Patents

Literature

106 results about "Flux tube" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A flux tube is a generally tube-like (cylindrical) region of space containing a magnetic field, B, such that the cylindrical sides of the tube are everywhere parallel to the magnetic field lines. It is a graphical visual aid for visualizing a magnetic field. Since no magnetic flux passes through the sides of the tube, the flux through any cross section of the tube is equal, and the flux entering the tube at one end is equal to the flux leaving the tube at the other. Both the cross-sectional area of the tube and the magnetic field strength may vary along the length of the tube, but the magnetic flux inside is always constant.

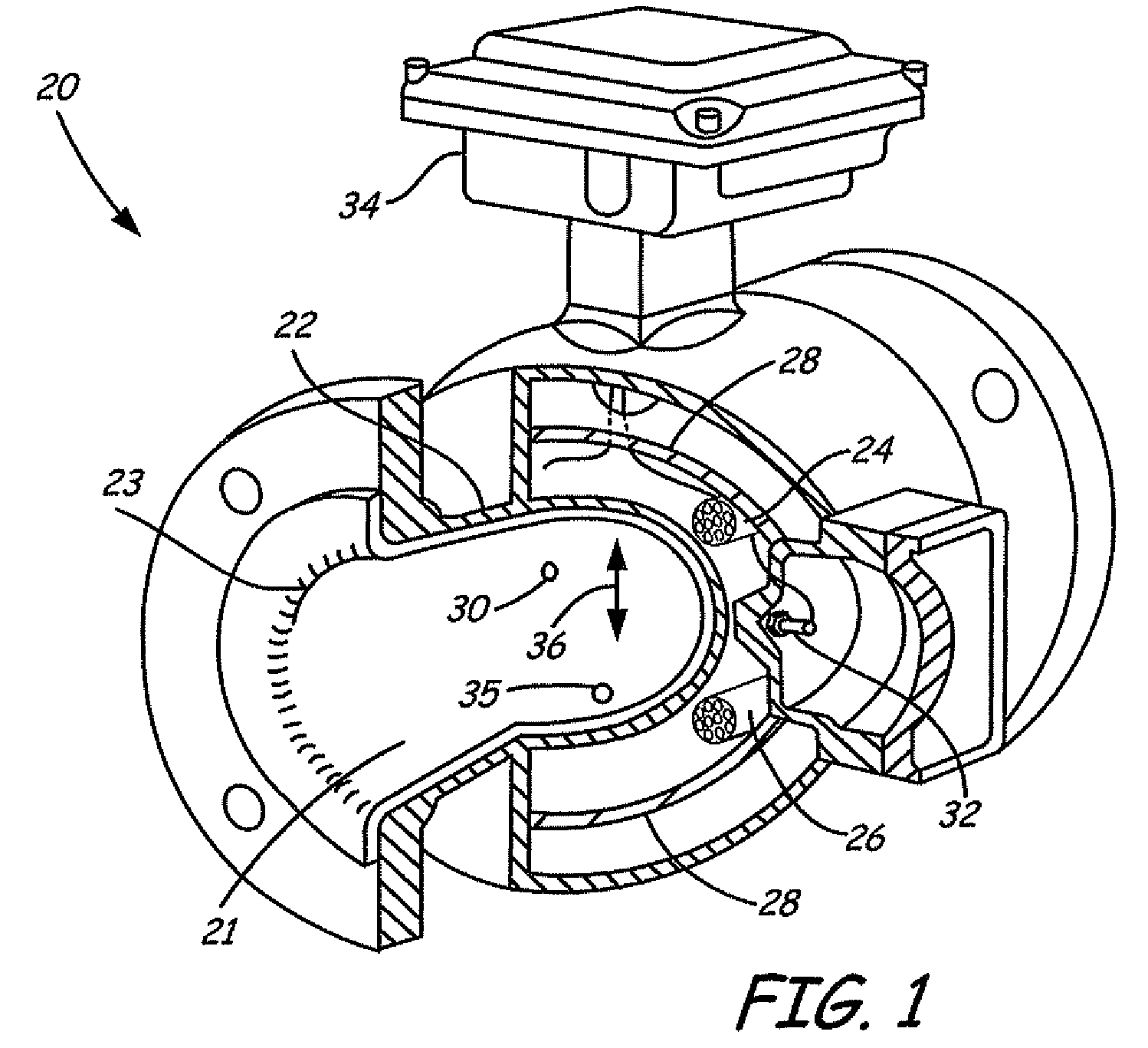

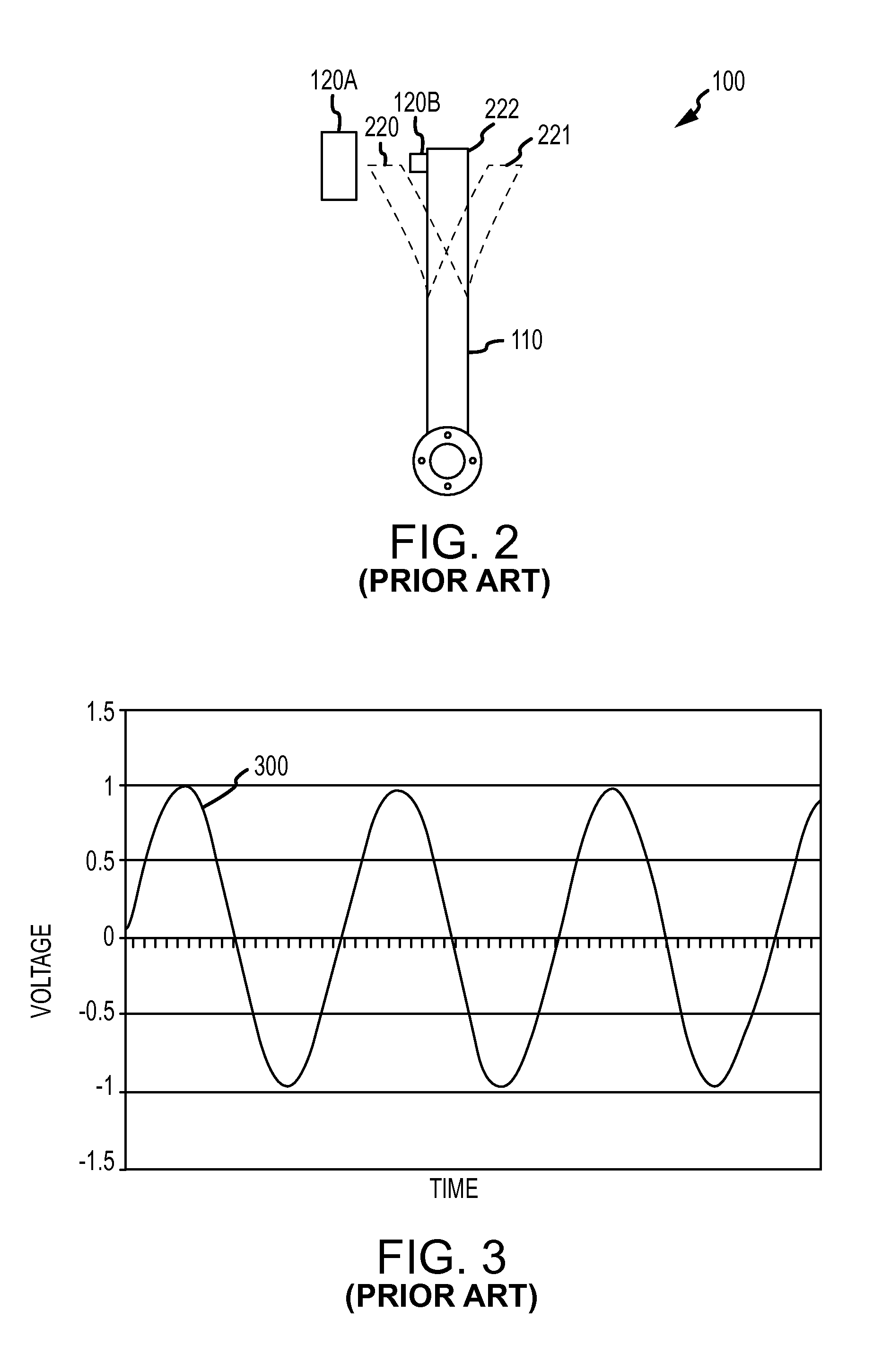

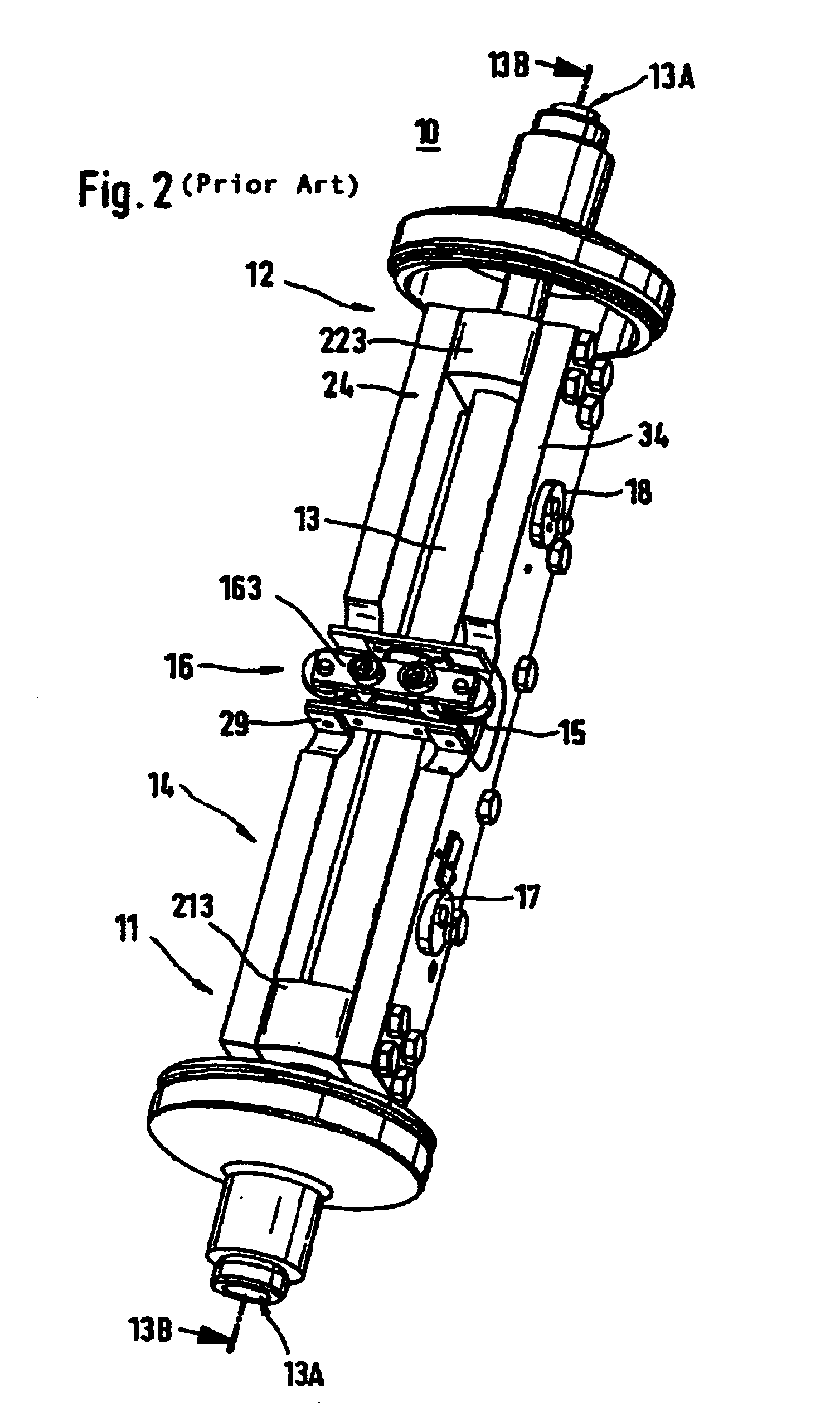

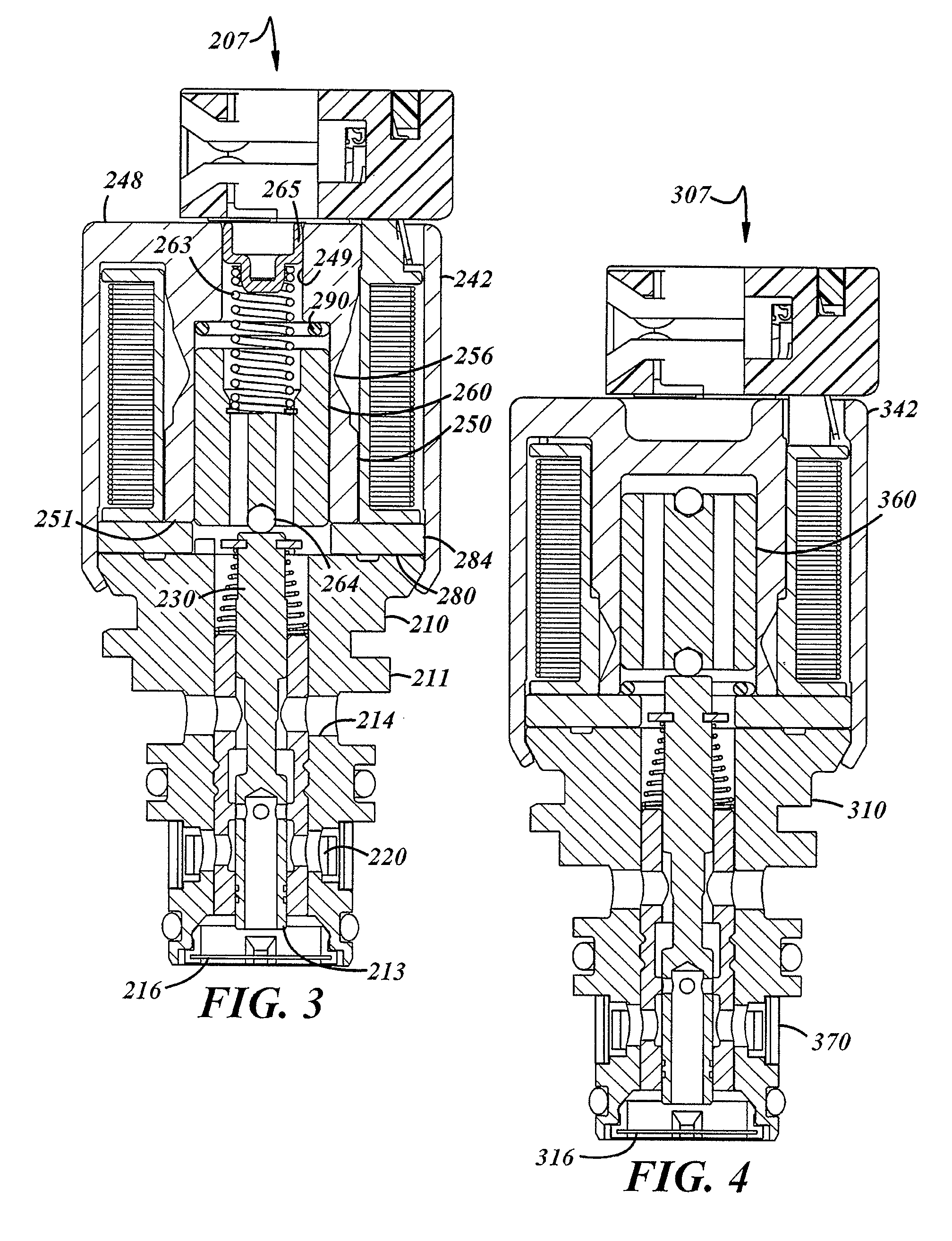

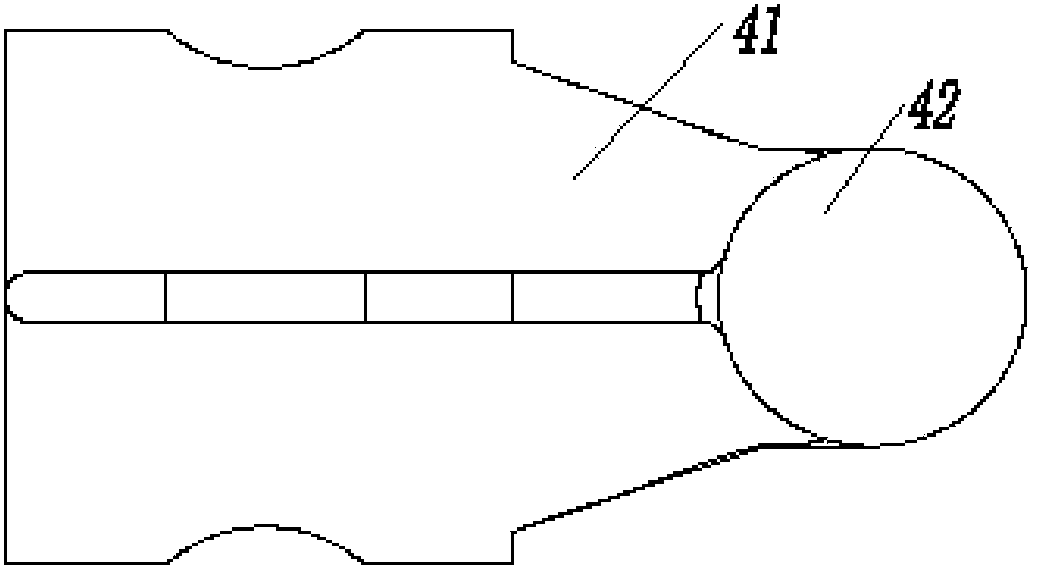

Flanged vortex flowmeter with unitary tapered expanders

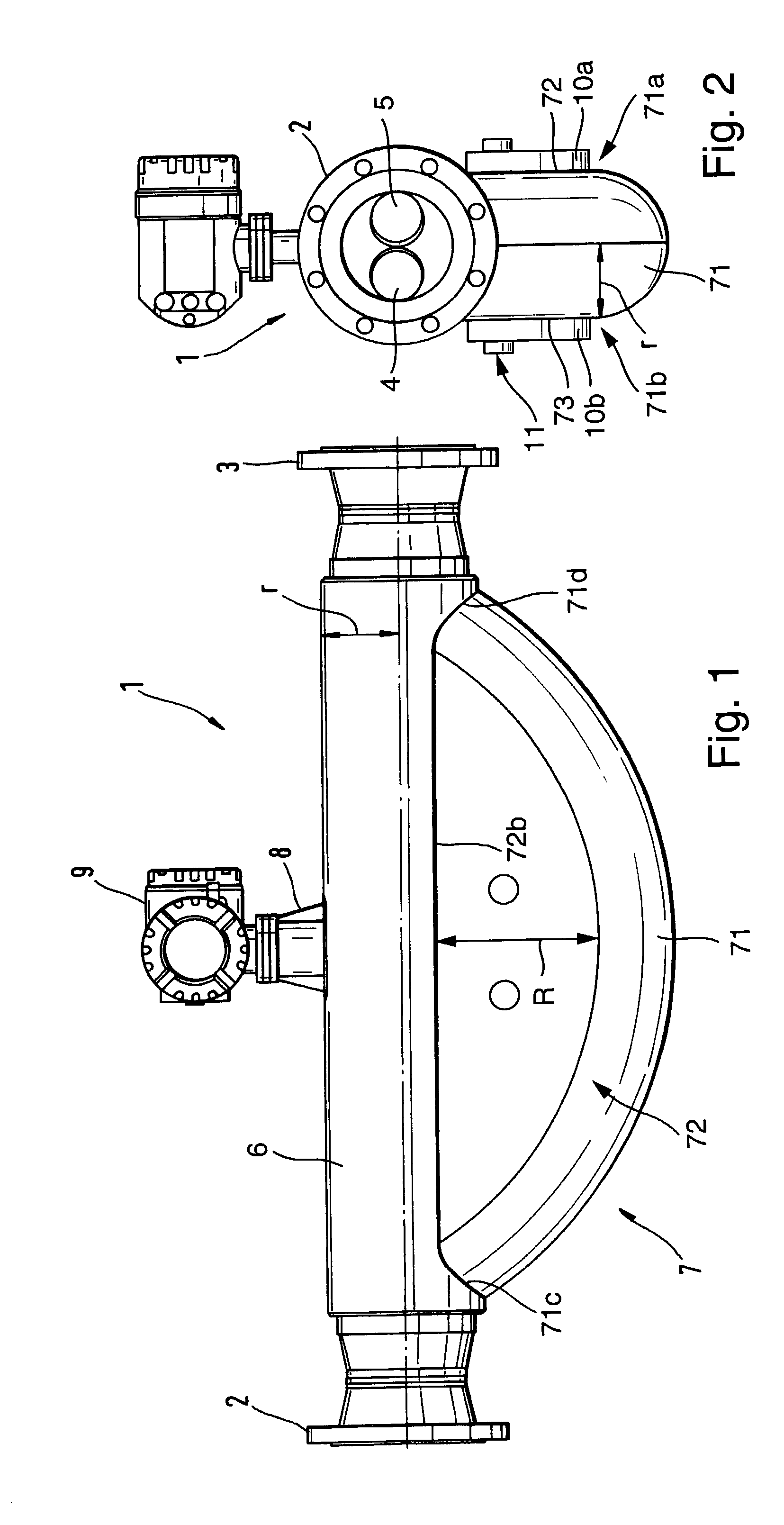

ActiveUS20050092101A1Smooth flow transitionSmooth transitionVolume/mass flow by dynamic fluid flow effectEngineeringReducer

