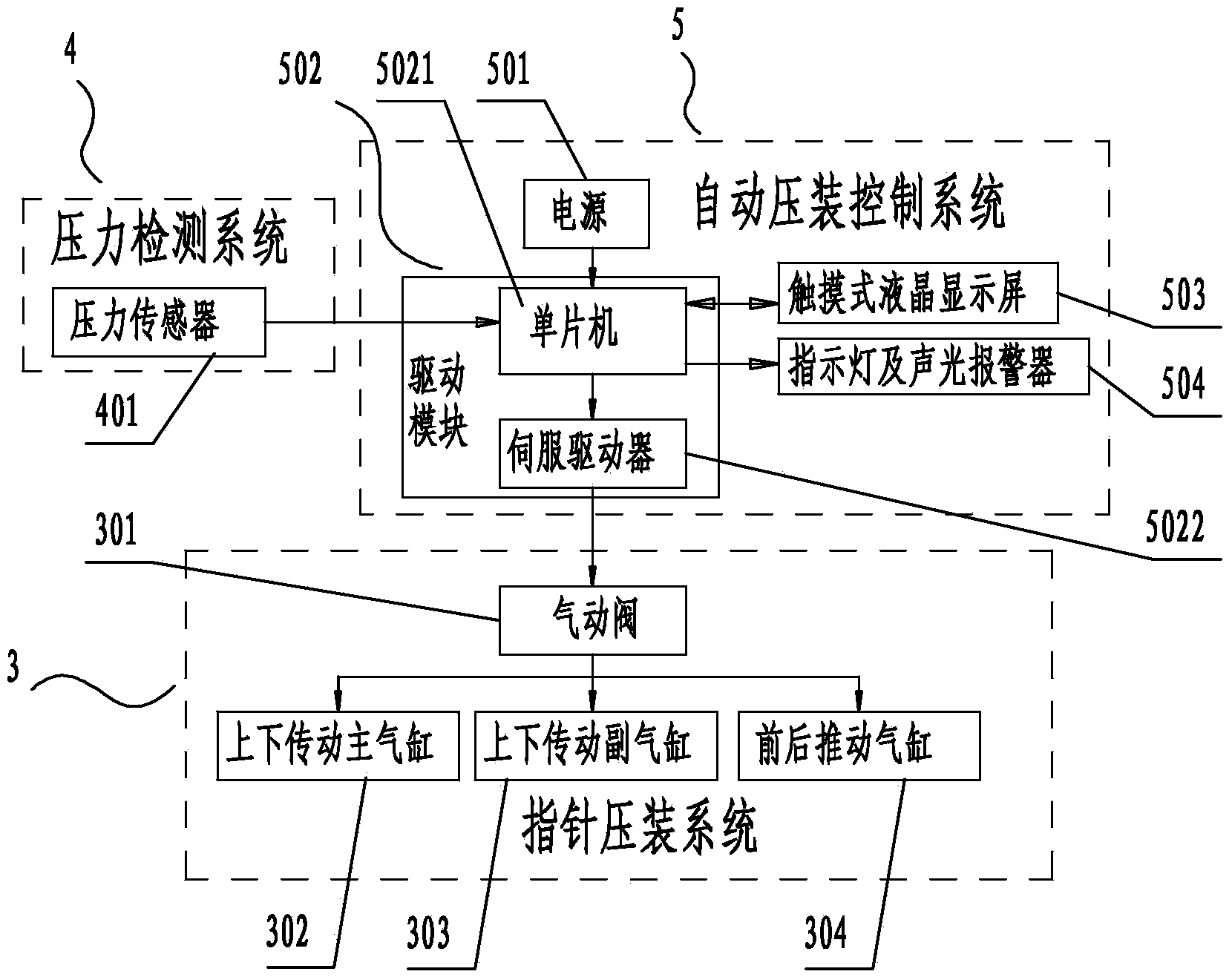

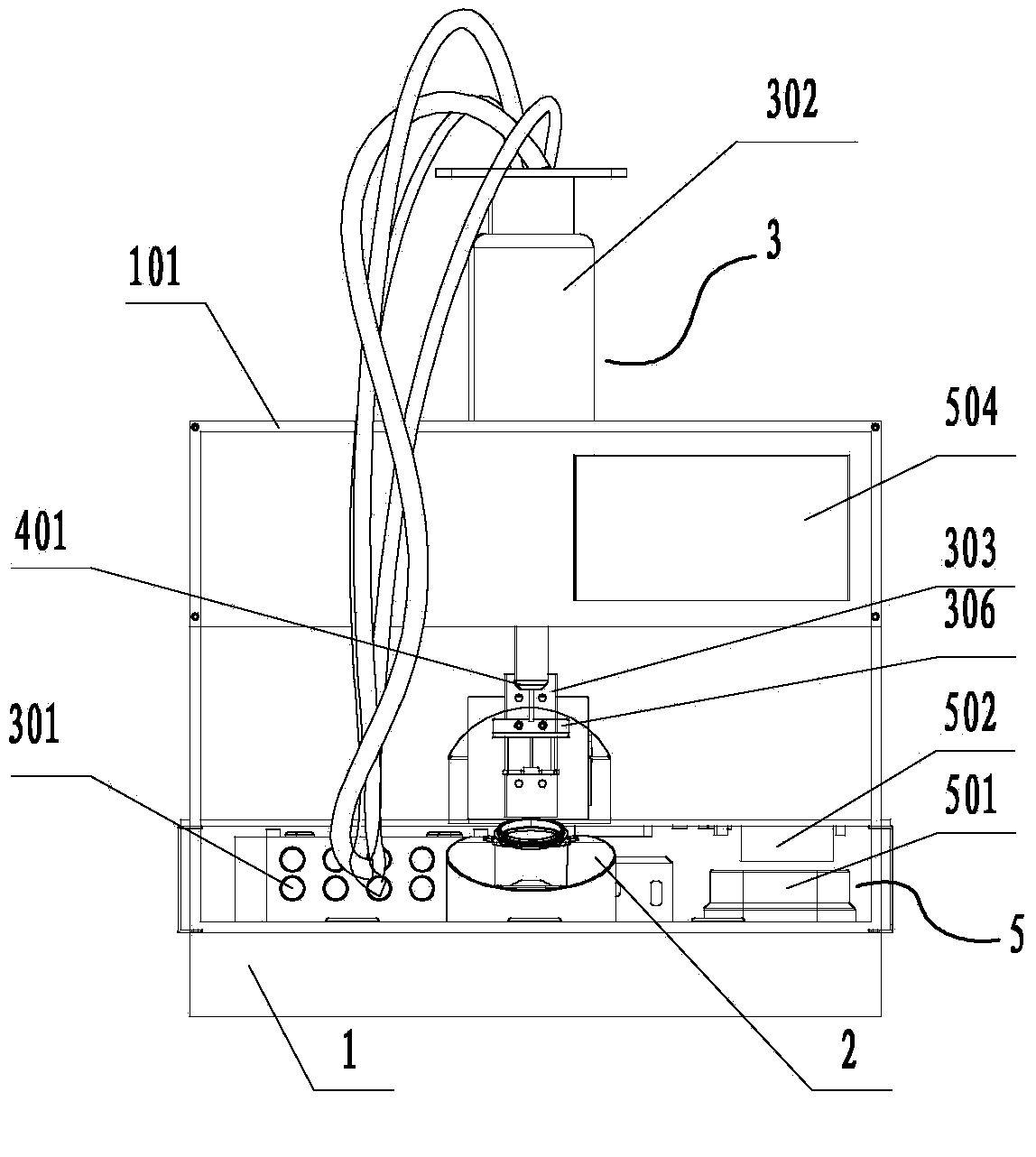

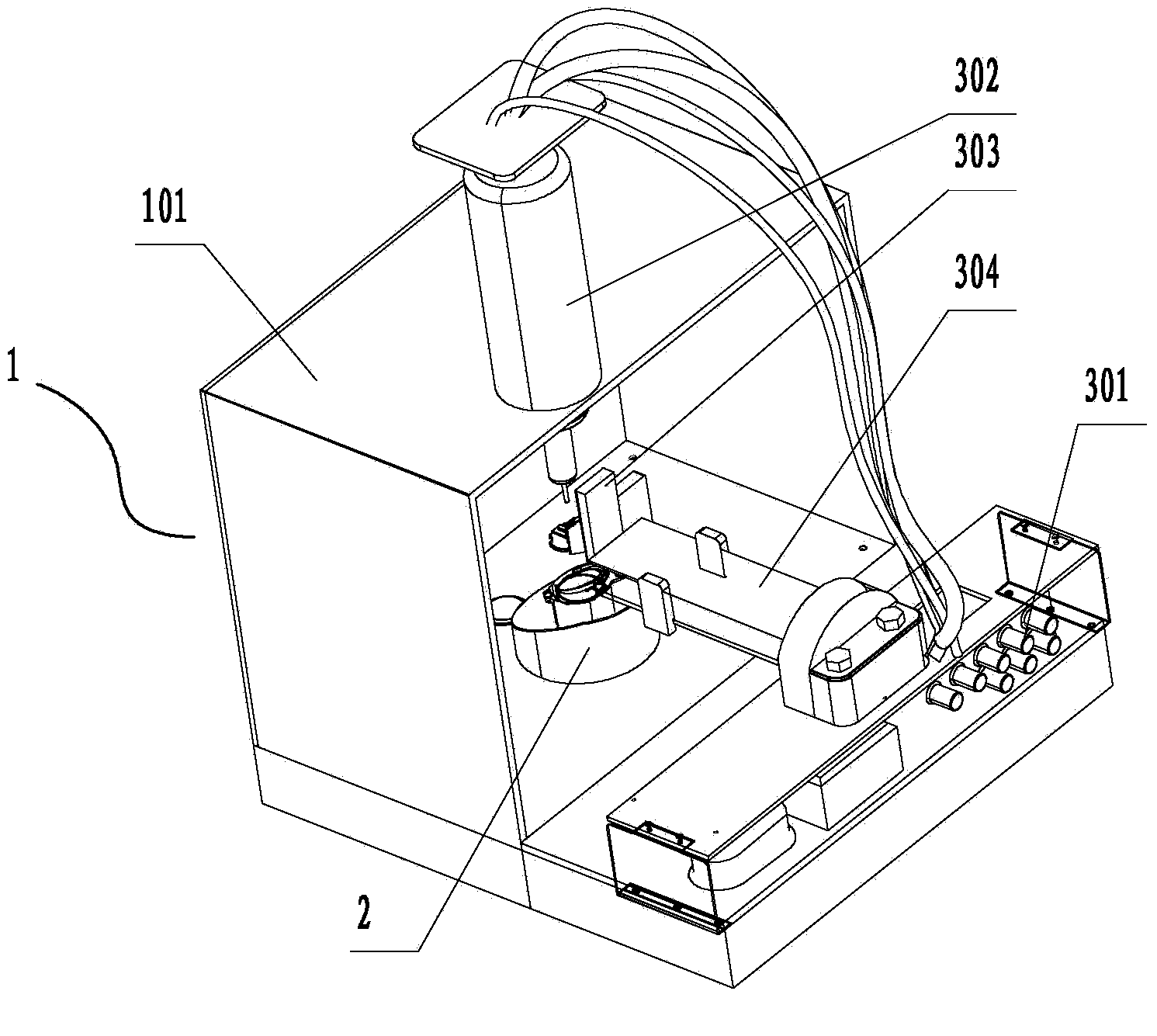

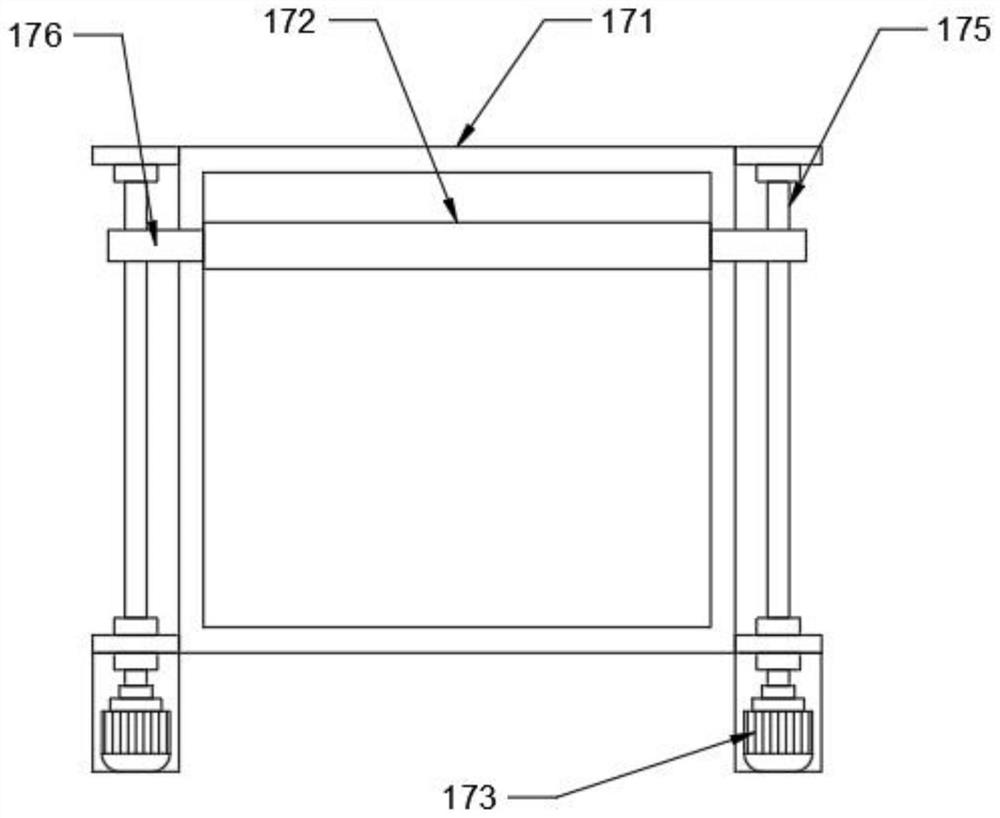

Automatic press-fitting system for pointers of vehicle-mounted pointer-type electronic clock

