Patents

Literature

46results about How to "Reduce material selection requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

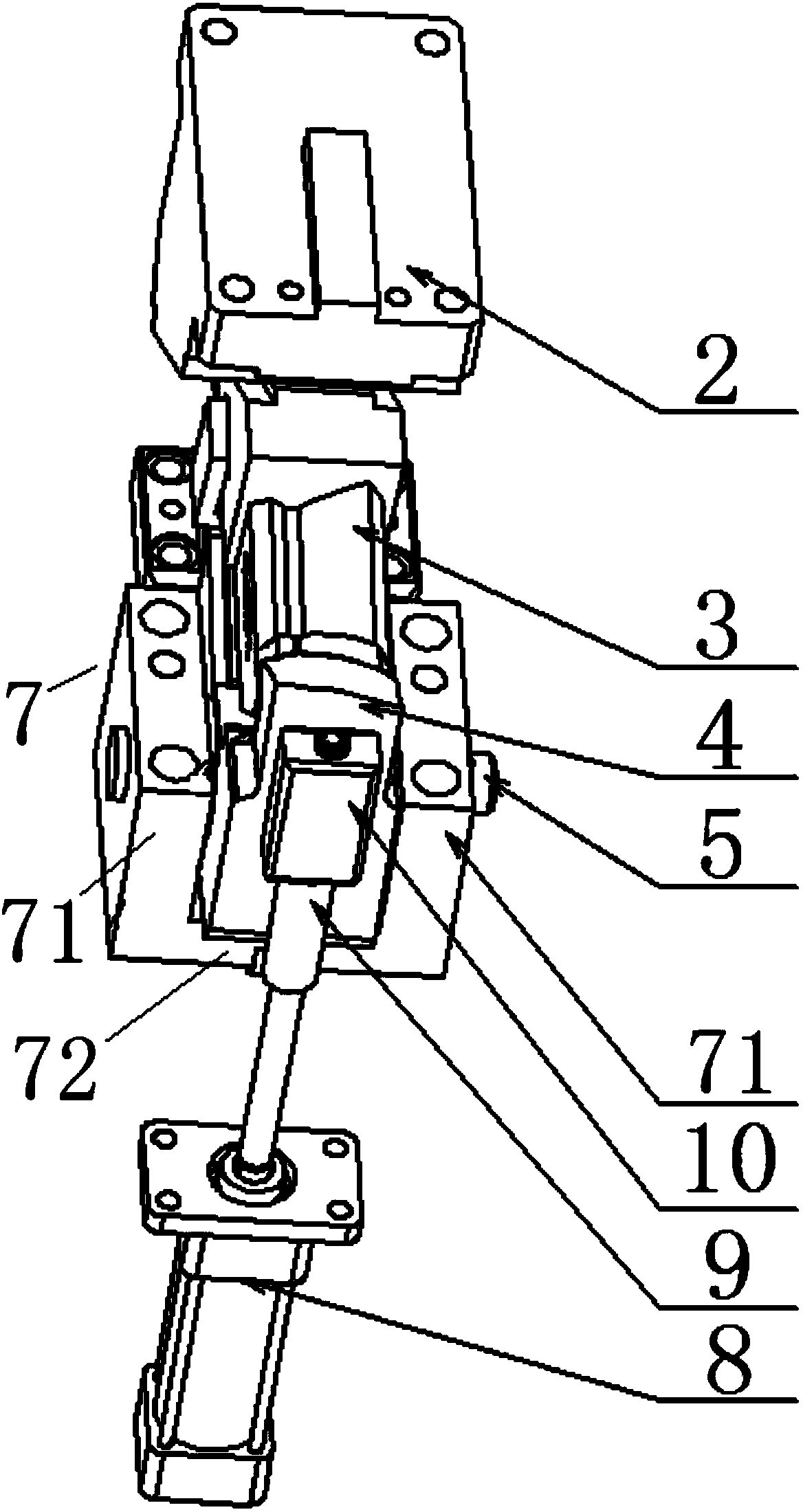

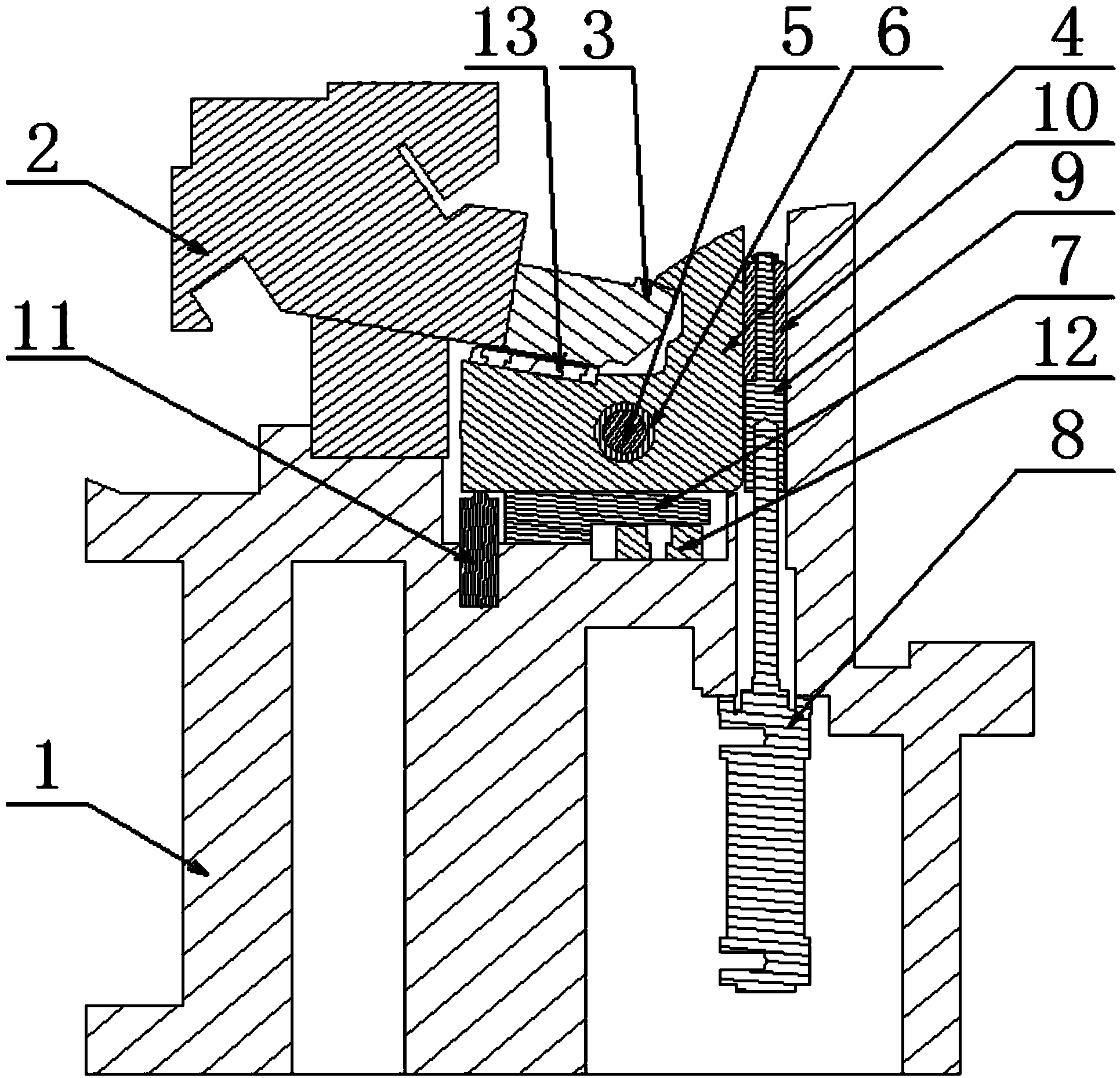

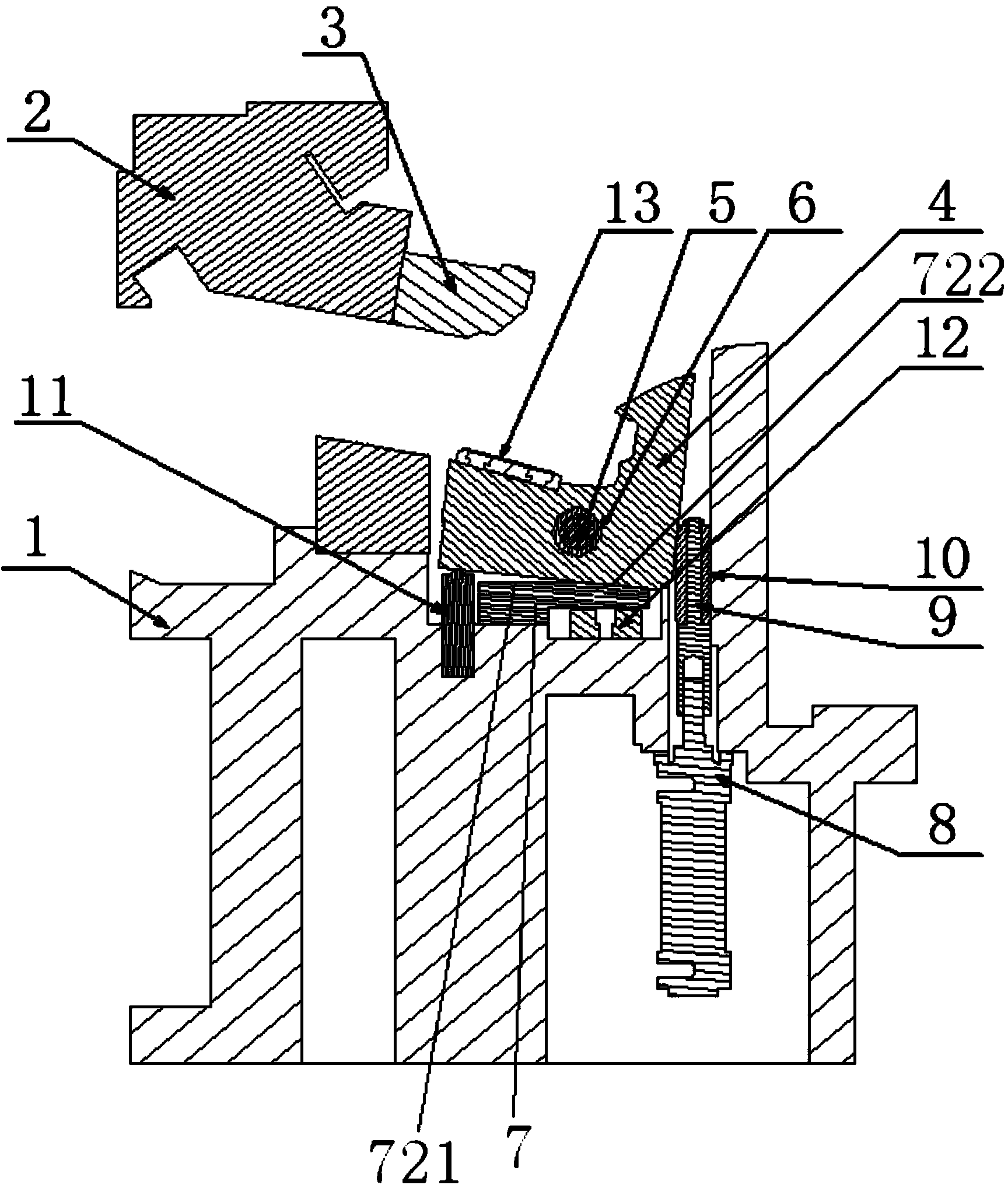

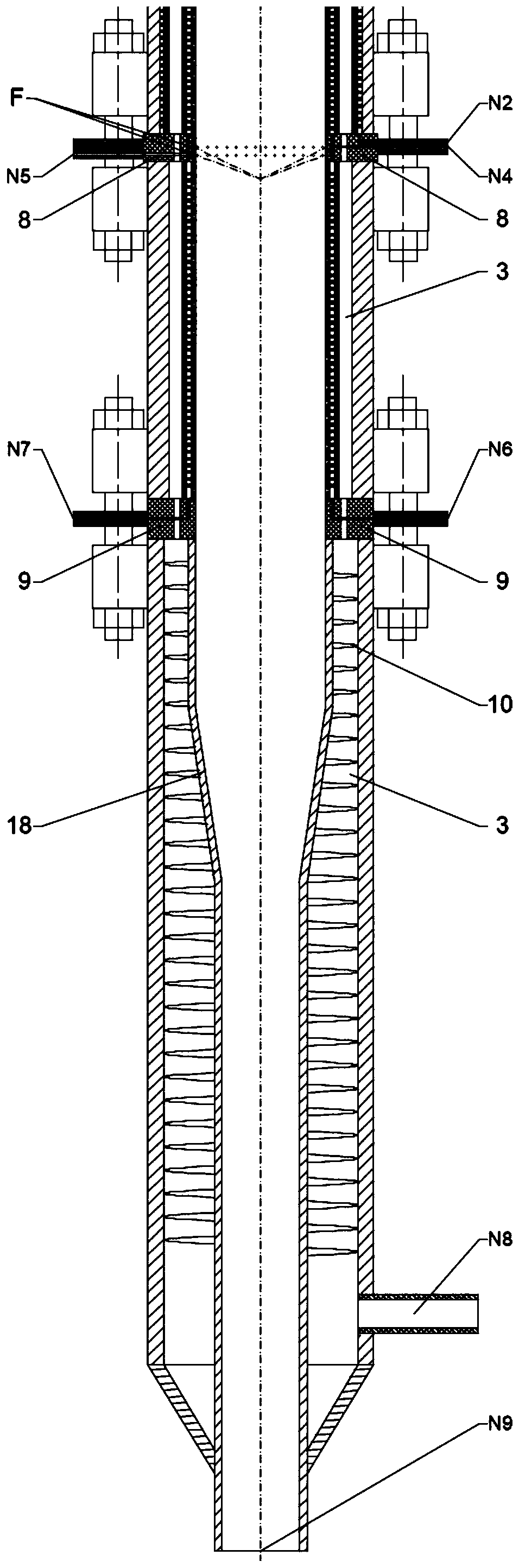

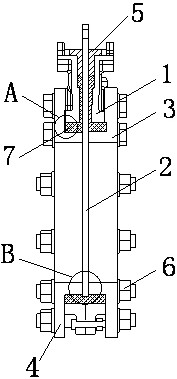

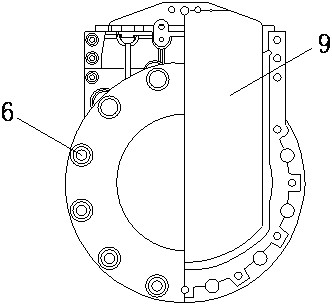

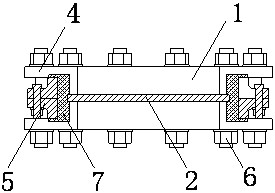

Regulatable supporter

InactiveCN1382873ASmooth rotationPrevent looseningBridge structural detailsConnectionsMechanical engineeringLocknut

A regulatable supporter is composed of top plate, top seat, ball hinge, screw piles, locking nuts, base of screw pile, locking screw and base, and can be regulated vertically and horizontally in stepless mode. Its advantages are less compression and high precision.

