High-thermal-conductivity engineering plastic and preparation method thereof

A technology of engineering plastics and high thermal conductivity, applied in the fields of high thermal conductivity engineering plastics and their preparation, functional plastics and their preparation, can solve problems such as the decline of mechanical properties of plastic processing performance products, achieve excellent mechanical mechanics, and the preparation method is simple and easy Line, the effect of high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

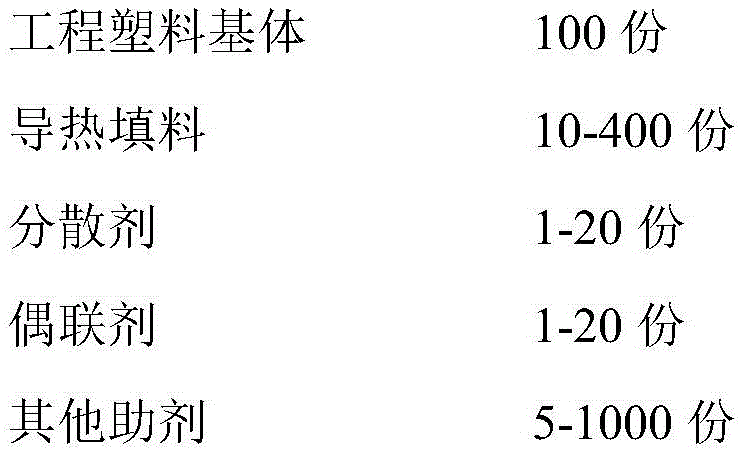

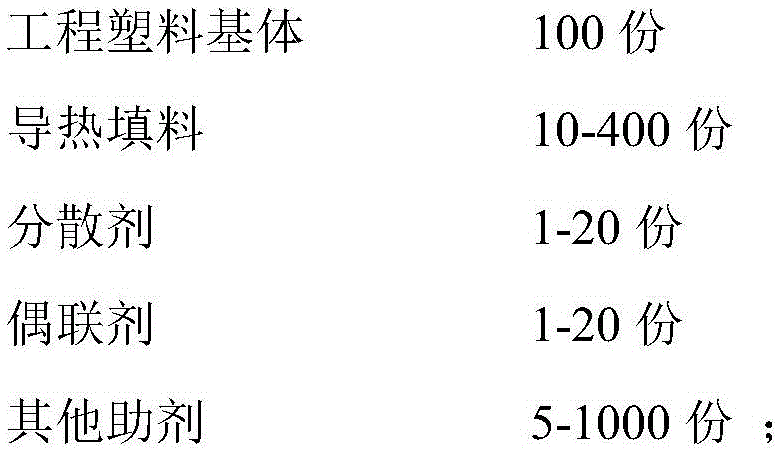

Method used

Image

Examples

Embodiment 1

[0031] Example 1: Boron Nitride / Polycarbonate Composite

[0032] 1. Pretreatment

[0033] Put 100 parts of polycarbonate particles and 25 parts of boron nitride into a vacuum drying oven for 10 hours at 80°C;

[0034] 2. Modification of thermally conductive fillers

[0035] Put the pretreated boron nitride into a ball mill, add 200 parts of absolute ethanol, 2.5 parts of silane coupling agent KH550, 5 parts of polyvinylpyrrolidone and 7 parts of calcium stearate at the same time, ball mill for 5 hours, and then Vacuum dry for 12 hours to obtain modified boron nitride; make the modified boron nitride into a boron nitride / chloroform suspension with a concentration of 5 mg / ml, ultrasonically disperse for 10 hours, and ultrasonic power 500W;

[0036] 3. Preparation of composite materials

[0037] Mix the pretreated polycarbonate particles with the ultrasonically dispersed boron nitride / chloroform suspension, add 5 parts of ethylene bisstearamide and 5 parts of higher fatty alco...

Embodiment 2

[0038] Example 2: Boron Nitride / Polycarbonate Composite

[0039] 1. Pretreatment

[0040] Put 100 parts of polycarbonate particles and 100 parts of boron nitride into a vacuum drying oven at 80°C for 10 hours;

[0041] 2. Modification of thermally conductive fillers

[0042] Put the pretreated boron nitride into a ball mill, add 250 parts of absolute ethanol, 4 parts of silane coupling agent KH550, 6 parts of sodium lauryl sulfate and 7 parts of calcium stearate, ball mill for 6 hours, and then Vacuum dry at 80°C for 12 hours to obtain modified boron nitride; prepare the modified boron nitride into a boron nitride / chloroform suspension with a concentration of 5mg / ml, ultrasonically disperse for 15h, and ultrasonic power is 500W;

[0043] 3. Preparation of composite materials

[0044] Mix the pretreated polycarbonate particles with the ultrasonically dispersed boron nitride / chloroform suspension, add 6 parts of ethylene bis stearamide and 6 parts of higher fatty alcohol and ...

Embodiment 3

[0045] Example 3: Boron Nitride / Polycarbonate Composite

[0046] 1. Pretreatment

[0047] Put 100 parts of polycarbonate particles and 230 parts of boron nitride into a vacuum drying oven at 80°C for 10 hours;

[0048] 2. Modification of thermally conductive fillers

[0049] Put the pretreated boron nitride into a high-speed shear disperser, add 400 parts of absolute ethanol, 5 parts of silane coupling agent KH570, 6 parts of sodium lauryl sulfate and 7 parts of calcium stearate, shear Cut and disperse for 5 hours, then vacuum dry at 80°C for 15 hours to obtain modified boron nitride; prepare the modified boron nitride into a boron nitride / chloroform suspension with a concentration of 5 mg / ml, and ultrasonically disperse for 15 hours with an ultrasonic power of 500W ;

[0050] 3. Preparation of composite materials

[0051] Mix the pretreated polycarbonate particles with the ultrasonically dispersed boron nitride / chloroform suspension, add 6 parts of ethylene bisstearamide an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com