Anti-tightening pull-ups and manufacturing process thereof

A manufacturing process and a technology for pulling pants, which are applied in the field of disposable hygiene products, can solve the problems of irregular wrinkles and poor appearance, and achieve the effects of good wearing shrinkage, reducing wrinkles and ensuring elastic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

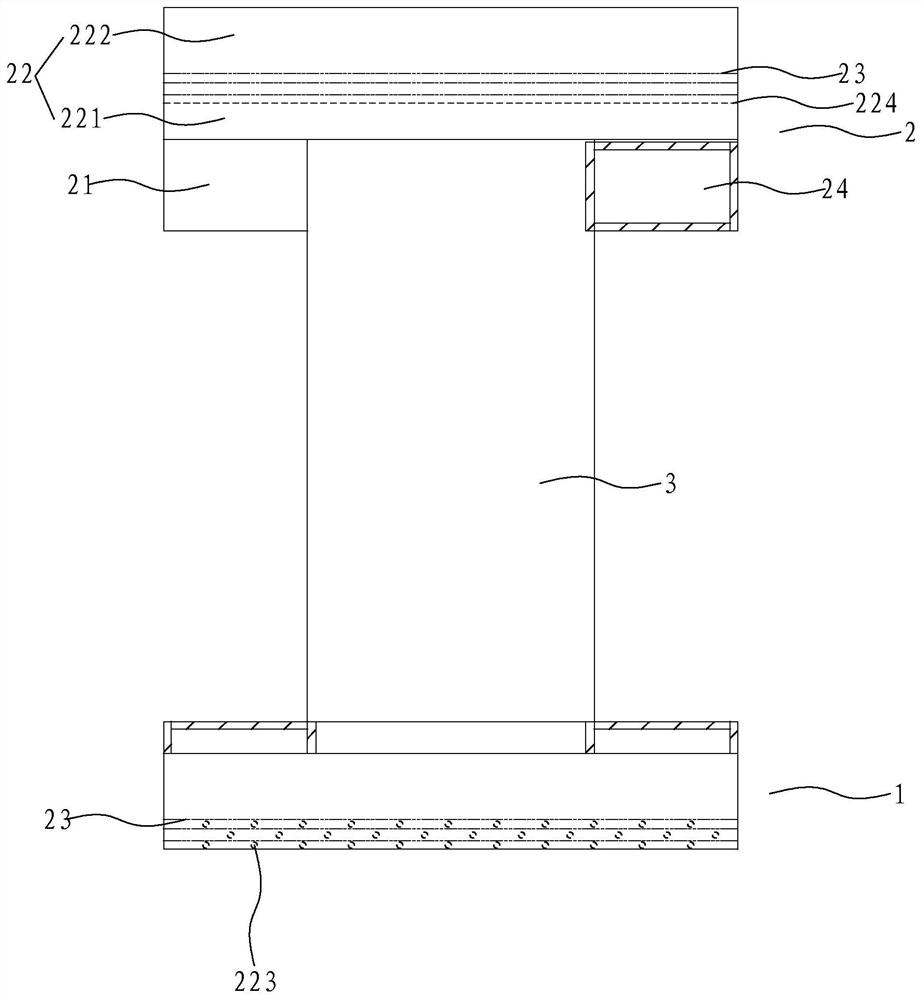

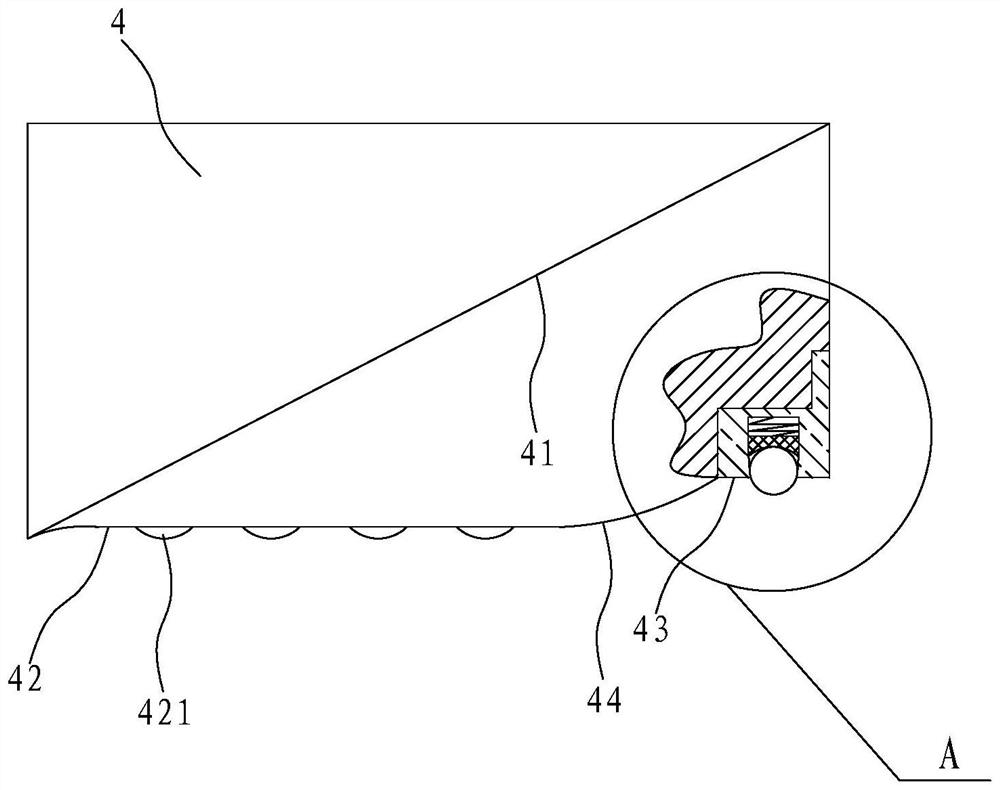

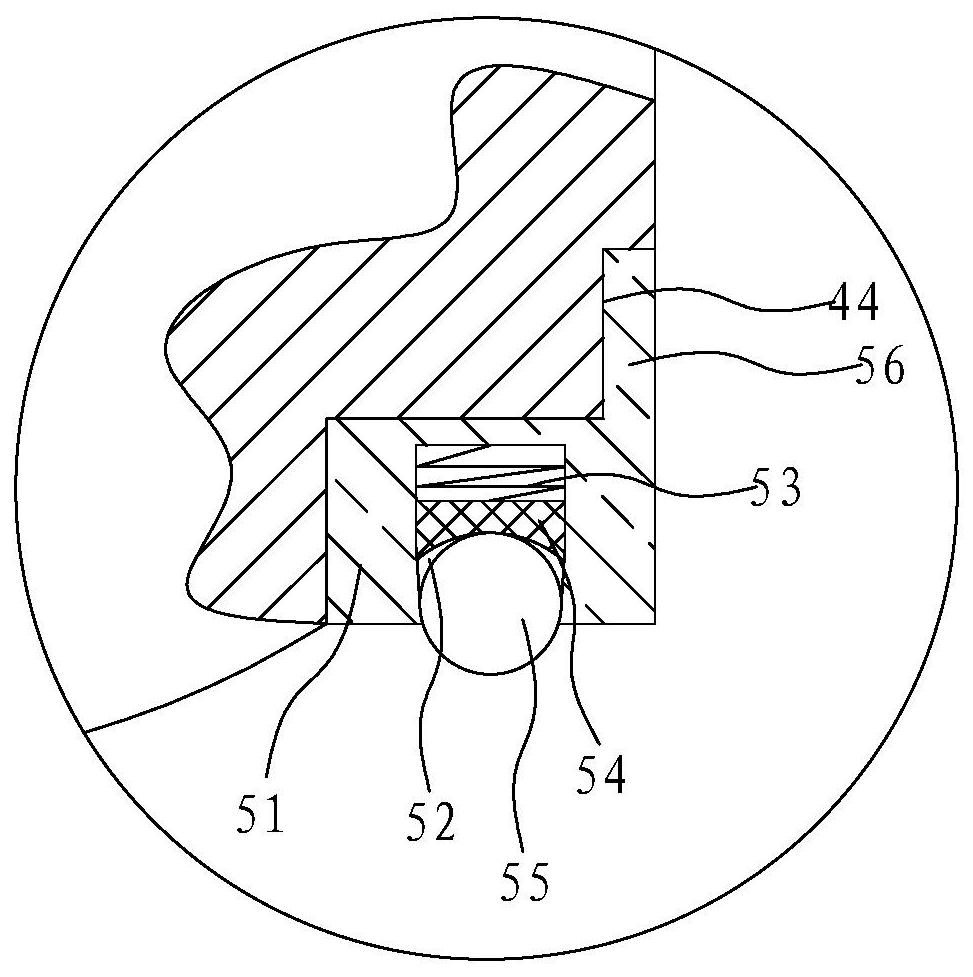

[0036] refer to figure 1, the present embodiment provides a kind of pull-proof pants, comprising a front waist 1, a back waist 2, an absorbent main body 3 arranged between the front waist 1 and the back waist 2, the back waist 2 includes a base material layer 21, the The upper end of the base material layer 21 extends beyond the absorbent main body 3 to form an extension part 22. The extension part 22 is provided with a plurality of elastic bands 23 along the width direction. There is an elastic sheet 24, the elastic sheet 24 extends and covers both sides of the absorbent main body 3, and is bonded with the absorbent main body 3, and the position where the elastic sheet 24 covers the absorbent main body 3 is realized by point breaking Loss of elasticity, and the broken part forms a broken area 241, the side of the elastic sheet 24 away from the abso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com