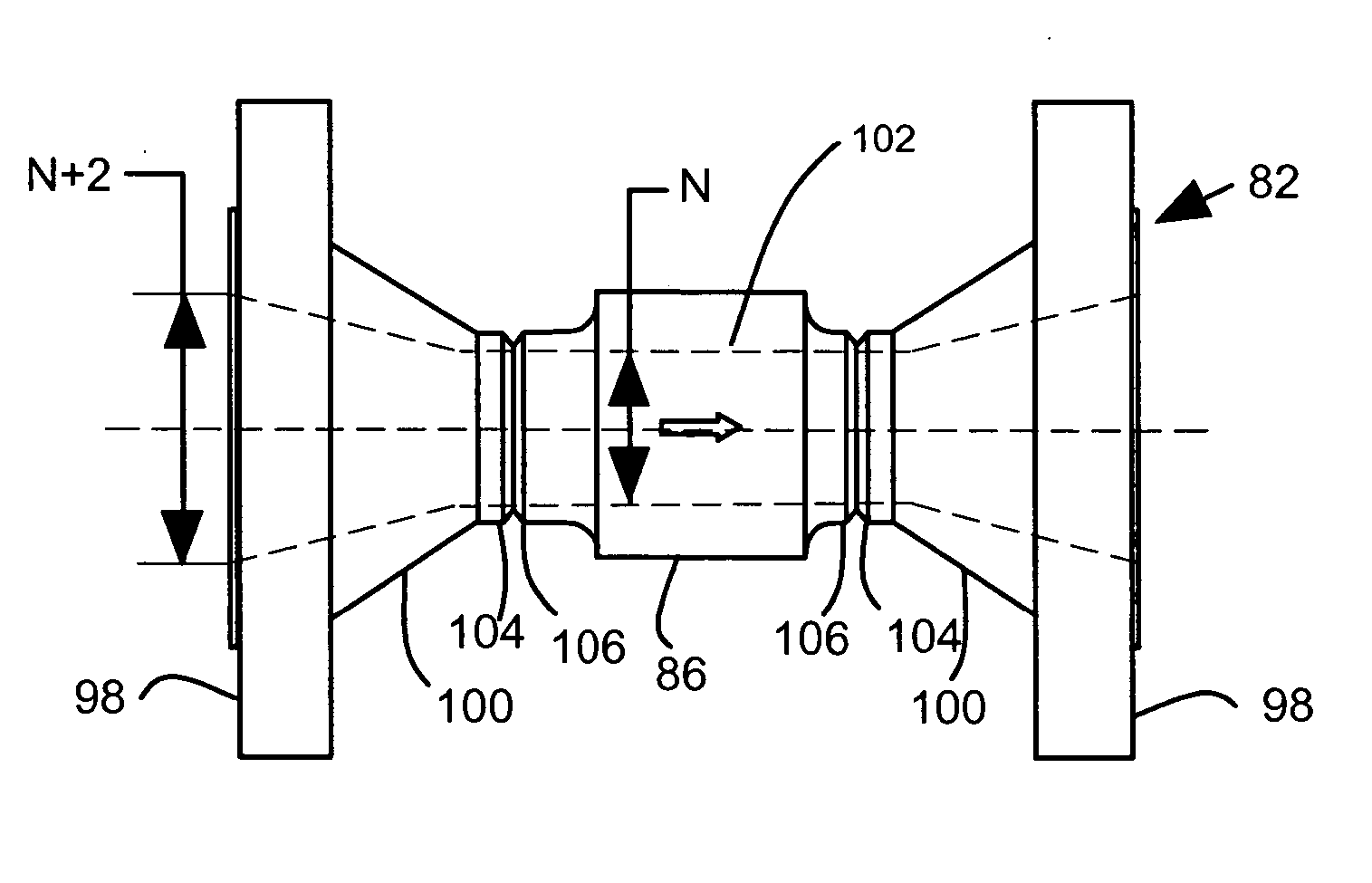

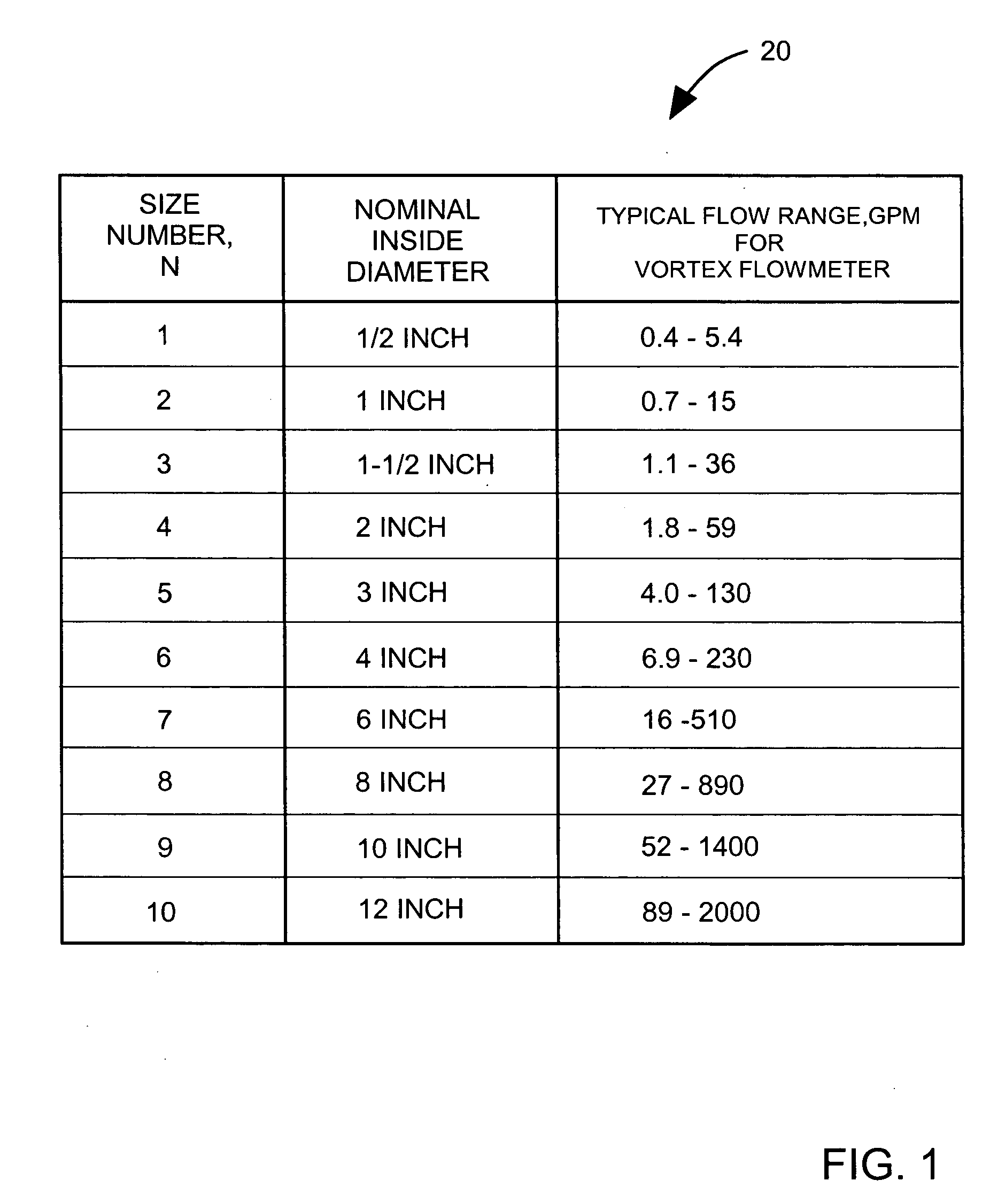

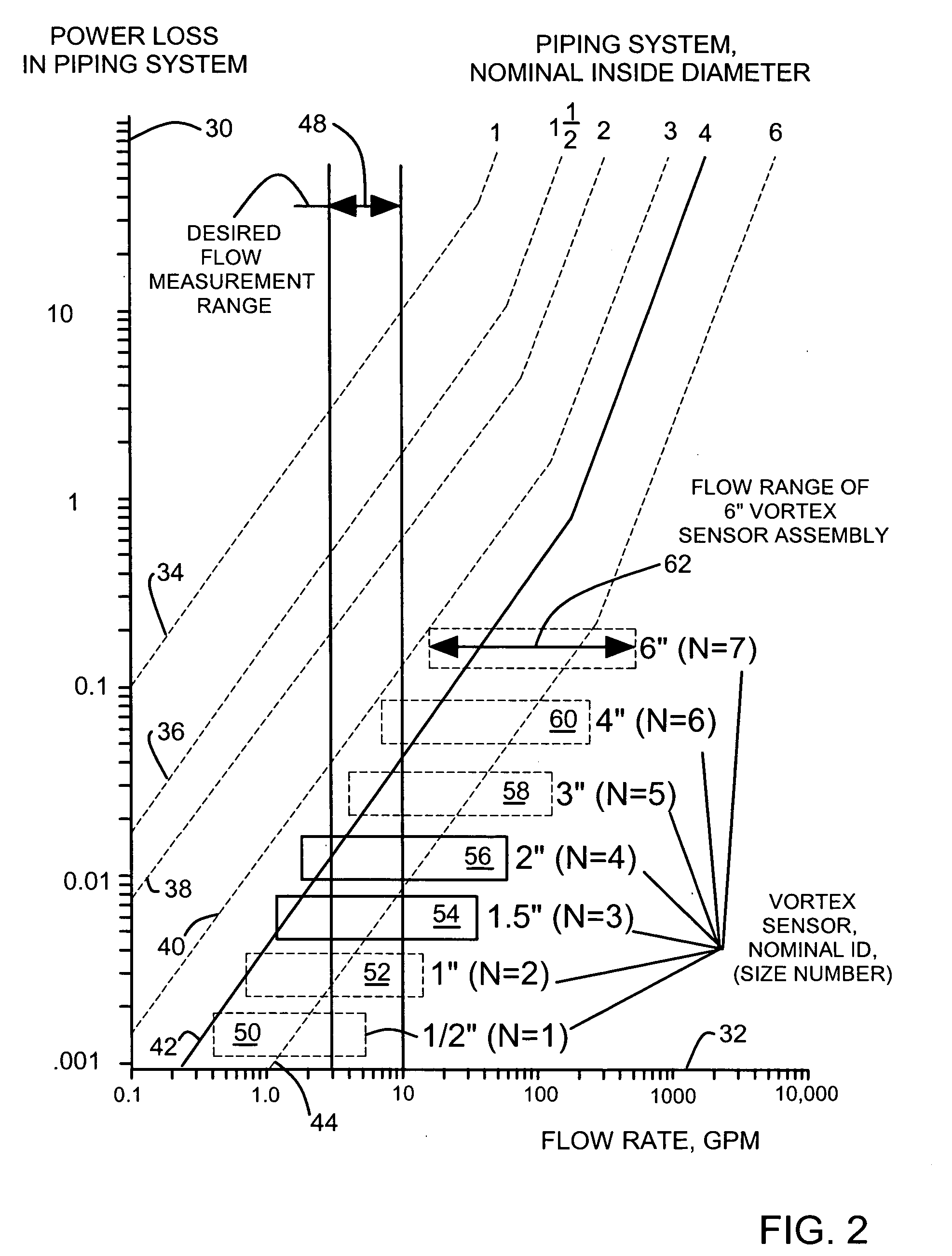

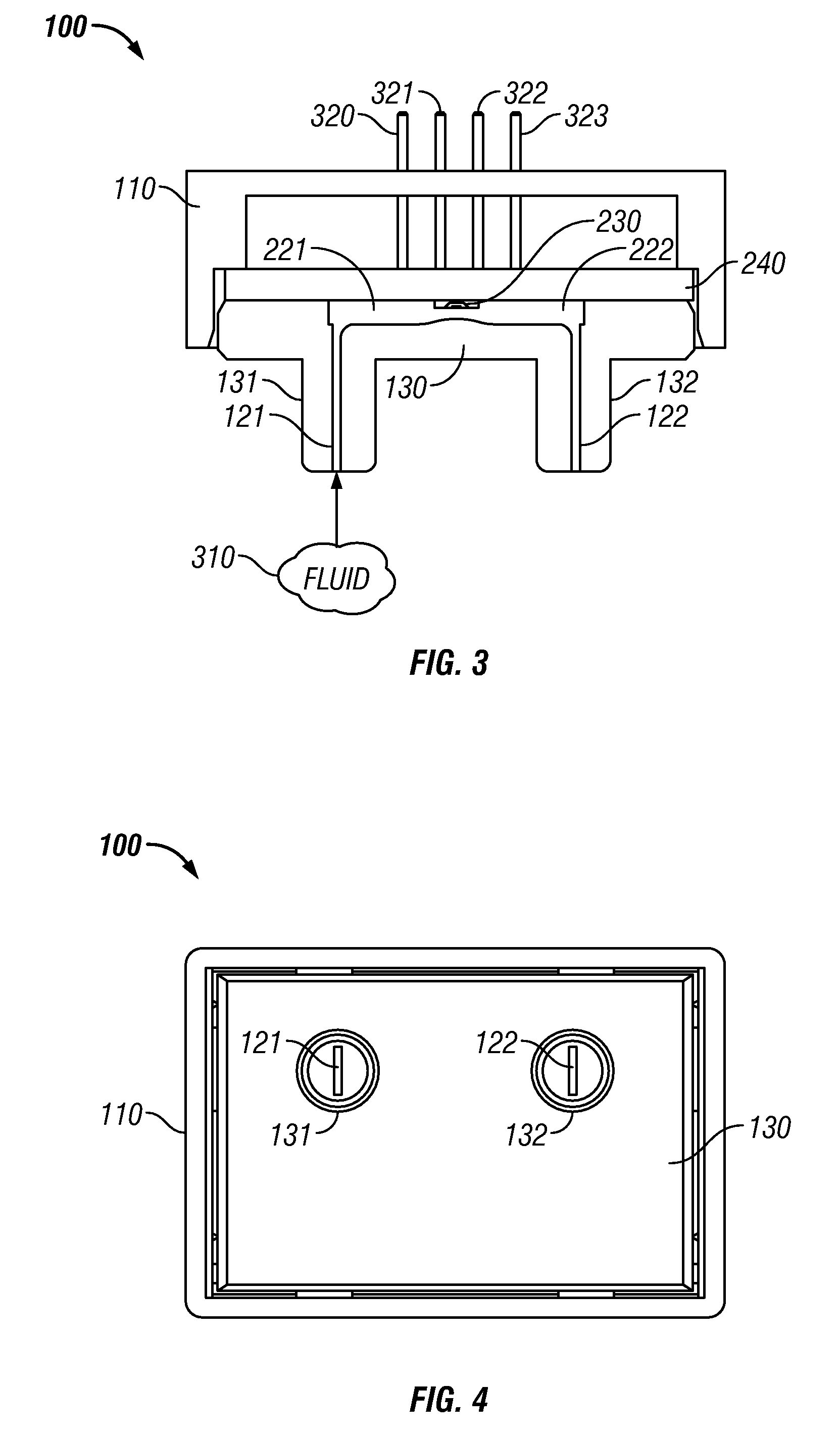

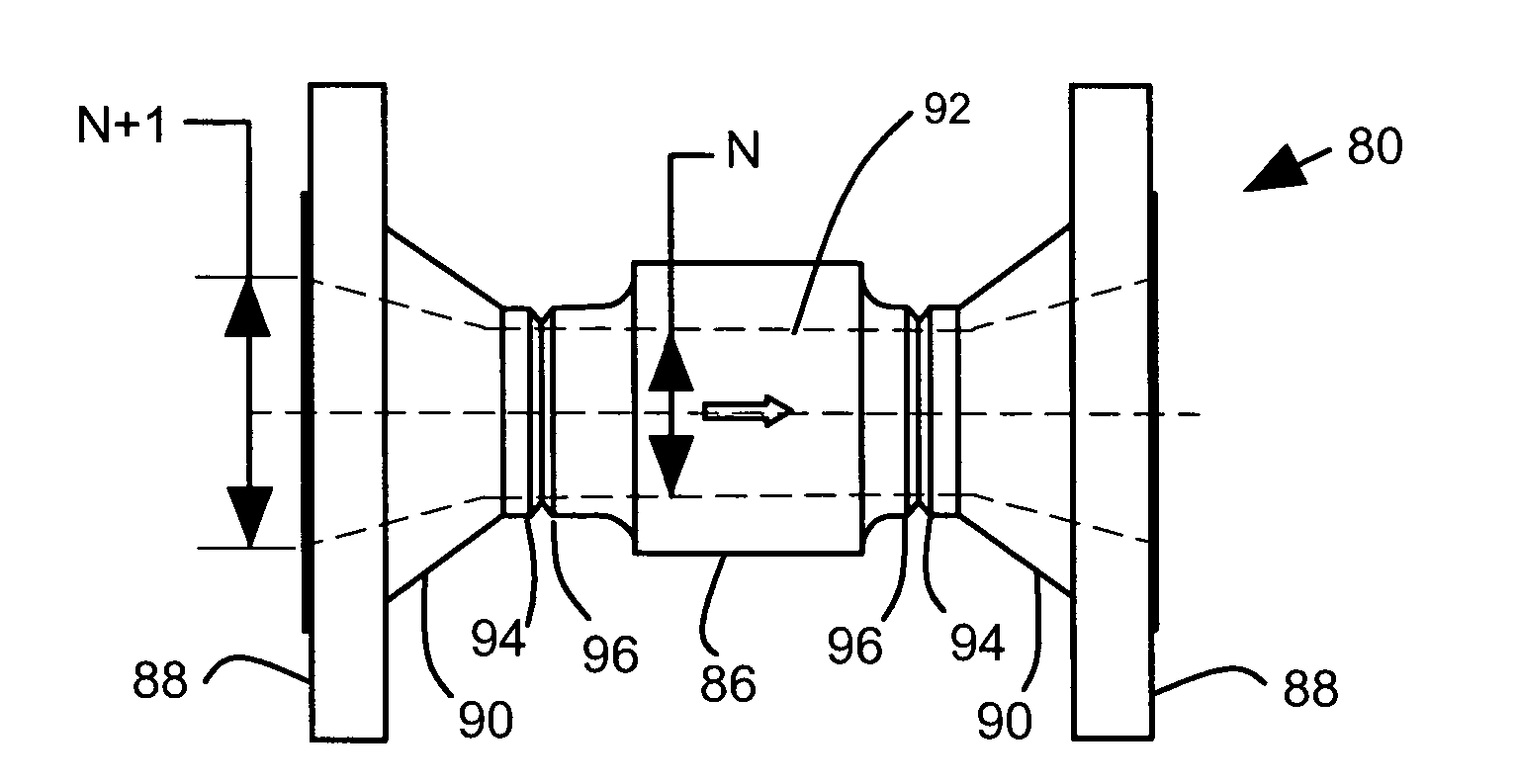

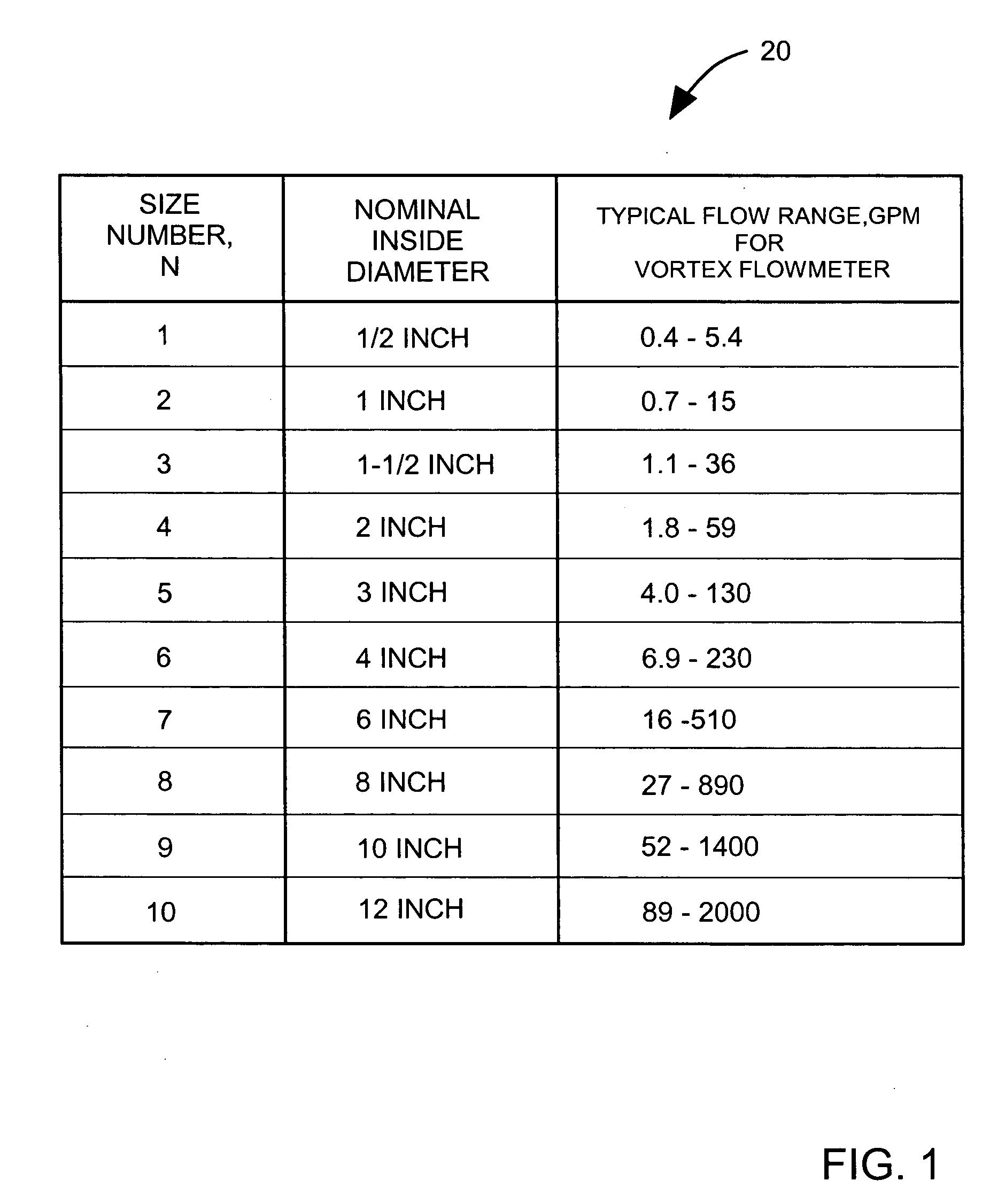

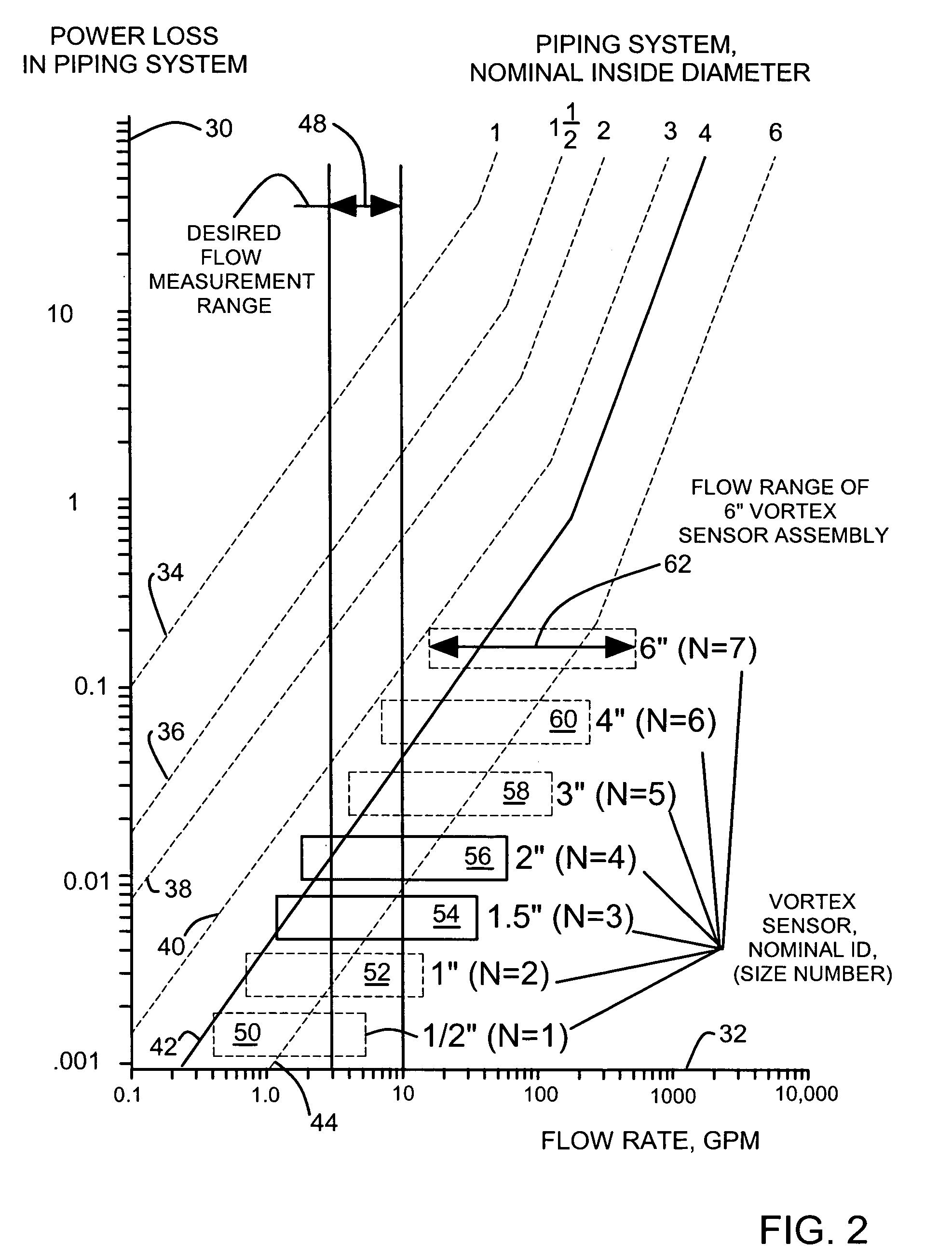

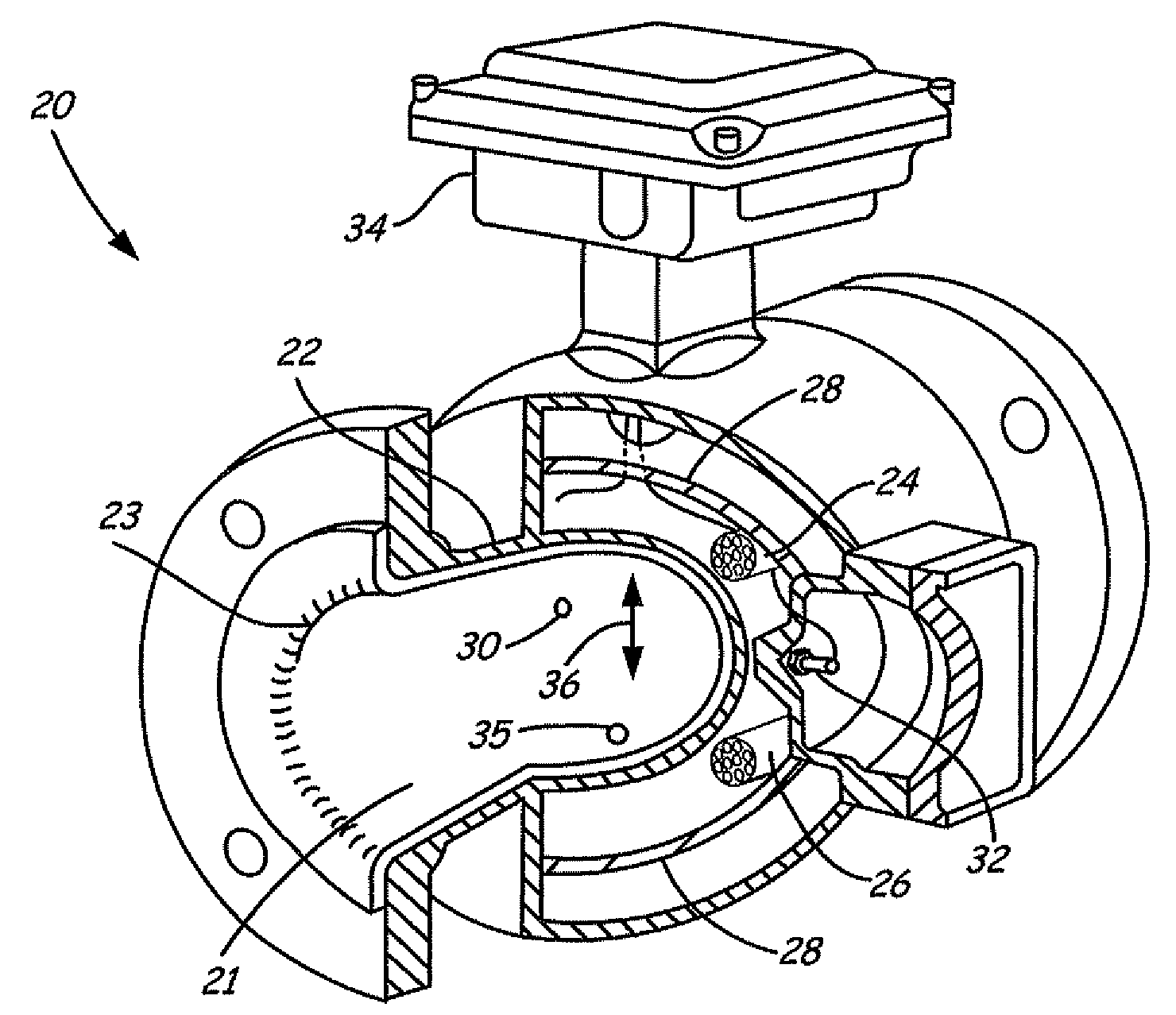

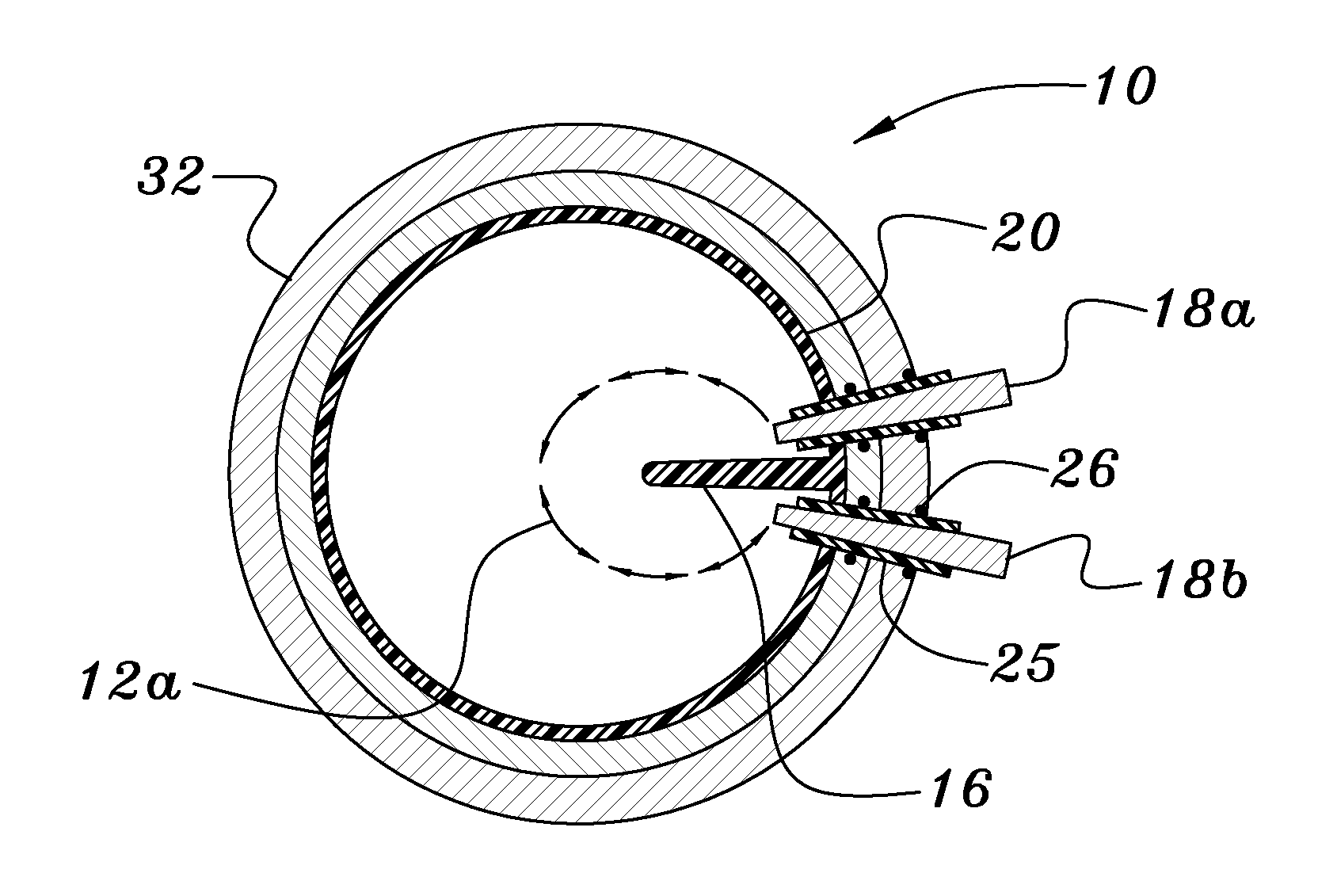

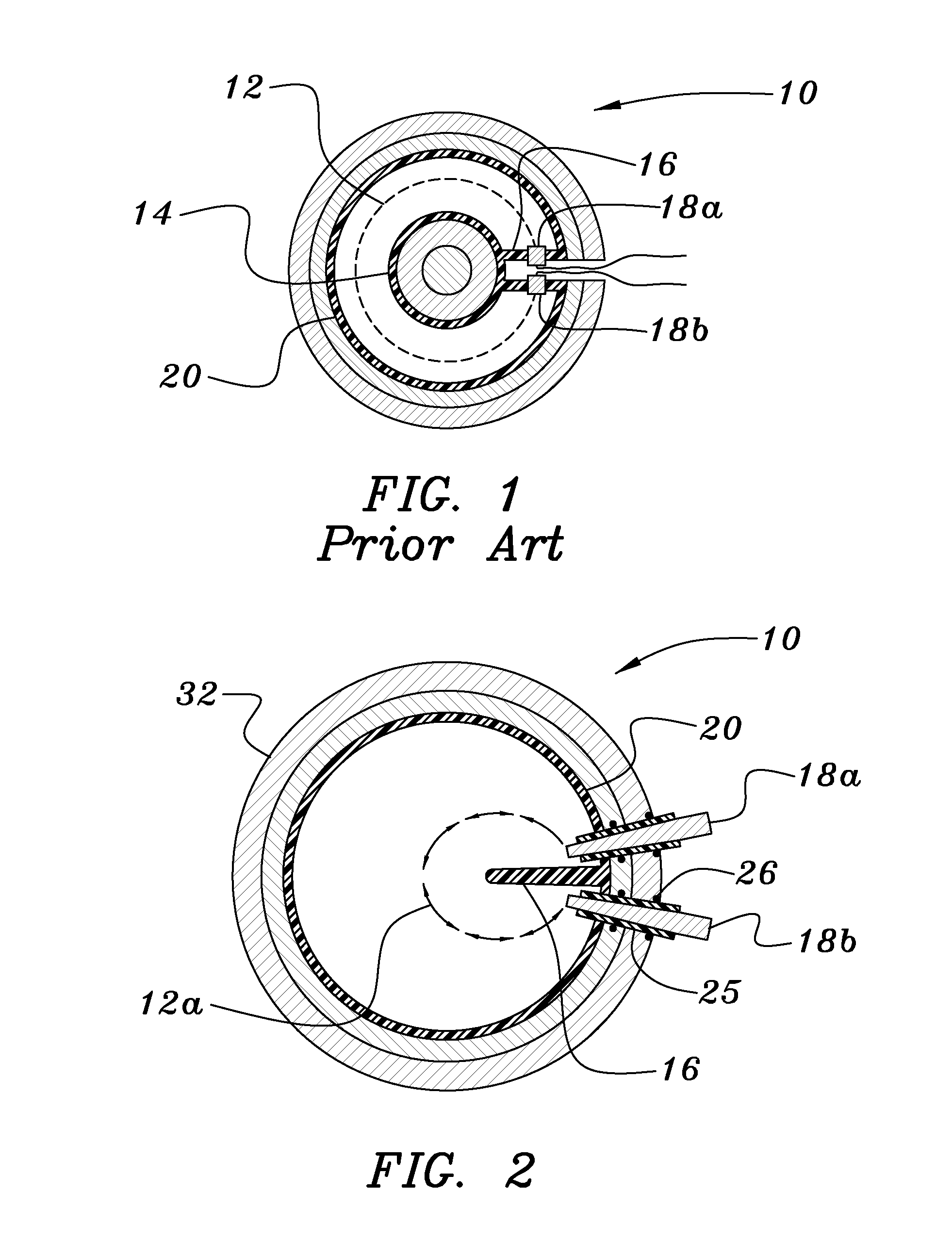

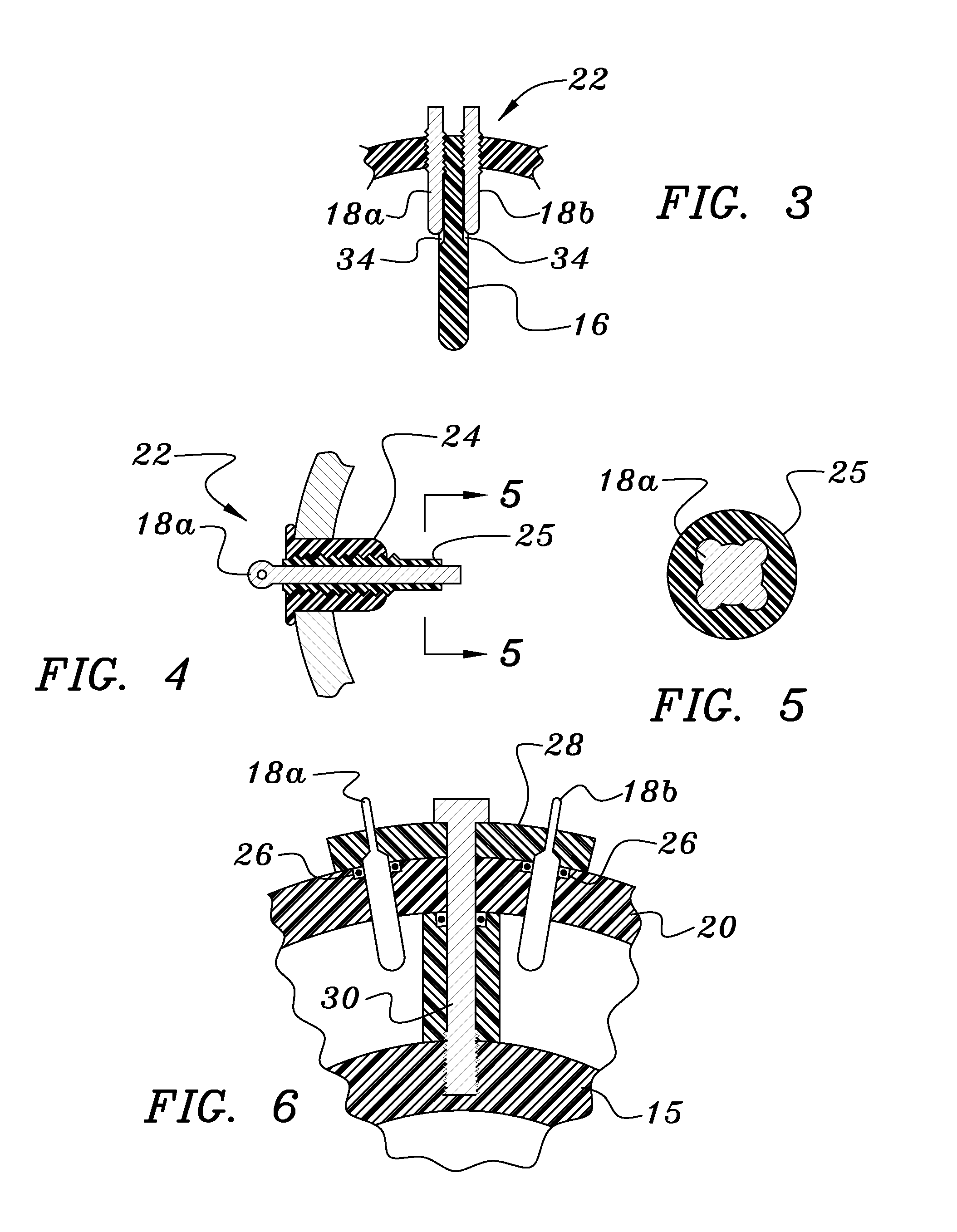

A manufacturing procedure of a vortex flowmeter is disclosed that allows for assembly of a vortex sensor assembly with one of two or more unitary flowtubes that have bores that are smaller than the flowtube flanges in two or more size number steps. The unitary flowtubes include flanges, flowtube bores and expanders (also called reducers) that provide a smooth flow transition from the larger flanges to the smaller bores.

Owner:MICRO MOTION INC

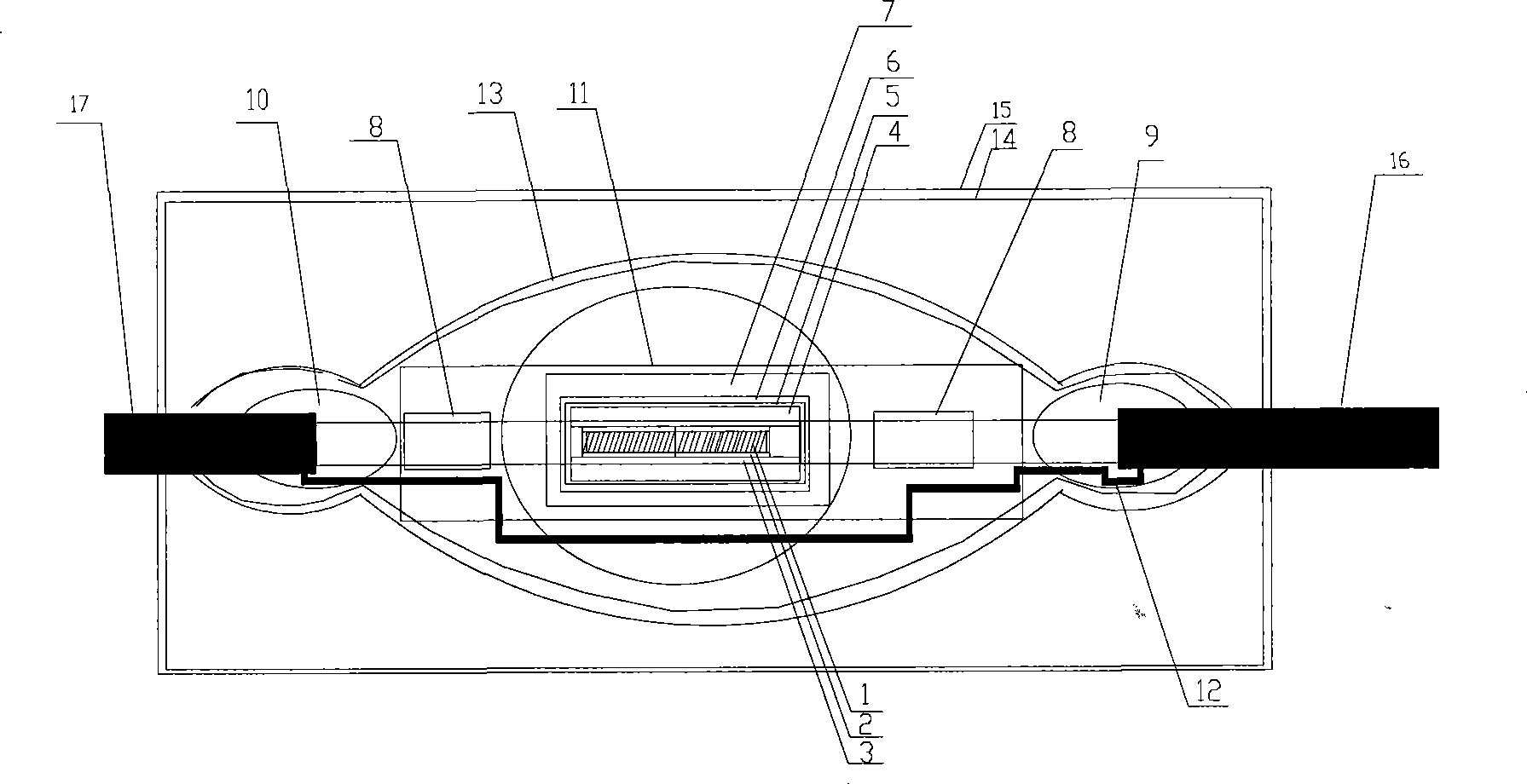

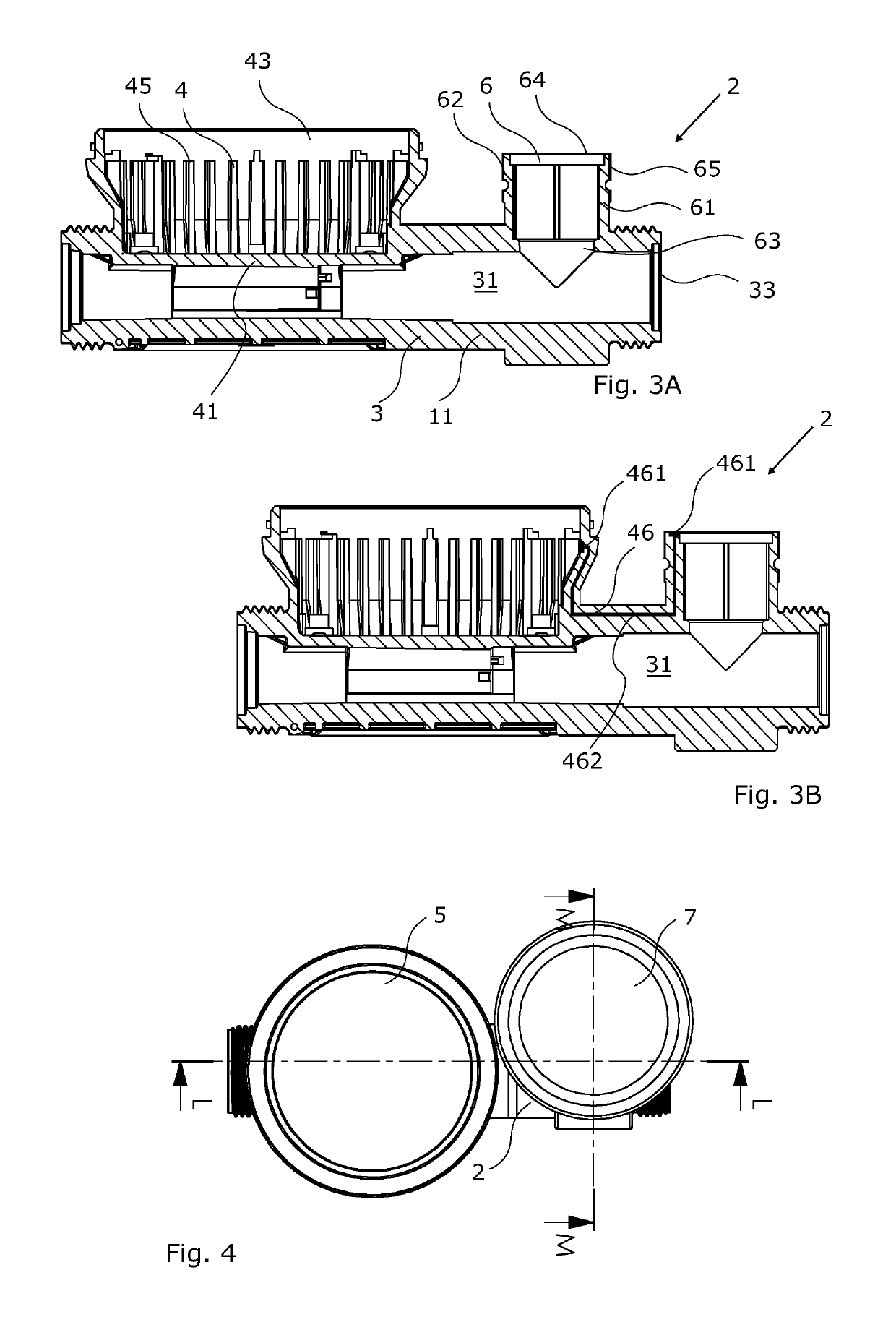

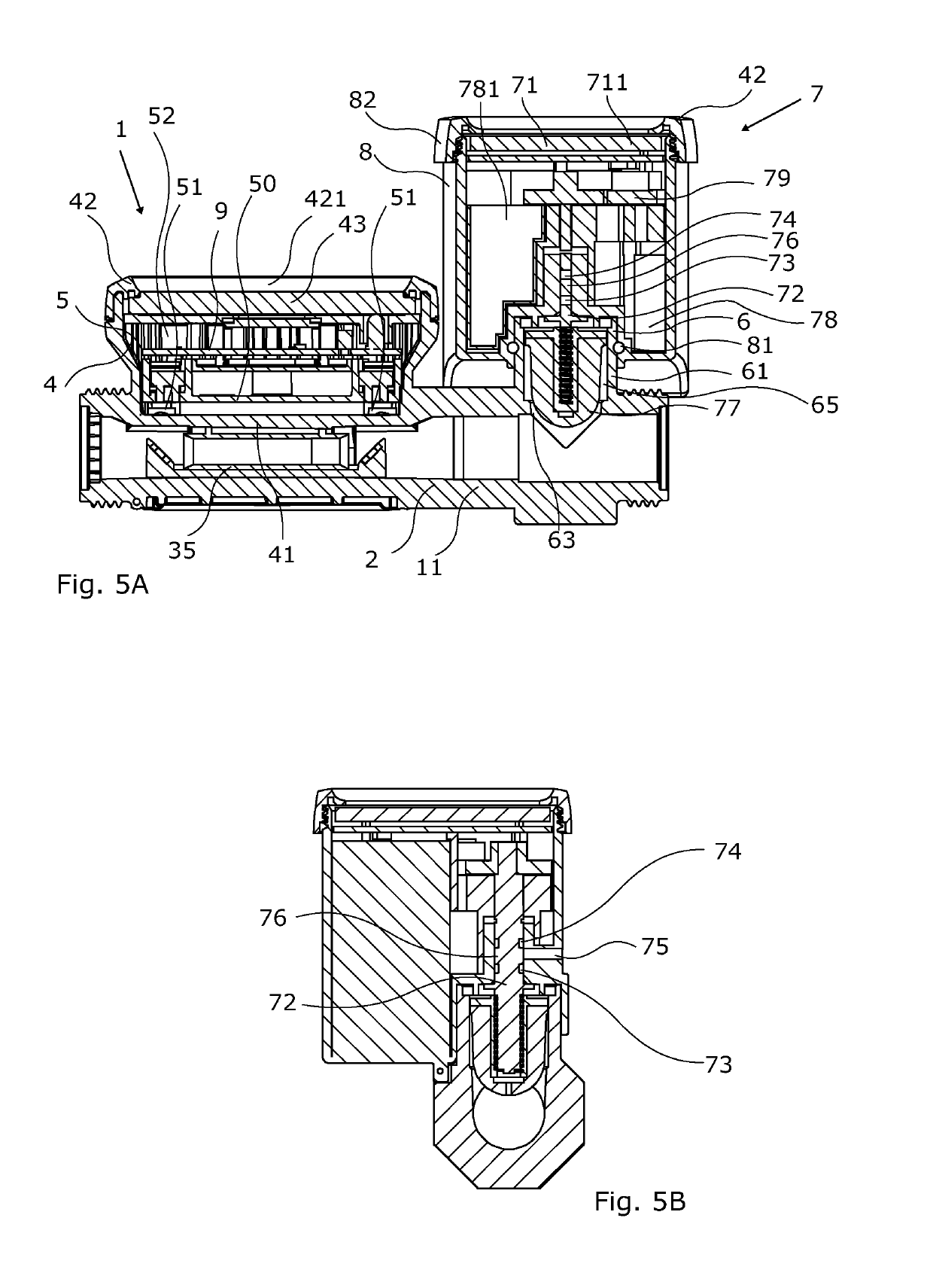

Ultrasonic Measuring Unit Having Integrated Humidity Analysis

InactiveUS20090178490A1Accurate detectionAccurate engine controlVolume/mass flow measurementVolume flow proportion measurementRunning timeElectron

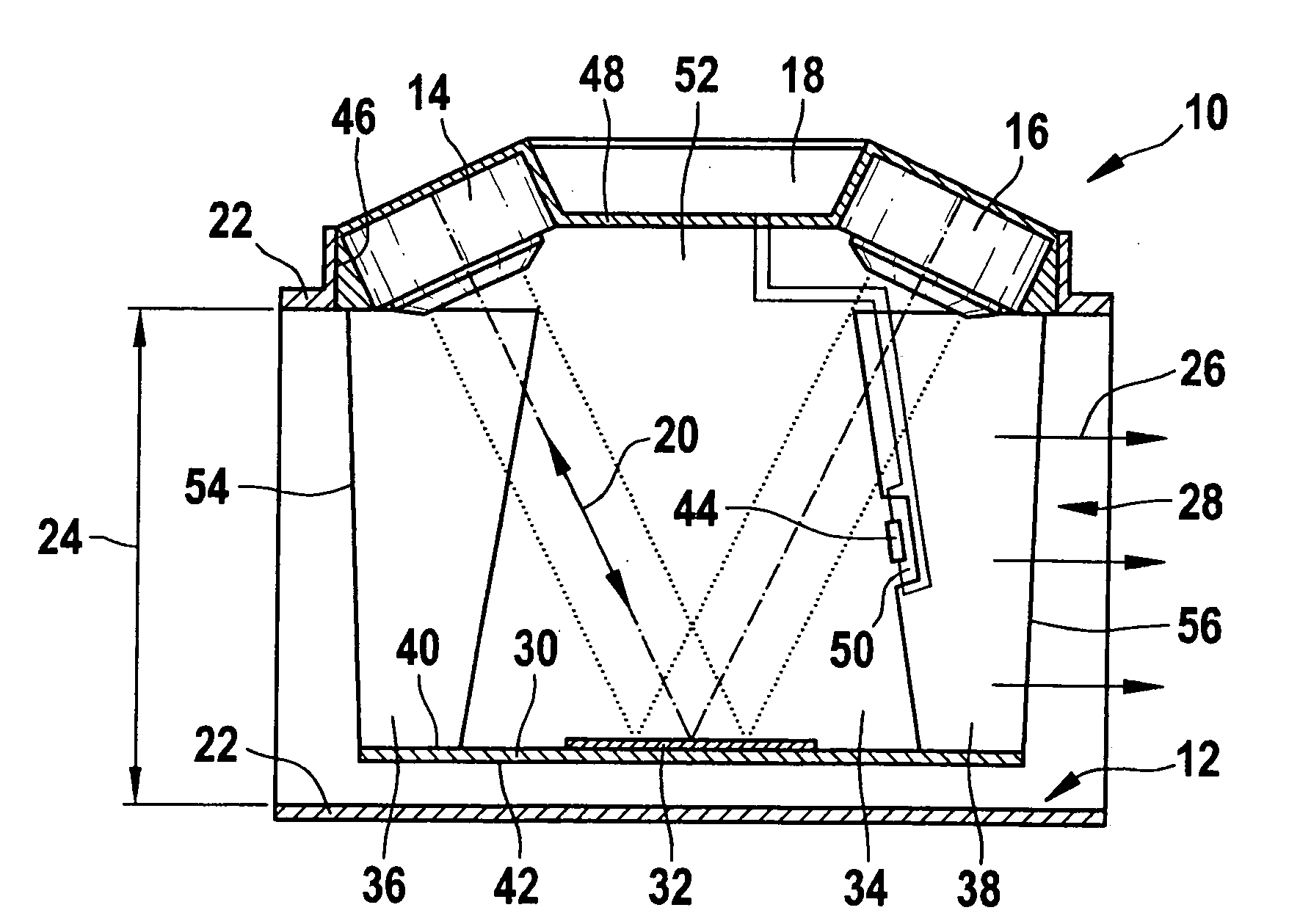

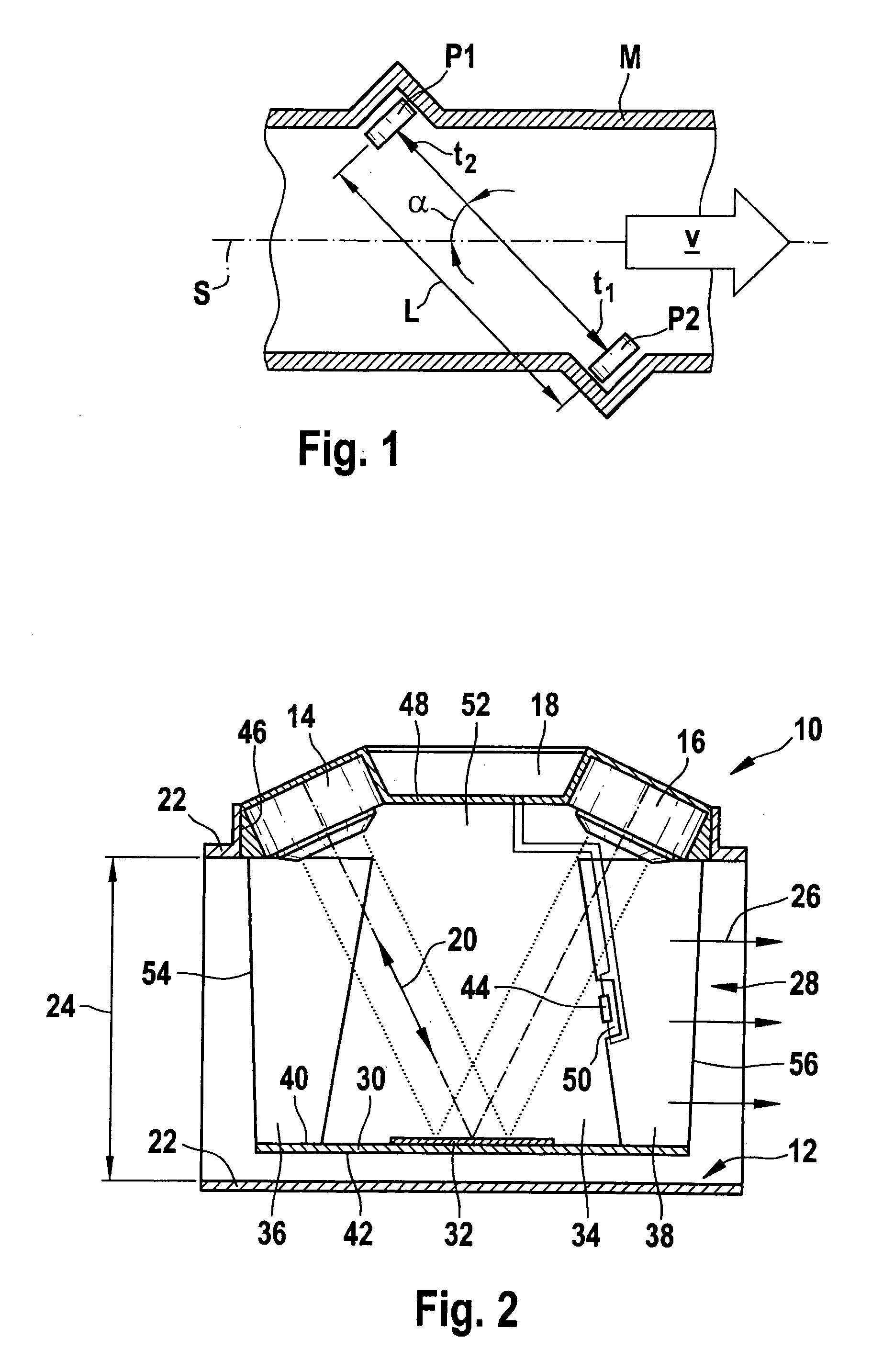

An ultrasonic measuring unit and a method for detecting ultrasonic signal run-times, in which the ultrasonic measuring unit has two ultrasonic transducers for coupling ultrasonic signals into a flowing medium. Analysis electronics are provided to be accommodated on or in a flow tube, in which a gaseous medium such as circulating air flows. A probe unit is accommodated in the flow tube, the probe unit being assigned a temperature probe having a flow around it, whose measured value is used for correcting a temperature signal detected by ultrasound.

