Patents

Literature

51results about How to "Large flow range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

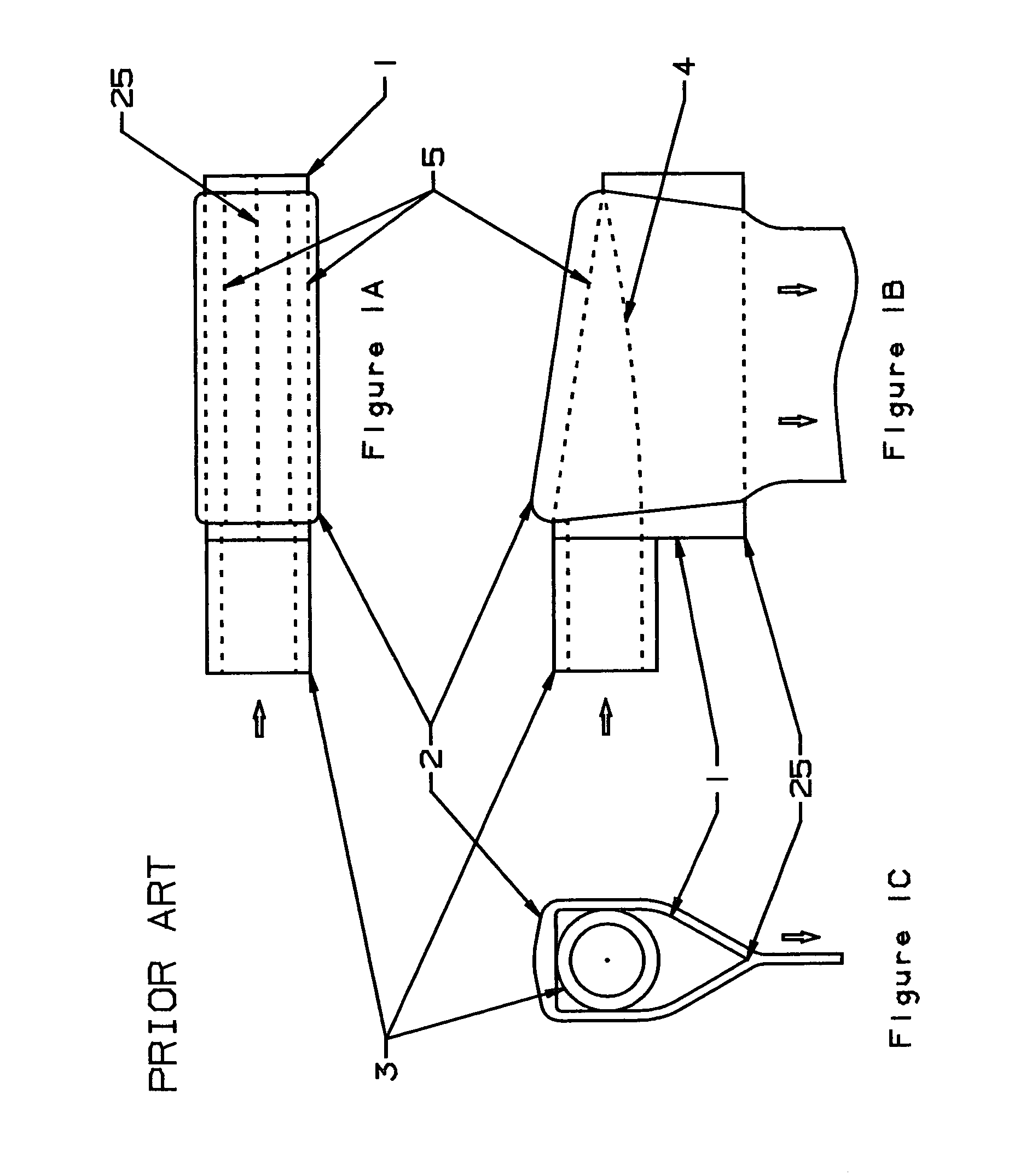

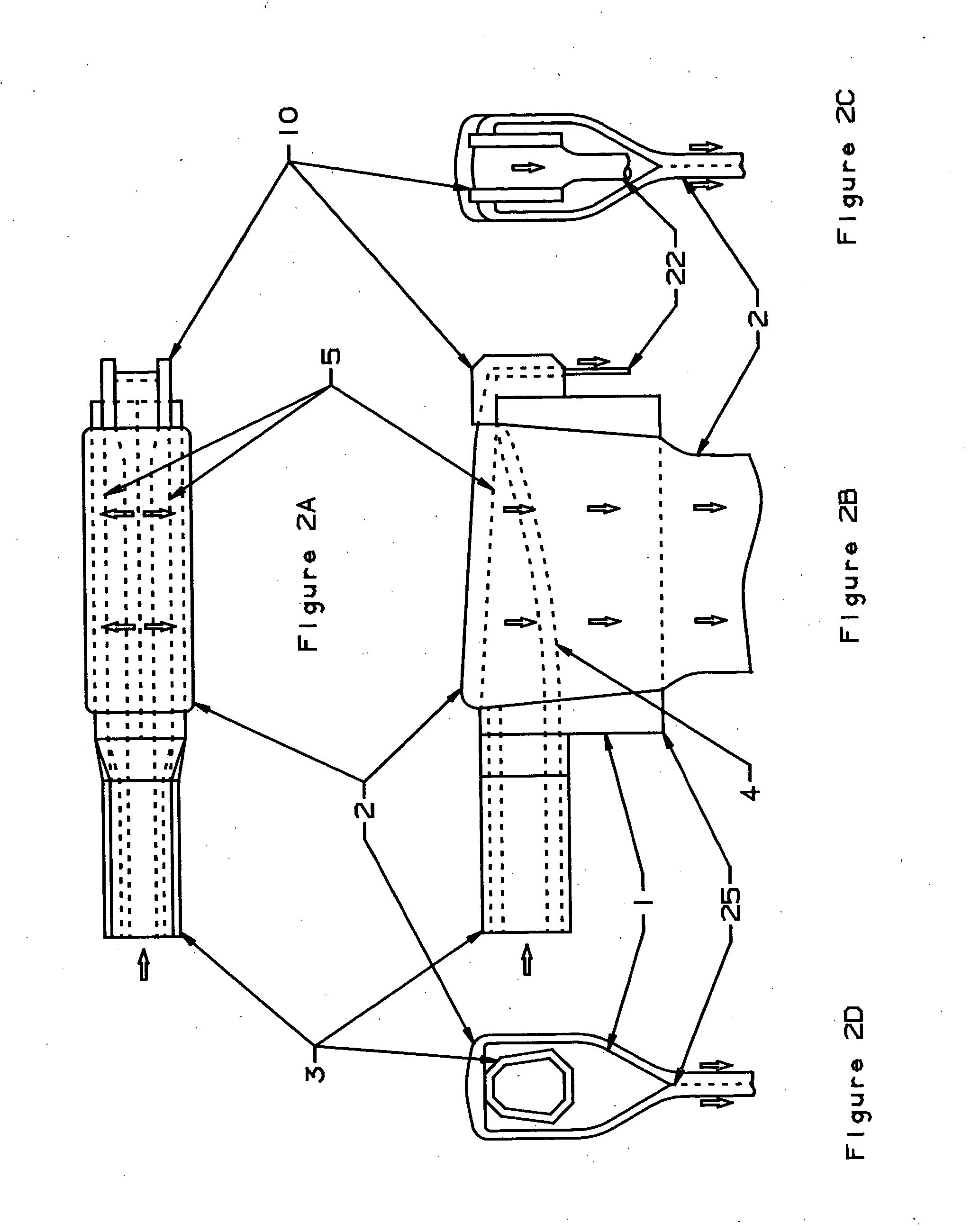

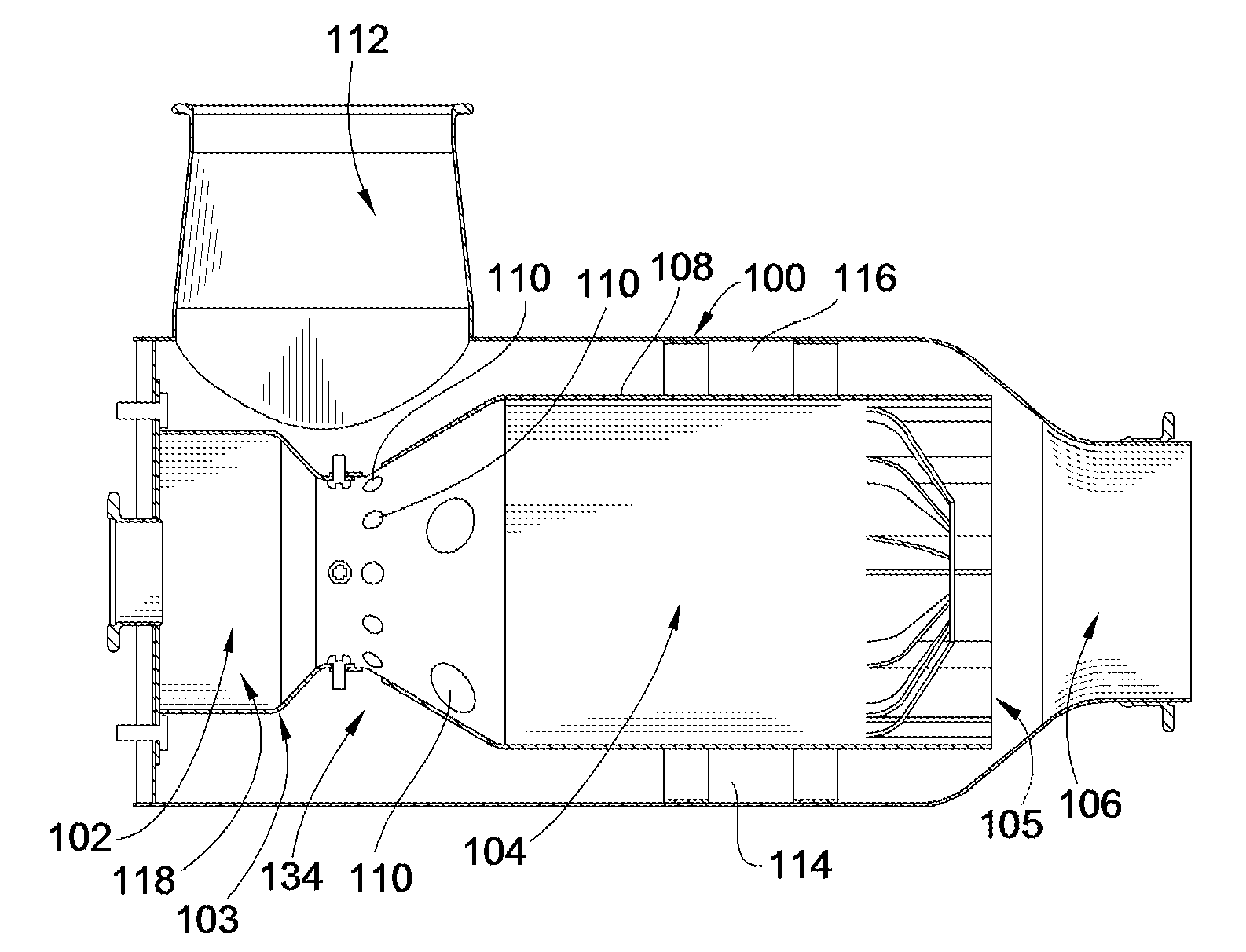

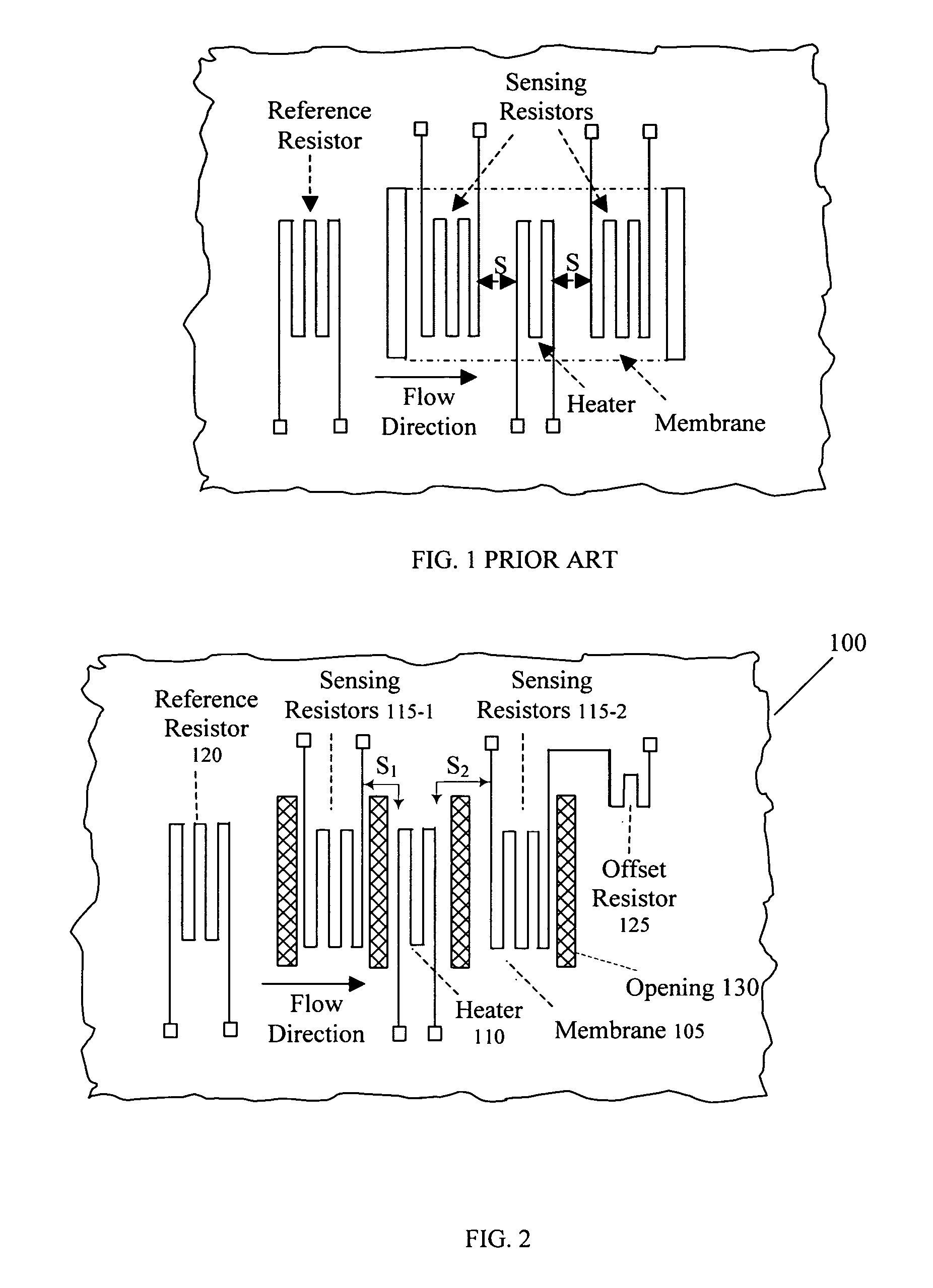

Overflow downdraw glass forming method and apparatus

InactiveUS6997017B2Facilitate faster and uniform flowIncrease rangeGlass furnace apparatusGlass drawing apparatusEngineeringFlow augmentation

The forming apparatus of the present invention preferably includes an orifice on top of the trough. The uniquely shaped orifice substitutes for the weirs as the controlling entity for glass thickness. The orifice is designed such that as it deforms, it maintains a linear flow characteristic with respect to its length. As the orifice is made larger by the applied stress, the percentage width increase is the same over its length and consequently the percentage flow increase is the same over the length of the orifice. In another embodiment, the present invention provides an adjustment to change the flow characteristics of the trough to compensate for the degradation of the forming trough during an extended production run. A flow control plug can be inserted into the trough, such that flow dynamics can be altered during hot operation by insertion, removal or position adjustment of the flow control plug.

Owner:CORNING INC

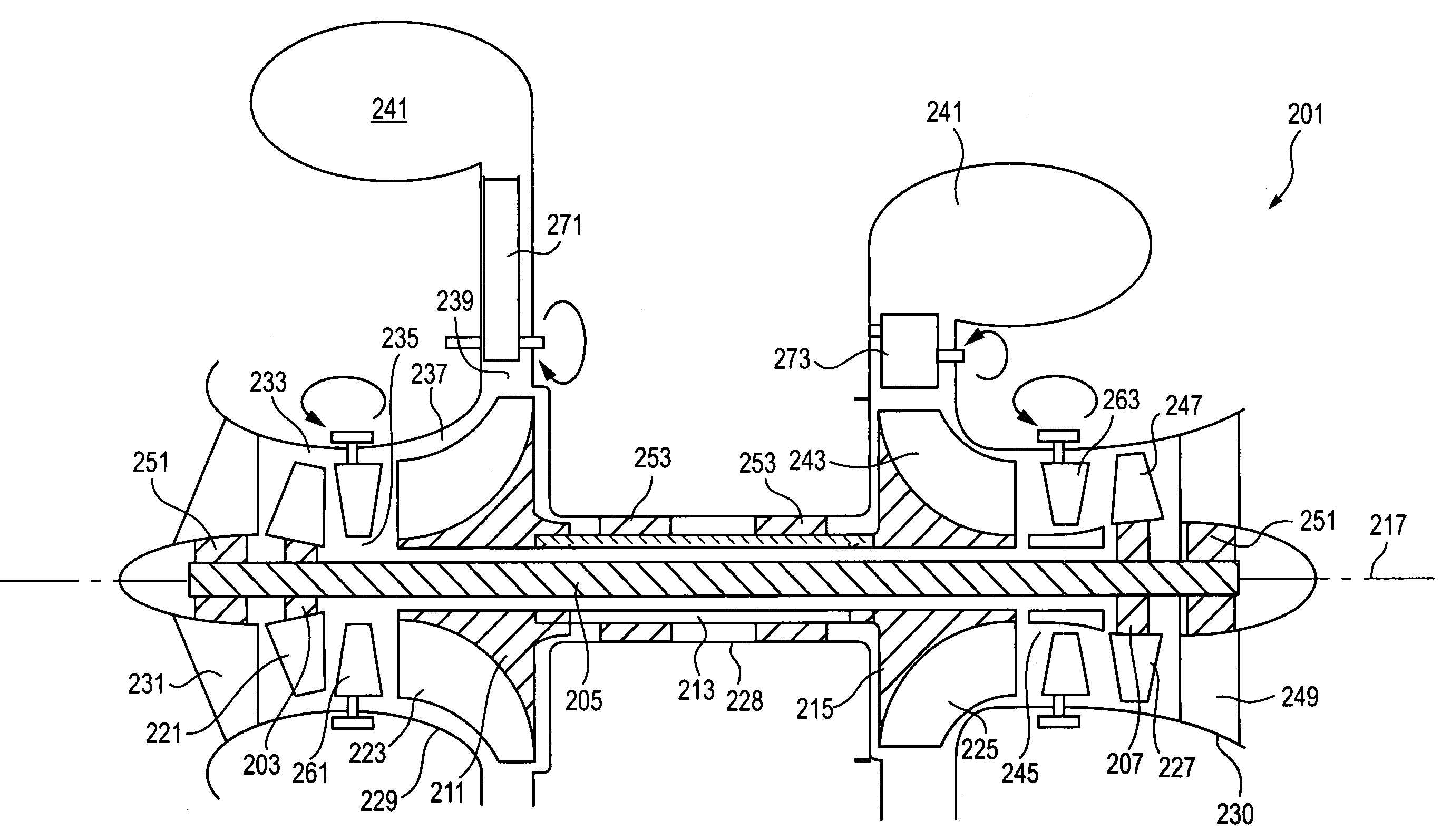

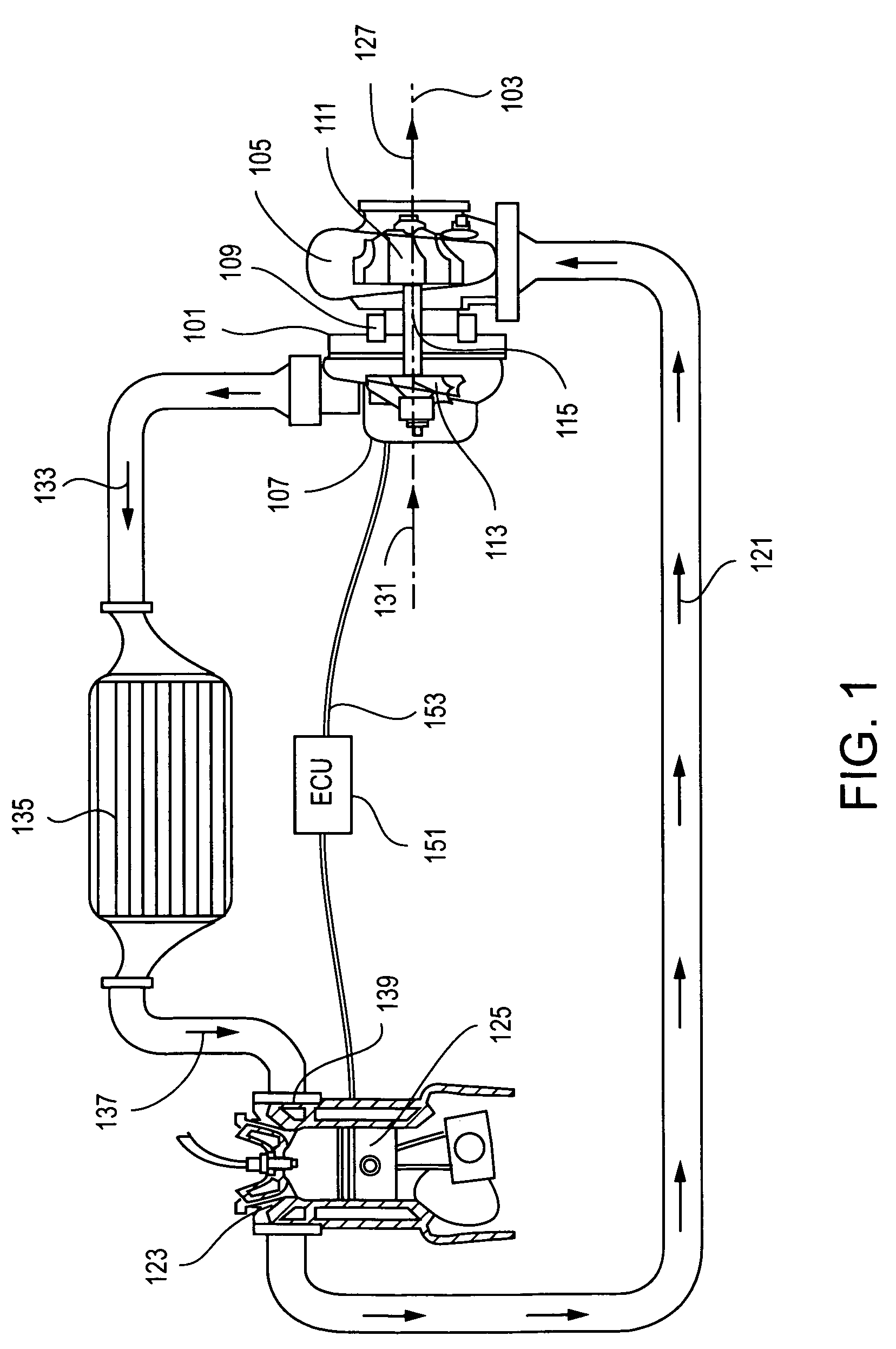

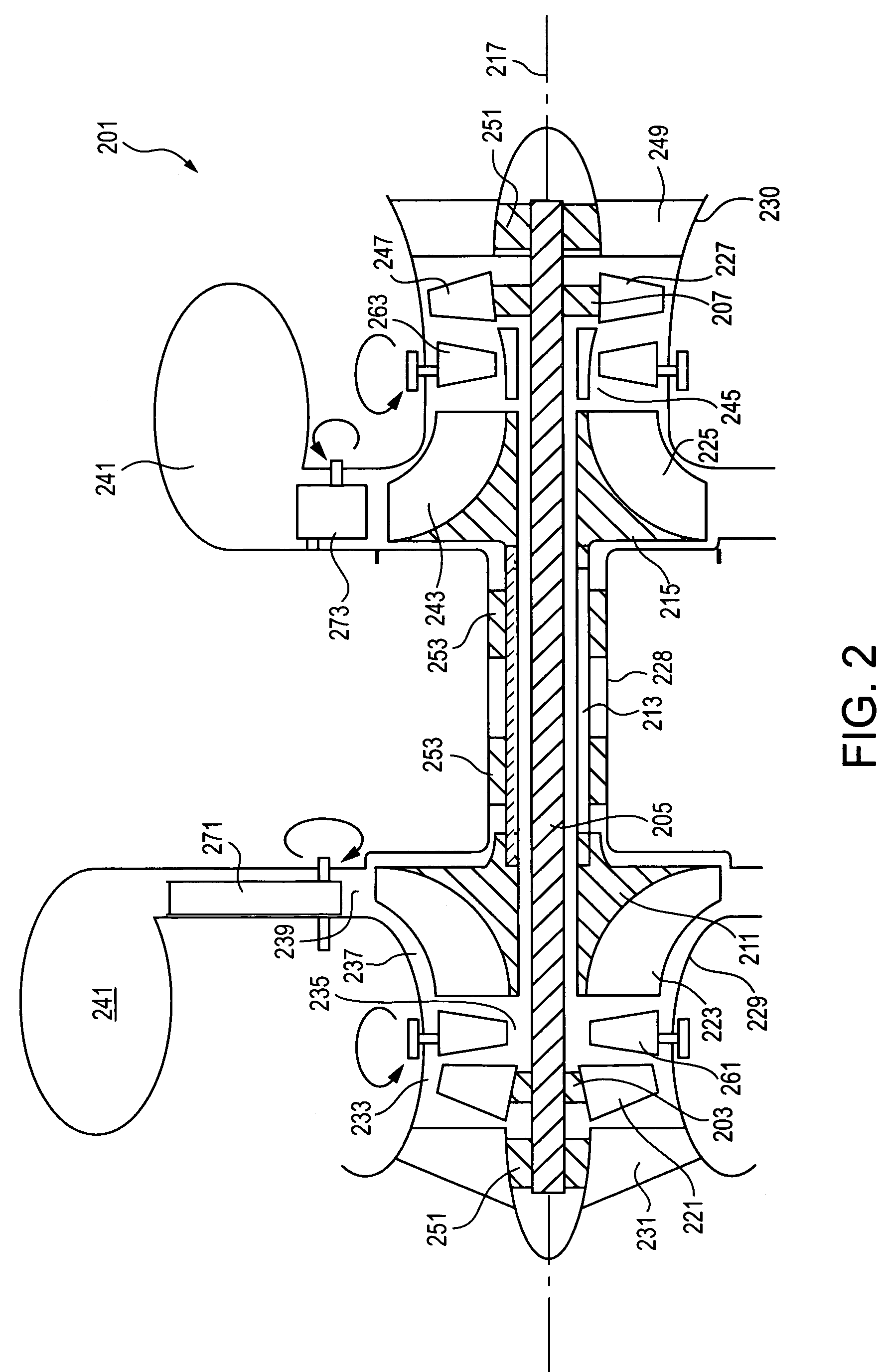

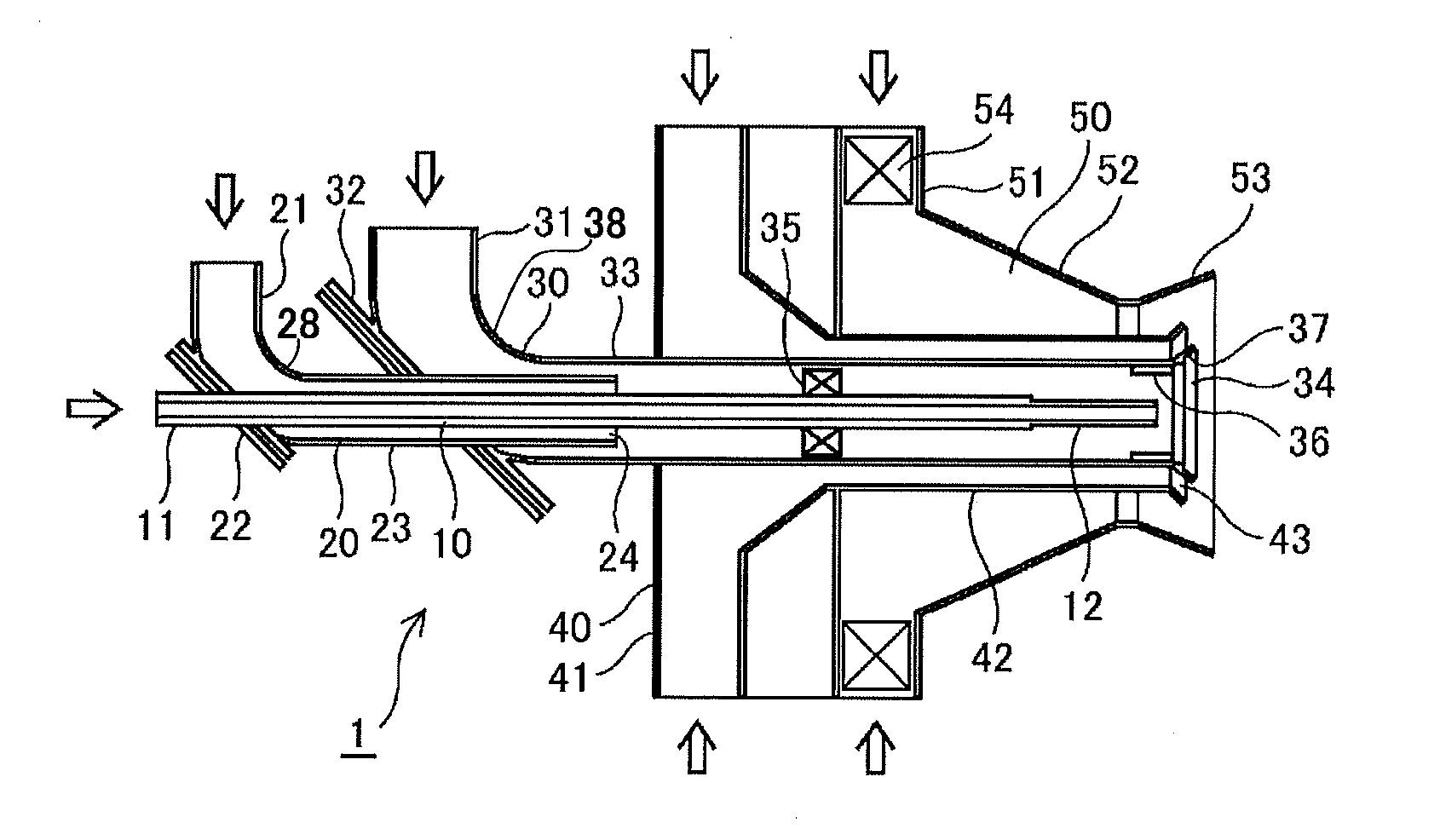

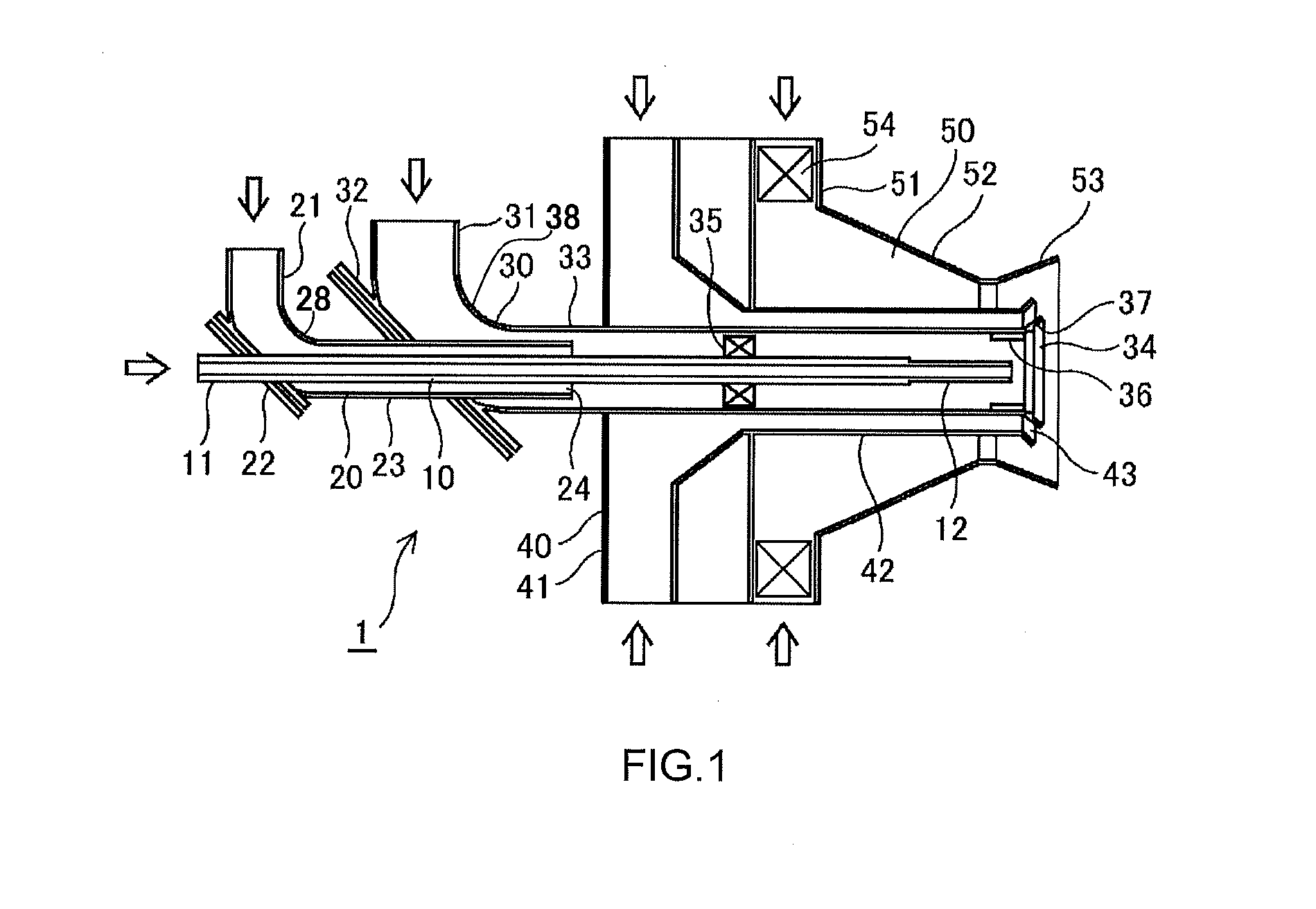

Two-shaft turbocharger

InactiveUS7571607B2Easy to controlIncrease pressure ratioInternal combustion piston enginesCombination enginesAxial compressorImpeller