Owner:SHANGHAI MAGLEV TRANSPORTATION DEVELOPMENT CO LTD

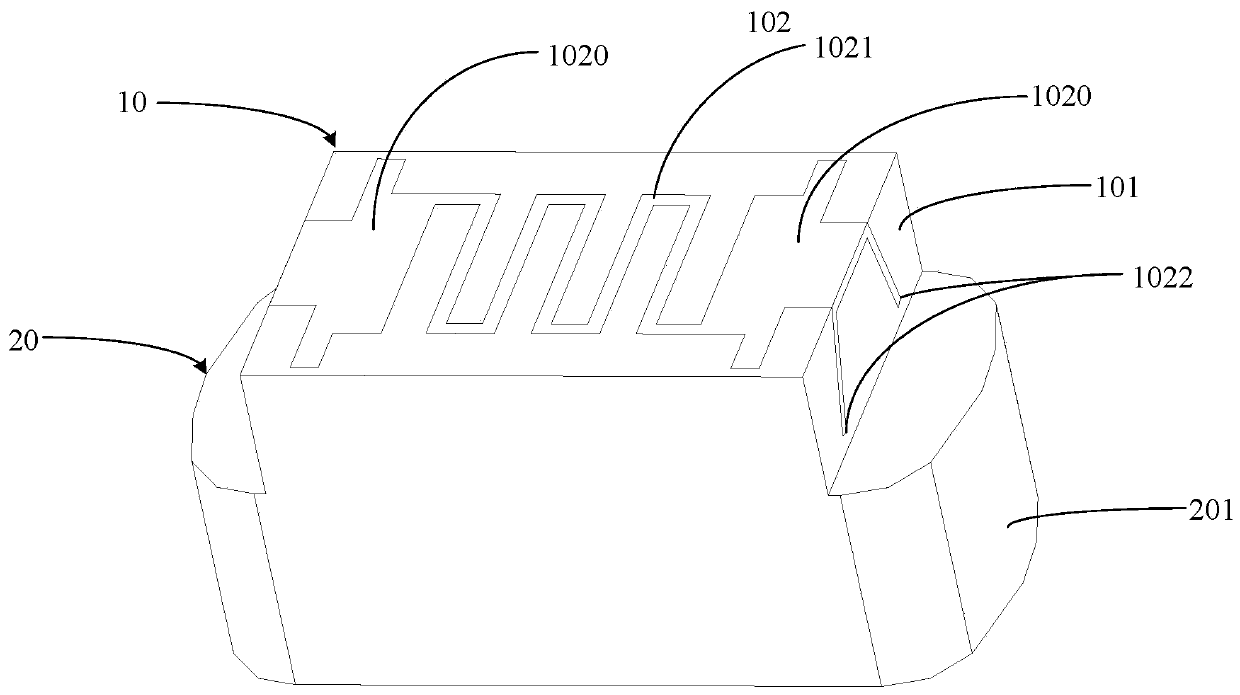

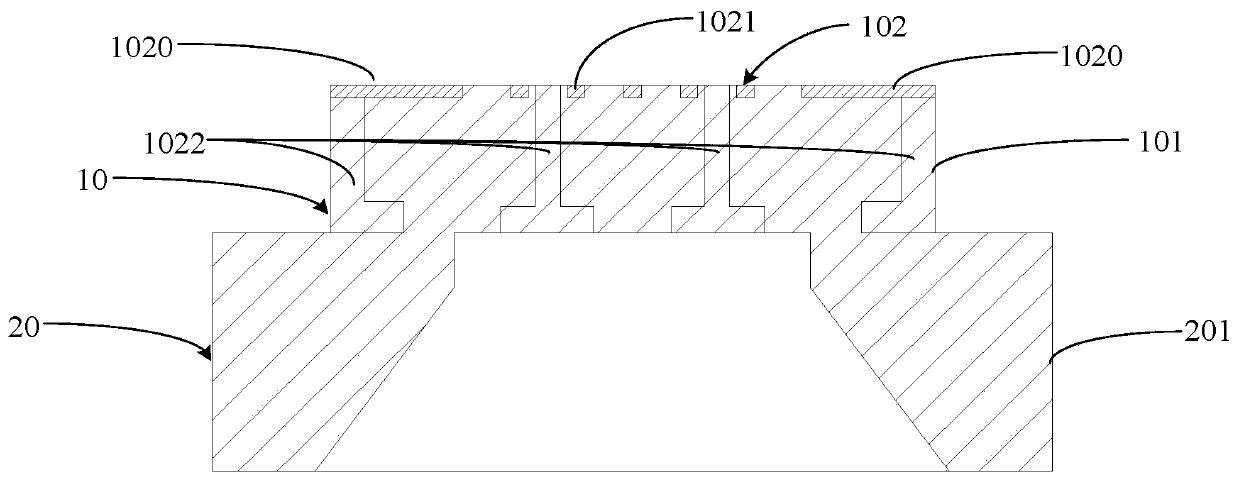

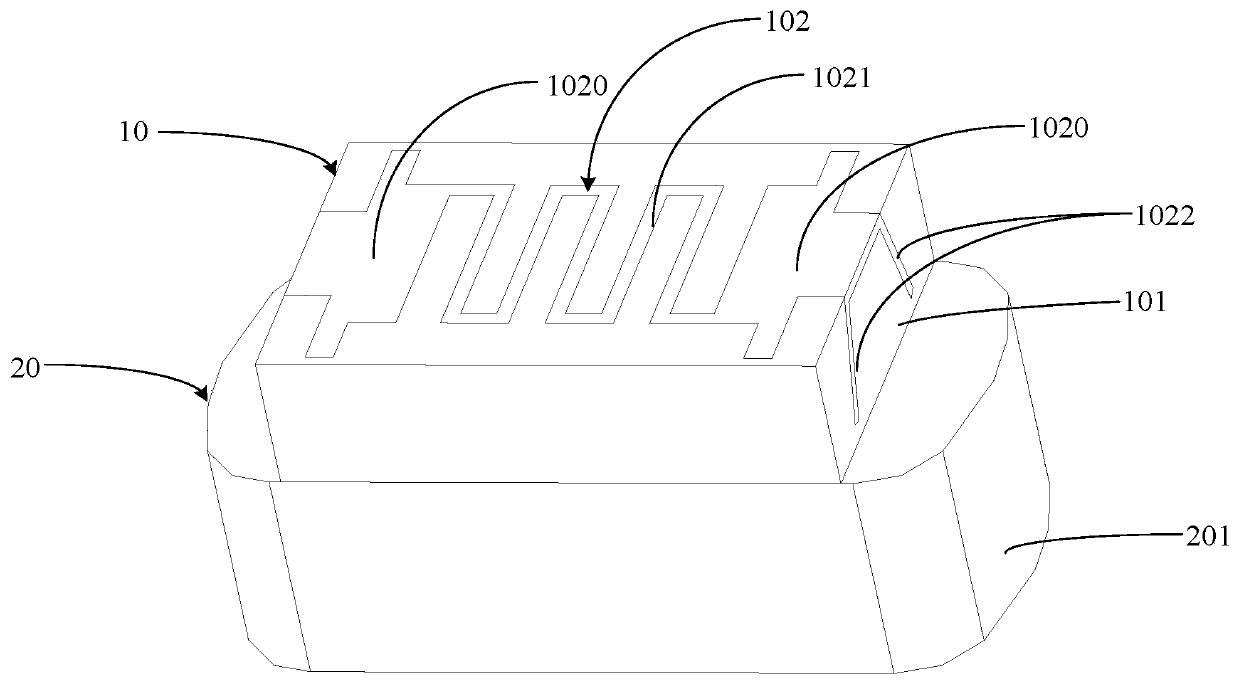

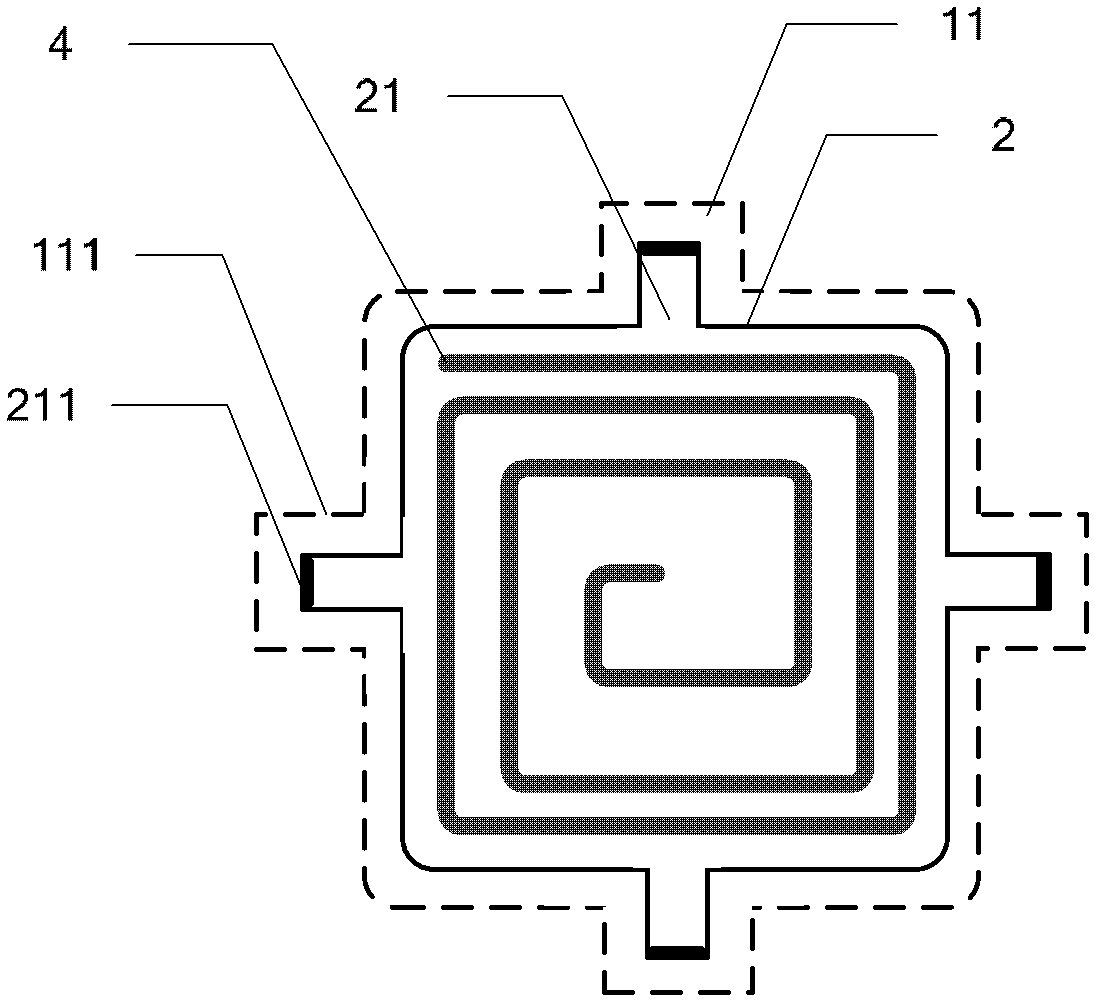

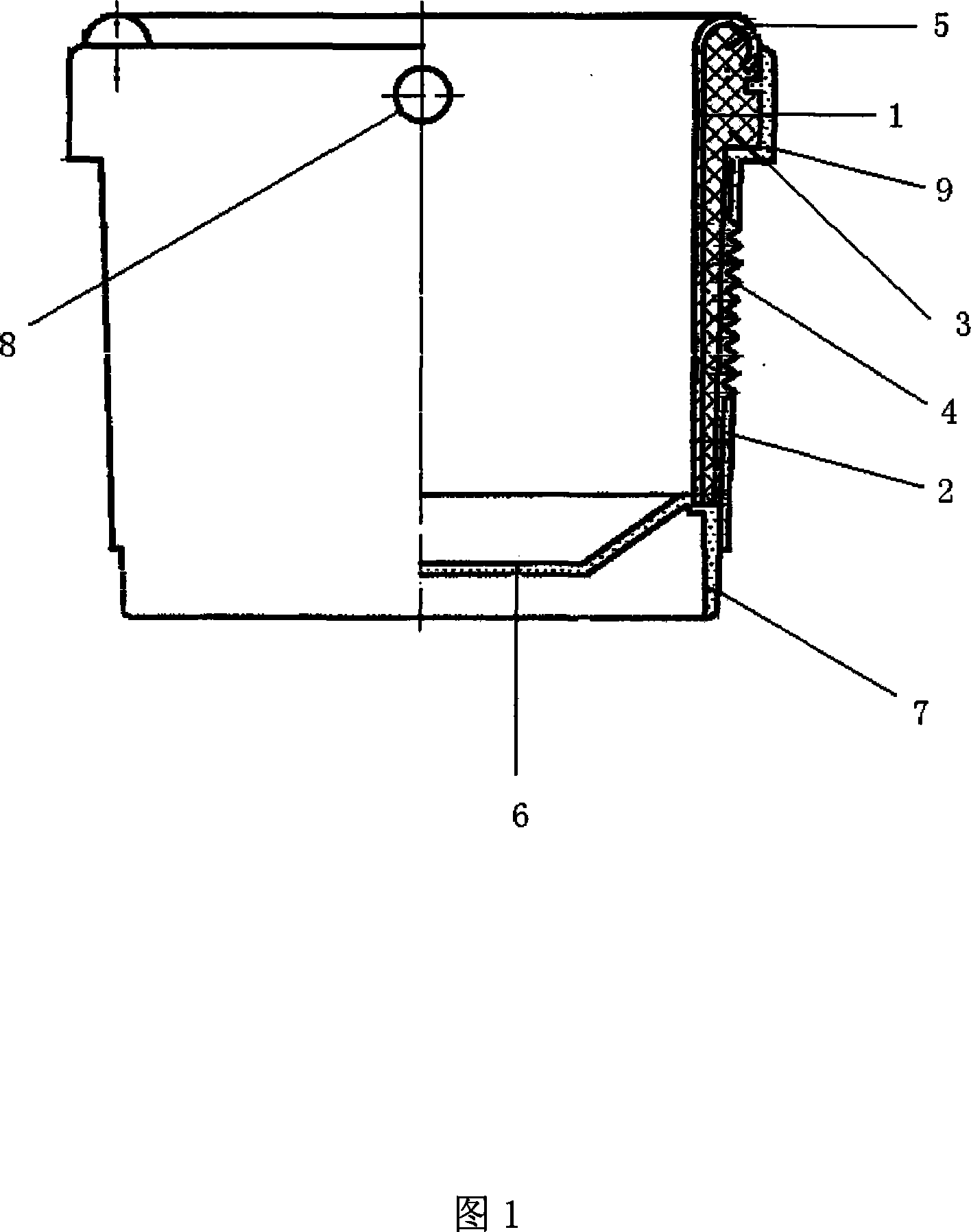

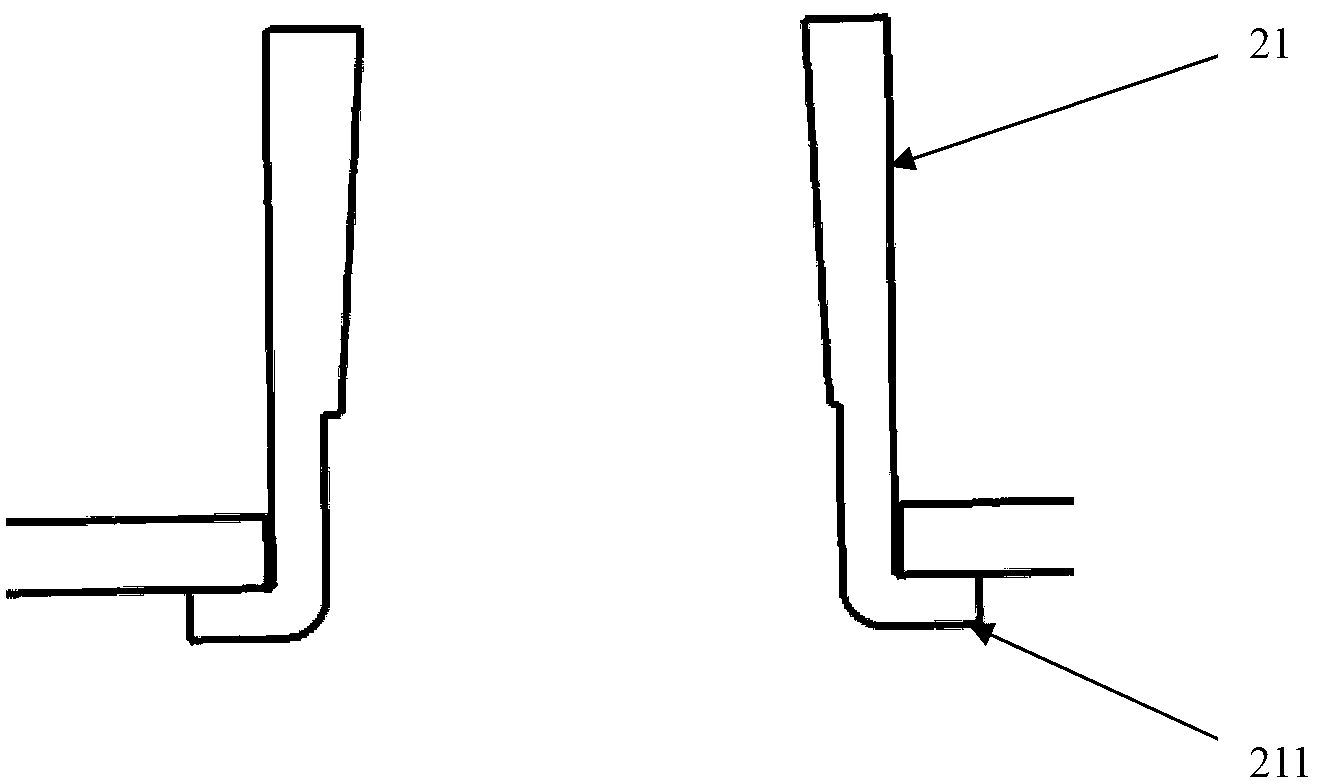

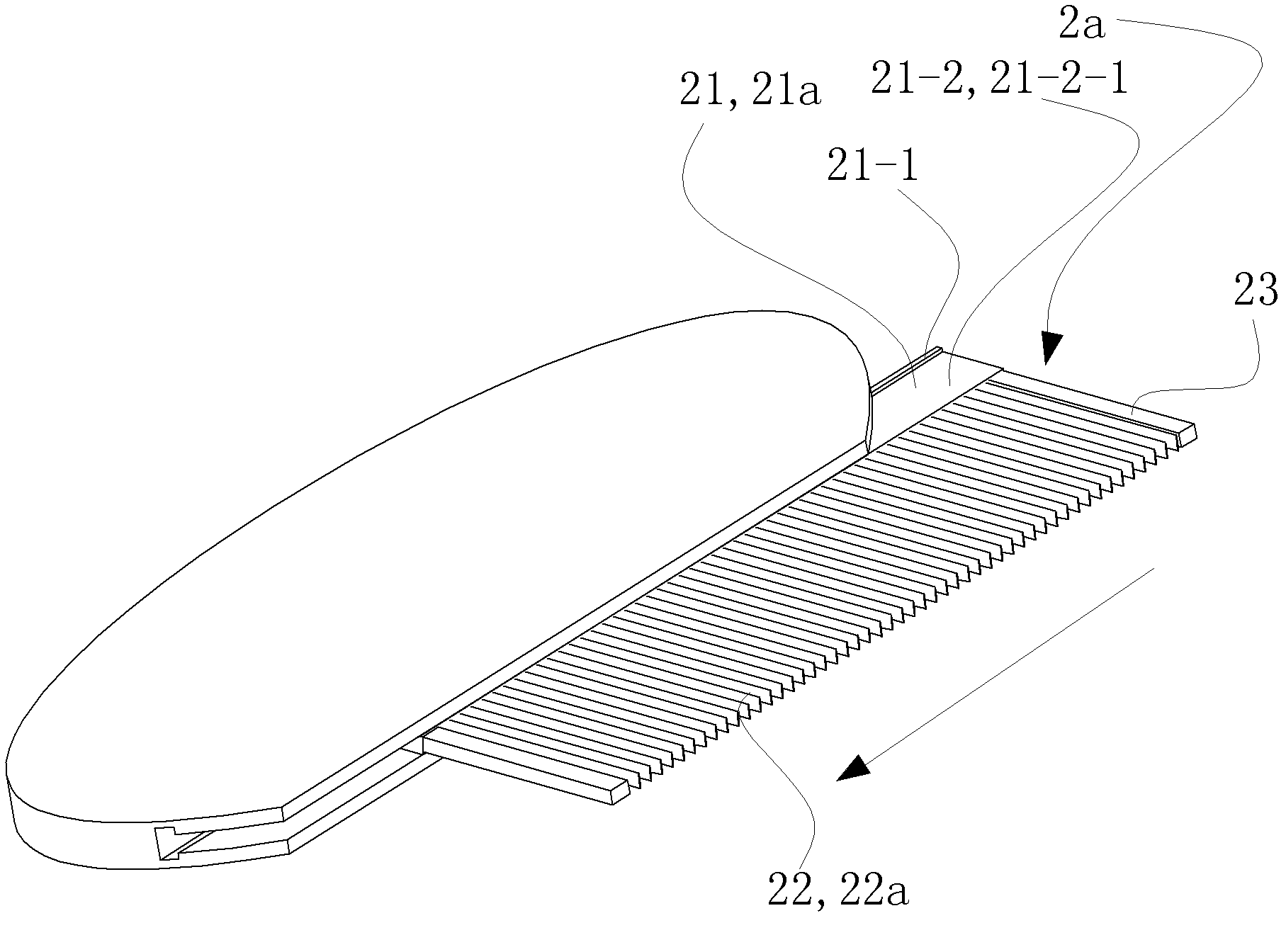

Electronic cigarette atomization core and preparation method thereof

PendingCN111000293AEasy to separateReduce material selection requirementsTobaccoElectronic cigaretteSmoke Emission

The invention relates to the technical field of electronic cigarettes, in particular to an electronic cigarette atomization core and a preparation method thereof. The electronic cigarette atomizationcore comprises a heating body and a tar storage body connected with the heating body; the heating body comprises a first ceramic block and a heating mesh embedded in the first ceramic block; the heating mesh comprises electrodes, a heating wire assembly connected between the electrodes and fixing pins. The depth of the electrodes and the heating wire assembly embedded in the first ceramic block is0.5-1 time of the thickness of the heating mesh; the depth of the fixing pins embedded in the first ceramic block is 0-1 time of the thickness of the first ceramic block, and the included angle between the fixing pins and the heating wire assembly is 0-180 degrees. By means of the mode, the heating mesh is not prone to being separated from the first ceramic block when heated, the requirement formaterial selection of the heating mesh and the first ceramic block is lowered, meanwhile, the requirement for the preparation process of the heating body is lowered, and the production yield is increased.

Owner:东莞市陶陶新材料科技有限公司

Recombined bamboo floor manufacturing method

InactiveCN104960062ALower requirementHigh hardnessFlat articlesDomestic articlesManufacturing engineeringMoisture

The invention discloses a recombined bamboo floor manufacturing method and relates to the technical field of bamboo product manufacturing. The method includes the steps that bamboos which are over four years old are broken into bamboo strips, and dried bamboo strips containing phenolic resin are manufactured through the procedures of carbonizing, drying, gum dipping, secondary drying and the like; then, bamboo strip square stocks with the density being 1.0-1.1 kg / cm<3> are manufactured by pressing the bamboo strips through a pressure machine and curing the bamboo strips through a curing oven; then, the square stocks are sawn into floor materials in a certain specification according to needs; finally, recombined bamboo floor products are manufactured through moisture control, planing, polishing, paint spraying and the like. The method can solve the problems that common bamboo floor manufacturing is limited in material source, and the service life is short.

