A two-phase bubbly flow mixing device and method at the bottom inlet of a vertical rod bundle channel

A technology of rod bundle channel and bubbly flow, which is applied to the field of two-phase bubbly flow mixing device at the bottom of vertical rod bundle channel, can solve the problems of device vibration, large flow resistance, increase vapor phase solubility, etc. The effect of frame vibration, uniform force and impact avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The method of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

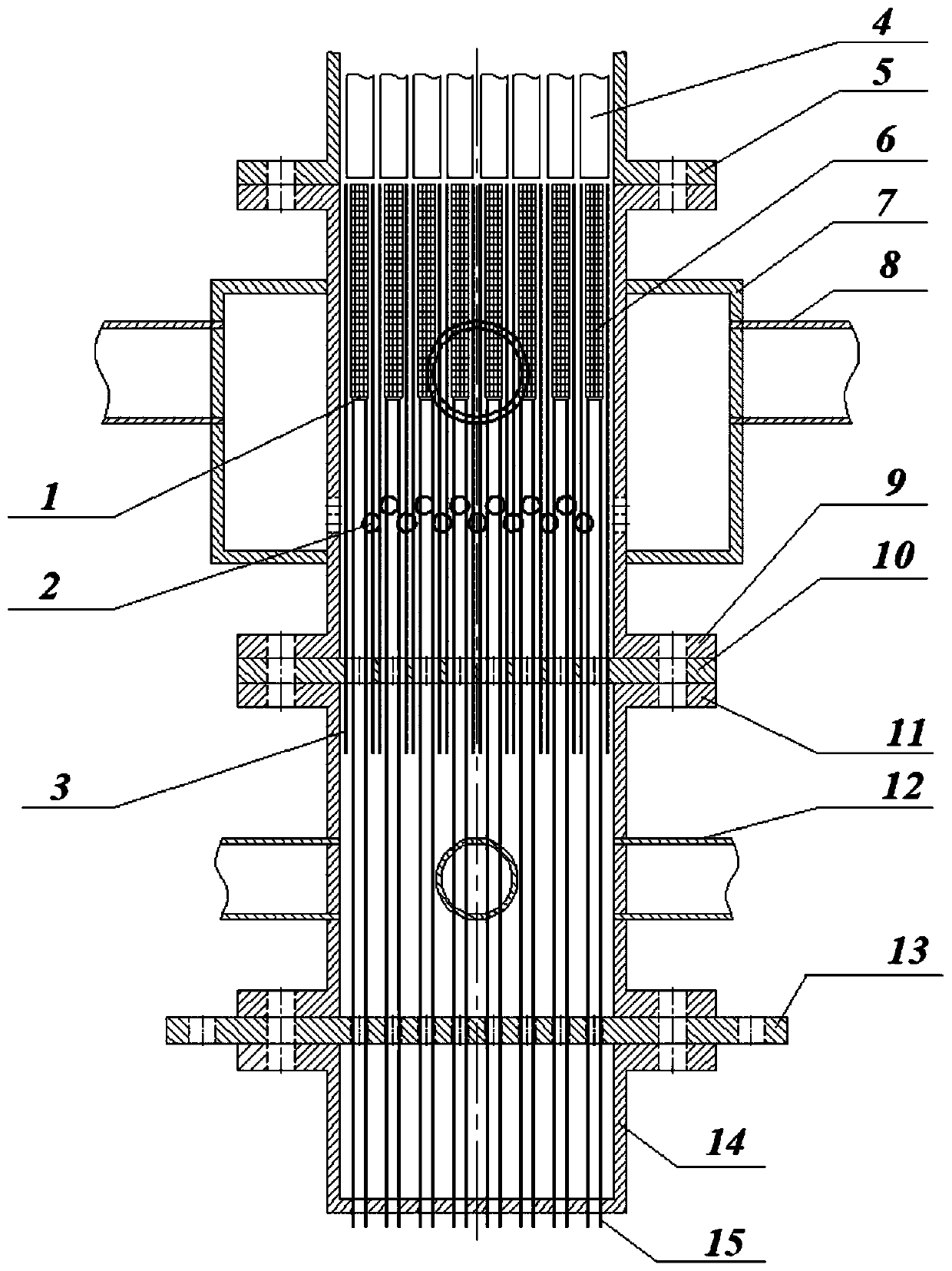

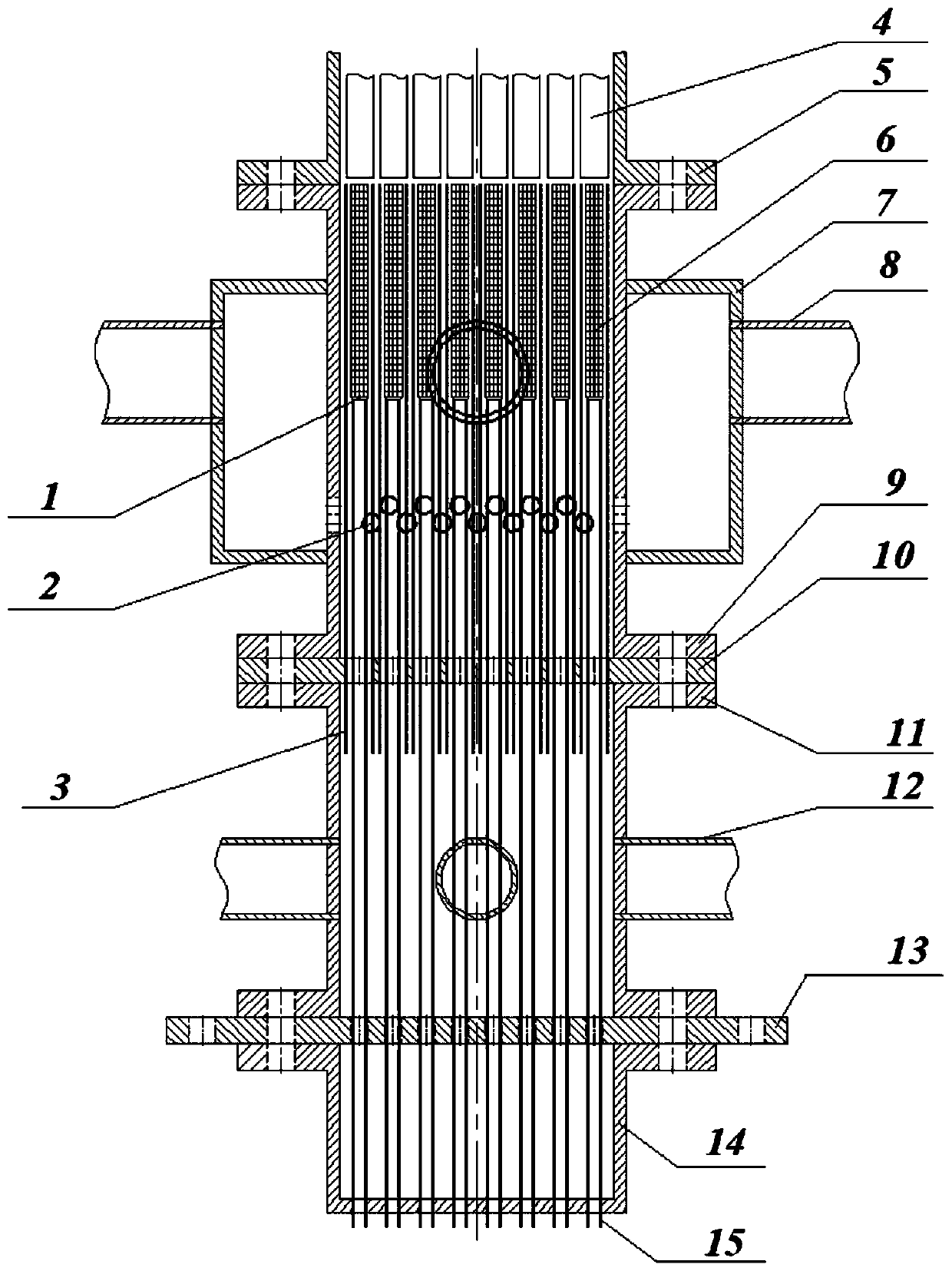

[0028] Such as figure 1 As shown, a two-phase bubbly flow mixing device at the bottom of the vertical rod bundle channel of the present invention includes a filter element transition section 1, a main water inlet hole 2, a filter element sleeve 3, an experimental rod bundle 4, a rod bundle sleeve 5, Porous section of filter element 6, main water inlet chamber 7, main water inlet pipe 8, device upper pipe seat 9, filter element sleeve fixing plate 10, auxiliary water inlet chamber 11, auxiliary water inlet pipe 12, filter element fixing plate 13, device lower pipe Seat 14 and filter core tube section 15.