Owner:HONEYWELL INT INC

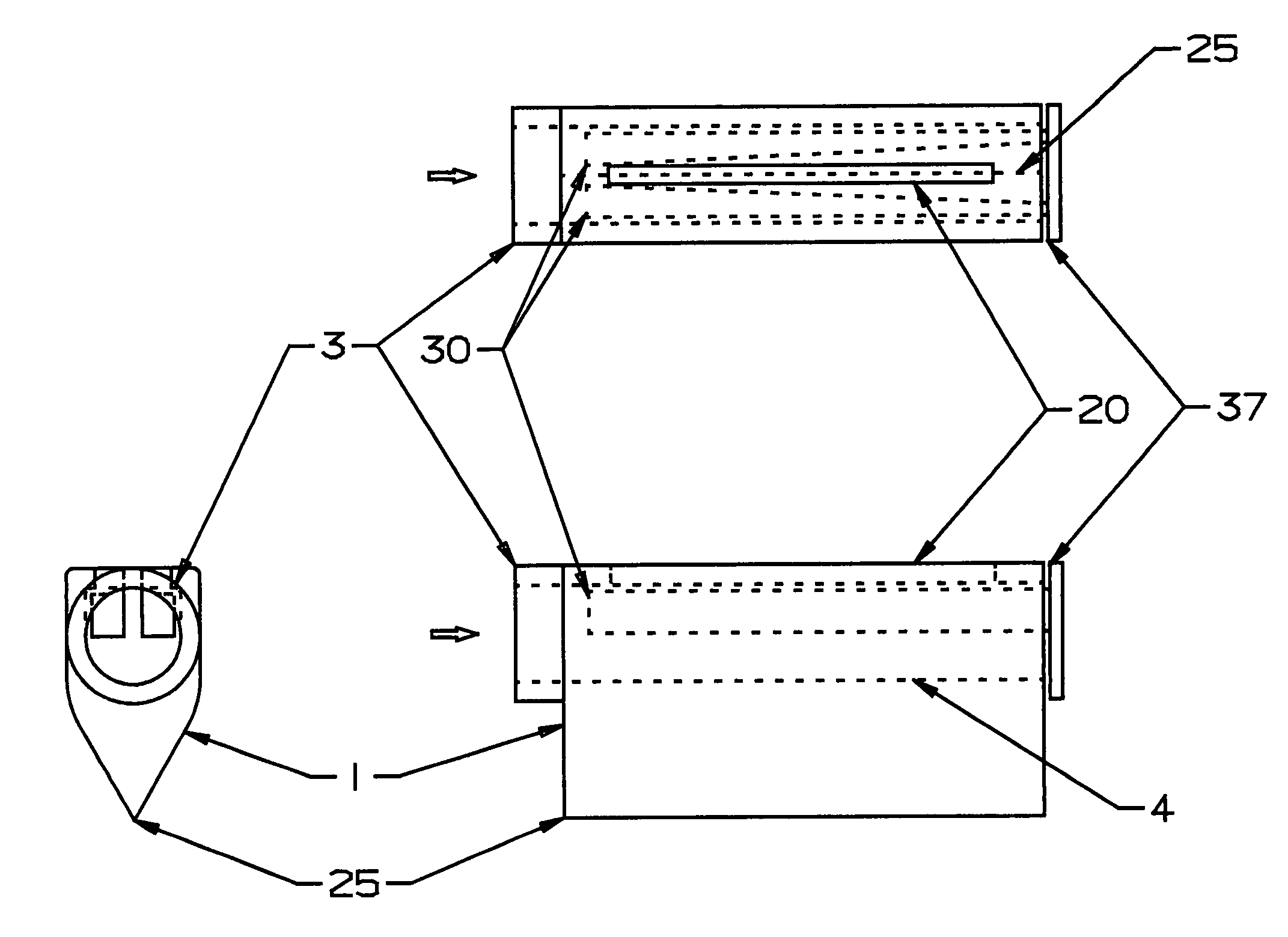

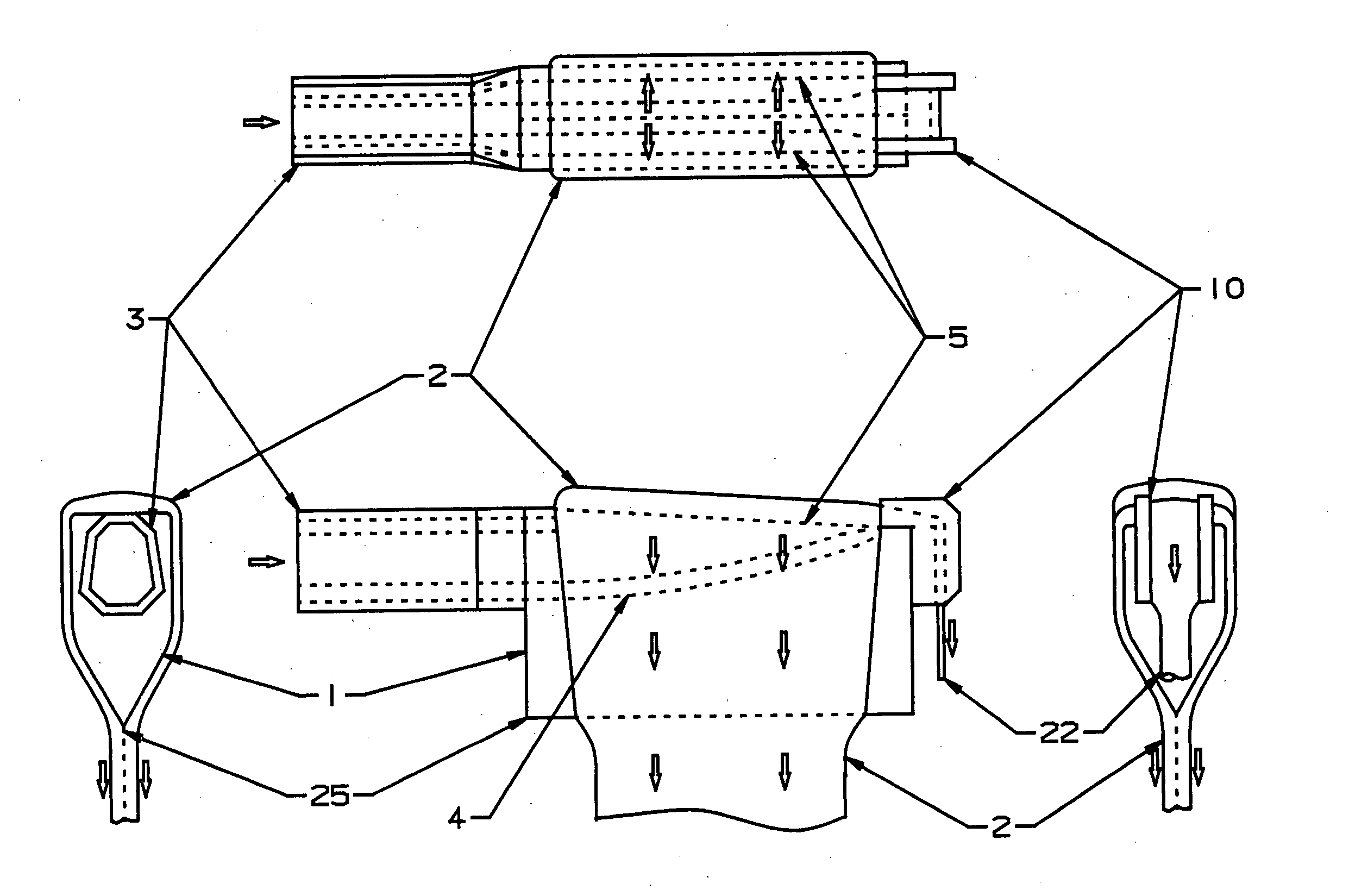

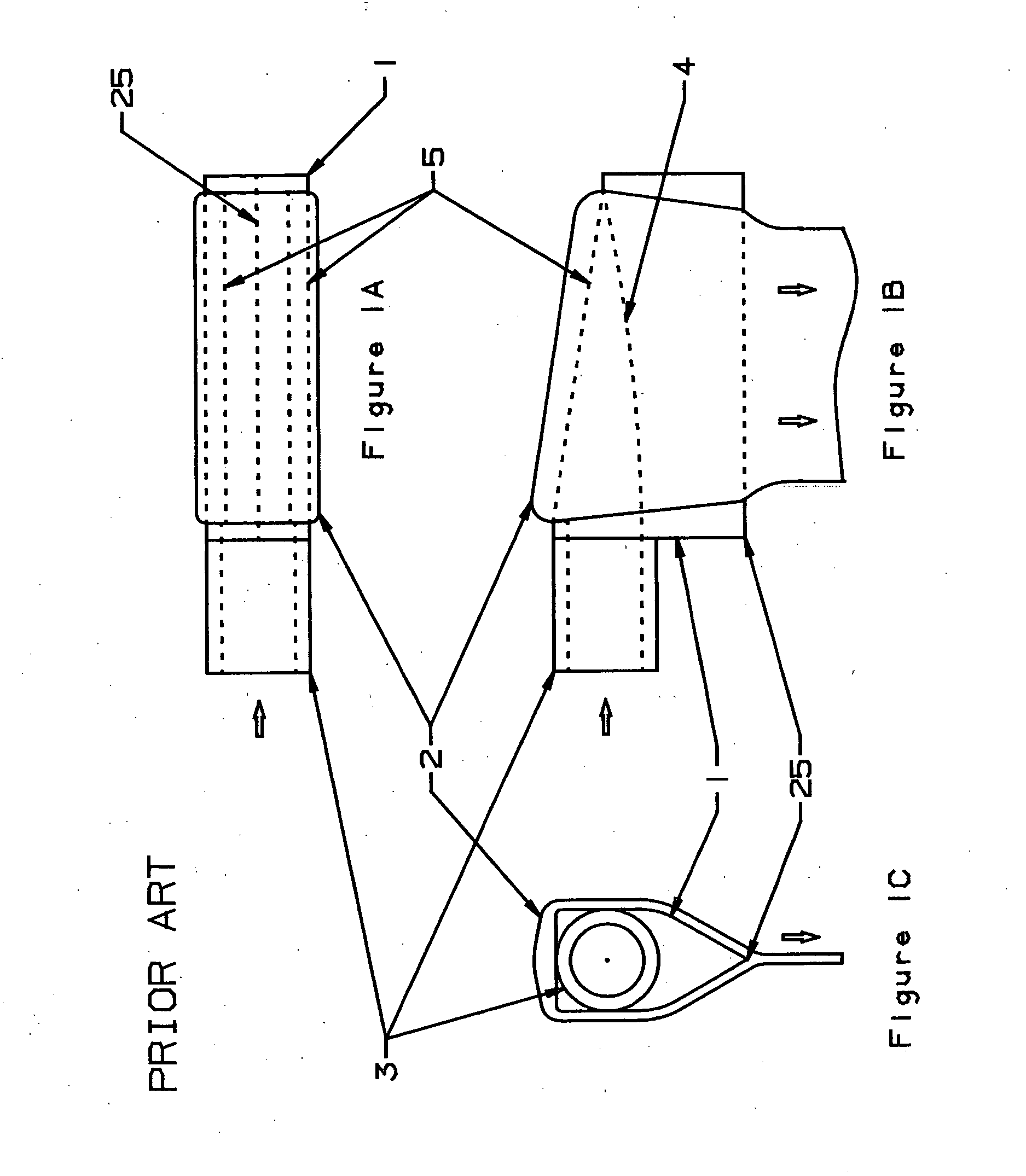

Sheet glass forming apparatus

InactiveUS20050076677A1Facilitate faster and uniform flowAdjustable thicknessGlass furnace apparatusGlass drawing apparatusFlat glassLinearity

The forming apparatus of the present invention preferably includes an orifice on top of the trough. The uniquely shaped orifice substitutes for the weirs as the controlling entity for glass thickness. The orifice is designed such that as it deforms, it maintains a linear flow characteristic with respect to its length. As the orifice is made larger by the applied stress, the percentage width increase is the same over its length and consequently the percentage flow increase is the same over the length of the orifice. In another embodiment, the present invention provides an adjustment to change the flow characteristics of the trough to compensate for the degradation of the forming trough during an extended production run. A flow control plug can be inserted into the trough, such that flow dynamics can be altered during hot operation by insertion, removal or position adjustment of the flow control plug.

Owner:CORNING INC

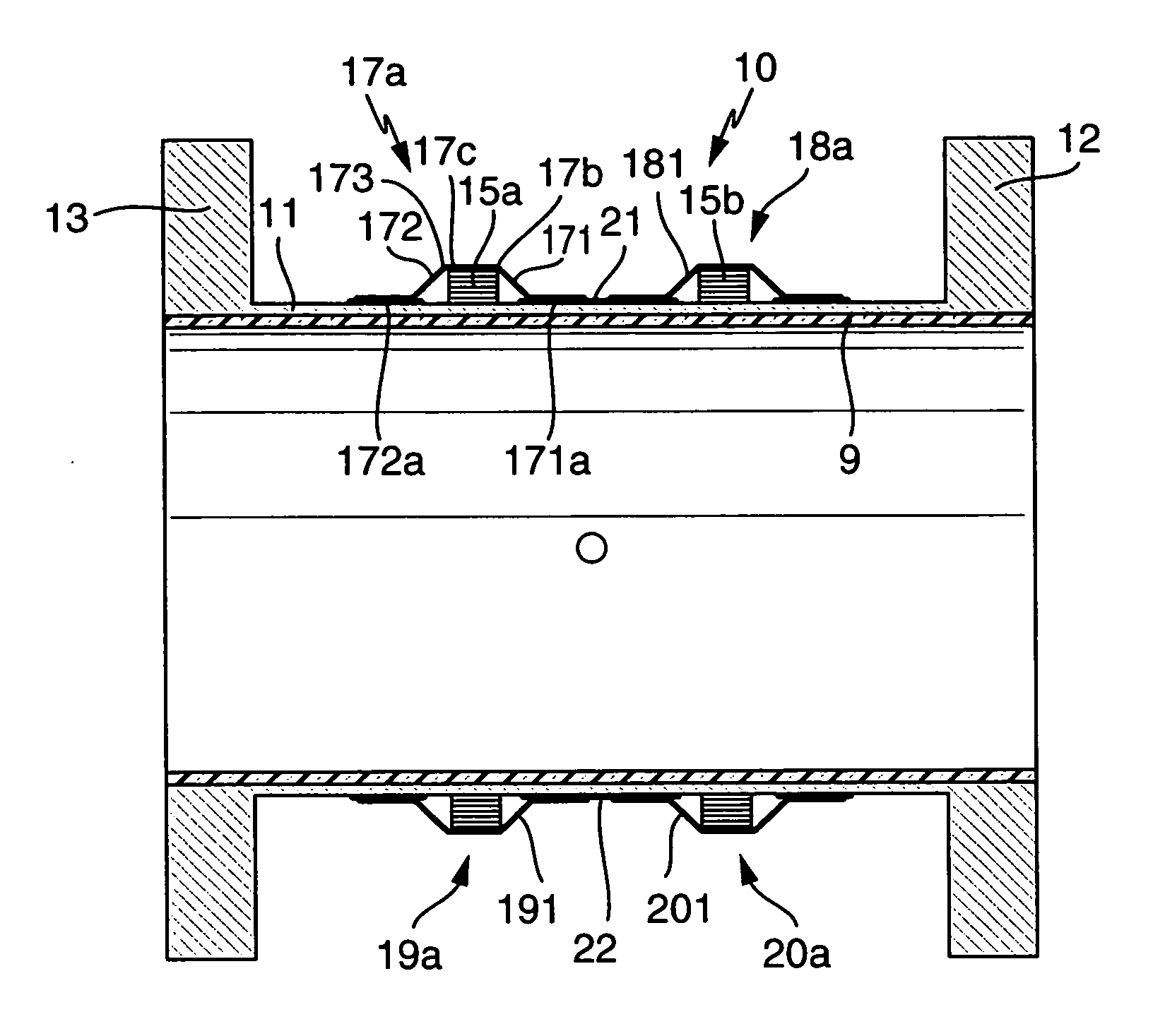

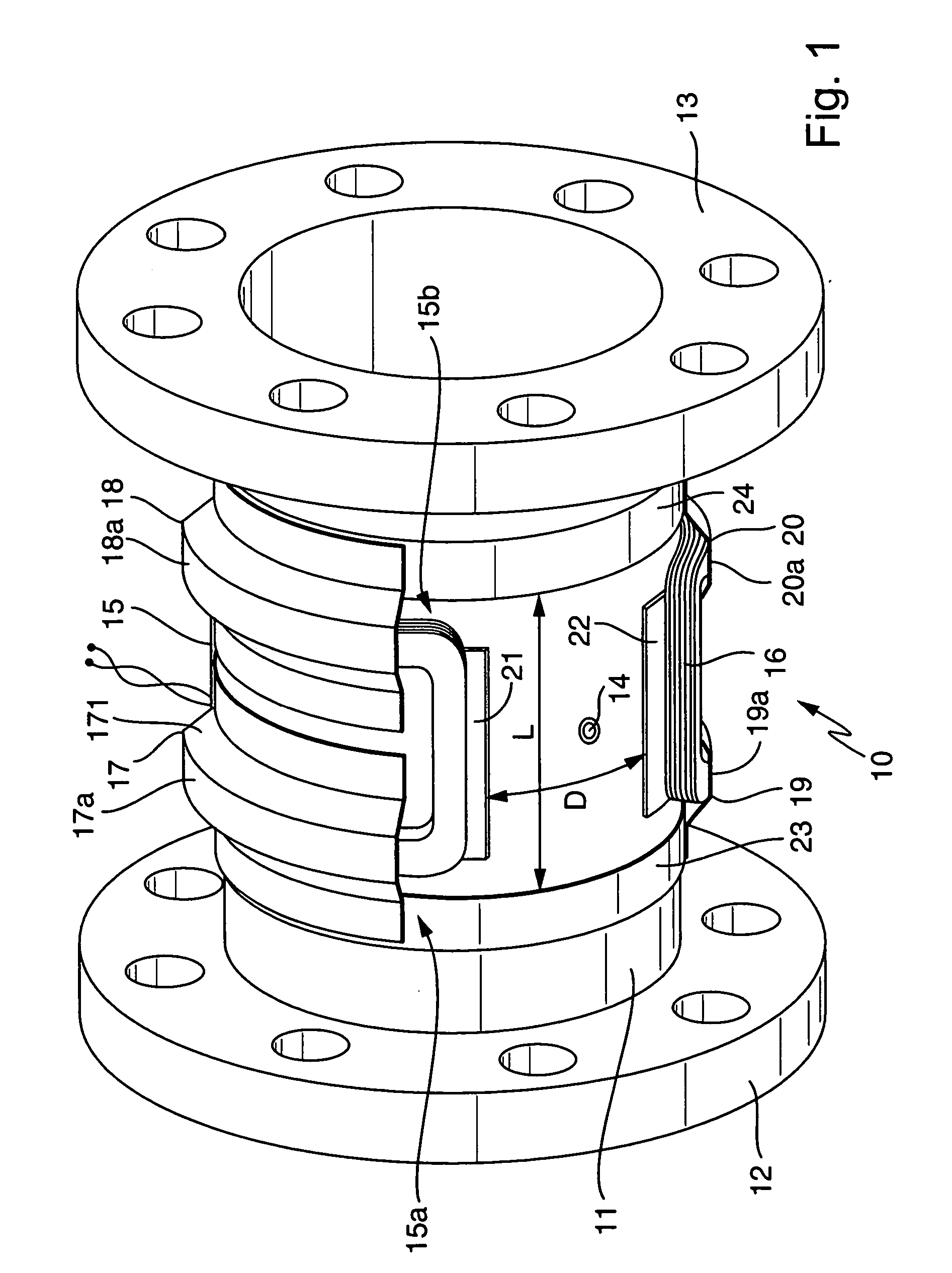

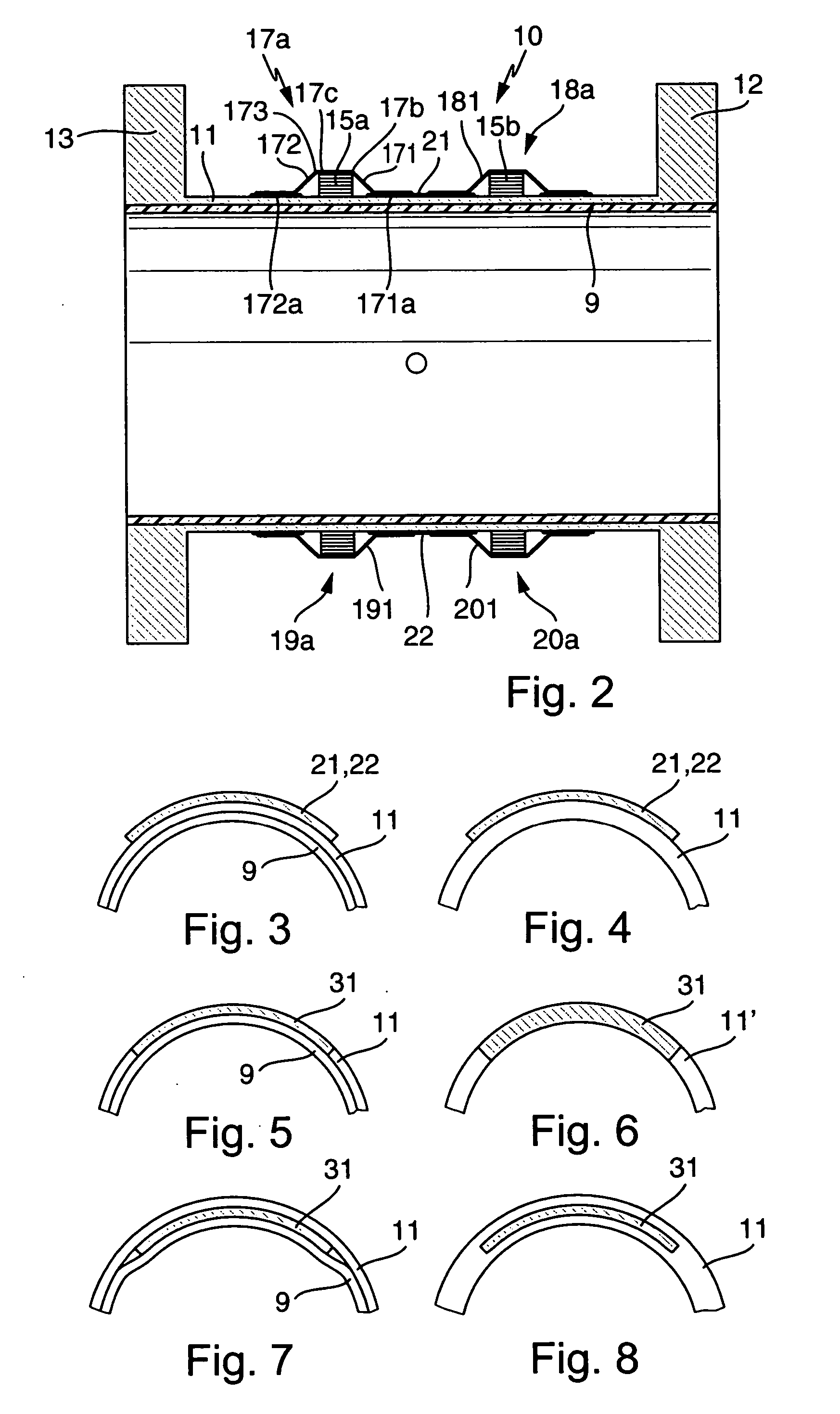

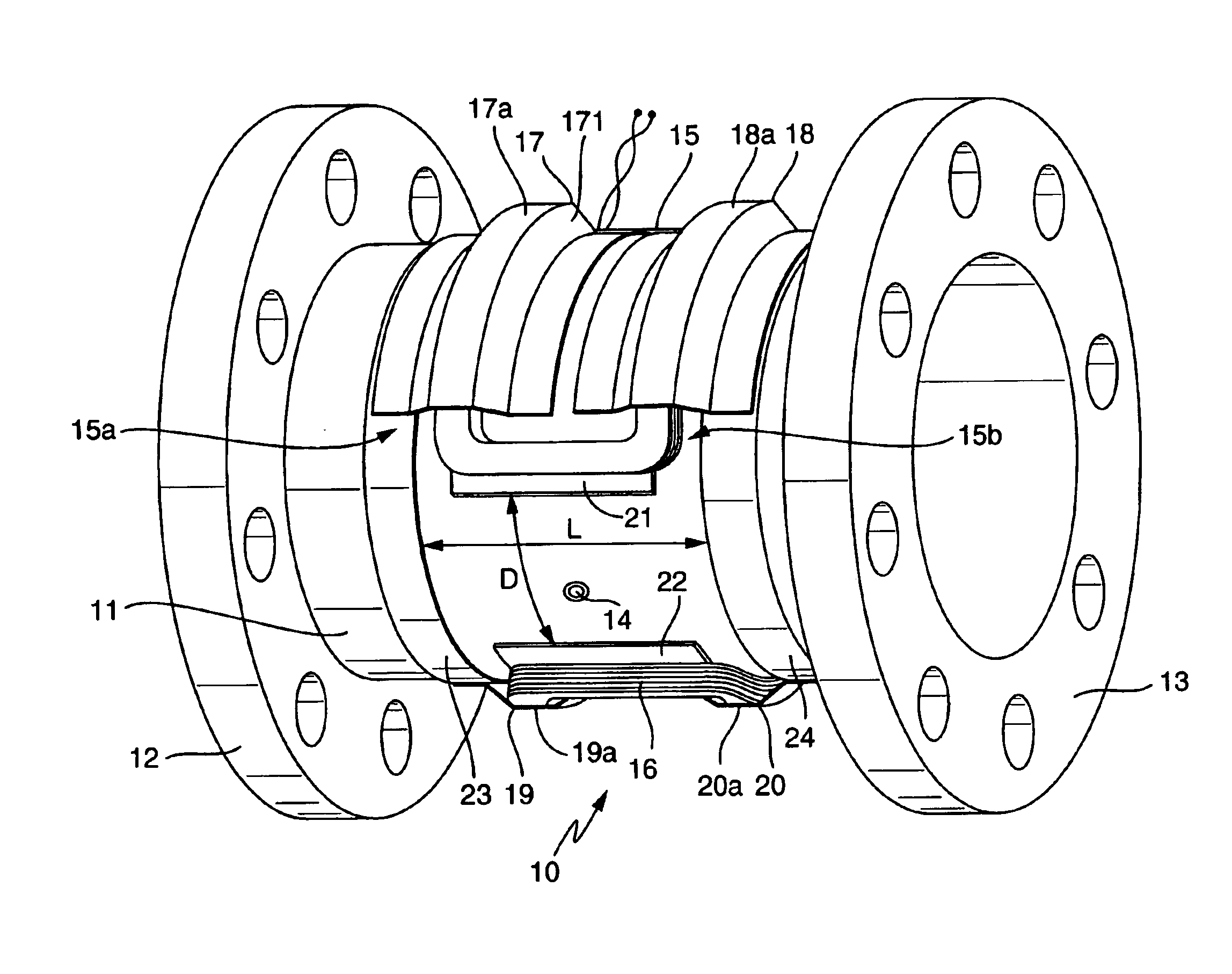

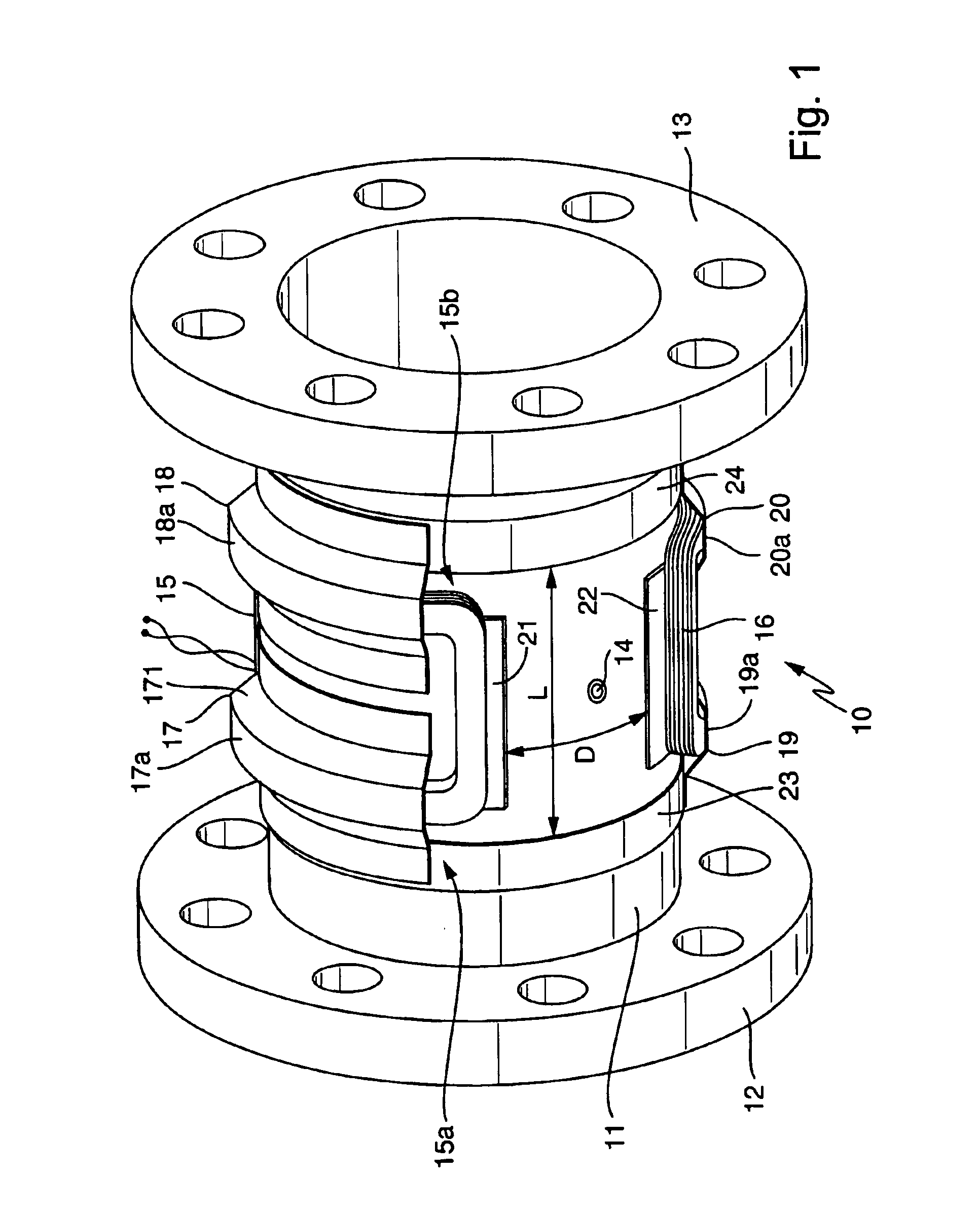

Electromagnetic flow sensor

InactiveUS20050000300A1Short build timeLarge flow rangeVolume/mass flow by electromagnetic flowmetersFlow transducerCoupling

The flow sensor serves to measure an electrically conductive fluid flowing in a pipe. It comprises a flow tube designed to be inserted into the pipe for conducting the fluid, the flow tube being electrically nonconductive at least on a fluid-contacting inner side, an electrode arrangement consisting of at least two measuring electrodes disposed on the flow tube for picking up a voltage induced in the fluid, and a magnetic field system likewise disposed on the flow tube. The magnetic field system comprises at least two saddle-shaped field coils for producing a magnetic field cutting the fluid during operation of the flow sensor, a respective ferromagnetic pole piece for each of the two field coils, as well as at least one ferromagnetic return path extending around the flow tube upstream of the two field coils and at least one ferromagnetic return path extending around the flow tube downstream of the two field coils for directing the magnetic field around the flow tube. The pole pieces are magnetically coupled to the return paths by means of ferromagnetic coupling elements. Each of the, preferably identically shaped, coupling elements has at least one essentially trough-shaped cover segment which receives a first winding section of the respective associated field coil, lying essentially on a first periphery of the flow tube, or a second winding section of the associated field coil, lying essentially on a second periphery of the flow tube.