Owner:LIUZHOU LONGTAI BAMBOO IND CO LTD

Method for preparing reconstituted bamboo floor through efficient glue dipping technique

InactiveCN106003344ALower requirementStrong glueRadiation/waves wood treatmentWood treatment detailsElastic modulusEngineering

The invention relates to a method for preparing a reconstituted bamboo floor through an efficient glue dipping technique. The method for preparing the reconstituted bamboo floor through the efficient glue dipping technique comprises the following steps of A, material selecting; B, cutting-off; C, shredding; D, two times of drying; E, glue dipping; F, pressing; G, dividing; and H, post-treatment. The elasticity modulus of the floor is not smaller than 7855 MPa, the static bending strength of the floor is not smaller than 96 MPa, and the glue stripping rate of the floor in boiling water is zero. By the adoption of the method for preparing the reconstituted bamboo floor through the efficient glue dipping technique, the problems that when an ordinary floor is manufactured, material limitation exists, and the service life is short can be solved.

Owner:FUJIAN GOLDEN BAMBOO IND

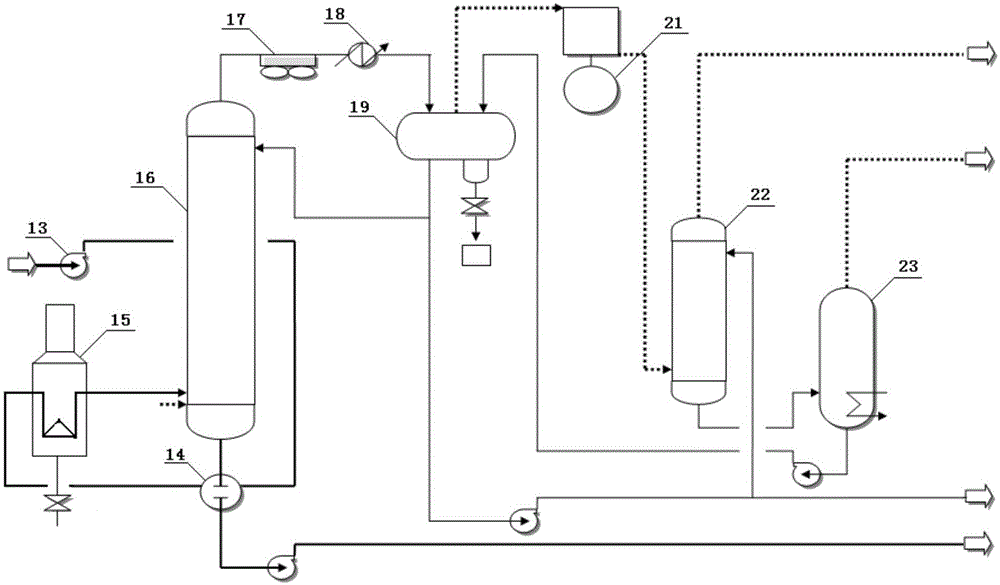

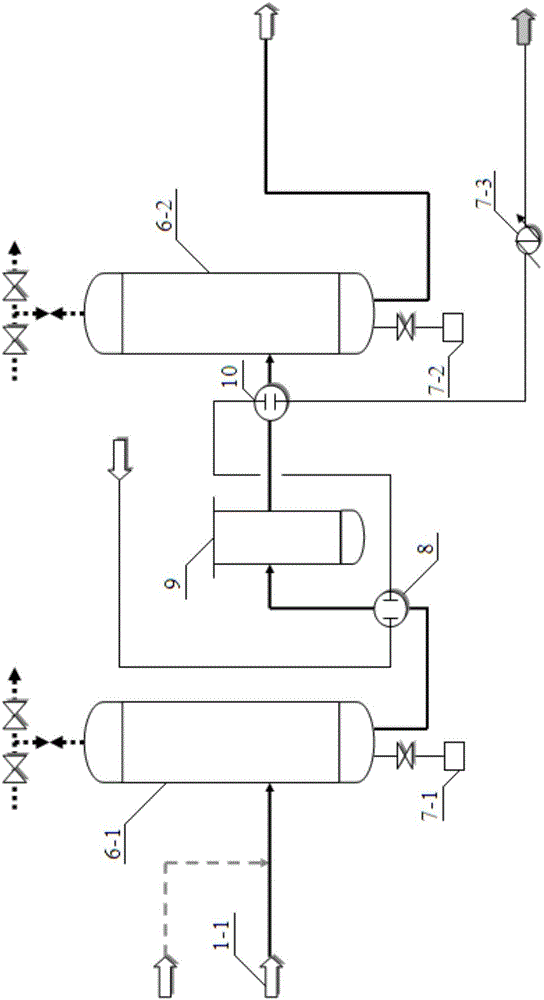

Method for preparing catalytic thermal cracking raw materials from full-fraction shale oil

ActiveCN105154134AImprove utilization efficiencyImprove the level of comprehensive utilizationDispersed particle separationTreatment with hydrotreatment processesPetroleum naphthaResidual oil

The invention discloses a method for preparing catalytic thermal cracking raw materials from full-fraction shale oil, relates to a full-fraction shale oil deep processing process, and aims to solve the technical problems of 'more money on exhibit and less money on counterfoil' and insufficiency in 'oil-chemical' combination degree of the current oil shale industrial structure in the conventional method. The method is conducted in the following units: 1, a raw material pretreatment unit; 2, an atmospheric distillation unit; 3, a reduced pressure distillation unit; 4, a hydrotreating unit; 5, a product fractional distillation unit. According to the method, the utilization ratio of the shale oil resource is effectively increased; the main product is hydrofined wax oil used as the raw material for a follow-up catalytic thermal cracking device; the by-products are high-value LPG, hydrogenated petroleum naphtha and hydrogenated diesel oil; light shale oil (lower than or equal to 350 DEG C) and residual oil (higher than 500 DEG C) which are thrown away from the process device can be further processed and utilized in a downstream device. The method belongs to the field of full-fraction shale oil deep processing.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