Owner:ROBERT BOSCH GMBH

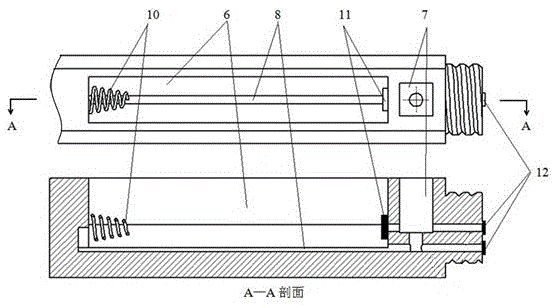

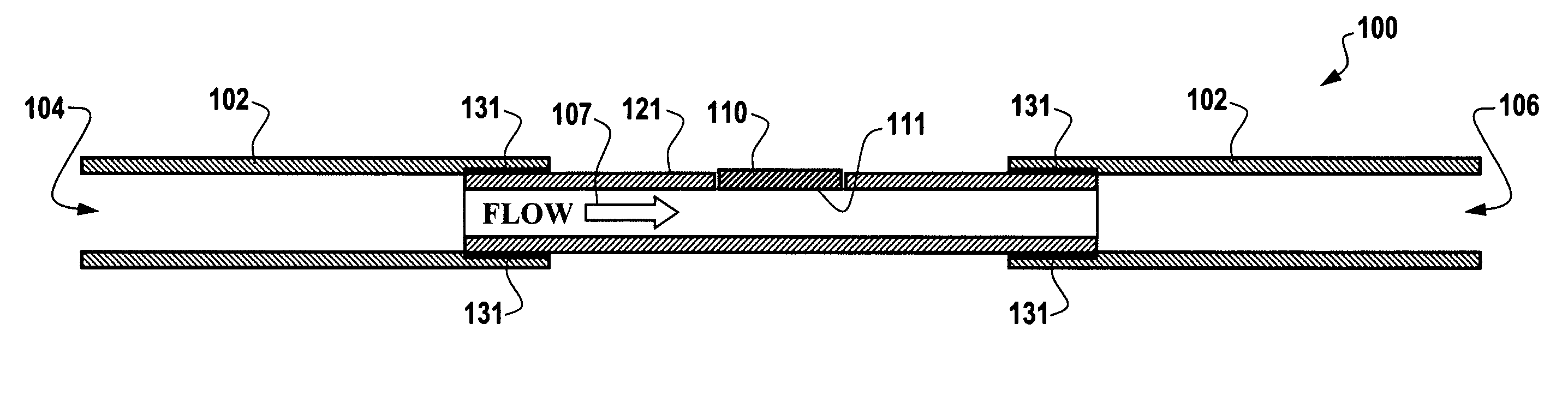

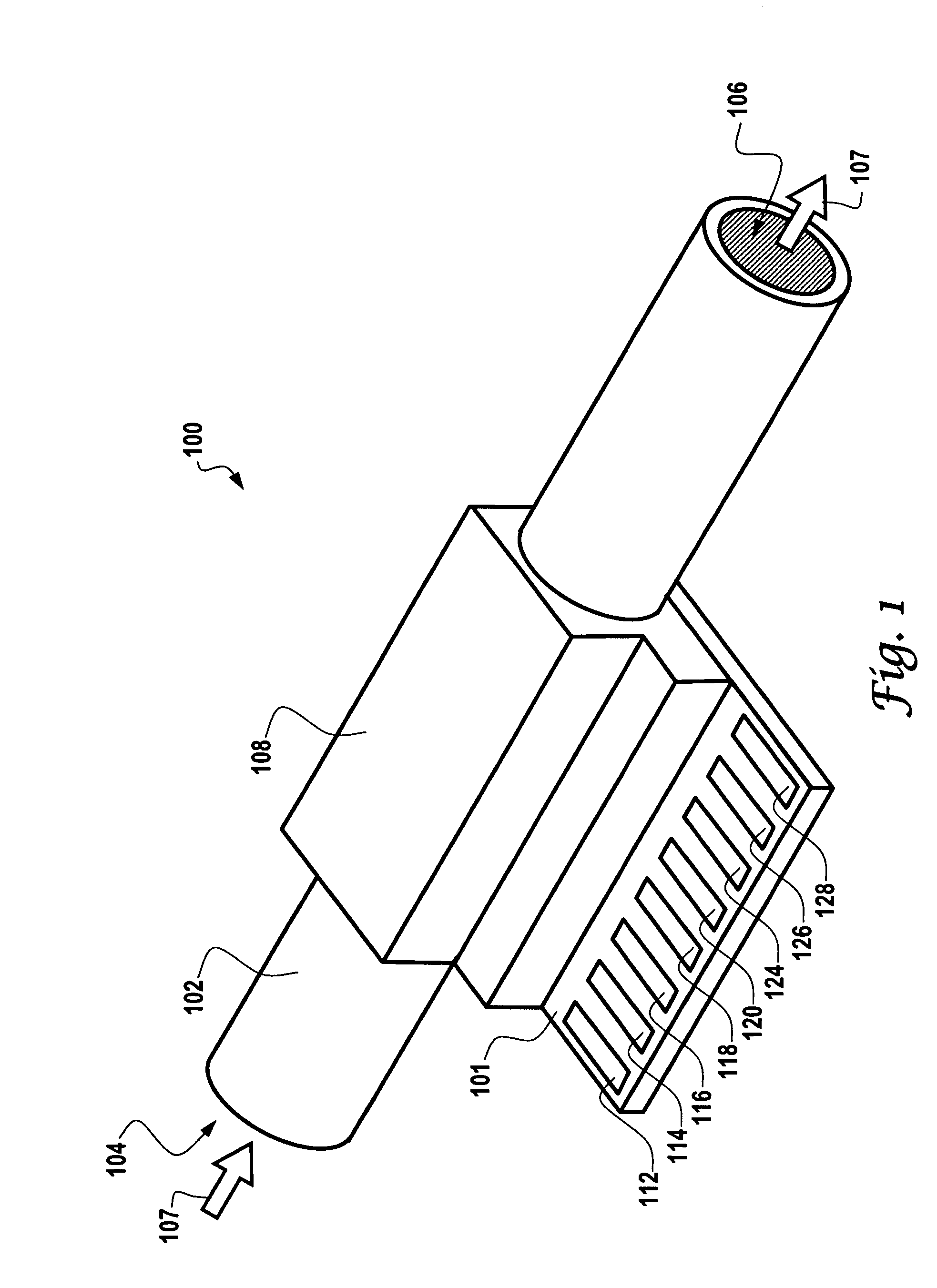

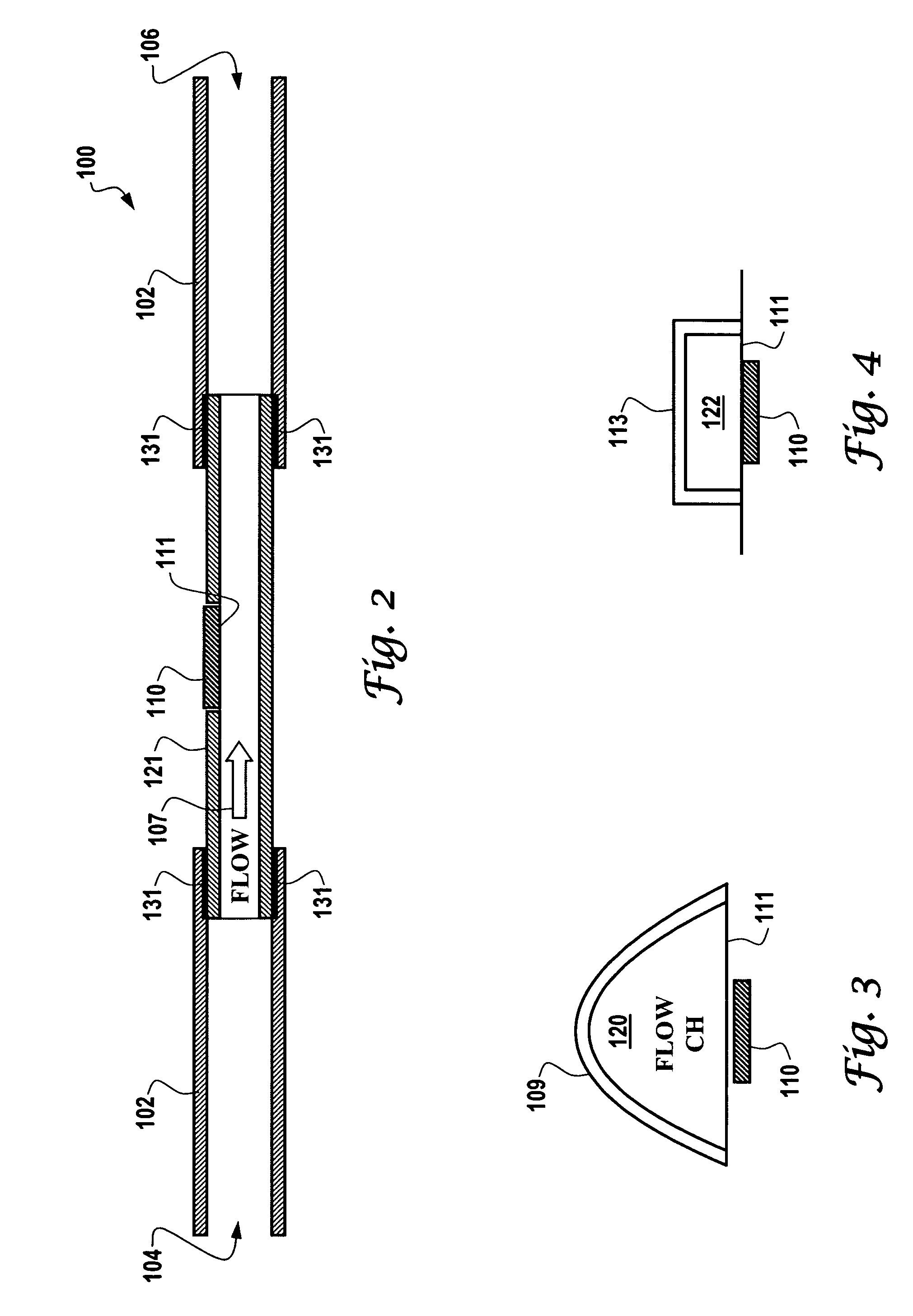

Mass-flow sensor with a molded flow restrictor

InactiveUS7631562B1Improve Sensing PerformanceReduce flow turbulenceVolume/mass flow by thermal effectsVolume meteringEngineeringMass flow sensor

A high mass-flow sensing apparatus and method of forming the same, comprising a flow tube bypassed in a flow path defined by a flow channel, through which a fluid flows. A flow sensor can be disposed in the flow tube for measuring a flow rate of the fluid in the flow channel. A set of narrow rectangular flow restrictors can be molded into the flow tube and adjacent to the flow sensor. Each flow restrictor can include several rectangular cutouts that are molded into upstream and / or downstream portions of the flow tube in order to limit the flow rate of the fluid across the flow sensor. The flow restrictors can laminarize the flow rate of the fluid in the flow tube and thereby reduce flow turbulence and lead to optimal sensing performance of the flow sensor.

Owner:HONEYWELL INT INC

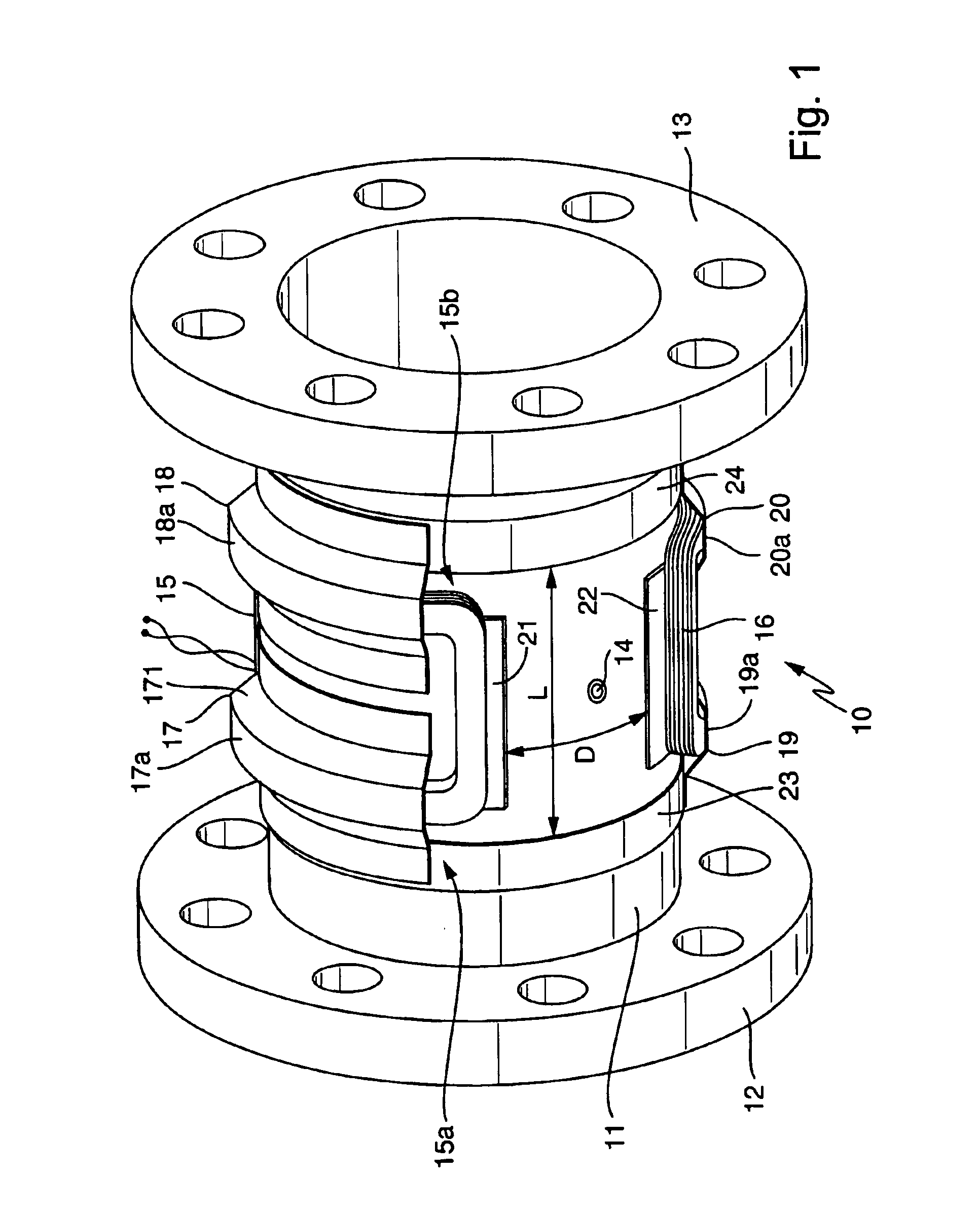

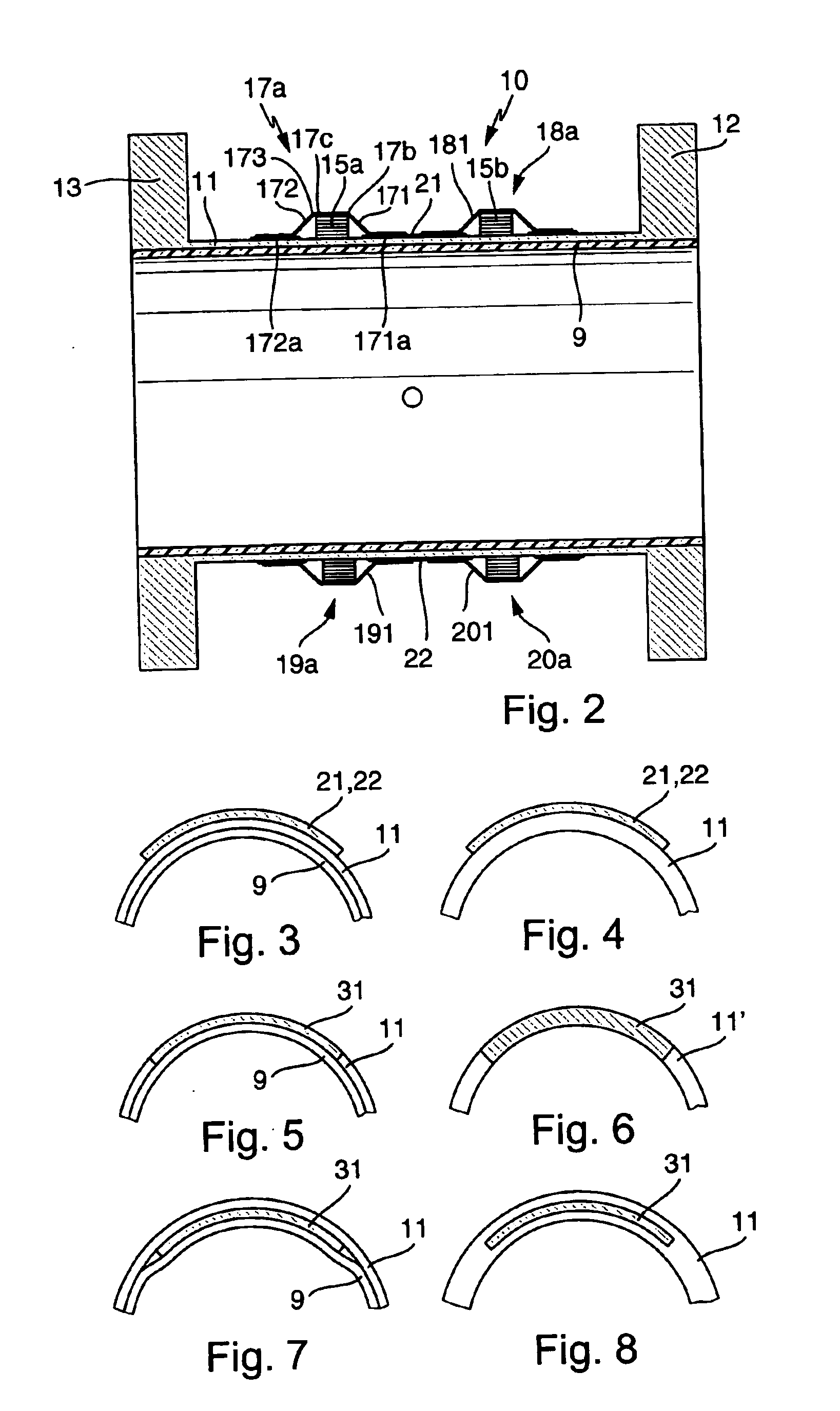

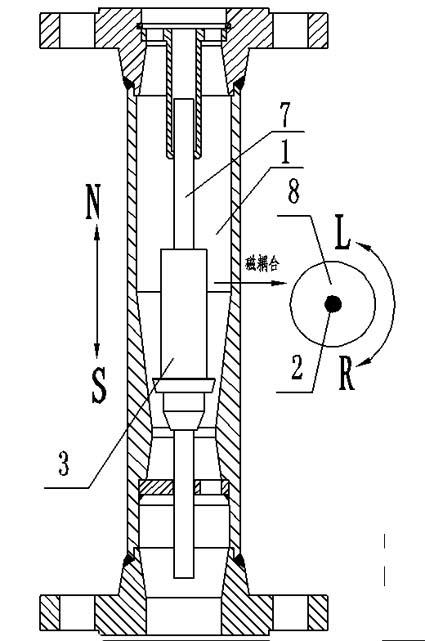

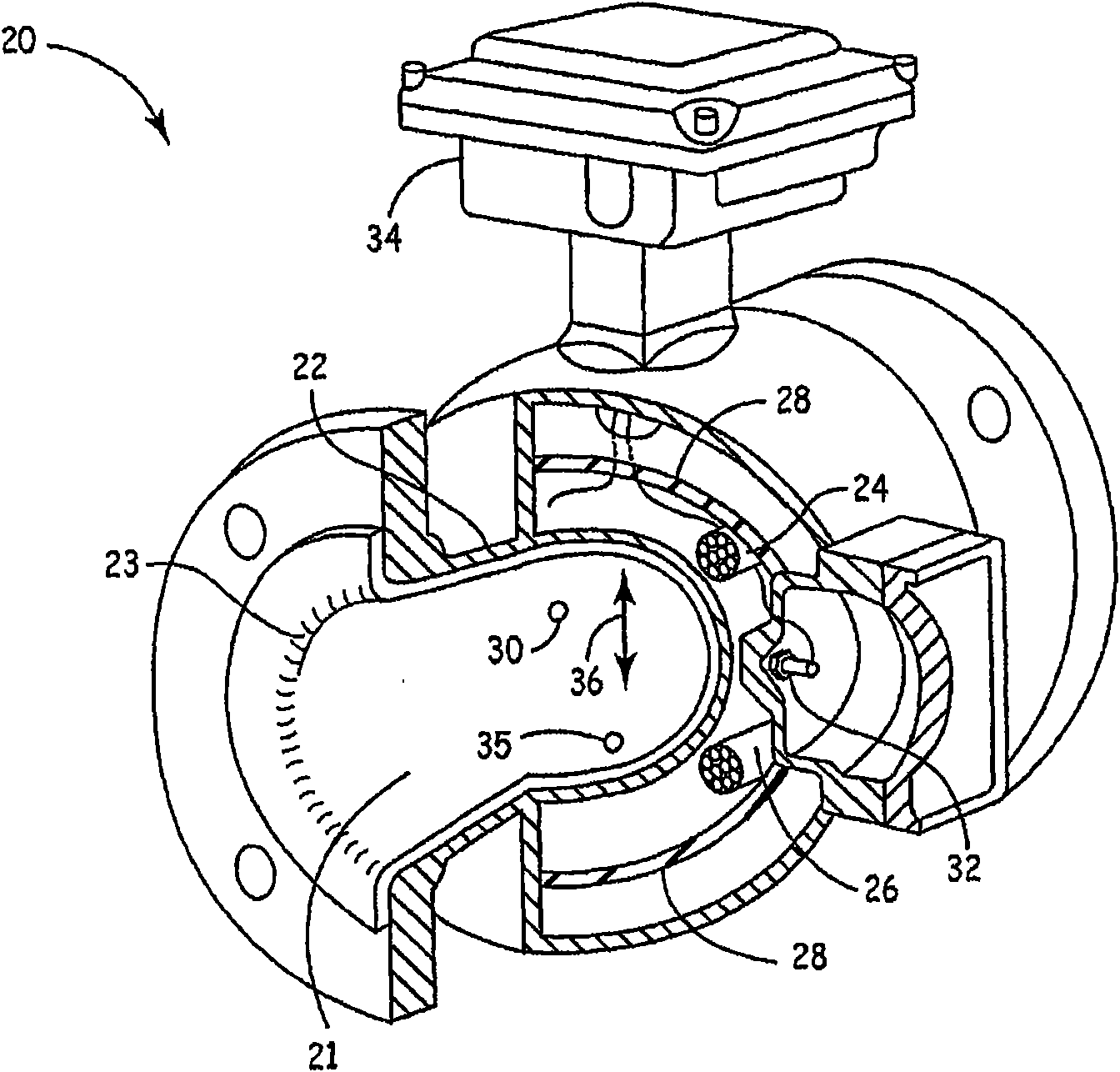

Electromagnetic flow sensor

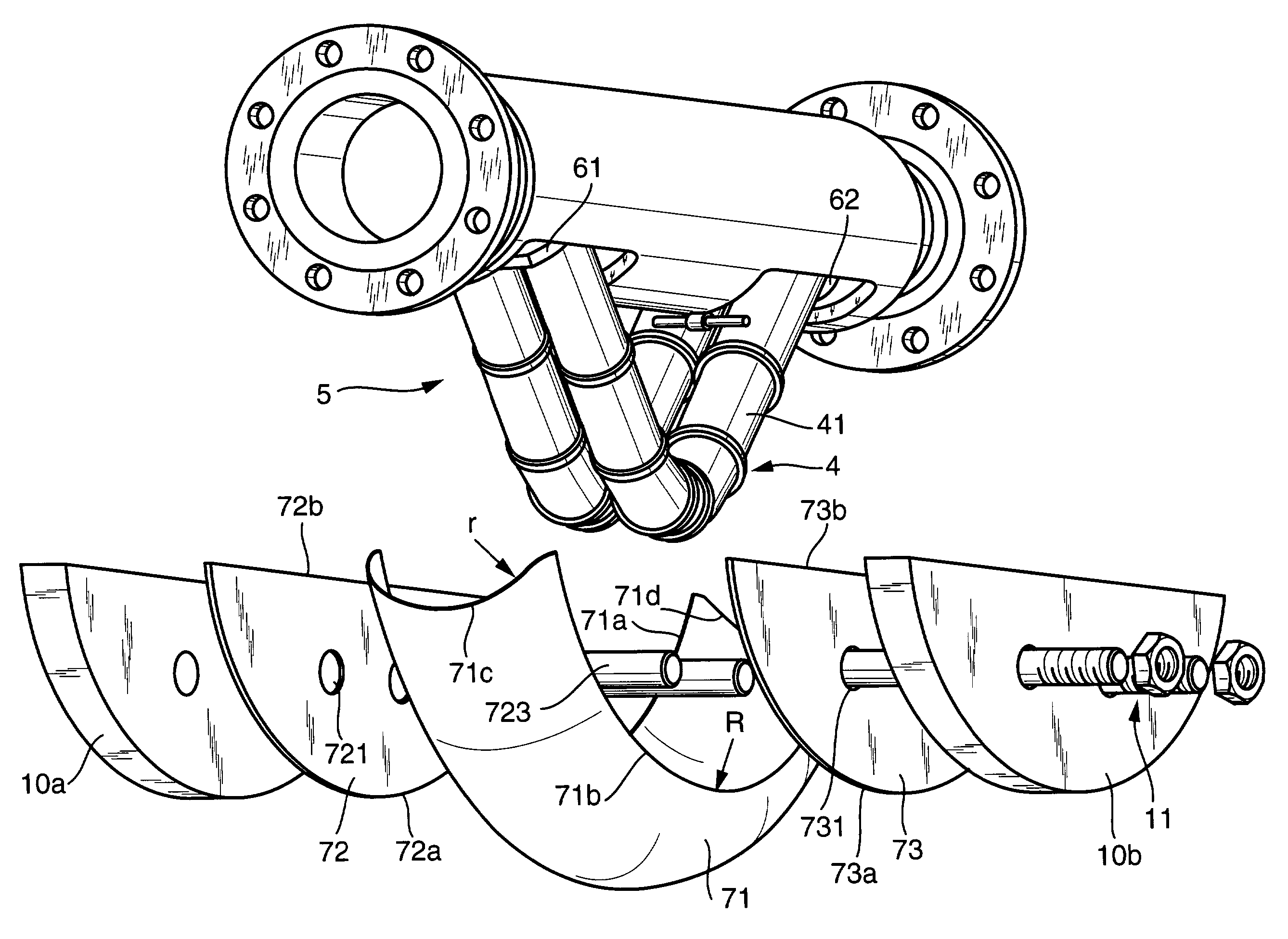

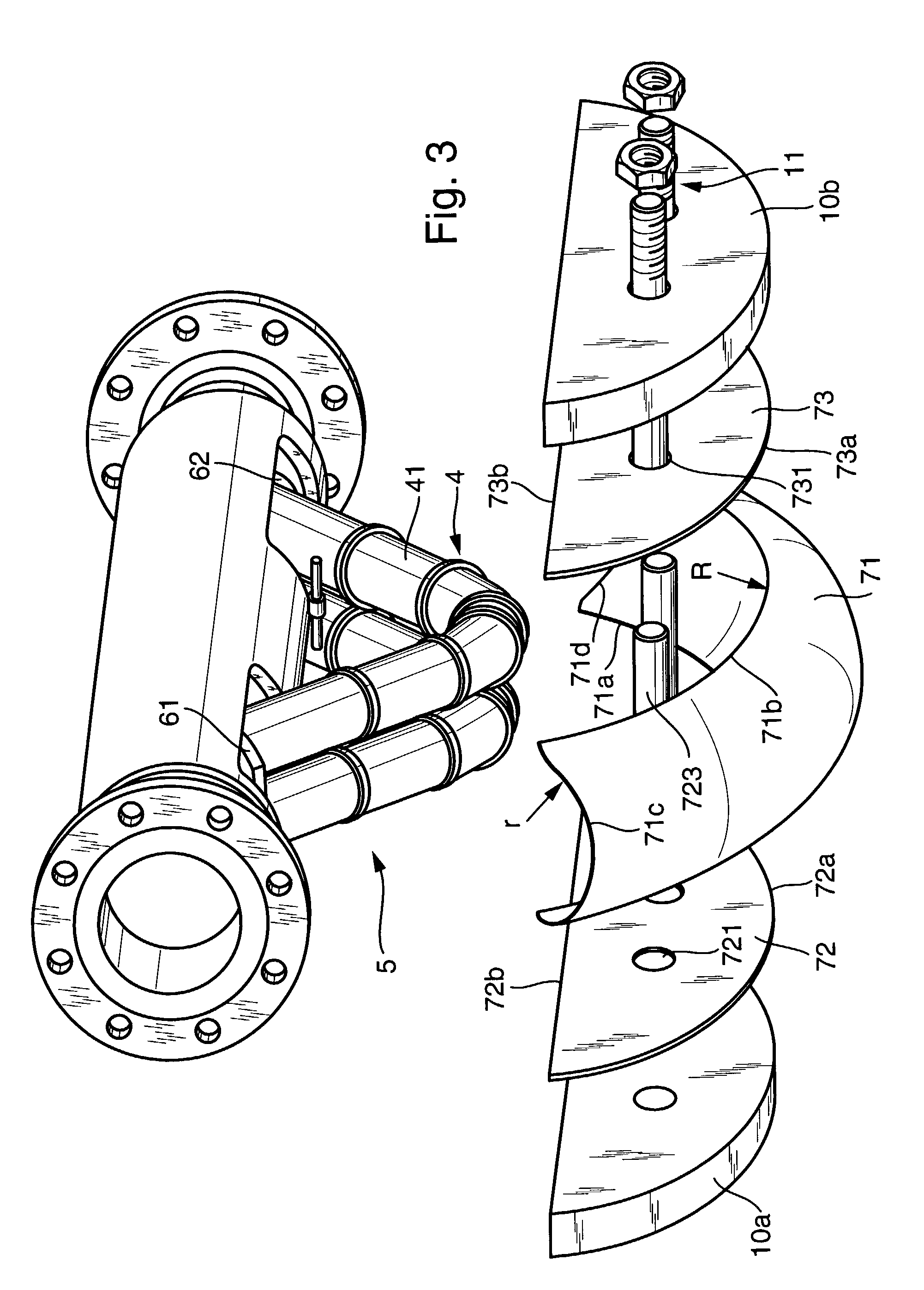

InactiveUS20050000300A1Short build timeLarge flow rangeVolume/mass flow by electromagnetic flowmetersFlow transducerCoupling