Owner:ENDRESS HAUSER FLOWTEC AG

Electromagnetic flow sensor

InactiveUS6983661B2Short build timeLarge flow rangeVolume/mass flow by electromagnetic flowmetersCouplingPole piece

The flow sensor serves to measure an electrically conductive fluid flowing in a pipe. It comprises a flow tube designed to be inserted into the pipe for conducting the fluid, the flow tube being electrically nonconductive at least on a fluid-contacting inner side, an electrode arrangement consisting of at least two measuring electrodes disposed on the flow tube for picking up a voltage induced in the fluid, and a magnetic field system likewise disposed on the flow tube. The magnetic field system comprises at least two saddle-shaped field coils for producing a magnetic field cutting the fluid during operation of the flow sensor, a respective ferromagnetic pole piece for each of the two field coils, as well as at least one ferromagnetic return path extending around the flow tube upstream of the two field coils and at least one ferromagnetic return path extending around the flow tube downstream of the two field coils for directing the magnetic field around the flow tube. The pole pieces are magnetically coupled to the return paths by means of ferromagnetic coupling elements. Each of the, preferably identically shaped, coupling elements has at least one essentially trough-shaped cover segment which receives a first winding section of the respective associated field coil, lying essentially on a first periphery of the flow tube, or a second winding section of the associated field coil, lying essentially on a second periphery of the flow tube.

Owner:ENDRESS HAUSER FLOWTEC AG

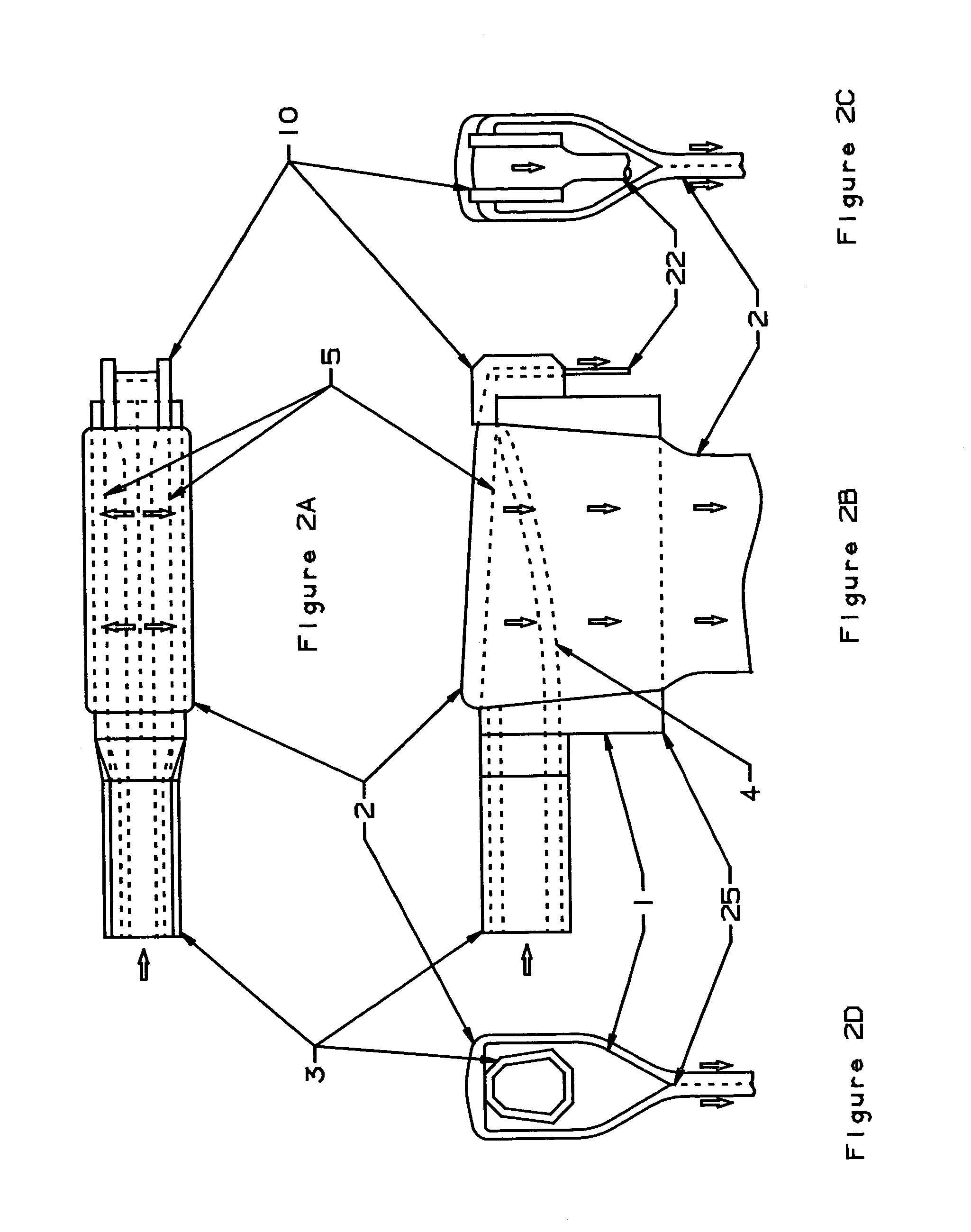

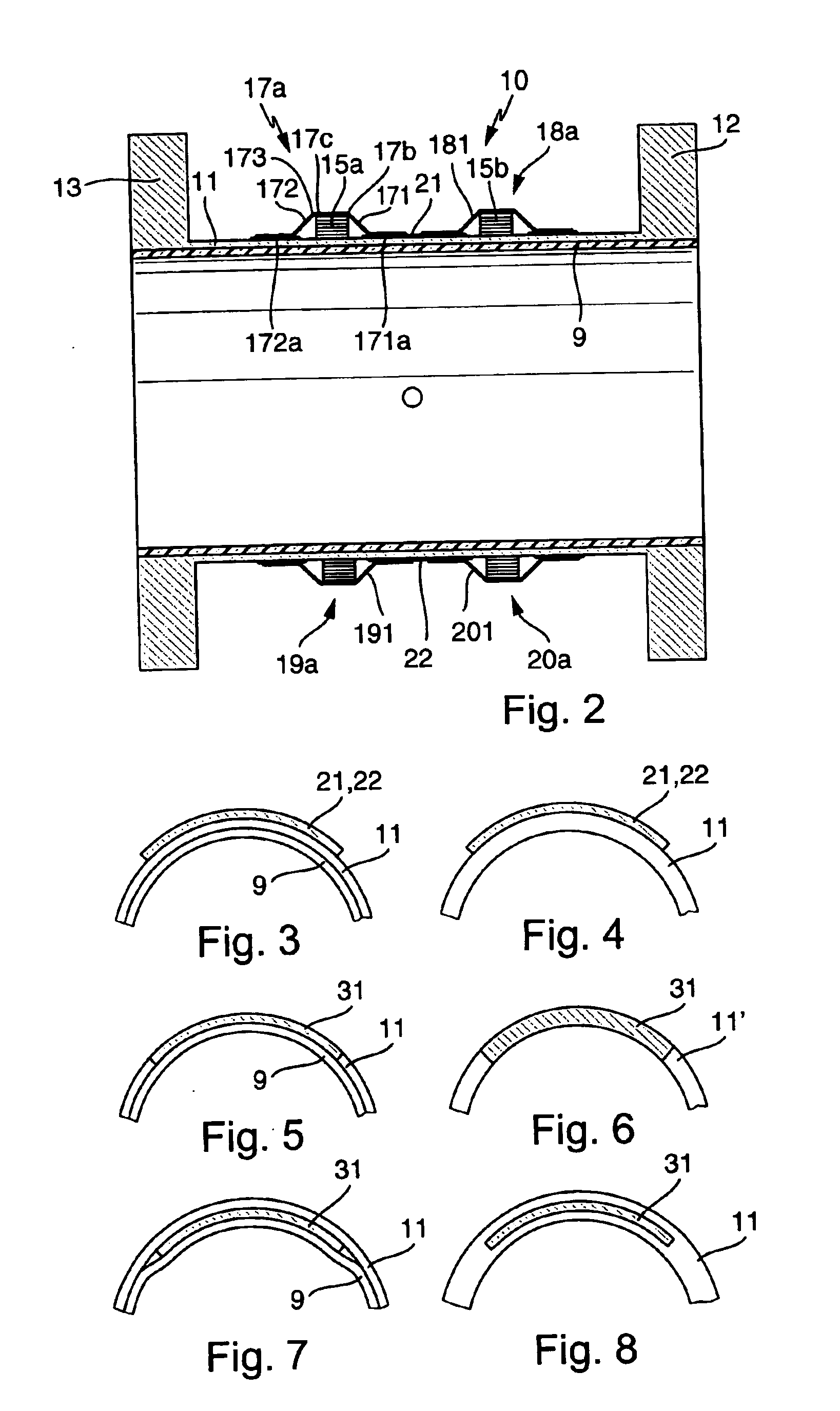

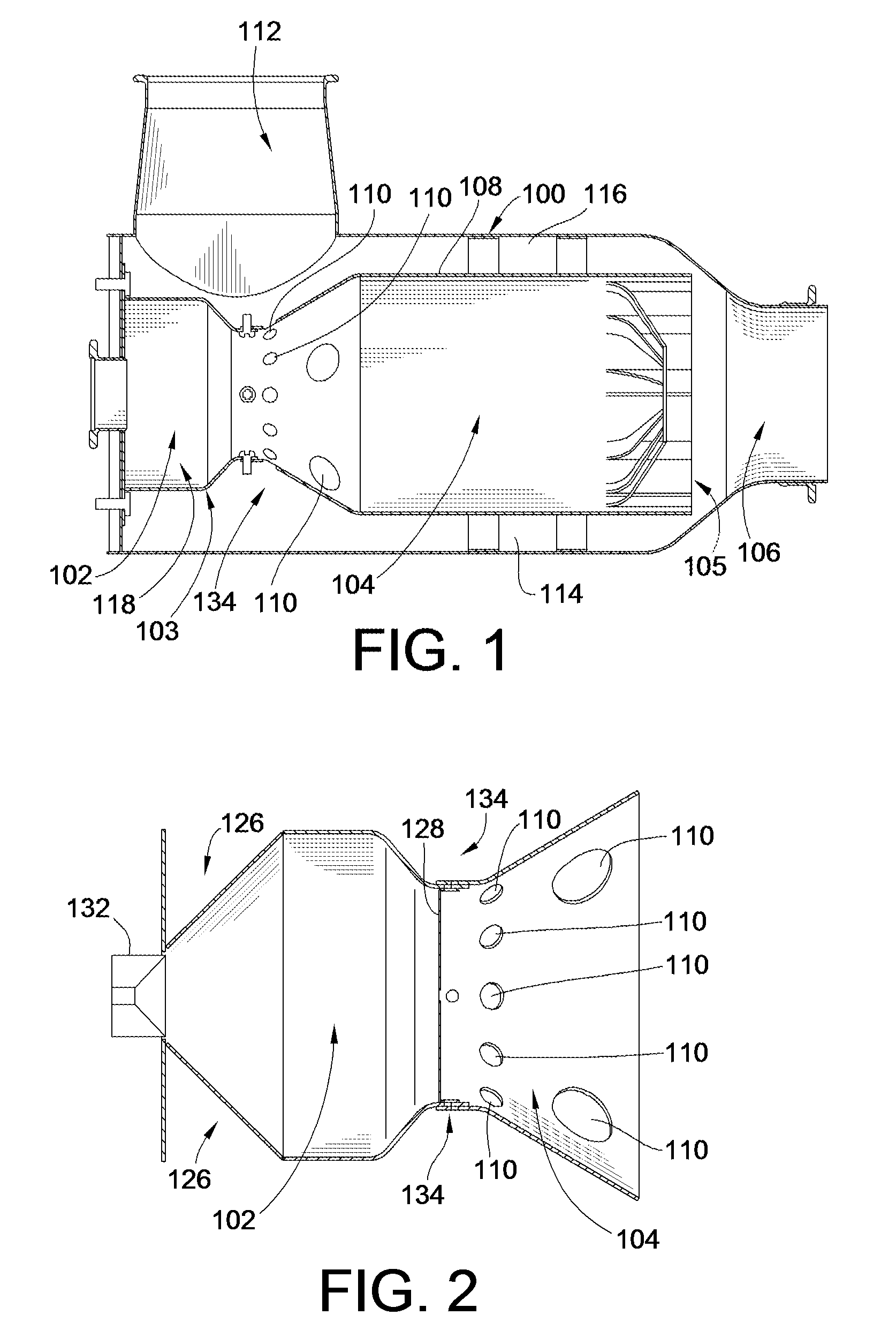

Low pressure drop mixer for radial mixing of internal combustion engine exhaust flows, combustor incorporating same, and methods of mixing

ActiveUS8459017B2Increase surface area and interactionLower overall pressure dropInternal combustion piston enginesFlow mixersCombustion chamberCombustor

An exhaust aftertreatment system is provided. The exhaust aftertreatment system includes a mixing arrangement for mixing flows of exhaust along a flow path. The mixing arrangement radially and angularly rearranges segments of two different portions of flow to mix the different portions of flow. The mixing arrangement initially converts a generally radially stratified temperature profile into an angularly stratified temperature profile to increase surface area between cool segments of exhaust gas and hot segments of exhaust gas. The aftertreatment system may also include a combustion chamber, a combustor housing and a combustor liner. The mixing arrangement is downstream from the combustion chamber to direct radially outward hot gas passing through the combustor liner and to direct radially outer cool gas passing between the liner and the combustor housing radially inward in an interleaving fashion.