ActiveCN103676618AReal-time monitoring of pressing pressureReduce scrap rateRepair toolsControl systemIn vehicle

Disclosed is an automatic press-fitting system for pointers of a vehicle-mounted pointer-type electronic clock. The automatic press-fitting system comprises a fixing platform, a die cavity, a pointer press-fitting system, a pressure detecting system and an automatic press-fitting control system, wherein the die cavity is used for conducting horizontal fixing and horizontal-movement fixing on the electronic clock, the pointer press-fitting system is used for conducting press-fitting on the pointers of the electronic clock, the pressure detecting system is used for detecting the pointer press-fitting pressure in real time, and the automatic press-fitting control system is used for controlling currents, pressure and the press-fitting procedure. The die cavity, the pointer press-fitting system and the automatic press-fitting control system are installed on the fixing platform respectively, the pressure detecting system is installed on the pointer press-fitting system, the input end of the automatic press-fitting control system is connected with the output end of the pressure detecting system and the output end of the automatic press-fitting control system is connected with the input end of the pointer press-fitting system. The automatic press-fitting system can guarantee the accuracy of the pointers during pressing by monitoring the pressure in the pressing process in real time and improve the production press-fitting efficiency, has the advantages of being high in universality, convenient to operate, safe, reliable, low in cost and the like, and is easy to popularize and use.

Owner:LIUZHOU HANGSHENG TECH

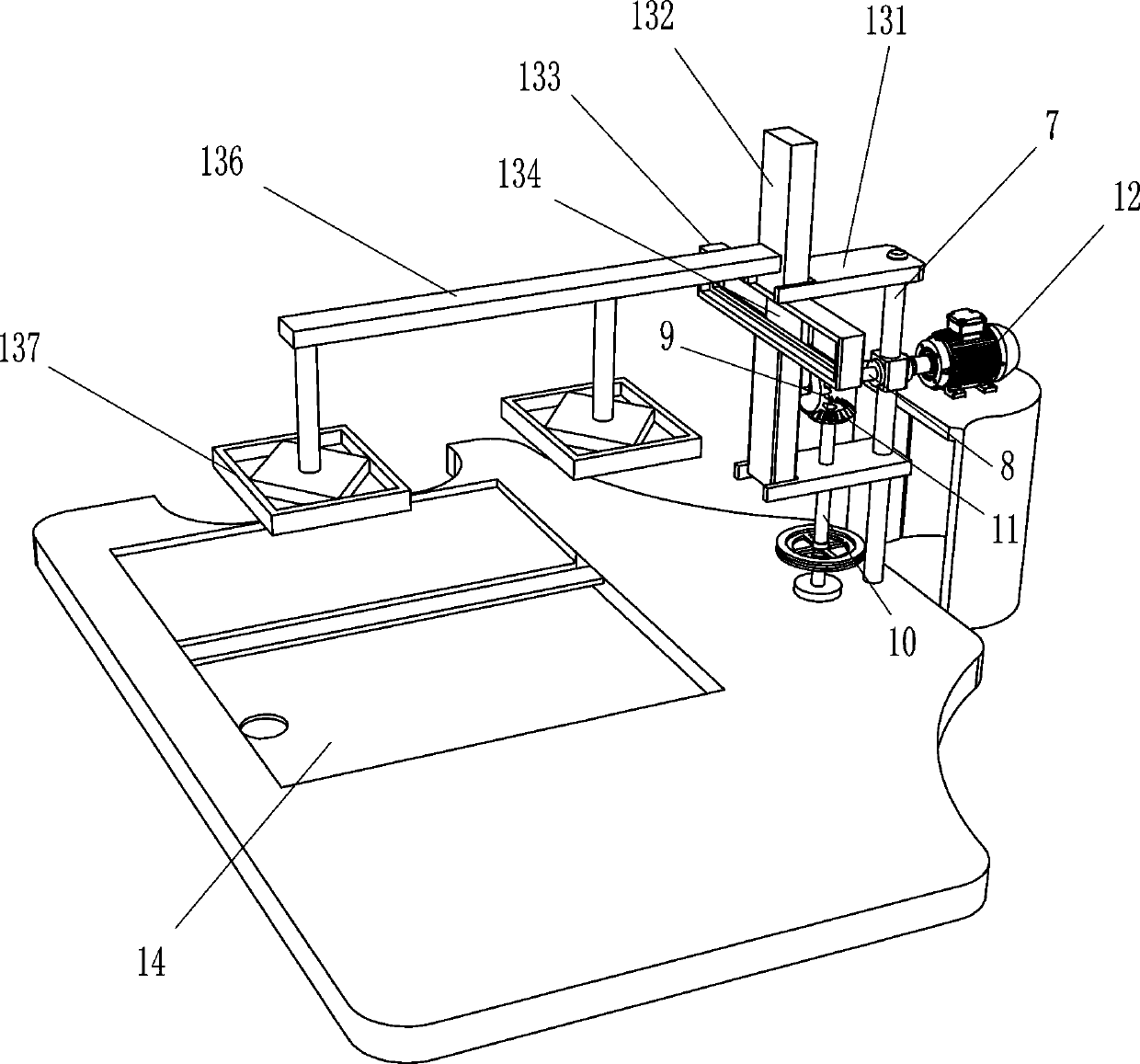

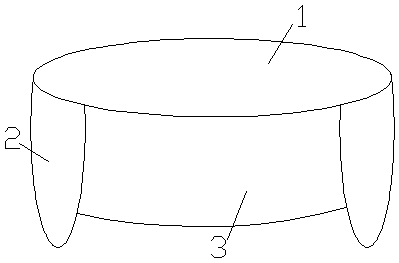

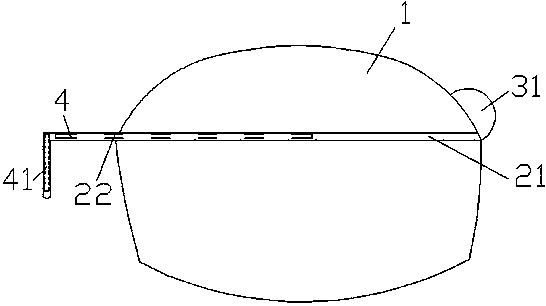

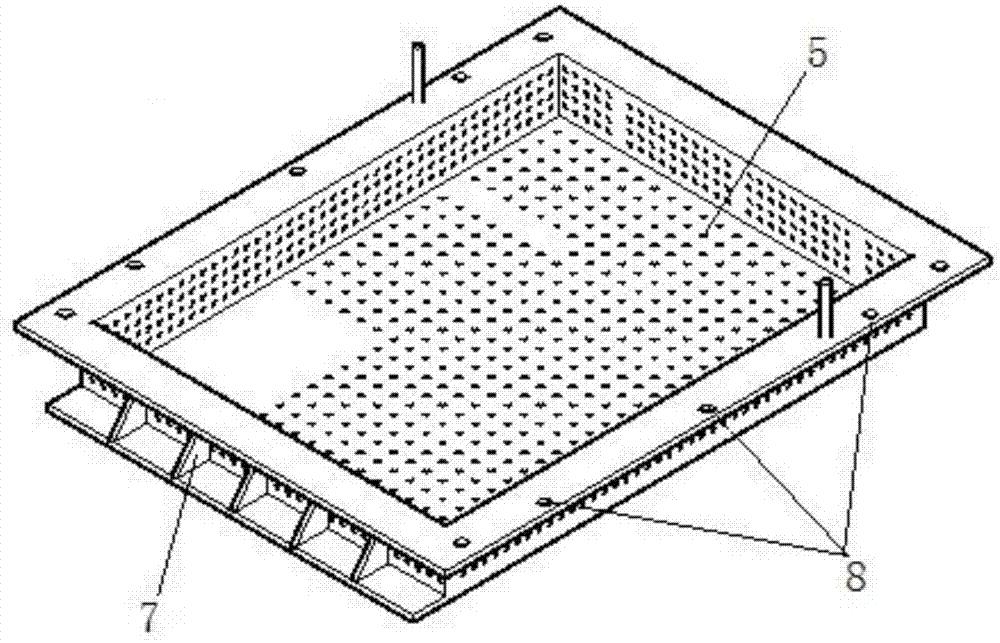

Automatic bean curd pressing device

InactiveCN111557344AEasy to pressEasy to take out the containerCheese manufactureFood scienceAgricultural engineeringStructural engineering

The invention belongs to the technical field of bean curd making, and particularly relates to an automatic bean curd pressing device. The automatic bean curd pressing device aims at achieving the technical purposes that a container can be automatically moved, pressing is convenient, and the container can be conveniently taken out. automatic bean curd pressing device comprises a base, wherein a workbench is arranged on the base, a square frame is arranged on the workbench, treatment boxes are symmetrically arranged on the square frame in a sliding mode, and water falling grooves are formed inthe bottom of the square frame and the bottoms of the treatment boxes. The workbench is provided with a moving device for driving the treatment box to move back and forth; and a mounting plate is arranged at the position, close to the square frame and the moving device, of the workbench. The effects that the container is automatically moved, pressing is convenient, and the container is conveniently taken out are achieved.

Owner:朱婷婷

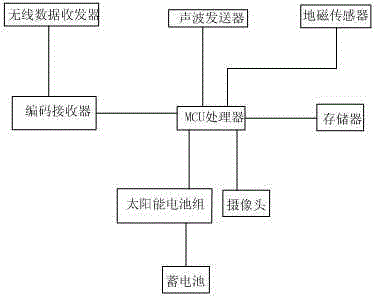

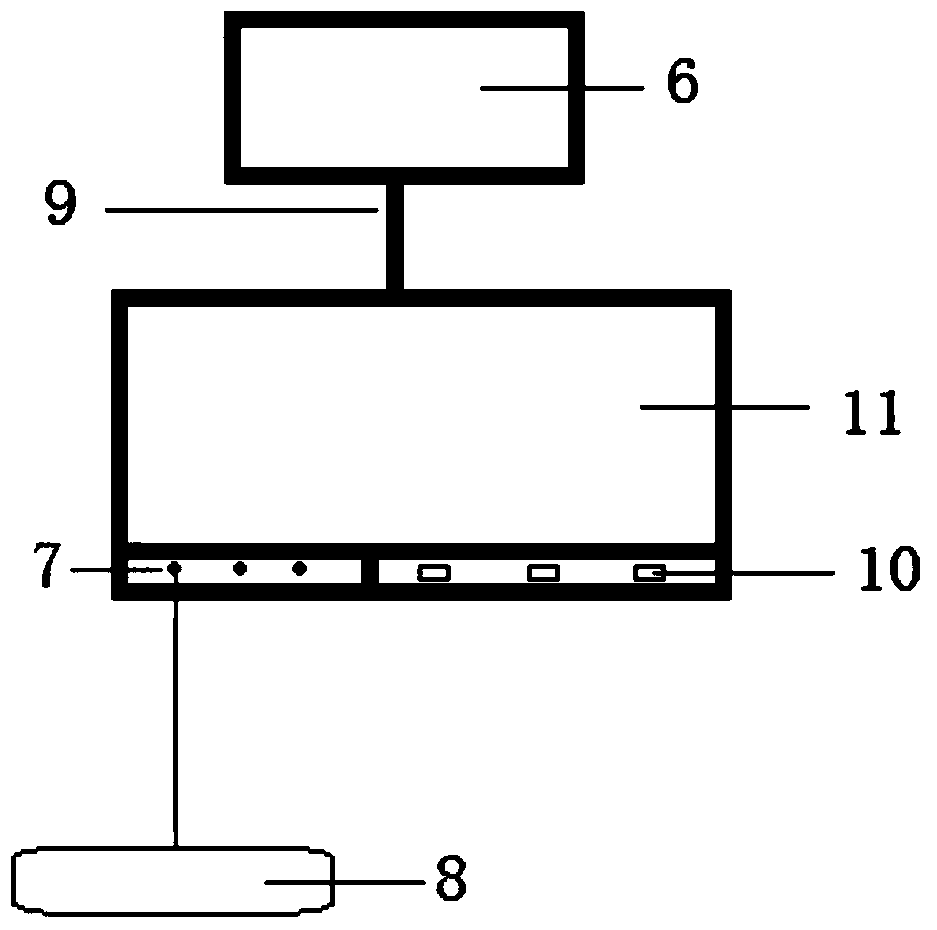

Improved vehicle detection terminal

InactiveCN104464364AReduced cases of non-paying vehiclesReduce the situationIndication of parksing free spacesTransceiverWireless data

The invention discloses an improved vehicle detection terminal. The terminal comprises an MCU processor, a geomagnetic sensor, an acoustic transmitter, a camera, a code receiver and a wireless data transceiver. The geomagnetic sensor, the camera, the acoustic transmitter and the code receiver are connected to the MCU processor, the code receiver is further connected with the wireless data transceiver, and a storage device is connected to the MCU processor. On the basis of the principle, whether cars are parked in a stall, types of the cars and the car parking time can be rapidly identified, the camera can shoot the cars in time through the camera so as to preserve evidence, transmitting is carried out in time through a wireless network, the evidence is grasped, the corresponding measures are taken to the cars which do not pay fee, and the situation that the cars do not pay the fee is greatly reduced.