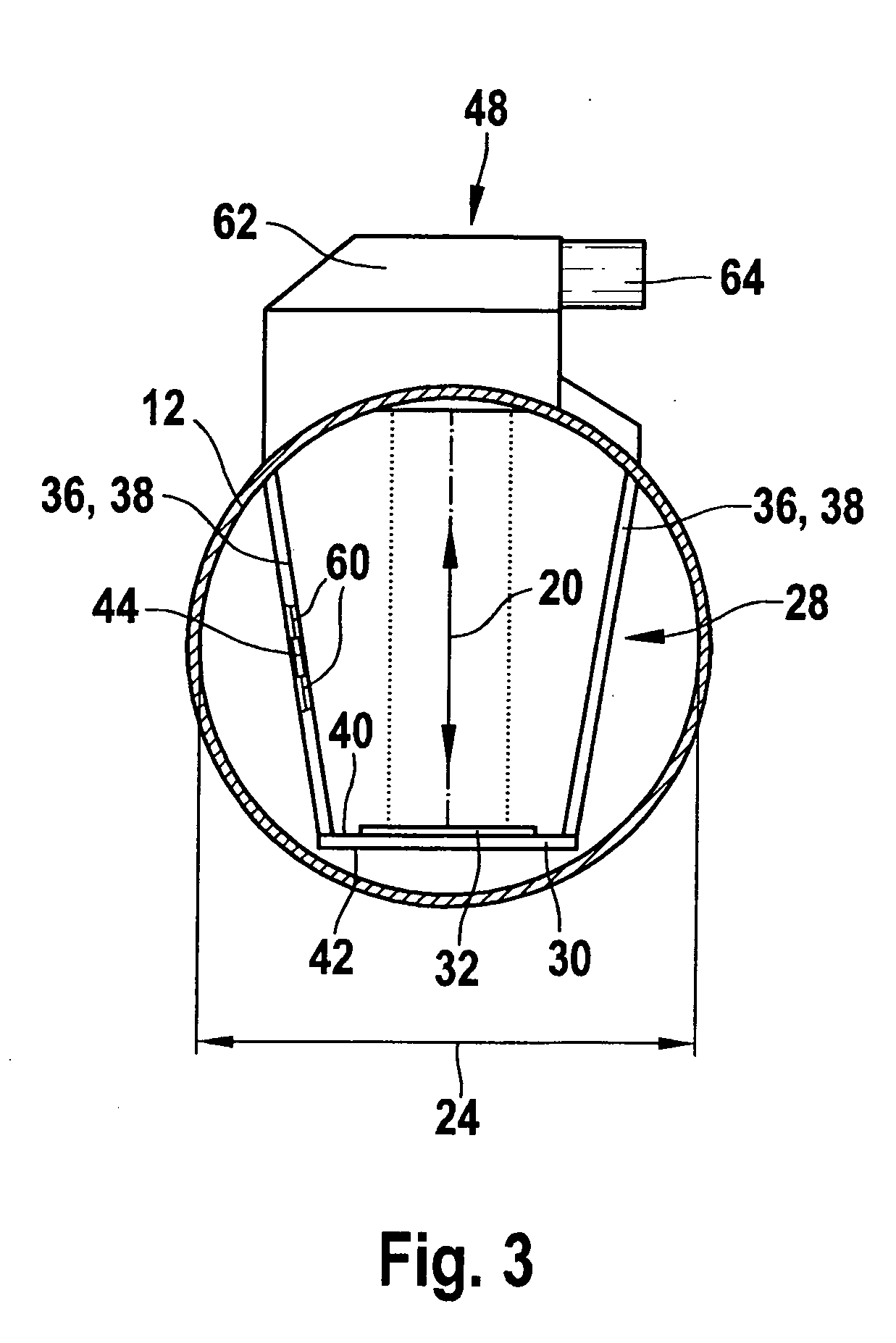

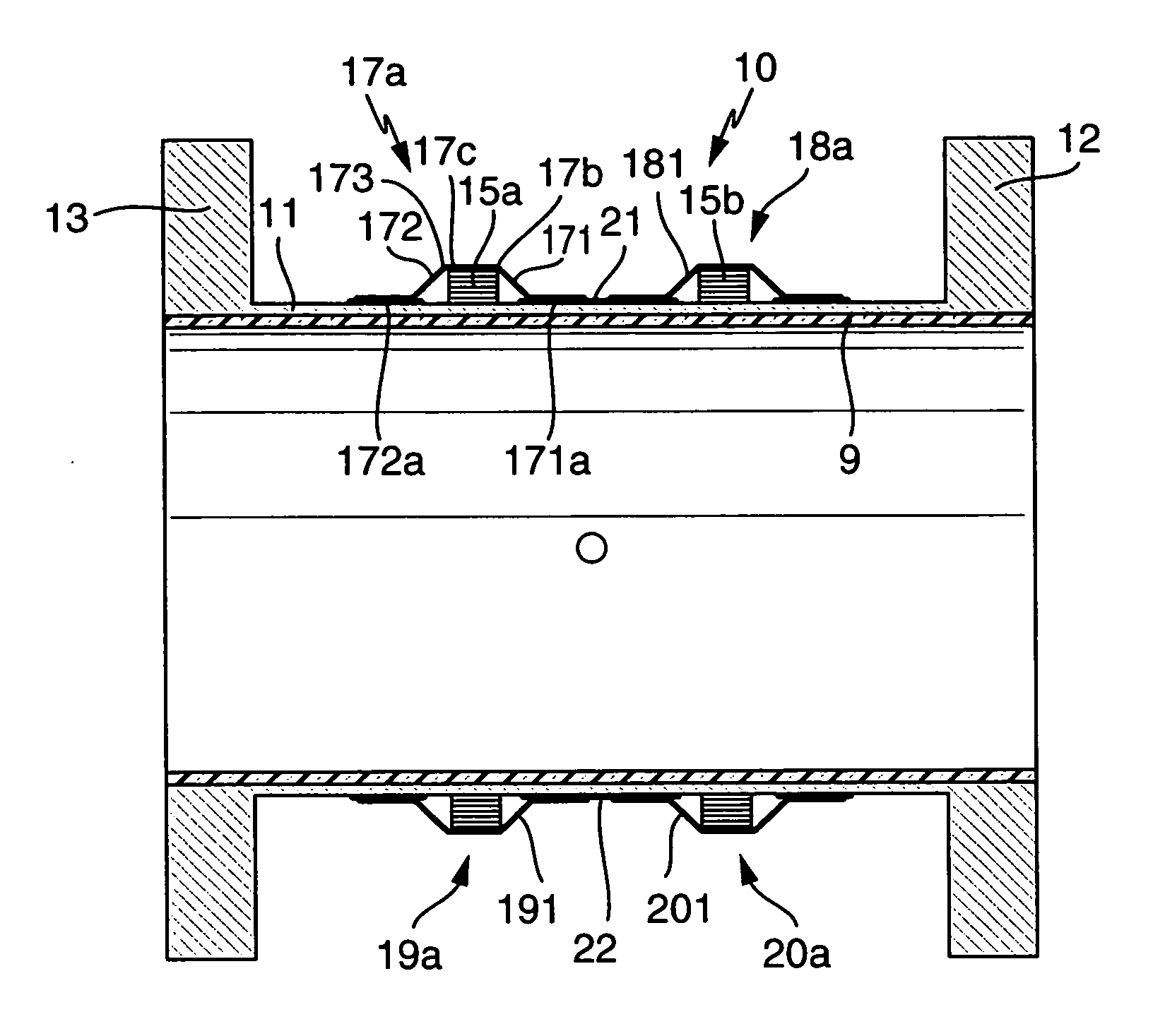

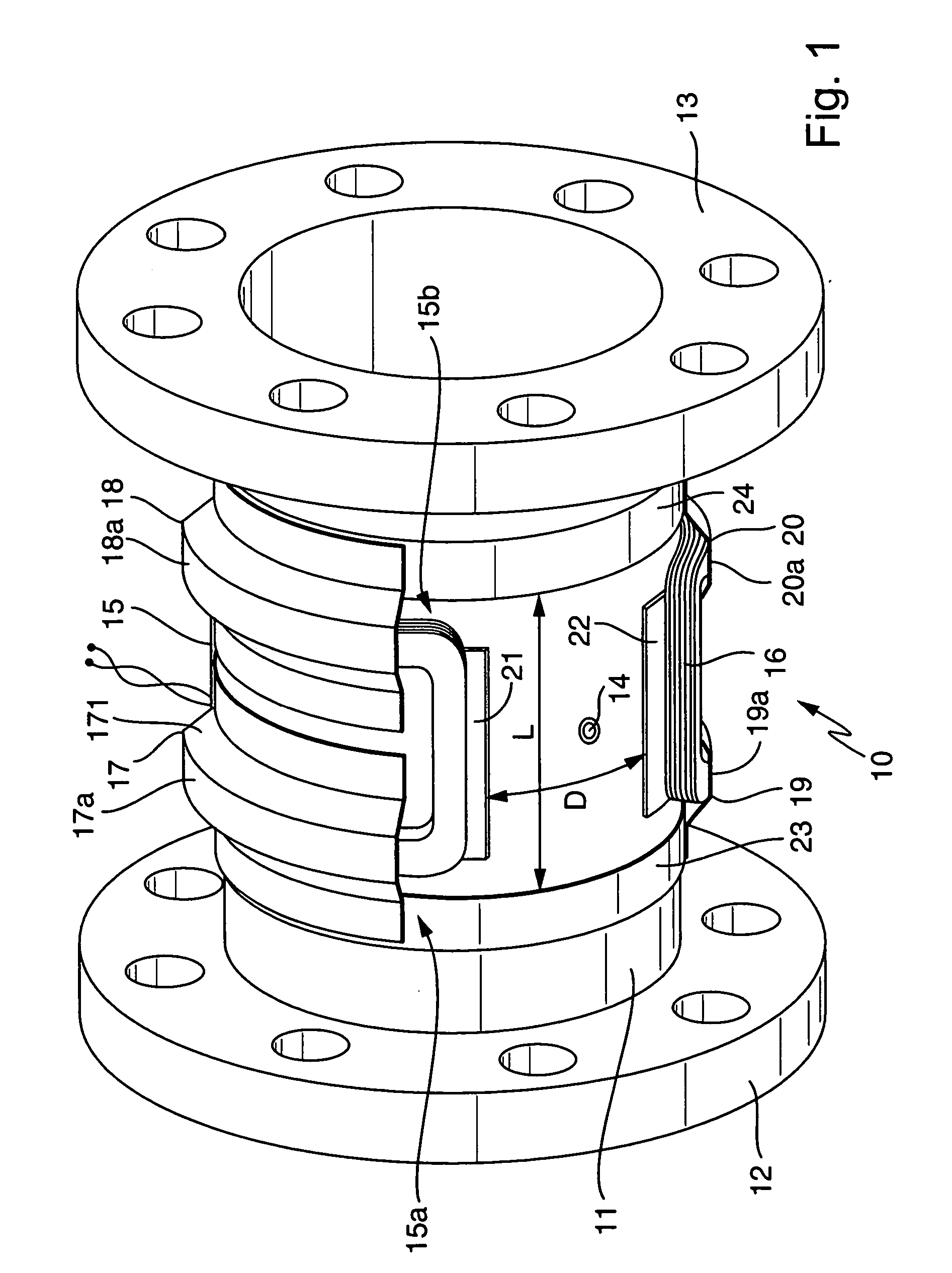

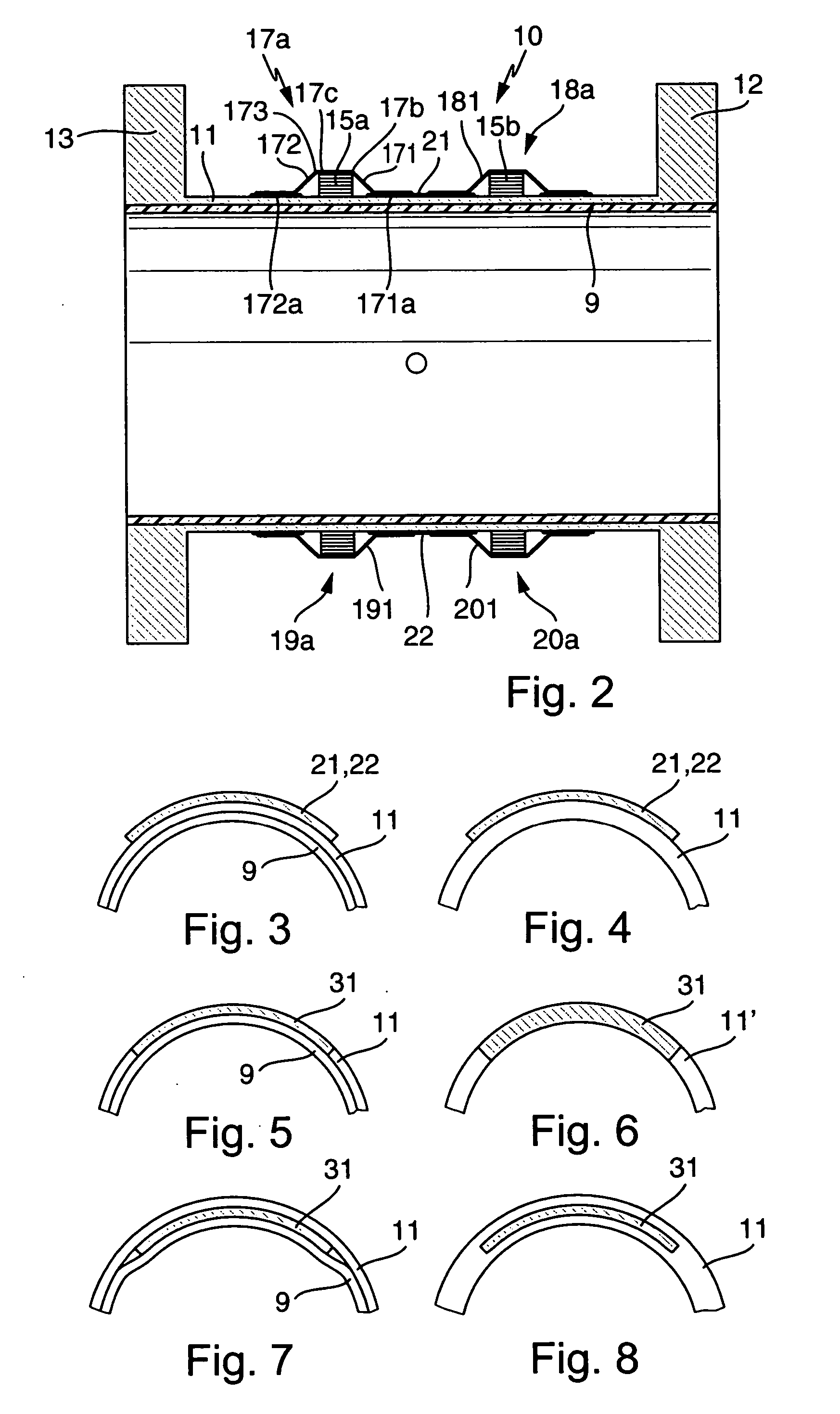

The flow sensor serves to measure an electrically conductive fluid flowing in a pipe. It comprises a flow tube designed to be inserted into the pipe for conducting the fluid, the flow tube being electrically nonconductive at least on a fluid-contacting inner side, an electrode arrangement consisting of at least two measuring electrodes disposed on the flow tube for picking up a voltage induced in the fluid, and a magnetic field system likewise disposed on the flow tube. The magnetic field system comprises at least two saddle-shaped field coils for producing a magnetic field cutting the fluid during operation of the flow sensor, a respective ferromagnetic pole piece for each of the two field coils, as well as at least one ferromagnetic return path extending around the flow tube upstream of the two field coils and at least one ferromagnetic return path extending around the flow tube downstream of the two field coils for directing the magnetic field around the flow tube. The pole pieces are magnetically coupled to the return paths by means of ferromagnetic coupling elements. Each of the, preferably identically shaped, coupling elements has at least one essentially trough-shaped cover segment which receives a first winding section of the respective associated field coil, lying essentially on a first periphery of the flow tube, or a second winding section of the associated field coil, lying essentially on a second periphery of the flow tube.

Owner:ENDRESS HAUSER FLOWTEC AG

Flanged vortex flowmeter with unitary tapered expanders

A manufacturing procedure of a vortex flowmeter is disclosed that allows for assembly of a vortex sensor assembly with one of two or more unitary flowtubes that have bores that are smaller than the flowtube flanges in two or more size number steps. The unitary flowtubes include flanges, flowtube bores and expanders (also called reducers) that provide a smooth flow transition from the larger flanges to the smaller bores.

Owner:MICRO MOTION INC

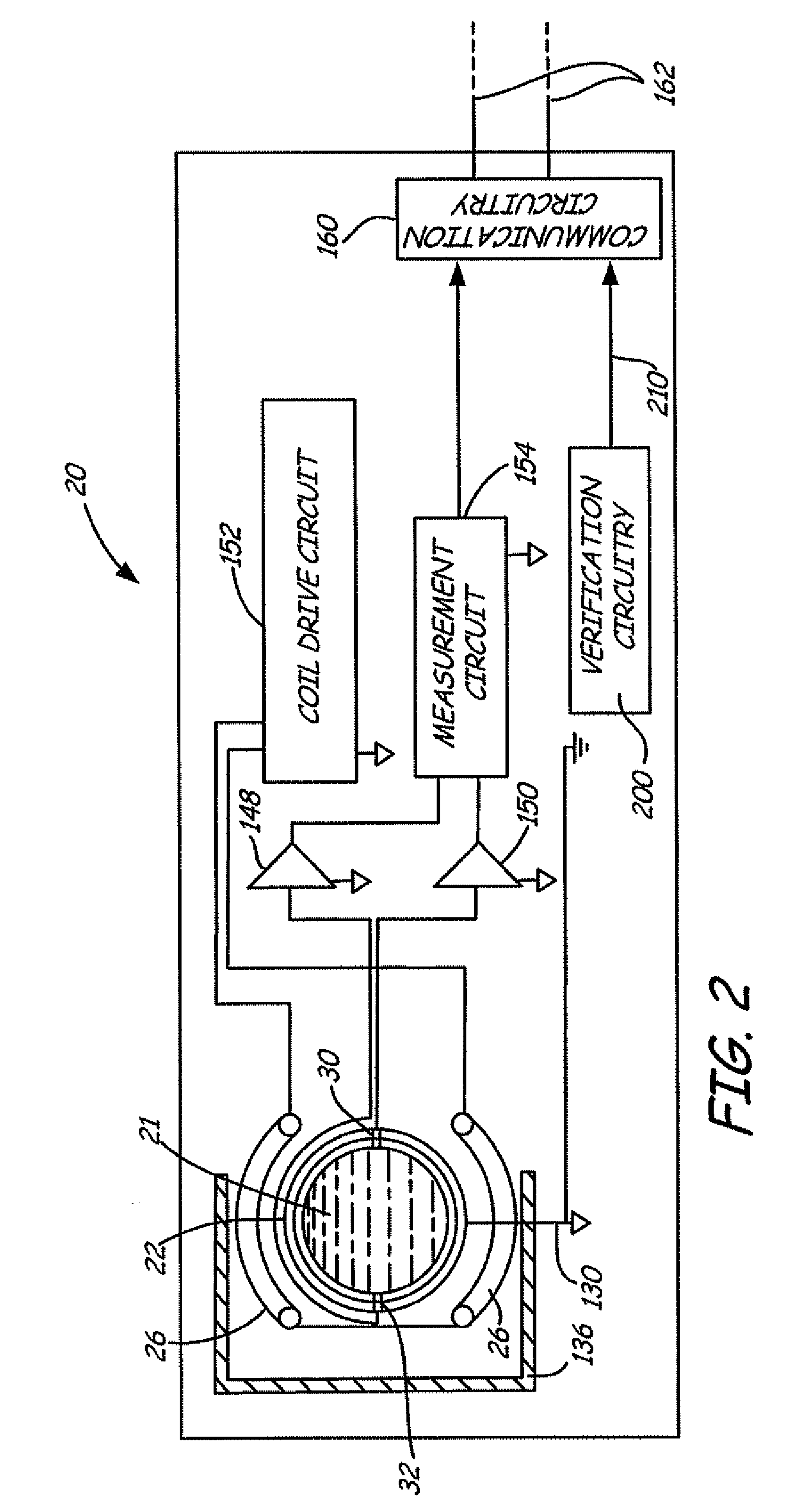

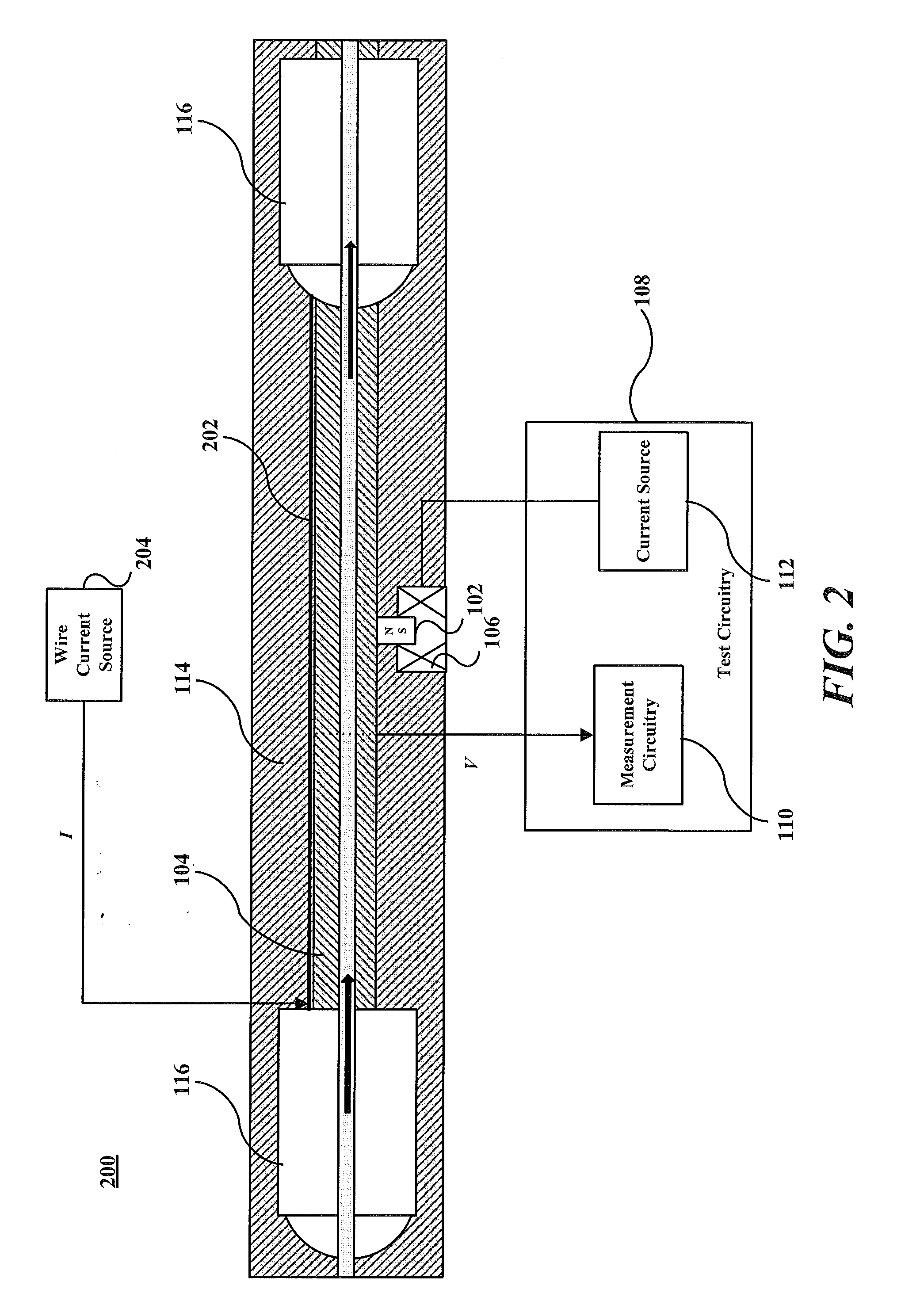

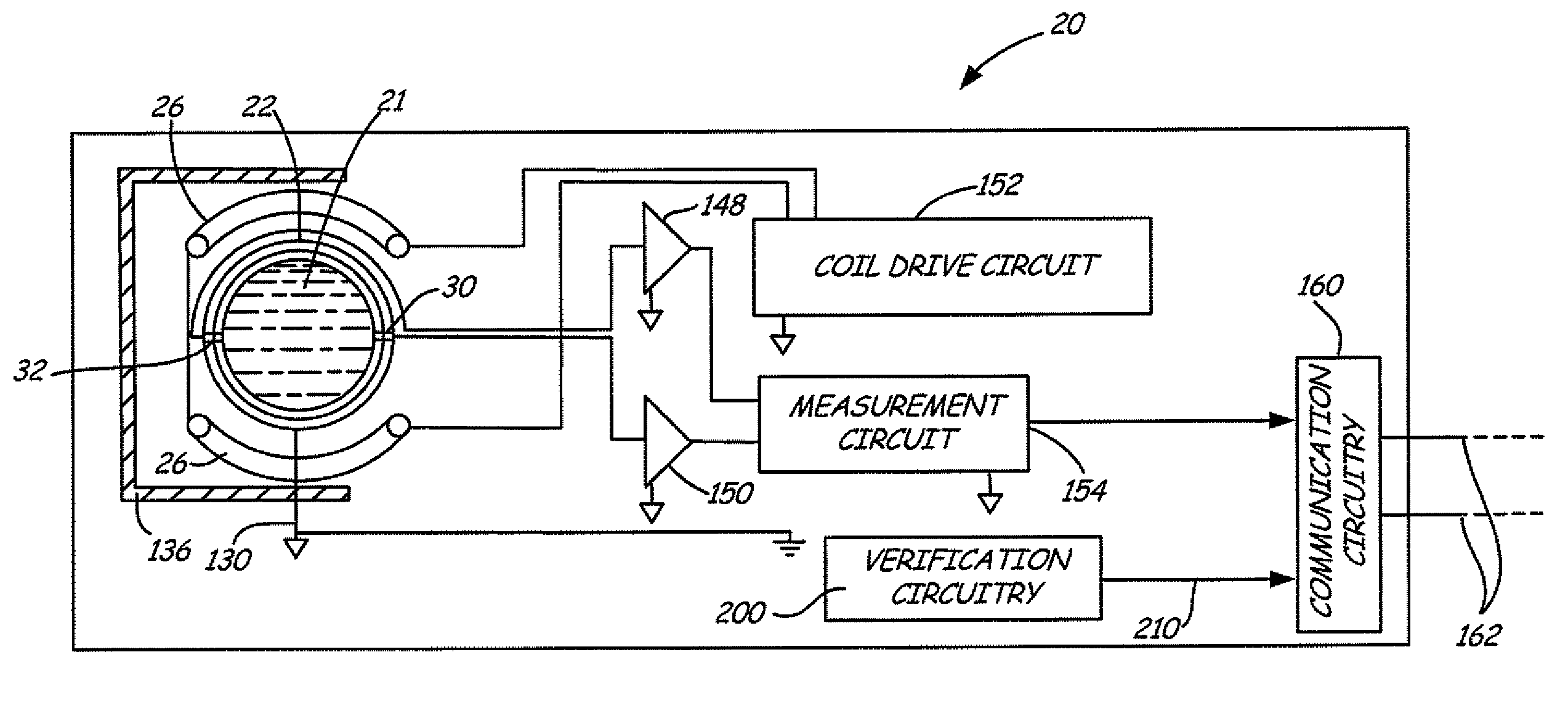

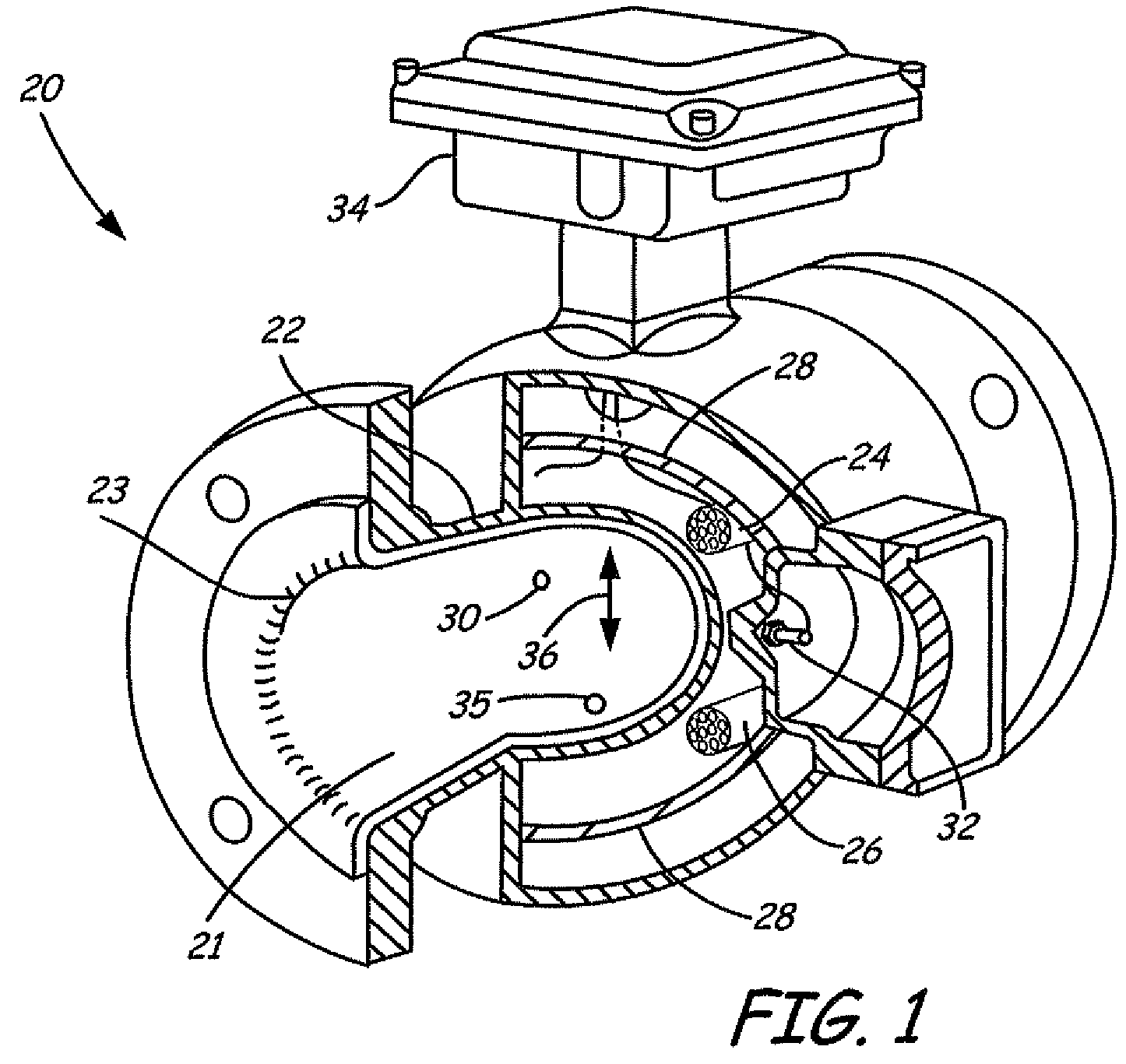

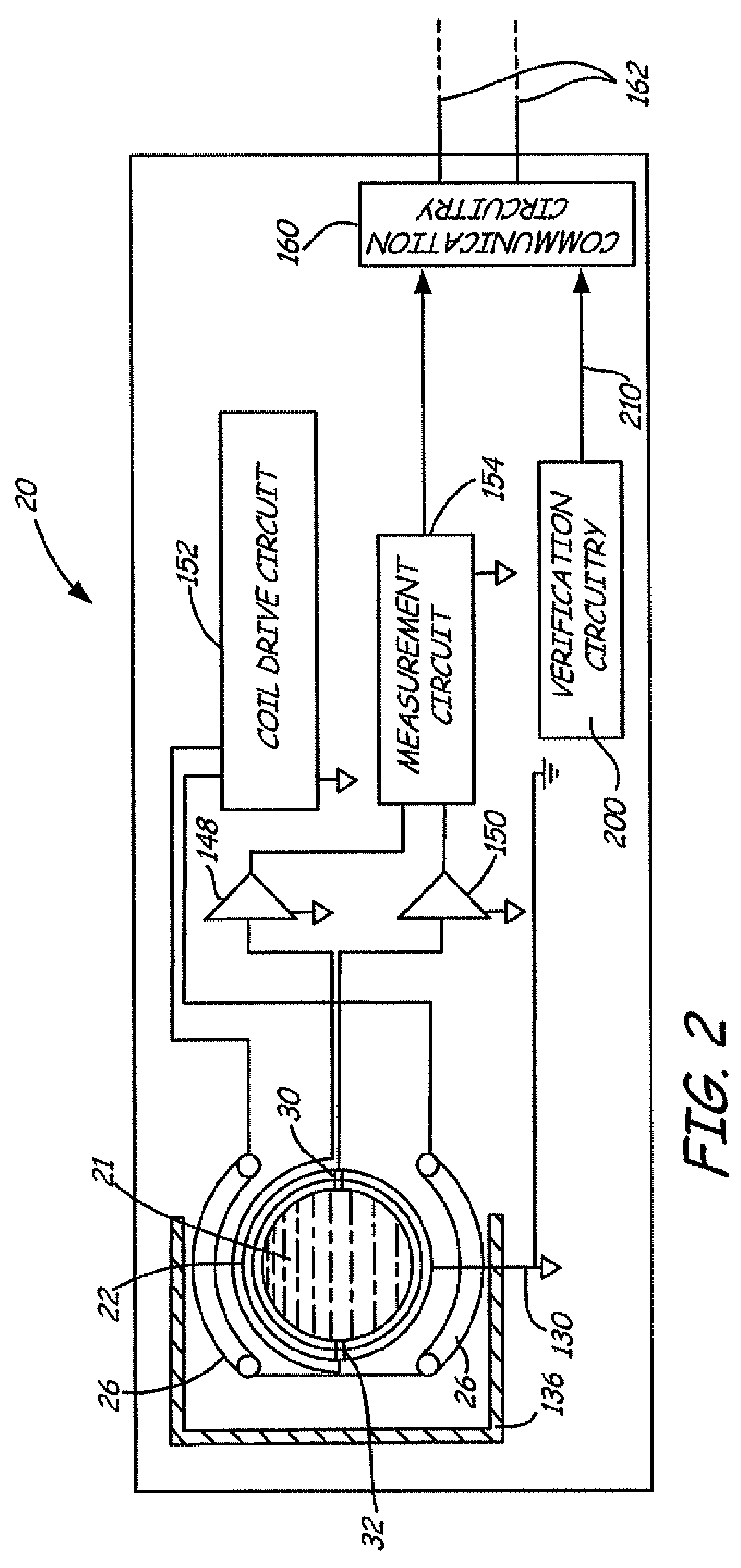

Flowmeter verification on a magnetic flowmeter

ActiveUS20080078252A1Testing/calibration for volume flowMaterial impedanceElectromagnetic flowmeterElectrical and Electronics engineering

A magnetic flowmeter is provided including a magnetic flowtube arranged to receive a flow of process fluid. The magnetic flowtube includes a drive coil and at least one sense electrode. Measurement circuitry is coupled to the flowtube and is configured to provide a drive signal to the drive coil and measure flow of process fluid through the flow tube based upon an output from the sense electrode. A memory contains a stored value related to a nominal parameter of the flowtube. Verification circuitry is arranged to measure a parameter of the magnetic flowtube and responsively provide a verification output related to operation of the magnetic flowmeter based upon a comparison of the measured parameter and the stored value.

Owner:MICRO MOTION INC

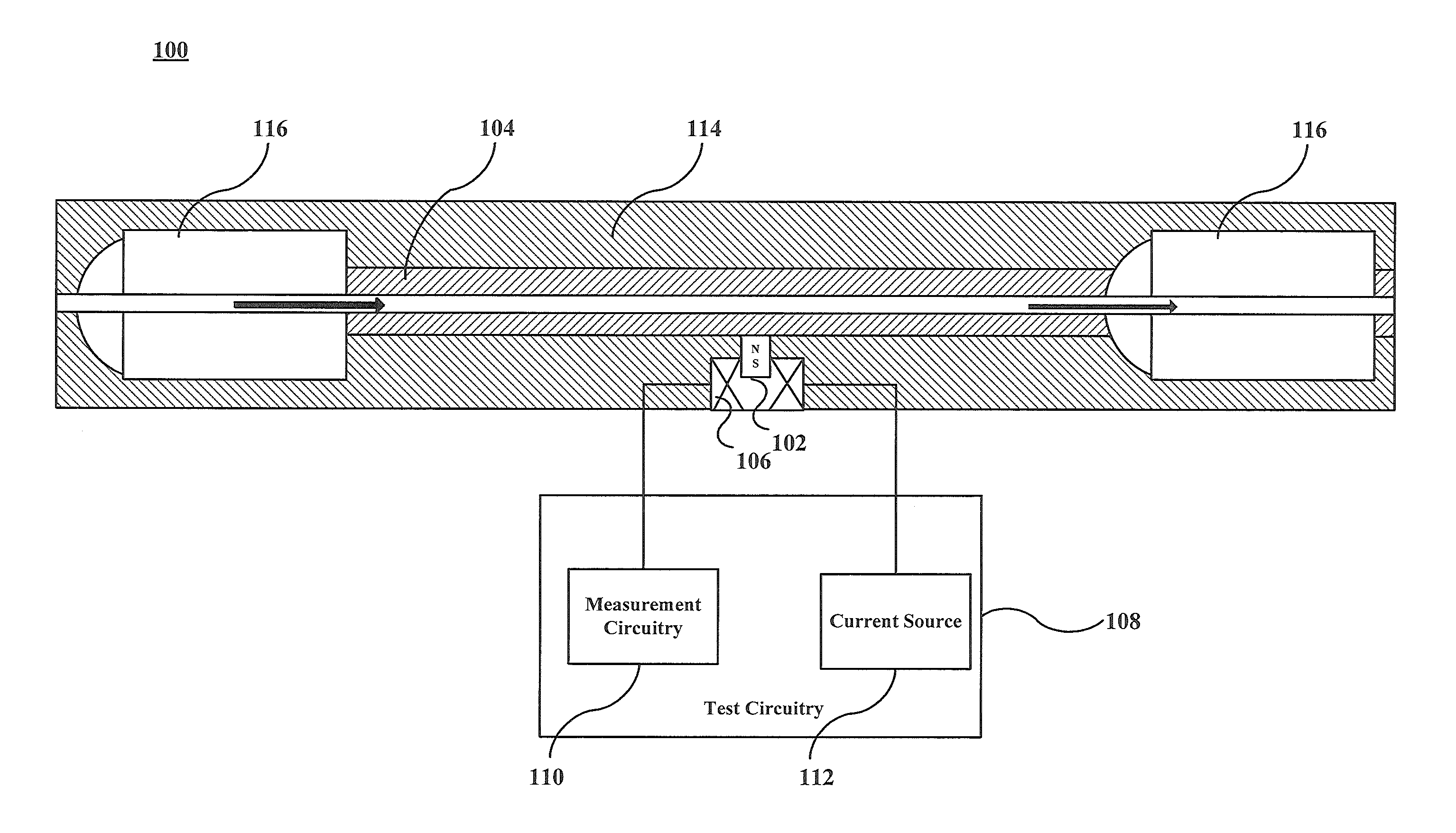

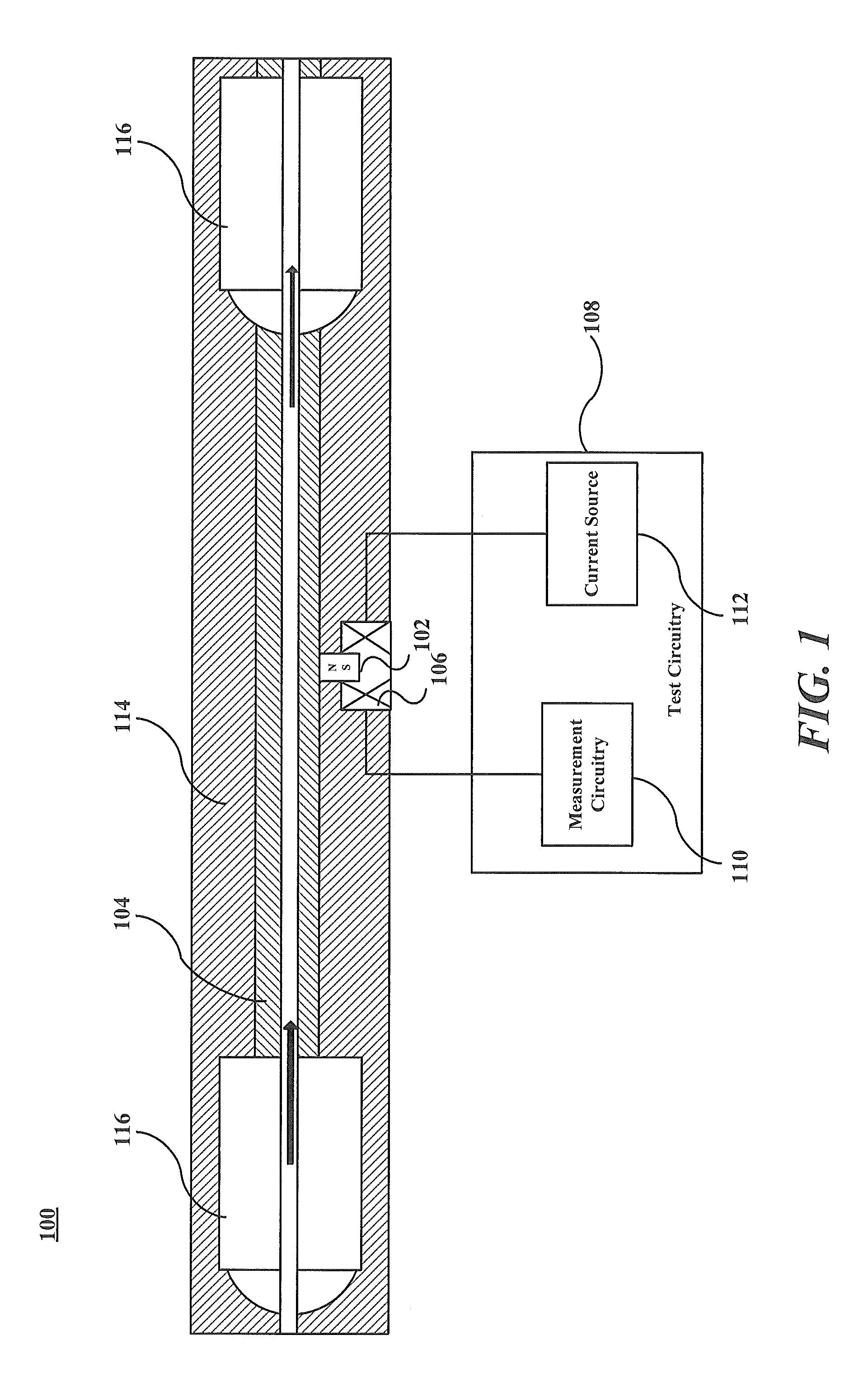

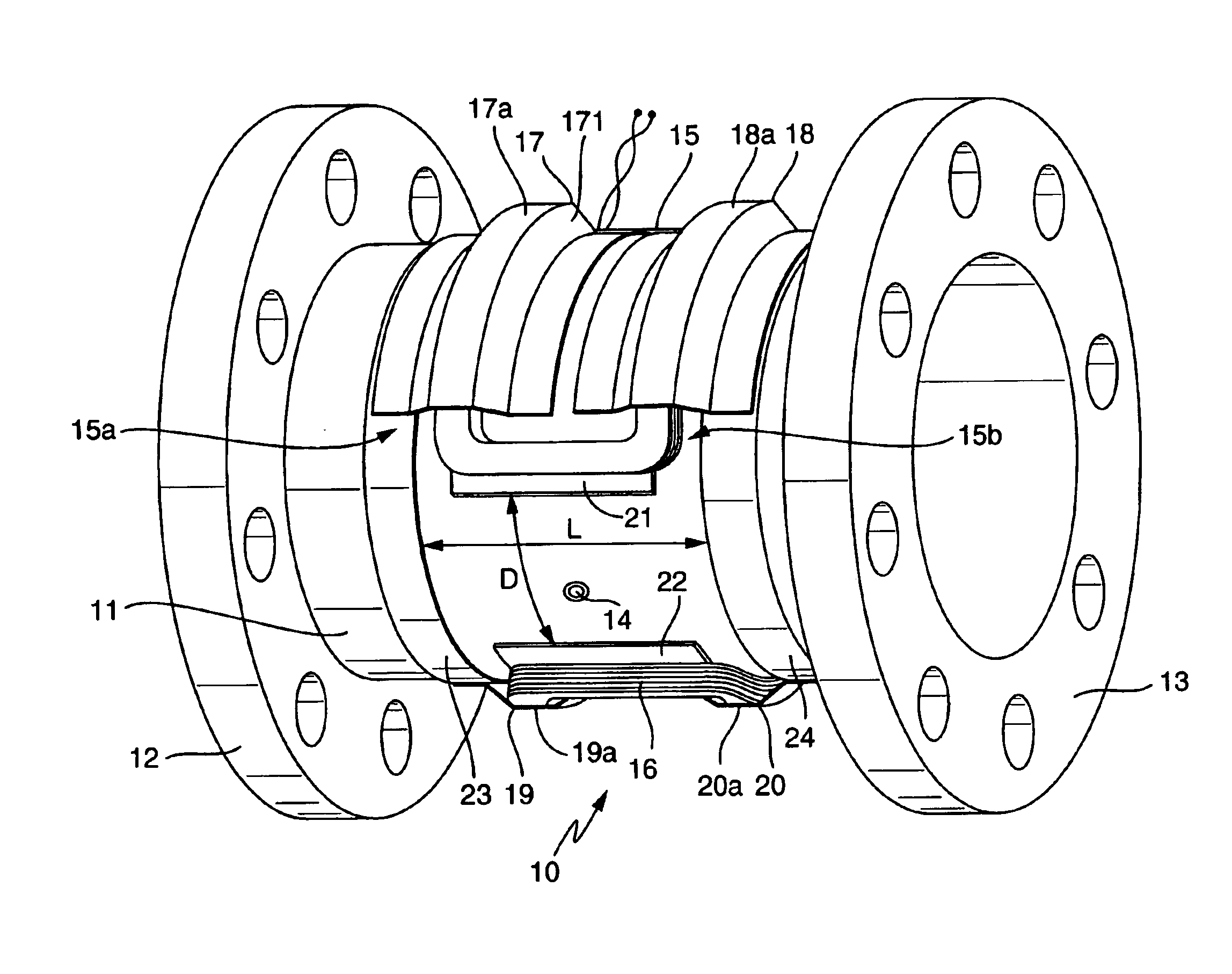

Fluid densitometer with temperature sensor to provide temperature correction

ActiveUS20130180330A1Thermometer detailsSpecific gravity using flow propertiesThermodynamicsFluid density

A sensor for measuring a density of a fluid is provided. The sensor (200) includes a flow tube (104) for receiving the fluid and a vibration driver (102) coupled to the flow tube, the vibration driver configured to drive the flow tube to vibrate. The sensor also includes a vibration detector (106) coupled to the flow tube, the vibration detector detecting characteristics related to the vibrating flow tube, and a distributed temperature sensor (202) coupled to the flow tube, the distributed temperature sensor measuring a temperature of the flow tube as the flow tube vibrates. The sensor further includes measurement circuitry (110) coupled to the vibration detector and the distributed temperature sensor, the measurement circuitry determining a density of the fluid from the detected characteristics related to the vibrating flow tube and the measured temperature of the flow tube.