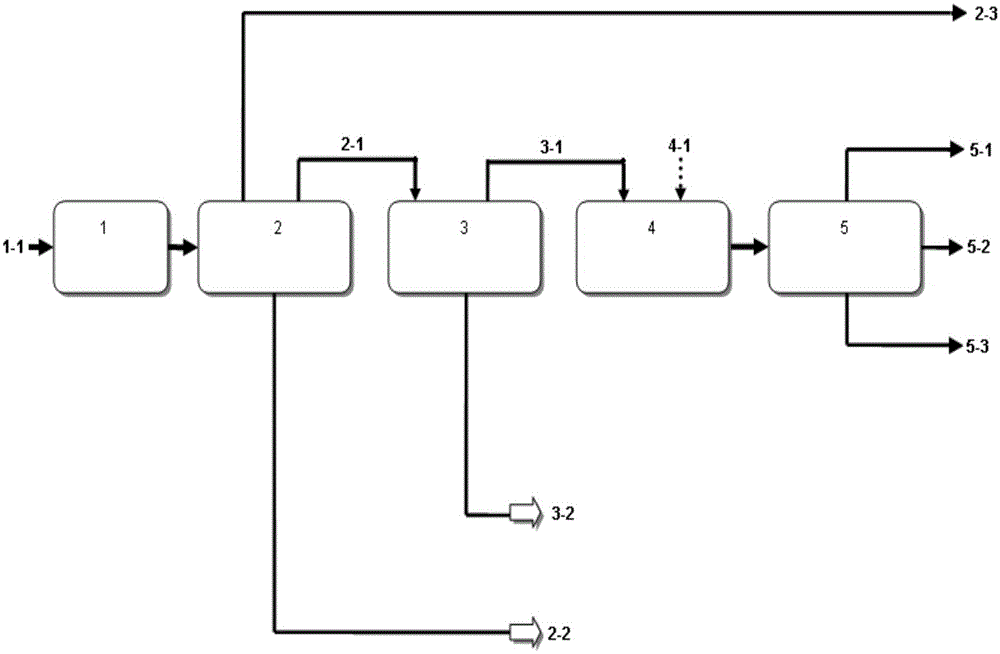

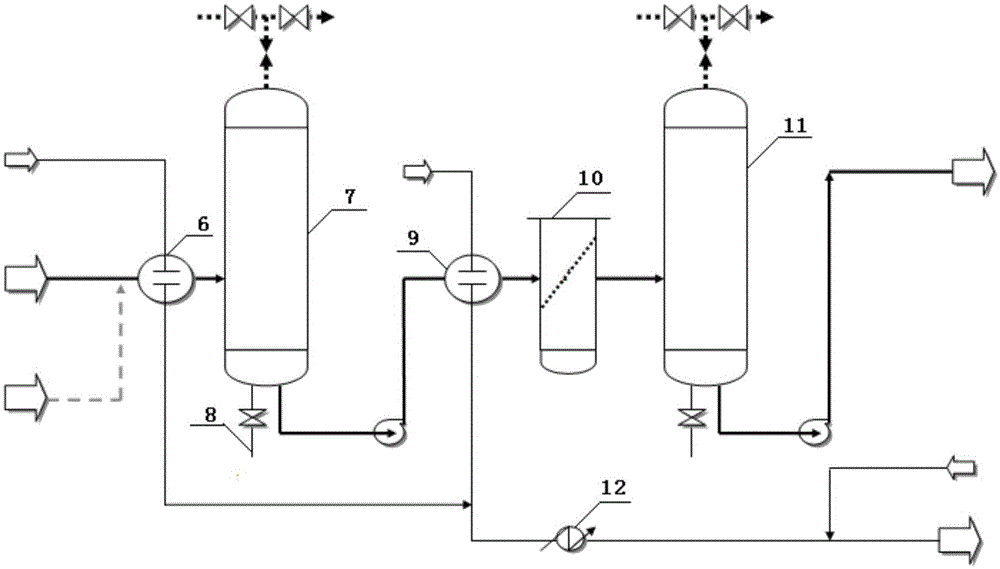

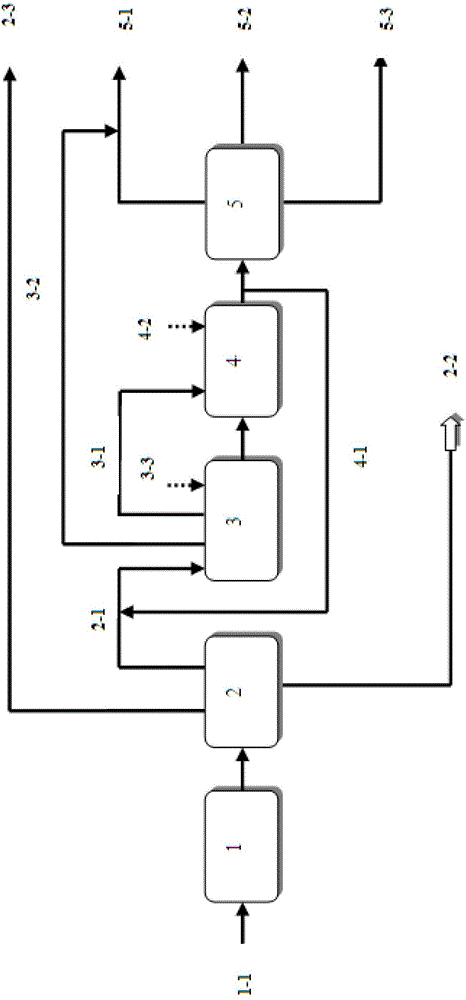

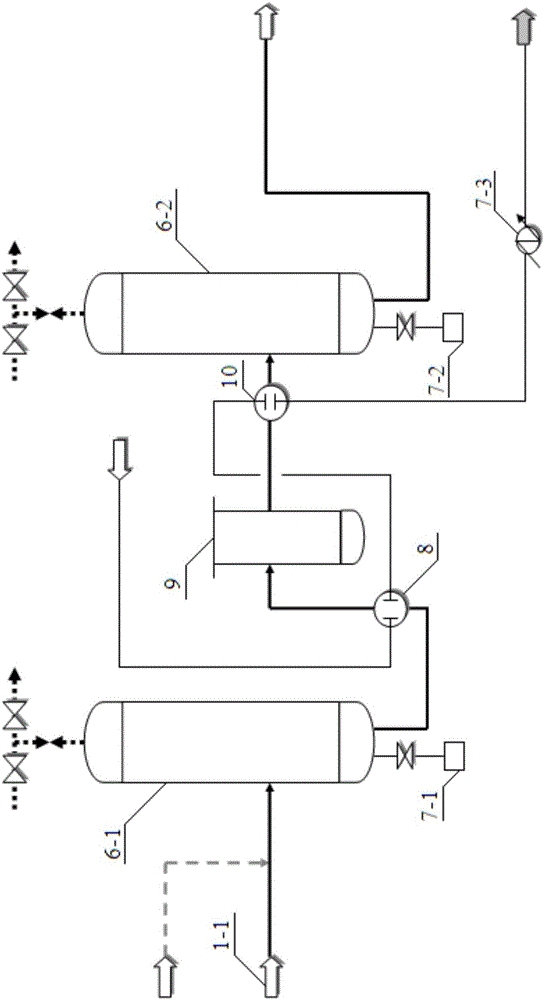

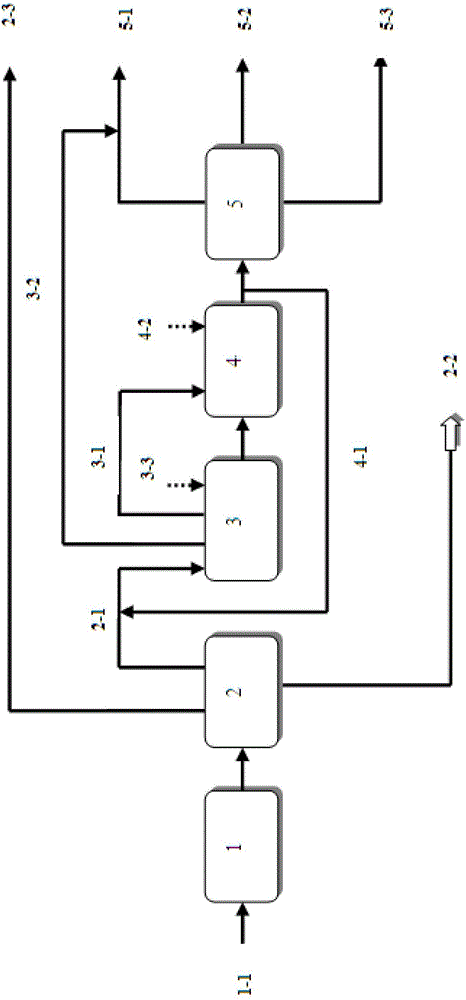

Method for improving shale oil hydrorefining denitrification rate

ActiveCN105838418AImprove utilization efficiencyImprove the level of comprehensive utilizationTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaFractionation

The invention provides a method for improving the shale oil hydrorefining denitrification rate, and relates to a whole fraction shale oil hydro-denitrification process. The method aims at solving the technical problems that in the existing method for producing diesel oil through shale oil hydrorefining, the stability of a diesel oil product is low, and the operation running period of a hydrorefining catalyst is short. According to the method, a raw material pretreatment unit 1, a raw material pre-fractionation unit 2, a primary hydrorefining reaction unit 3, a secondary hydrorefining reaction unit 4 and a product fractionation unit 5 are used. When the method provided by the invention is used for processing shale oil, the light oil yield is high; the nitrogen content of the diesel oil product is low; the chromaticity and the stability conform to national V standard requirements; the goal of light oil product deep denitrification can be achieved; the service life of the hydrorefining catalyst is prolonged; the operation running period of the catalyst is improved. A main product of the method is hydrorefining diesel oil; byproducts are high-value LPG and hydrogenated naphtha; heavy shale oil and hydrogenation tail oil thrown out in the technical process can be further processed and used in a downstream device. The method provided by the invention belongs to the field of whole-fraction shale oil deep processing.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

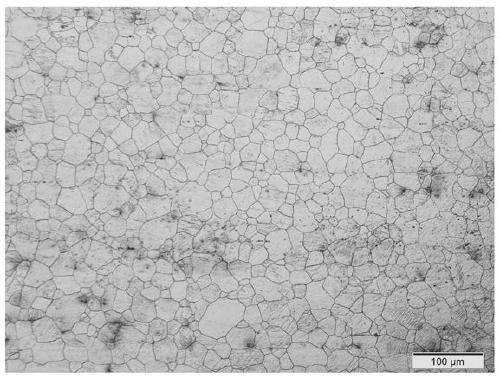

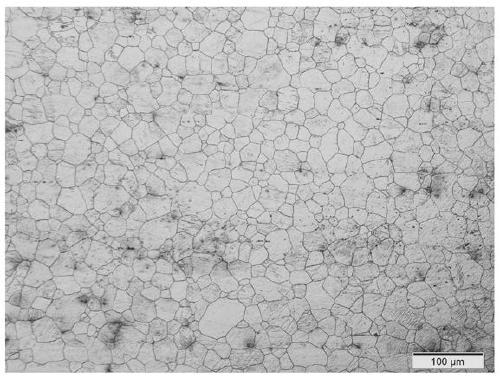

Method for quickly preparing magnesium alloy fine crystalline wire and superfine magnesium alloy wire based on drawing process

ActiveCN110193525AIncrease the degree of deformationReduce the temperatureNonferrous metalRoom temperature

The invention discloses a method for quickly preparing a magnesium alloy fine crystalline wire and a superfine magnesium alloy wire based on a drawing process, belongs to the field of nonferrous metalplastic forming, and aims to solve the technical problem that an existing magnesium alloy drawing process is liable to have wire breakage, and is not ideal in crystalline grain size. The method for preparing the magnesium alloy fine crystalline wire comprises the following steps: thermally extruding magnesium alloy cast ingots into bars with diameters Phi being 6mm-10mm, and annealing the bars; II, performing thermal drawing on the bars, and immediately water-cooling the bars to the room temperature after each-pass thermal drawing; III, performing continuous cold-drawing on the bars, and air-cooling the bars to the room temperature; and IV, repeating operations of steps II to III until the diameters Phi of the bars are 1.0mm-1.5mm. The method for preparing the superfine magnesium alloy wire comprises the following steps: step 1, performing continuous cold-drawing on the magnesium alloy fine crystalline wire until the diameter Phi of the wire is lower than 1.0 mm, and air-cooling the wire to the room temperature after annealing; and step 2, repeating the operation of step 1 until the diameter Phi of the wire is 0.10mm. The Phi 0.10mm wire prepared by the method has an average crystalline grain size of 1[mu]m.

Owner:HARBIN UNIV OF SCI & TECH

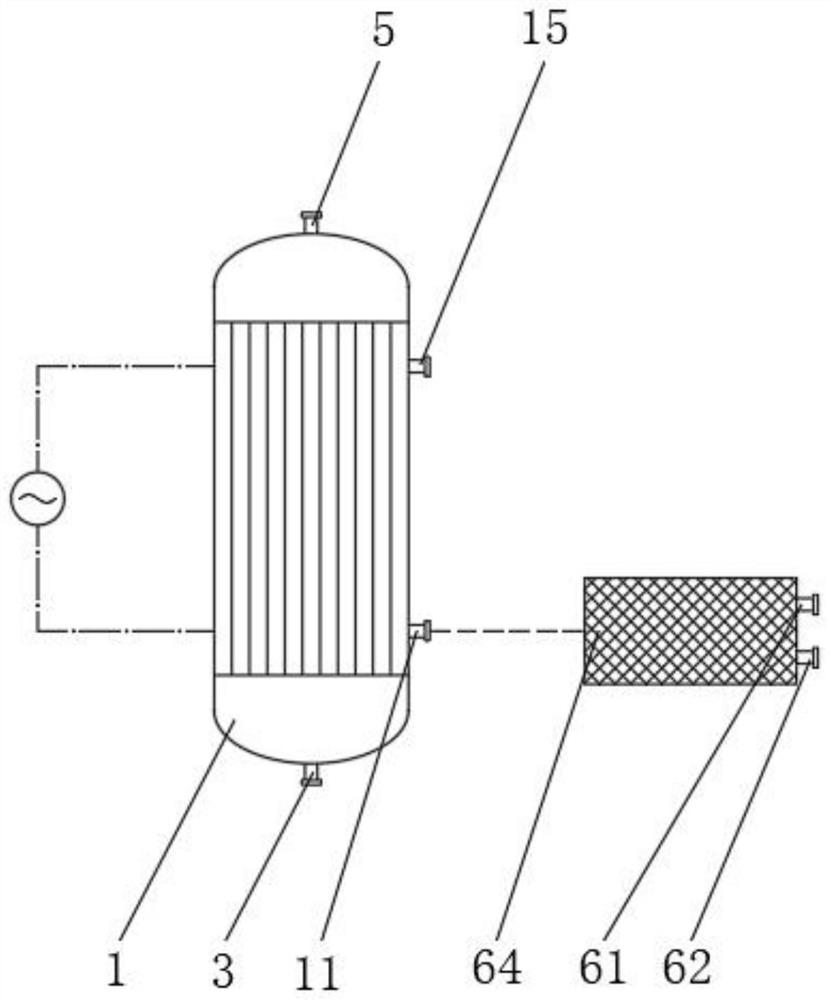

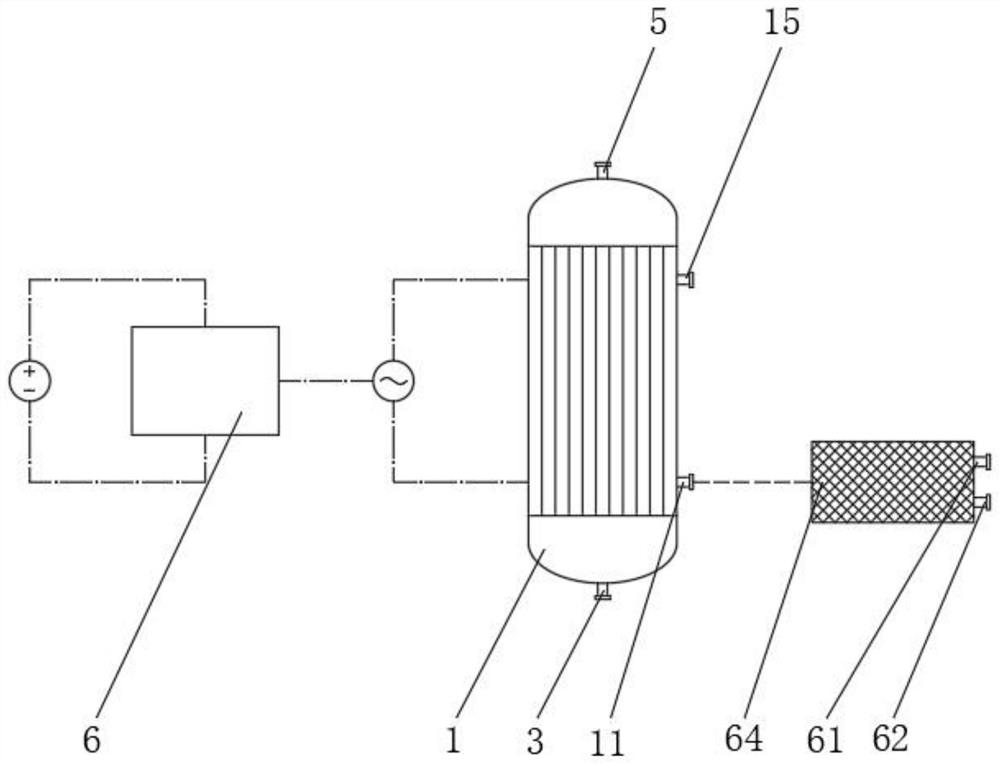

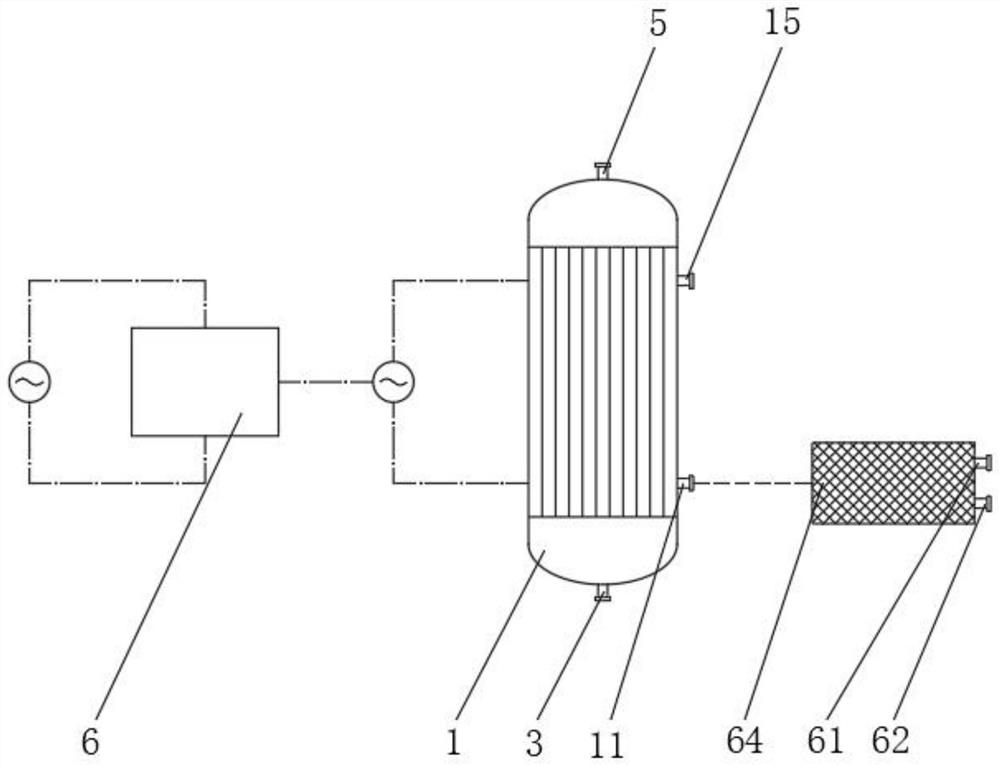

Electrical synergistic heat supply reforming reaction system

ActiveCN112265962AContinuous and smooth operationFast startupHydrogenHydrogen/synthetic gas productionThermodynamicsFlue gas

The invention discloses an electric synergistic heat supply reforming reaction system which comprises a reforming reactor and an electric synergistic heat supply device, a flue gas convection area anda reforming reaction area are formed in the reforming reactor, and the flue gas convection area comprises a flue gas distribution device and a flue gas flow guide device. According to the electric synergistic heat supply reforming reaction system, by switching the heat contribution ratio of electric heating to flue gas heating, the reactor continuously and stably operates when either electric power or fuel gas is insufficient in supply; electric synergistic heat supply is adopted, the reforming reactor is high in starting speed, and the reactor can enter a stable production state within a fewminutes; convection smoke is generated in a non-open-fire catalytic combustion mode, the combustion temperature of catalytic combustion is low, and generation of NOx gas is remarkably reduced; meanwhile, an ultra-high-temperature area in the reactor is avoided, the requirement for reactor material selection is lowered, the service life of equipment is prolonged, and wide application prospects areachieved.