Owner:WOODWARD GOVERNOR CO

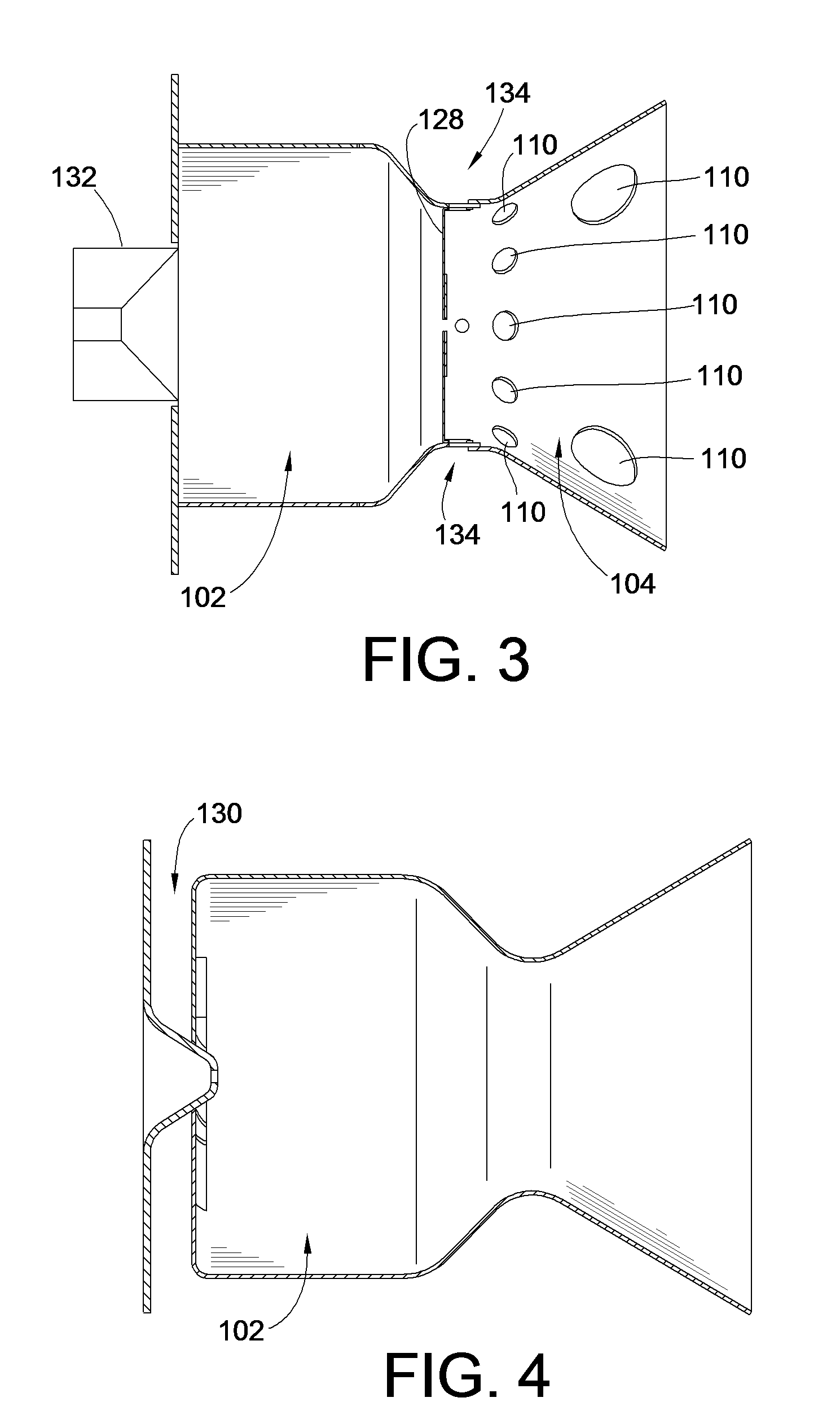

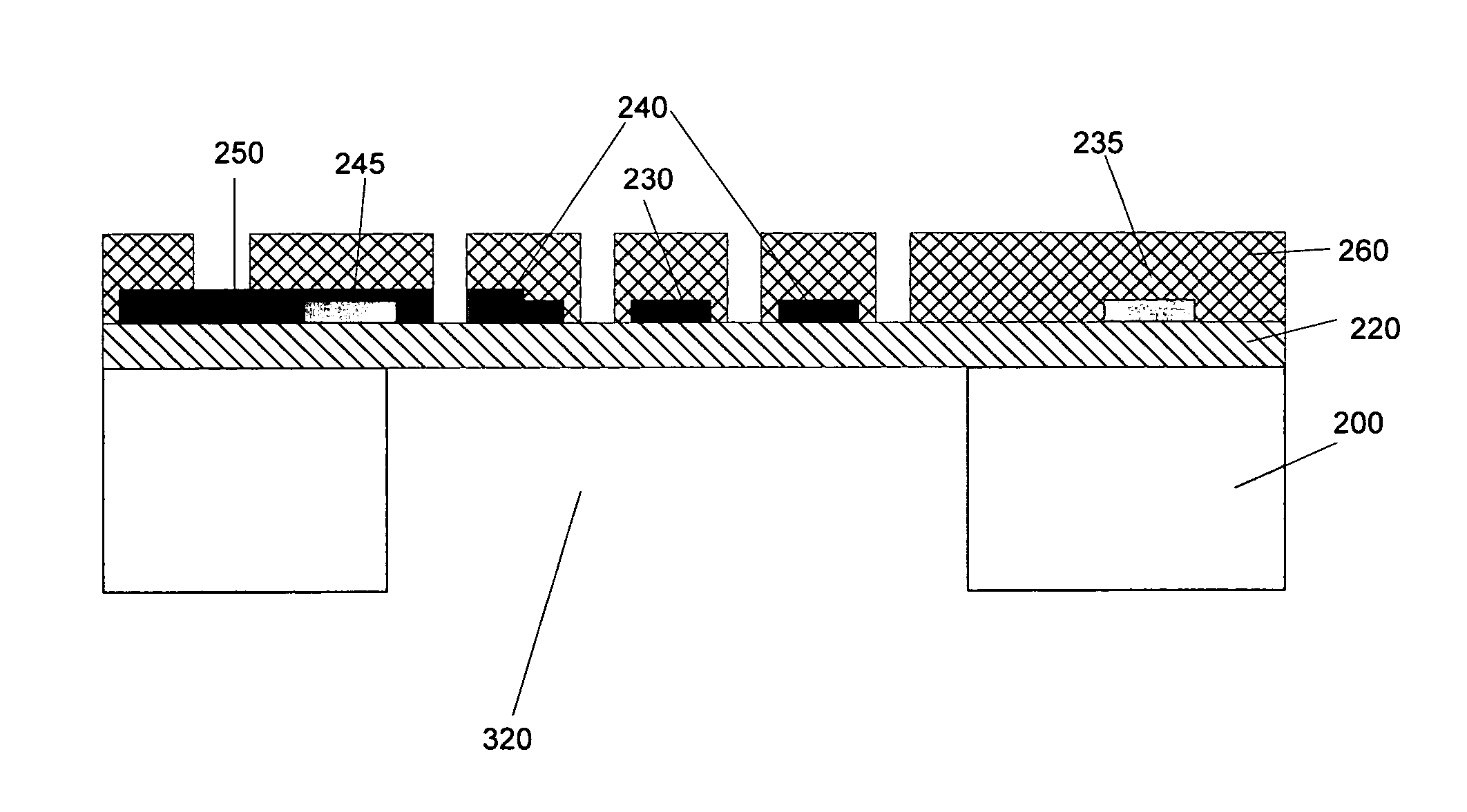

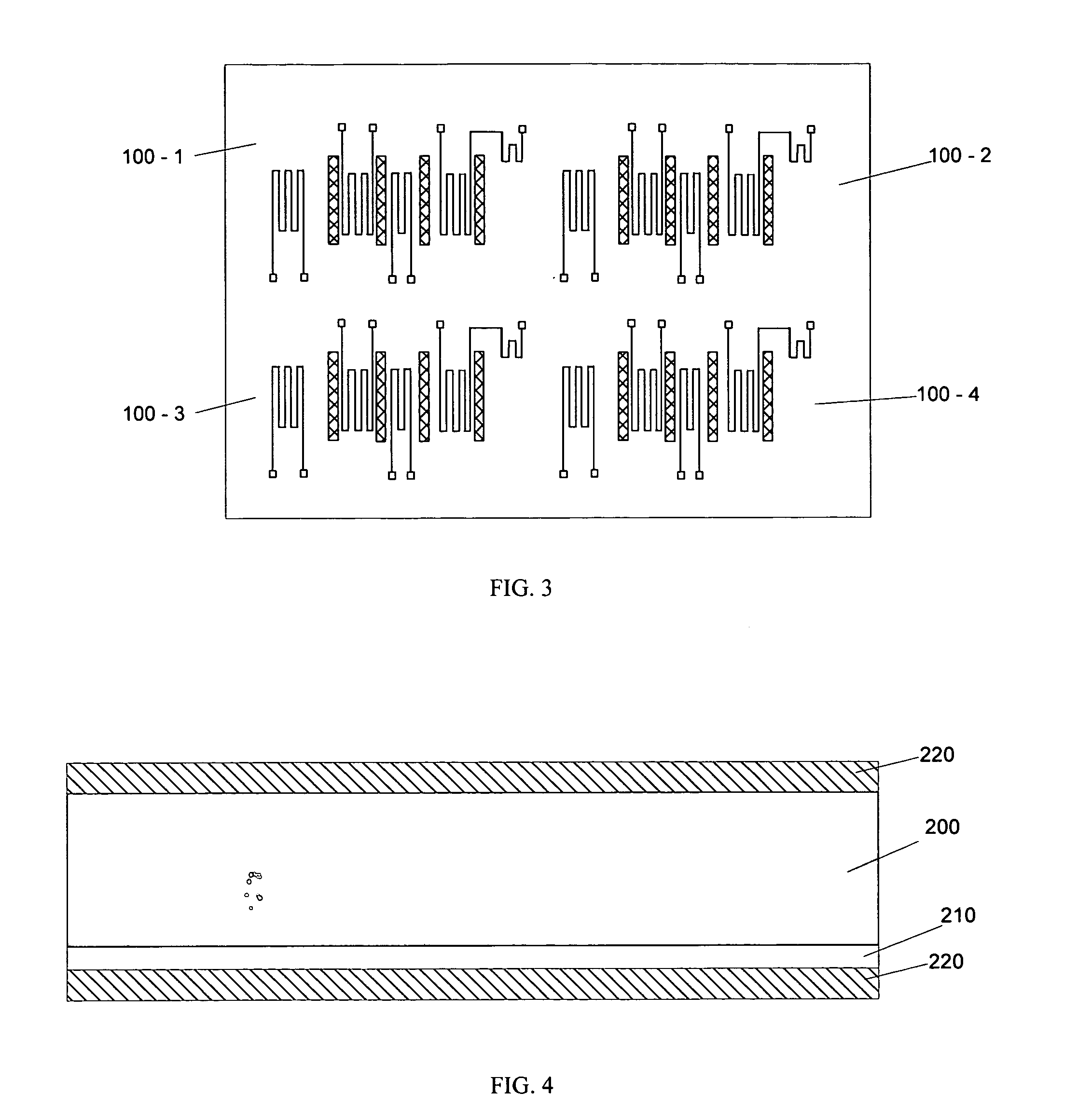

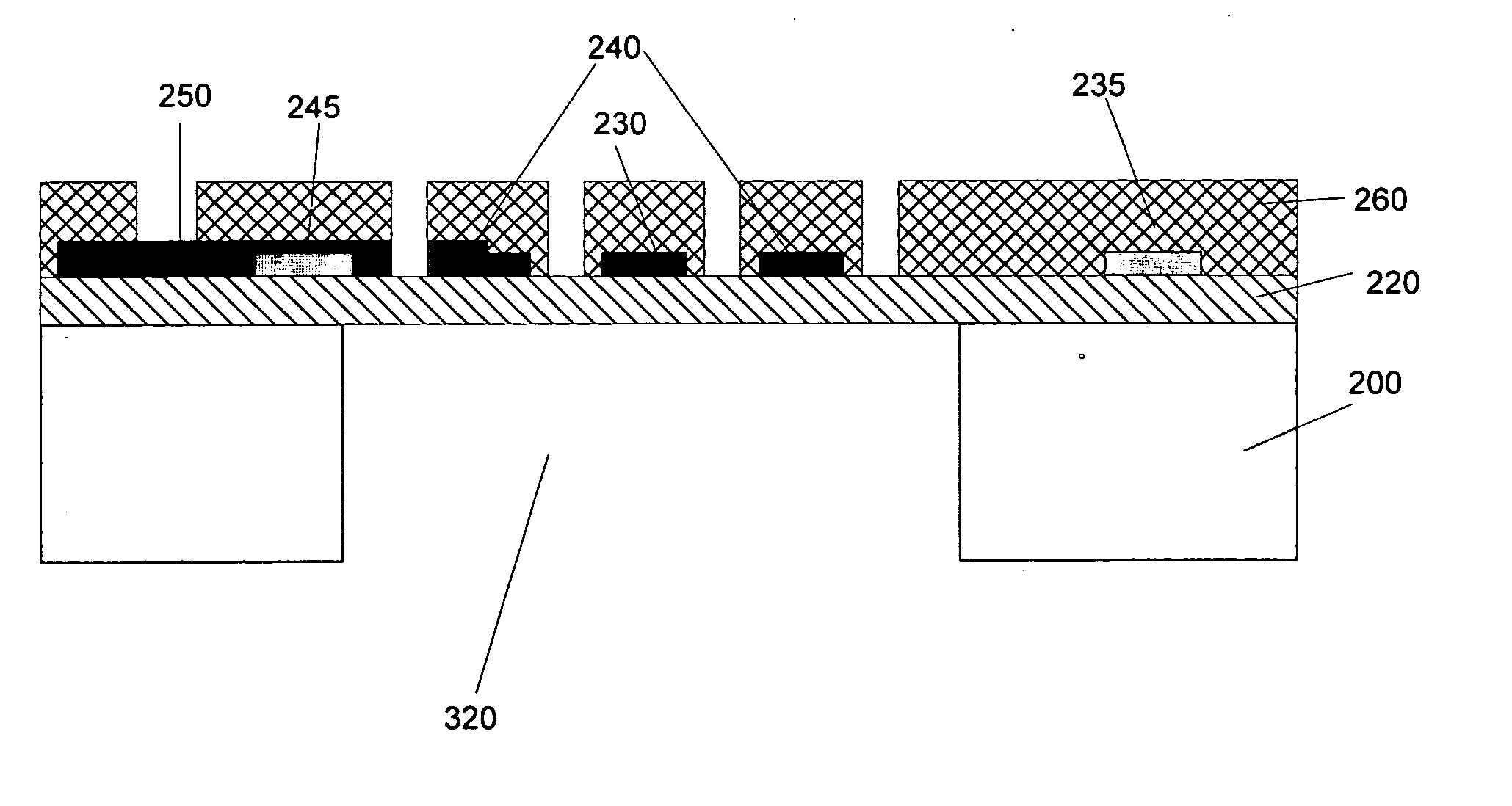

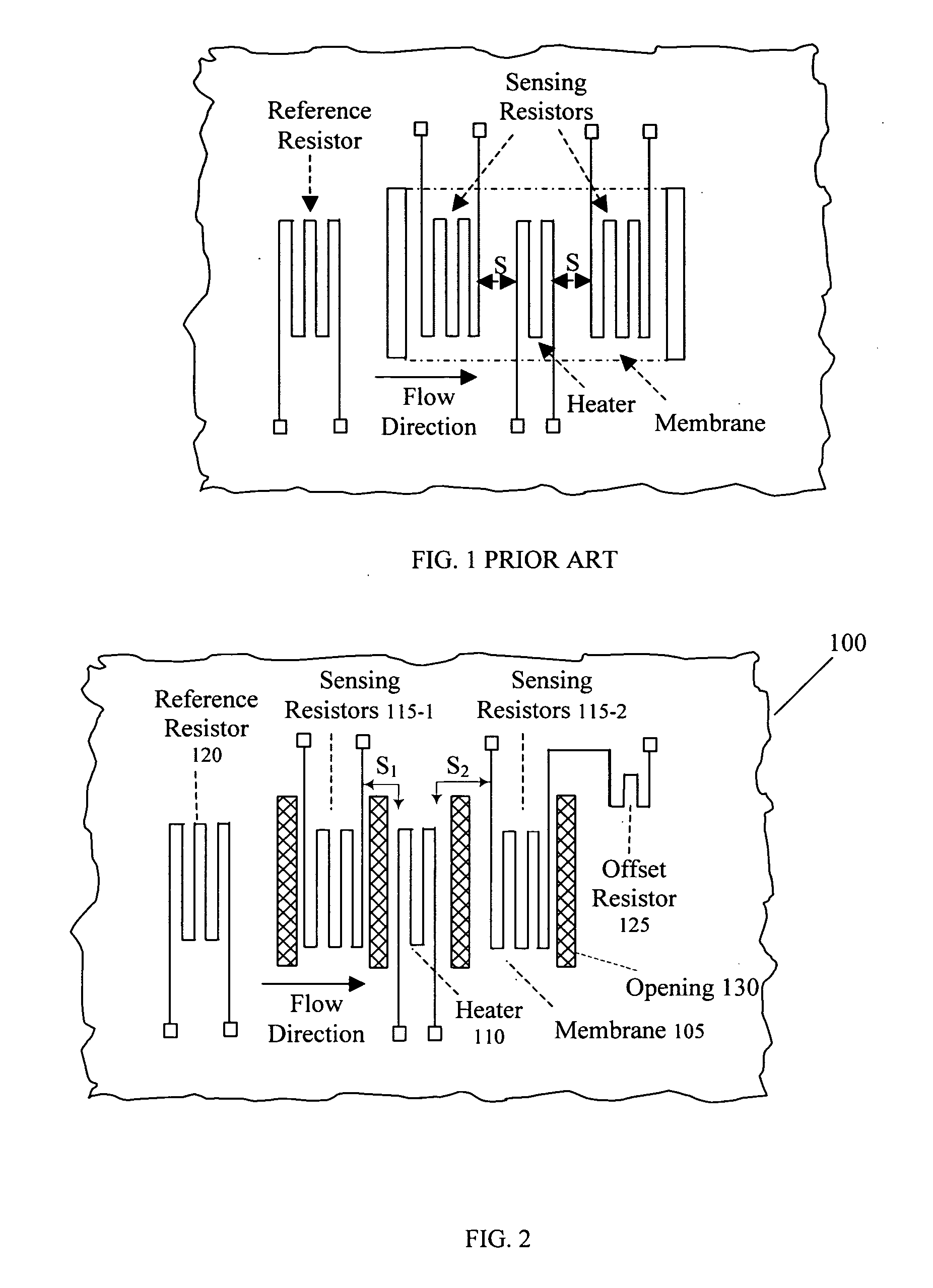

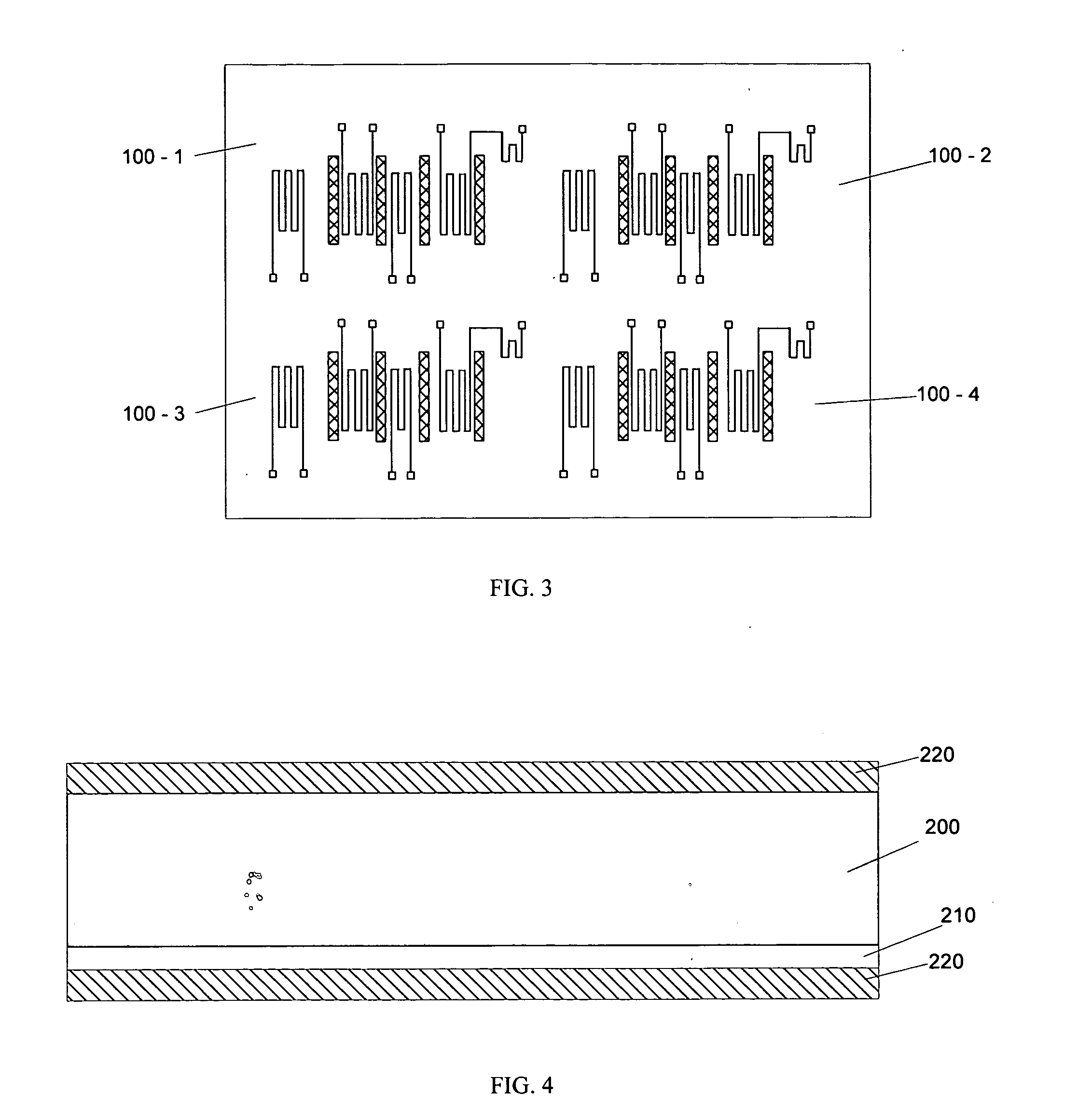

Method of manufacturing a flow rate sensor

ActiveUS7765679B2Reduce power consumptionLarge flow rangeLine/current collector detailsVolume/mass flow by thermal effectsEngineeringP type silicon

A mass flow sensor is manufactured by a process of carrying out a micro-machining process on an N or lightly doped P-type silicon substrate with orientation <100>. This mass flow sensor comprises a central thin-film heater and a pair of thin-film heat sensing elements, and a thermally isolated membrane for supporting the heater and the sensors out of contact with the substrate base. The mass flow sensor is arranged for integration on a same silicon substrate to form a one-dimensional or two-dimensional array in order to expand the dynamic measurement range. For each sensor, the thermally isolated membrane is formed by a process that includes a step of first depositing dielectric thin-film layers over the substrate and then performing a backside etching process on a bulk silicon with TMAH or KOH or carrying out a dry plasma etch until the bottom dielectric thin-film layer is exposed. Before backside etching the bulk silicon, rectangular openings are formed on the dielectric thin-film layers by applying a plasma etching to separate the area of heater and sensing elements from the rest of the membrane.

Owner:M TECH INSTR HLDG

Micromachined mass flow sensor and methods of making the same

ActiveUS20070011867A1Increased dynamic measurement rangeReduce power consumptionLine/current collector detailsVolume/mass flow by thermal effectsFlow transducerEngineering

A mass flow sensor is manufactured by a process of carrying out a micro-machining process on an N or lightly doped P-type silicon substrate with orientation <100>. This mass flow sensor comprises a central thin-film heater and a pair of thin-film heat sensing elements, and a thermally isolated membrane for supporting the heater and the sensors out of contact with the substrate base. The mass flow sensor is arranged for integration on a same silicon substrate to form a one-dimensional or two-dimensional array in order to expand the dynamic measurement range. For each sensor, the thermally isolated membrane is formed by a process that includes a step of first depositing dielectric thin-film layers over the substrate and then performing a backside etching process on a bulk silicon with TMAH or KOH or carrying out a dry plasma etch until the bottom dielectric thin-film layer is exposed. Before backside etching the bulk silicon, rectangular openings are formed on the dielectric thin-film layers by applying a plasma etching to separate the area of heater and sensing elements from the rest of the membrane.

Owner:M TECH INSTR HLDG

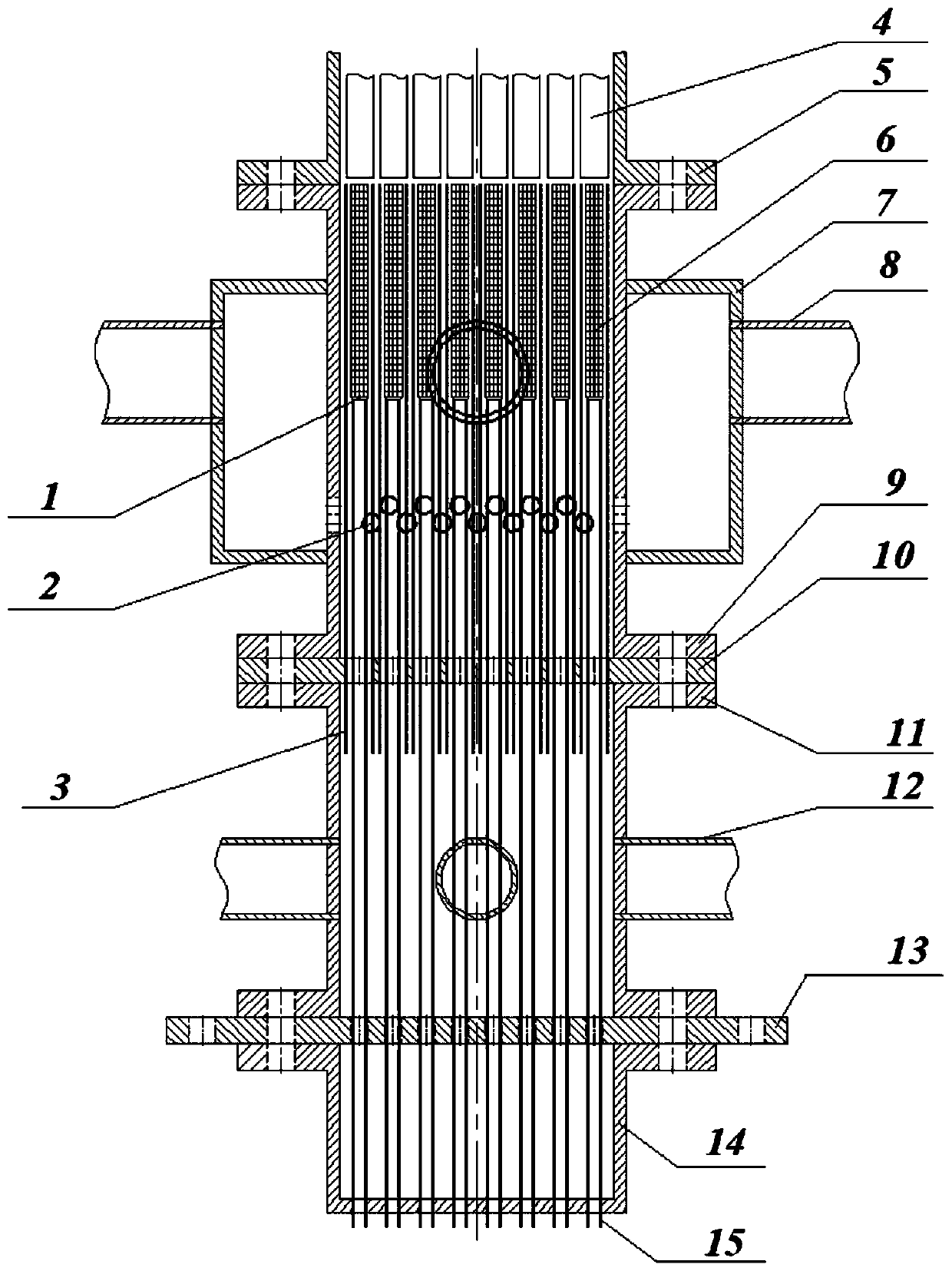

Gas flow standard device

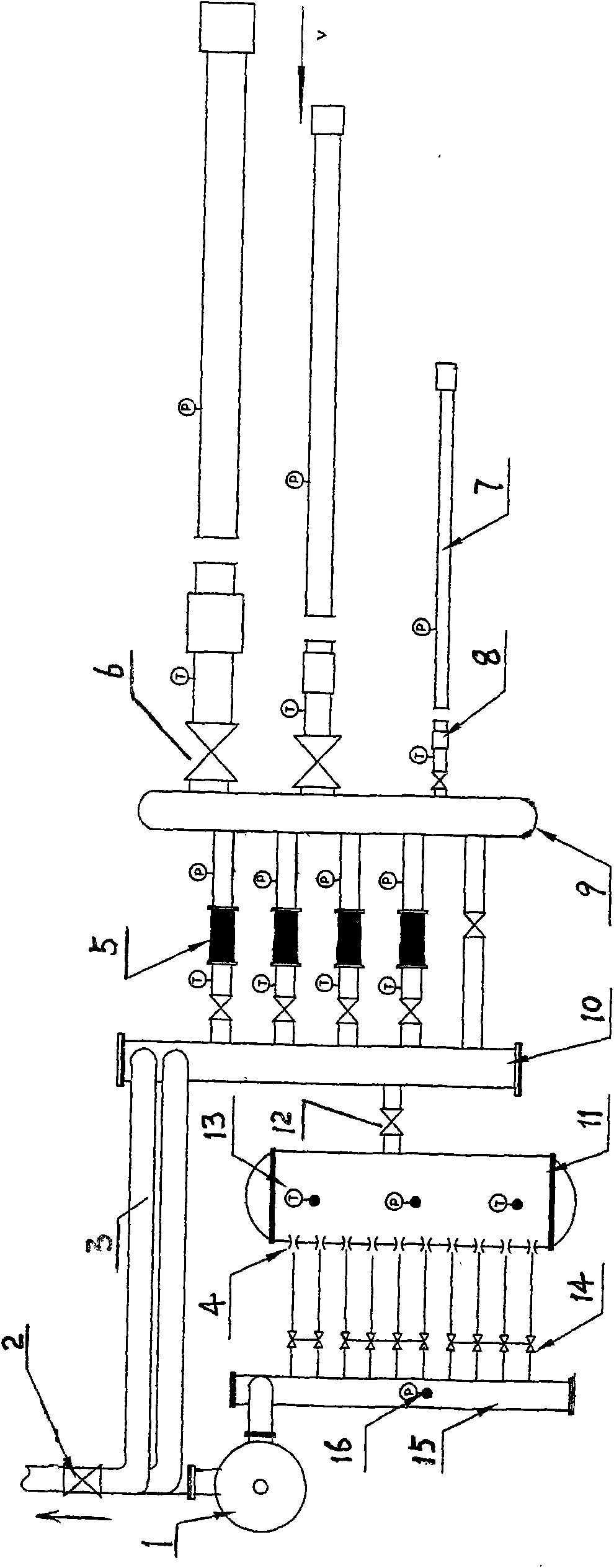

InactiveCN101576403AImprove stabilityGood repeatabilityTesting/calibration apparatusEngineeringTurbine

The invention discloses a gas flow standard device. The input end of a pressure-stabilizing tank (1) is connected with a nozzle collecting tube (15) which is correspondingly connected with a plurality of nozzles (4) on a nozzle container (11); the input end of a nozzle container (12) is connected with a first output end of a standard meter influx tube (10), and a second output end of the standard meter influx tube (10) is connected with a draught fan; one or more standard turbine flowmeters (5) are connected in parallel between the standard meter influx tube (10) and a detected meter influx tube (9), and the input end of the detected meter influx tube (9) is connected with one or more meter clamps (8) for mounting detected meters. A mode of combining the sound-velocity nozzles and the standard turbine flowmeters is adopted so as to exert the advantages of high stability and good repetitiveness of the sound-velocity nozzles and exert the advantages of high precision and wide measuring range of each standard turbine flowmeter.