Owner:HALLIBURTON ENERGY SERVICES INC

Electromagnetic flow sensor

InactiveUS6983661B2Short build timeLarge flow rangeVolume/mass flow by electromagnetic flowmetersCouplingPole piece

The flow sensor serves to measure an electrically conductive fluid flowing in a pipe. It comprises a flow tube designed to be inserted into the pipe for conducting the fluid, the flow tube being electrically nonconductive at least on a fluid-contacting inner side, an electrode arrangement consisting of at least two measuring electrodes disposed on the flow tube for picking up a voltage induced in the fluid, and a magnetic field system likewise disposed on the flow tube. The magnetic field system comprises at least two saddle-shaped field coils for producing a magnetic field cutting the fluid during operation of the flow sensor, a respective ferromagnetic pole piece for each of the two field coils, as well as at least one ferromagnetic return path extending around the flow tube upstream of the two field coils and at least one ferromagnetic return path extending around the flow tube downstream of the two field coils for directing the magnetic field around the flow tube. The pole pieces are magnetically coupled to the return paths by means of ferromagnetic coupling elements. Each of the, preferably identically shaped, coupling elements has at least one essentially trough-shaped cover segment which receives a first winding section of the respective associated field coil, lying essentially on a first periphery of the flow tube, or a second winding section of the associated field coil, lying essentially on a second periphery of the flow tube.

Owner:ENDRESS HAUSER FLOWTEC AG

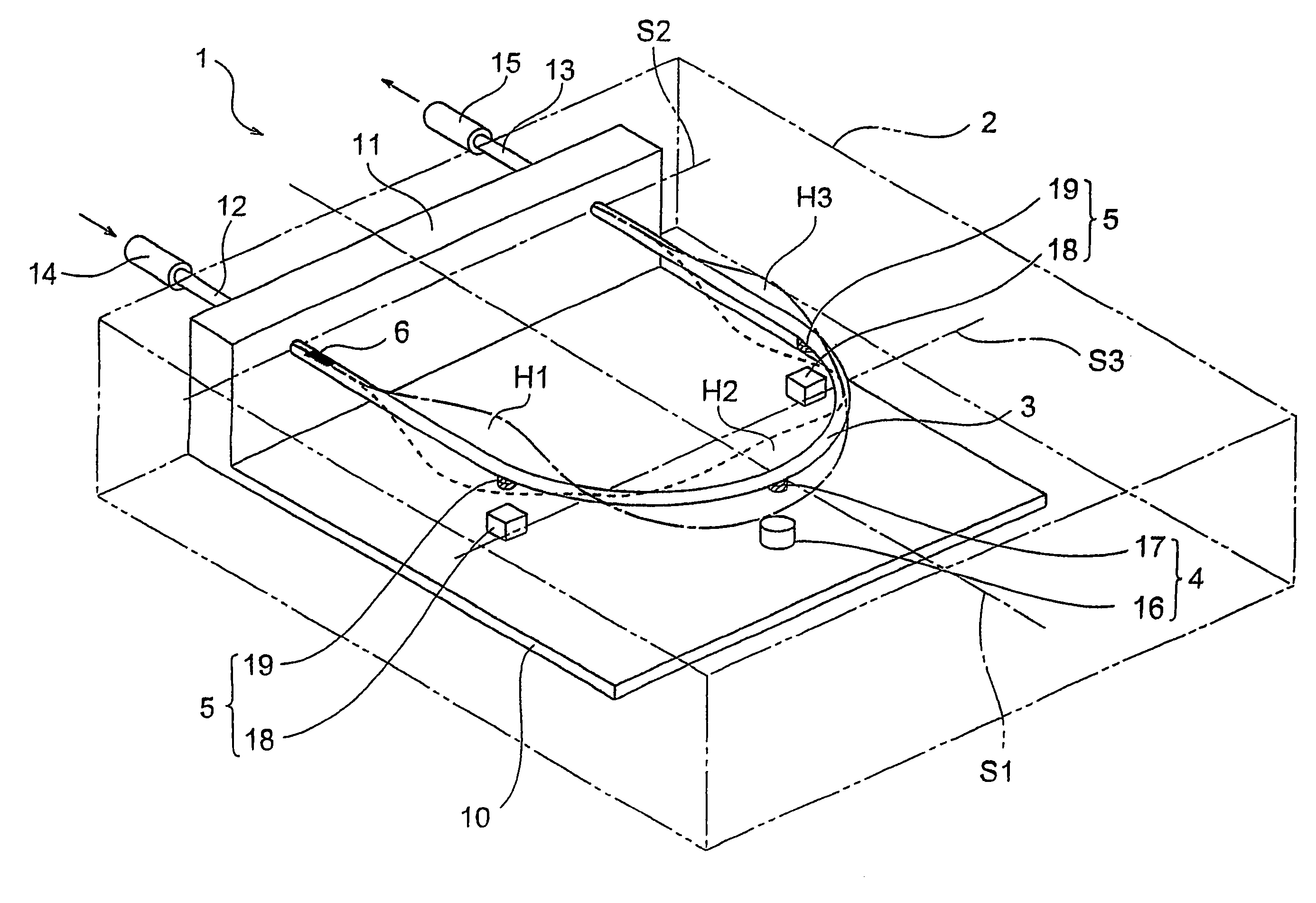

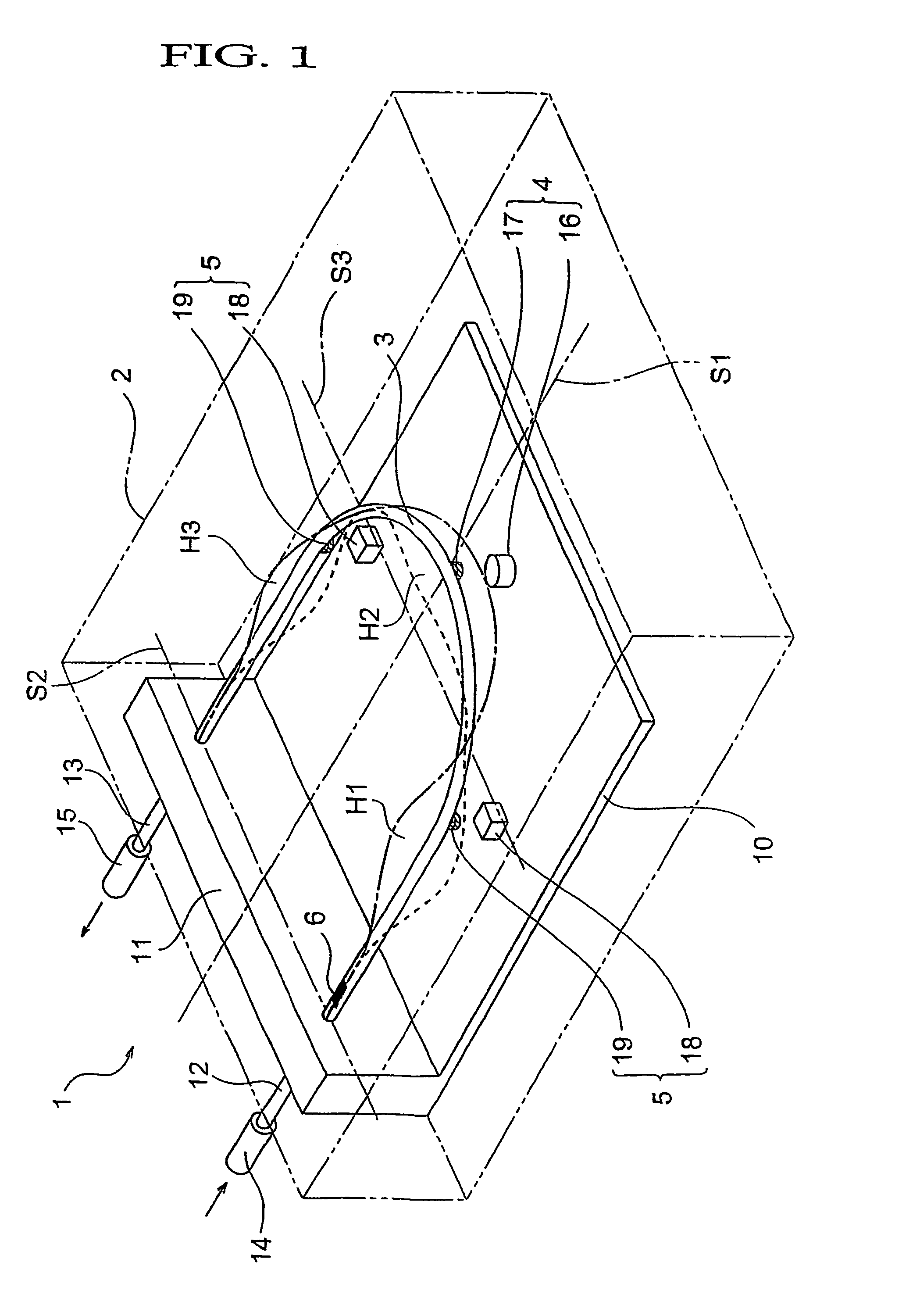

Vibratory transducer

InactiveUS6957587B2Small massImprove stress resistanceVolume meteringDirect mass flowmetersTransducerEngineering

Owner:ENDRESSHAUSER FLOWTECH

Mono bearing one piece core solenoid

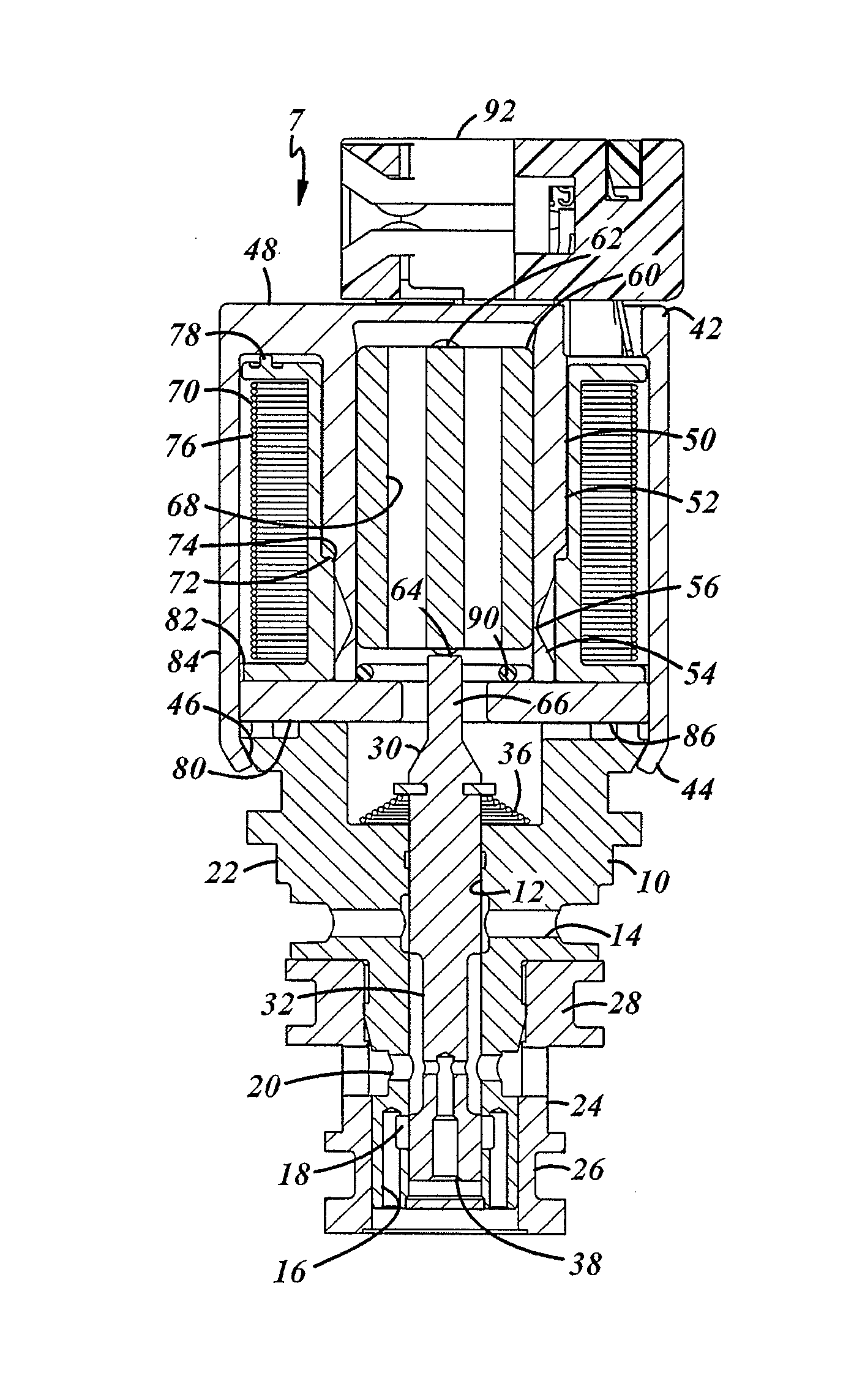

ActiveUS20140361206A1Increase flux densityReduce discontinuityOperating means/releasing devices for valvesMagnetsSolenoid valveElectromagnet

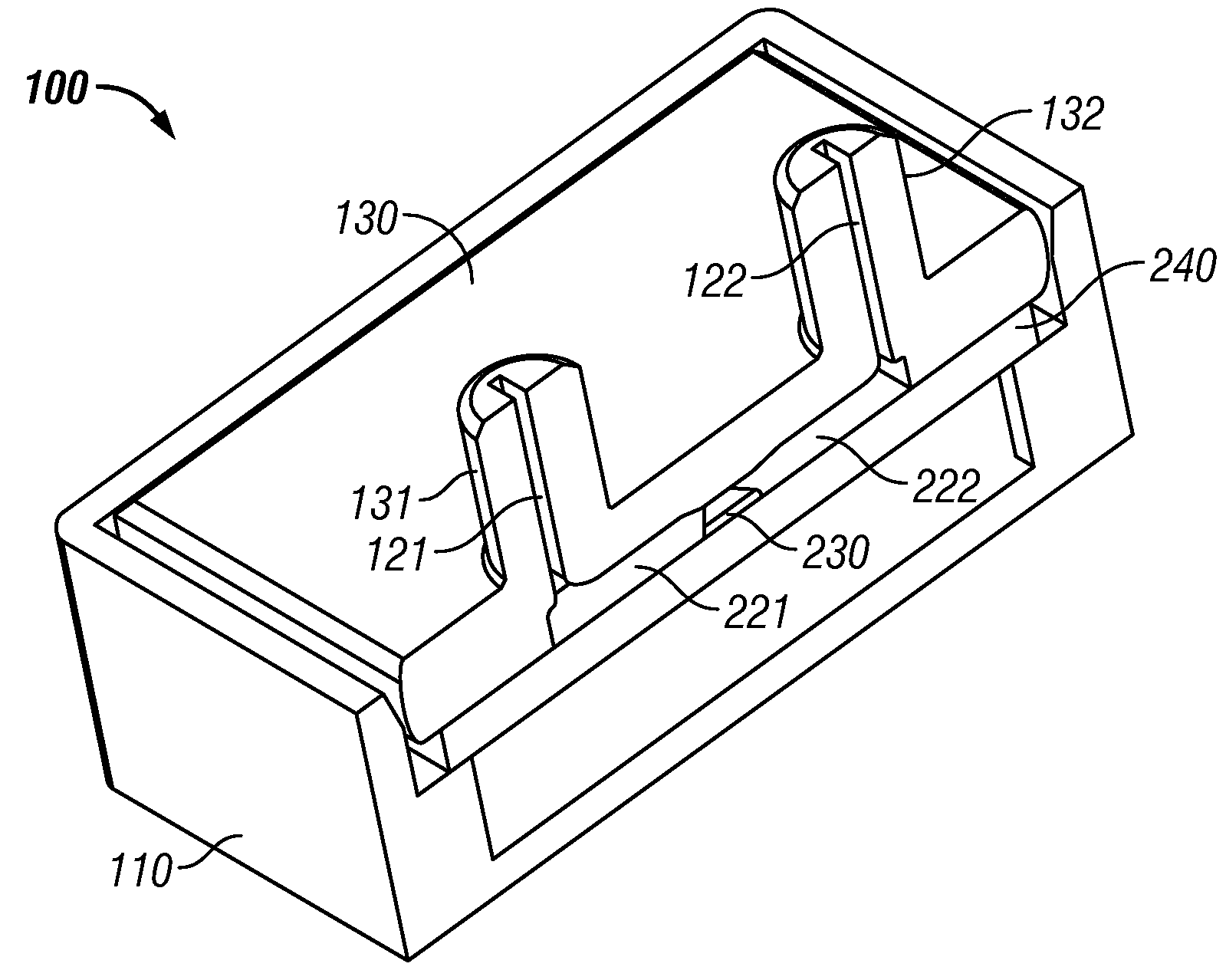

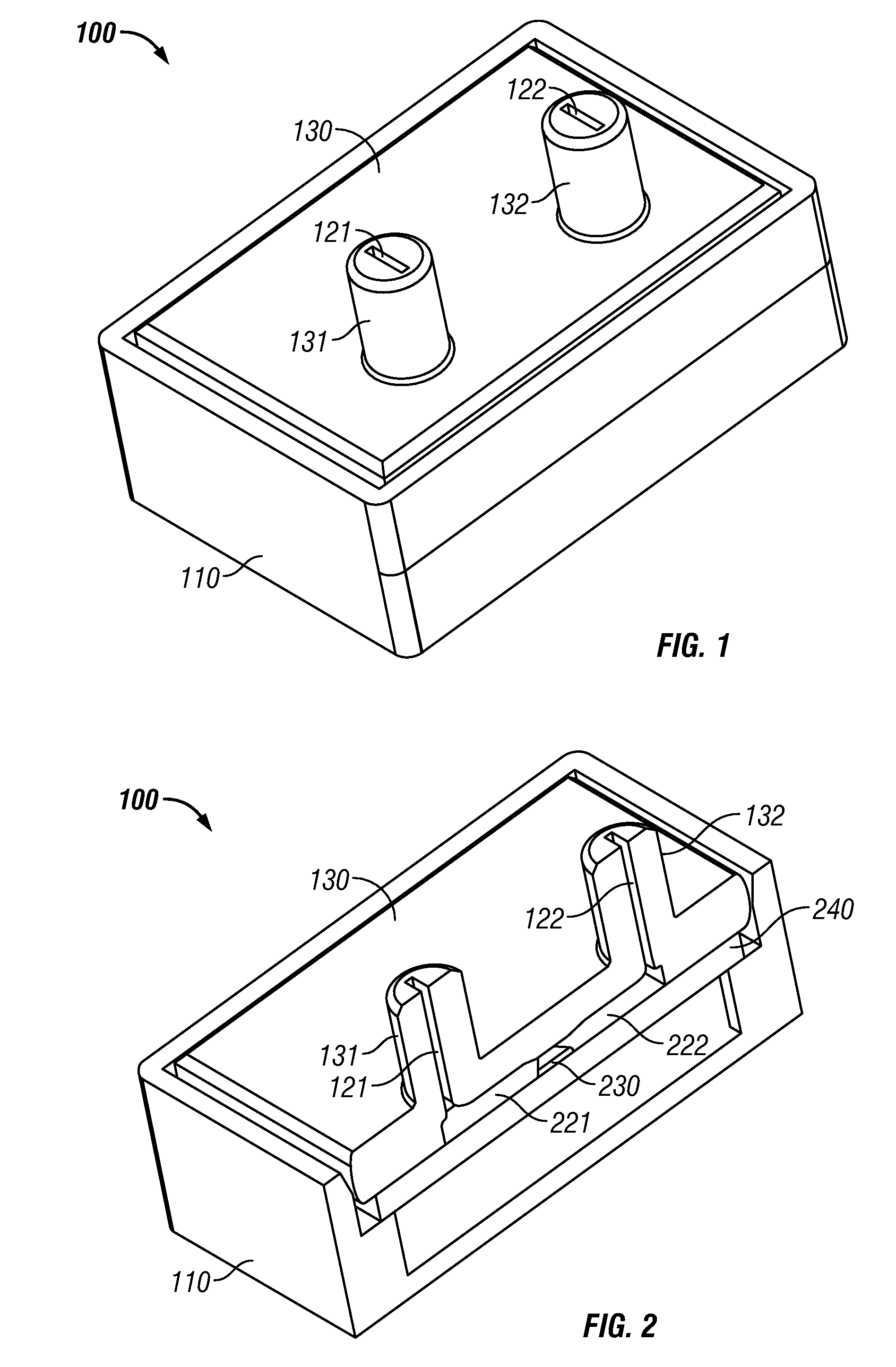

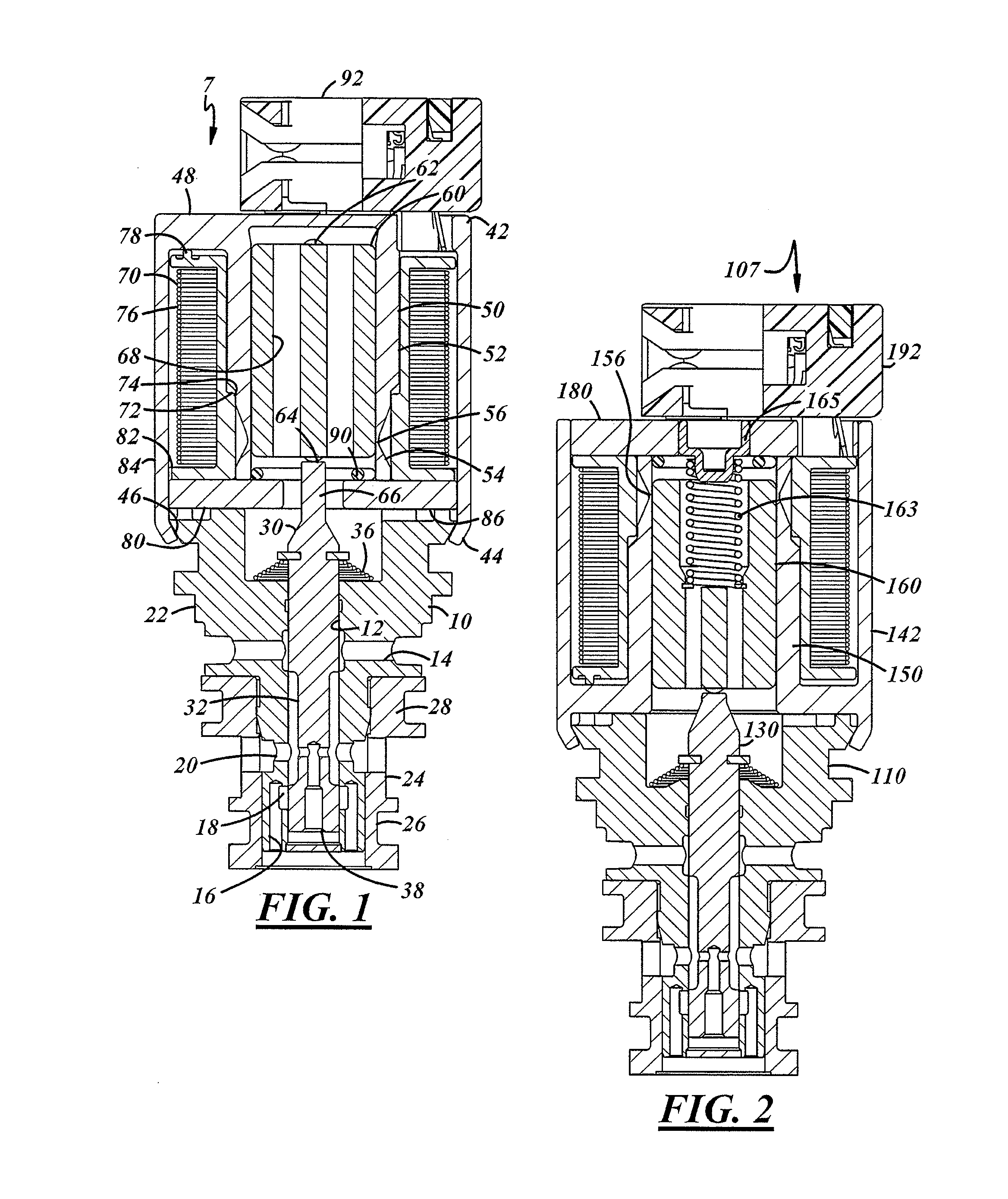

A solenoid valve assembly is provided which includes a ferromagnetic casing forming a generally tubular envelope, a flux tube integrally formed with the casing and extending axially generally there from defining and axially extending annular space there between, the flux tube having a first portion connected with the casing and a second portion integral with the first portion be divided there from by a flux choke, and also including an armature aligned and slidably mounted within the flux tube for imparting movement to a valve member.

Owner:BORGWARNER INC

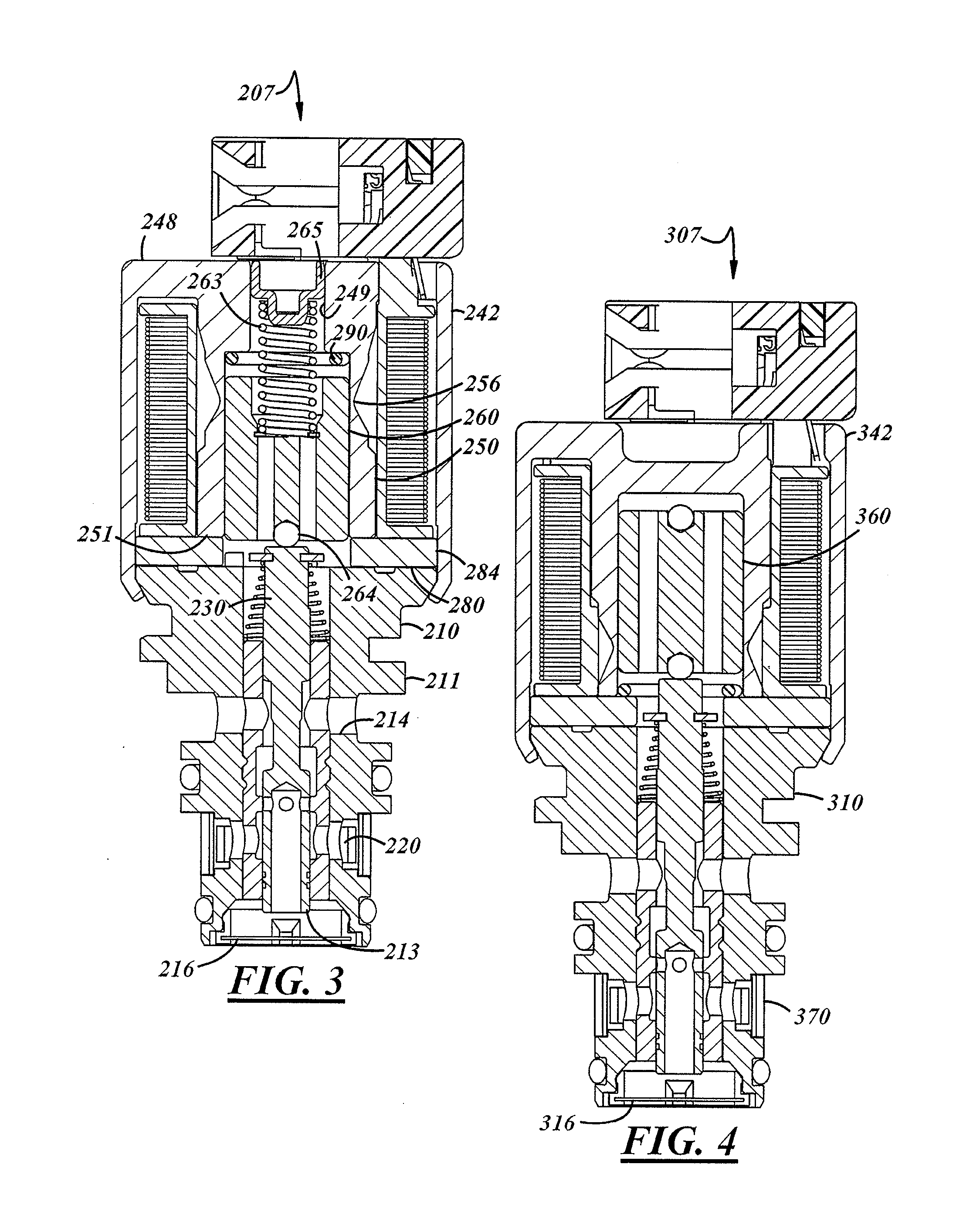

Method and apparatus for vibrating a flow tube of a vibrating flow meter

A flow measurement system (20) is provided according to an embodiment of the invention. The flow measurement system (20) comprises a vibrating flow meter (400) including at least one flow tube (410) and a driver (420) adapted to apply a biasing force on the flow tube (410). The flow measurement system (20) also comprises a meter electronics (450) configured to generate a drive signal to vibrate the flow tube (410) about a first deflected position (1002), wherein the first deflected position (1002) is offset from a flow tube rest position (1001).

Owner:MICRO MOTION INC

Tertiary mode vibration type Coriolis flowmeter

ActiveUS7437949B2Simple structureLow costVolume meteringDirect mass flowmetersElectrical polarityEngineering

Owner:OVAL CORP

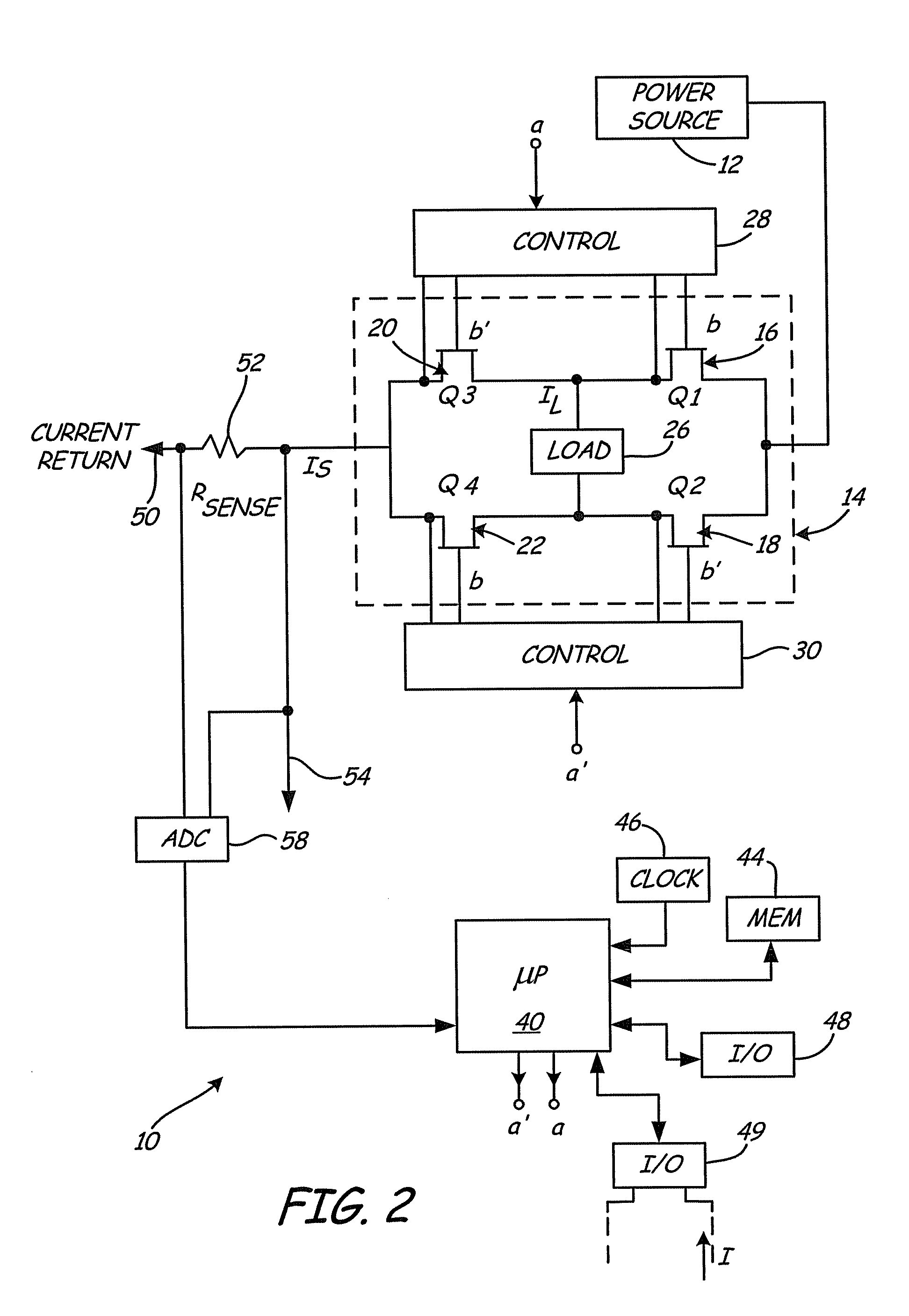

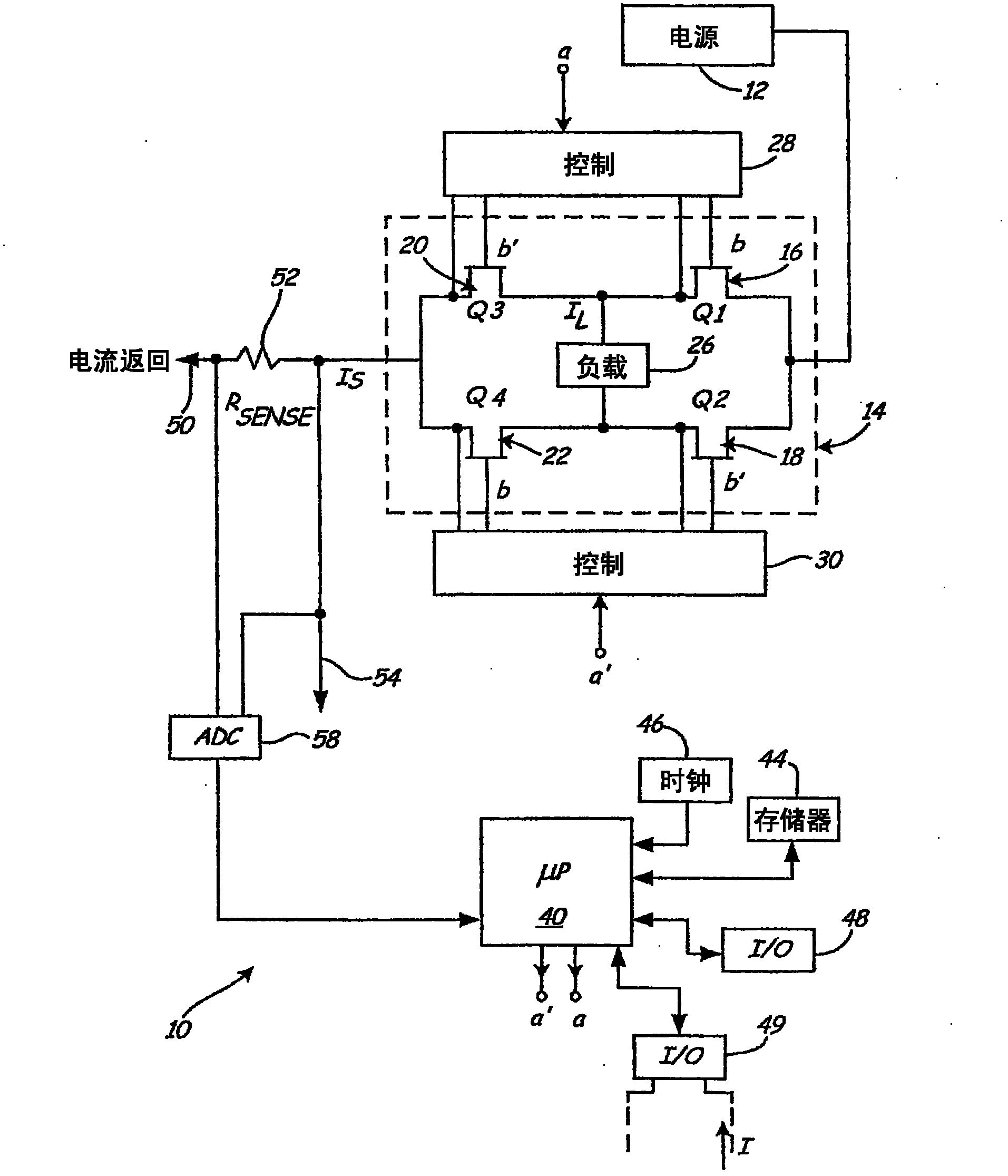

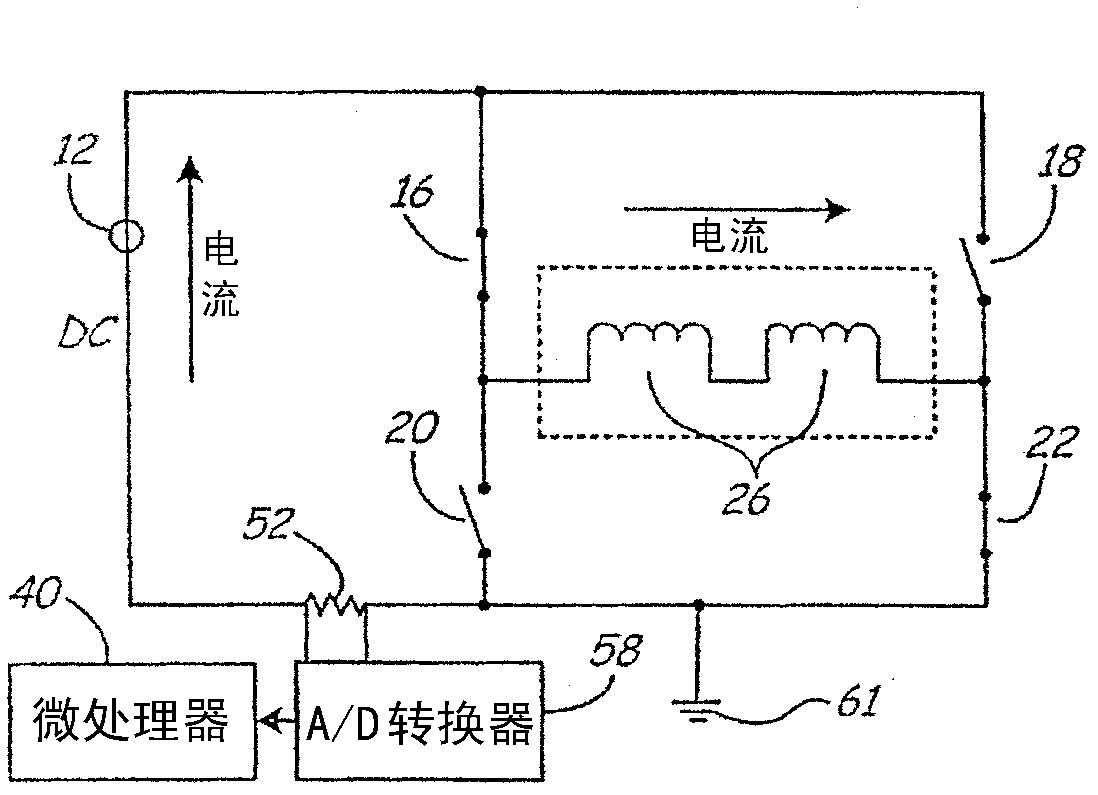

Magnetic flowmeter with coil ground path detection

ActiveUS20100224008A1Testing/calibration for volume flowVolume/mass flow by electromagnetic flowmetersElectricityEngineering

A magnetic flow meter includes a flowtube arranged to receive a flow of process fluid and a coil proximate the flowtube arranged to apply a magnetic field to the process fluid. A sense electrode is arranged to sense a voltage potential in the flowtube in response to the applied magnetic field. The sensed voltage is indicative of flow rate of process fluid through the flowtube. Diagnostic circuitry provides an output related to an electrical path between the coil and electrical ground.