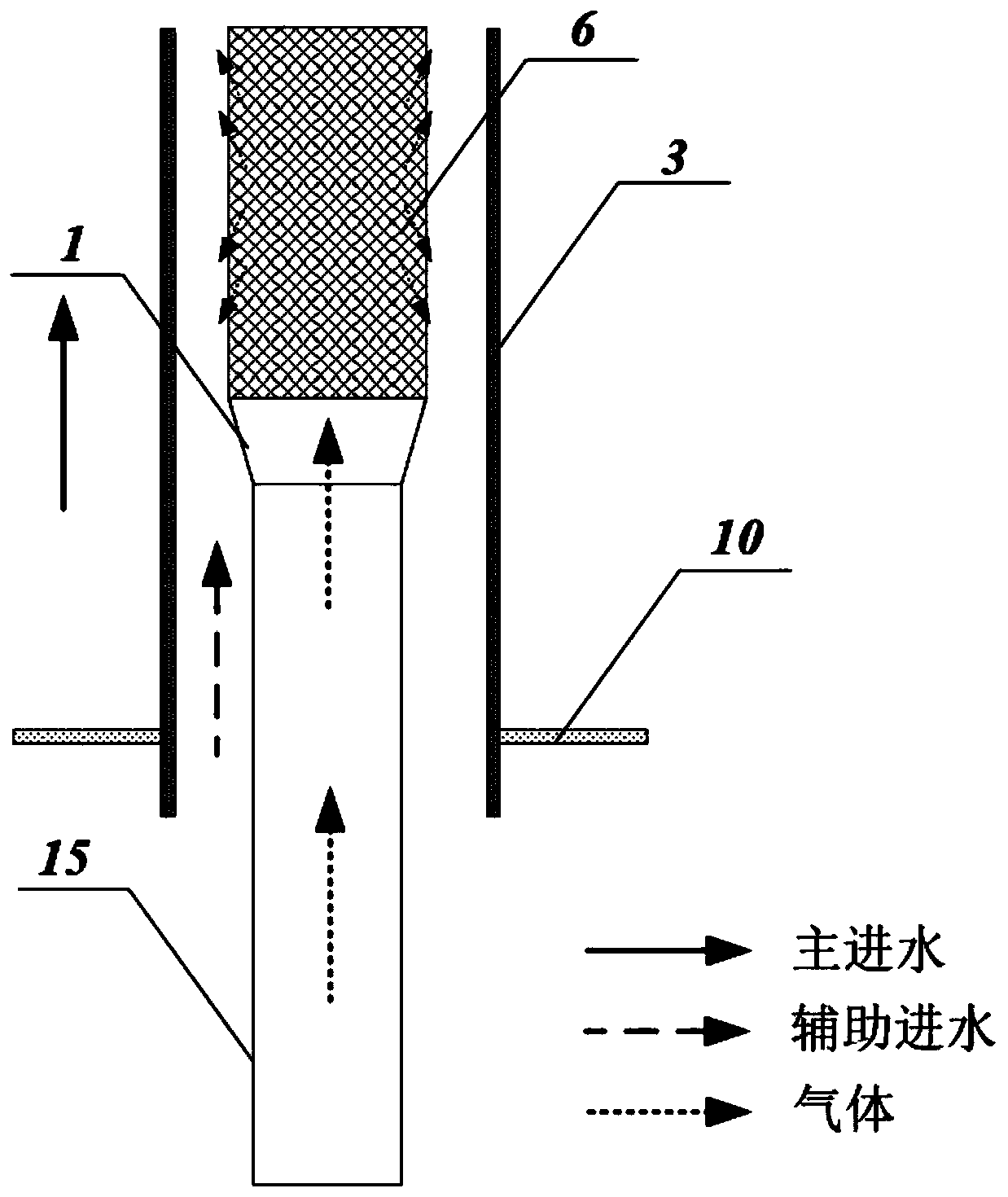

[0029] Such as figure 2 As shown, the filter element circular tube section 15, filter element transition section 1 and filter element porous section 6 are the basic components of the filter element structure, and are the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com