Owner:孙永岐

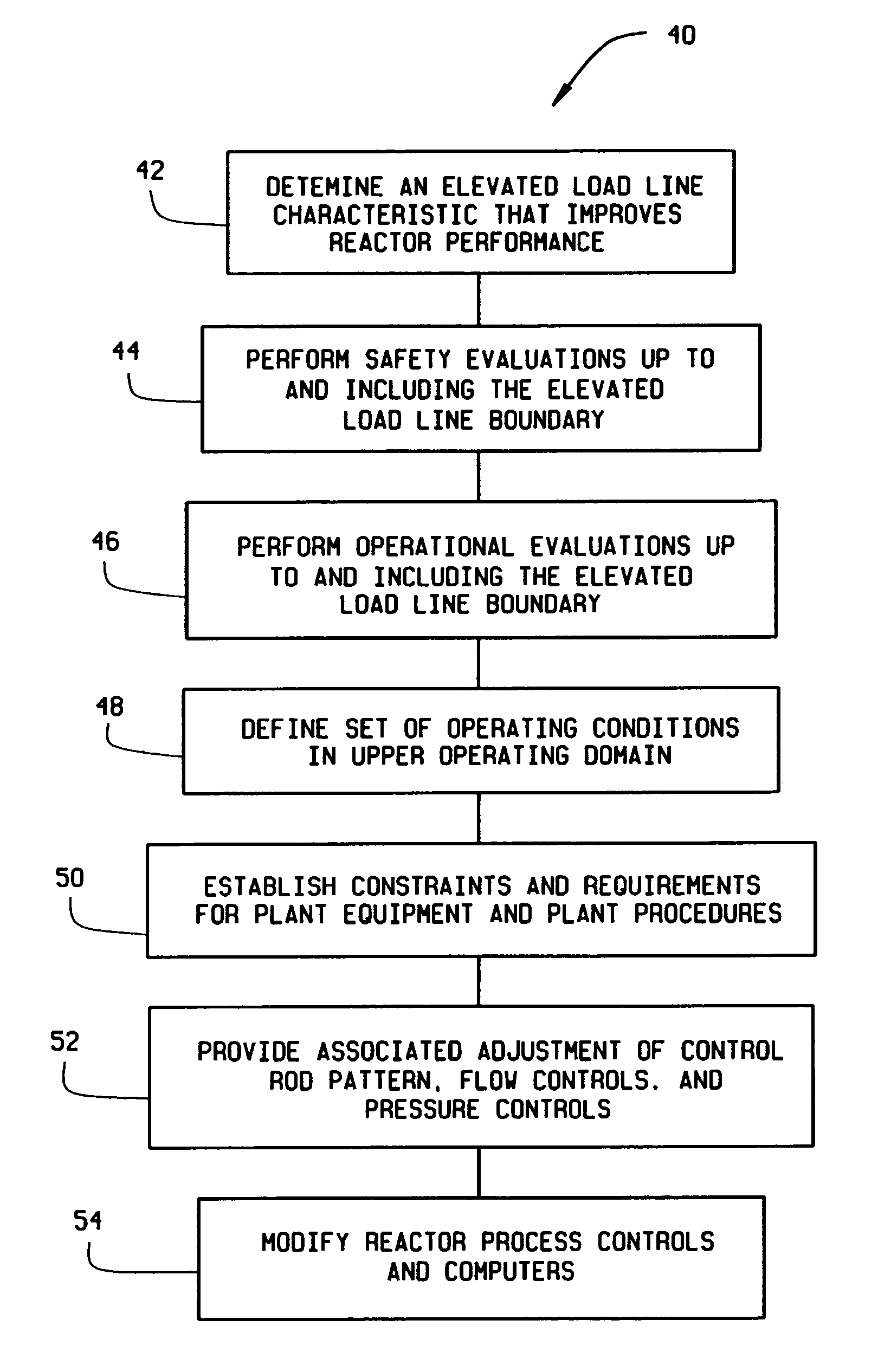

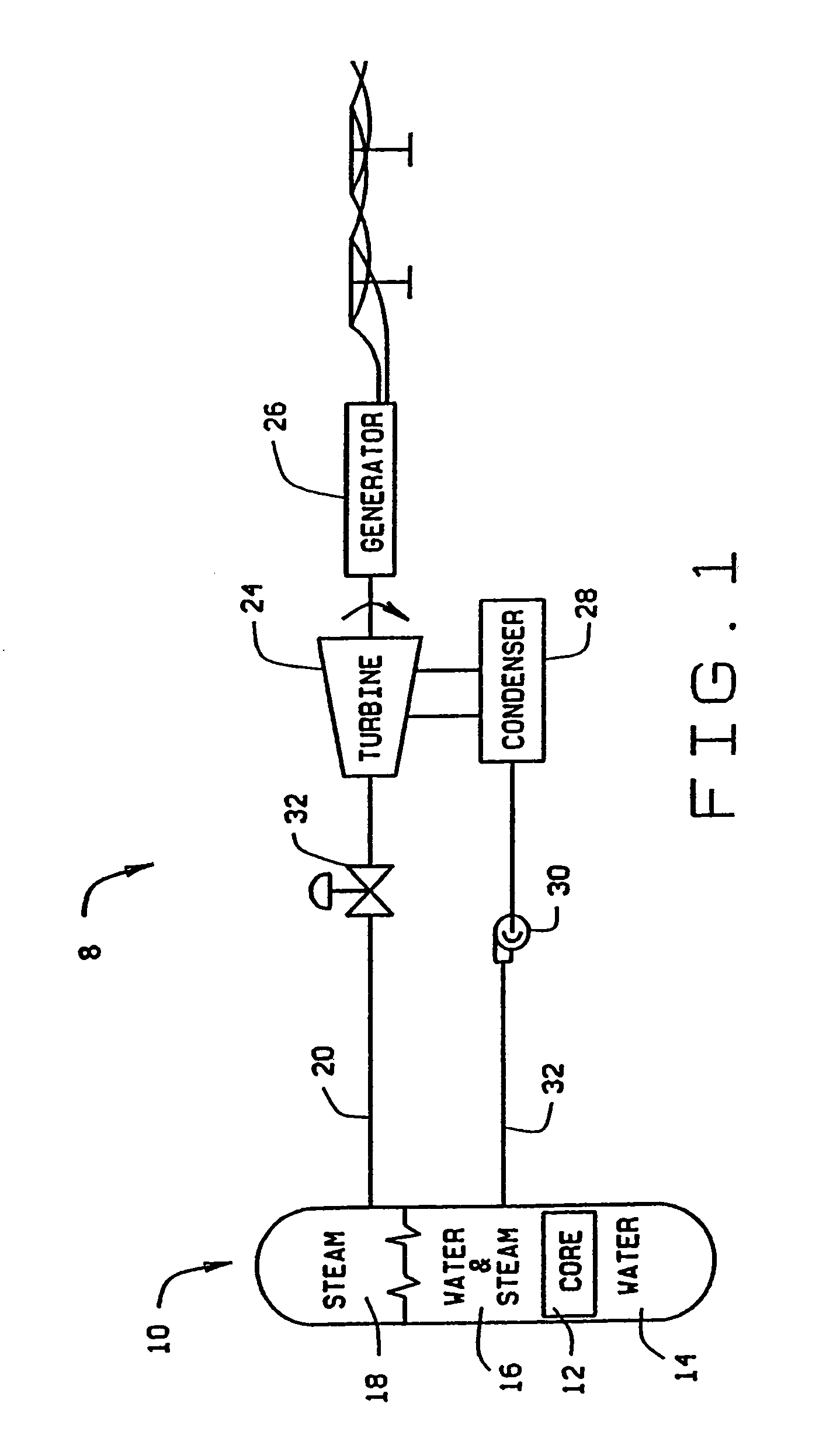

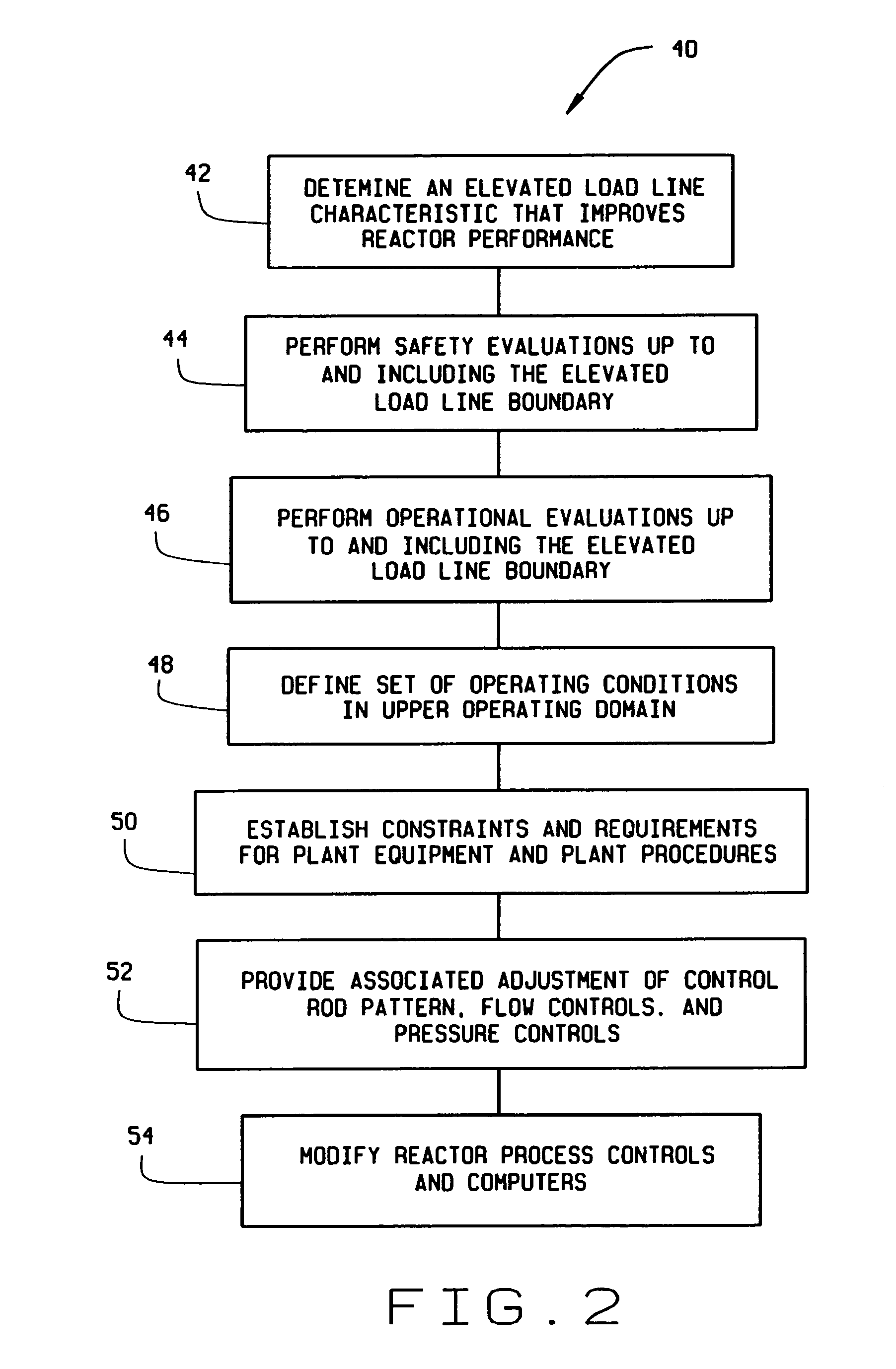

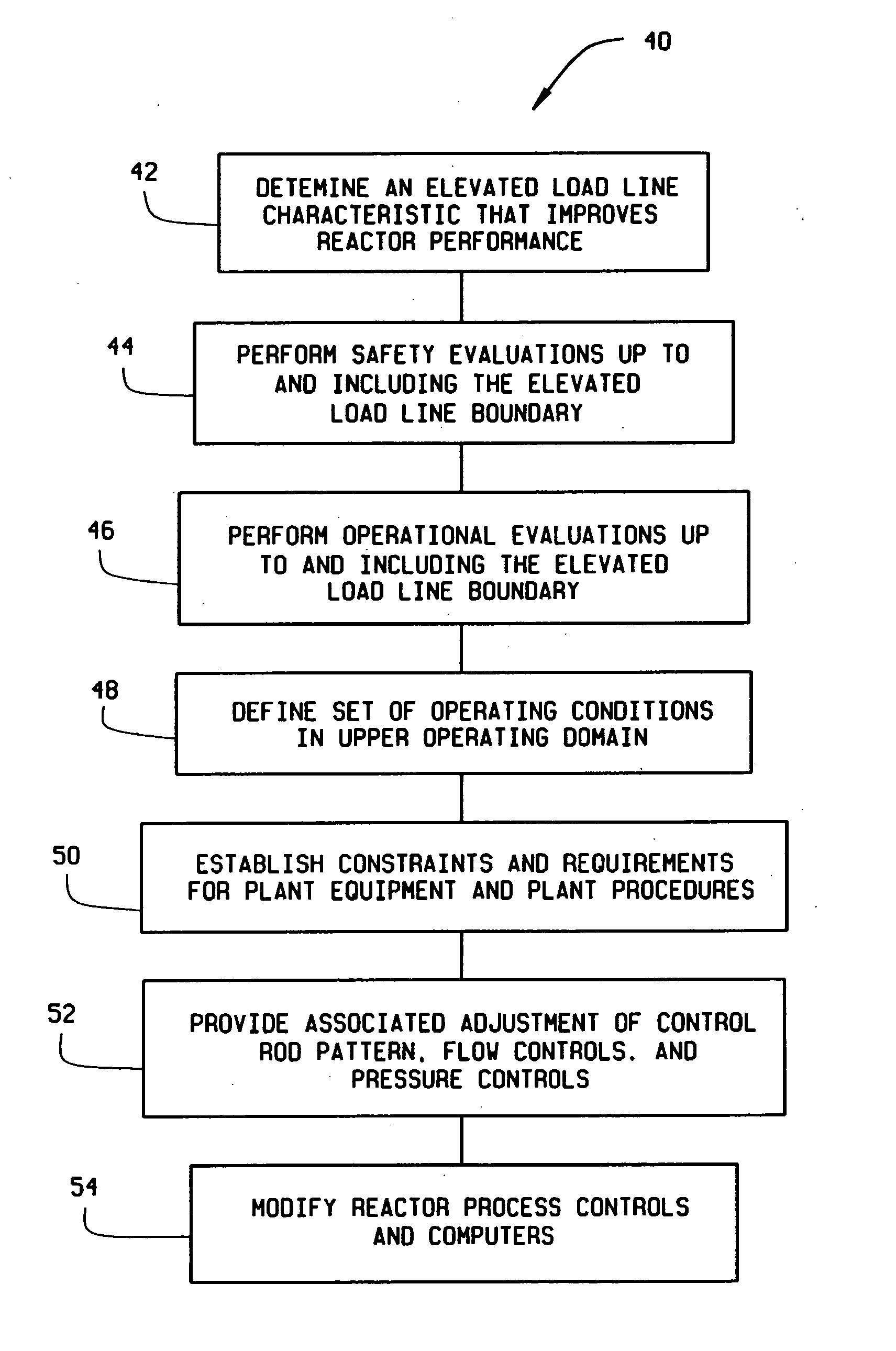

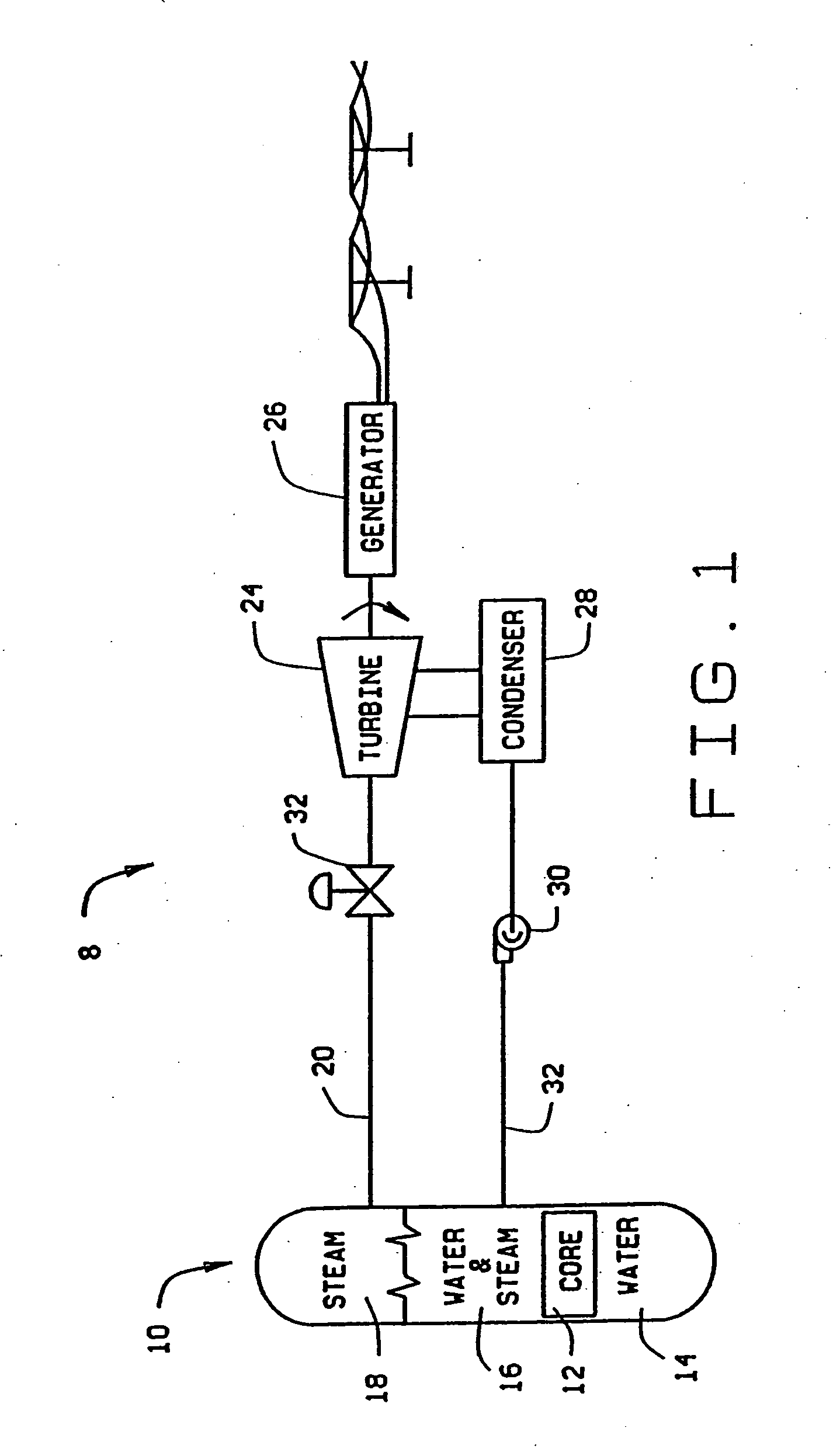

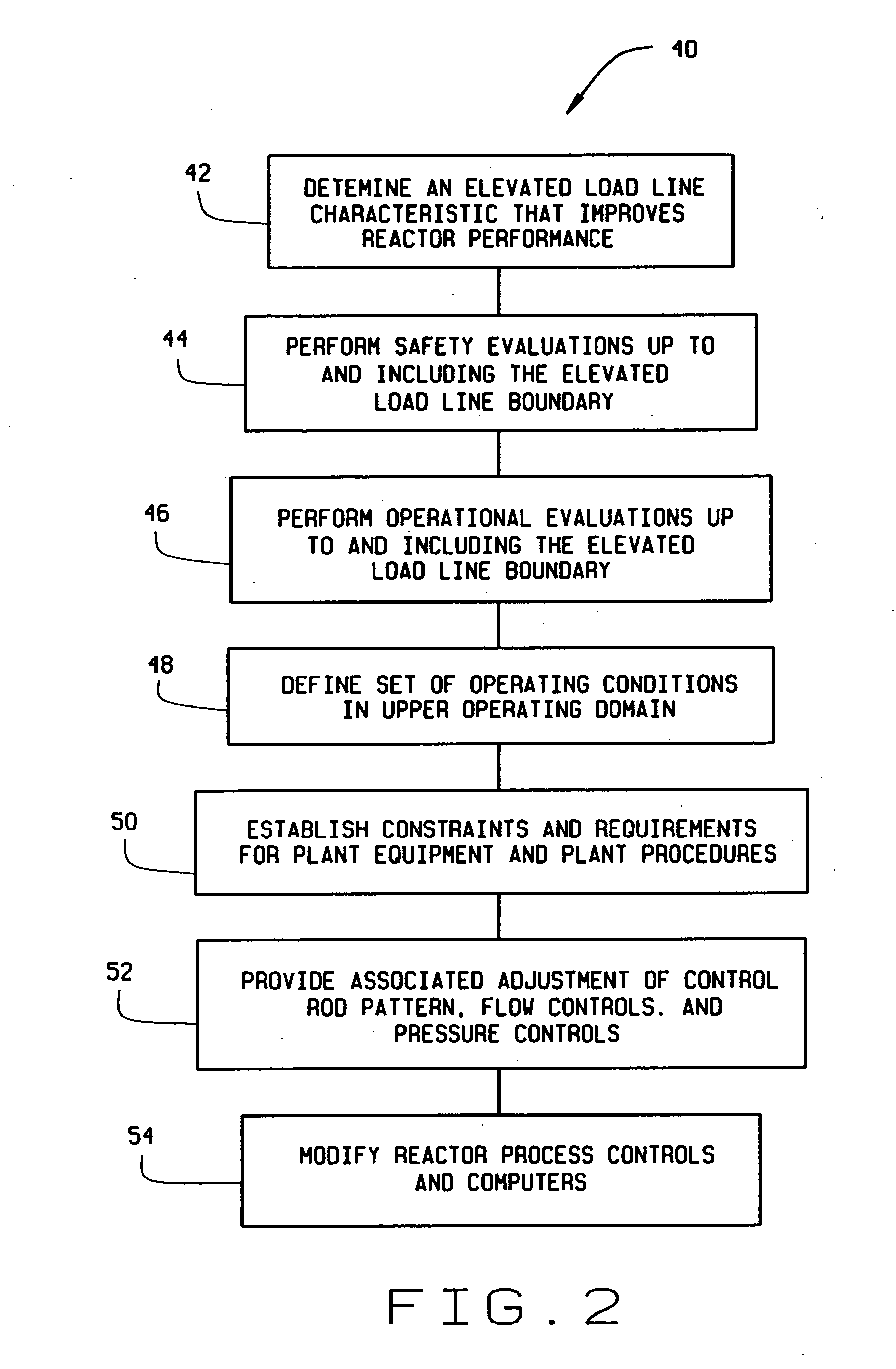

Maximum extended load line limit analysis for a boiling water nuclear reactor

InactiveUS6987826B2Improve performanceLarge flow rangePlant parameters regulationNuclear energy generationNuclear reactorOperant conditioning

A method for expanding the operating domain of a boiling water nuclear reactor that permits safe operation of the reactor at low core flows is described. The operating domain is characterized by a map of the reactor thermal power and core flow. In an exemplary embodiment, the method for expanding the operating domain of a boiling water nuclear reactor permits operation of the reactor between about 120 percent of rated thermal power and about 85 percent of rated core flow to about 100 percent of rated thermal power and about 55 percent of rated core flow. The method includes determining an elevated load line characteristic that improves reactor performance, performing safety evaluations at the elevated load line to determine compliance with safety design parameters, and performing operational evaluations at the elevated load line. The method also includes defining a set of operating conditions for the reactor in an upper operating domain characterized by the elevated load line. Additionally, the method includes performing a detailed analysis of the performance of the core recirculation system and the system control components. further, the method provides for modifying the reactor process controls and computers to permit the reactor to operate in the expanded operating domain within predetermined safety parameters. Also, safety mitigation action setpoints are adjusted to permit reactor operation in the expanded operating domain.

Owner:GENERAL ELECTRIC CO

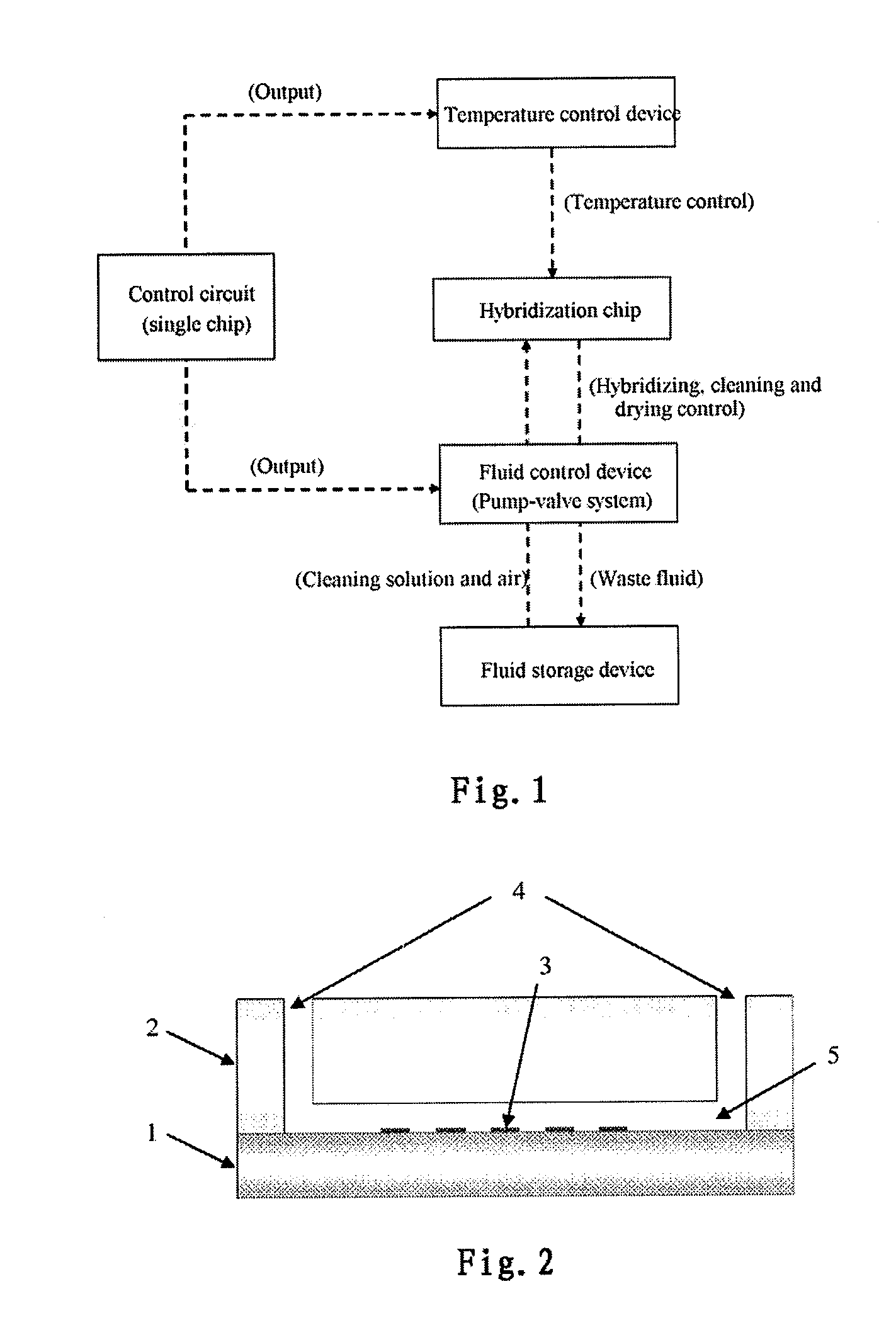

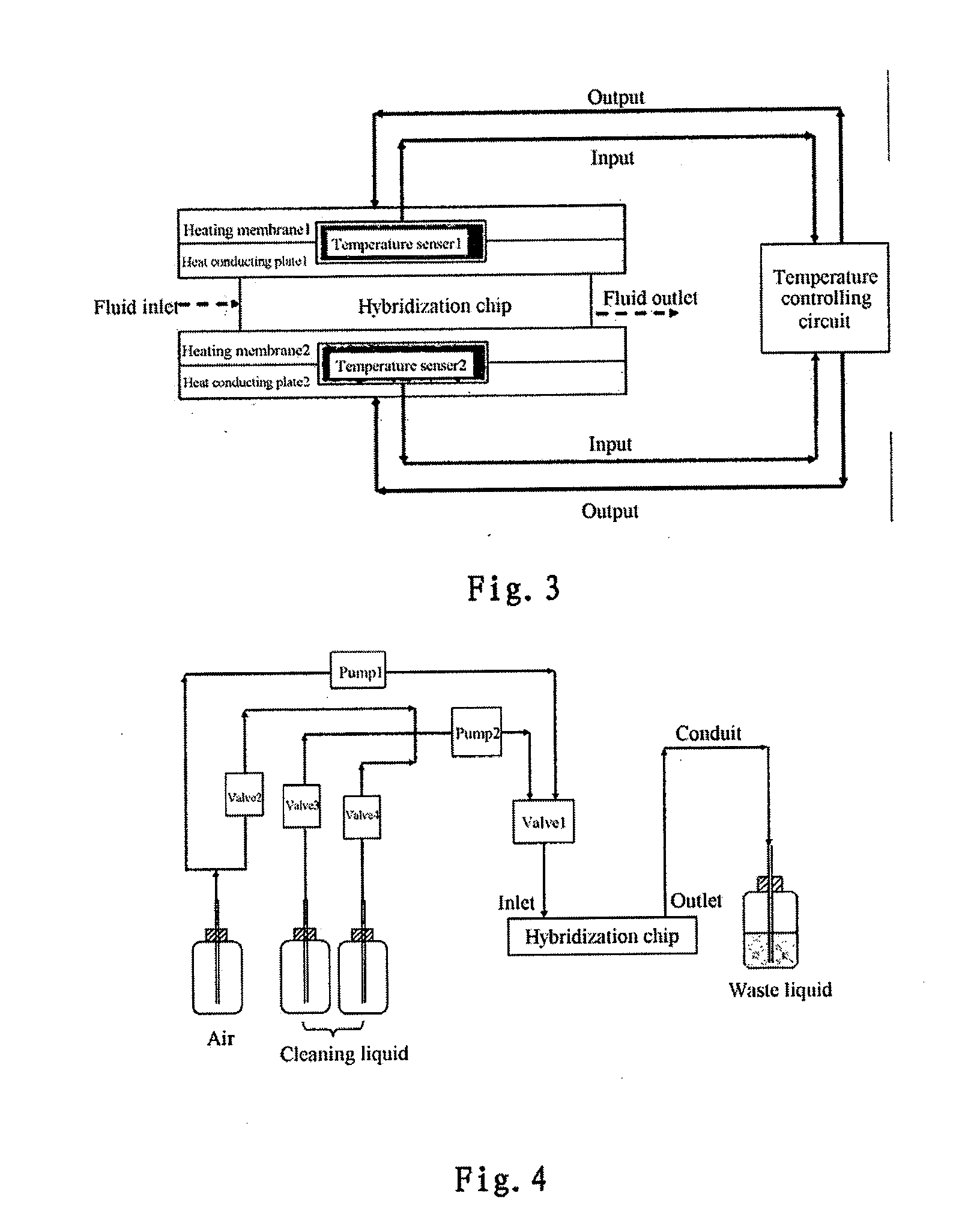

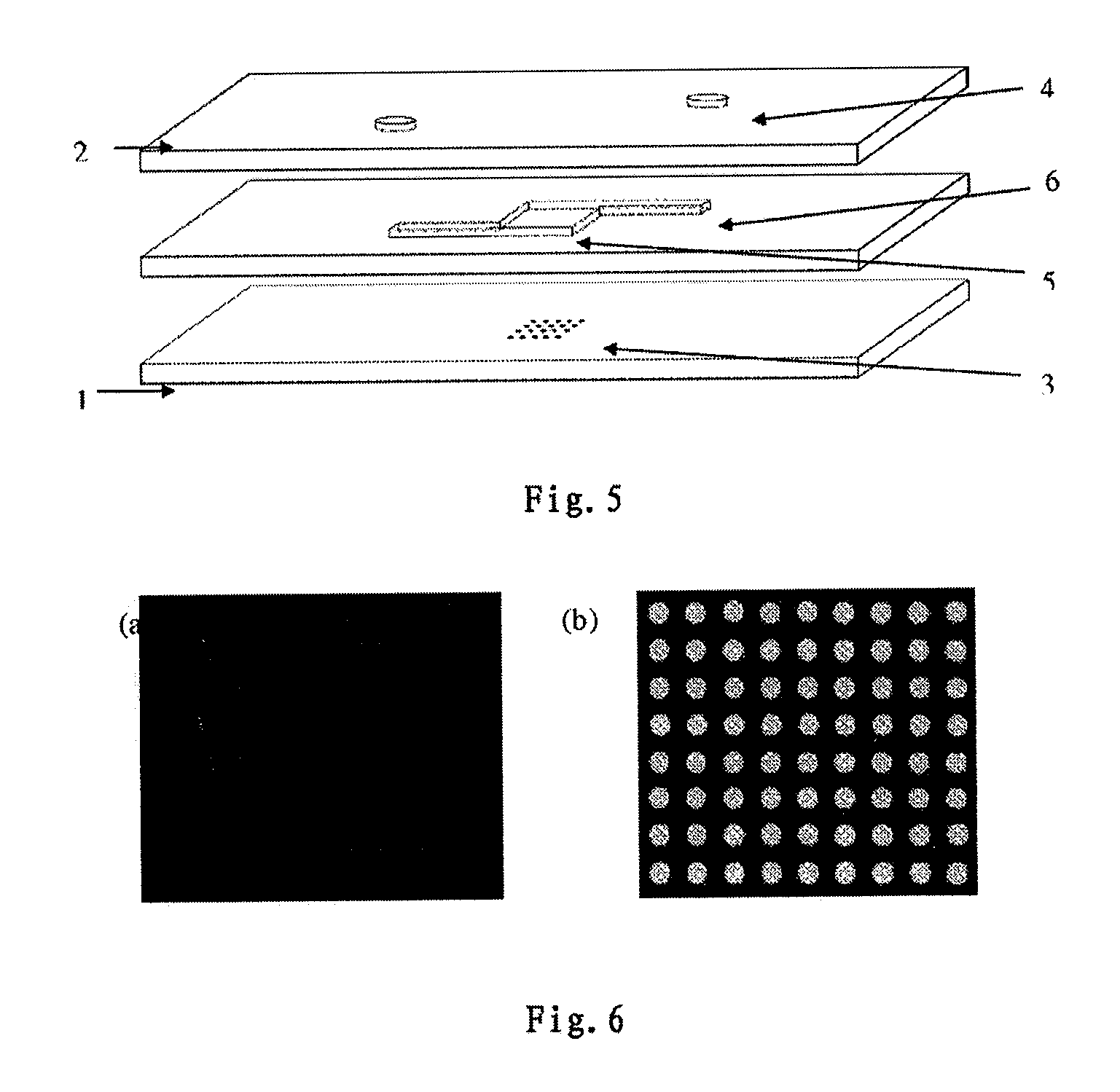

Biological chip hybridization system

ActiveUS20140011707A1Increase and reduces pressureEasy to controlHeating or cooling apparatusNucleotide librariesFluid controlAutomatic control

A hybridization system is provided, which comprises a biological chip having a substrate (1) with a probe dot matrix (3) and a cover plate (2) with at least two through-holes (4), where a hybrid chamber (5) is formed between the substrate (1) and the cover plate (2), at least two fluid channels (6) are interconnected respectively with the hybrid chamber (5) by the two through-holes (4), and a fluid control device is interconnected with the fluid channels (6). The biological chip hybridization system integrates hybridizing, cleaning and drying functions, uses power provided by the fluid control device as the drive force for promoting the liquid flow for automatically reciprocation flow in the fluid channels (6) and the chamber (5) to achieve a dynamic hybridization, thus improving the hybrid efficiency and uniformity, and achieving automatic control.

Owner:CAPITALBIO CORP +1

Maximum extended load line limit analysis for a boiling water nuclear reactor

InactiveUS20050117685A1Improve performanceLarge flow rangePlant parameters regulationNuclear energy generationNuclear reactorSafe operation

A method for expanding the operating domain of a boiling water nuclear reactor that permits safe operation of the reactor at low core flows is described. The operating domain is characterized by a map of the reactor thermal power and core flow. In an exemplary embodiment, the method for expanding the operating domain of a boiling water nuclear reactor permits operation of the reactor between about 120 percent of rated thermal power and about 85 percent of rated core flow to about 100 percent of rated thermal power and about 55 percent of rated core flow. The method includes determining an elevated load line characteristic that improves reactor performance, performing safety evaluations at the elevated load line to determine compliance with safety design parameters, and performing operational evaluations at the elevated load line. The method also includes defining a set of operating conditions for the reactor in an upper operating domain characterized by the elevated load line. Additionally, the method includes performing a detailed analysis of the performance of the core recirculation system and the system control components. further, the method provides for modifying the reactor process controls and computers to permit the reactor to operate in the expanded operating domain within predetermined safety parameters. Also, safety mitigation action setpoints are adjusted to permit reactor operation in the expanded operating domain.

Owner:GENERAL ELECTRIC CO

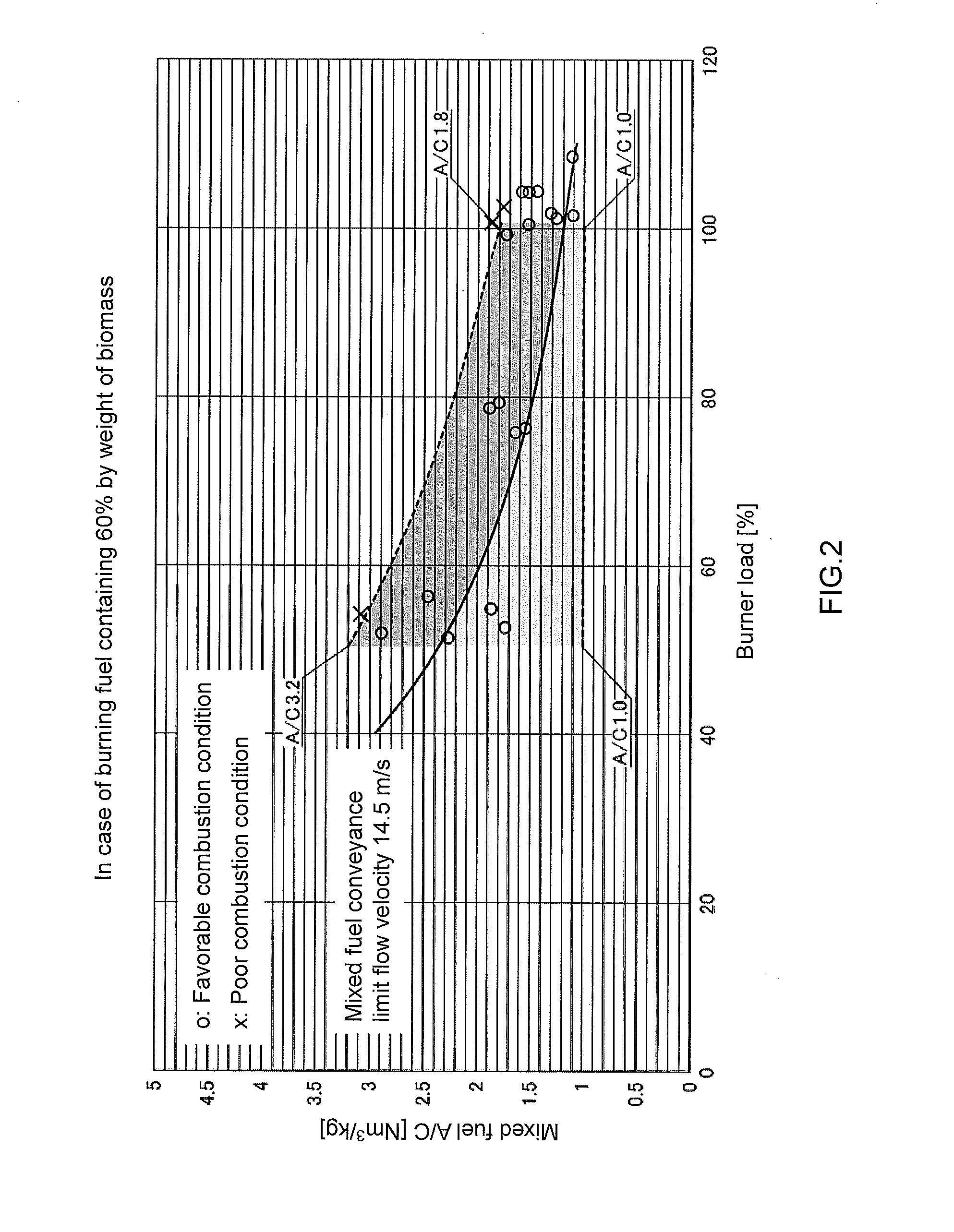

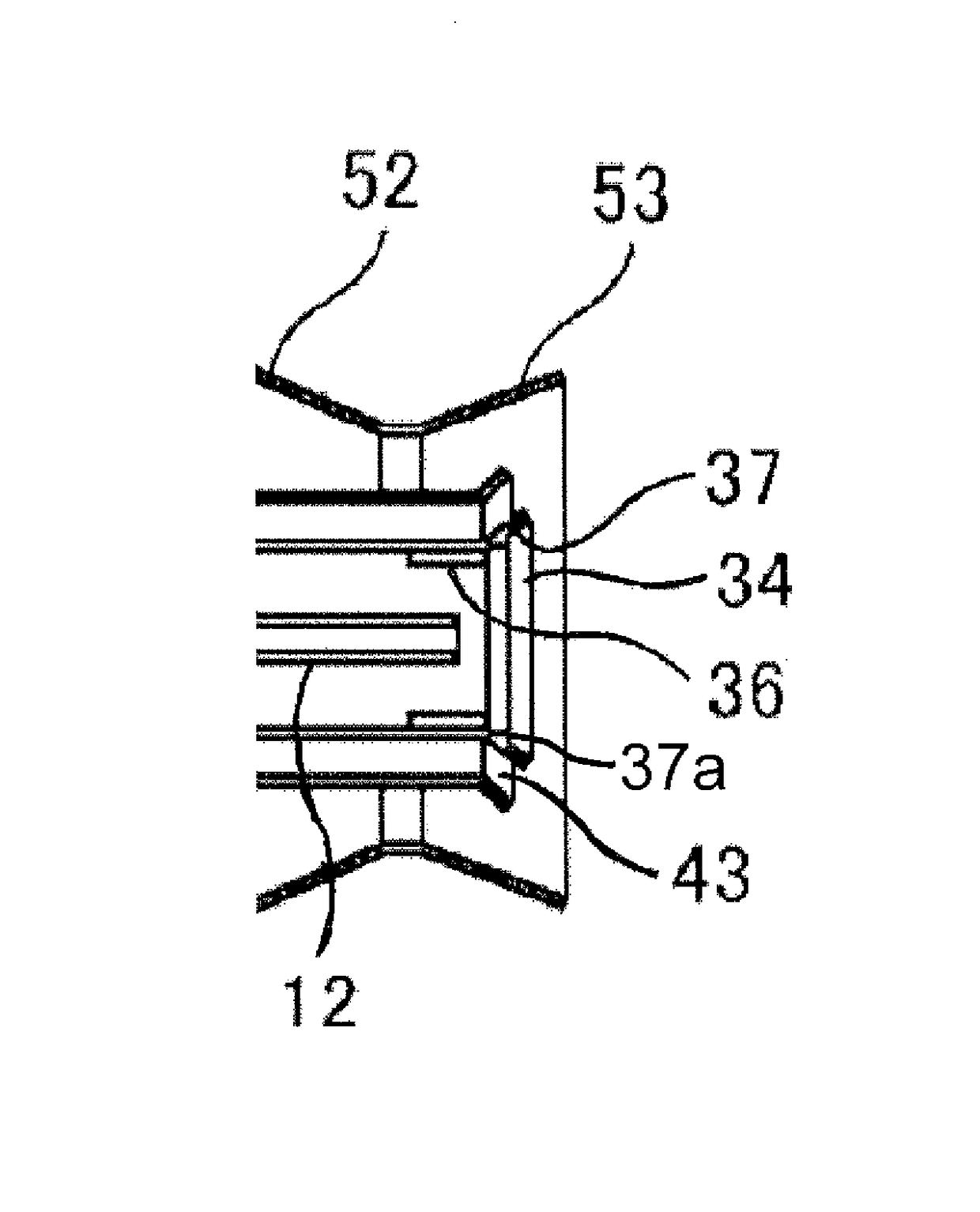

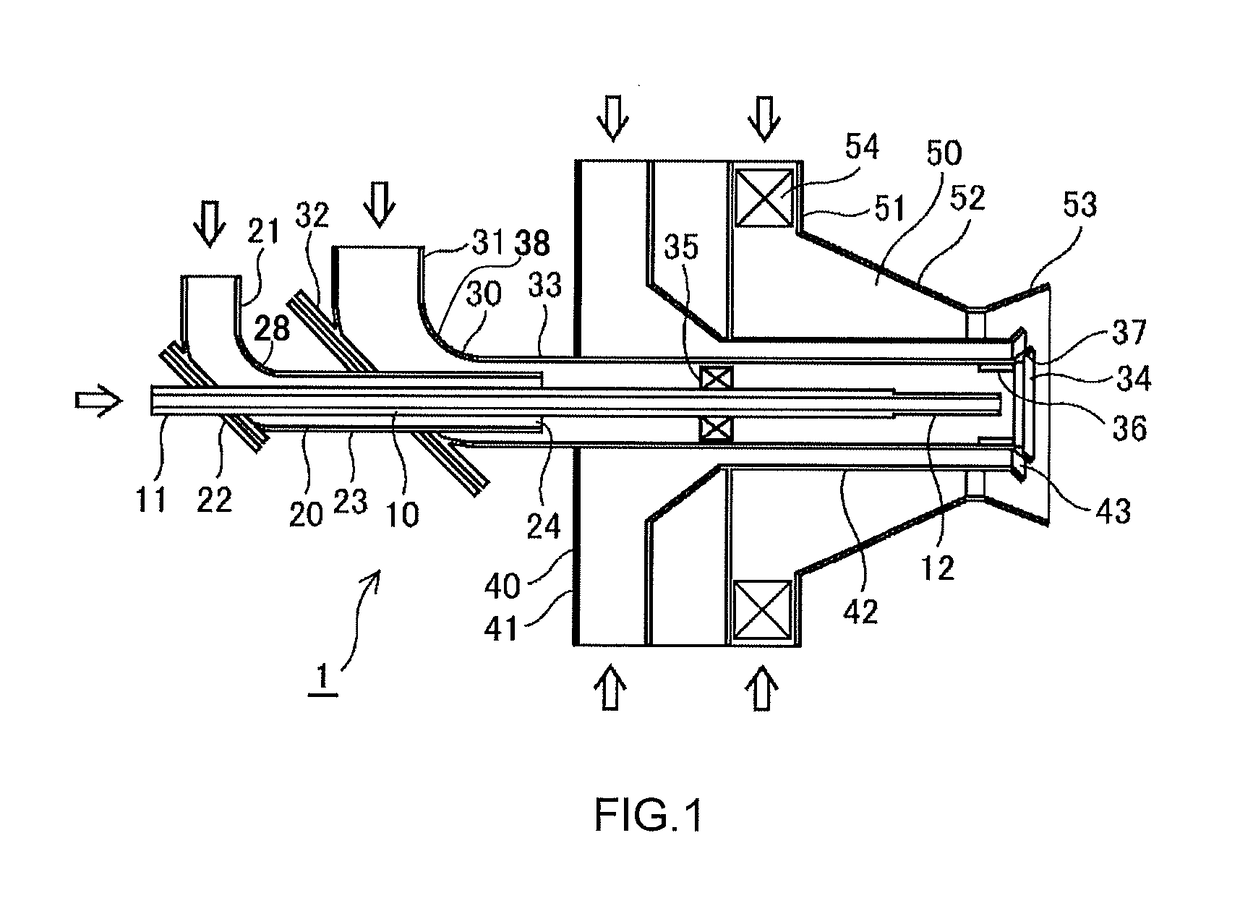

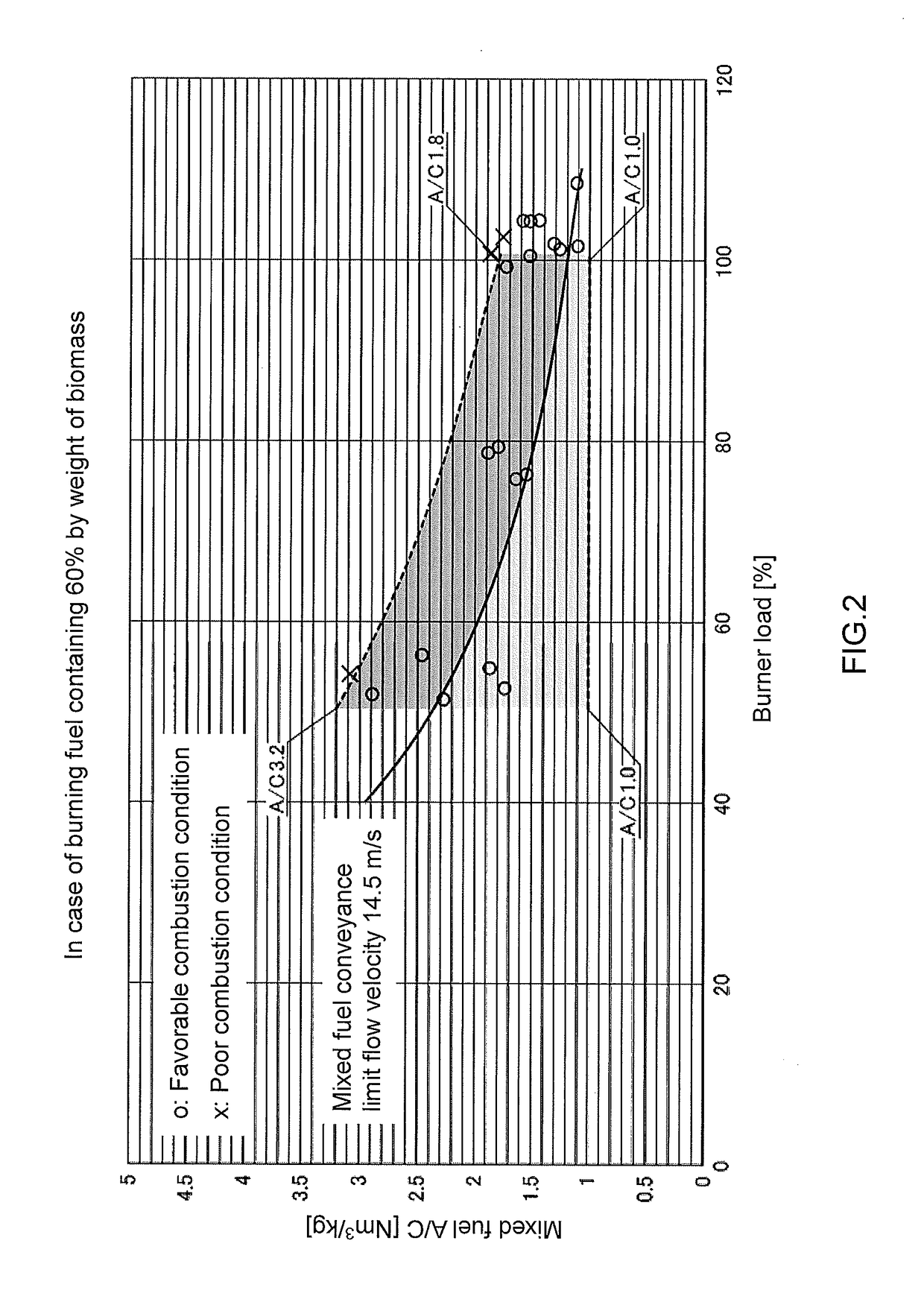

Biomass-mixed, pulverized coal-fired burner and fuel combustion method

ActiveUS20150053124A1Reduce NOxImprove flame stabilityPilot flame ignitersStaged combustionHigh concentrationCombustion

A biomass-mixed, pulverized coal-fired burner is provided, capable of burning biomass fuel as auxiliary fuel in large quantities and burning only pulverized coal when the biomass fuel is not sufficiently available. The biomass-mixed, pulverized coal-fired burner includes a biomass fuel jet nozzle that extends axially along the biomass-mixed, pulverized coal-fired burner, a fuel jet nozzle that is open midway in the biomass fuel jet nozzle, a secondary air nozzle that surrounds the fuel jet nozzle, and a tertiary air nozzle that surrounds the secondary air nozzle. A pulverized coal component in a fuel stream as a mixture of the pulverized coal fuel stream and the biomass fuel stream is distributed with a higher concentration on an outer circumferential wall side and a biomass fuel component in the fuel stream is distributed inside of the pulverized coal fuel component.