Owner:MICRO MOTION INC

Self-propagating electrode based on electronic ignition

ActiveCN104096964BCompact and reliableEasy to disassembleWelding/cutting media/materialsSoldering mediaElectricityCombustion

Owner:成都银河动力有限公司

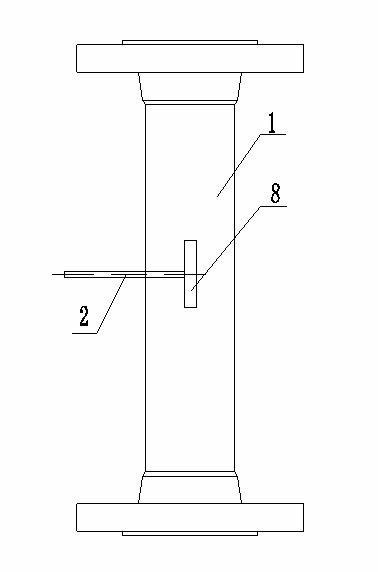

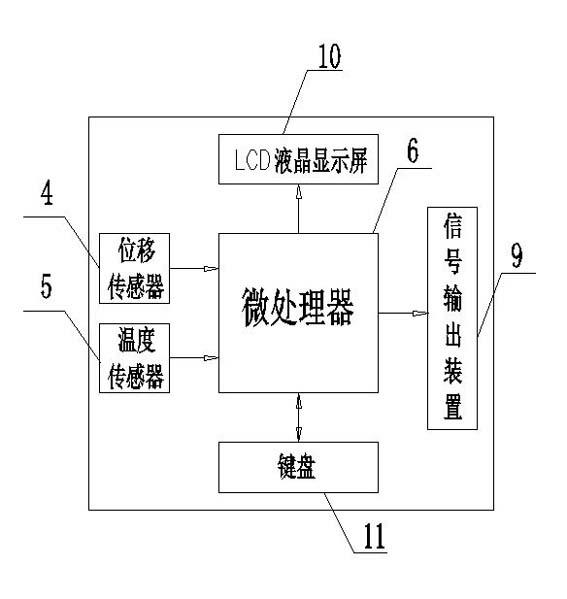

Electronic Temperature Compensated Rotameter

InactiveCN102279023AHigh precisionCompensation errorVolume variation compensation/correction apparatusVolume/mass flow by mechanical effectsElectron temperatureEngineering

The invention relates to an electron temperature compensated float flowmeter, which comprises a flow pipe with a conical pipe cavity, a first guide rod arranged by penetrating the flow pipe, a float arranged in the conical pipe cavity of the flow pipe, a displacement sensor, a temperature sensor and a microprocessor, wherein the float is fixedly sleeved on the first guide rod; the displacement sensor and the temperature sensor respectively output a displacement signal and a temperature signal to the microprocessor. Fluid body flows through the conical pipe cavity of the flow pipe to push the float to move up and down with the first guide rod; the displacement sensor converts the measured displacement quantity into an electric signal to input to the microprocessor, meanwhile, the temperature sensor senses the environment temperature and inputs the temperature electric signal to the microprocessor; and the microprocessor modifies the displacement signal according to the temperature signal. Compared with the flow signal obtained by the unmodified displacement signal, the flow signal obtained according to the modified electric signal has a higher accuracy.

Owner:ZHEJIANG DIYUAN INSTR

Disposable fluid flow sensor

ActiveUS20050268712A1Easy to understandVolume/mass flow by thermal effectsFlow transducerThin membrane

A disposable fluid flow sensor is disclosed herein, which generally includes a flow channel assembly comprising a flow channel tube in association with a disposable flow channel portion. A sensor die is located approximate to a thin interface or membrane formed from the disposable flow channel portion, such that the sensor die measures a flow of fluid flowing through the flow channel tube and the disposable flow channel portion of the flow channel assembly. Additionally, a substrate can be provided upon which the sensor die is formed and located. A seal can also be provided for sealing the disposable flow channel portion to the flow channel tube. Such a flow sensor can be implemented in the context of a “non-isolated” sensor die approach in which the sensor die, substrate and flow tube are assembled together into a complete disposable assembly, in which a thin interface does not cover the sensor die. The flow sensor can also be implemented in the context of an “isolated” sensor die approach in which a thin membrane material or thin interface prevents the fluid from touching the surface of the sensor die. In such an “isolated” configuration, the sensor die is not actually part of the disposable flow tube assembly. The only disposable portion in this approach is the flow tube itself.

Owner:HONEYWELL INT INC

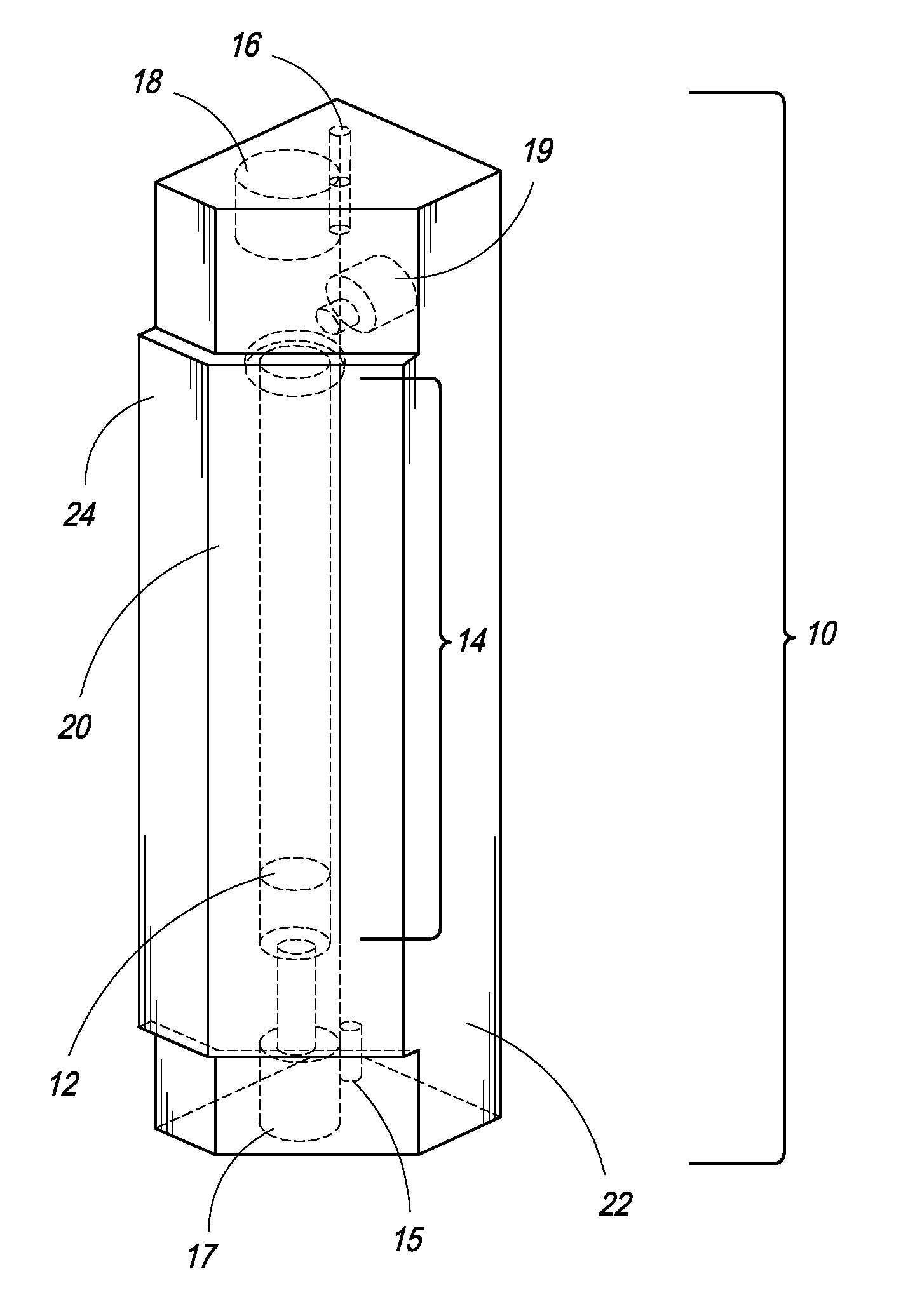

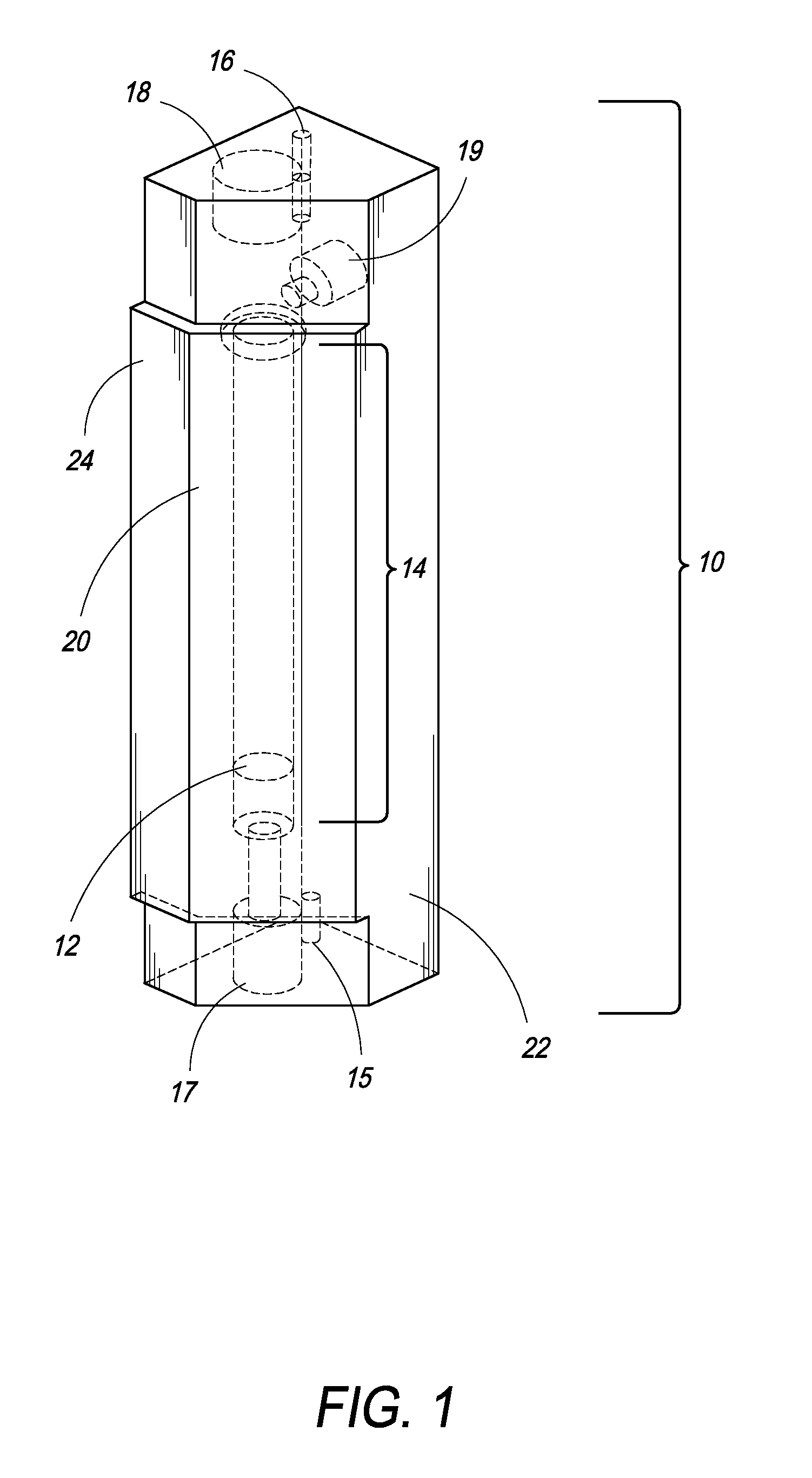

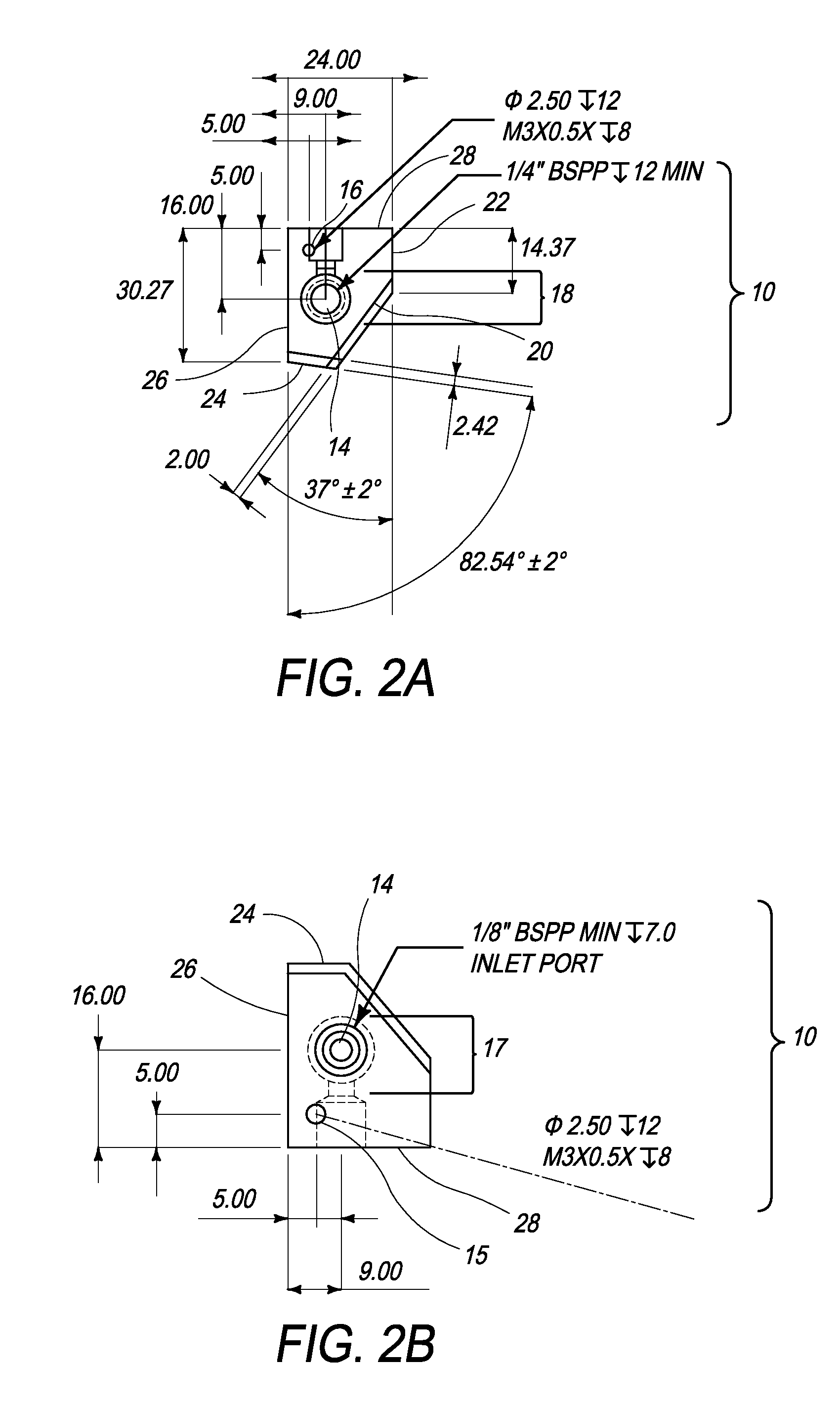

Light Enhanced Flow Tube

An improved fluid flow gauging device includes a light enhanced acrylic block flow tube to optimize visualization of pressure readings. An LED or other light source is fitted to the top of the flow tube and illuminates a float or bobbin from above to provide more accurate readings, especially in low light conditions such as modern operating rooms. In addition, the light enhanced flow tube provides a mechanical backup in the case of failure of newer electronic systems and visually matches the graphical flow display, simultaneously providing a double-check of the electronic system.

Owner:SPACELABS HEALTHCARE INC

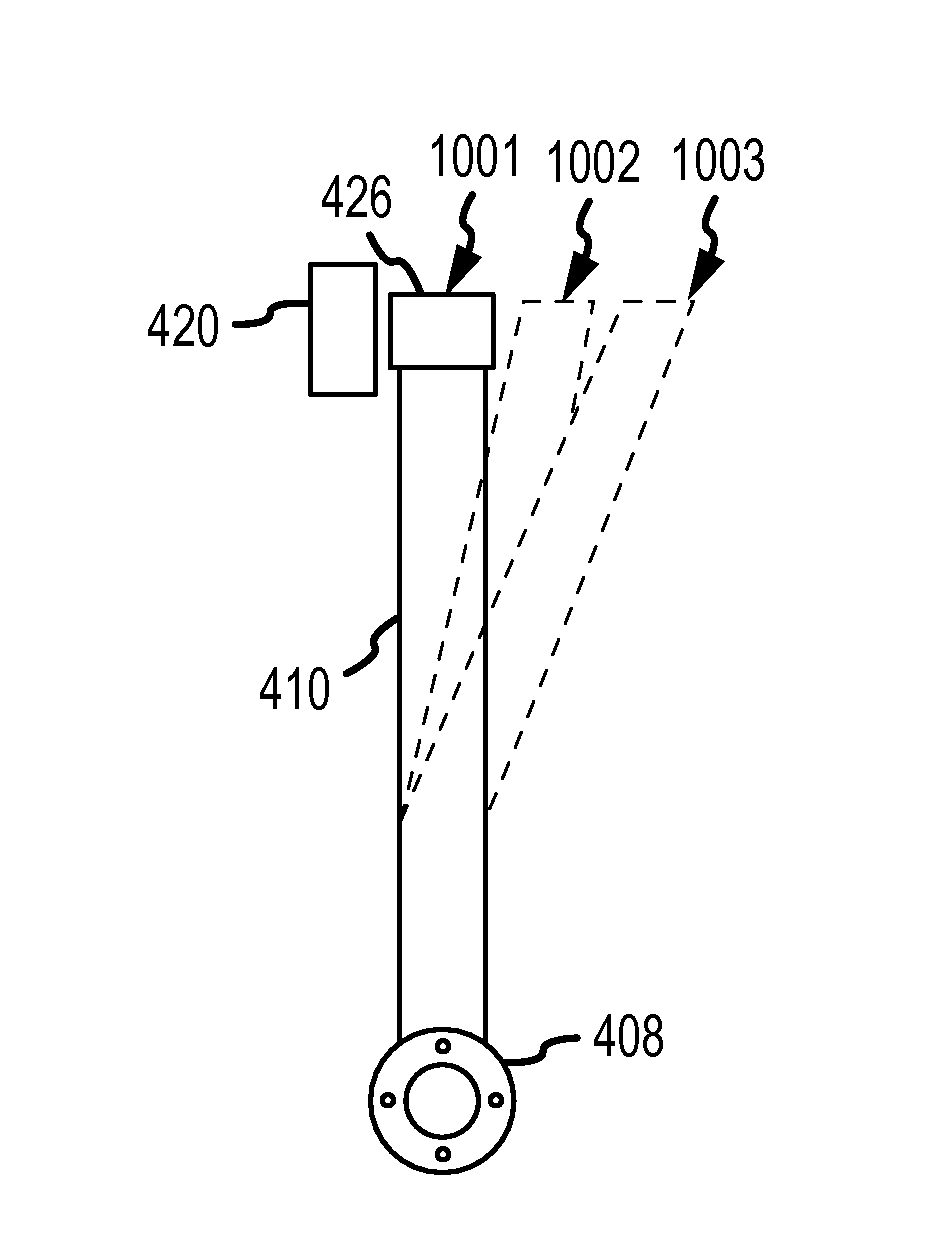

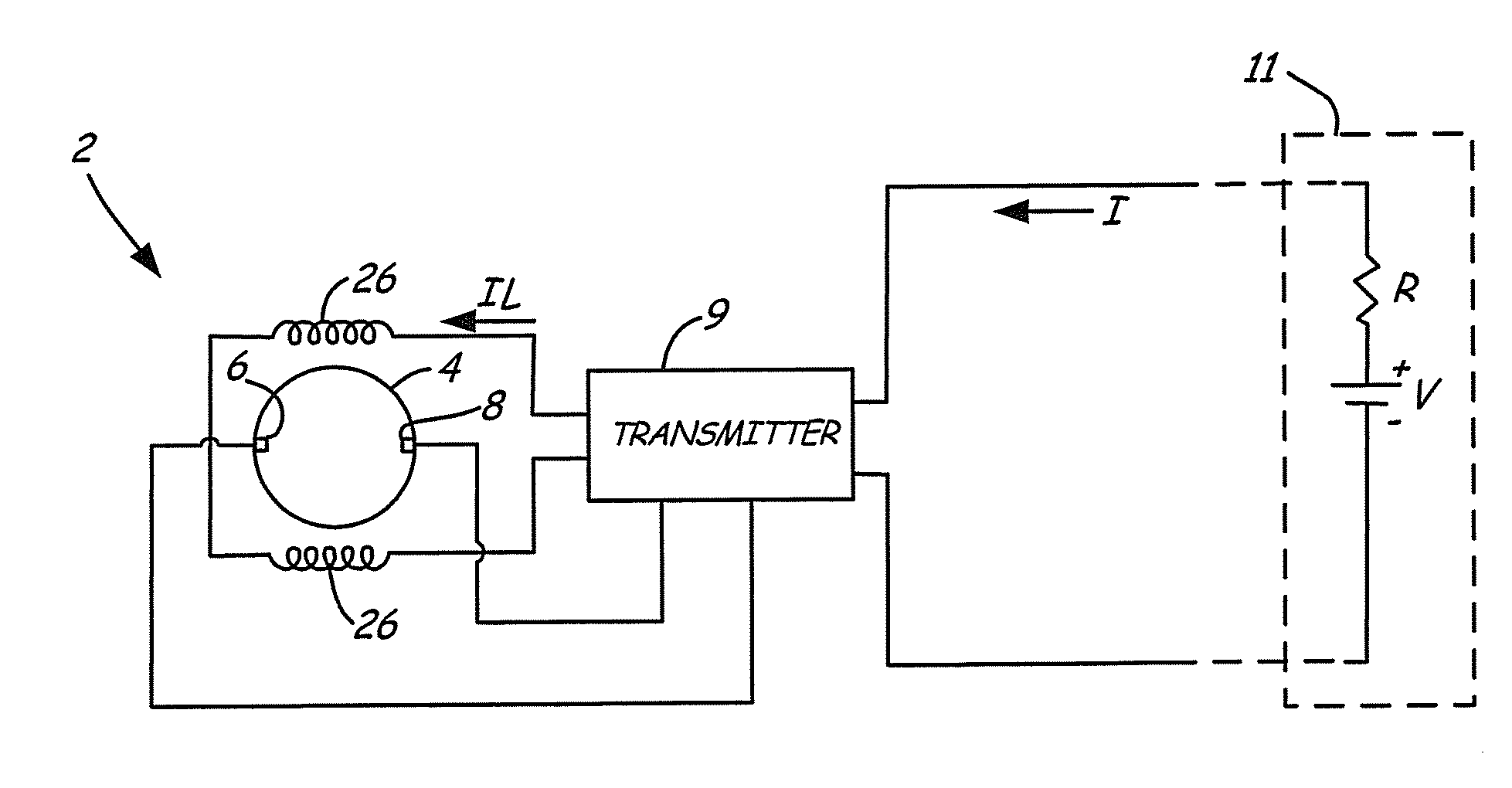

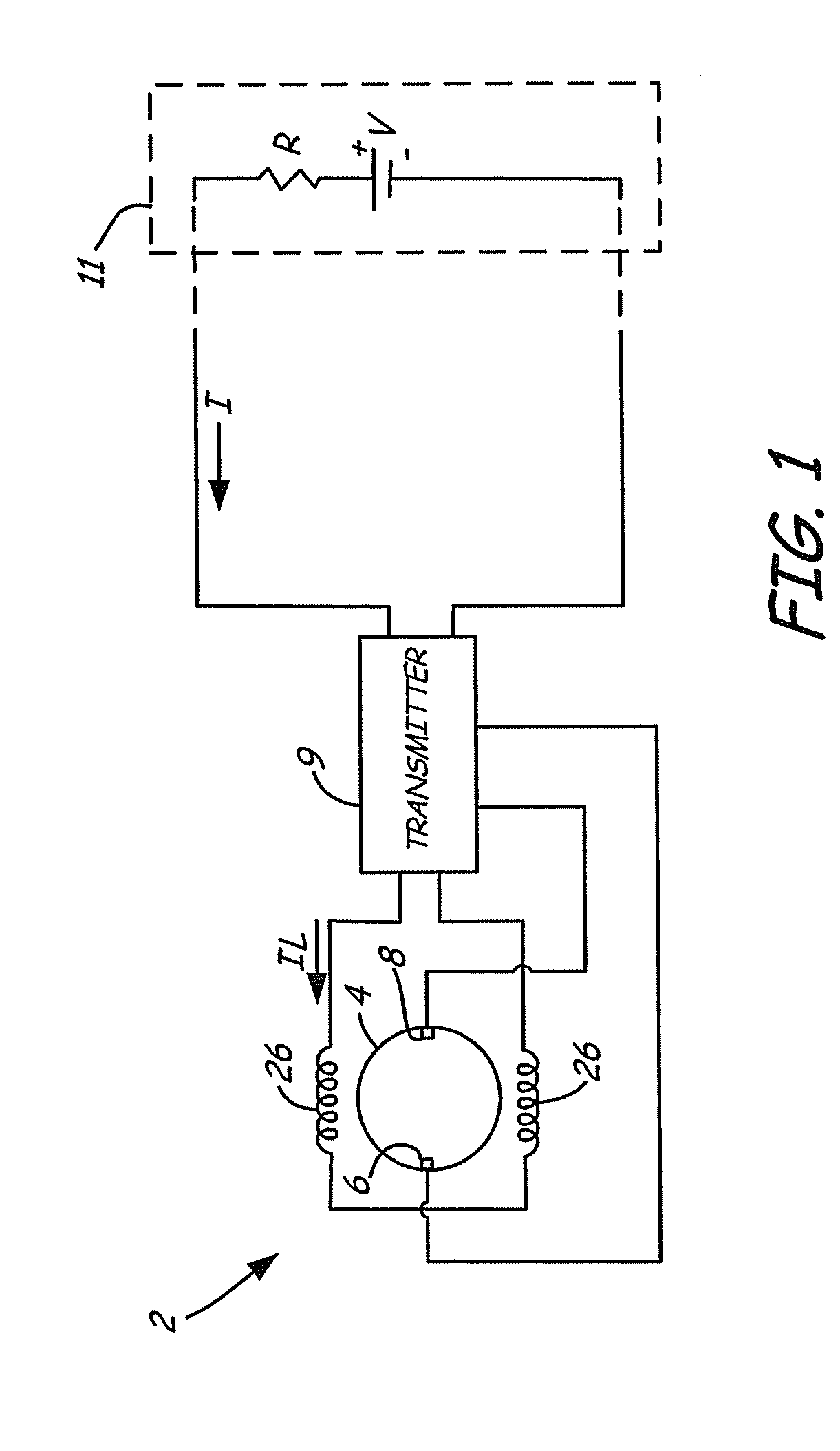

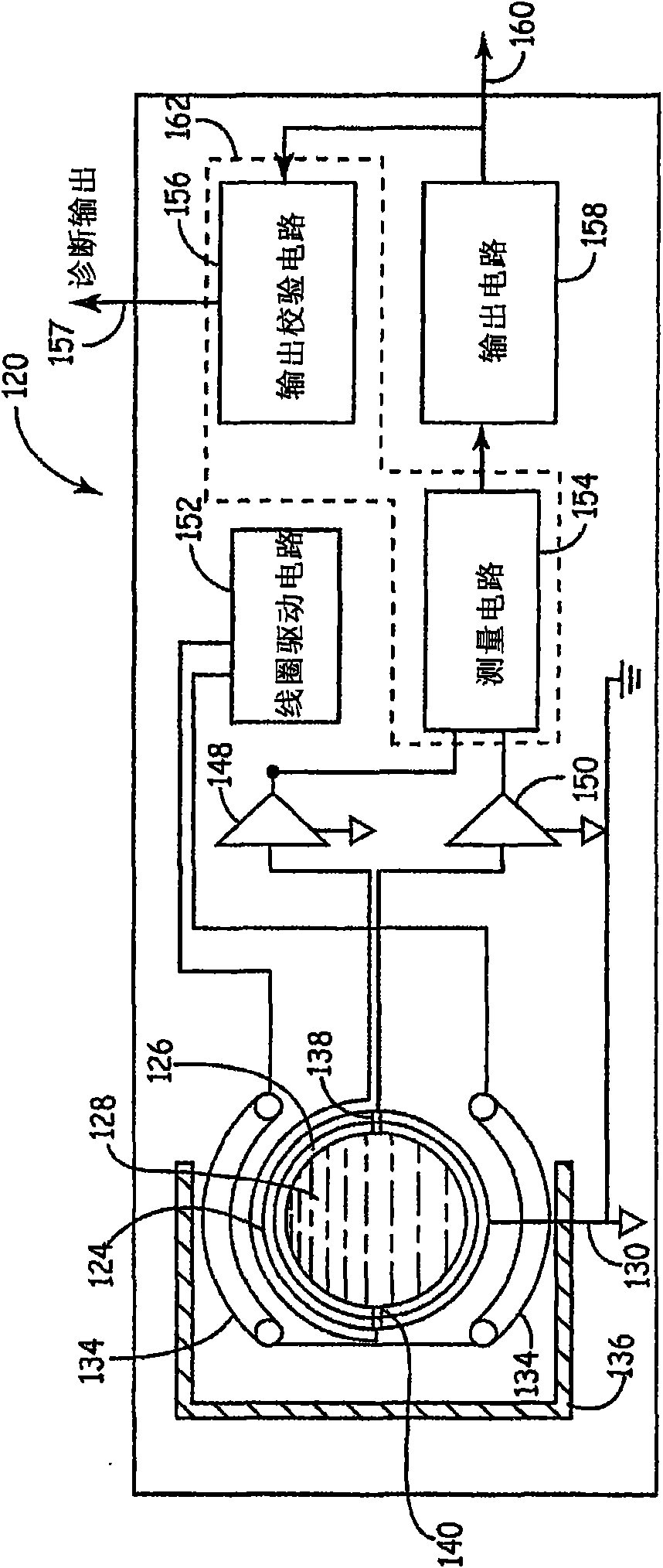

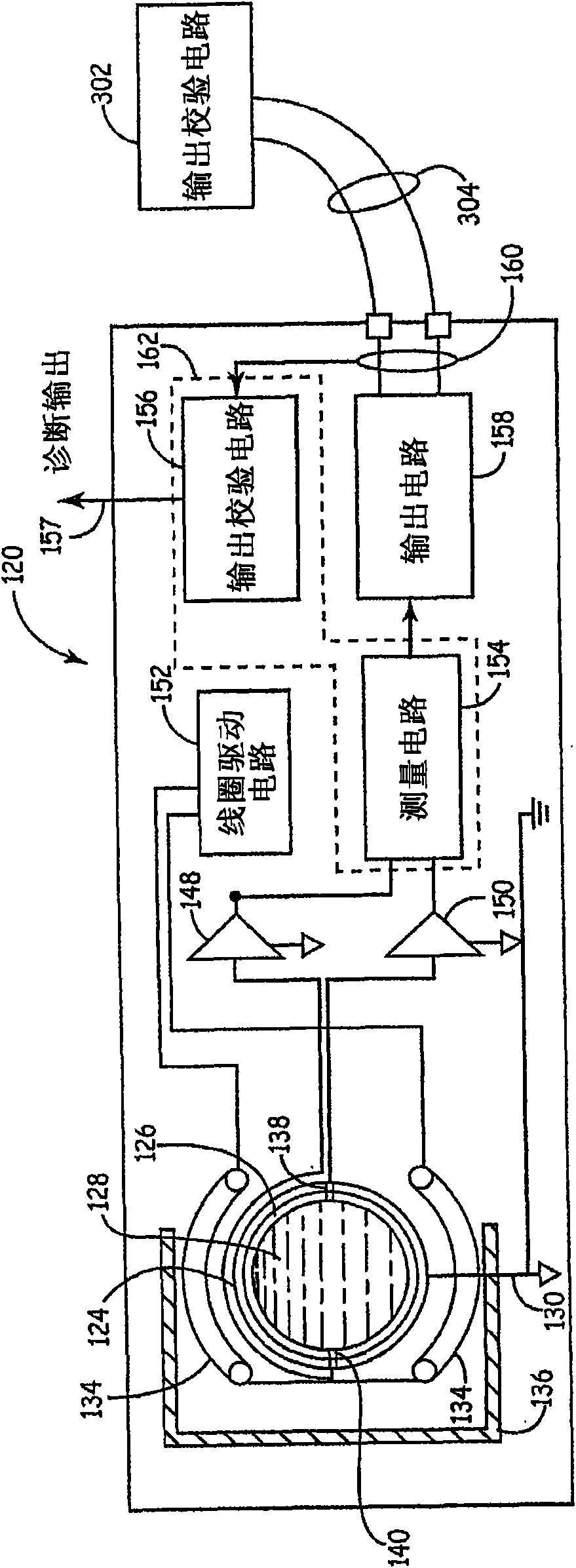

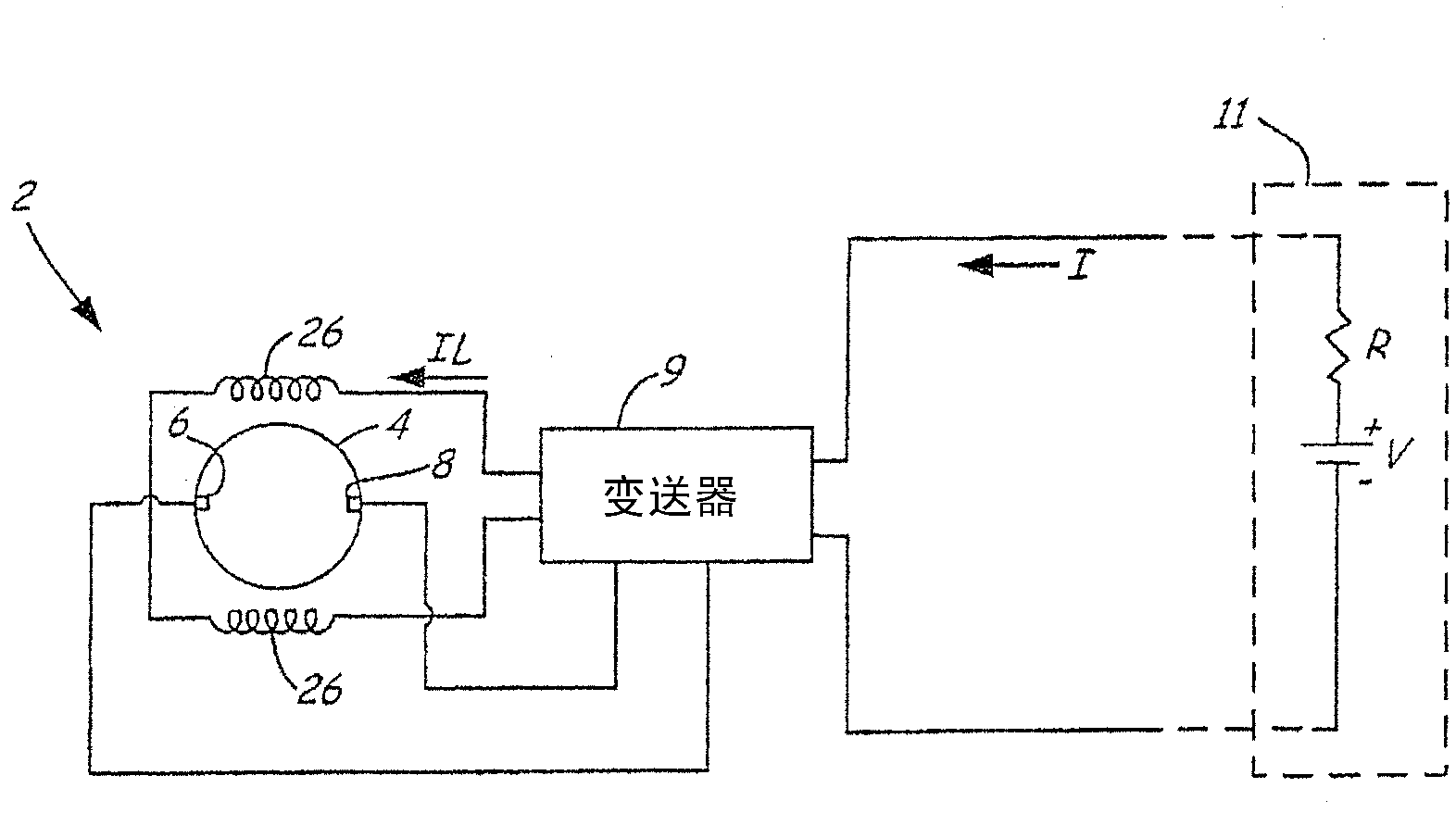

Magnetic flowmeter output verification

ActiveCN101688798AElectric signal transmission systemsVolume/mass flow measurementEngineeringTransmitter

A magnetic flowmeter transmitter (120) includes a flowtube (124) and measurement circuitry (154) which provides an output related to flow through the flowtube (124). Output circuitry (158), such as analog and pulse output circuitry, provides transmitter output(s) related to flow through the flowtube (124). Output verification circuitry (156) of the transmitter (120) is coupled to the output circuitry (158) and provides verification of proper operation of the output circuitry (158) by analyzing the output signals.

