Automatic bean curd pressing device

A technology of automatic pressing and moving device, applied in dairy products, cheese substitutes, applications, etc., can solve the problems of only pressing one container of tofu, cumbersome operation, low efficiency, etc., saving manpower, easy to take out the container, easy to press Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

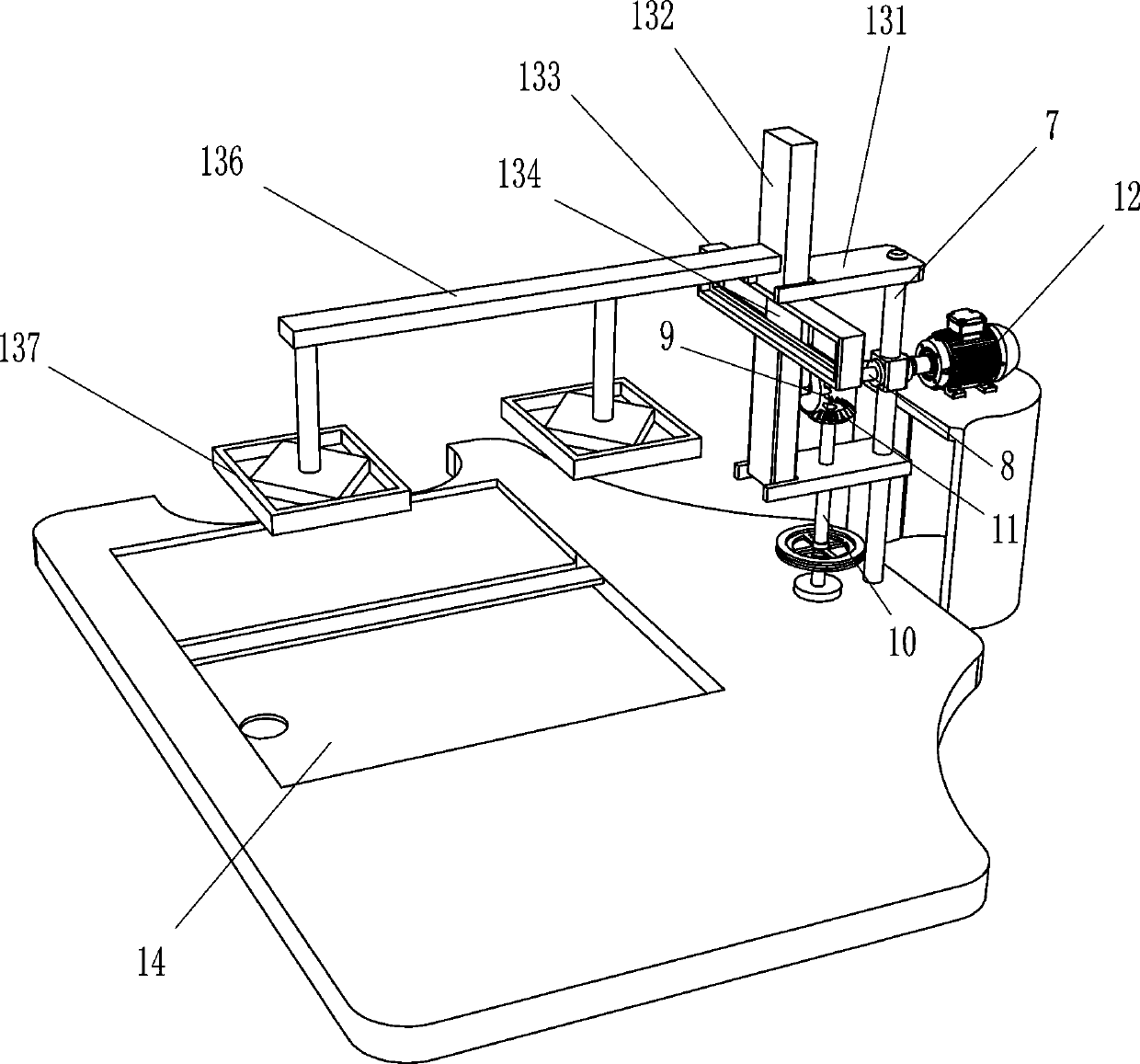

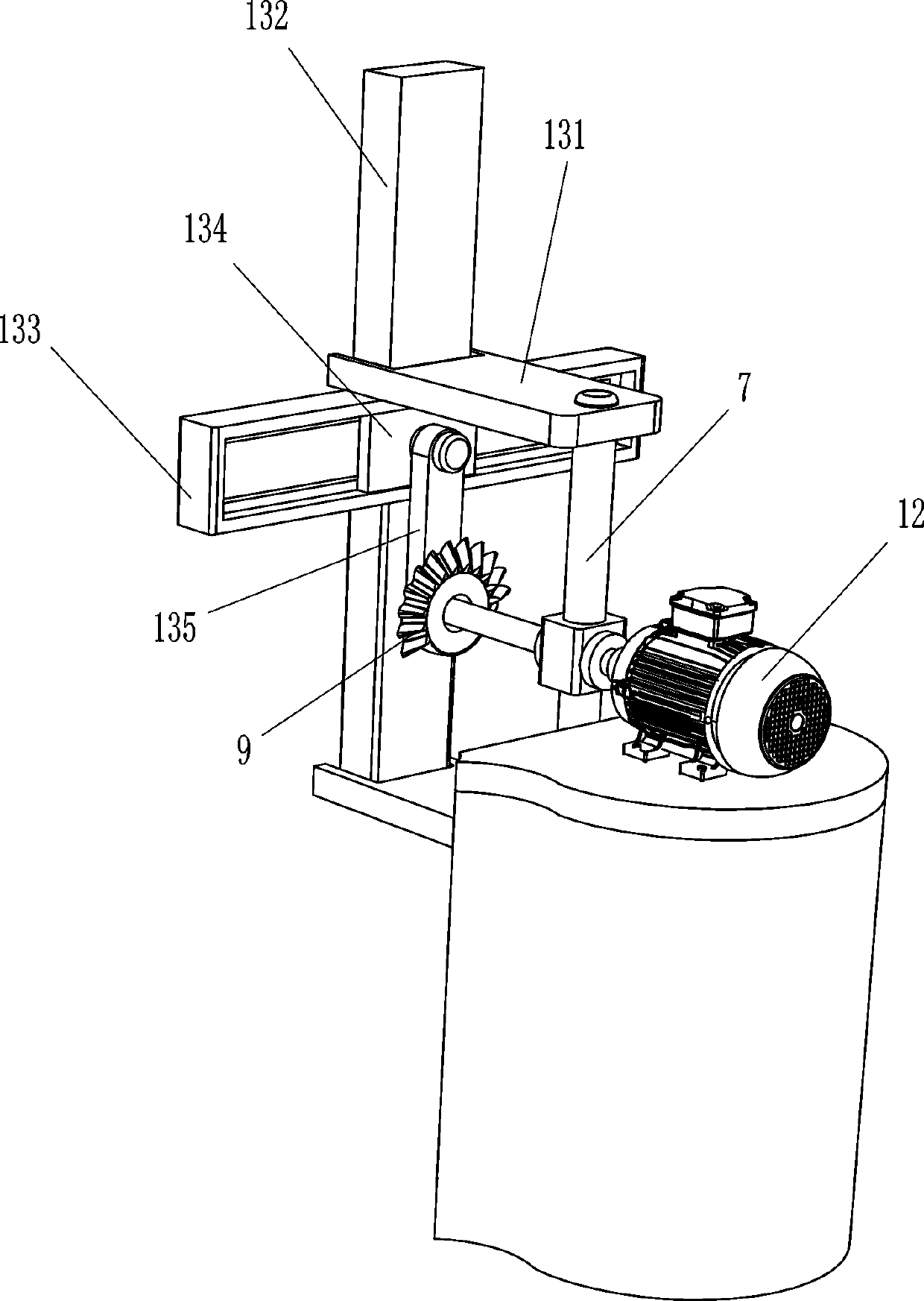

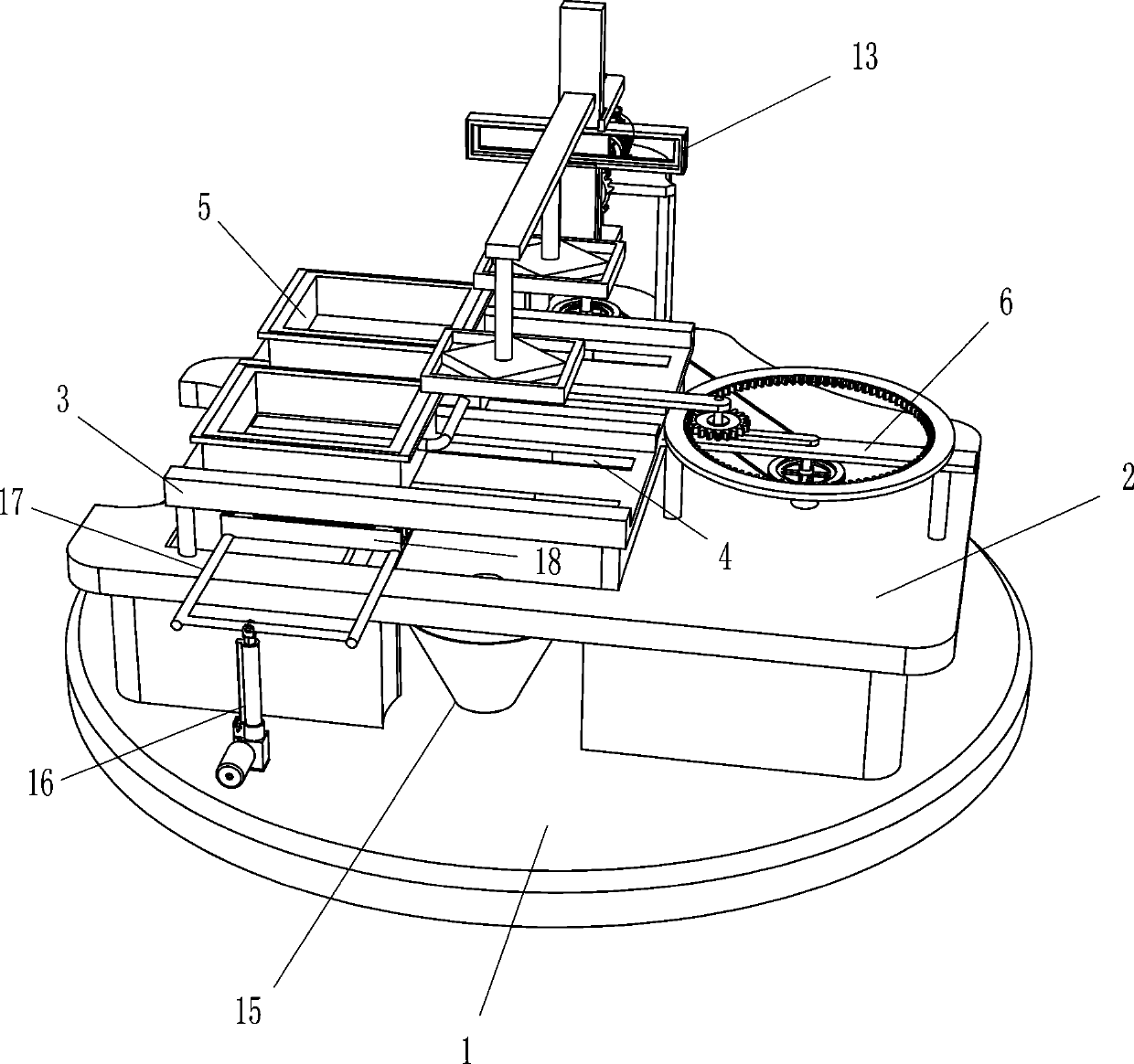

[0023] Such as Figure 1-4 Shown, a kind of tofu automatic pressing device comprises base 1, workbench 2, square frame 3, processing box 5, moving device 6, mounting plate 7, first rotating shaft 8, half bevel gear 9, second rotating shaft 10, Small bevel gear 11, servo motor 12, press-down mechanism 13 and collection barrel 15, workbench 2 is