Owner:KAWASAKI HEAVY IND LTD

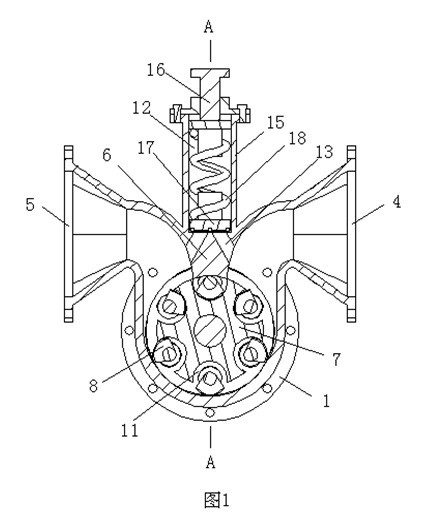

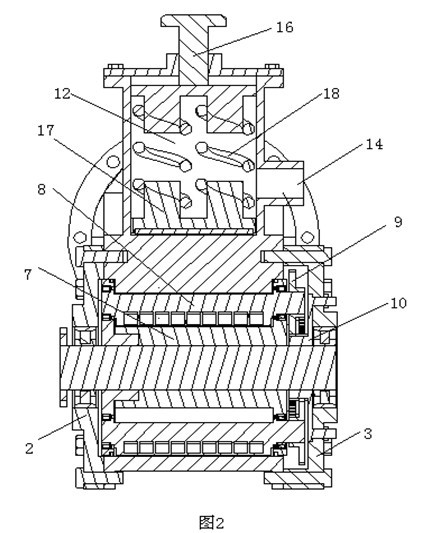

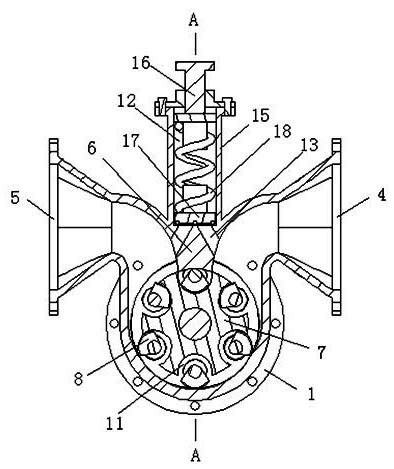

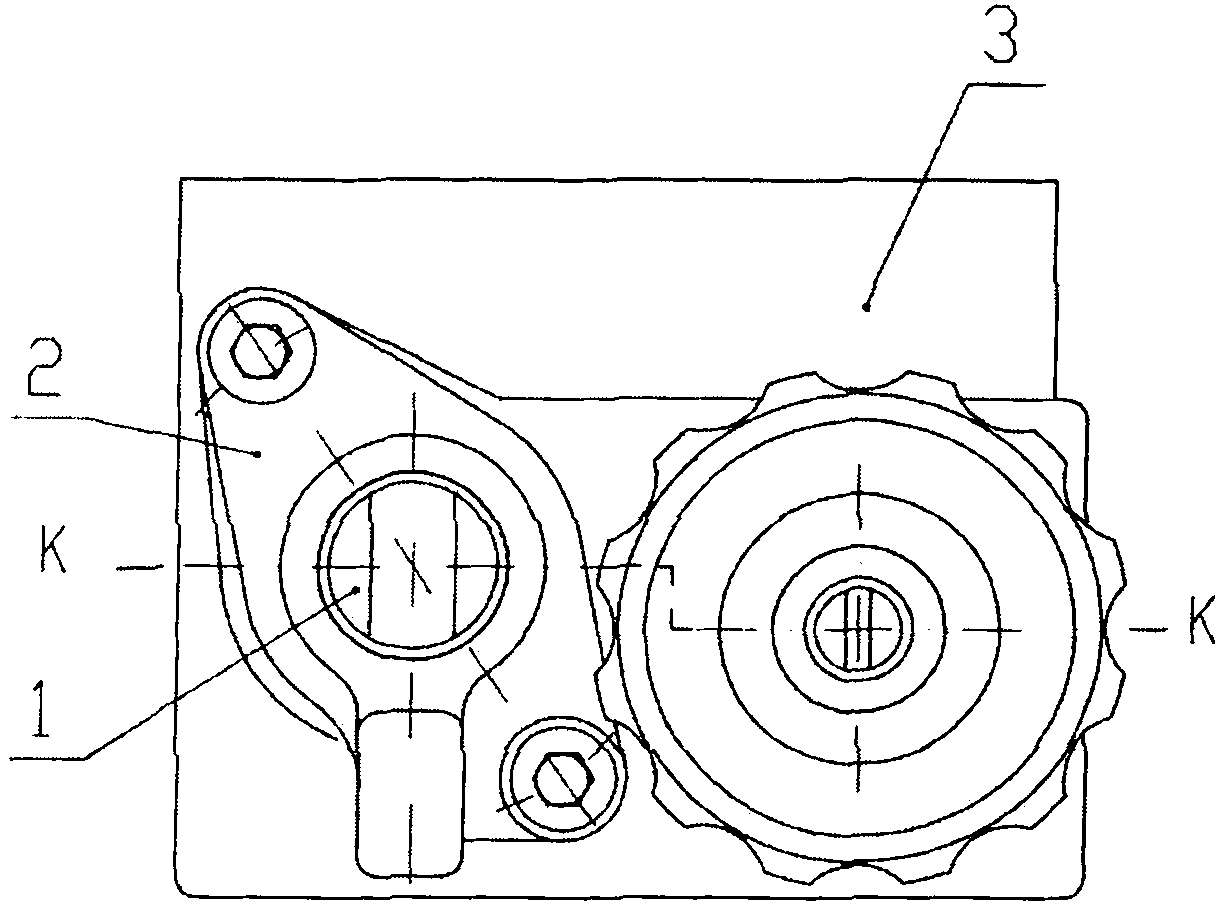

Rotary piston pump

InactiveCN102032174ARealize functionSimple working principleRotary piston pumpsRotary piston liquid enginesEngineeringHigh pressure

The invention discloses a rotary piston pump and relates to a rotary piston pump for continuously changing pressure at water inlet and outlet ends of a pump cavity through a rotary piston structure so as to fulfill the aims of pumping and sucking water. In order to overcome the defects in the prior art, the invention provides a rotary piston pump with the advantages of high efficiency, high pressure, simple structure, excellent performance and wide application range. In order to fulfill the aims, the technical scheme is that: the rotary piston pump comprises a hollow shell, wherein two ends of the shell are open and are respectively provided with a front cover and a rear cover with sealing performance; the upper part of the shell is respectively provided with a water inlet and a water outlet; an isolated body is arranged between the water inlet and the water outlet; a rotating device is arranged inside the shell; and the water inlet is separated from the water outlet through the rotating device and the isolated body. The rotary piston pump overcomes the defects of low efficiency and low pressure in the prior art, and can be applied to high-pressure fluid transmission on various occasions.

Owner:杨家轩

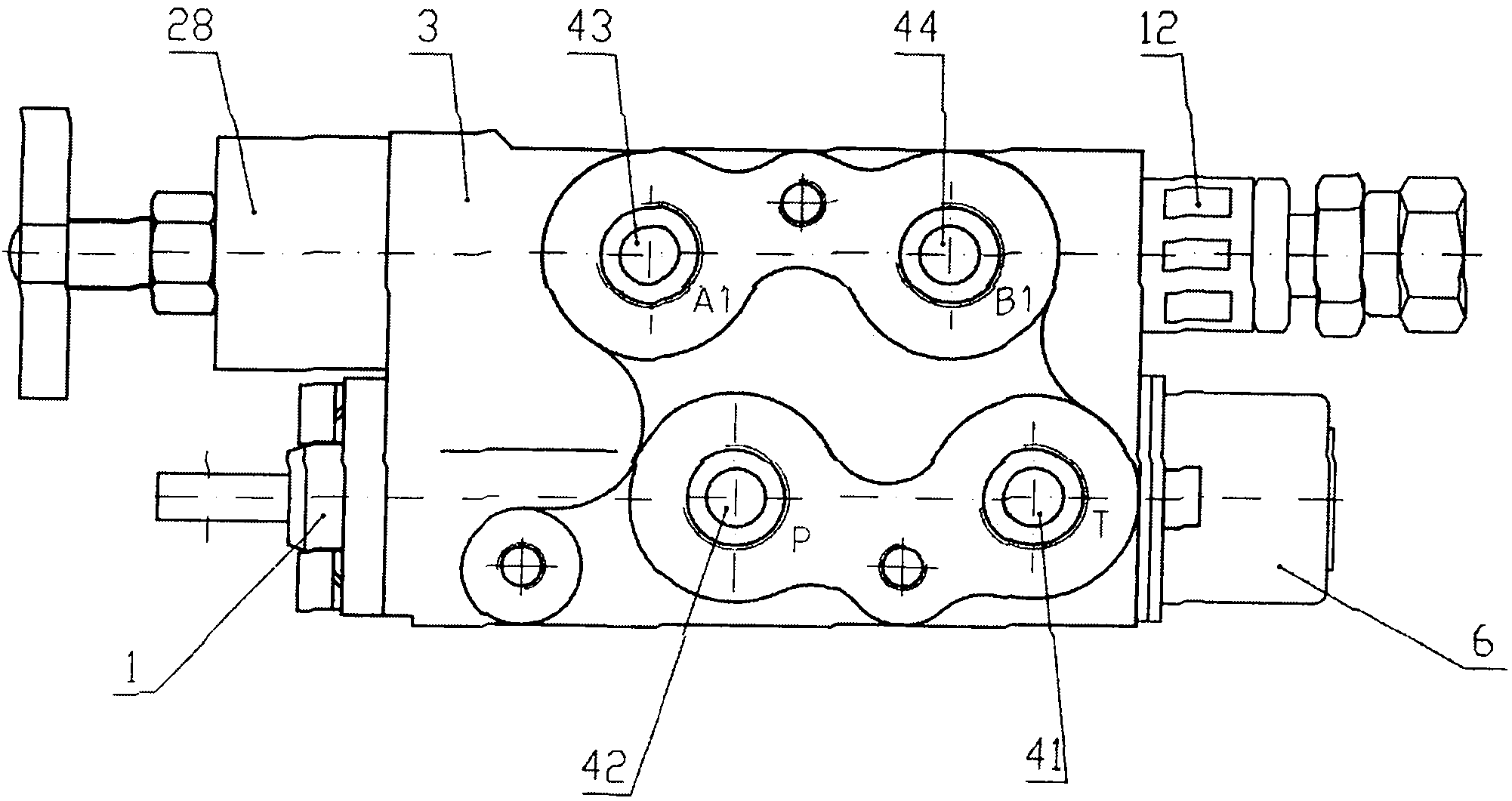

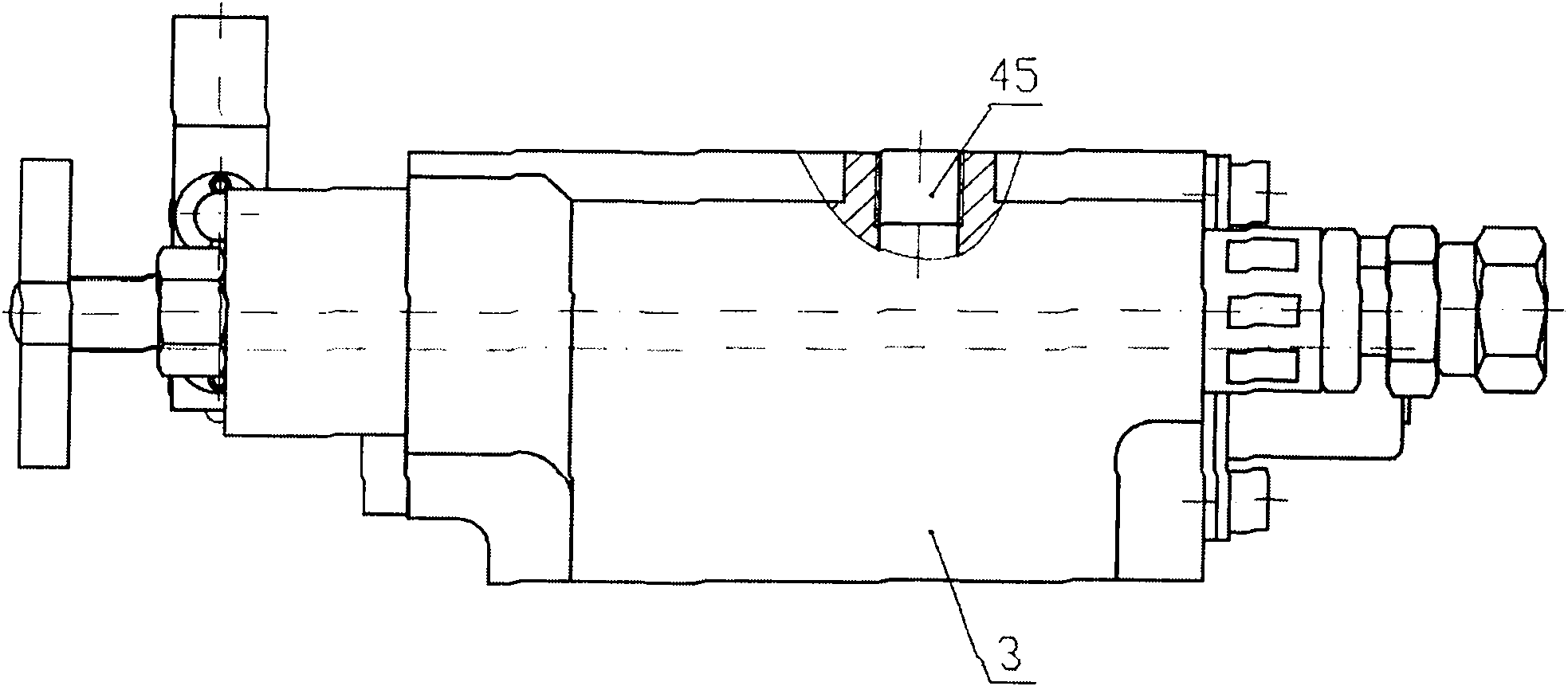

Small-sized drill pile-up valve

This invention discloses a small-sized drill pile-up valve, which comprises a valve body. The small-sized drill pile-up valve is characterized in that: a reversing valve, an overloading valve and a balanced one-way throttle valve are arranged in the valve body; the valve cavity of the overloading valve and the valve cavity of the balanced one-way throttle valve are communicated with the valve cavity of the reversing valve through casting flow channels respectively; and the valve body is provided with a first oil port, a second oil port, a third oil port, a fourth oil port and a pressure gauge port. The integrated control valve adopts an inserting mode, is organically fused and integrated with the reversing functions into a whole, has the advantages of compact structure, high working pressure, low loss of flow channel pressure, sensitive feedback, convenient operation, attractive appearance, and convenient maintenance. The small-sized drill pile-up valve is suitable for coal seam drilling machinery and small-sized drilling machinery for geological prospecting, is also suitable for small-sized engineering machinery, highway machinery, environmental health sanitation machinery, agricultural machinery and the like.

Owner:泸州众大科技液压件有限公司

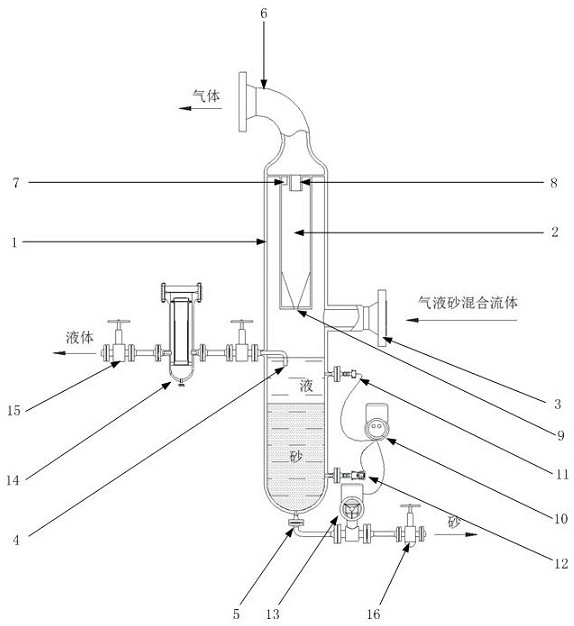

Gas-liquid-sand mixed fluid automatic desanding system for natural gas extraction

InactiveCN113209762AReduce manual operationsImprove adaptabilityCombination devicesFluid removalThermodynamicsAutomatic control

A gas-liquid-sand mixed fluid automatic desanding system for natural gas extraction comprises a shell and a desanding feeding port in the shell, a main separation cavity communicating with the desanding feeding port is formed in the shell, a first liquid discharging port and a sand discharging port are formed below the desanding feeding port, and the sand discharge port is connected with an automatic sand discharge branch; and a sand discharging system further comprises an automatic control system, the automatic control system comprises a controller, a sand level detector and a liquid level detector, the sand level detector and the liquid level detector are connected with the controller, the sand level detector is installed below the main separation cavity, the liquid level detector is installed between the installation height of the sand level detector and the installation height of the sand discharging opening, and the automatic sand discharging branch is controlled by the controller. By arranging a sensor and the control system, sand can be automatically discharged according to the stacking height in a sand remover, the whole sand discharging process is fully automatically completed, and manual operation is greatly reduced; and liquid is discharged through the liquid outlet, so that the desilting operation frequency and the subsequent sand-liquid separation work are reduced. By arranging a cyclone sand discharger, the equipment adaptability is improved, the advantages of gravity settling and cyclone separation are integrated, and the flow adaptation range is large.

Owner:成都汇川新能科技有限公司 +1

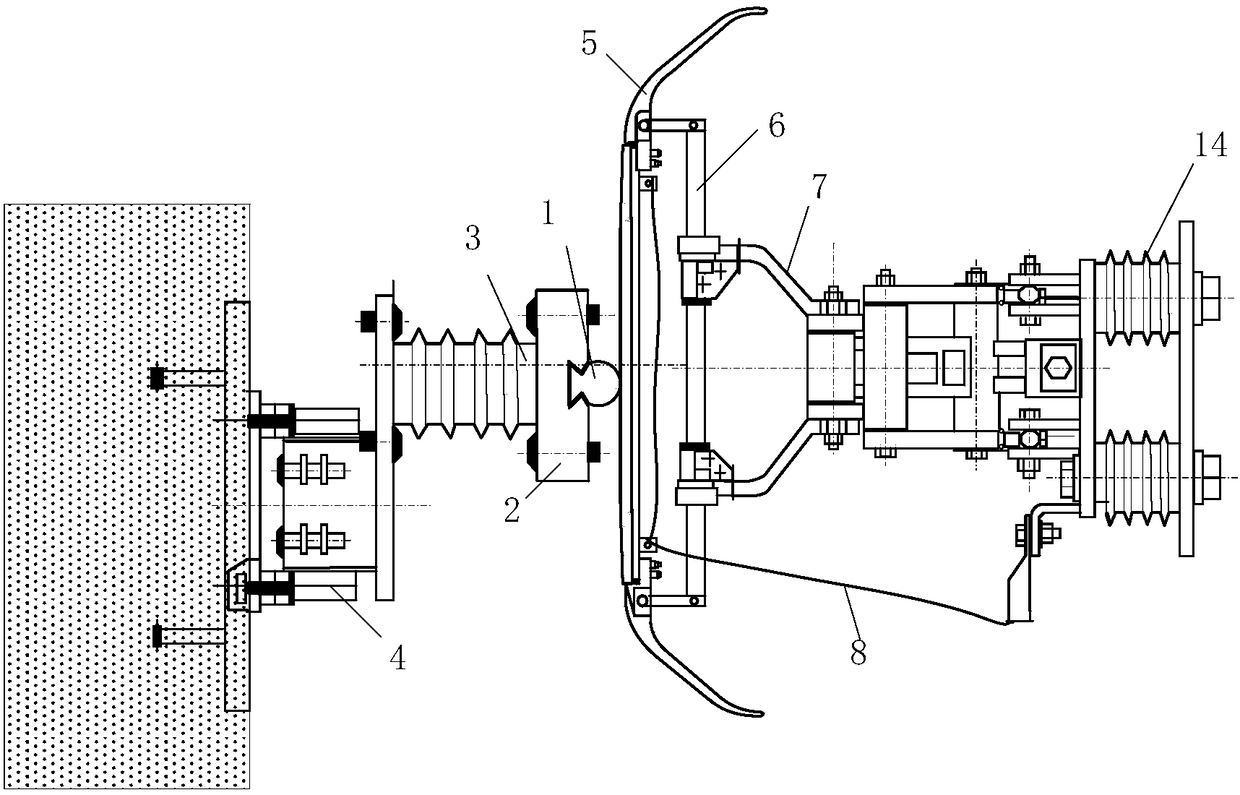

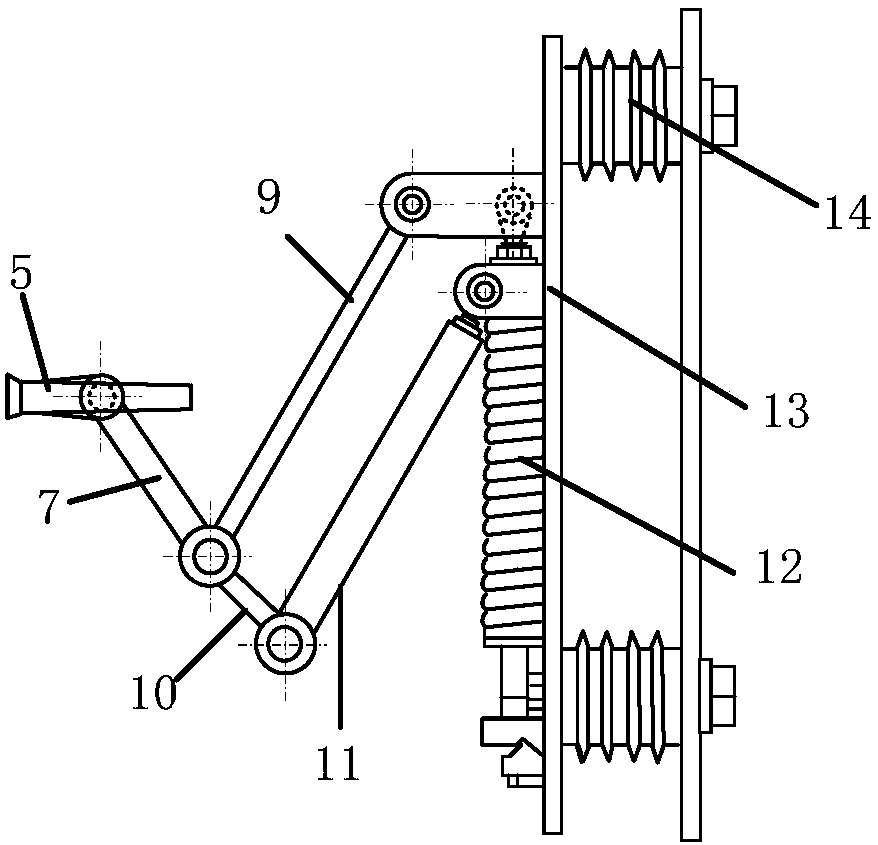

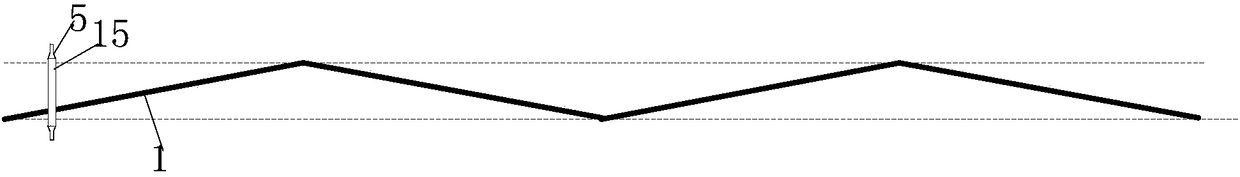

Low-noise current collecting system for medium-and low-speed maglev train

The invention relates to a low-noise current collecting system for a medium-and low-speed maglev train. The system comprises a ground power supply unit and a lateral current collector. The ground power supply unit comprises a power supply contact line laid below a maglev guide rail and along the lateral side of a rail beam, a current collecting face of the lateral current collector is in an arch current collecting structure, and slide contact current collection between the arch current collecting structure and the power supply contact line is realized. Compared with the prior art, the system has advantages that the noise level and probability of occurrence of impulsive noise in a current collecting process of the maglev train can be lowered, loss of the current collector is reduced, reliability and comfort of the system are improved, and system maintenance cost is reduced.