Owner:庄焱法

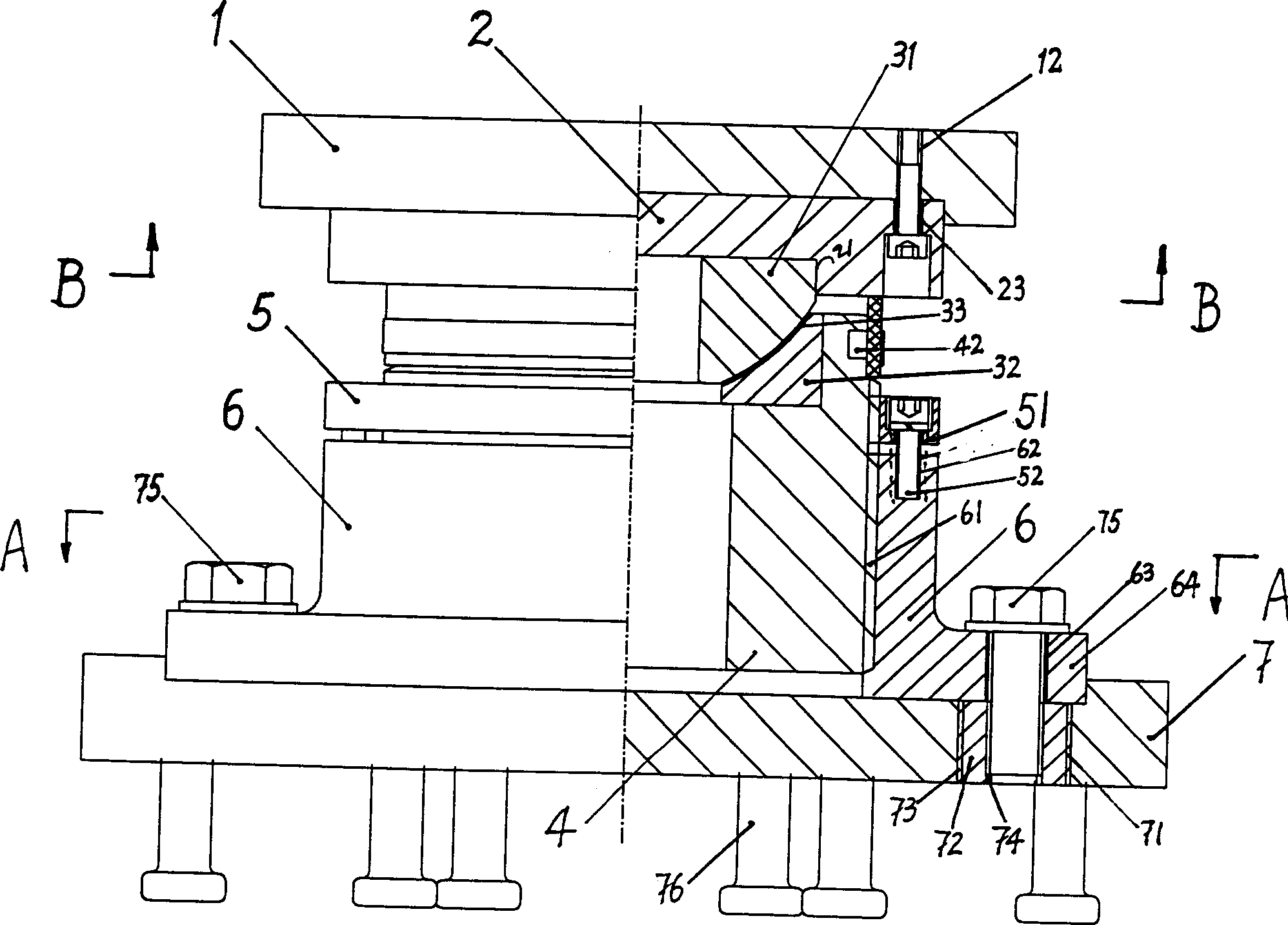

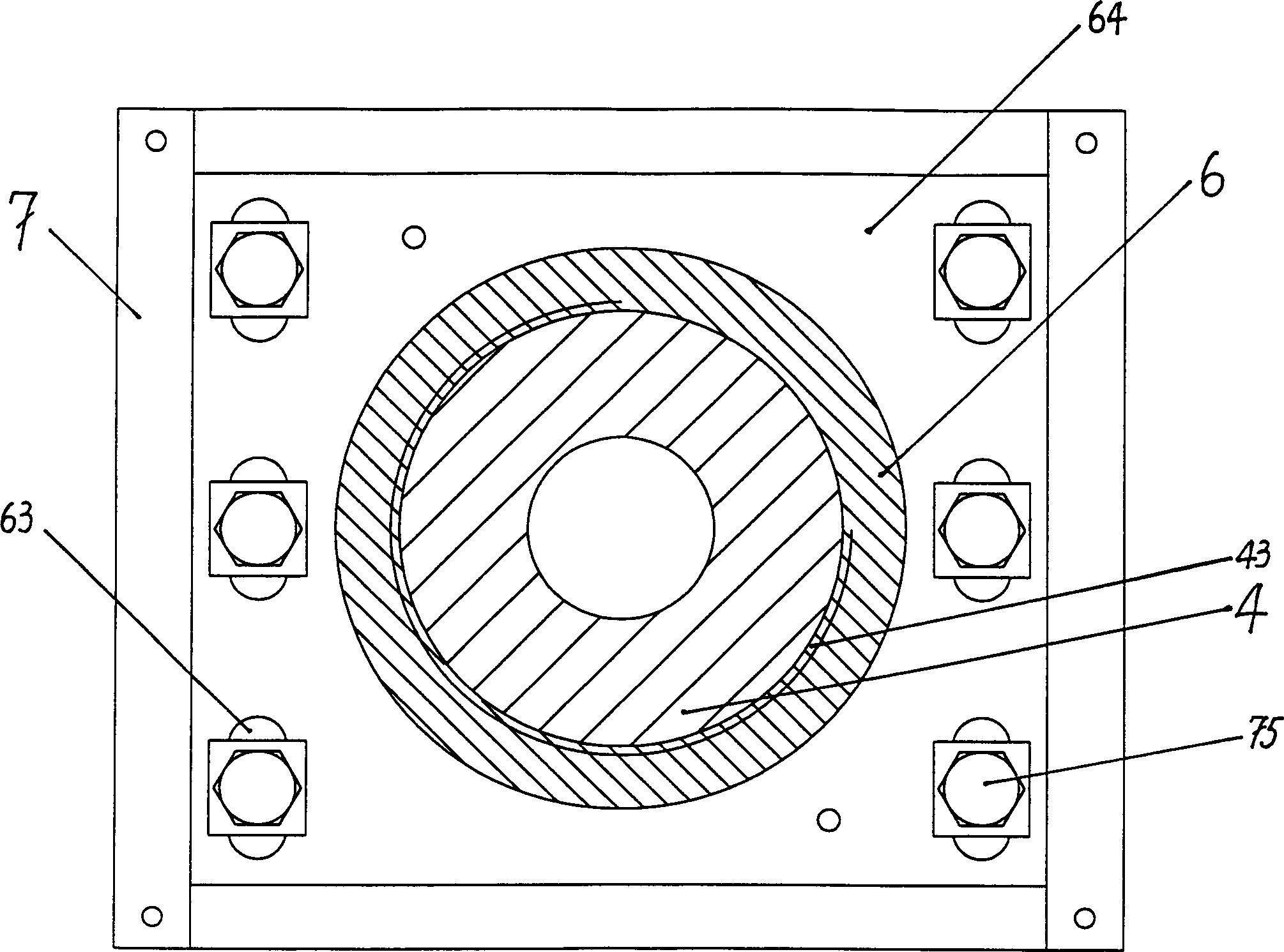

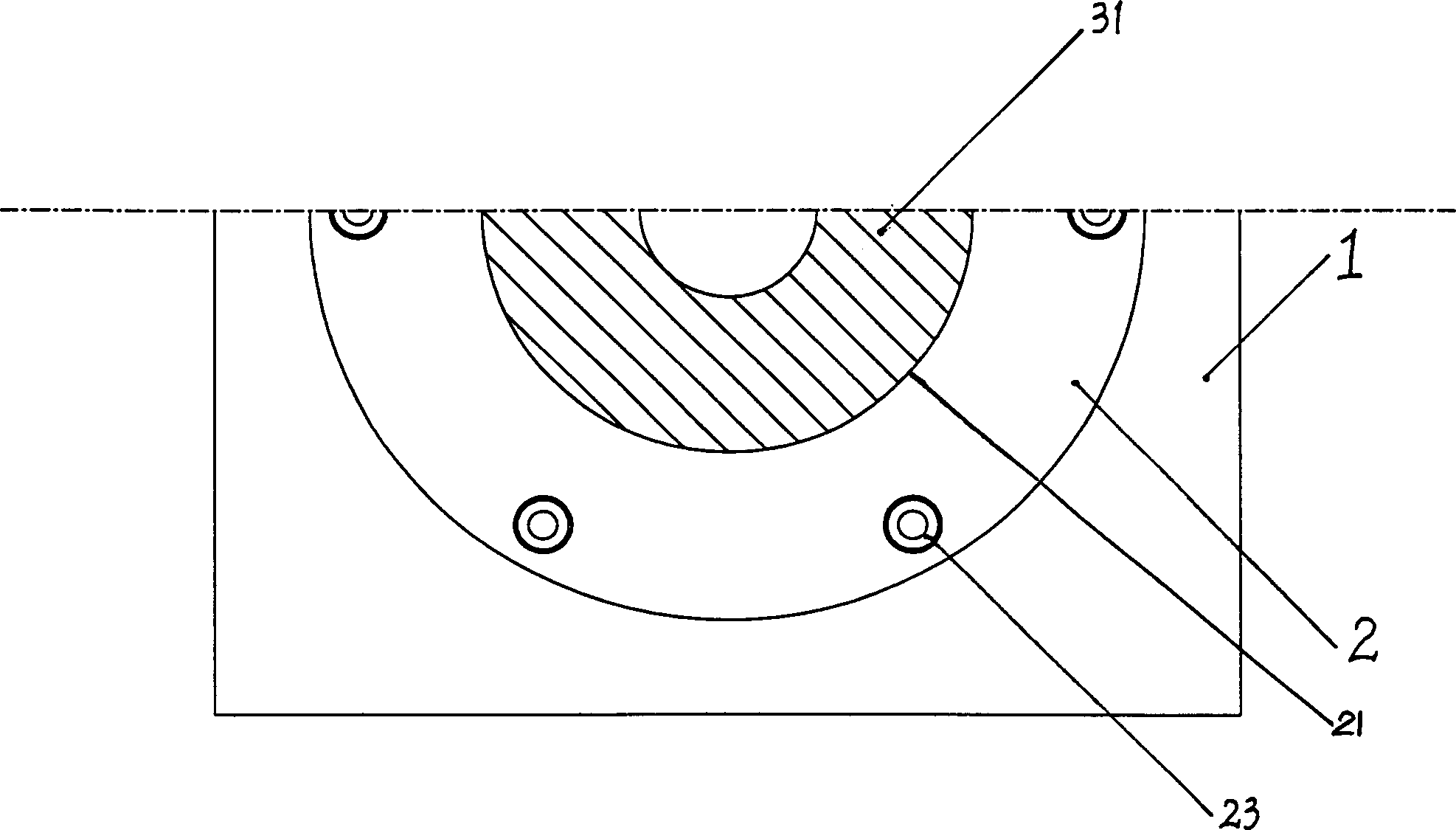

Rotational inclined wedge mechanism

ActiveCN103537561AReduced machining profileEasy to repair and replaceShaping toolsAngular degreesEngineering

The invention discloses a rotational inclined wedge mechanism. A base is fixedly arranged inside a lower die holder of the rotational inclined wedge mechanism and is provided with a pair of connecting lugs arranged oppositely in the longitudinal direction and a base plate connected between the connecting lugs, and rotating shafts with axes coincide in the longitudinal direction are fixedly arranged on the connecting lugs; a rotating portion and the rotating shaft are arranged in a matched mode through a shaft sleeve, the rotating portion can rotate relative to the rotating shafts, and the rotating portion rotates to a working position under the pushing function during the movement of an inclined wedge sliding block and rotates to a workpiece picking position under the reset function of a driving elastic piece; the inner surface of the base plate is provided with two planes which are connected at an angle, and the two planes are respectively a first limit plane and a second limit plane against which the bottom plane of the rotating portion abuts at the working position and the workpiece picking position; a positioning block is arranged on a return stroke cylinder in the lower die holder and is clamped between the lower die holder and the rotating portion when the return stroke cylinder is in a state corresponding to the working position to limit the rotating portion to rotate relative to a lower die. According to the rotational inclined wedge mechanism, through the improvement on rotating and positioning structures, the manufacturing costs and the overall size of the rotational inclined wedge mechanism are optimized.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

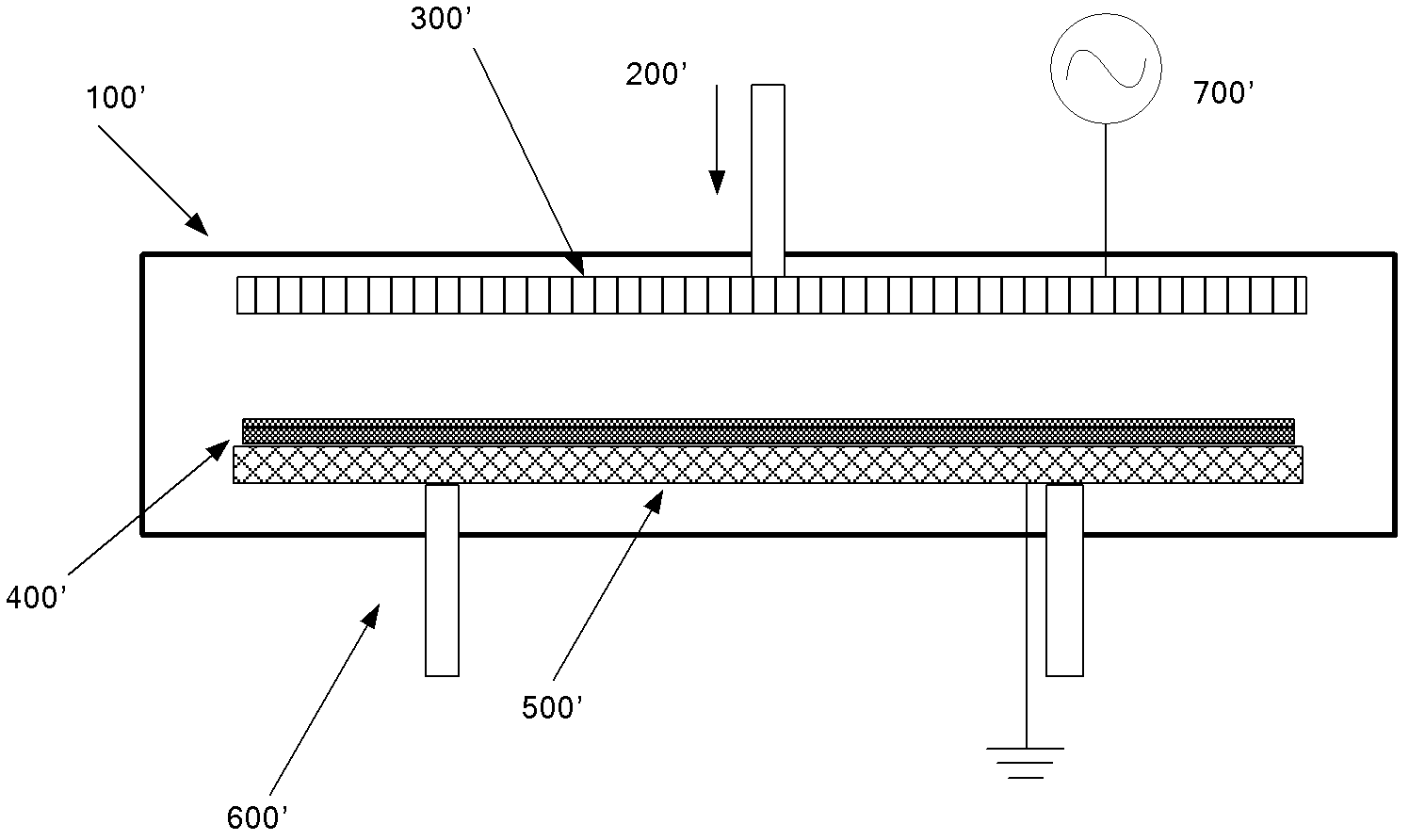

Lower electrode assembly and chemical vapor deposition equipment comprising the same