Owner:CHENGDU HEYIN TECH

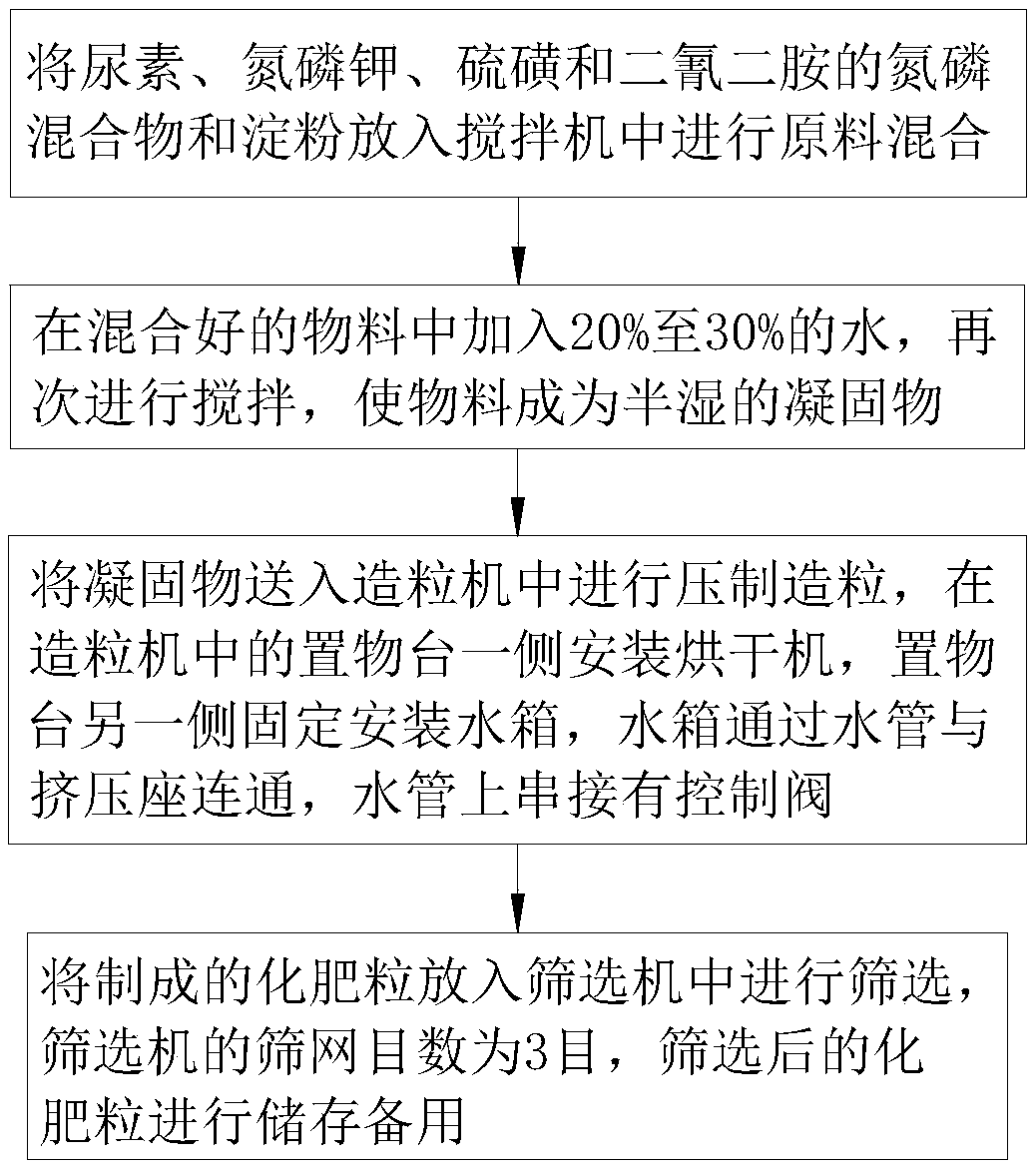

Chemical fertilizer production process

InactiveCN109180280AIncrease productivityFine grainUrea compound fertilisersPotassium fertilisersPulp and paper industryExtrusion

The invention belongs to the technical field of chemical fertilizer production, in particular to a chemical fertilizer production process. A granulator used in the process comprises a work box, a base, a controller and a pillar. The controller controls the automatic operation of the granulator. An extrusion module is disposed in the work box. The extrusion module comprises a motor, a rotating roller, No. 1 sliding blocks, a sliding shaft, a No. 2 sliding block, a pressing rod, a balancing weight and a guide rail, wherein the sliding shaft is horizontally mounted on the inner roof of the work box; two No.1 sliding blocks are slidably connected to the sliding shaft; the No. 2 sliding blocks are both hinged to the No.2 sliding block through a connecting rod; the No.2 sliding block is slidablyinstalled in the guide rail, which is fixedly installed on the bottom of the work box; and the balancing weight is hinged between the two No.1 sliding blocks through two struts. After materials are mixed by using an agitator, an appropriate amount of water is added for stirring to prepare a solidified material, thus facilitating the granulation of the granulator. And then, the chemical fertilizerproduction efficiency is improved.

Owner:张振洋

Compression molding device for cement brick production

PendingCN113927709AAchieve suppressionQuick changeFeeding arrangmentsShaping press ramCompression moldingHydraulic cylinder

The invention discloses a compression molding device for cement brick production. The compression molding device comprises a mounting frame, a mixing box is mounted at the upper end of the mounting frame, a second motor is mounted at one side of an extrusion box through a mounting seat, the output shaft end of the second motor is fixedly connected with a rotating shaft where an extrusion rod is located, and a manufacturing platform is mounted at one side of the mounting frame; and a mounting groove is formed in the surface of the upper end of the manufacturing platform, a fixing mechanism is mounted at the inner side of the mounting groove, a manufacturing mold is mounted at the inner side of the fixing mechanism, fixing frames are mounted at the two sides of the manufacturing platform, material flattening mechanisms are mounted at the inner sides of the fixing frames, and compacting mechanisms are mounted at the upper ends of the inner sides of the fixing frames. According to the compression molding device, a third motor is started to drive a threaded rod to rotate, then a scraping plate is driven to move back and forth, then the scraping plate is driven to flatten materials, after material flattening is completed, a hydraulic cylinder is started to compact the manufacturing mold, exhaust is conducted through an exhaust fork while compacting is conducted, and then cement bricks are pressed.

Owner:惠州市久盛新型建材有限公司

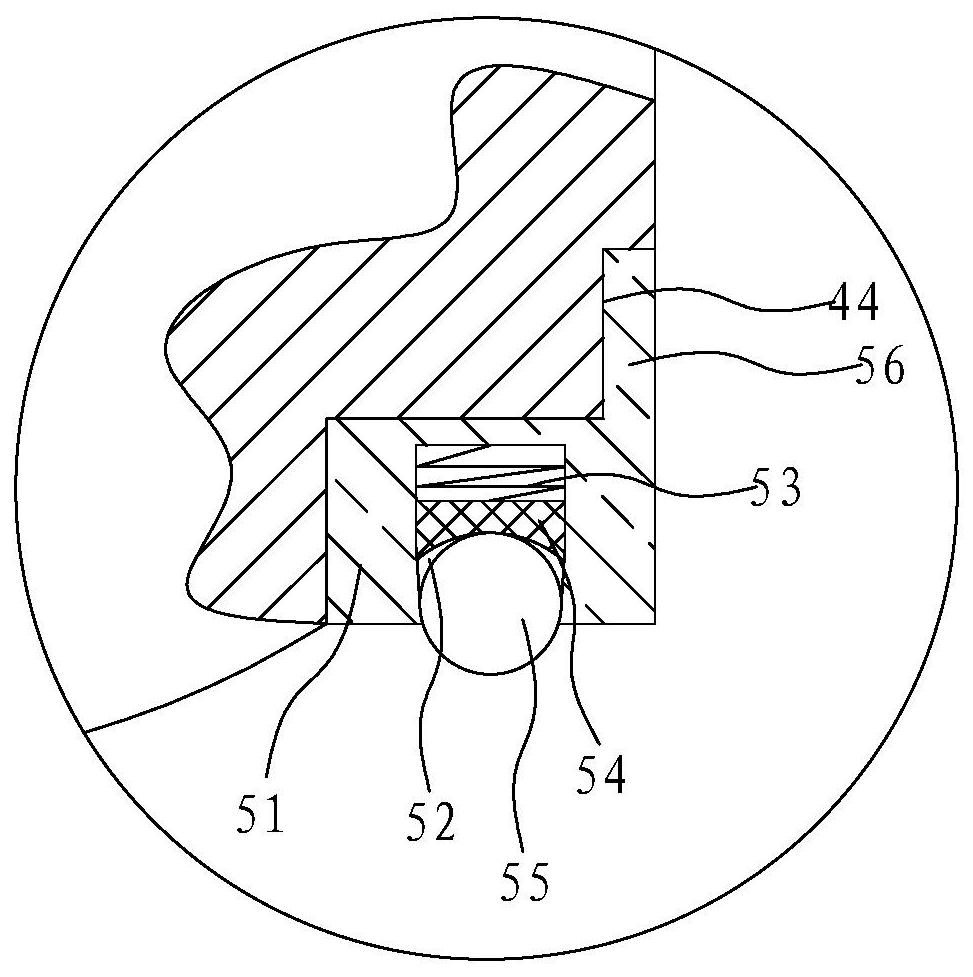

Plate cutter capable of automatically feeding and machining method thereof

InactiveCN105945700AAchieve suppressionDoes not affect progressGrinding machinesGrinding feedersEngineeringGrinding wheel

The invention provides a plate cutter capable of automatically feeding. A worktable is sawed as a left worktable and a right worktable by a grinding wheel saw; a pushing mechanism includes at least one conveying part; the right worktable has a gap for accommodating the conveying part; a pushing part is at least arranged at an incoming end of the conveying part; plates are put on the worktable, and are forwards pushed in the direction of the grinding wheel saw through matching between the pushing part and the conveying part; the grinding wheel saw is positioned between two ends of the conveying part; the pushing mechanism further includes at least one plate pressing device; the plate pressing device is fixed on the left worktable, and includes a pressing wheel; and the height from the pressing wheel to the worktable is equal to or smaller than the height of the plates. Compared with the prior art, as the conveying part is arranged on the worktable, and the pushing device is arranged on the conveying part, when the plates are put on the worktable, the conveying part drives the pushing device to move, and the pushing device drives the plates to move so as to realize conveying of the plates to the grinding wheel saw; and the plate pressing device realizes no upward floating in pressing of the plates.