Owner:上海启喆科技有限公司

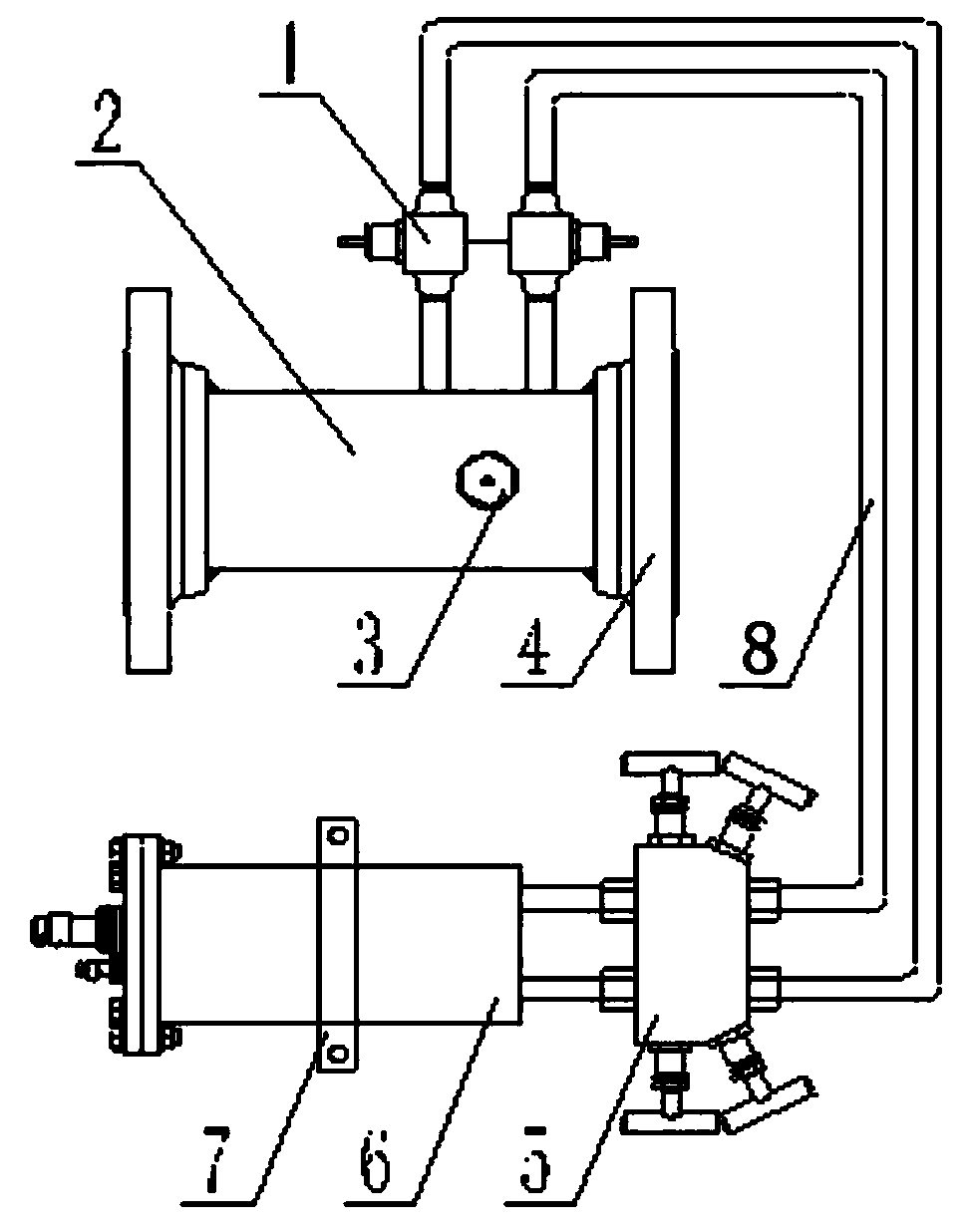

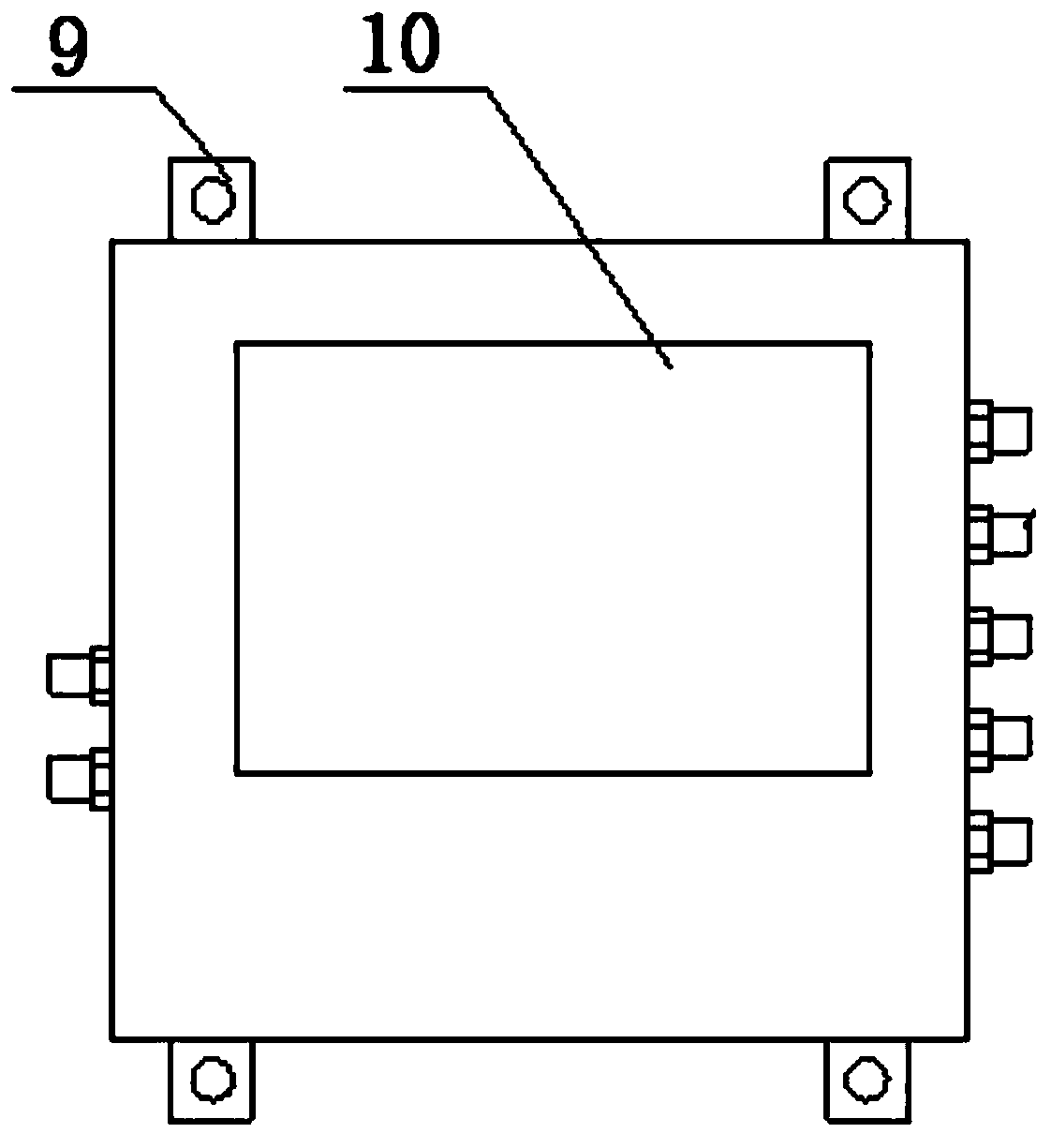

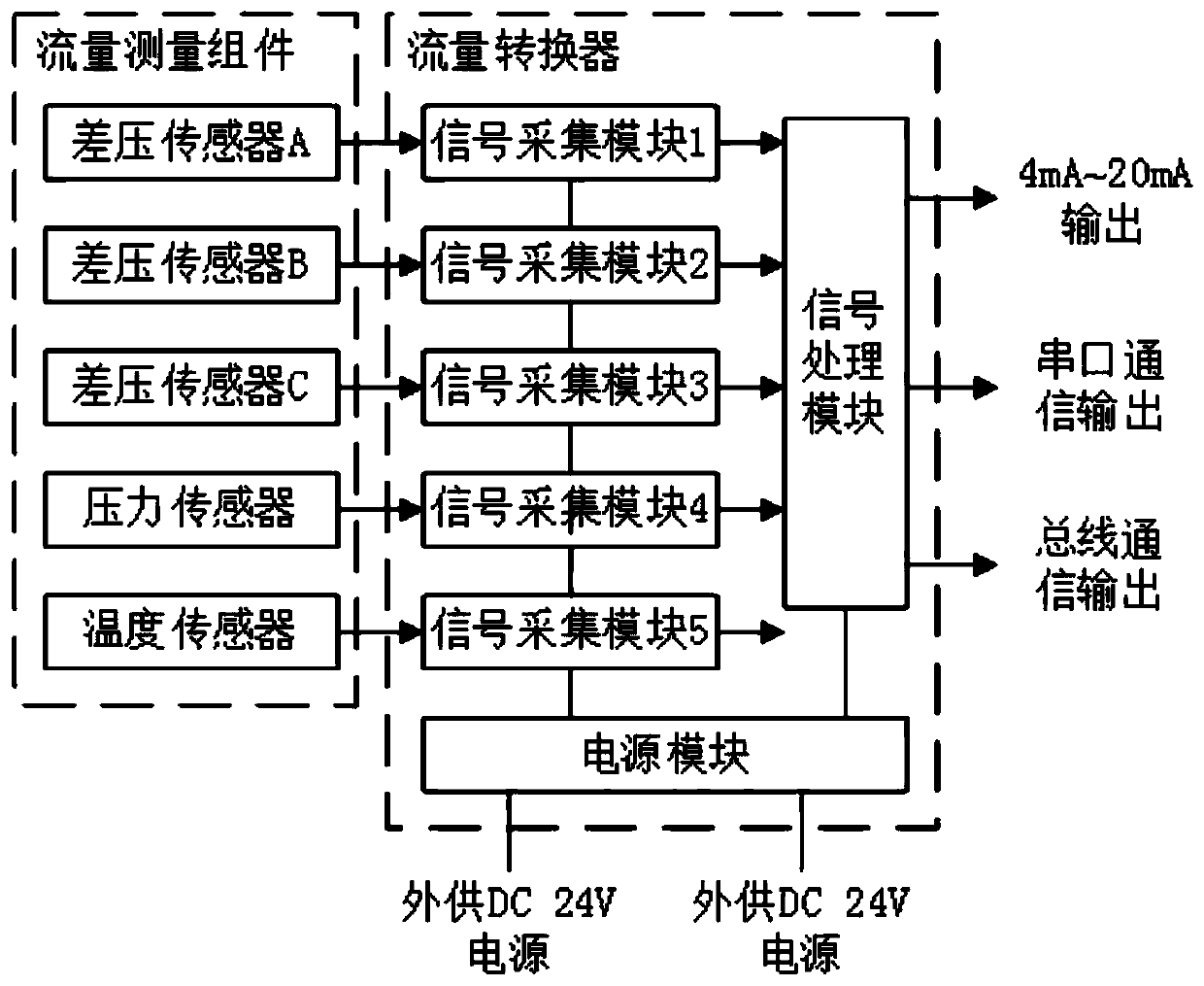

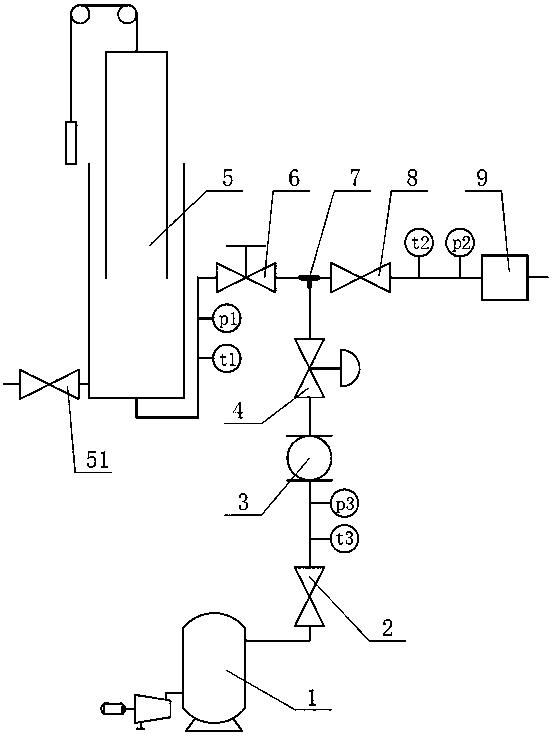

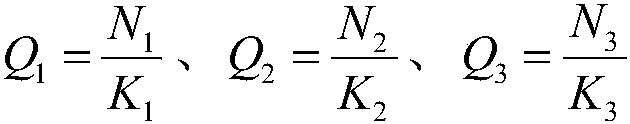

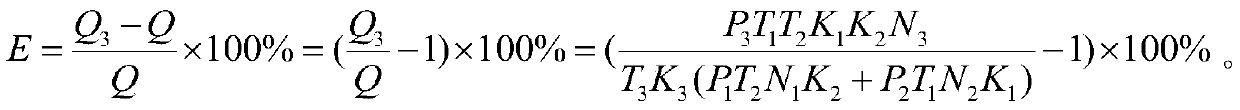

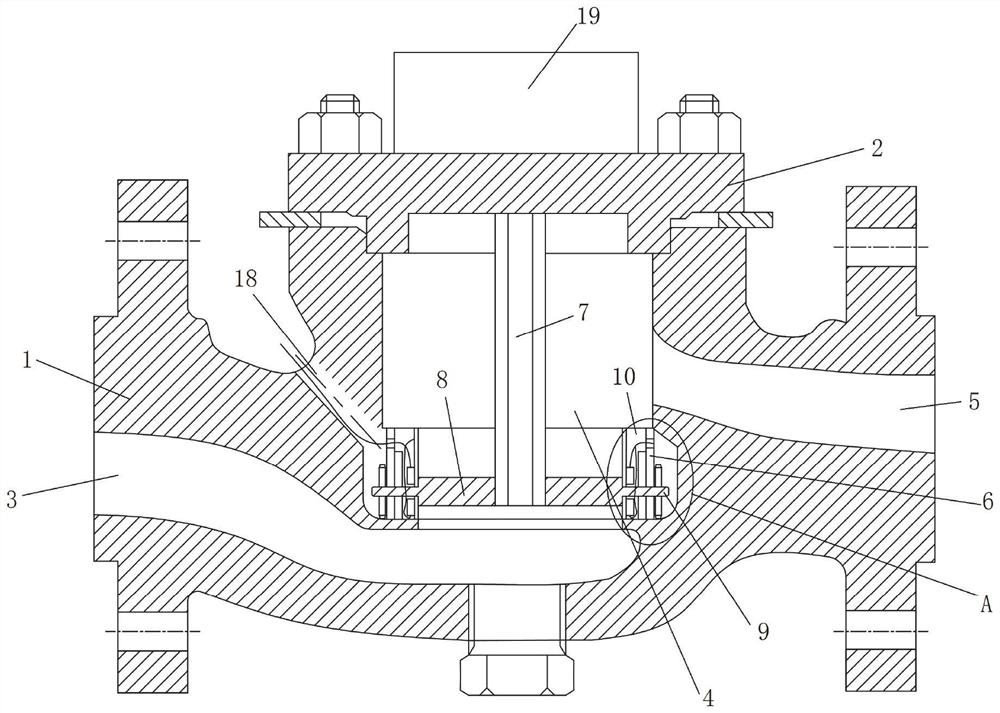

Marine steam flow measuring device and method

InactiveCN111351533AEfficient measurementLarge flow rangeVolume/mass flow by differential pressureConvertersMarine engineering

The invention provides a marine steam flow measuring device and method. The device comprises a flow measuring assembly and a flow converter, the flow measuring assembly is composed of a throttle pipesection, a pressure guide pipe, a valve set and a sensor assembly, connecting flanges are arranged at the two ends of the throttle pipe section, two ends of the throttle pipe section are connected with a steam pipeline, and the sensor assembly is provided with a pressure sensor and three differential pressure sensors with different measuring ranges and is connected to the throttle pipe section through the valve set and the pressure guide pipe; and the flow converter comprises a shell, a signal acquisition module, a signal processing module and a power module are arranged in the shell, a display screen is arranged on the front face of the shell, and a plurality of electric connectors are arranged on the two side faces of the shell and are connected with an external power source, the sensorassembly and an upper computer respectively. The straight pipe section of the flow measuring assembly is short, other special requirements of the straight pipe sections on the upstream and the downstream are avoided, and saturated steam measurement can be conducted in a narrow space of a ship.

Owner:CHINA SHIP DEV & DESIGN CENT

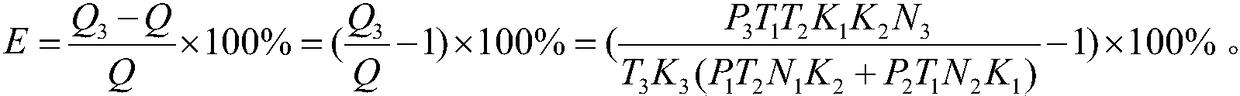

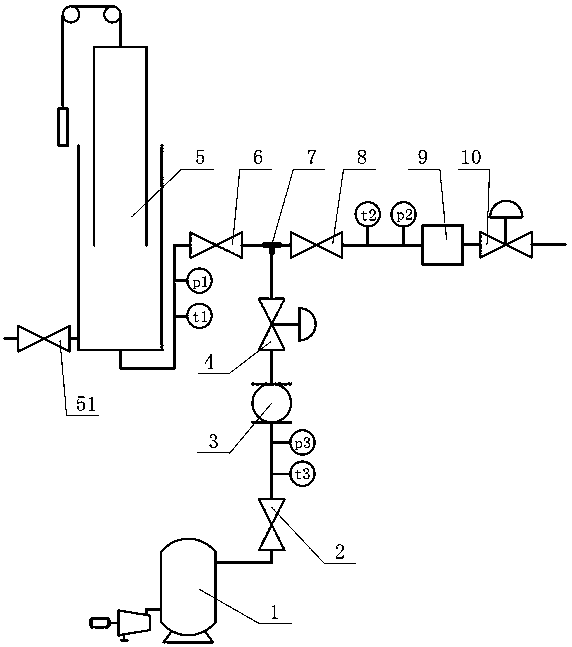

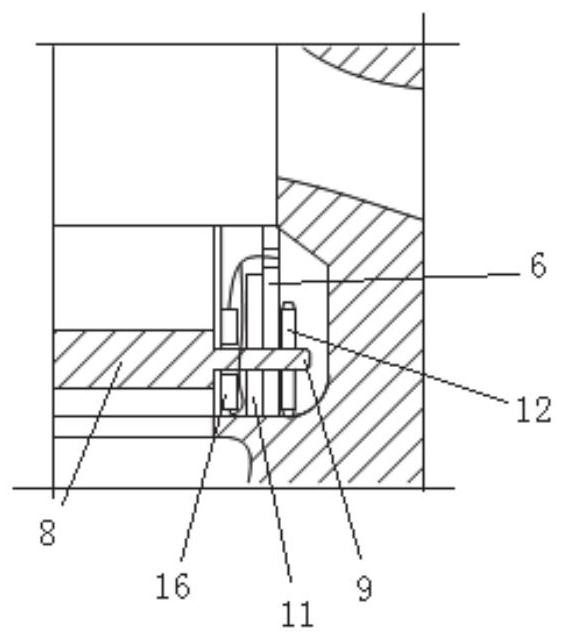

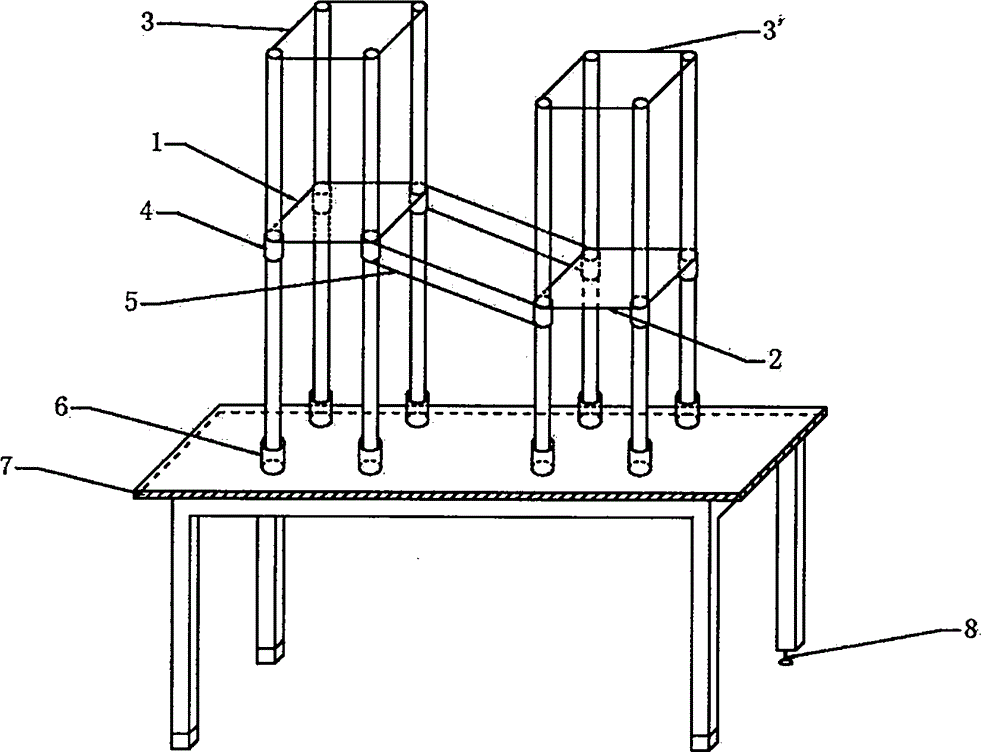

Parallel structure and detection method of dual-gas flow standard device

InactiveCN108444576ALarge flow rangeEnrichment testTesting/calibration apparatusSingle typeEngineering

The invention provides a parallel structure and detection method of dual-gas flow standard device, and relates to the technical field of measurement. The gas source is connected with a tested flow meter, and the tested flow meter is respectively connected with a bell jar and a standard gas flowmeter through a tee joint; the gas accumulation amount of the bell jar, the standard gas flow meter and the tested flow meter is calculated through the pulse calculation, the gas accumulation amount of the bell jar and the standard gas flow meter is converted into the gas accumulation amount under the pressure and temperature state of the tested flow meter and is added to obtain a standard gas magnitude, and the measured flow meter value error is calculated according to the gas accumulation amount ofthe tested flow meter. The parallel structure and detection method of dual-gas flow standard device solves the technical problems that in the prior art, only the 'single type' standard device value is adopted, the flow range cannot be expanded, and the pressure loss is large. The parallel structure and detection method of dual-gas flow standard device has the advantages that different detection methods are achieved on the same set of devices, and meanwhile, the method is applied to the operation process; compared with a single or serial standard device, the flow range is larger; the test is richer than that of the method; the pressure loss is smaller.

Owner:GUANGZHOU INST OF ENERGY TESTING

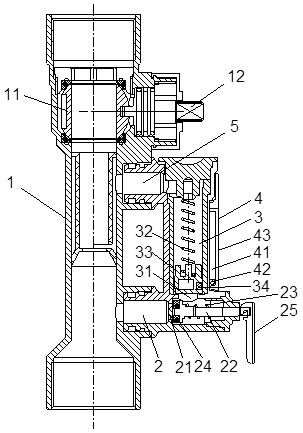

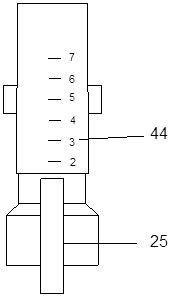

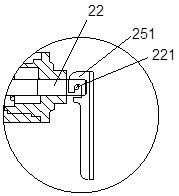

Large-range flow meter and large-range flow measuring method

ActiveCN111693100ALarge flow rangeHigh sensitivityVolume/mass flow by mechanical effectsVolume meteringEngineeringMechanics

The invention discloses a large-range flow meter and a flow adjusting method thereof. The large-range flow meter comprises a shell, the shell internally comprises a liquid inlet channel, a measuring channel and a liquid outlet channel which are connected in sequence, and the liquid inlet channel is connected with the measuring channel through a channel inlet; a spring and a floater are arranged inthe measuring channel; a piston valve seat and a piston rod are arranged in the liquid inlet channel, the piston rod is sleeved with a reset spring, and a piston is arranged on the piston rod; and the flow meter further comprises an opening degree control mechanism which drives the piston rod to move and drives the piston rod to generate at least two stroke changes from an initial state. The large-range flow meter can provide a large-range flow measurement function, and theoretically, the flow range measured by the flow meter can be infinitely large due to the fact that the opening degree control mechanism drives the piston rod to generate a plurality of stroke changes from the initial state. The flow meter and flow measuring method have the advantages of simple structure, sensitive index, high sensitivity and large measurement range.

Owner:NINGBO HUACHENG VALVE

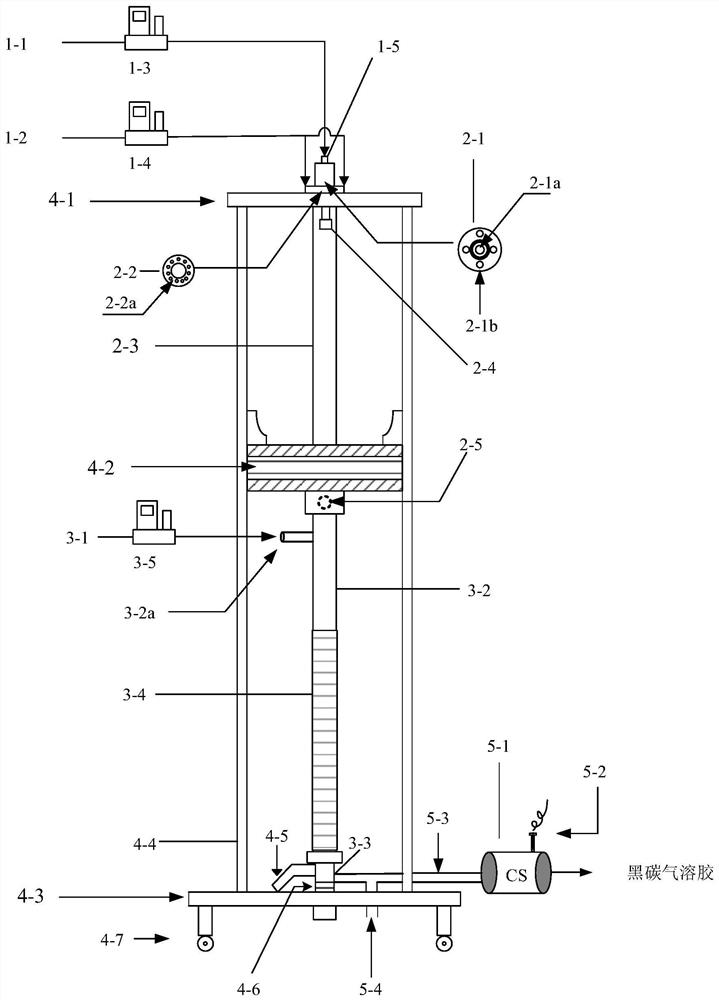

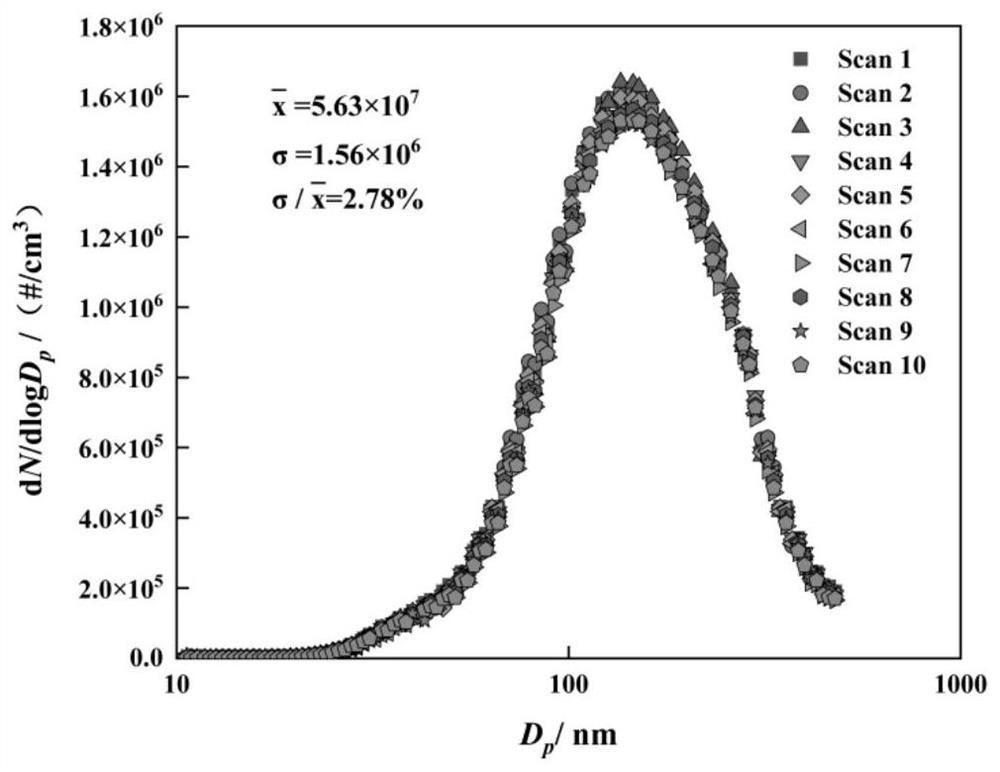

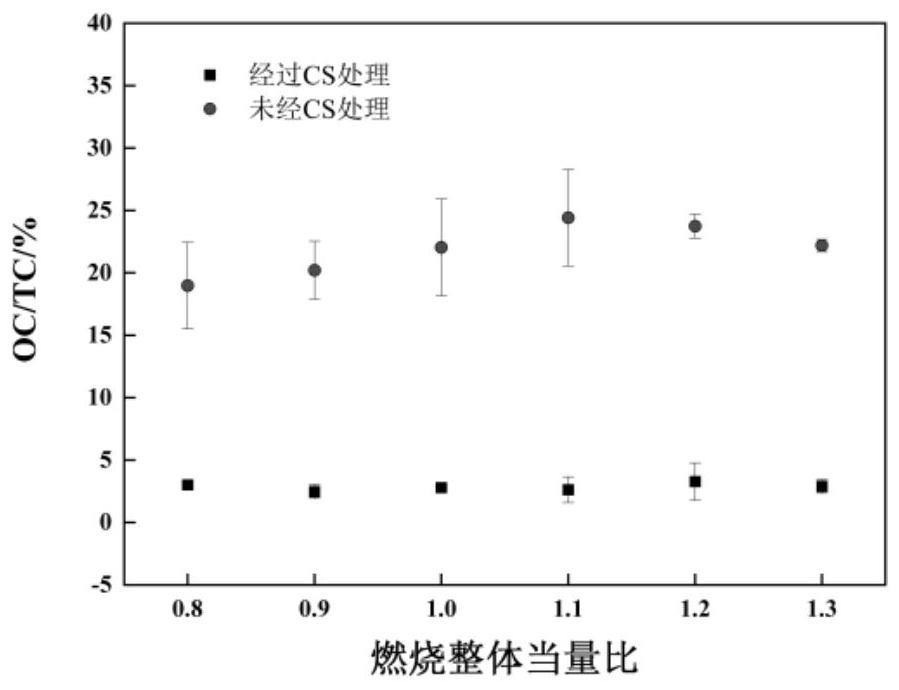

A kind of black carbon aerosol generator

ActiveCN112999989BInto the uniformStable concentrationColloidal chemistry detailsAerosol preparationCombustion chamberCatalytic oxidation

The invention belongs to the field of environmental monitoring, in particular to a black carbon aerosol generator, comprising a gas supply system, a combustion system, a dilution system, a catalytic oxidation device and a fixing frame; the gas supply system includes a first Air supply pipe and a second air supply pipe for supplying combustion-supporting gas; the combustion system includes an air intake device, a combustion chamber, a combustion head and an ignition hole; the dilution system includes a third air supply pipe for supplying dilution gas, a dilution chamber , a sampling port and a heat preservation device; the catalytic oxidation device includes a catalytic oxidizer and a heating device, the sampling port is connected to the inlet end of the catalytic oxidizer through a pipeline, and an exhaust port is arranged on the pipeline; a gas supply system, a combustion system and a dilution system It is fixedly installed on the fixed frame, so that the generator is in a vertical and stable state. The generator can produce stable and pure black carbon aerosols with different particle sizes and concentration ranges, and can generate a large flow rate to meet the subsequent simultaneous measurement of multiple instruments.

Owner:BEIHANG UNIV

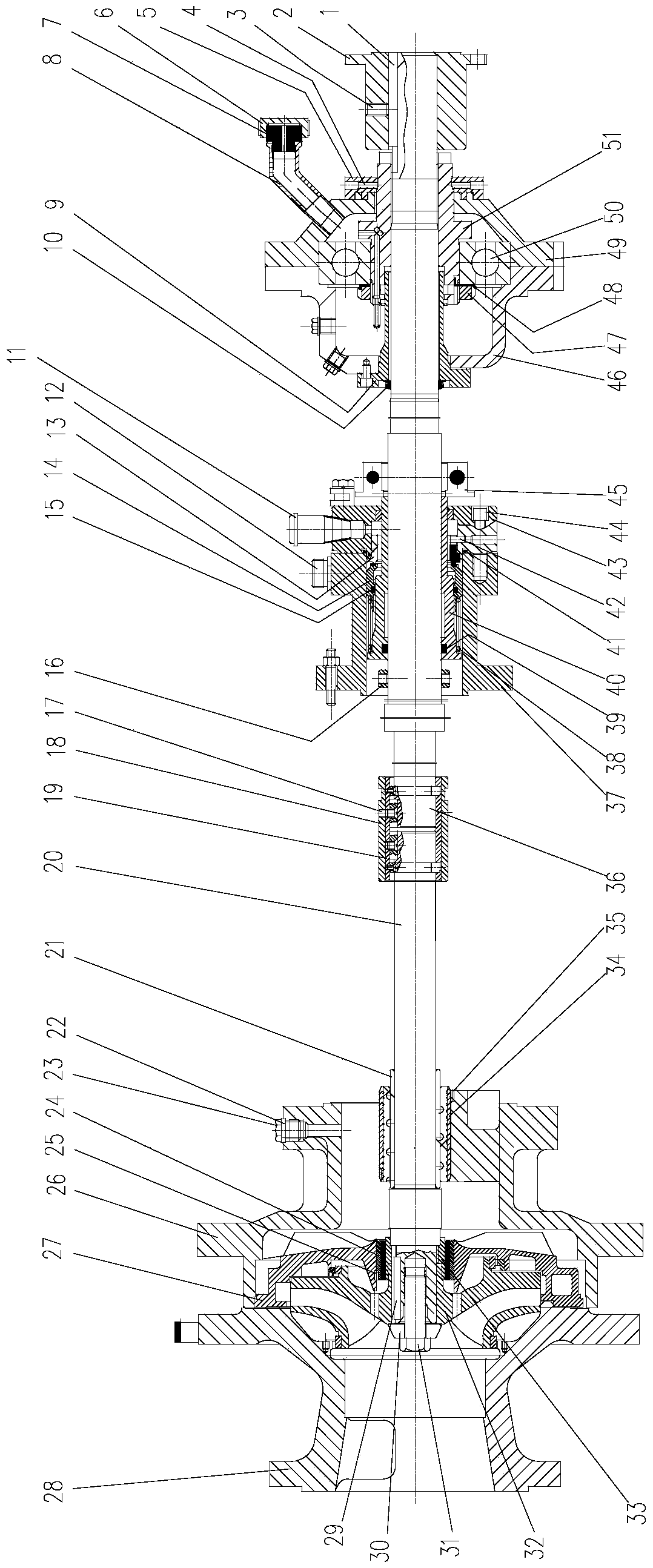

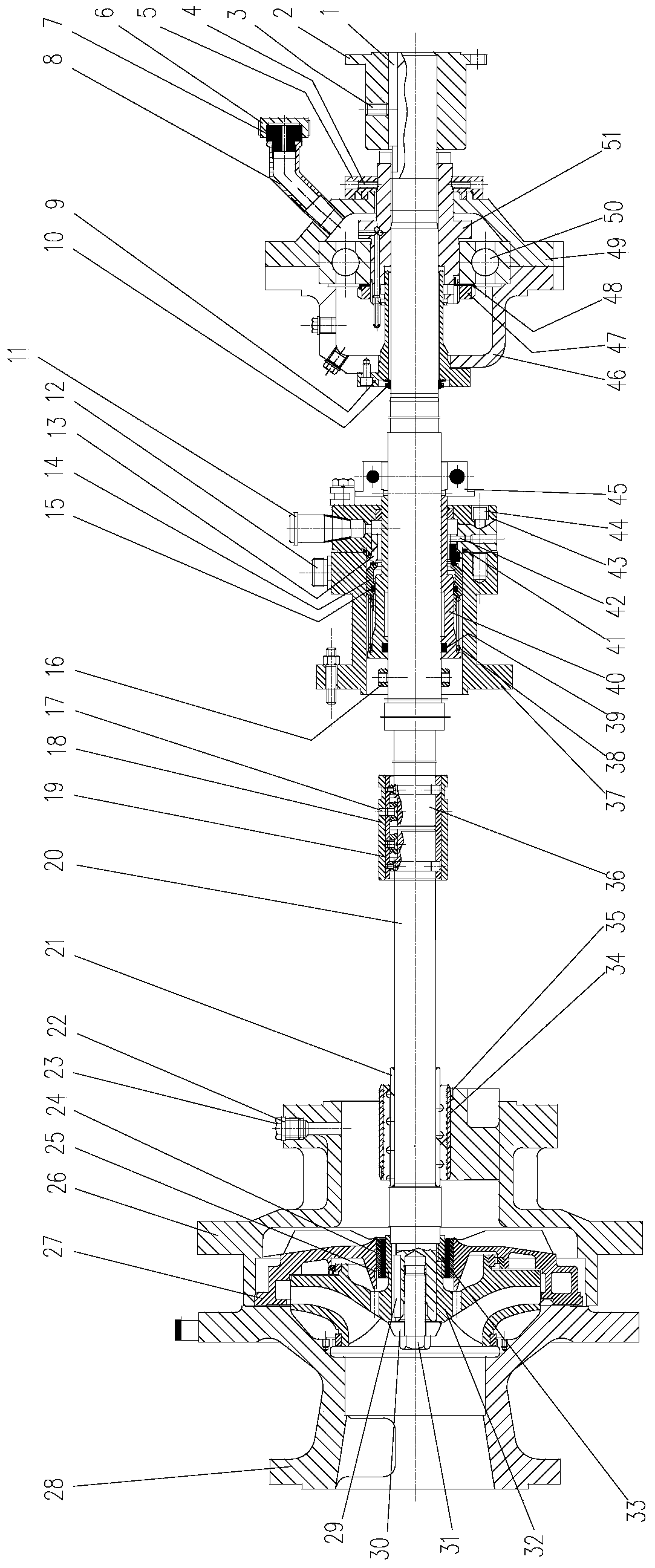

Urea condensate pump

The invention discloses a urea condensate pump. The pump comprises a first shaft and a second shaft which are arranged coaxially, wherein the right end of the first shaft is detachably connected with the left end of the second shaft; a bearing sleeve, a third shaft sleeve and a couplingsleevesthe second shaft in sequence from the left end of the second shaft; a bearing seat and a bearing seat end cover connected with the bearing seat sleeve the bearing sleeve and the third shaft sleeve separately; a bearing sleeves the third bearing sleeve, and the axial movement of the bearing along the third shaft sleeve is limited by a round nut; the bearing seat end covercommunicateswith a bend pipe; the second shaft is sleeved by a stopper ring, a second shaft sleeve and a fixed sleeve from the left end to the right end; the second shaft sleeve is sleeved by a first shaft sleeve, a spring, a movable ring, a static ring and a cooling sleeve from the left end to the right end; a first pipe joint communicatingwith the side wall of the cooling sleeve is a coolant inlet, a second pipe joint communicatingwith the side wall of the first shaft sleeve is an outlet; a pump port, an impeller sleeve, an impeller and a medium shell sleeve the first shaft in sequence from the left end; a diversion disk communicating with the pump outlet sleeves the impeller sleeve by the bearing; and the axial movement of the impeller along the first shaft is limited by a fourth screw.

