Gas dispenser and gas station composed of the same

A technology of gas filling machine and gas filling gun, applied in the field of gas filling station, can solve the problems of large investment, high power consumption, mechanical wear of compressors or hydraulic pumps, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

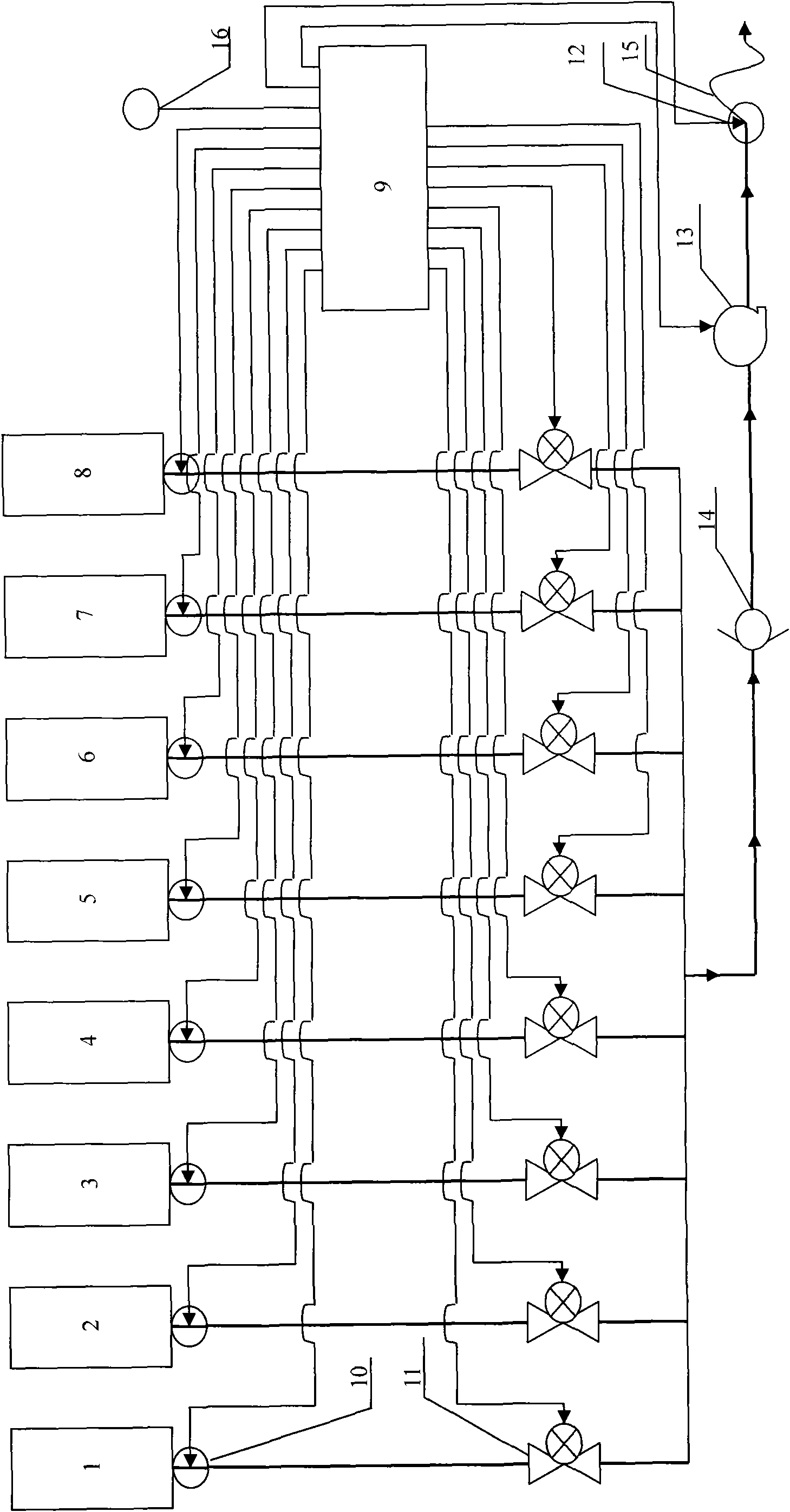

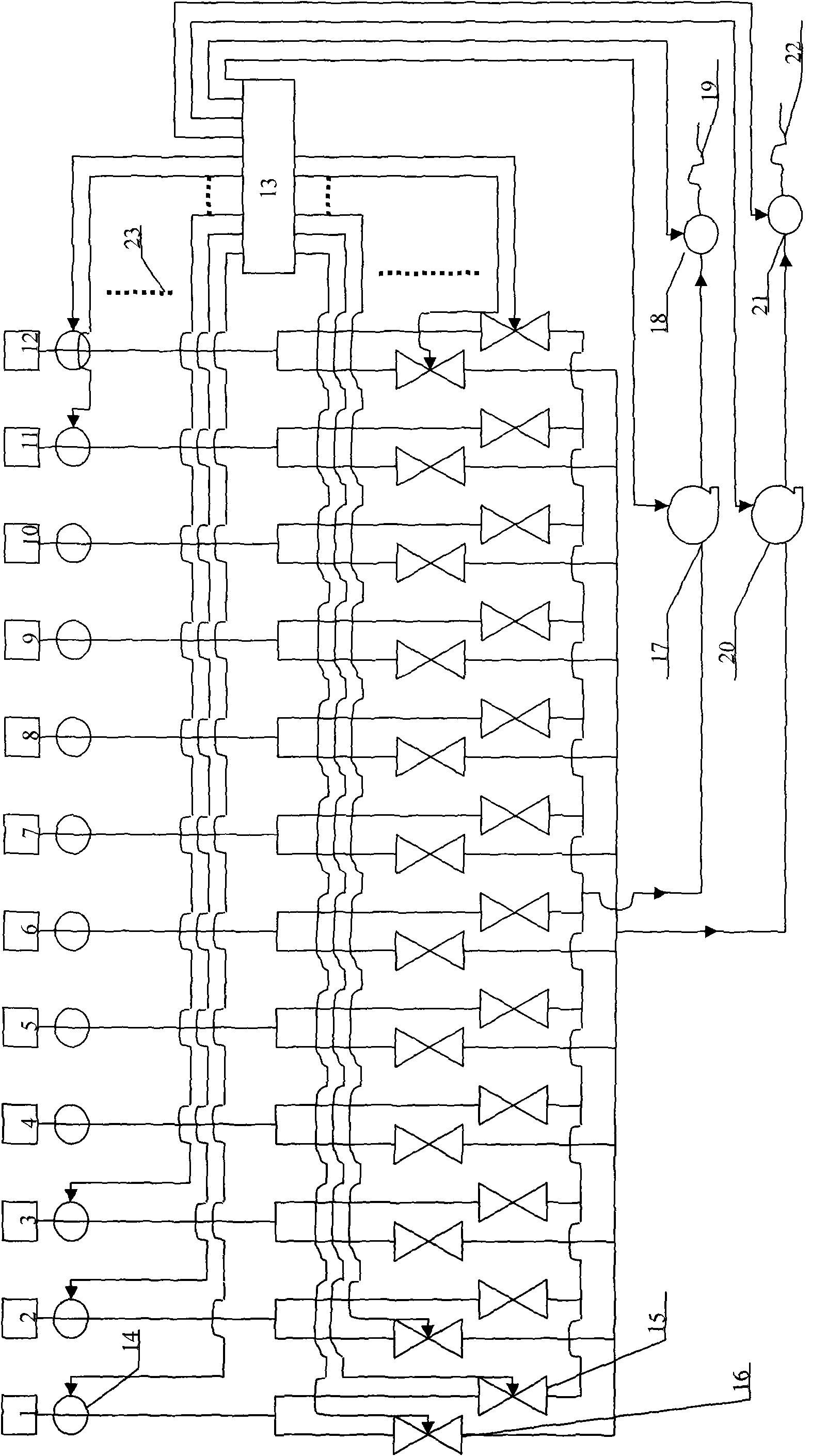

[0094] Technical solution 1:

[0095] The gas path under the multi-gas bottle mouth is a single-channel pipeline, and the sensors and valves are installed on the single-channel pipeline, and the corresponding sensors and valves are connected in parallel and then connected in series with the metering device and the gas filling gun;

[0096] or,

[0097] The gas path under the multi-gas cylinder mouth is divided into multiple outlet pipelines in parallel. Sensors and valves are installed on the corresponding multi-channel pipelines. One of the metering device and the air gun is connected in series;

[0098] Connected with PLC and under its control, it constitutes a single-gun or multi-gun gas dispenser;

[0099] Its technical features are: PLC first collects the pressure value of the pressure sensor in the air gun, that is, the pressure value in the automobile gas cylinder, plus a set value, 0 < set value < 20, the sum of the sum is added to the multi Compare the pressure val...