Owner:SUZHOU TIANYUAN FURNITURE CO LTD

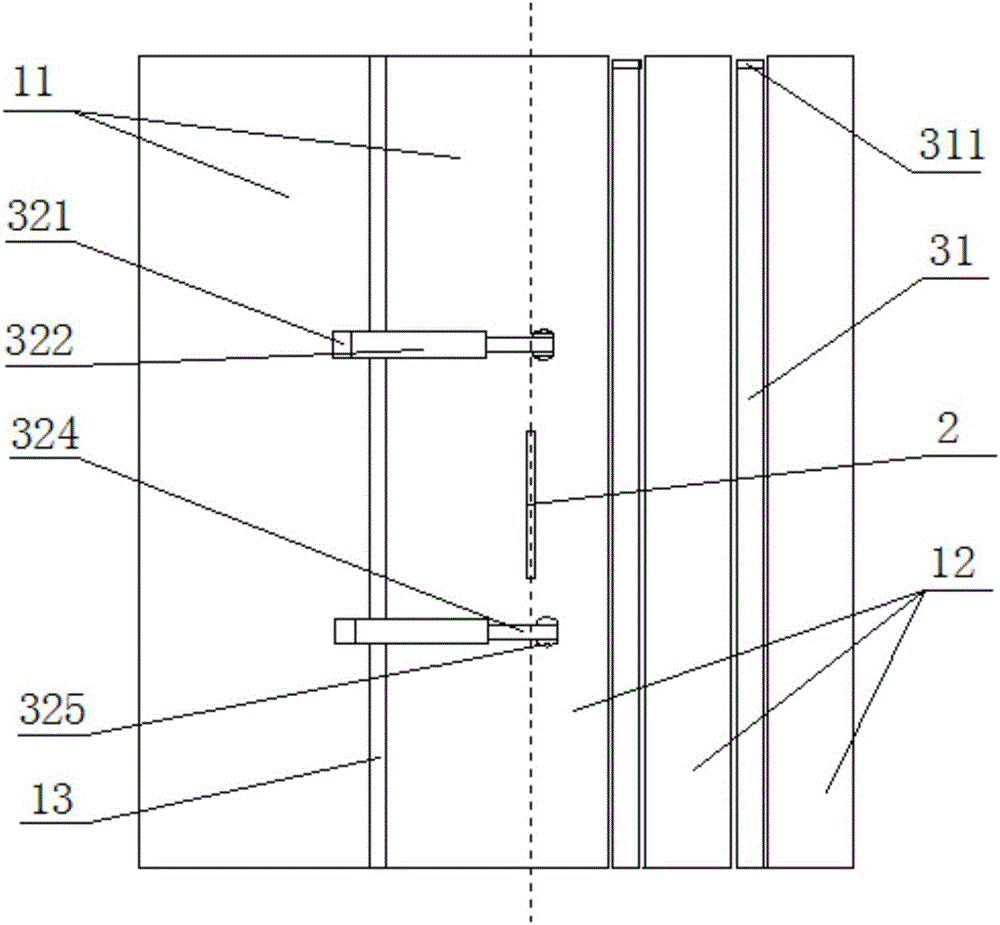

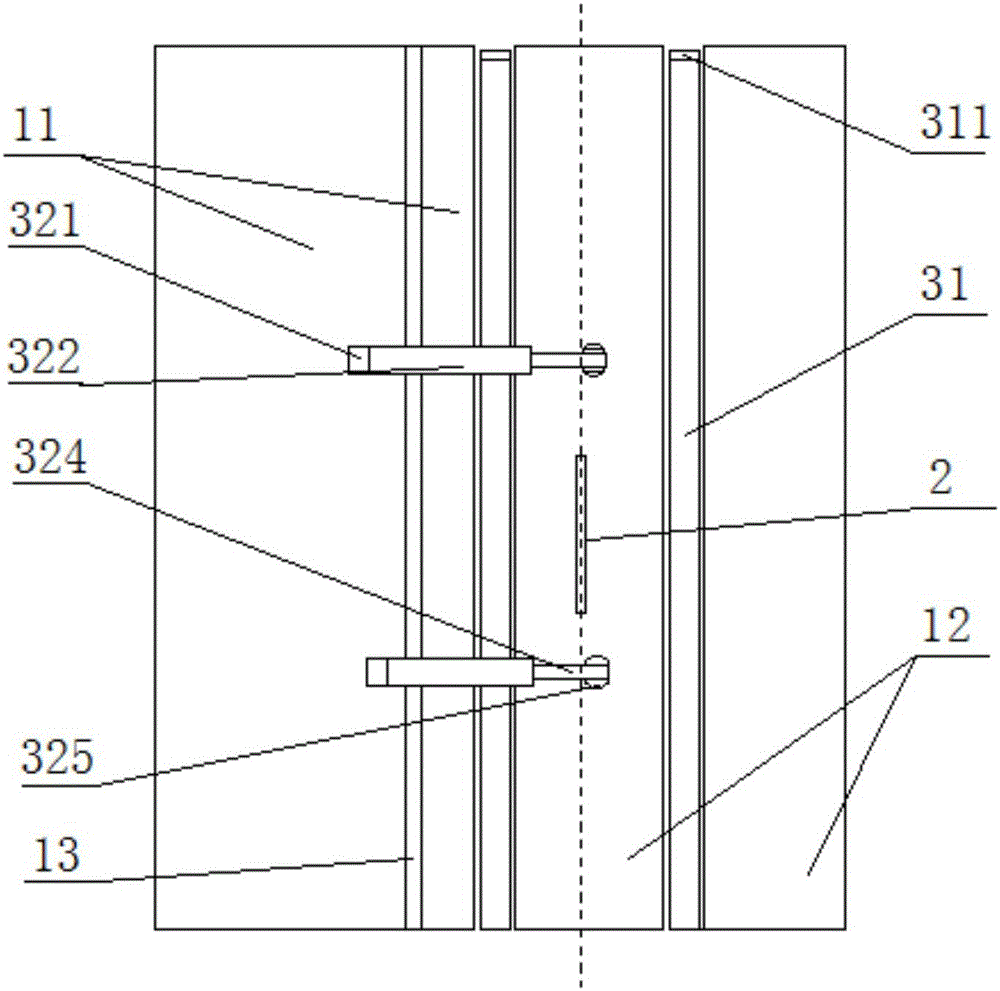

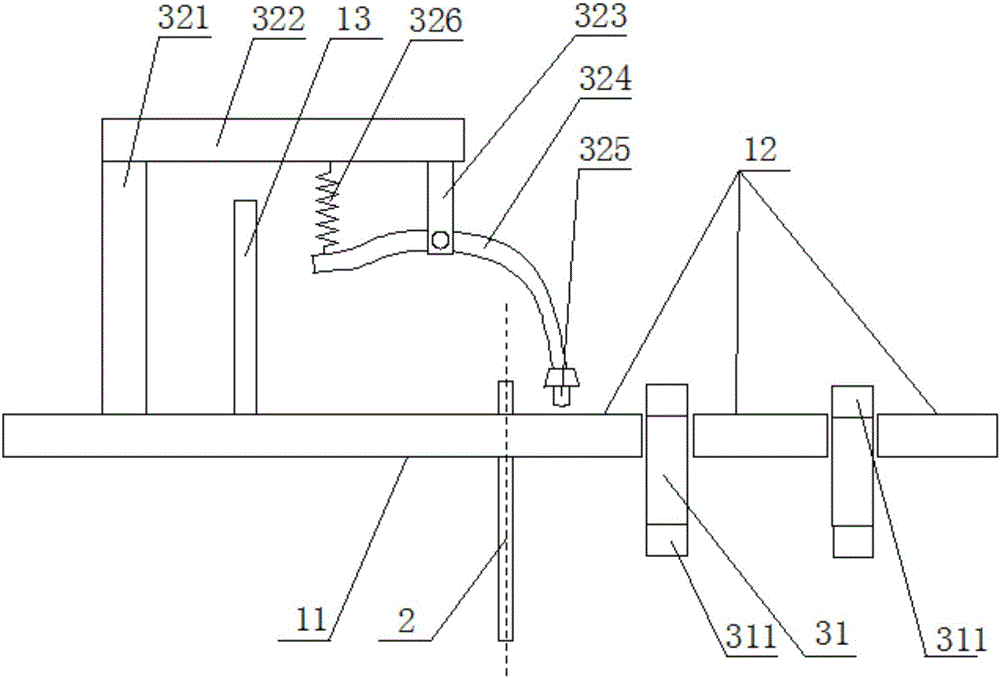

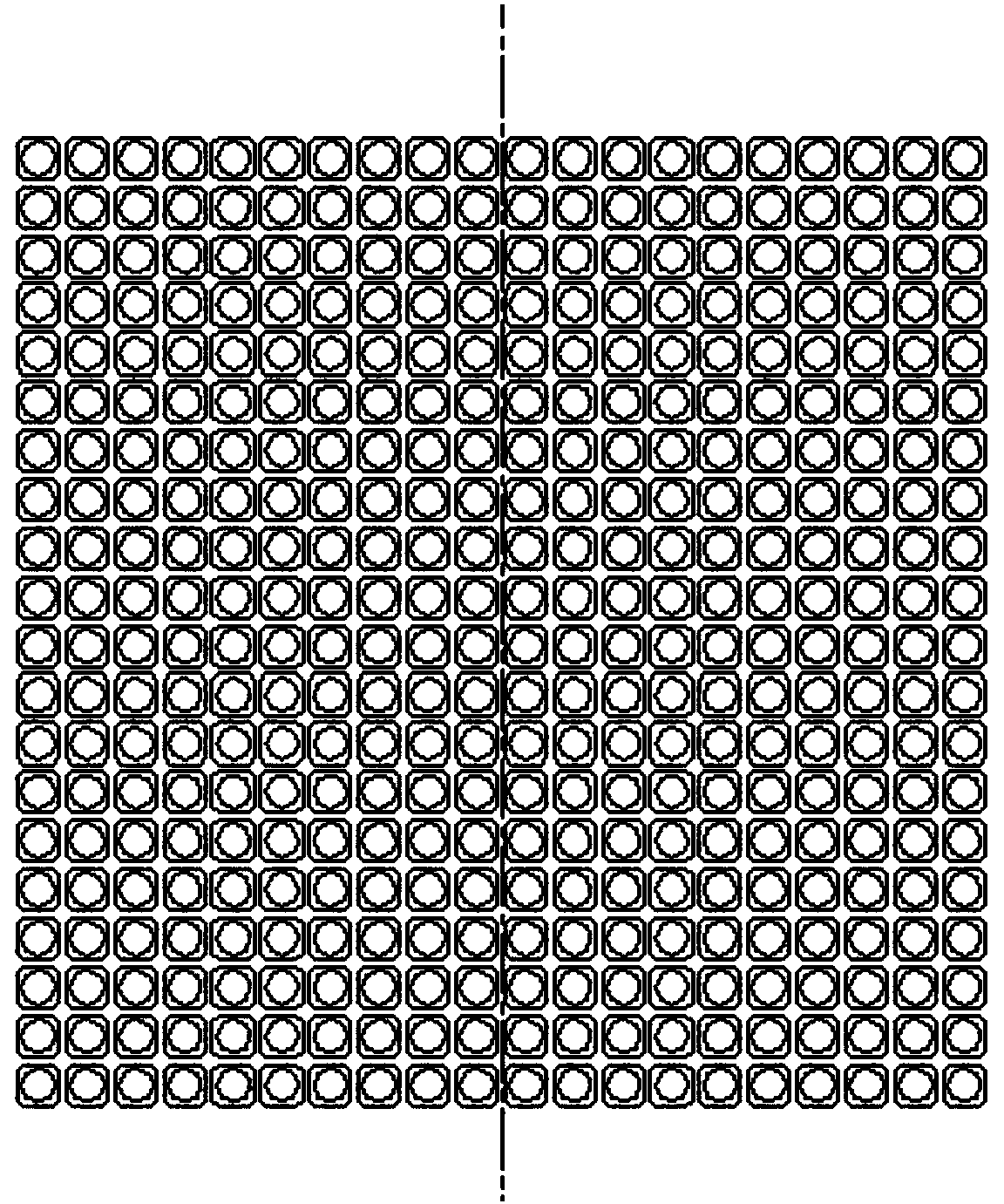

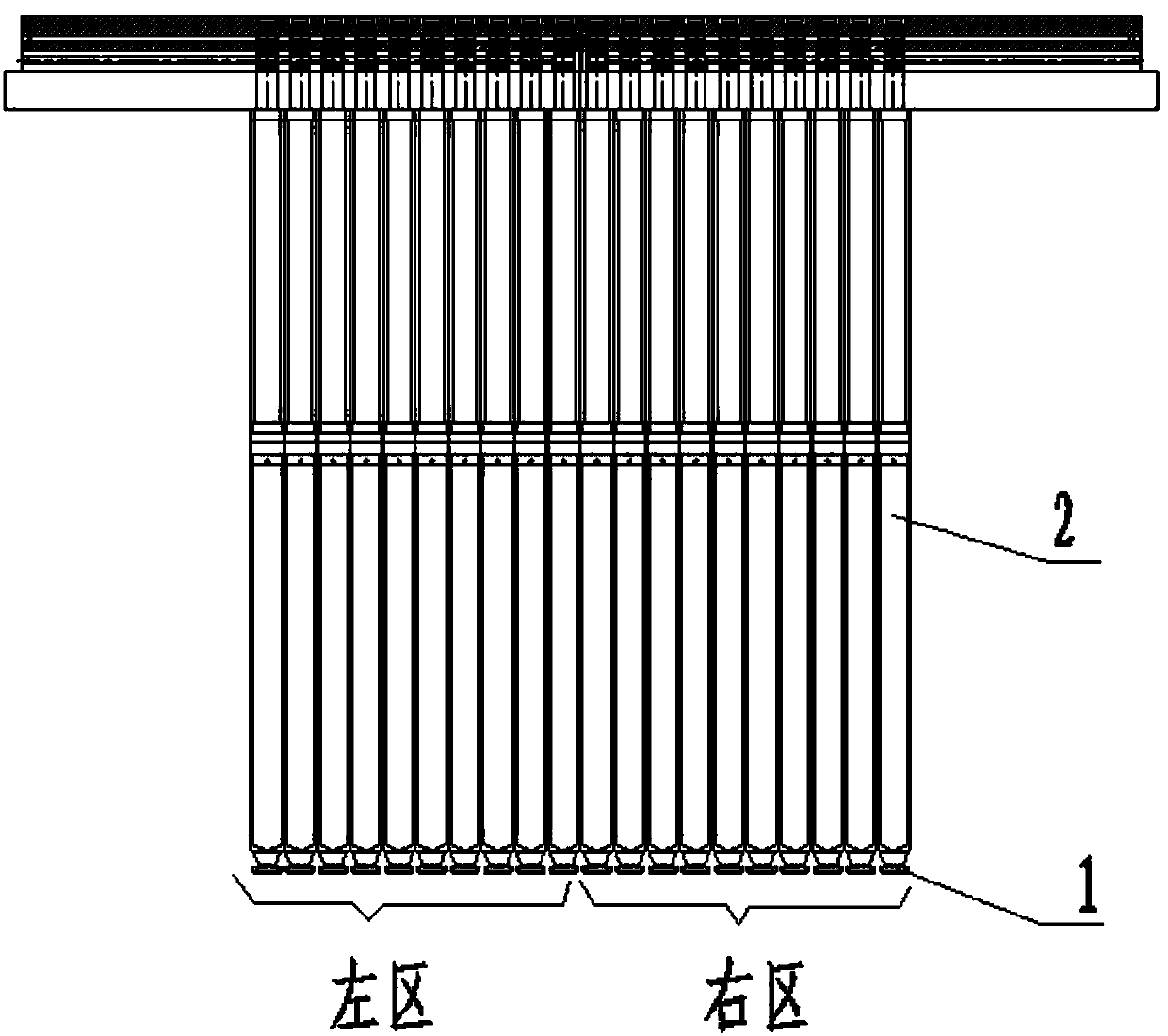

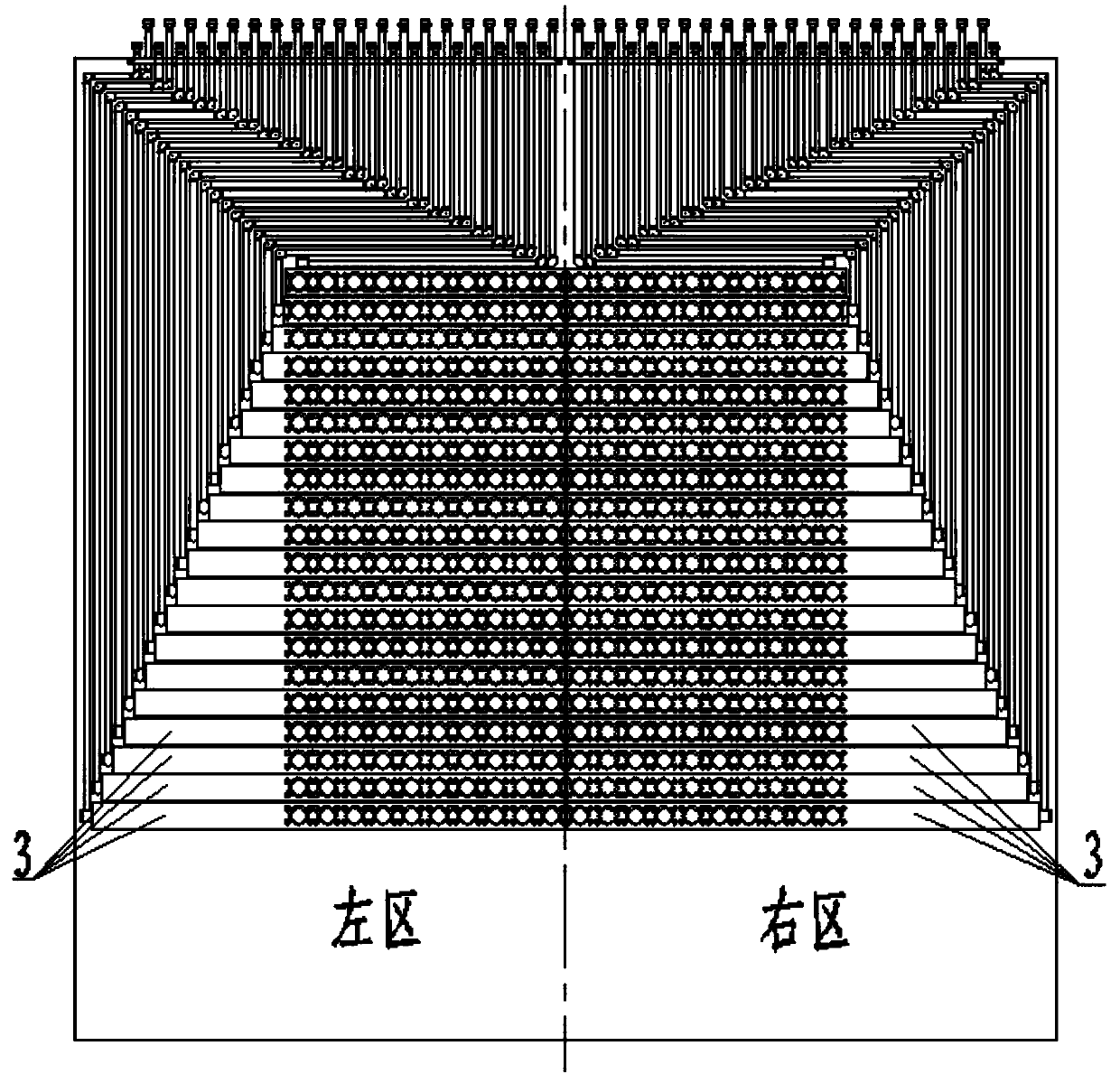

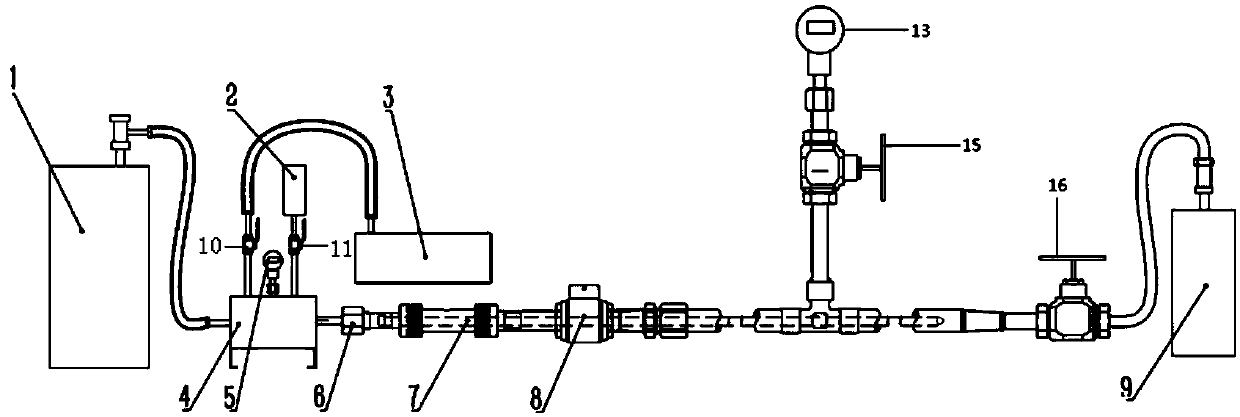

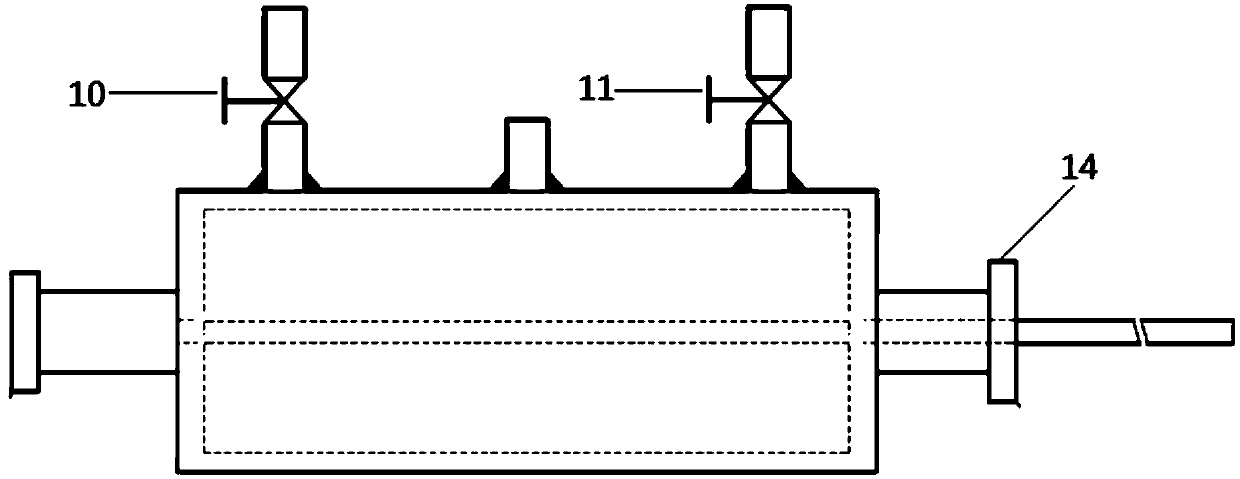

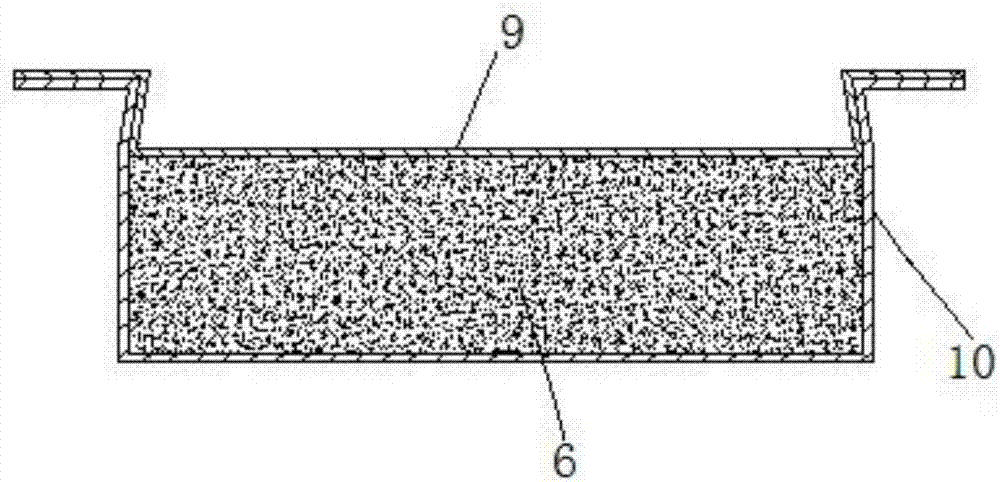

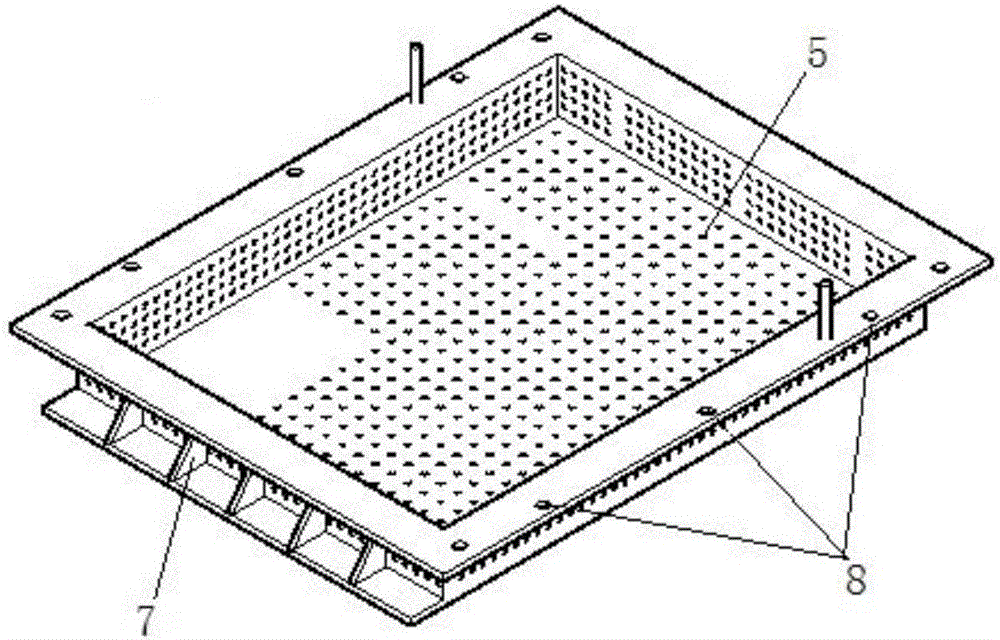

Oil channel structure of cold bending machine for forming three-dimensional curved surface plate material and method for pressing plate material

InactiveCN108097763AEasy to processAchieve suppressionVehicle componentsHydraulic cylinderEngineering

The invention discloses an oil channel structure of a cold bending machine for a three-dimensional curved surface plate material and a method for pressing the plate material, and particularly discloses the oil channel structure of the cold bending machine for forming the three-dimensional curved surface plate material. The oil channel structure includes a hydraulic cylinder connected with indenters of an upper die / a lower die of the cold bending machine, and the upper die / the lower die of the cold bending machine is provided with M * N indenters. The oil channel structure is characterized in that the indenters are divided into a left area and a right area from the center of the die by indenter array corresponding to the upper die / the lower die of the cold bending machine; the indenters ofeach area are correspondingly arranged an independent oil channel according to a line or a column of the indenter array; each oil channel is in communication with a hydraulic cylinder, and the hydraulic cylinder is correspondingly connected with each indenter in the corresponding line or column of the area; the setting mode of the oil channel in the left area is the same as the setting mode of theoil channel in the right area; and the oil supply of each oil channel is controlled separately. The indenters of the dies are partitioned and controlled, and machining of plates with large twist andlongitudinal curvature can be realized.

