Isostatic pressing flush vertical press type die capable of telescoping freely and pressing method

An isostatic pressing and plain packaging technology, applied in the field of static pressing, can solve the problems of difficult powder loading, small slab size, easy tearing of the film mouth, etc., to ensure the pass rate, ensure the regularity, and achieve uniform distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to the following embodiments.

[0039] The flat-pack vertical press mold for isostatic pressing in this embodiment includes a flat-pack mold 1 , a flat-pack rubber sleeve 2 , a top plate 3 and a shaping pressure bar 4 .

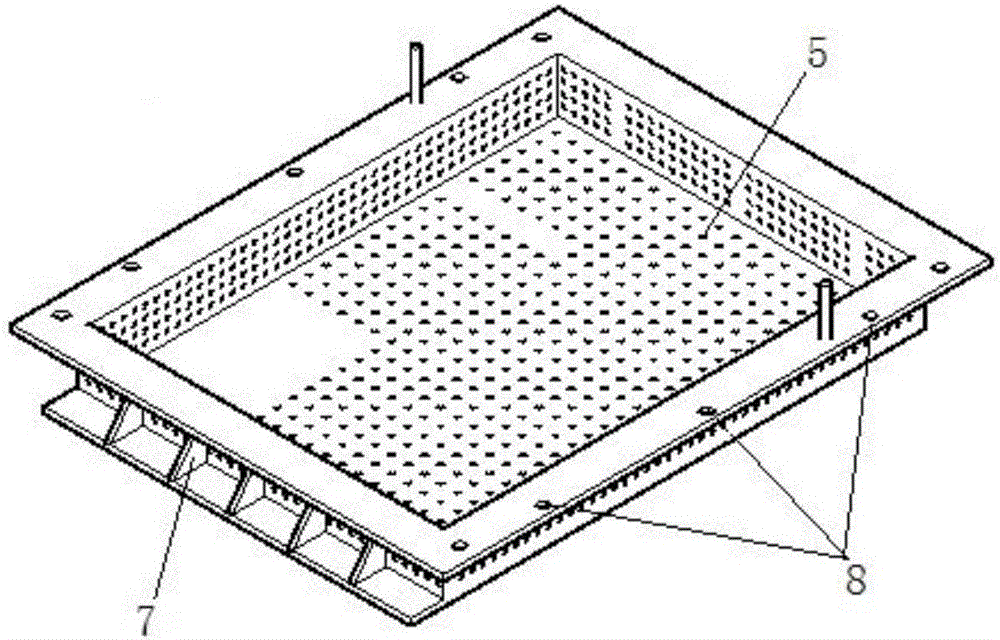

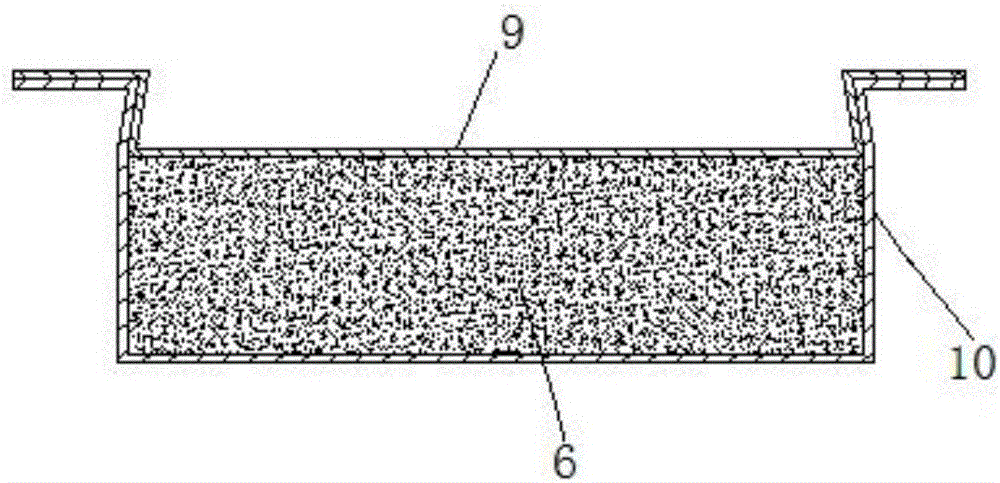

[0040] Such as figure 1 As shown, the flat-pack mold 1 is a square structure, made of a thicker steel plate, with a flat cavity and no upper cover, and through holes 5 are evenly distributed on the bottom plate and the surrounding side walls of the mold. During isostatic pressing, the emulsified The liquid can pass through the through hole 5 and transmit the pressure to the rubber sleeve 2 and the powder 6 . In order to improve the strength of the mould, reinforcing ribs 7 are added outside the surrounding side walls. In order to facilitate fixing other parts, the upper part o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com