Owner:陕西奥维乾元化工有限公司

Double standard gas flow device parallel structure and detection method

ActiveCN110160609AEliminate the influence of installation factorsLarge flow rangeTesting/calibration apparatusSingle typeEngineering

The invention provides a double standard gas flow device parallel structure and a detection method, and relates to the technical field of measurement. A gas source is connected to a to-be-detected flowmeter. The to-be-detected flowmeter is connected to a bell jar and a standard gas flowmeter through a tee joint. Gas accumulation amount of the bell jar, the standard gas flowmeter and the to-be-detected flowmeter through pulse. The gas accumulation amount of the bell jar and the standard gas flowmeter is converted into gas accumulation amount of the to-be-detected flowmeter under pressure and temperature, and the gas accumulation amount of the bell jar and the standard gas flowmeter and the gas accumulation amount of the to-be-detected flowmeter under pressure and temperature are added together to obtain a standard gas volume value. A to-be-detected flowmeter value error is obtained by calculation of the gas accumulation amount of the to-be-detected flowmeter. The double standard gas flow device parallel structure and the detection method solve the technical problems in the prior art that a standard device only uses a ''single type'' standard device value, a flow range cannot be expanded and the pressure loss is large. The double standard gas flow device parallel structure and the detection method have the beneficial effects that different detection methods are implemented on thesame set of device and applied in calculation processes, the flow range is large, the pressure loss is small, and the device calibrates single points of the standard gas flowmeter on line, which eliminates mounting errors.

Owner:GUANGZHOU INST OF ENERGY TESTING

A liquid flow control valve

ActiveCN114135683BAvoid damageIncrease disturbanceOperating means/releasing devices for valvesHydro energy generationControl valvesValve stem

The invention relates to a liquid flow control valve, which comprises a valve body, a flow channel is arranged in the valve body, a valve seat is arranged in the flow channel, the valve body is fixedly connected with a valve stem, the bottom end of the valve stem is located inside the valve seat, and the bottom end of the valve stem is located in the valve seat. There are a plurality of blades distributed along the circumference. The blades are rotatably connected with the valve stem and the valve seat through the rotating shaft. One end of the blade is attached to the valve stem and the other end is attached to the valve seat. The rotating shaft extends to the outside of the valve seat and is connected with the drive mechanism. The two sides of the blade along the circumferential direction of the blade are wave-shaped surfaces, and the two sides of the blade along the circumferential direction of the blade are provided with a plurality of protrusions and grooves, and the protrusions and grooves of adjacent blades can cooperate with each other. The control valve of the invention has high control sensitivity, wide adjustment range and long service life.

Owner:SHANDONG UNIV

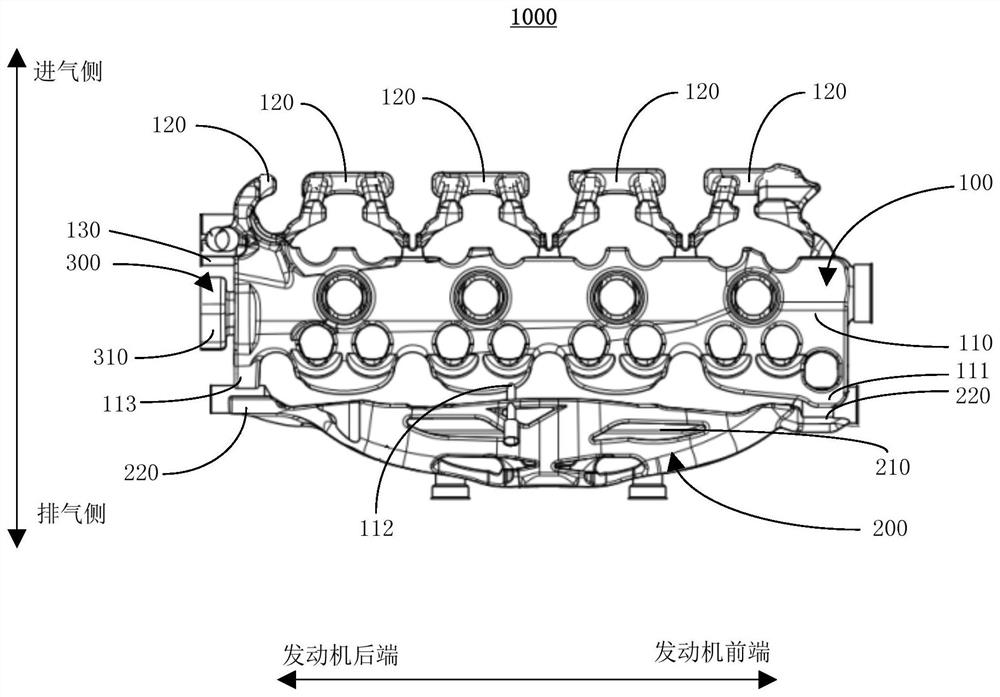

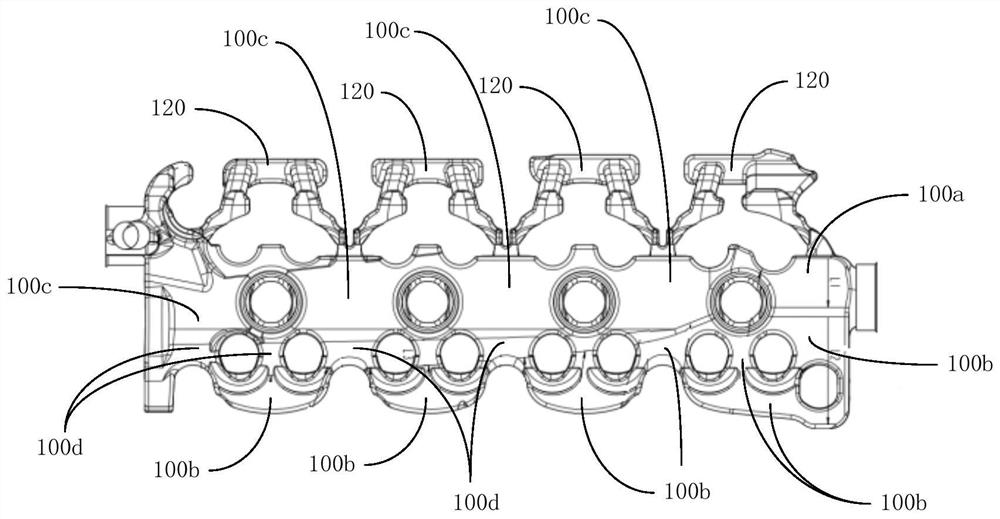

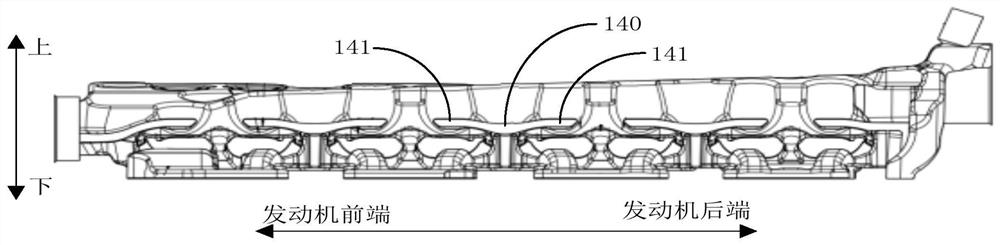

Engine cylinder head water jacket and engine

ActiveCN112648103BImprove cooling effectLarge flow rangeCylinder headsCylindersMarine engineeringCylinder head

The invention discloses an engine cylinder head water jacket and an engine, comprising a main casing body and a side casing body; The main water chamber and the main casing are provided with a water inlet and a water outlet connected to the main water chamber. The water chamber, the side water chamber is located on the exhaust side of the main water chamber, and is connected to the water outlet through the main water chamber. The exhaust side of the main casing is sequentially provided with the first water port, The second water port and the third water port are respectively provided with two side water ports at the two ends of the side body, the first water port is connected to one side water port, the third water port is connected to the other side water port, and the second water port extends into the side water chamber through a conduit. The engine cylinder head water jacket and the engine of the invention aim to solve the problem in the prior art that the cylinder head water jacket has poor cooling performance and cannot meet the heat dissipation requirements of the engine.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Biomass-mixed, pulverized coal-fired burner and fuel combustion method

ActiveUS10107492B2Easy to igniteLarge flow rangeStaged combustionPulverulent fuel combustion burnersHigh concentrationCombustion

Owner:KAWASAKI HEAVY IND LTD

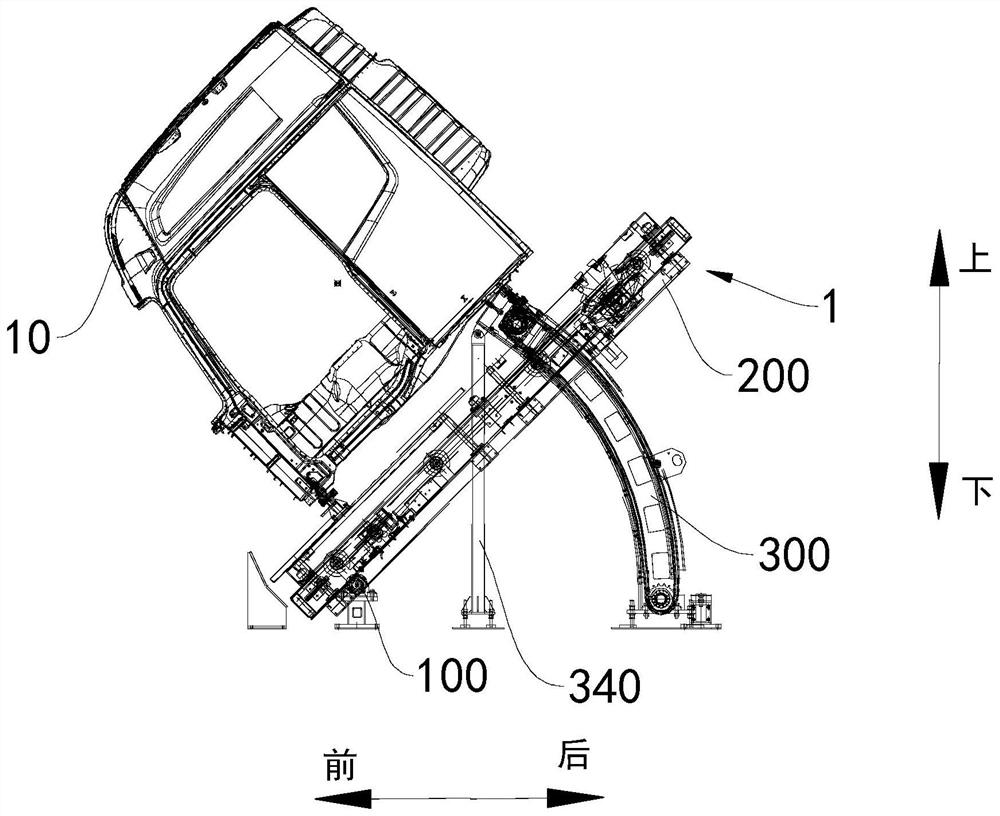

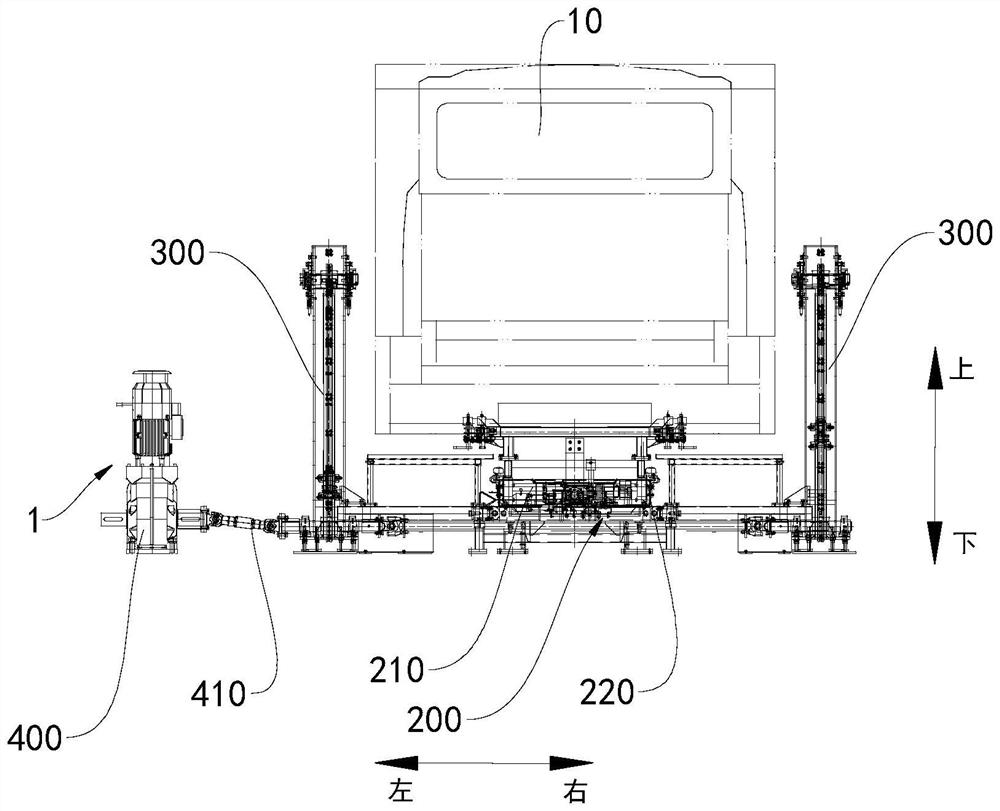

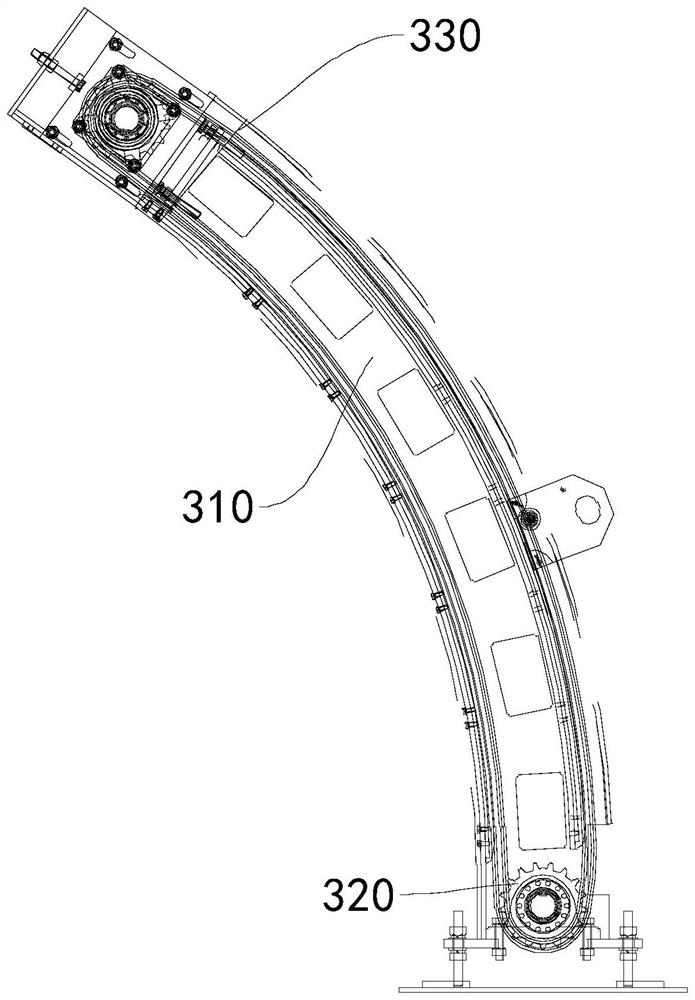

Wax draining equipment

PendingCN114345592AImprove anti-corrosion performanceLarge flow rangeSpraying apparatusWaxChain link

The invention discloses wax draining equipment, which comprises a rotating shaft, a wax draining device and a wax draining device, and the rotating shaft is suitable for being mounted on the ground; the bottom of the cab is suitable for being installed on the roller bed, one side of the roller bed is rotatably installed on the rotating shaft, and the side, away from the rotating shaft, of the roller bed rotates around the rotating shaft to drive the cab to incline; the chain assembly is mounted on one side, far away from the rotating shaft, of the roller bed; and the lifting driving mechanism is connected to the chain assembly, and the lifting driving mechanism drives the chain assembly to rotate so as to drive the other side of the roller bed to rotate around the rotating shaft. The wax draining equipment has the advantages of being large in wax liquid flowing range, uniform in wax draining, high in corrosion resistance and the like.

Owner:BEIJING FOTONDAIMLER AUTOMOTIVE

A urea condensate pump

The invention discloses a urea condensate pump. The pump comprises a first shaft and a second shaft which are arranged coaxially, wherein the right end of the first shaft is detachably connected with the left end of the second shaft; a bearing sleeve, a third shaft sleeve and a couplingsleevesthe second shaft in sequence from the left end of the second shaft; a bearing seat and a bearing seat end cover connected with the bearing seat sleeve the bearing sleeve and the third shaft sleeve separately; a bearing sleeves the third bearing sleeve, and the axial movement of the bearing along the third shaft sleeve is limited by a round nut; the bearing seat end covercommunicateswith a bend pipe; the second shaft is sleeved by a stopper ring, a second shaft sleeve and a fixed sleeve from the left end to the right end; the second shaft sleeve is sleeved by a first shaft sleeve, a spring, a movable ring, a static ring and a cooling sleeve from the left end to the right end; a first pipe joint communicatingwith the side wall of the cooling sleeve is a coolant inlet, a second pipe joint communicatingwith the side wall of the first shaft sleeve is an outlet; a pump port, an impeller sleeve, an impeller and a medium shell sleeve the first shaft in sequence from the left end; a diversion disk communicating with the pump outlet sleeves the impeller sleeve by the bearing; and the axial movement of the impeller along the first shaft is limited by a fourth screw.

Owner:陕西奥维乾元化工有限公司

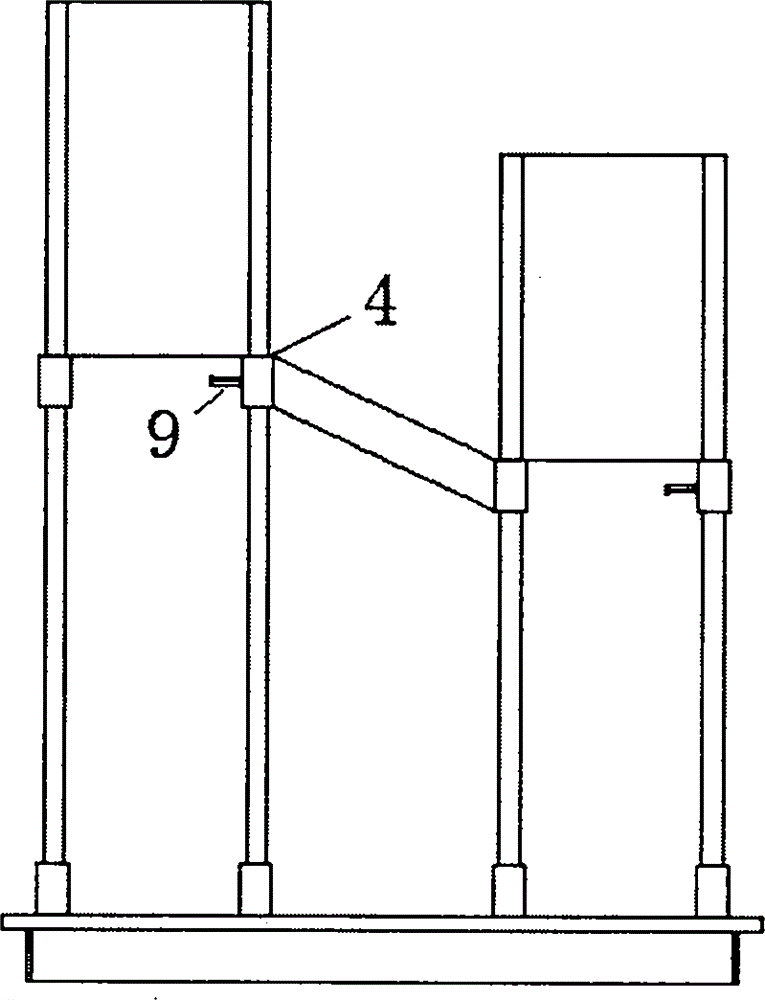

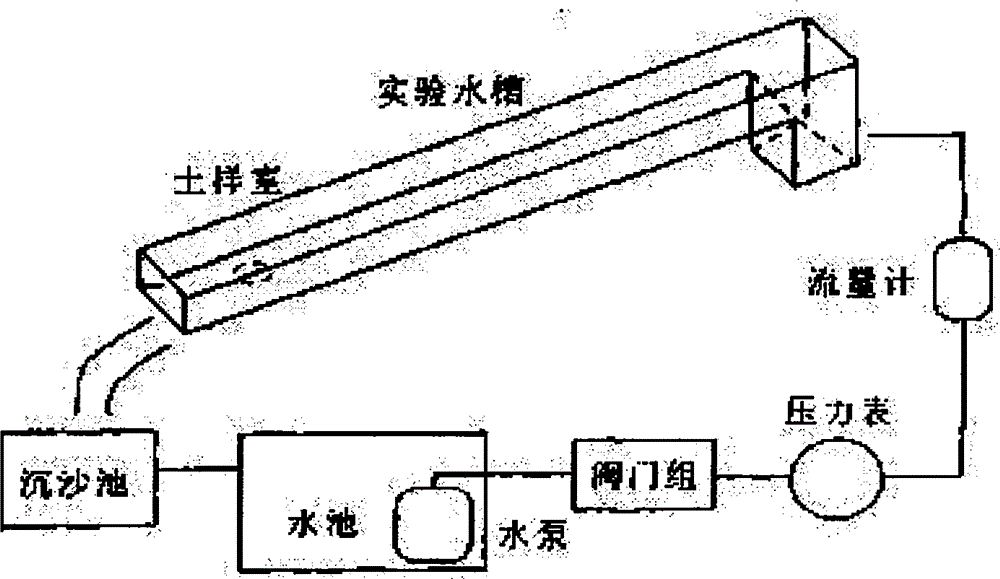

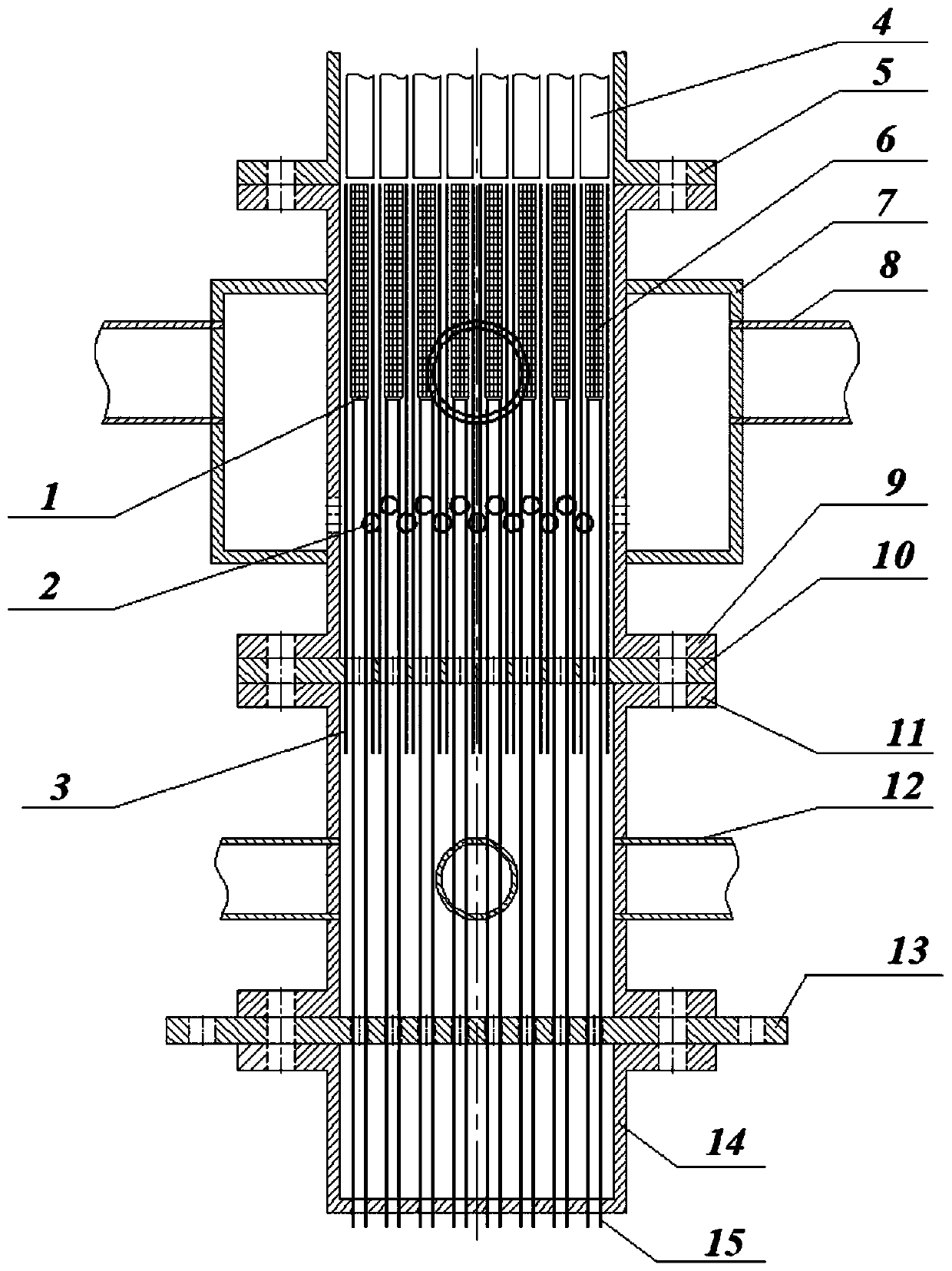

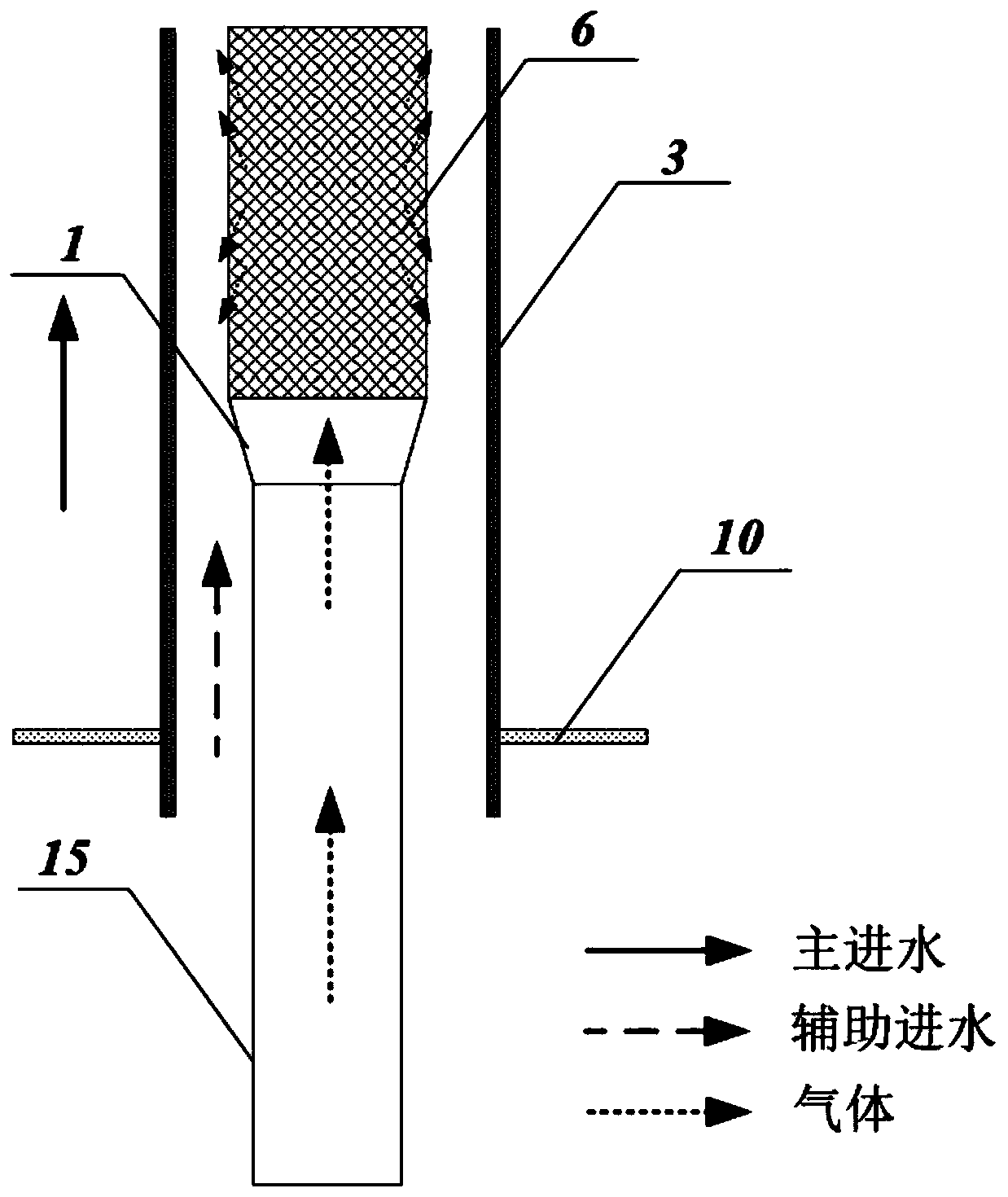

Sand supply instrument for slope-variable water flume

Owner:BEIJING FORESTRY UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com