Owner:山东中硕机械装备制造有限公司

Neutron flux tube inspection integrated device

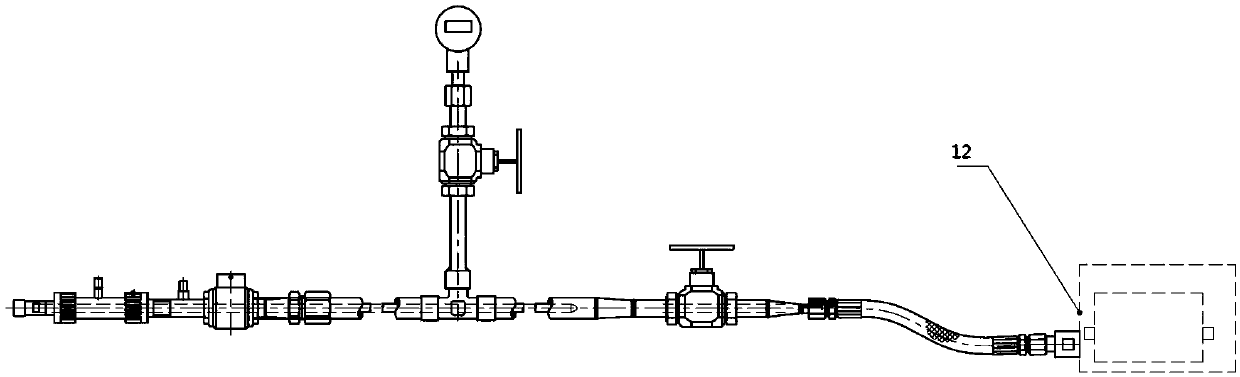

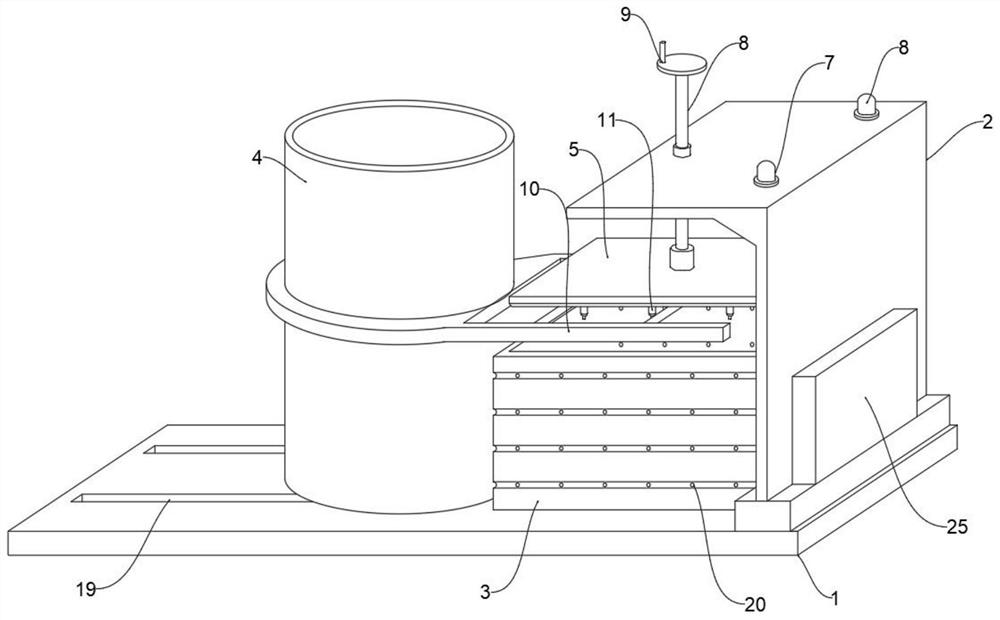

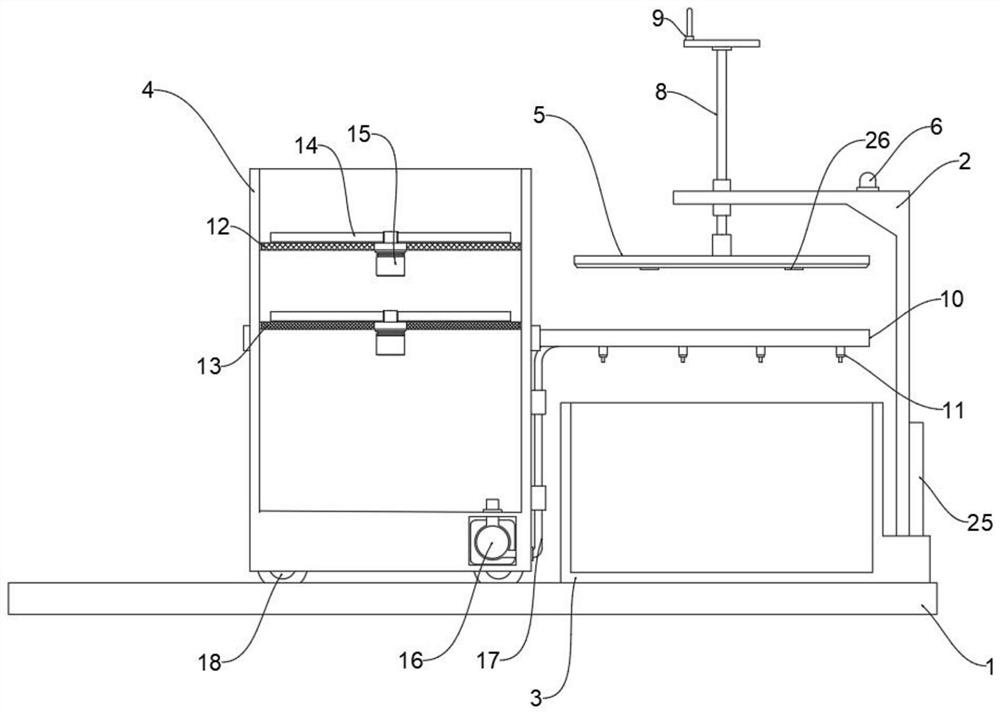

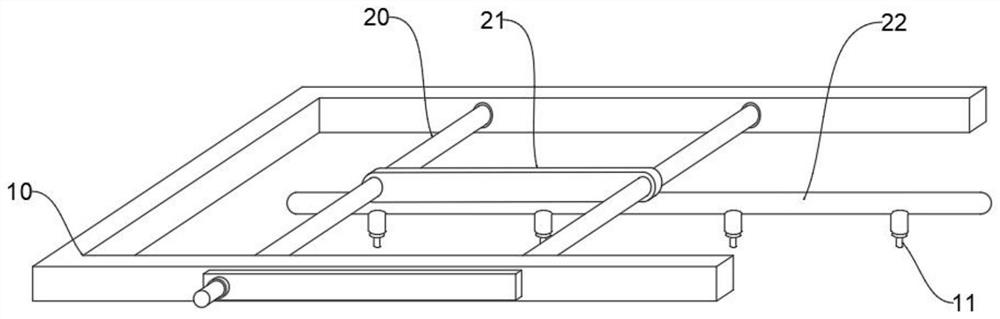

PendingCN111091918ASimple structureImprove sealingNuclear energy generationNuclear monitoringNuclear powerHelium gas

The invention relates to the technical field of nuclear power station maintenance, in particular to an integrated device suitable for nuclear reactor neutron flux tube overall water pressure test andhelium inspection. After a neutron flux tube spare part is prepared, a leakage detection device is designed for the requirements of a water pressure test and a nondestructive test, and support is provided for quality inspection of the spare part. In the invention, a helium leakage detector is connected with a helium leakage detection connecting device through a corrugated pipe buckle, a neutron flux tube is connected with the helium leakage detection device, a handle end is fixed at a sealing section of a middle body, the sealing section of the middle body is connected with a sealing ball valve through a bolt; in a helium leakage detection state, the outer wall helium filling device of the neutron flux tube is connected with the sealing ball valve through a transverse stop valve, a pressure gauge is connected with the sealing ball valve through a vertical stop valve; and in a water pressure test state, a hydraulic booster pump is connected with the sealing ball valve through the transverse stop valve. The efficiency is improved, the cost is saved, and the purpose of leakage detection can be well achieved.

Owner:CNNC NUCLEAR POWER OPERATION MANAGEMENT +1

Preparation method of dried bean curd sheets

InactiveCN113057289AImprove qualityFortified calcium nutritionFood preservationCheese manufactureBiotechnologyNutrition

The invention discloses a preparation method of dried bean curd sheets, relates to the technical field of bean curd sheet preparation, and aims to solve the problems of serious nutrition loss and uneven forming quality in the existing bean curd sheet preparation process. The method comprises the following steps: 1, soaking soybeans in soaking water for a fixed time; 2, putting the washed soybeans into a pulping machine for pulping; 3, heating the raw soybean milk in a cooking container at high temperature; 4, filtering the cooked soybean milk by using a 100-mesh gauze, and naturally cooling the filtered soybean milk in a marinating barrel; 5, when the cooked soybean milk in the marinating barrel is cooled to 80 DEG C, 0.3% of edible salt is preferentially added, the use taste is improved, and a coagulating agent is gradually poured into the marinating barrel after the edible salt is dissolved; 6, after marinating, standing and curing to form the beancurd jelly flower; 7, crushing the uncongealed beancurd flower by using a forming machine; and 8, after the cloth liner is wetted, spreading the cloth liner in a forming cavity, and injecting the crushed beancurd jelly into the forming cavity for compression forming.

Owner:安徽花蜜花开食品有限公司

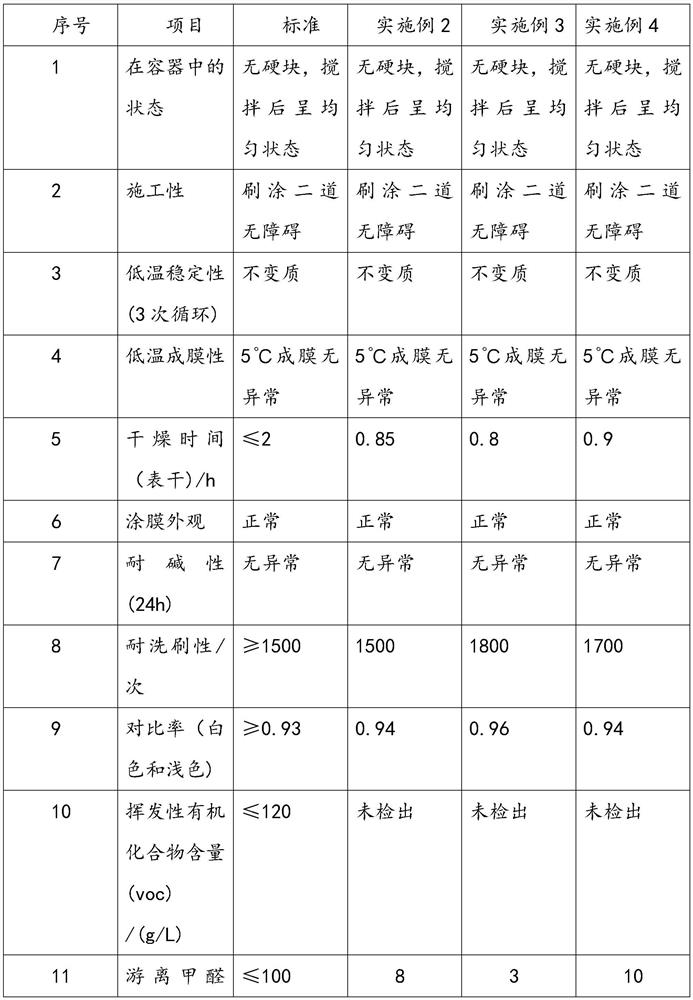

Odor-free total-effect interior wall paint and preparation method thereof

PendingCN114621642AImprove performanceLow VOCAntifouling/underwater paintsPaints with biocidesCellulosePolymer science

The invention relates to the technical field of latex paint, in particular to odor-free full-effect interior wall paint and a preparation method thereof.The odor-free full-effect interior wall paint is prepared from, by weight, 19%-21% of deionized water, 35%-37% of pigment and filler, 30%-32% of emulsion, 7.2%-7.3% of film-forming agent, 0.3%-0.4% of bactericide, 0.6%-0.7% of cellulose, 0.6%-0.7% of defoaming agent, 0.8%-1% of dispersing agent and 3.15%-3.25% of assistant.The odor-free full-effect interior wall paint can effectively reduce VOC of latex paint and has the advantages that the odor-free full-effect interior wall paint is environmentally friendly, the environment-friendly effect is achieved, and the environment-friendly effect is achieved. The functions of inhibiting and killing germs, removing carcinogenic toxic substances, removing peculiar smell and purifying air are realized.