Owner:MICRO MOTION INC

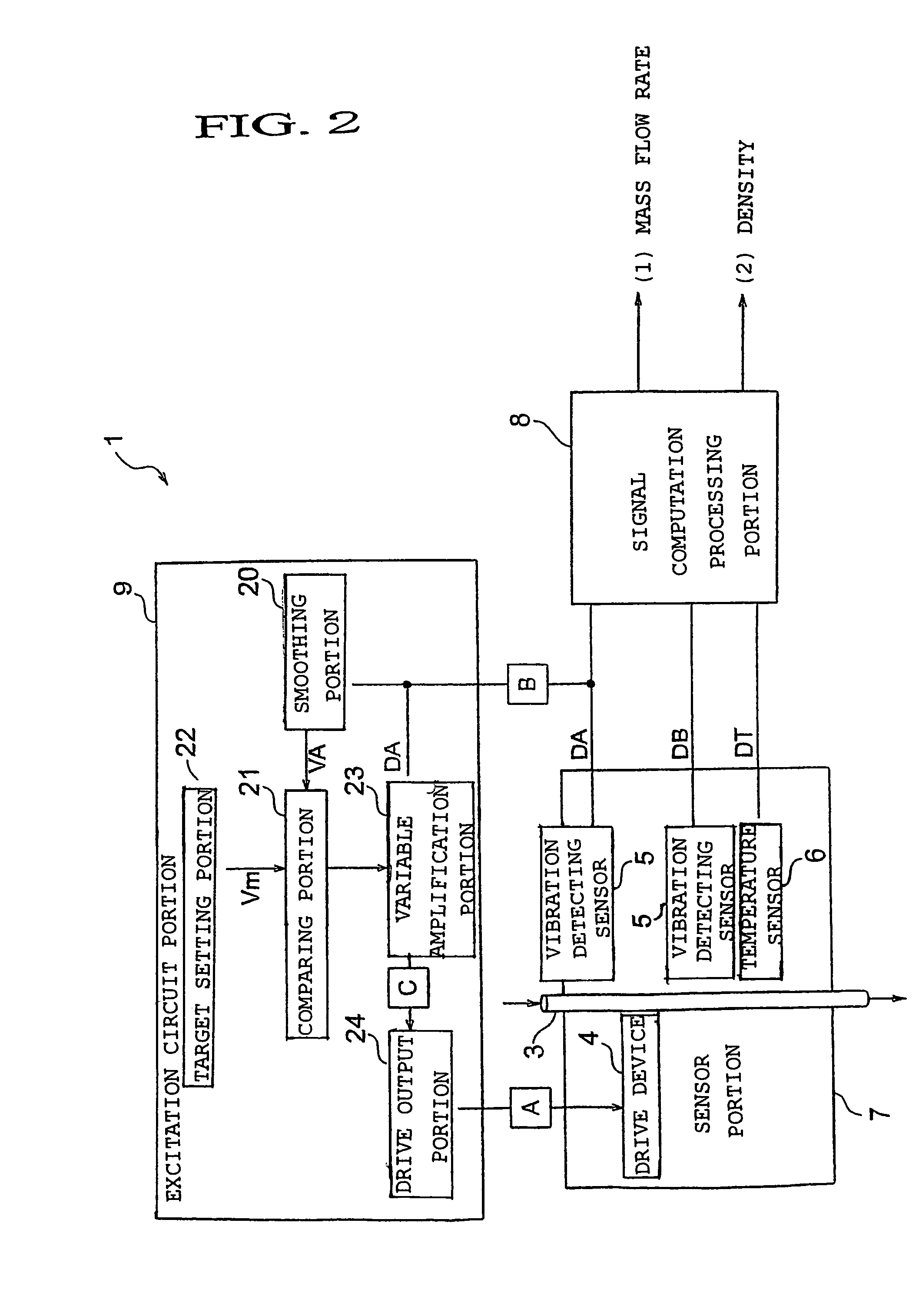

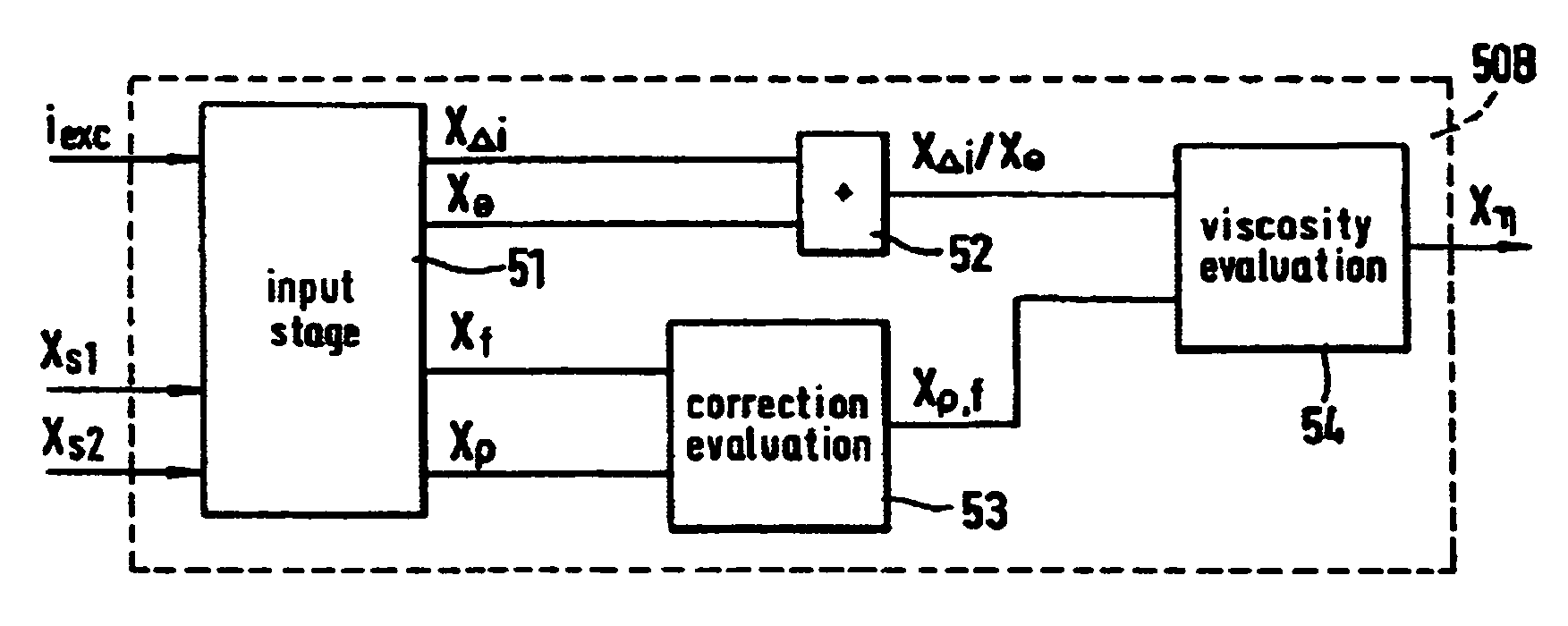

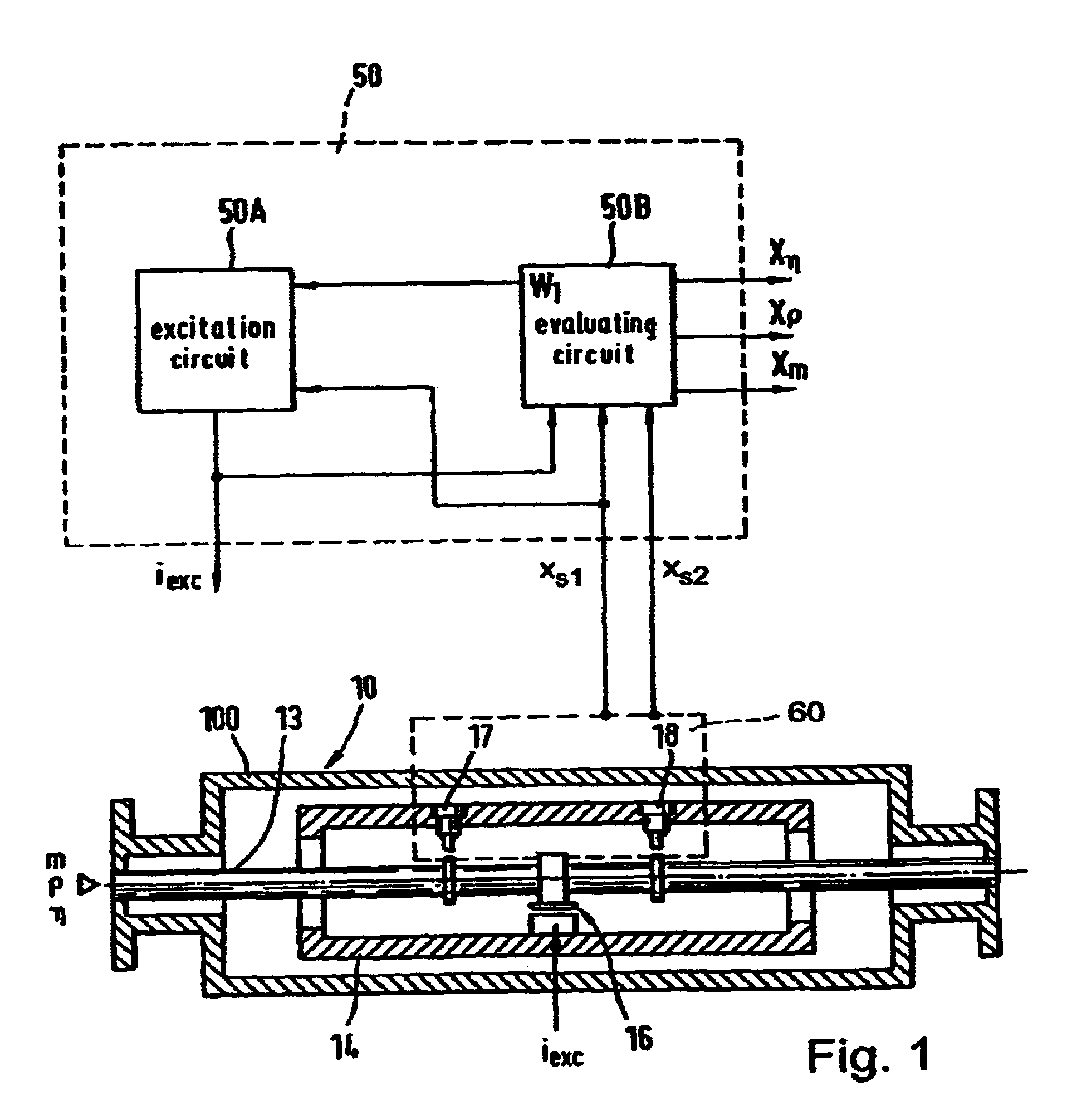

Vibration meter and method of measuring a viscosity of a fluid

A vibration meter and a method of measuring a viscosity of a fluid flowing through a pipe are disclosed. The vibration meter comprises meter electronics and a transducer assembly with an electromechanical excitation arrangement and with a flow tube which oscillates in operation. A sensor arrangement produces sensor signals representative of inlet-side and outlet-side deflections of the flow tube. An evaluation circuit derives from said sensor signals and from an excitation current generated by an excitation circuit for the excitation arrangement a viscosity value representative of the viscosity of the fluid.

Owner:ENDRESS HAUSER FLOWTEC AG

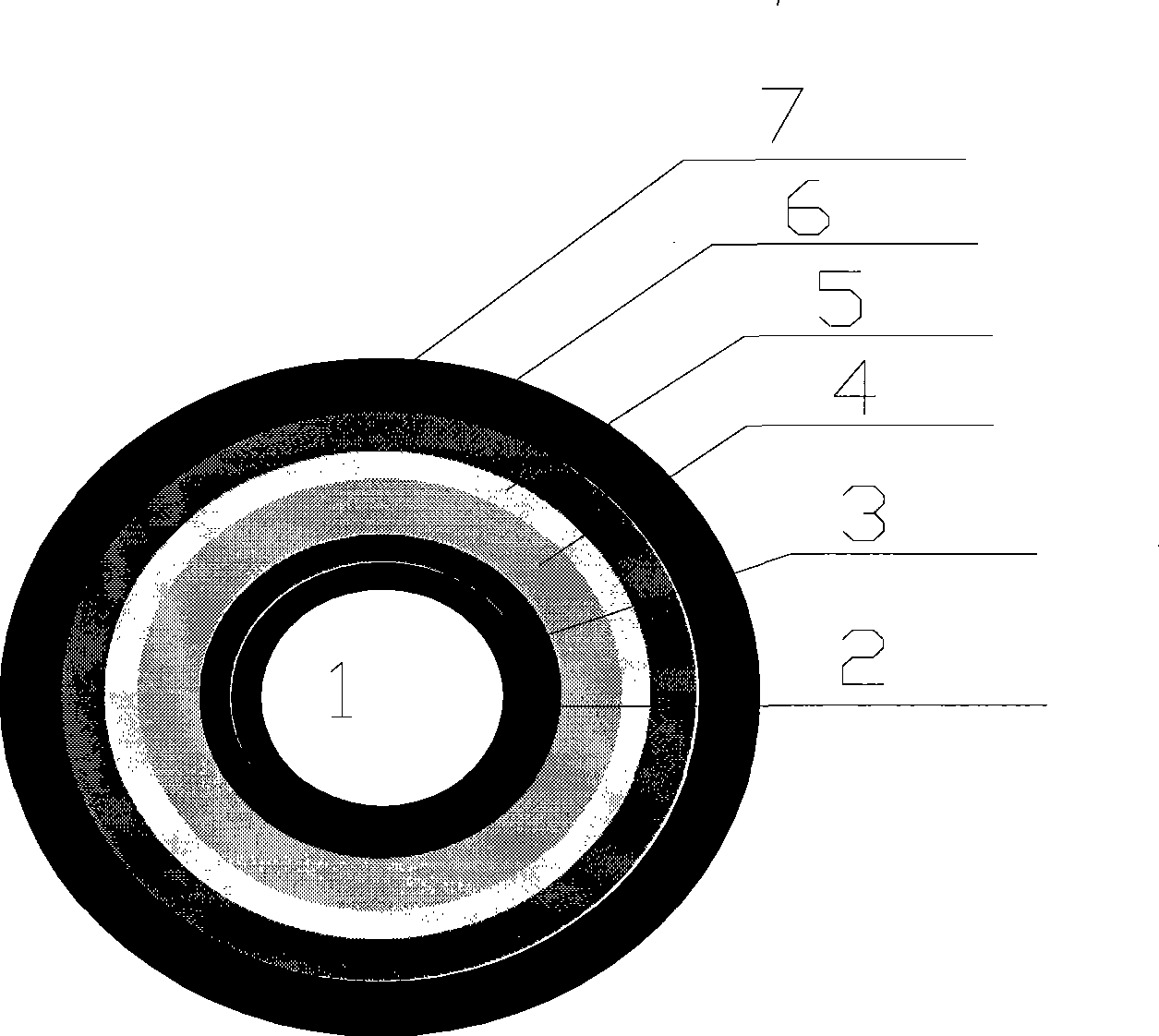

Butt joint technique for 10KV oil-paper insulated cable and cross-linked polyethylene insulated cable

InactiveCN101431189ANot easy to leak oilGuaranteed uptimeConnections effected by permanent deformationCable fittings in presence of gas/oilStress distributionCross-link

The invention relates to a butt joint process for a 10 kV oil-impregnated paper insulated cable and a cross-linked polyethylene insulated cable. A stress distribution tube is utilized to realize the even distribution of the point electric field of butt joint cables, thereby eliminating the damage to the operation of the cables caused by the point electric field; a composite tube made of heat-shrinkable materials is utilized to realize the insulation restoration of a cross-linked cable and the even distribution of the electric field, and the composite tube is an integral tube compounded by a transistor, an insulating tube and the stress distribution tube, thereby eliminating the errors of overlapping sizes when the transistor, the insulating tube and the stress distribution tube are manually made and mounted, so as to ensure the success ratio of the production of cable heads; a metal connection conducting tube separates and seals the existing metal conducting tube with a flux tube in the middle thereof; and after the cables are butted with each other, and the oil of the oil-impregnated paper insulated cable cannot flow into the cross-linked cable by a metal wire core, so as to avoid the pollution of the oil of the oil-impregnated paper insulated cable to the cross-linked cable after butt joint. The invention has the advantages that after the oil-impregnated paper insulated cable is butted with the cross-linked cable by the process, the butt joint position is easy to leak the oil, the operation is stable, and the time is long.

Owner:咸阳市高新天然气集中供热有限公司

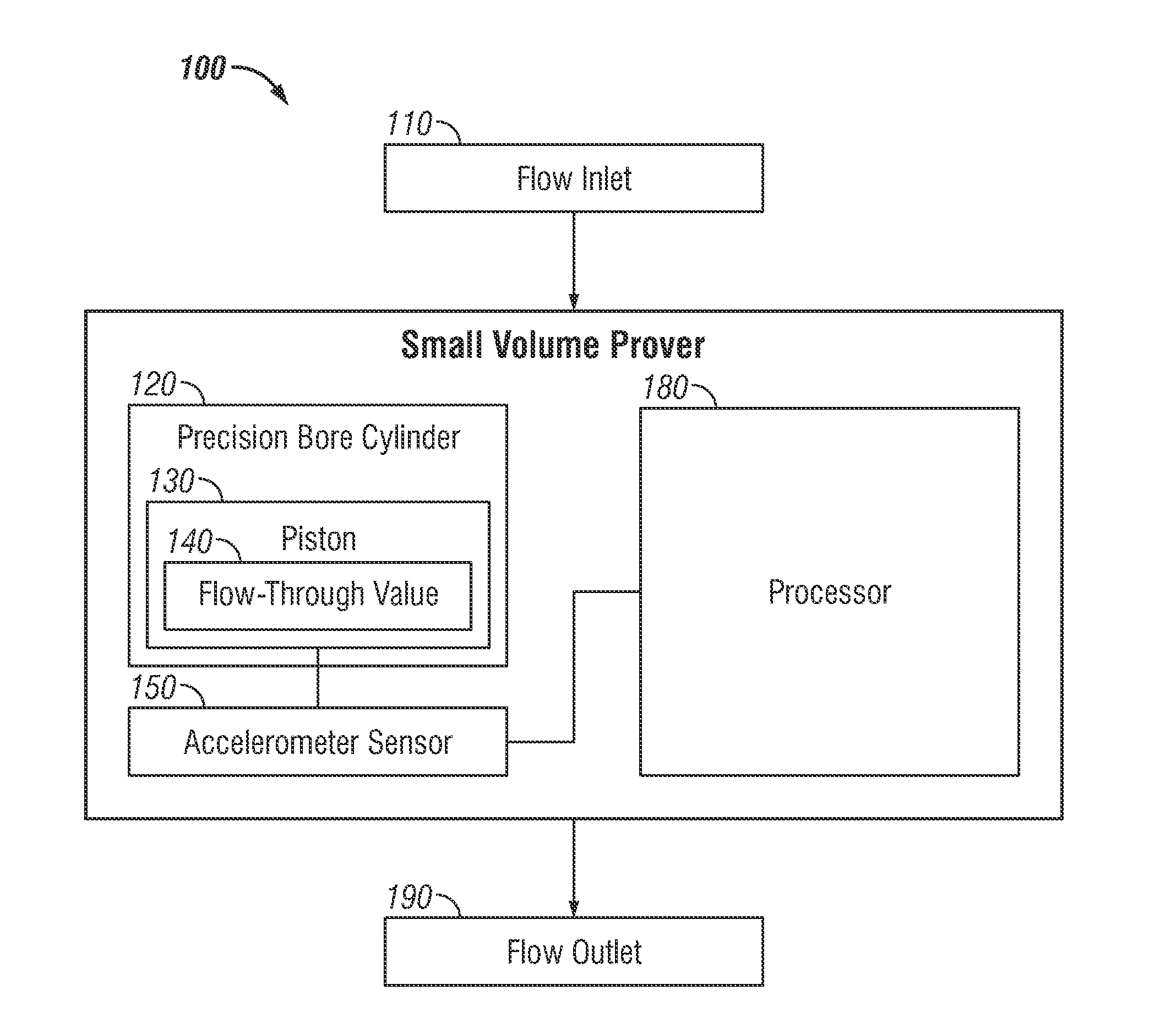

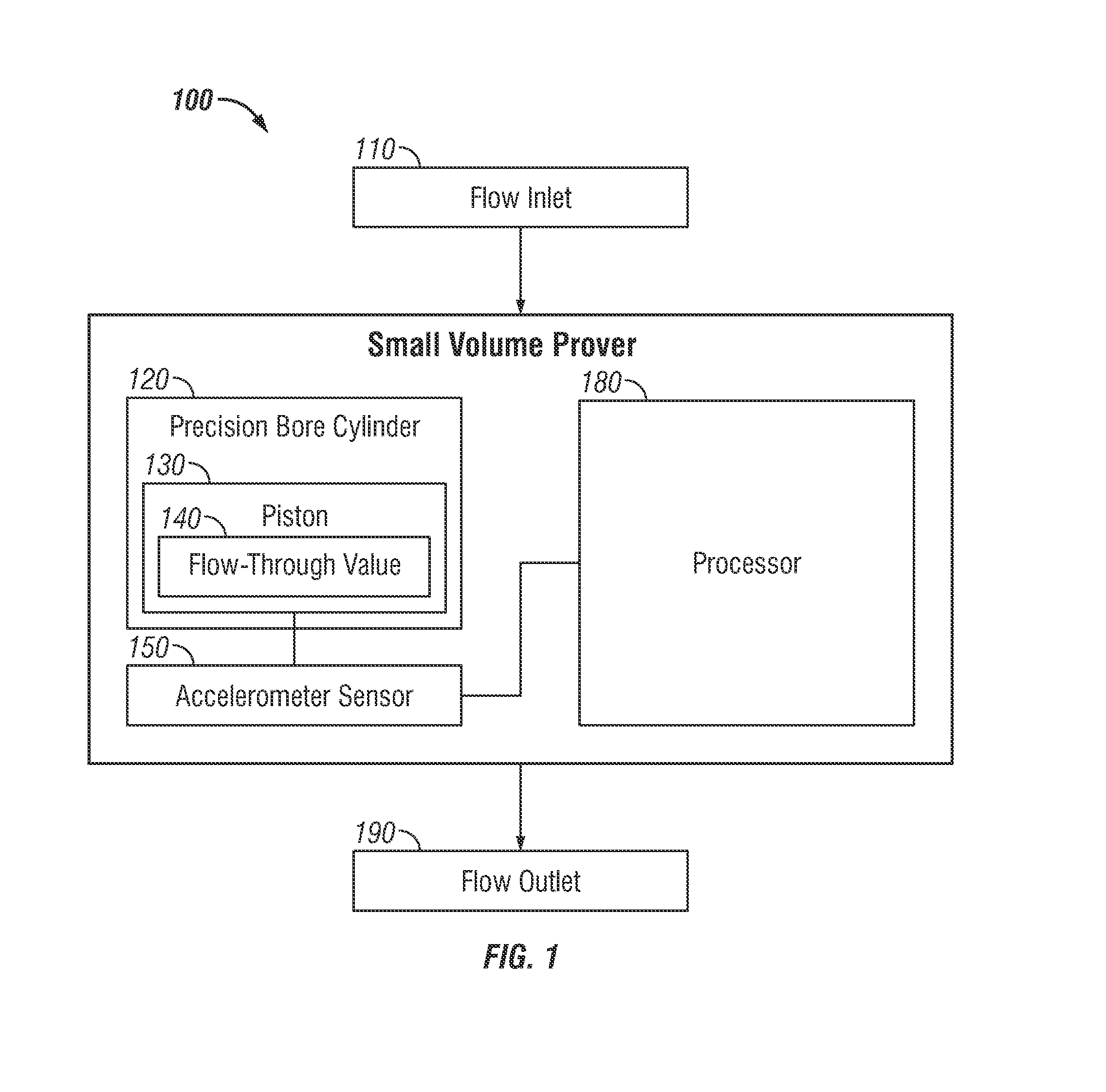

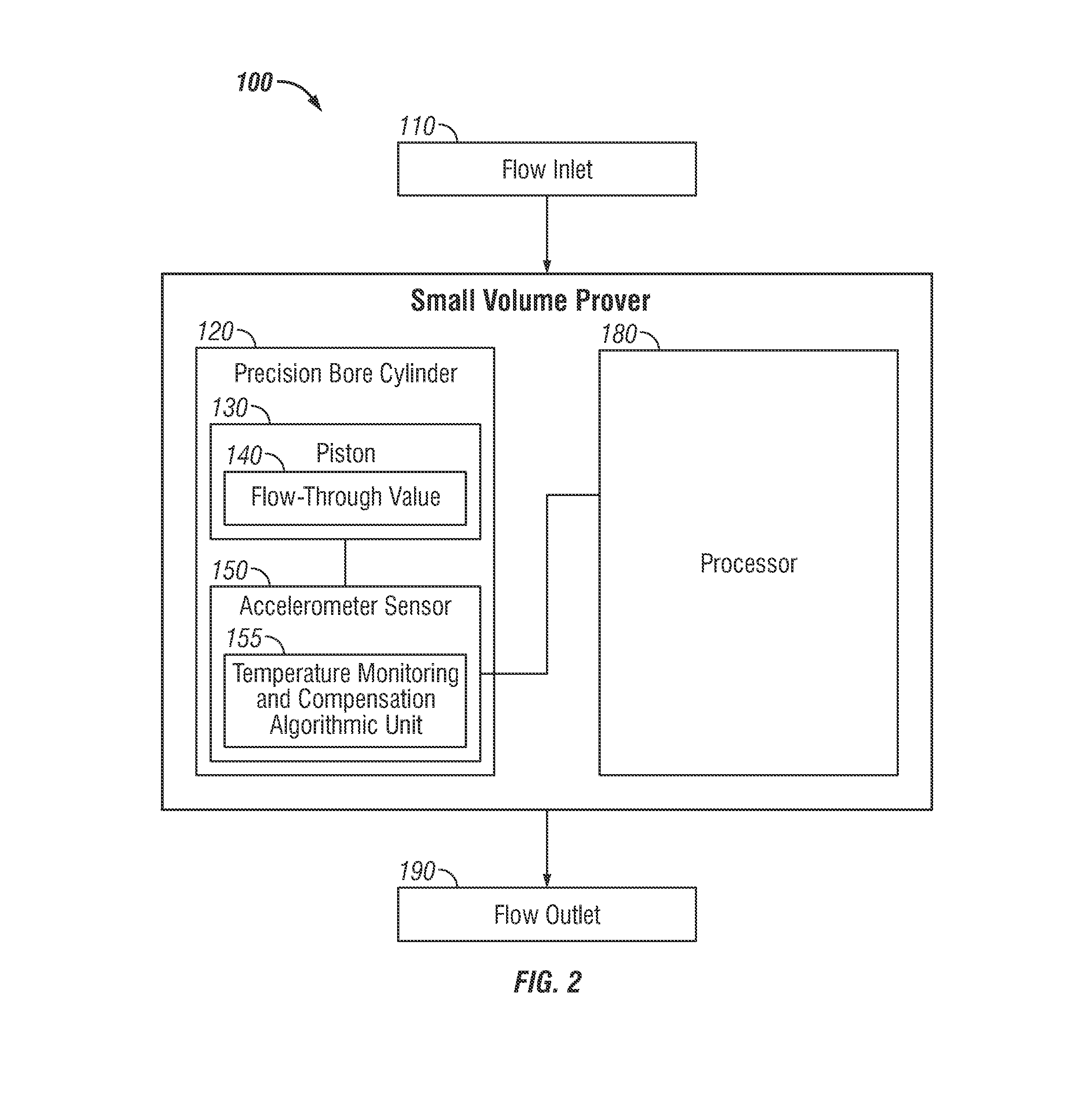

Small volume prover apparatus and method for measuring flow rate

InactiveUS20130073242A1High speedAccurate measurementTesting/calibration apparatusFluid pressure measurementAccelerometerEngineering

A small volume prover apparatus and method for precisely measuring the flow rate of a fluid via a cylindrical component such as a flow tube. A precision bore cylinder and a piston can be configured with a valve arrangement in order to permit fluid to pass through an annular passage when the piston travels from one position to an opposite position. An accelerometer sensor can be mounted to the piston for continuously detecting the velocity of the piston traveling in the pipe by integrating acceleration data with respect to time data. The volumetric flow rate can be automatically calculated by multiplying the velocity with respect to the area of the flow tube.

Owner:HONEYWELL INT INC

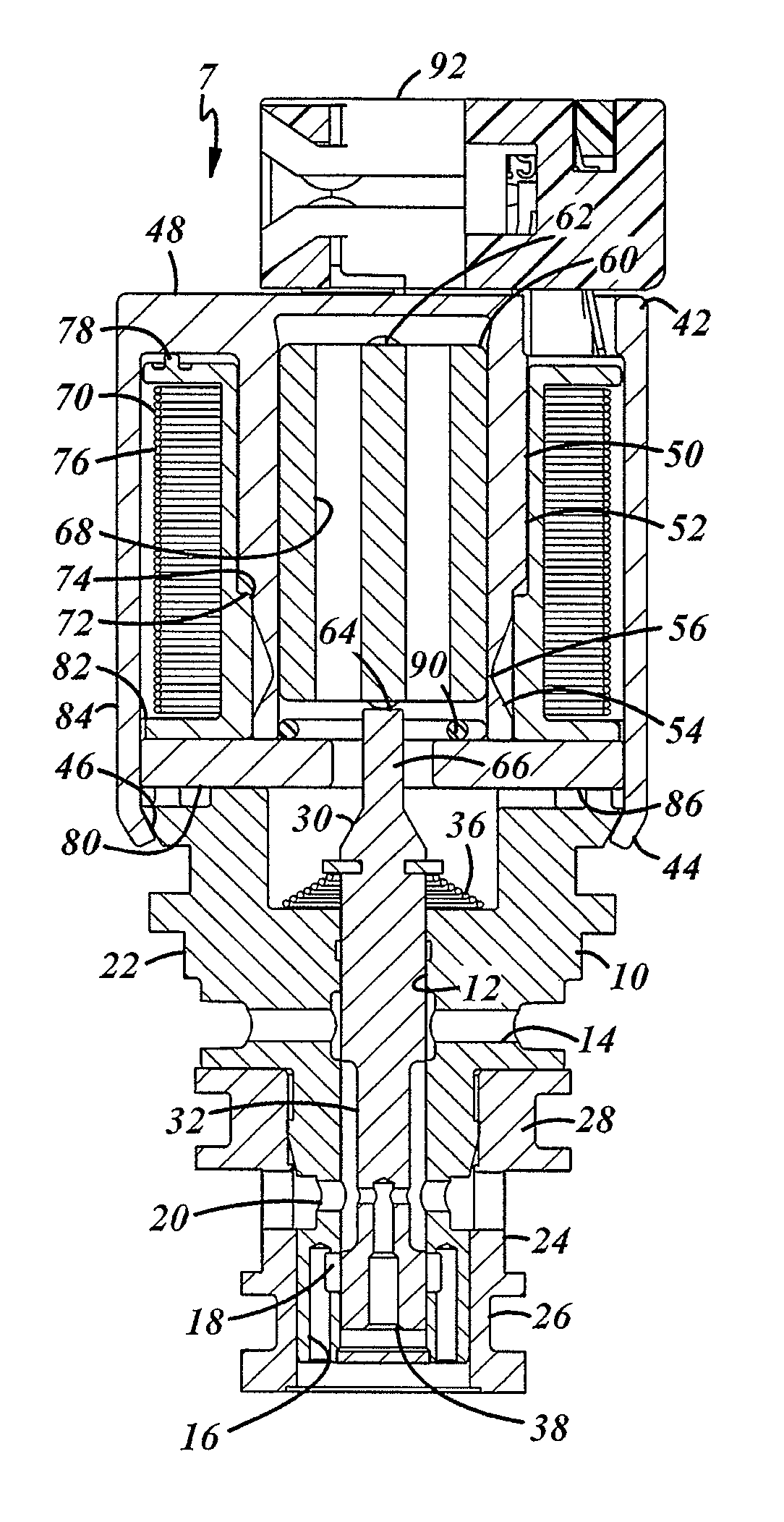

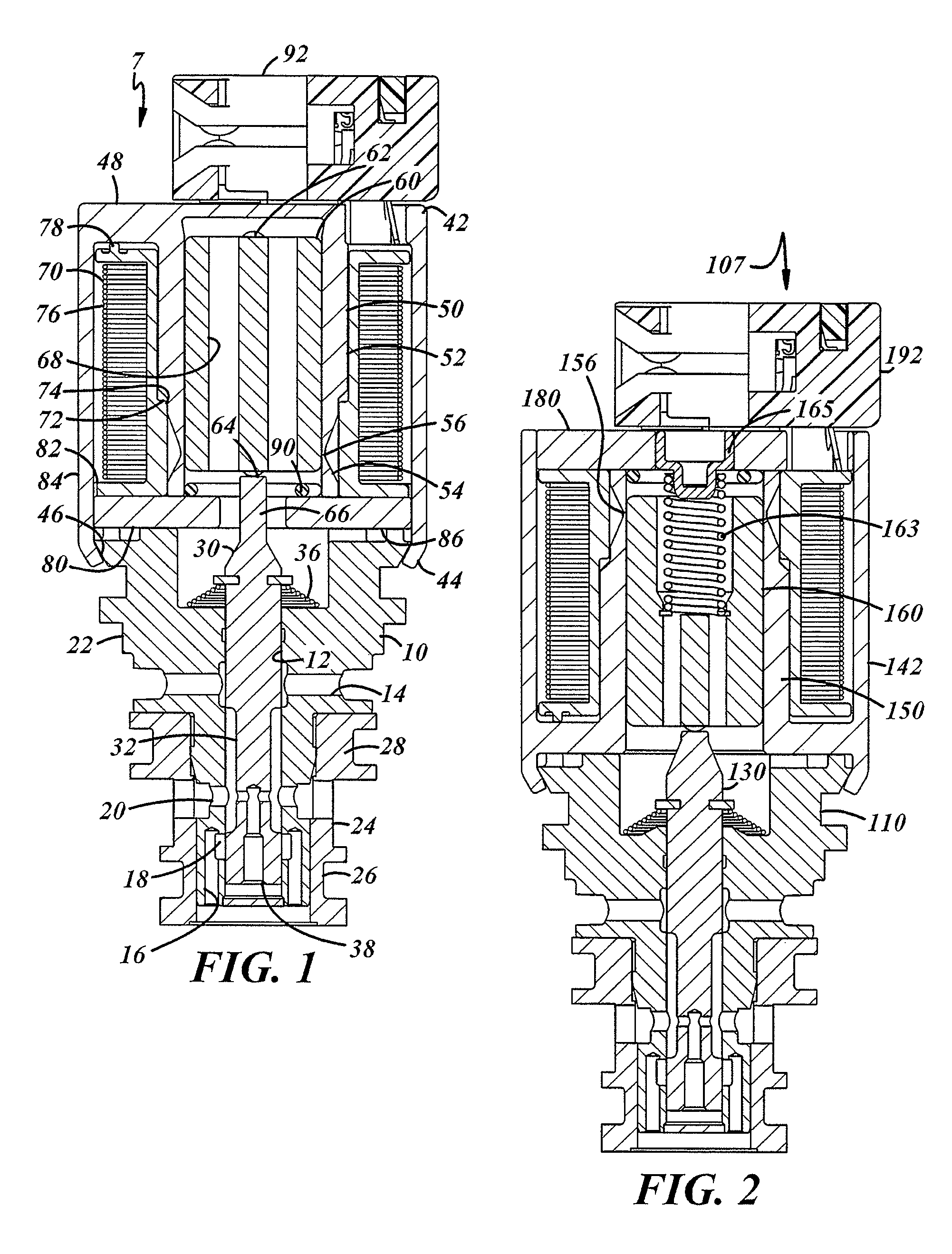

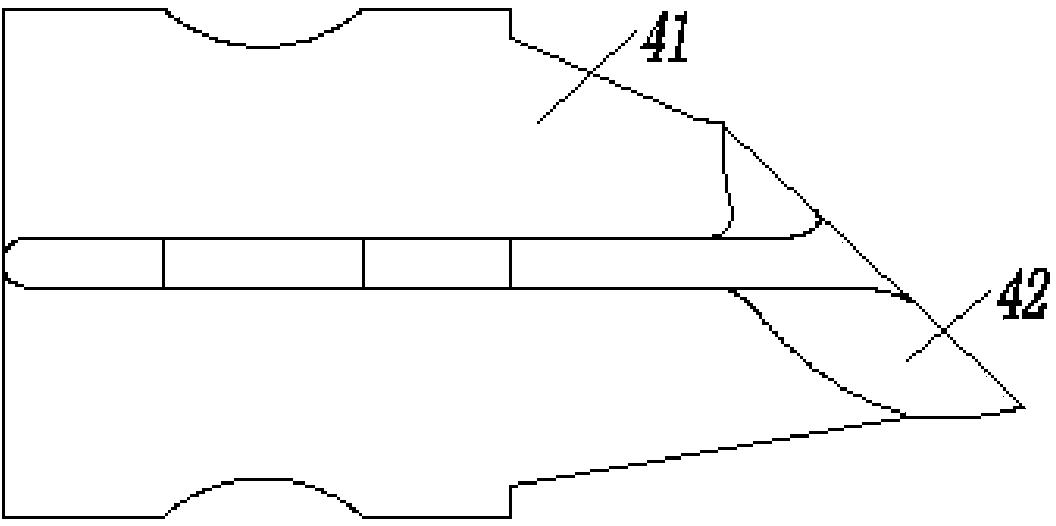

Mono bearing one piece core solenoid

ActiveUS9528626B2Increase flux densityReduce discontinuityOperating means/releasing devices for valvesSlide valveSolenoid valveEngineering

A solenoid valve assembly is provided which includes a ferromagnetic casing forming a generally tubular envelope, a flux tube integrally formed with the casing and extending axially generally there from defining and axially extending annular space there between, the flux tube having a first portion connected with the casing and a second portion integral with the first portion be divided there from by a flux choke, and also including an armature aligned and slidably mounted within the flux tube for imparting movement to a valve member.

Owner:BORGWARNER INC

Magnetic flowmeter with verification

ActiveUS7750642B2Testing/calibration for volume flowMaterial impedanceElectrical and Electronics engineeringElectrode

A magnetic flowmeter is provided including a magnetic flowtube arranged to receive a flow of process fluid. The magnetic flowtube includes a drive coil and at least one sense electrode. Measurement circuitry is coupled to the flowtube and is configured to provide a drive signal to the drive coil and measure flow of process fluid through the flow tube based upon an output from the sense electrode. A memory contains a stored value related to a nominal parameter of the flowtube. Verification circuitry is arranged to measure a parameter of the magnetic flowtube and responsively provide a verification output related to operation of the magnetic flowmeter based upon a comparison of the measured parameter and the stored value.