Embodiment 2

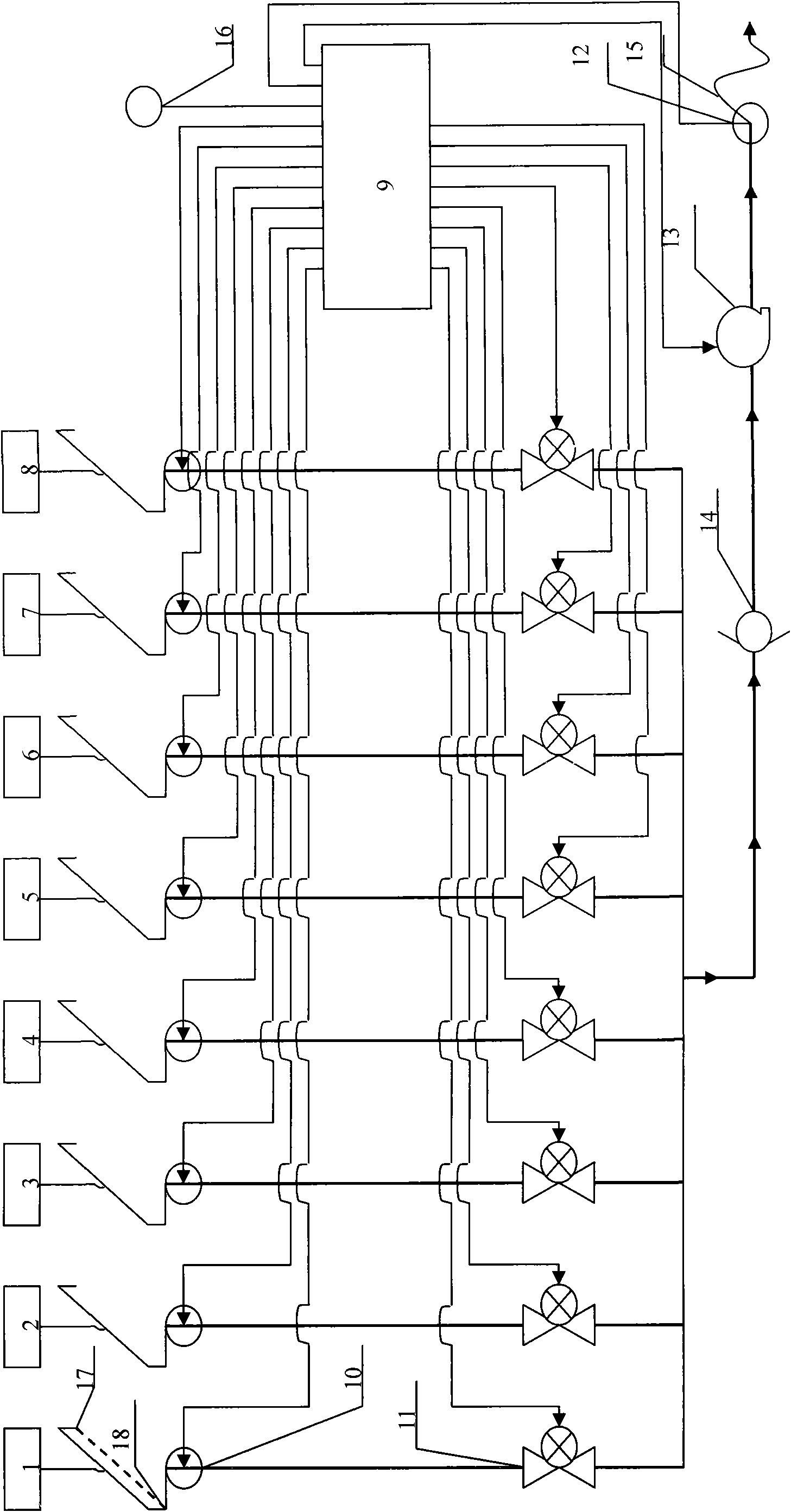

[0120] Technical solution 2:

[0121] The gas filling station is composed of multiple gas cylinders and gas filling machines. Its technical features are: multiple gas cylinders alternately provide high-pressure gas, which meets the continuous filling volume of single or multiple guns of the gas filling machine for automobile gas cylinders.

[0122] Multi-gas cylinders alternately circulate to provide high-pressure gas technical features:

[0123] One or a group of gas cylinders in the multi-gas cylinder needs multiple or one or more groups of gas cylinders behind it to provide high-pressure gas for use. The set value is less than 12MPa, remove the parent gas filling station and fill up with high-pressure gas, then connect it again or directly connect another gas cylinder or group of gas cylinders filled with high-pressure gas, which is the first gas cylinder or group of gas cylinders after the last round Provide high pressure gas;

[0124] For the first cylinder or group of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com