InactiveCN103160812AImprove heating efficiency and heat utilizationLow costChemical vapor deposition coatingHeating efficiencySemiconductor

The invention provides a lower electrode assembly and semiconductor processing equipment comprising the lower electrode assembly. The lower electrode assembly comprises a substrate, a tray, a tray support, a heater and a lifting mechanism, wherein the substrate is used for conveying and carrying a wafer; the tray support is connected with the tray to support the tray; the heater is arranged in the tray; and the lifting mechanism is connected with the tray support and used for lifting and descending the tray so that the heater can better heat the wafer. According to the lower electrode assembly, the heating efficiency and the heat utilization rate are improved, and cost is lowered.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

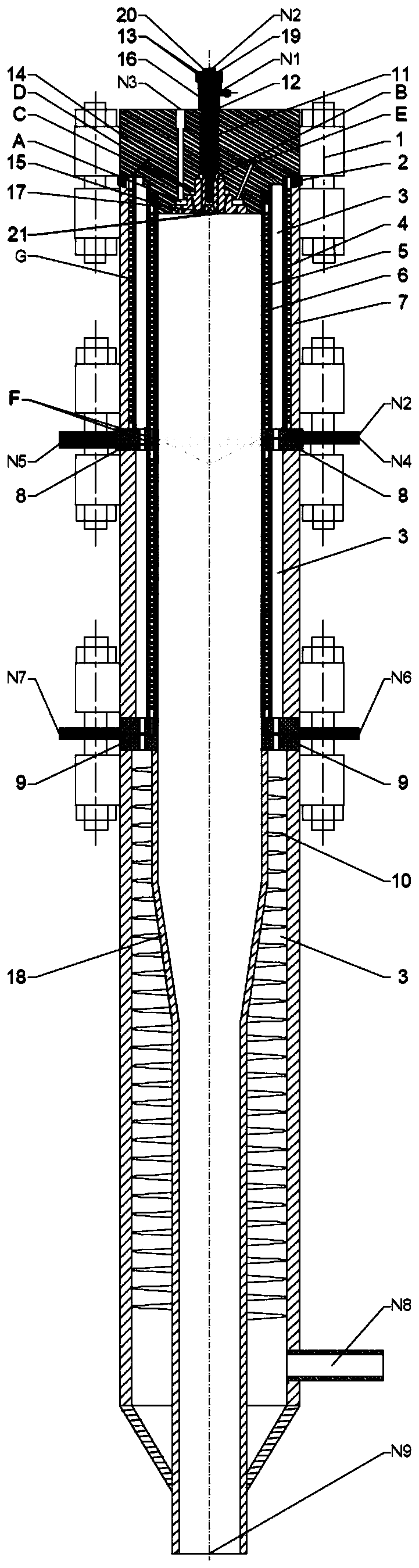

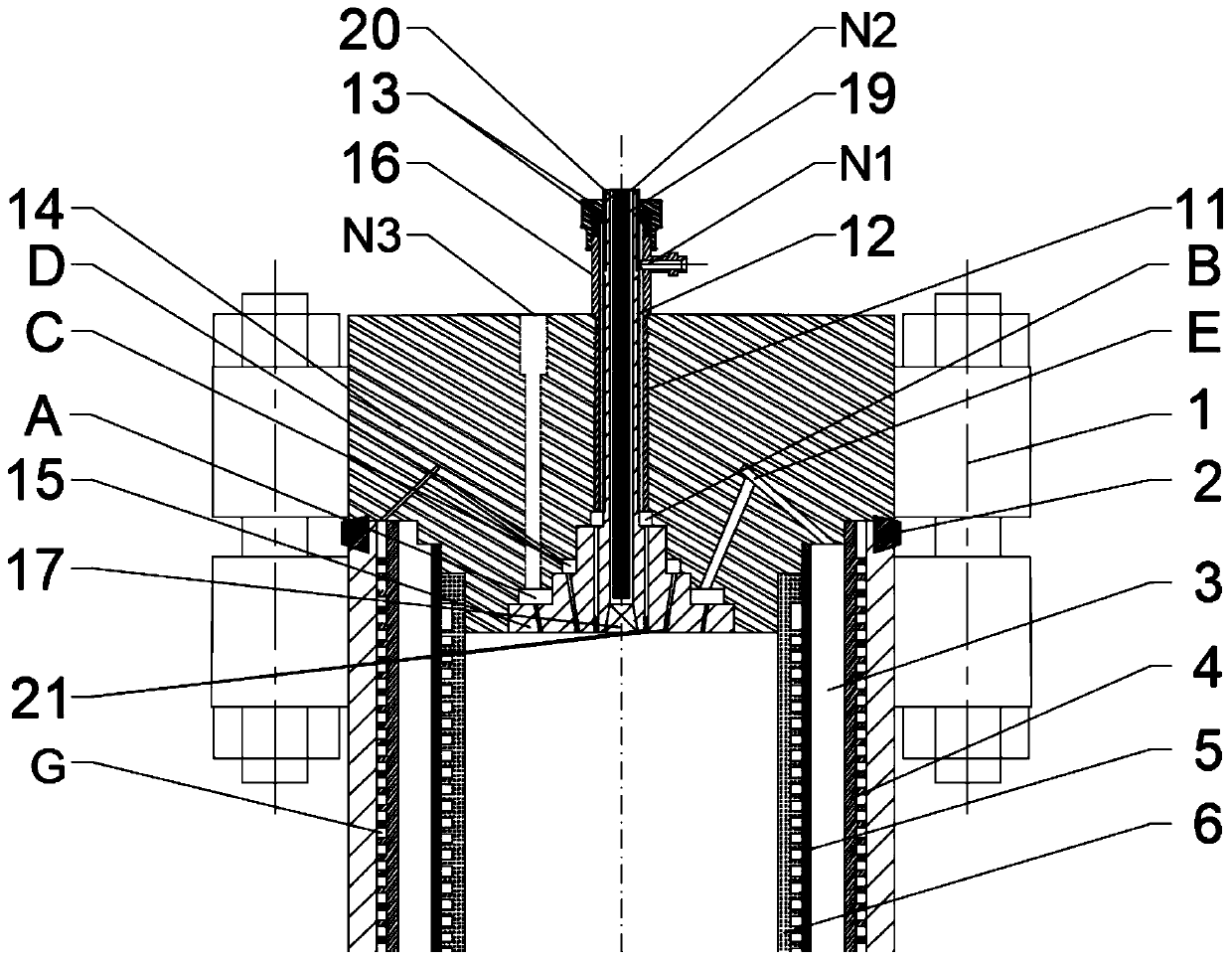

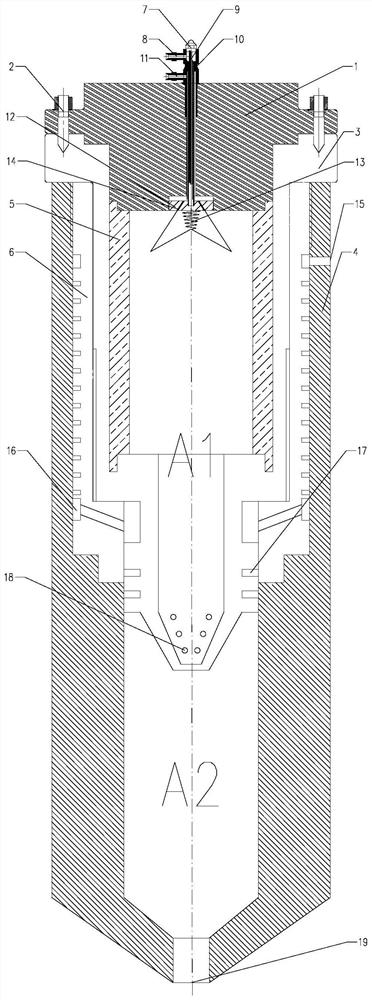

Supercritical water reactor which integrates material preheating, multi-stage enhanced degradation of pollutants and corrosion prevention into one

PendingCN110642362AReduce consumptionPromote degradationWater contaminantsWater/sewage treatment by oxidationEnvironmental engineeringCoaxial nozzle

The invention discloses a supercritical water reactor which integrates material preheating, multi-stage enhanced degradation of pollutants and corrosion prevention into one. An outer end cover and a split pressure-bearing wall of the reactor are connected through a sealing part and a connecting structure so as to achieve tight connection under supercritical pressure, wherein the end cover is disposed at the upper end of the split pressure-bearing wall, a coaxial nozzle abutment is arranged at the center of the bottom of the end cover, and a plurality of annular space of reactants are formed through exquisite cooperation of the end cover and the nozzle abutment. The reactor is provided with multiple stages of oxygen injection mouths and multiple stages of auxiliary fuel injection mouths soas to enhance the reaction process. The reactor is provided with an evaporation wall structure, and a subcritical / supercritical water film or a high-temperature gas film is formed inside the reactor through the evaporation wall, so that corrosion to the inner wall surface of the reactor is slowed down effectively, and the temperature of the reactor is maintained effectively. Through the reactor, heat exchange between organic waste and reaction products in the reactor can be achieved, exothermic heat of the reaction can be made full use of, and heat consumption can be reduced effectively in thepreheating process.

Owner:XI AN JIAOTONG UNIV

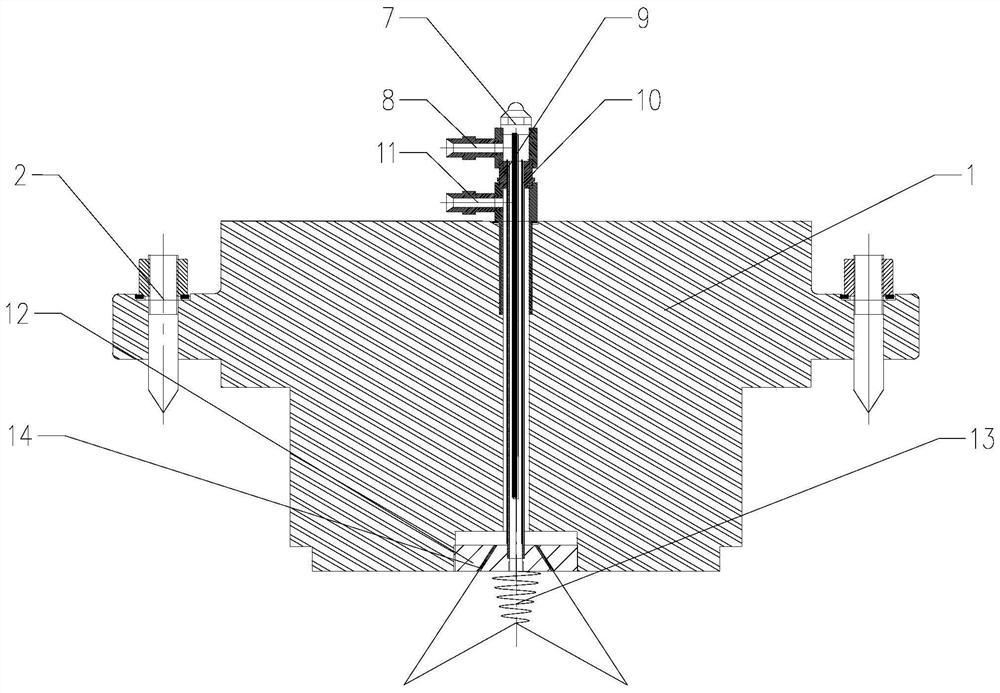

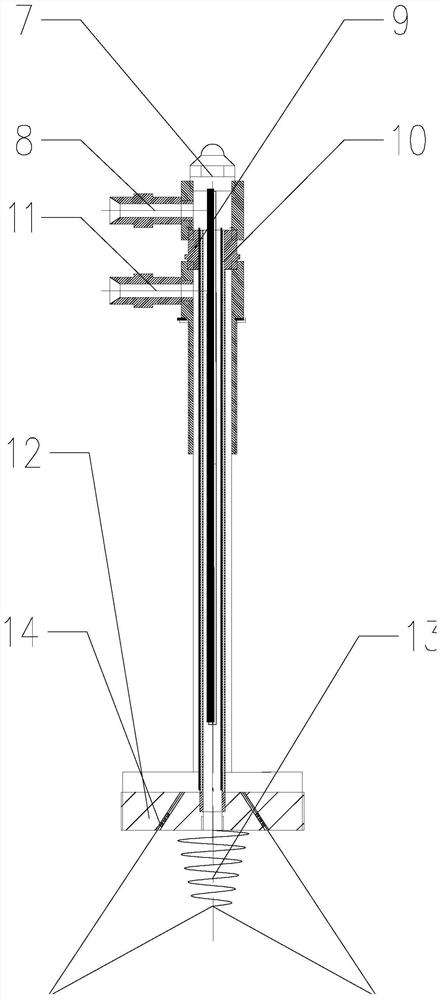

Supercritical hydrothermal combustion device capable of realizing temperature control and pressure control

ActiveCN113739137AAchieve cryogenic incidenceReduce consumptionBurnersBulk chemical productionTemperature controlCombustion chamber

The invention discloses a supercritical hydrothermal combustion device capable of realizing temperature control and pressure control. The supercritical hydrothermal combustion device comprises a generator end cover, a mixing barrel, a reactor wall and a spiral cooling barrel. A nozzle platform is arranged at the bottom of the reactor end cover, is provided with an oxidant spiral nozzle, and is in threaded connection with an atomizing nozzle to ensure that fuel and an oxidant are uniformly mixed. A heat preservation groove is formed in a connecting barrel so that it can be guaranteed that the fuel is heated to the set temperature by a heating rod. Water in a cooling spiral channel flows downwards to cool a combustion chamber, then enters a mixing spiral channel and is mixed with reaction fluid flowing out of a mixing barrel outlet hole group, and the temperature control target is achieved. A necking-down structure of the middle of the combustion chamber, a necking-down structure of the bottom of the combustion chamber, the mixing cylinder outlet hole group and the like can achieve the purpose of pressure control.