Owner:MICRO MOTION INC

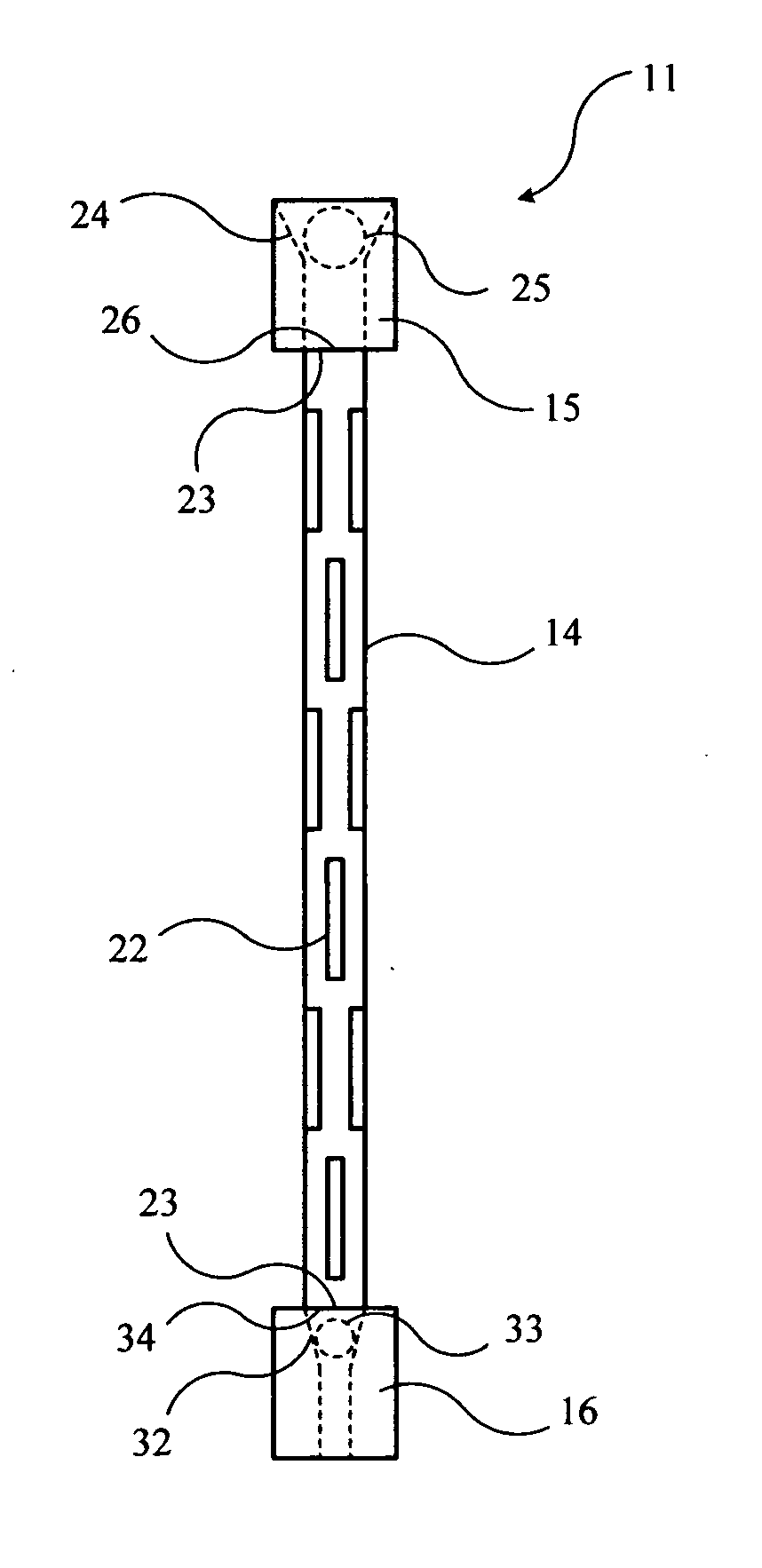

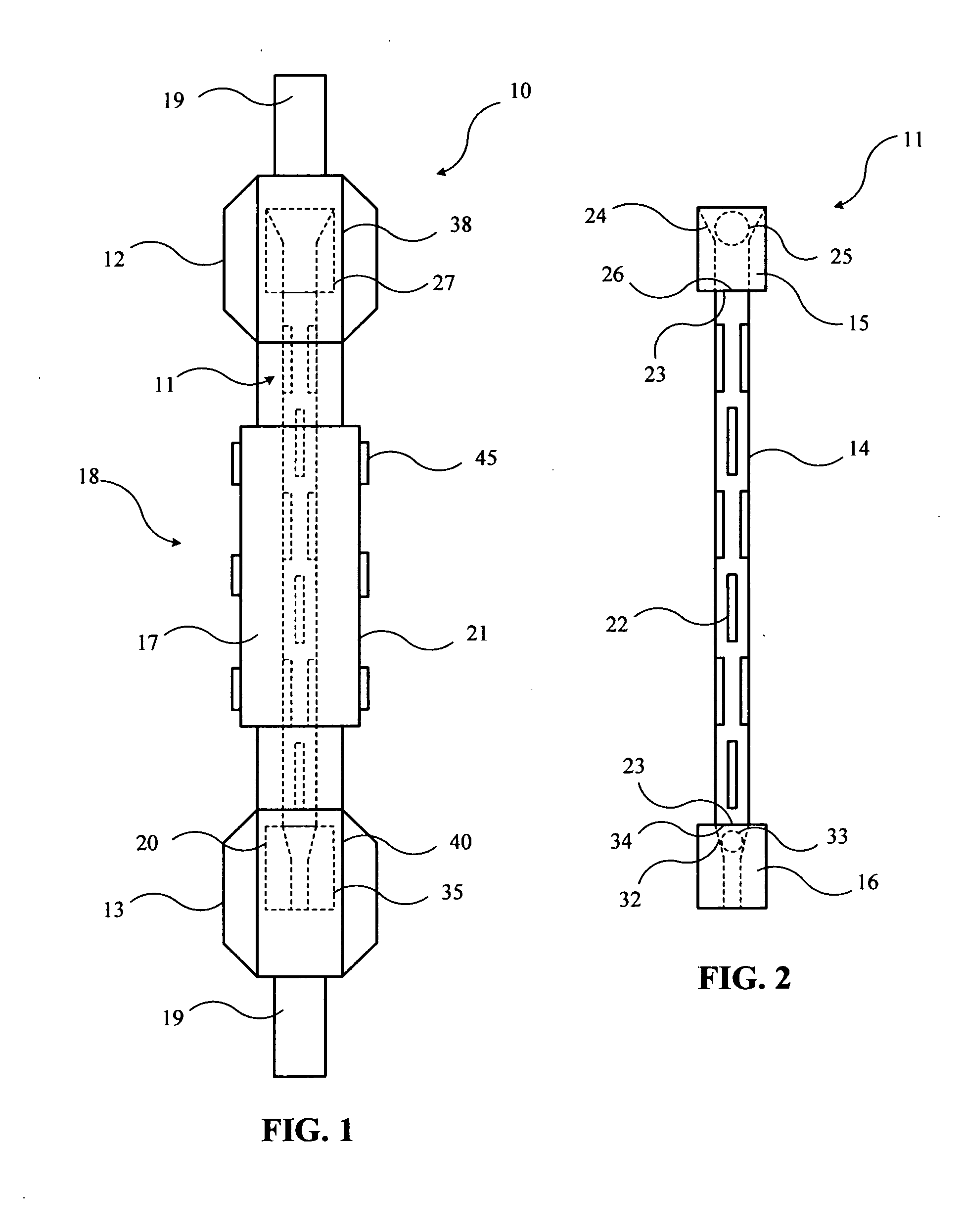

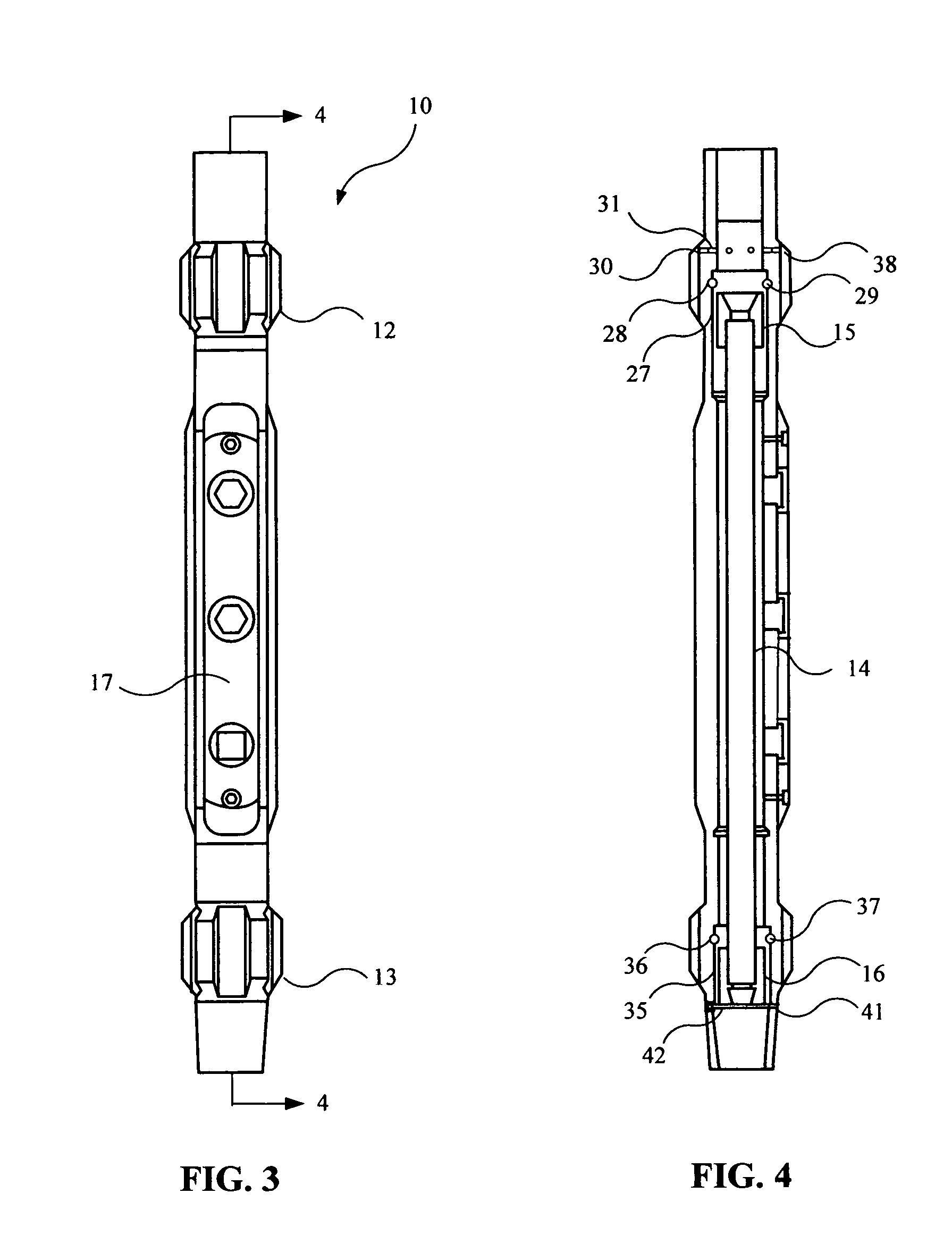

Apparatus and method for isolating flow in a downhole tool assembly

An apparatus for isolating fluid flow in a bottomhole tool assembly comprises a generally cylindrically shaped flow tube with a side, a top, and a bottom; an upper ball seat connected to the top of the flow tube; a lower ball seat connected to the bottom of the flow tube; a plurality of openings in the side of the flow tube; a tapered inner diameter in the upper ball seat, acting as a ball valve; a tapered inner diameter in the lower ball seat, acting as a ball valve, smaller than the tapered inner diameter in the upper ball seat; an upper sub attached to the bottomhole tool assembly; a lower sub attached to the bottomhole tool assembly; shear pins connecting the upper ball seat to the upper sub; and a limiting pin in the lower sub below the lower ball assembly.

Owner:TD TOOLS

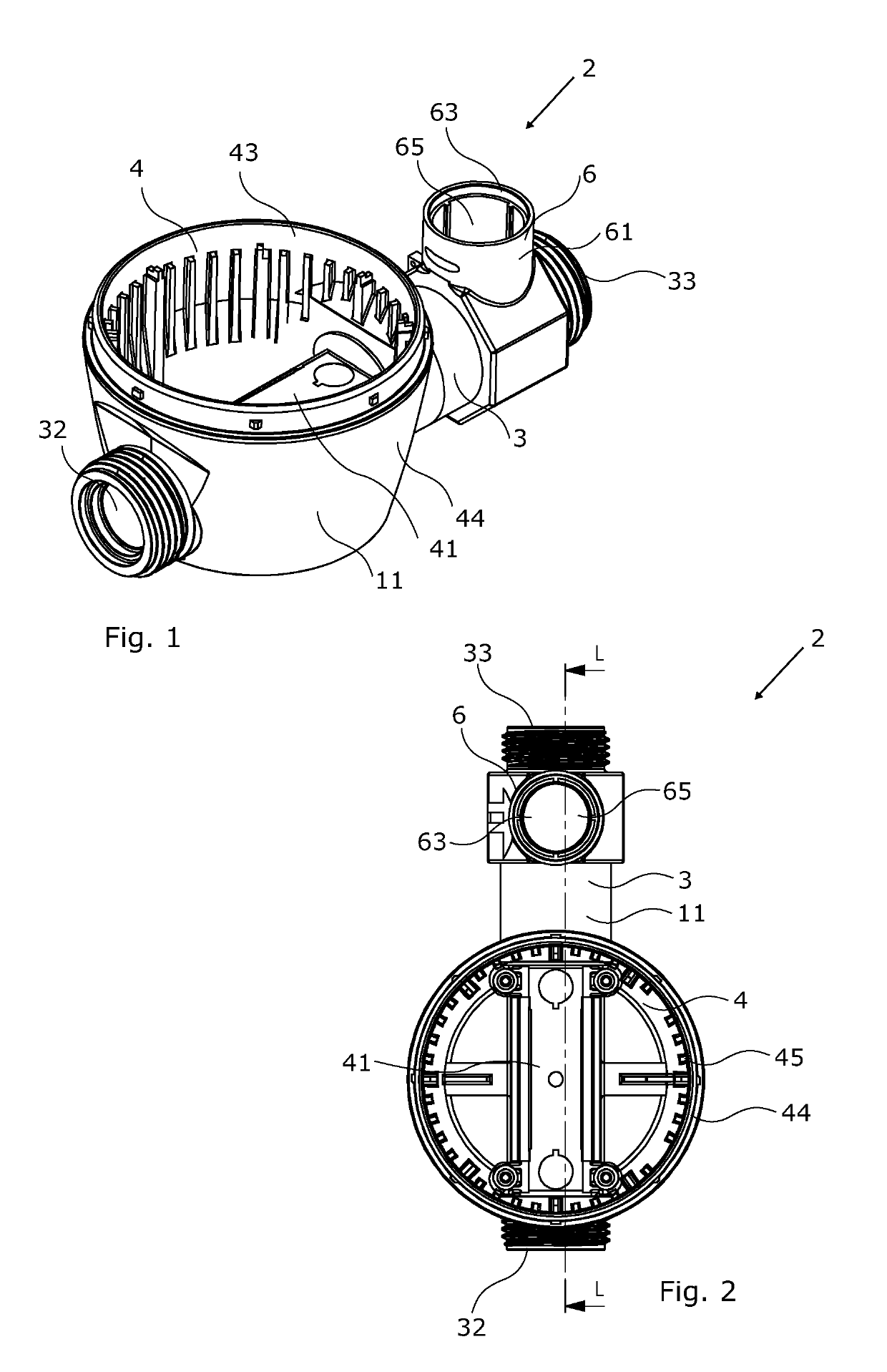

Water meter platform

ActiveUS20190113376A1Reduce manufacturing costLow costVolume/mass flow measurementVolume meteringEngineeringFlux tube

Owner:KAMSTRUP

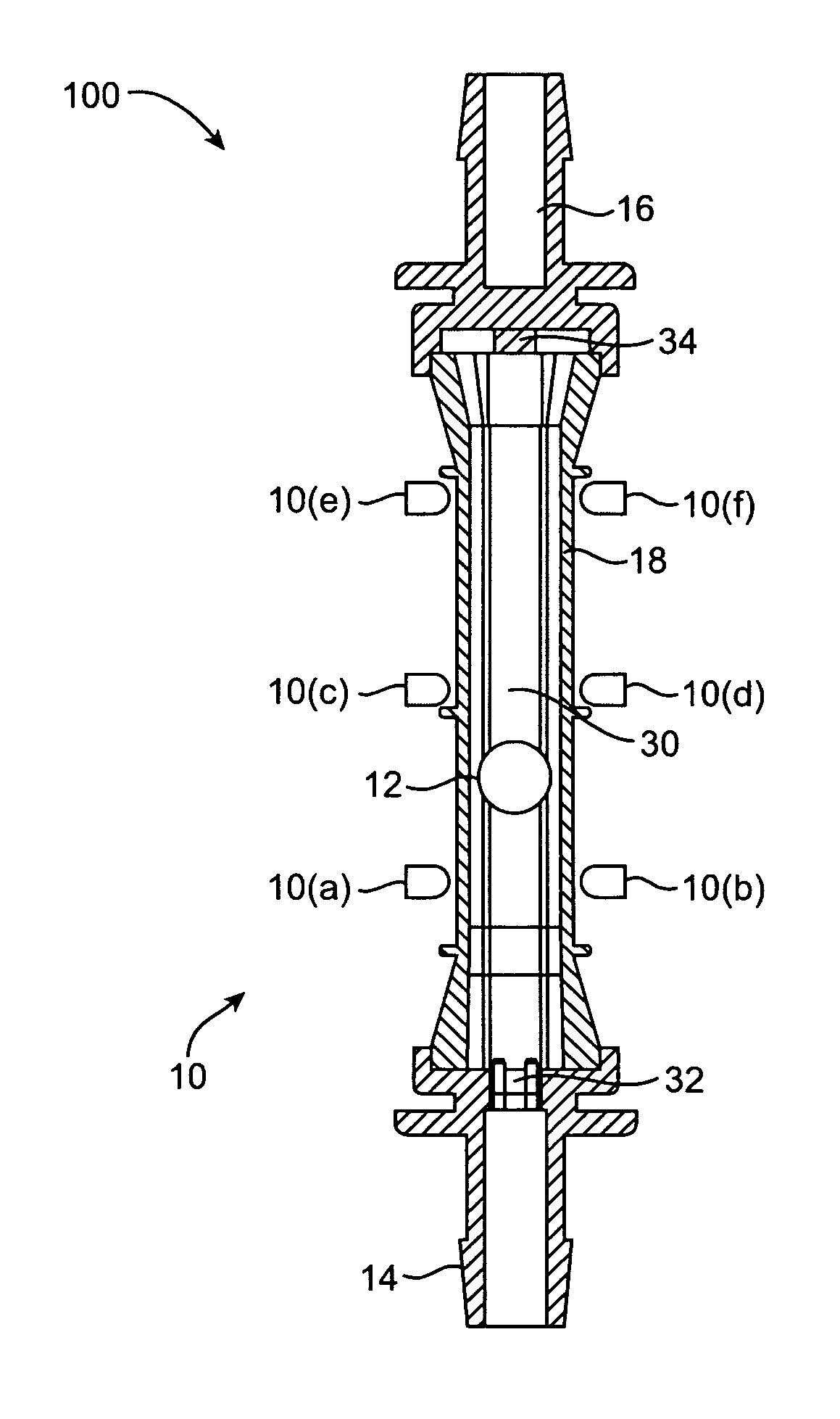

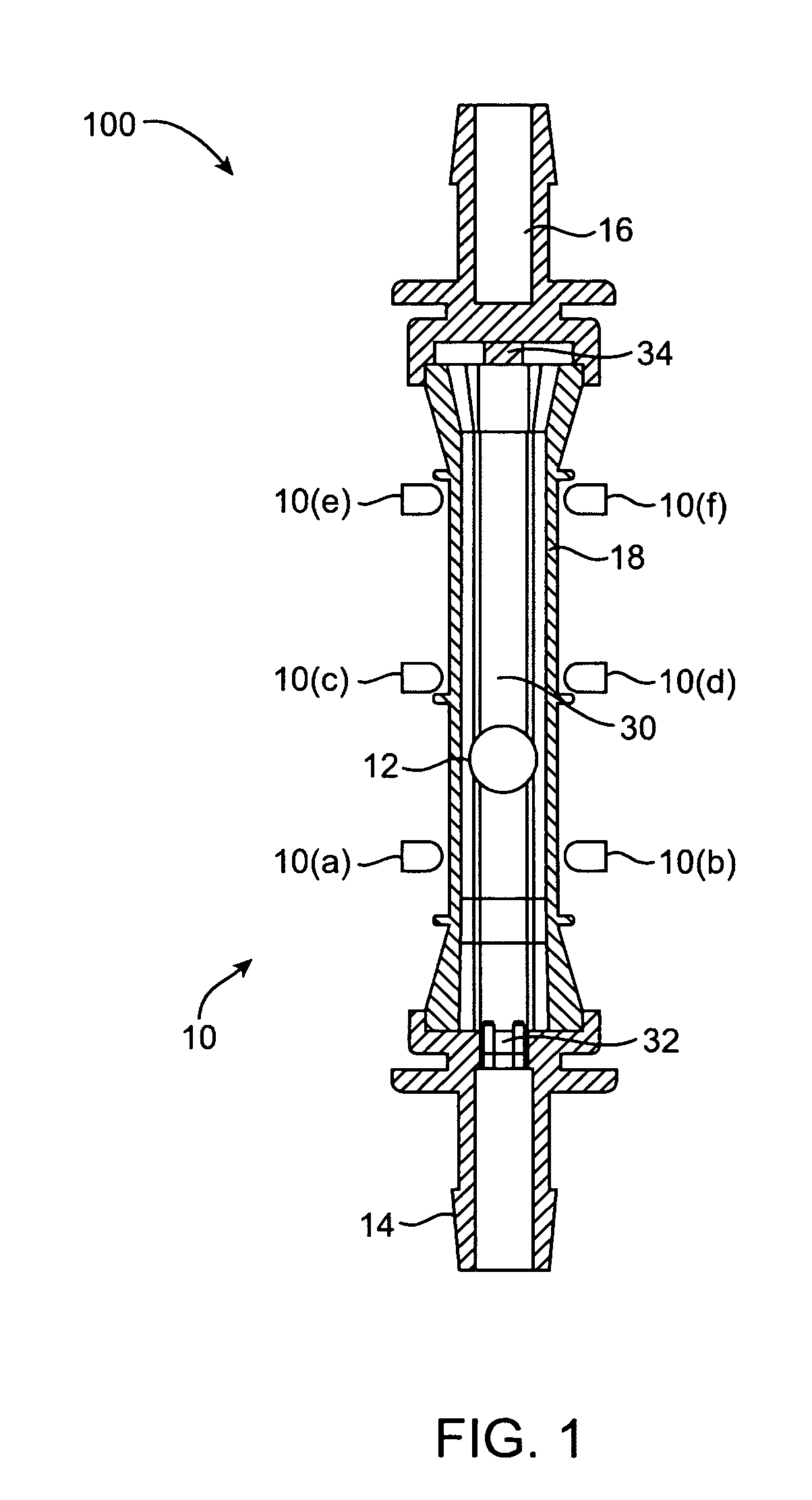

Flowmeter

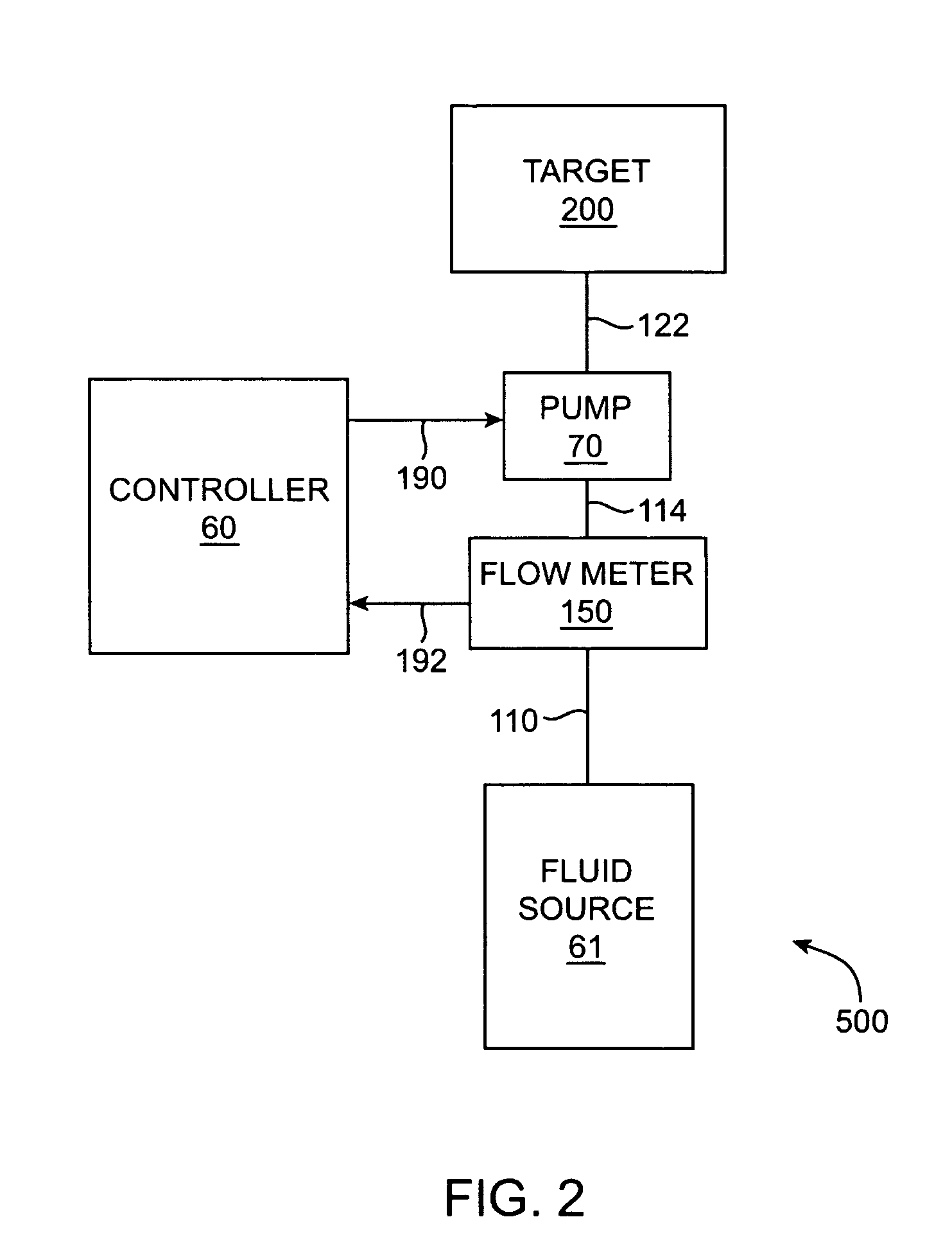

An apparatus, for use with a fluid moving device that moves a fluid from a container. The apparatus includes a flowtube having a passage, the flowtube having a first end and a second end. A body is positioned in the passage of the flowtube, and a sensor array comprising at least two sensors is positioned along the length of the flowtube and between the first end and second end of the flowtube. The sensors in the sensor array sense (e.g., detect) the body as the body flows past the sensors. The sensors in the sensor array are adapted to generate signals, and a controller is operatively coupled to the sensor array. The controller is adapted to control the fluid moving device in response to the signals generated by the sensor array.

Owner:DELAWARE CAPITAL FORMATION INC

Magnetic flow meter with selective electrode positioning

A magnetic flow meter has an electrically insulating member extending inward from an inner wall of a flow tube and extending along a selected axial portion of the tube. At least one pair of electrodes are placed adjacent opposite sides of the insulating member at a selected axial position so as to define a voltage sensing path. At least one of the electrodes is connected to an adjustment mechanism that allows the electrode to be set at a selected radial position, where the position can be selected so that the sensed voltage varies linearly with volumetric flow rate.

Owner:ONICON INC

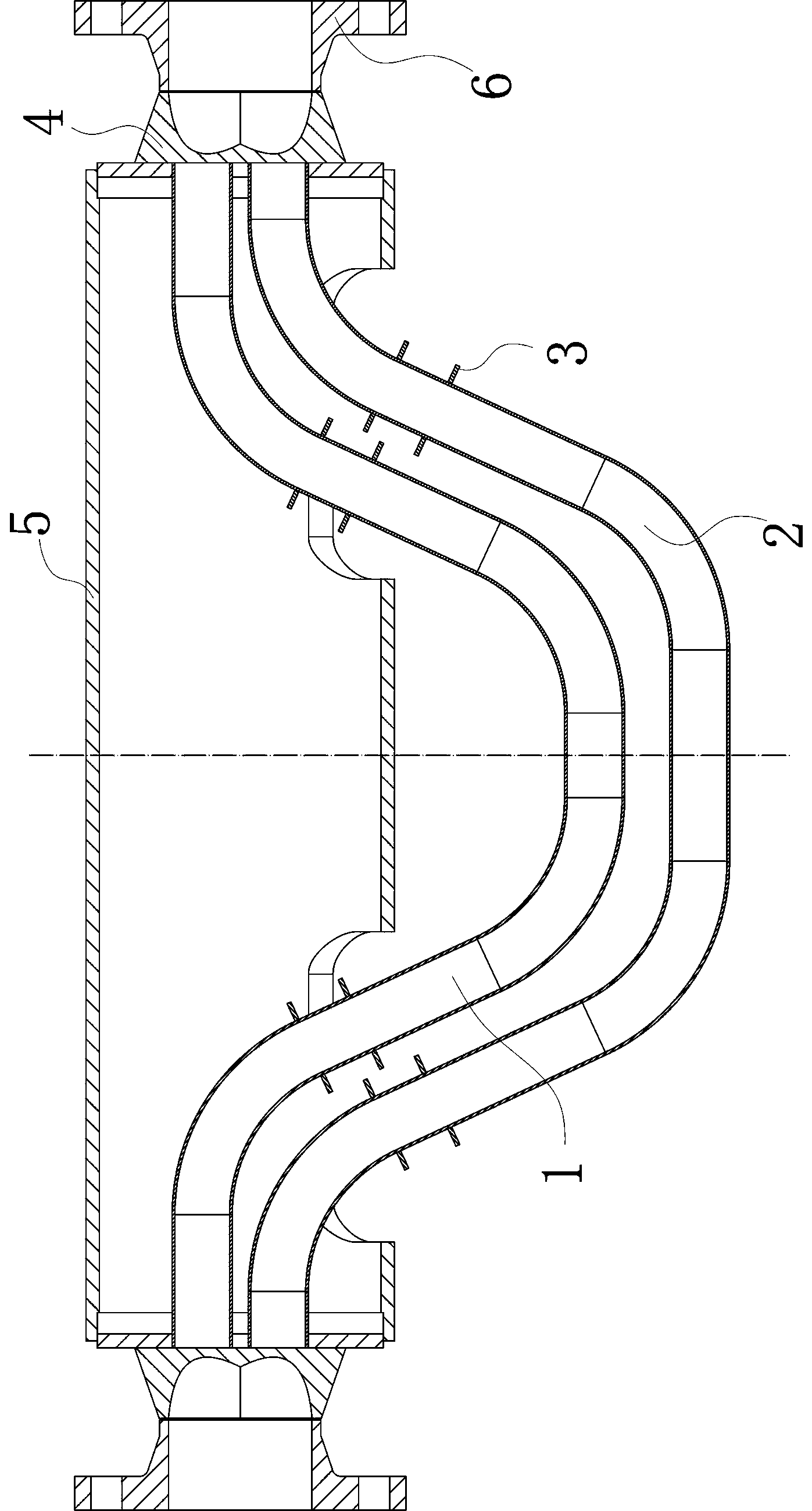

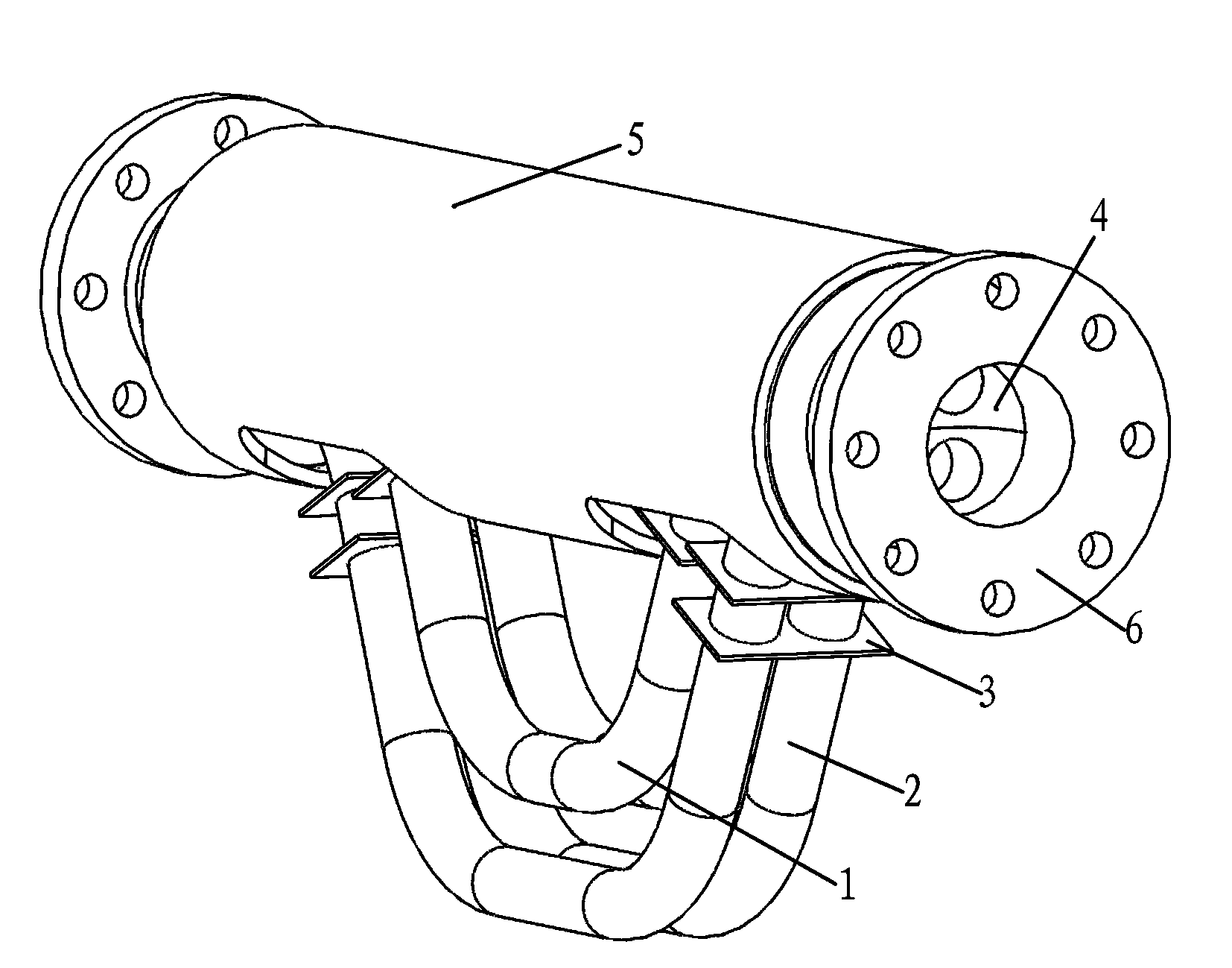

Multi-runner Coriolis mass flowmeter sensor fluid main part

A multi-runner Coriolis mass flowmeter sensor fluid main part comprises flow pipes, a support pipe, distribution bodies and connecting flanges. Two ends of each flow pipe are respectively fixedly connected to one sides of the distribution bodies. The other sides of the distribution bodies are fixedly connected with the connecting flanges. The support pipe is fixed between the two distribution bodies. The multi-runner Coriolis mass flowmeter sensor fluid main part is characterized in that the flow pipes are U-shaped and divided into an upper group and a lower group. Every two flow pipes form one group. Each group of flow pipes is of the same shape. The outer walls of two inclined straight pipes on two sides of each group of flow pipes are jointly fixedly provided with at least one damping plate. Compared with the prior art, the multi-runner Coriolis mass flowmeter sensor fluid main part has the advantages that the defects of currently-popular mass flowmeters are overcome, and the multi-runner Coriolis mass flowmeter sensor fluid main part is low in pressure loss, simplified in structure, high in flexibility, less prone to environmental influence, and the like.

Owner:SHANGHAI YINUO INSTR

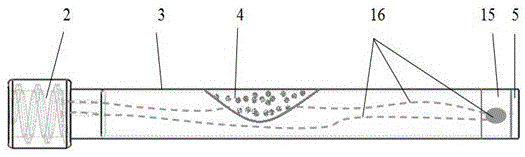

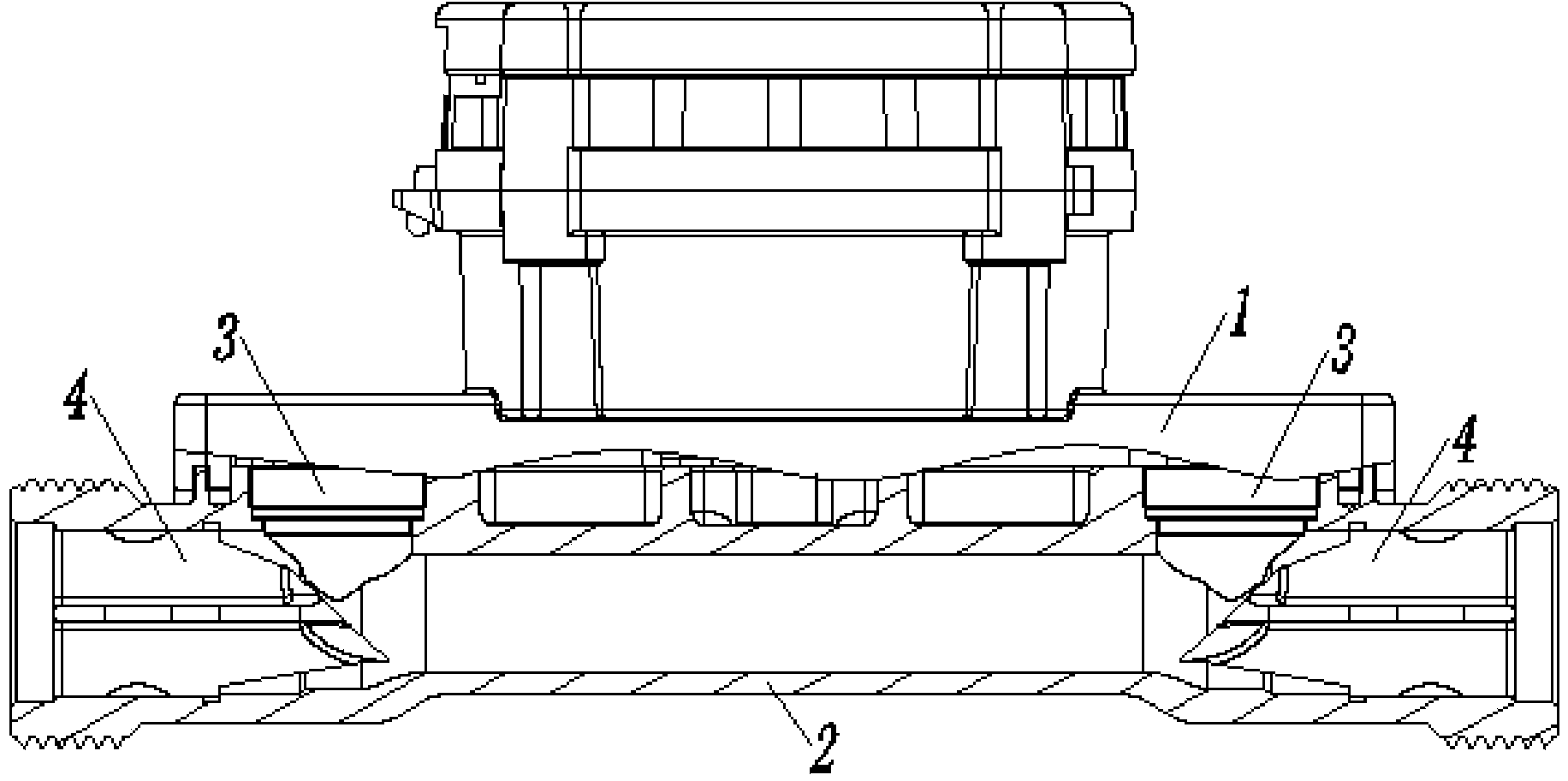

Water gauge

ActiveCN103940480AEliminate instabilityReduce the difference in flow rateVolume/mass flow measurementUltrasonic sensorWater flow

The invention discloses a water gauge. The water meter comprises a gauge outfit, a flux tube and an ultrasonic transducer. A transduction hole is formed in the flux tube, and the ultrasonic transducer is installed in the transduction hole. The gauge outfit is installed on the flux tube. The ultrasonic transducer is connected with the gauge outfit. A flow-splitting reflector is installed inside the flux tube and arranged corresponding to the ultrasonic transducer. The flow-splitting reflector comprises a splitter plate, and one end of the splitter plate is connected with an acoustic beam reflecting plate in an inclined mode. The ultrasonic transducer corresponds to the acoustic beam reflecting plate, and an acoustic beam emitted by the ultrasonic transducer is reflected on the acoustic beam reflecting plate. By the adoption of the water gauge, water flow in the flux tube can be split and neatened, the unstable state of the water flow is eliminated, differences in flow rates at all points of the same section are reduced, and therefore the accuracy of flow measurement is improved.

Owner:CHONGQING WECAN PRECISION INSTR

Magnetic flowmeter with coil ground path detection

ActiveCN102341680AVolume/mass flow measurementTesting/calibration for volume flowHemt circuitsEngineering

A magnetic flow meter (2) includes a flowtube (4) arranged to receive a flow of process fluid and a coil (26) proximate the flowtube arranged to apply a magnetic field to the process fluid. A sense electrode (68) is arranged to sense a voltage potential in the flowtube in response to the applied magnetic field. The sensed voltage is indicative of flow rate of process fluid through the flowtube. Diagnostic (40) circuitry provides an output related to an electrical path between the coil and electrical ground.

Owner:MICRO MOTION INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com