Owner:广西印建奇新型建筑材料有限公司

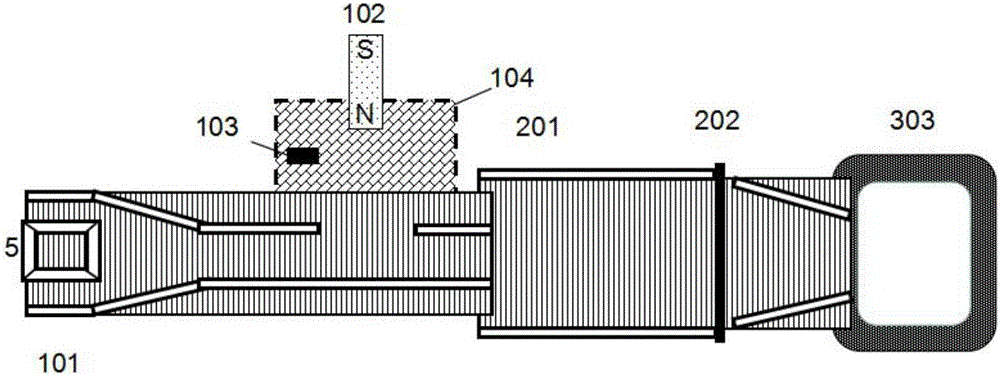

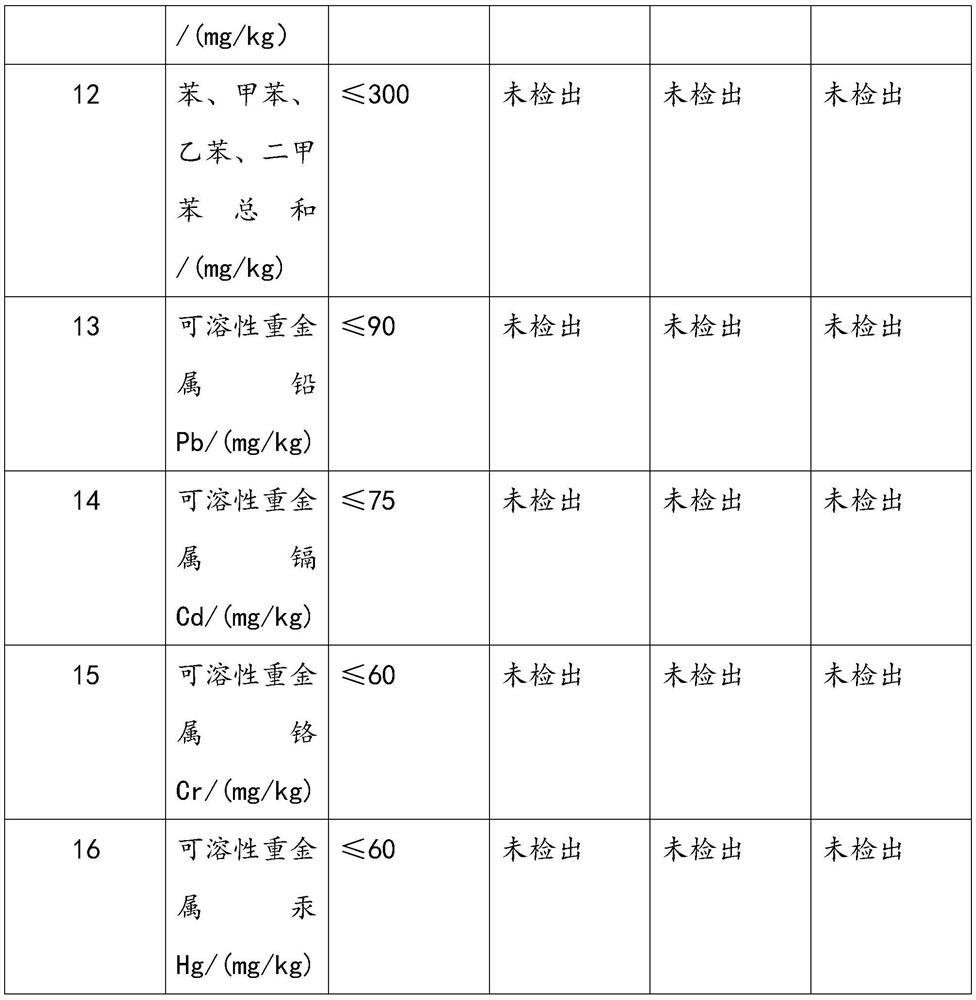

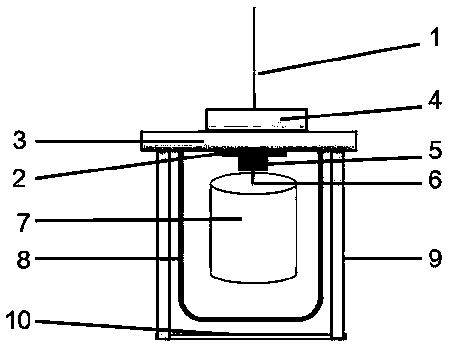

A deep-sea long-life electric field sensor

ActiveCN106291015BAvoid deformationAvoid frackingManufacture of electrical instrumentsEpoxyElectric field sensor

The invention provides an electric field sensor suitable for a deep-sea environment. The electric field sensor comprises a protective shell, and an inner electrode core and a filter element arranged inside the shell from top to down. The electric field sensor is characterized in that the filter element is a diatom ceramic cylinder, the inner electrode core is formed by pressing and calcining nano silver and nano silver chloride powder and graphene slurry, the upper end of the inner electrode core is sealed and filled with epoxy resin, an electrode wire is led out of the shell from the upper end of the inner electrode core, via a solder joint and through the epoxy resin sealing filler, the inner electrode core is fixed to a fixed sealing sleeve at the upper end of the protective shell, the diatom ceramic cylinder and the protective shell are arranged in sequence outside, the other side of the protective shell is connected with the external environment, and the protective shell is equipped with a fixed pressure cap at the bottom. The electric field sensor can be applied to electric field signal detection and automatic equipment probe control in deep-sea oil pipelines, deep-sea communication cables, and deep-sea detection equipment. The electric field sensor has the advantages of simple structure, stable performance, high sensitivity, long life, and the like, and has a good application prospect.

Owner:QINGDAO UNIV OF SCI & TECH

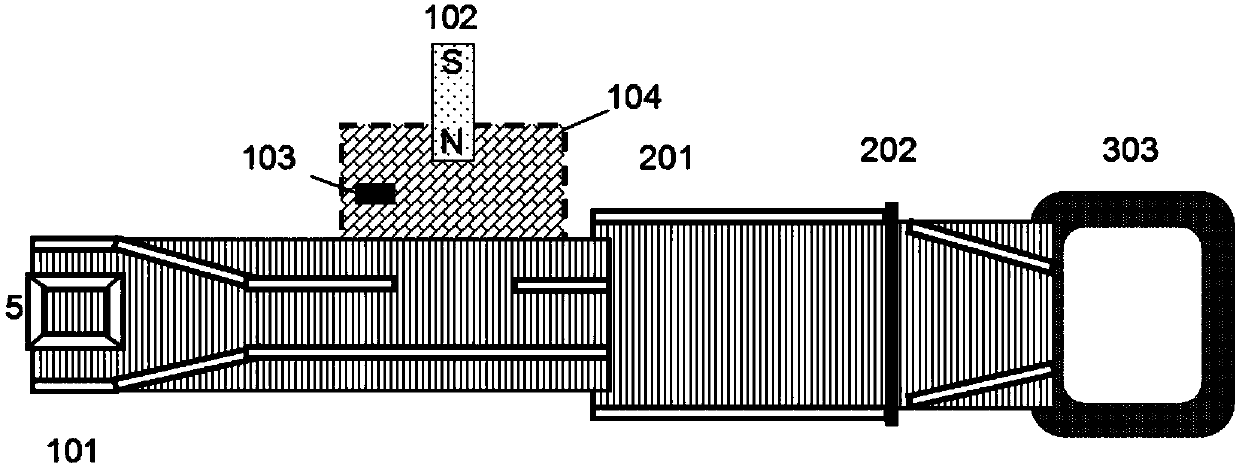

A pretreatment can packaging device for removing iron cans from waste cans

ActiveCN106915109BRealize automatic identificationAchieve weighingMagnetic separationPressesMaterial resourcesFully automatic

The invention discloses a pretreatment type pop-top can packing device for eliminating iron pop-top cans in waste pop-top cans, and belongs to the automatic packing field, and the pretreatment type pop-top can packing device can be used for eliminating iron pop-top cans in a process of packing aluminum pop-top cans. The equipment comprises a loading system (1), a feeding system (2), a pop-top can packing system (3), an unloading system (4), a pretreatment funnel (5) and a control host (6). A pretreatment funnel is used for eliminating impurities such as dust in the pop-top cans, a strong magnet is adopted to eliminate the iron pop-top cans in a conveying process, and the pop-top cans are pressed into blank, so that fully-automatic pressing for the pop-top cans can be realized, manual intervention is not needed throughout the process, and a great deal of manpower and material resources are saved.

Owner:平湖市宸信机械有限责任公司

Two-piece cap structure

The invention discloses a two-piece cap structure. The two-piece cap structure comprises a cap top, two side cap pieces and a rear end cap piece, wherein the two side cap pieces are fixedly mounted atthe lower left and lower right ends of the cap top, the rear end cap piece is fixedly mounted at the lower end of the rear side of the cap top, the two side cap pieces and the rear end cap piece areof an integrally formed structure, a projecting groove is formed in the middle of the rear end cap piece, a cap brim is connected into the cap top, a passages a is formed in the joint between each ofthe two side cap pieces and the cap top, a telescopic support rod is mounted in each passage a, and a stop piece device is fixedly mounted in each of the two side cap pieces. The two-piece cap structure has the advantage that the passage a is formed in the joint between each of the two side cap pieces and the cap top and used for mounting the telescopic support rod, a passage c is formed in the front end of the cap brim, and during use, the telescopic support rods penetrate through the passages a and c to fix two sides of the cap brim, so that the cap brim is stiff.

Owner:IANGSU COLLEGE OF ENG & TECH

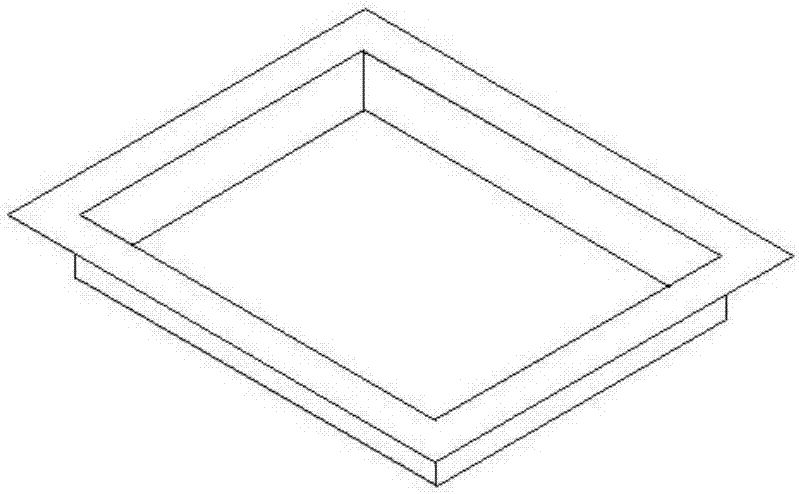

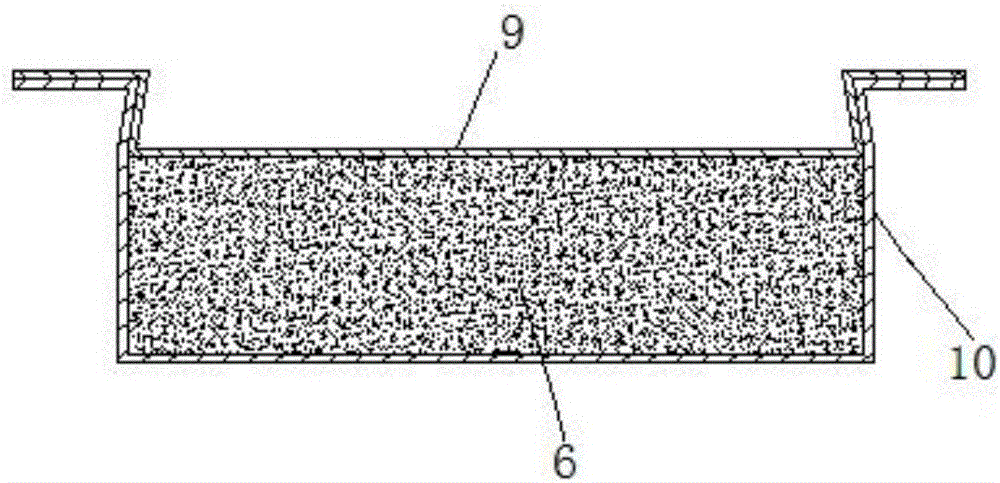

A freely shrinkable flat-pack vertical pressure mold for isostatic pressing and its pressing method