Owner:XI AN JIAOTONG UNIV

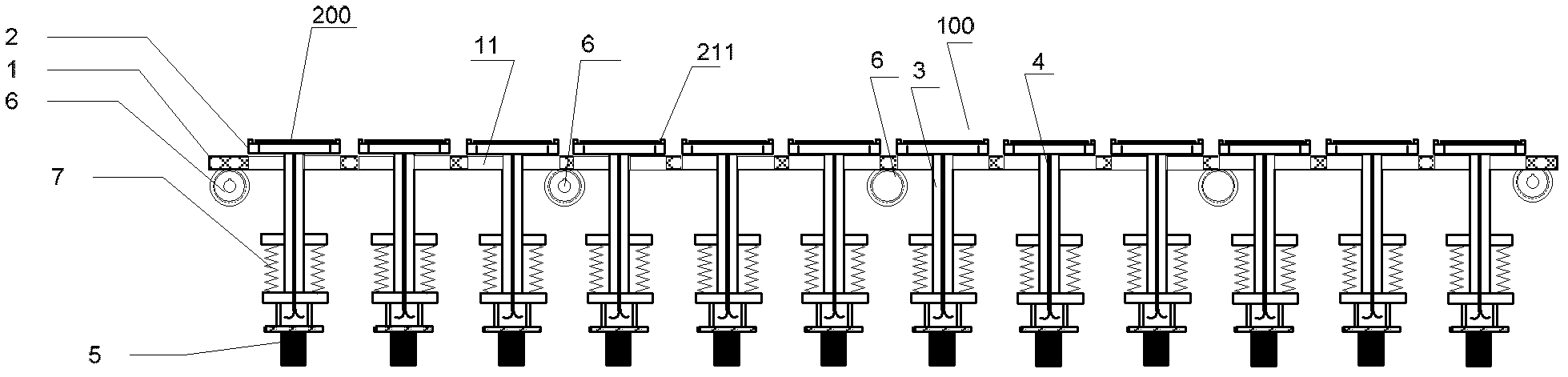

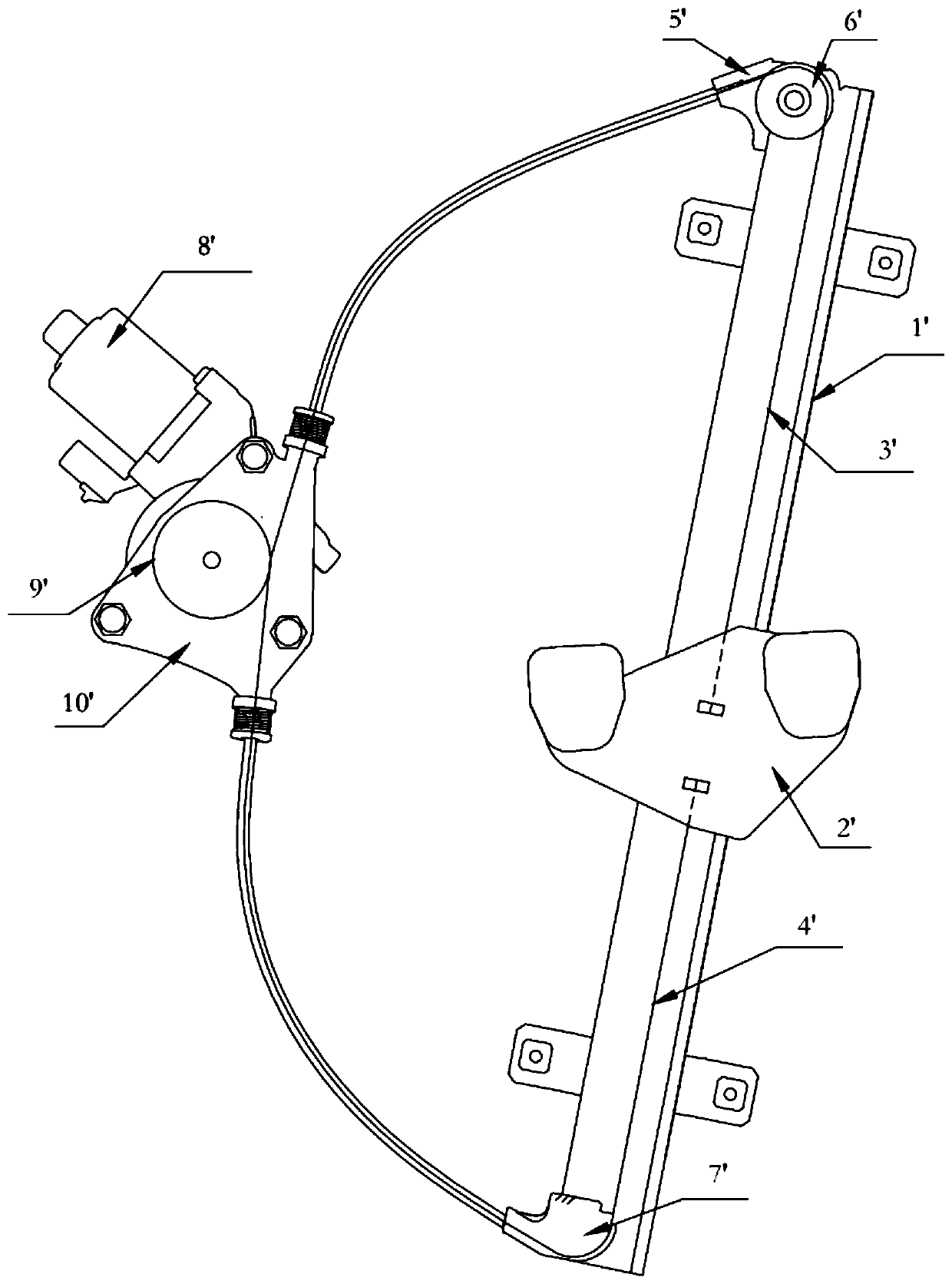

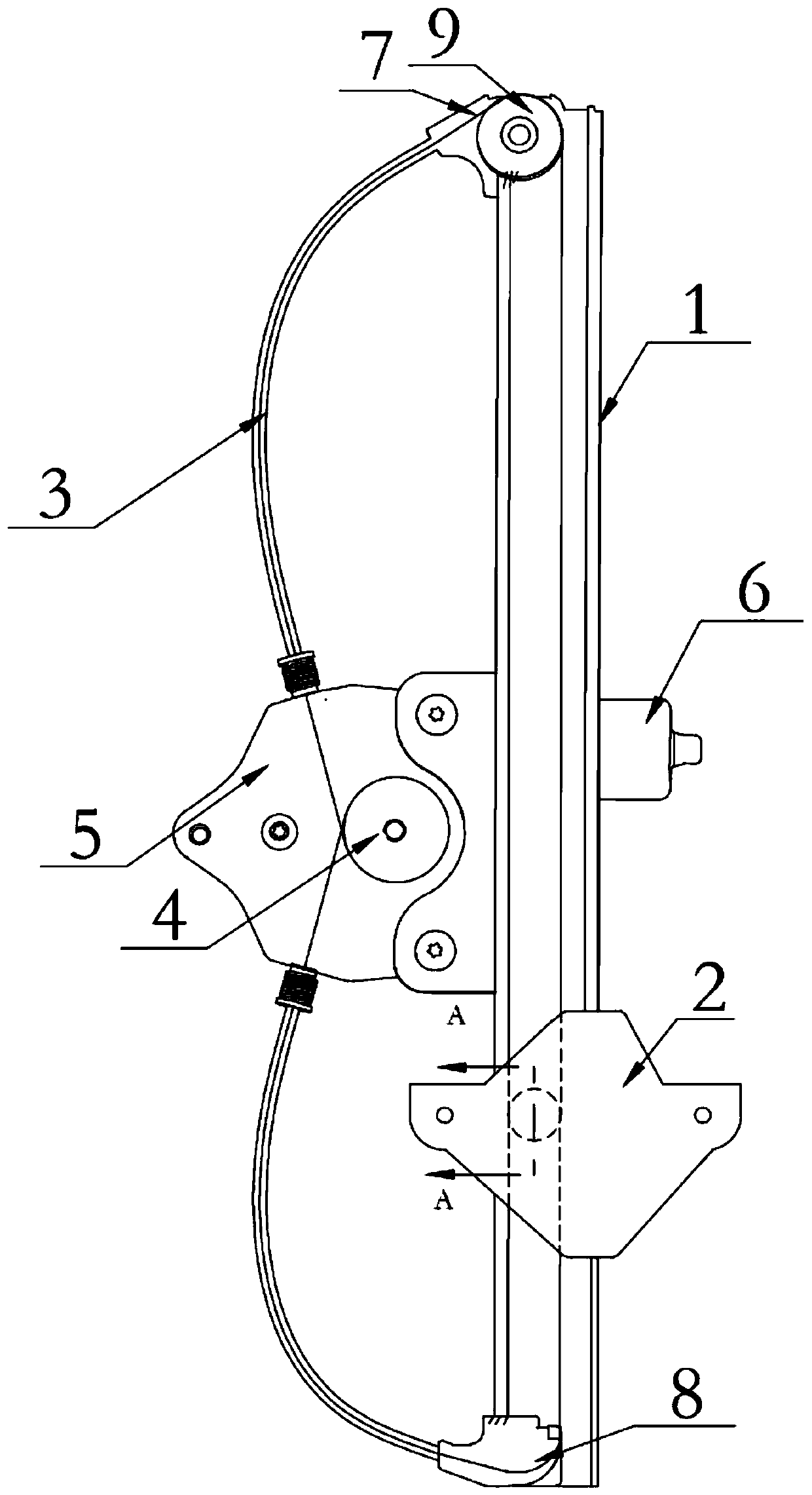

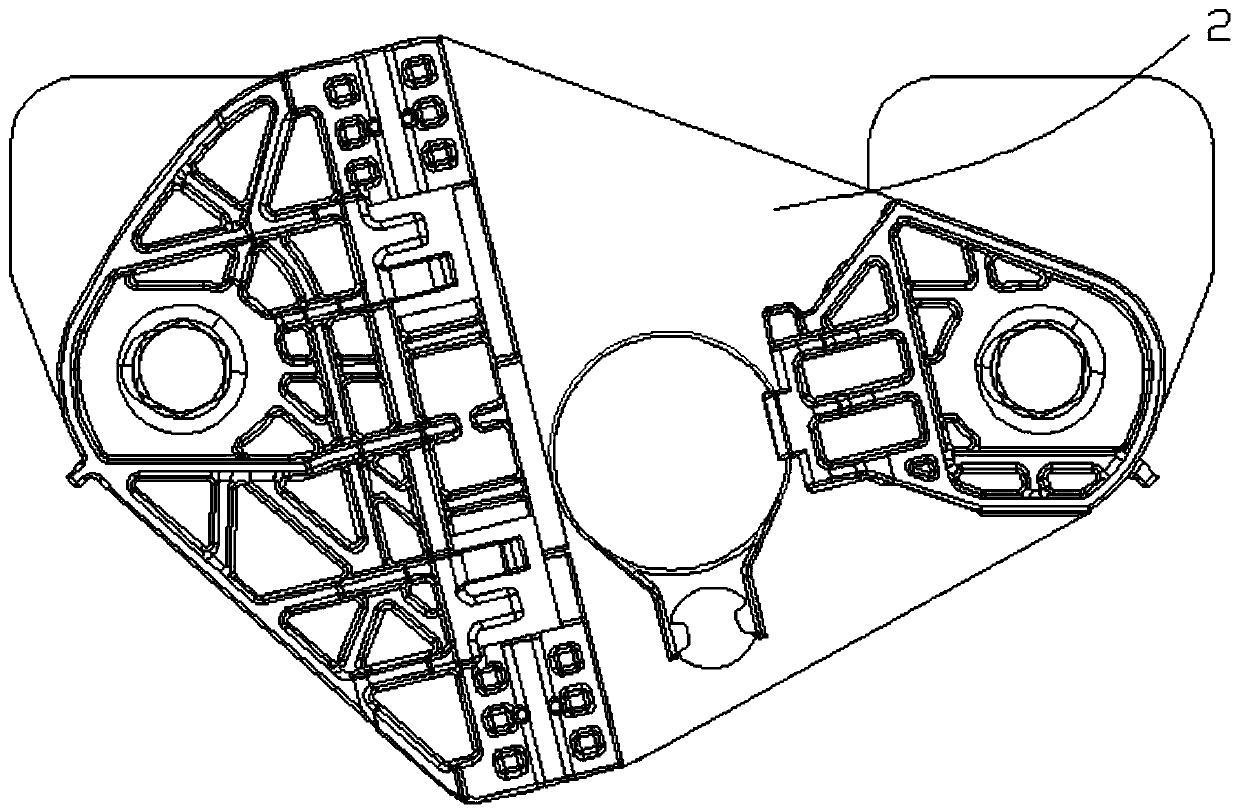

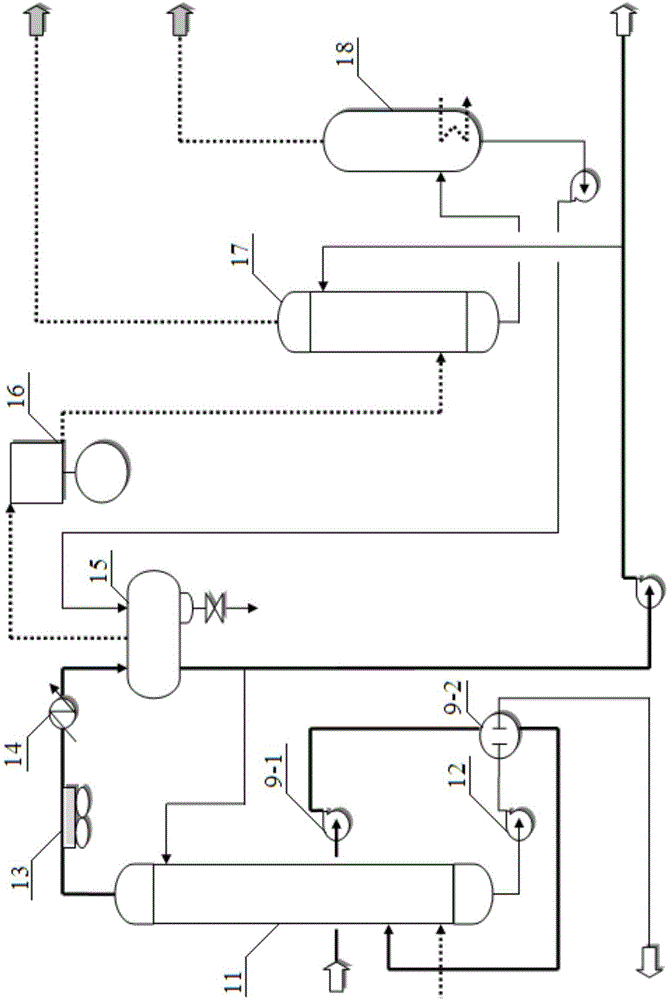

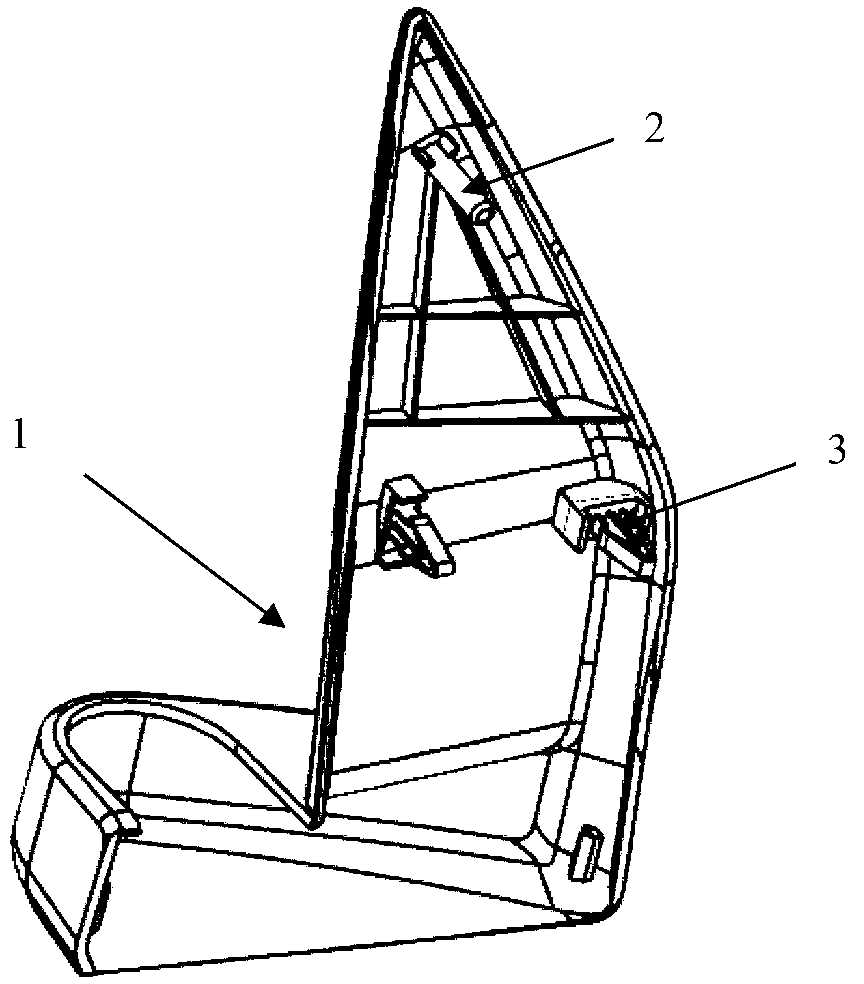

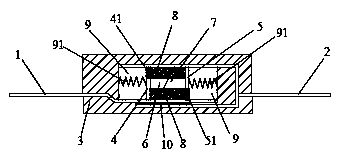

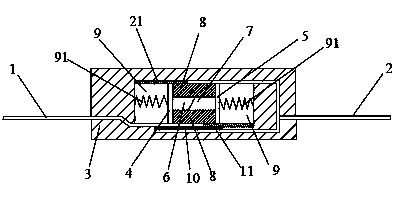

Automobile rope wheel type glass lifter system

PendingCN110374445AReduce output torqueReduce material selection requirementsPower-operated mechanismElectric machineryEngineering

The invention discloses an automobile rope wheel type glass lifter system which comprises a guide rail, a bracket, a motor, a winding wheel and an inhaul cable. An output shaft of the motor is connected with the winding wheel. The bracket and the guide rail are in sliding fit. A guide portion is arranged on the bracket. One end of the inhaul cable is fixed and wound on the winding wheel, and the other end of the inhaul cable is fixed to the end of the guide rail after passing through the guide portion. The guide portion is arranged on the bracket, one end of the inhaul cable is fixed and woundon the winding wheel, the other end of the inhaul cable is fixed to the end of the guide rail after passing through the guide portion, the output torque of the motor can be greatly reduced, under thesame conditions, the power requirements for glass ascending and descending can be met through the low-torque and small motor, the material selection requirements of glass lifter parts are low, and the structure is simple.