arranged on the base 1, a square frame 3 is arranged on the left side of the top of the workbench 2, and a front and rear symmetrical sliding type is arranged on the square frame 3. Box 5, the bottom of square frame 3 and the bottom of processing box 5 are provided with gutter 4, the right side of the top of workbench 2 is provided with a mobile device 6 that drives the processing box 5 to move back and forth, and the rear side of the top of workbench 2 is provided with a mounting plate 7. The mounting plate 7 is rotatably provided with a first rotating shaft 8, the front side of the first rotating shaft 8 is provided with a half bevel g...

Embodiment 2

[0028] On the basis of Example 1, such as figure 1 with 5 Shown, also comprise cylinder 16, mounting frame 17, guide chute plate 18, top plate 19 and slide bar 20, workbench 2 top left side is provided with cylinder 16 symmetrically front and back about square frame 3, connects on the movable bar of cylinder 16 Mounting frame 17 is arranged, and mounting frame 17 is positioned at square frame 3 bottoms, is positioned at the mounting frame 17 positions of processing box 5 bottoms and is provided with guide chute plate 18 symmetrically front and back, and processing box 5 inner bottom is placed with top plate 19, top plate 19 bottom front and rear sides Two slide bars 20 are arranged symmetrically, and the slide bar 20 on the top plate 19 lower side passes through the gutter 4 of the treatment box 5 and the square frame 3 to slide and cooperate with the guide chute plate 18.

[0029] When the tofu pressing is completed and the processing box 5 returns to the leftmost side, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com