The invention discloses a flat-packed vertical pressure mold for isostatic pressing that can shrink freely, including a flat-packed mold, a flat-packed rubber sleeve, a top pressure plate and a shaping pressure bar; wherein the flat-packed mold has a flat cavity and no upper cover, and the flat-packed rubber The sleeve includes upper and lower rubber sleeves that are both concave, and the shape of the concave part is consistent with the shape of the cavity of the paper-pack mold, and the two are nested with each other to form a cavity for containing powder. The invention also discloses a method of using the mold for isostatic pressing: lay the flat-packed mold flat, put the lower rubber sleeve on the mold, install the powder, then put the upper rubber sleeve on the lower rubber sleeve, and seal the two through a sealing device ; Cover the top pressure plate on the upper surface of the concave part of the upper rubber sleeve, then push the supporting legs of the shaping pressure rod on the top surface of the top pressure plate, and fix it with the flat-pack mold; then put the mold vertically into the isostatic press for suppress. The device and method of the invention have high powder loading efficiency, uniform powder, can prepare large-size slabs, and have a high qualified rate of products.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Isostatic pressing flush vertical press type die capable of telescoping freely and pressing method

The invention discloses an isostatic pressing flush vertical press type die capable of telescoping freely. The isostatic pressing flush vertical press type die comprises a flush die, a flush rubber sleeve, a top pressing plate and shaping pressing rods. The flush die is provided with a flat cavity and no upper cover. The flush rubber sleeve comprises a U-shaped upper rubber sleeve body and a U-shaped lower rubber sleeve body. The shape of the U-shaped portion of the upper rubber sleeve body or the lower rubber sleeve body is identical to that of the cavity of the flush die. The upper rubber sleeve body is embedded in and sleeved with the lower rubber sleeve body to form a cavity for containing powder. The invention further discloses an isostatic pressing method with the isostatic pressing flush vertical press type die applied. The method comprises the steps that the flush die is placed flatwise, the lower rubber sleeve body is placed on the flush die in a sleeved mode, the lower rubber sleeve body is loaded with the powder, then the upper rubber sleeve body is placed on the lower rubber sleeve body in the sleeved mode, and the upper rubber sleeve body and the lower rubber sleeve body are sealed through a sealing device; the upper surface of the downward concave portion of the upper rubber sleeve body is covered with the top pressing plate, supporting legs of the shaping pressing rods are placed on the upper surface of the top pressing plate in an abutting mode, and the shaping pressing rods are fixed to the flush die; and then the die is vertically placed into an isostatic pressing machine for pressing. The device and method provided by the invention are high in powder loading efficiency, capable of manufacturing large-sized plate blanks and high in product qualification rate, and the powder is even.

Owner:JINDUICHENG MOLYBDENUM CO LTD

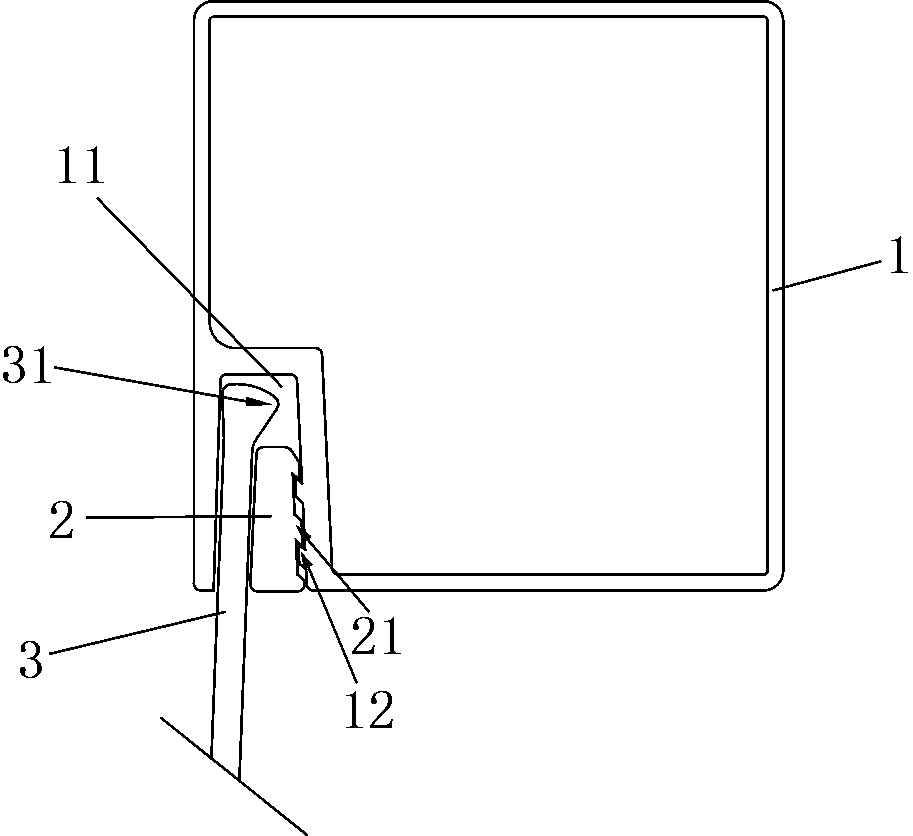

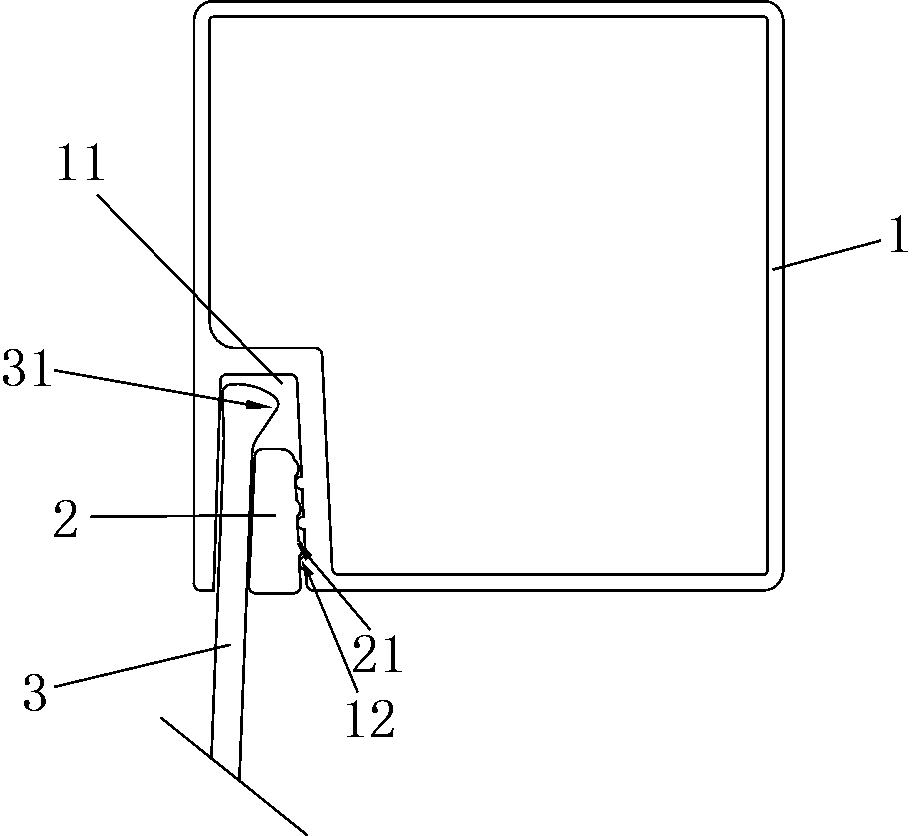

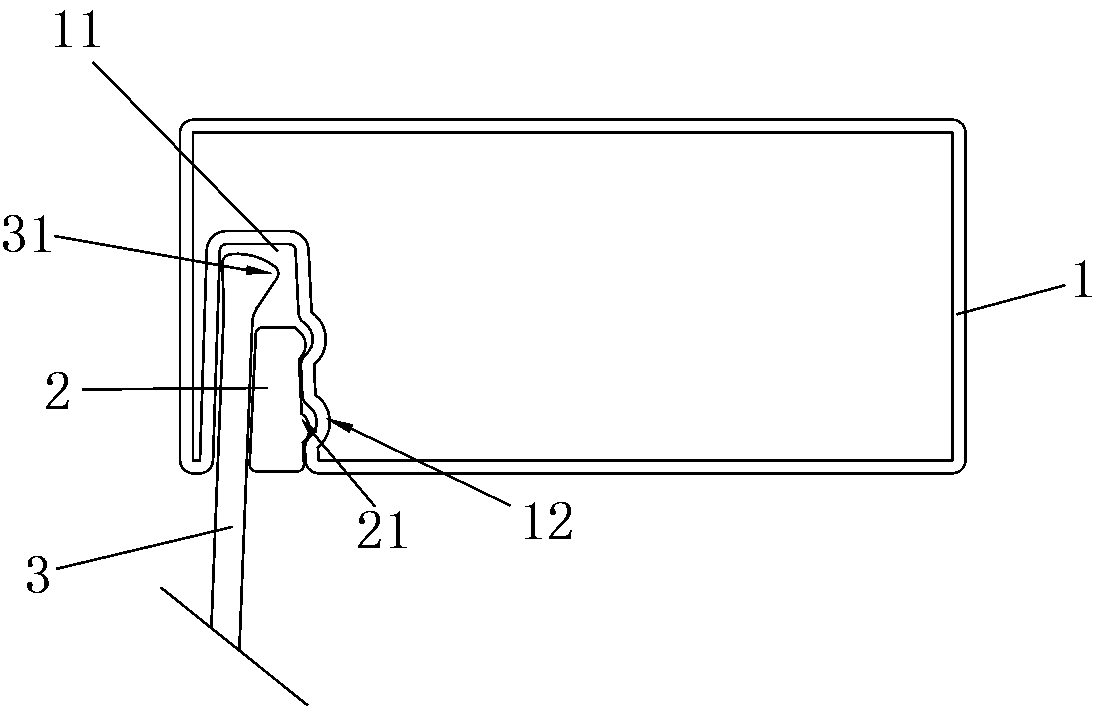

Rattan braided fabric assembling structure and method

PendingCN111070361AAchieve suppressionHigh degree of automationWood working apparatusEngineeringStructural engineering

The invention discloses a rattan braided fabric assembling structure and method. The assembling structure comprises a frame, a limiting piece and a rattan braided fabric. An installing groove is formed in the frame. A clamping position is arranged at the wall of the installing groove. The limiting piece is provided with a clamping portion which is in clamping fit with the clamping position. At least part of the rattan braided fabric is installed inside the installing groove, and the portion, located inside the installing groove is installed at the limiting piece inside the installing groove tobe limited. By improving the assembling mode of the rattan braided fabric, the automatic degree is increased, possibility is supplied to full-automatic operation, the technology is simple, an assembled product is attractive in appearance, and rattan pieces with bevel edges can be pressed.

Owner:浙江天戈实业有限公司

A hand-held moxibustion tablet press

ActiveCN105193623BAchieve suppressionDigitalization of manufacturing pressurePharmaceutical product form changeMedicineAdditive ingredient

Owner:金华市谷腾健康科技有限公司

High-efficiency die forging and pressing device

InactiveCN108817291AAchieve suppressionEasy to controlForging press detailsForging press drivesDrive motorEngineering

The invention discloses a high-efficiency die forging and pressing device. The high-efficiency die forging and pressing device comprises a bottom plate, wherein a workbench is fixedly connected to theleft side of the top of the bottom plate, a die forging machine body is fixedly connected to the top of the workbench, and a fixed forging and pressing device is arranged on the right side of the workbench. The fixed forging and pressing device comprises a clamping box, a movable frame is movably connected to an inner cavity of the clamping box, transmission columns are separately and fixedly connected to the four corners of the movable frame, and a clamping plate is arranged at the top of the clamping box; the top portions of the transmission columns penetrate through the clamping box to theouter side of the clamping box and are fixedly connected to the bottom of the clamping plate, a slide block is fixedly connected to the outer side of the bottom portions of the transmission columns,and the side, far away from the transmission columns, of the slide block is slidably connected to the inner cavity of the clamping box; and a sliding device is arranged at the bottom of the inner cavity of the clamping box, and the sliding device comprises a sliding rail. According to the high-efficiency die forging and pressing device, a threaded rod is driven to rotate by a driving motor, so that left and right movement of a first transmission plate is realized, lifting of the clamping plate is realized, and thus pressing of a workpiece is realized. The high-efficiency die forging and pressing device is easy to control, simple in structure and good in use effect.

Owner:ANHUI SIYUAN SANQING INTELLIGENT MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com