Owner:周唐丽

Environmental protection type flexible graphite packing for recovery

InactiveCN1569972AGood sealing performanceReduce material selection requirementsInorganic pigment treatmentGraphiteMaterials science

Disclosed is an environmental protection type flexible graphite packing for recovery characterized in that, subjecting the leftover bits and pieces of reclaimed flexible graphite plate material or less qualified filling product to compression, shearing and disintegration, producing graphite granulate, and compression moulding.

Owner:杨久新 +1

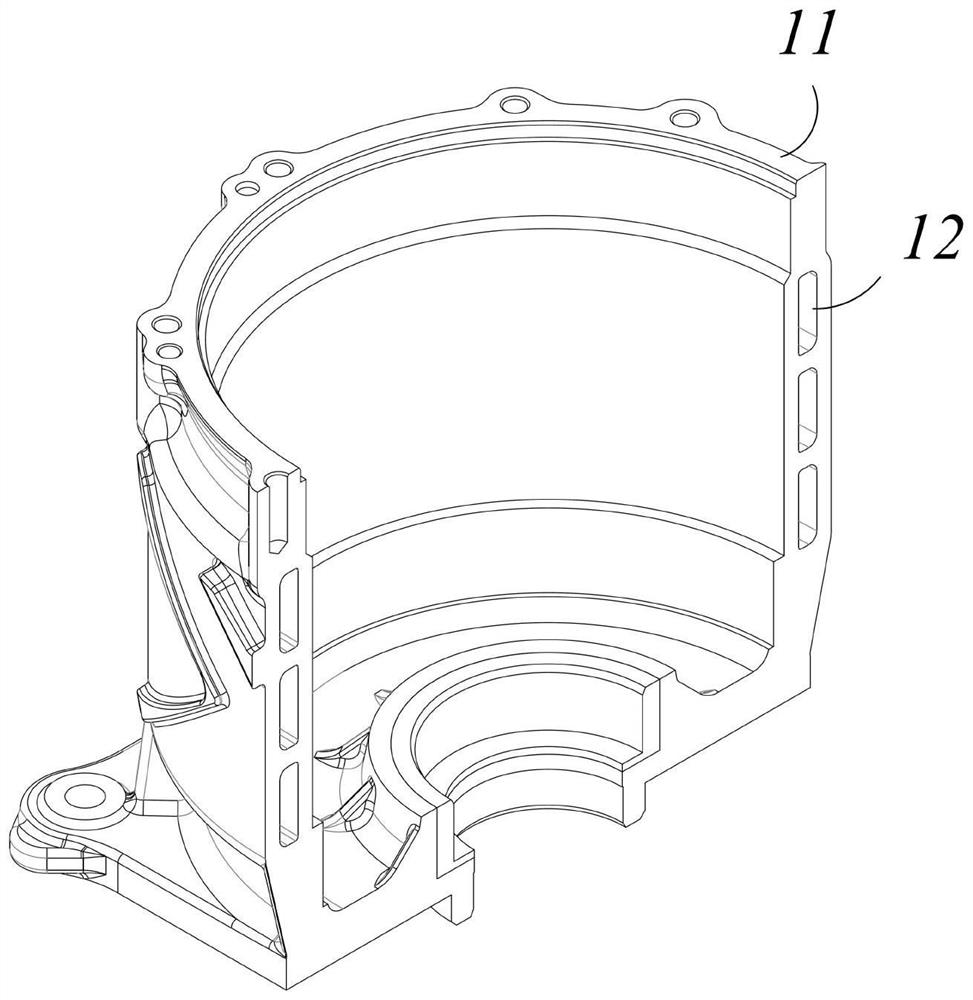

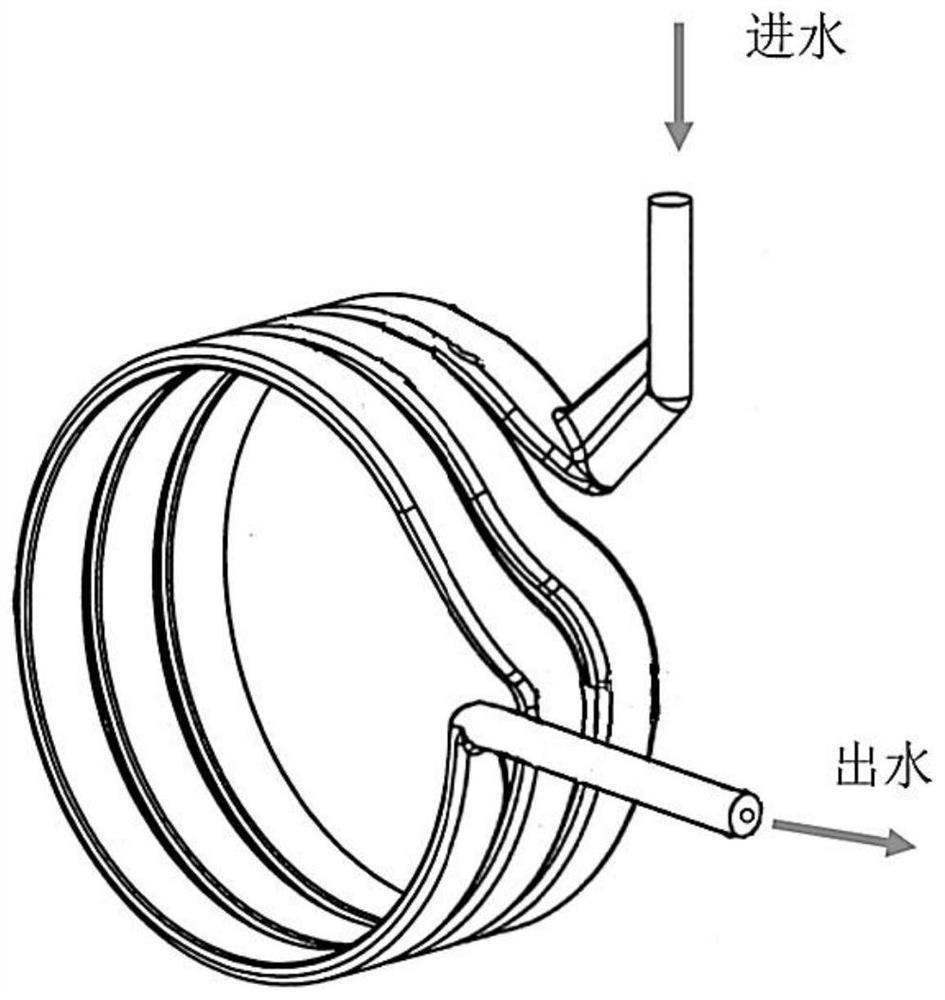

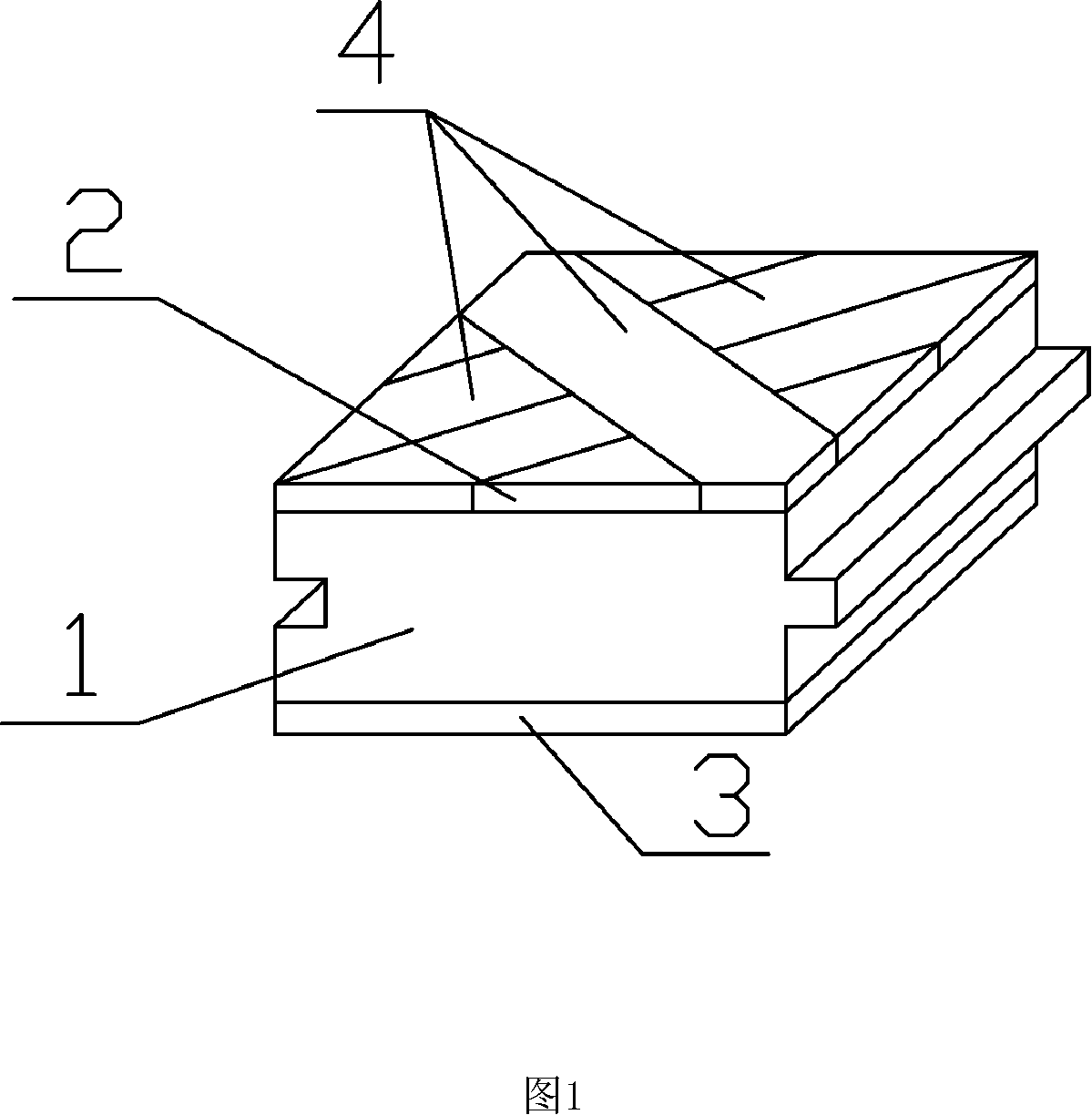

Casting method of integrated water-cooled motor casing of prefabricated spiral channel

InactiveCN111644596AReduce material selection requirementsImprove general performanceFoundry mouldsFoundry coresPressure castingElectric machine

The invention discloses a casting method of an integrated water-cooled motor casing of a prefabricated spiral channel. The casting method comprises the steps of providing the prefabricated spiral channel: fixing the prefabricated spiral channel to a casting die; introducing a cooling medium to the spiral channel; and forming by adopting a low-pressure casting process so as to obtain the high-quality integrated water-cooled motor casing. According to the casting method, the cooling medium is introduced into the circulating channel during casting, so that a pipeline of the prefabricated spiral channel can be prevented from being softened and deformed and even molten by alloy liquid during casting, an inner cavity of the pipeline is not damaged, and the production process and the product reliability are guaranteed. According to the casting method, the prefabricated spiral channel is made of materials which are the same as or close to that of the motor casing, so that the pollution of thechannel materials on the base material of the motor casing can be avoided or reduced when the waste motor casing is recycled and melted.

Owner:纳似韦科技(苏州)有限公司

Technology for producing parquet wood composite floor and its product

InactiveCN101125435AIncrease profitImprove stabilityWood working apparatusParquetinaUtilization rate

The present invention discloses a manufacturing technique of matched wood composite floor. The method comprises grooving a substrate (1) with common technique, which comprises the following steps: a. the substrate (1), a dash board (2) and a base board (3) are coated for assembly so as to obtain A product; b. combined design and shape are done to A product by a hot-press so as to obtain B product; c. hot pressing to B product is done for molding so as to obtain C product; d. the health of C product is preserved so as to obtain D product; e. D product is trimmed for precisely sanding so as to obtain E product; f. E product is led into a paint line for painting so as to obtain the finished product. The matching structure of the present invention is rich, with low requirement of material choice, high utilization rate of material, steady state of product use, non-easy deformation, good stability between units, and good durability and aesthetic effect. The product has easy manufacturing and operation, low manufacturing cost, high production efficiency and steady quality of product; moreover, the floor has clear wood grain and ideal paint film, and is bright and smooth, clean and aesthetic.

Owner:浙江永吉木业有限公司

Protector for inner thread in petroleum steel pipe and its making process

InactiveCN101066718AReduce material selection requirementsImprove impact resistanceClosuresSteel tubePetroleum

The present invention discloses one kind of protector for inner thread in petroleum steel pipe and its making process. The protector includes one ring rigid skeleton, one plastic outer layer with bottom and outside the skeleton, and one core layer in between. It is made through the steps of making ring rigid skeleton, injection molding the core layer outside the rigid skeleton, and injection molding outer plastic layer. The present invention has the advantages of high impact resistance, capacity of matching with the inner thread in protected pipe for effective protection, simple making process, low cost, capacity of being reused, etc.

Owner:杨泽景

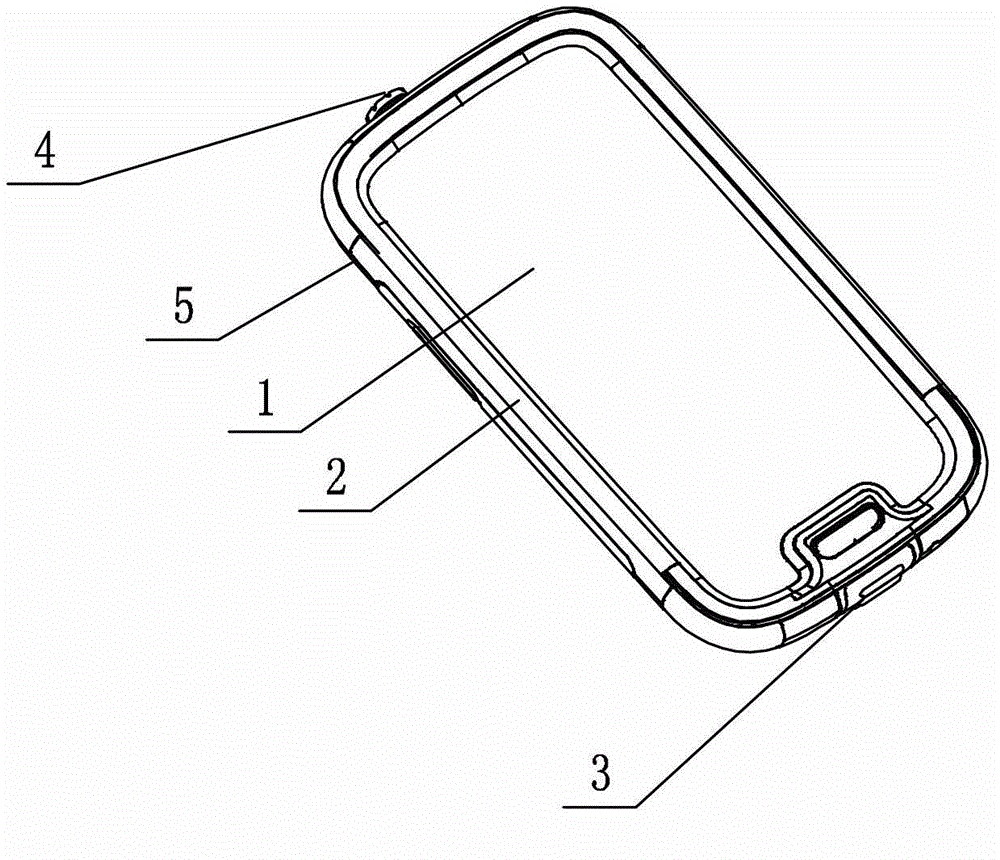

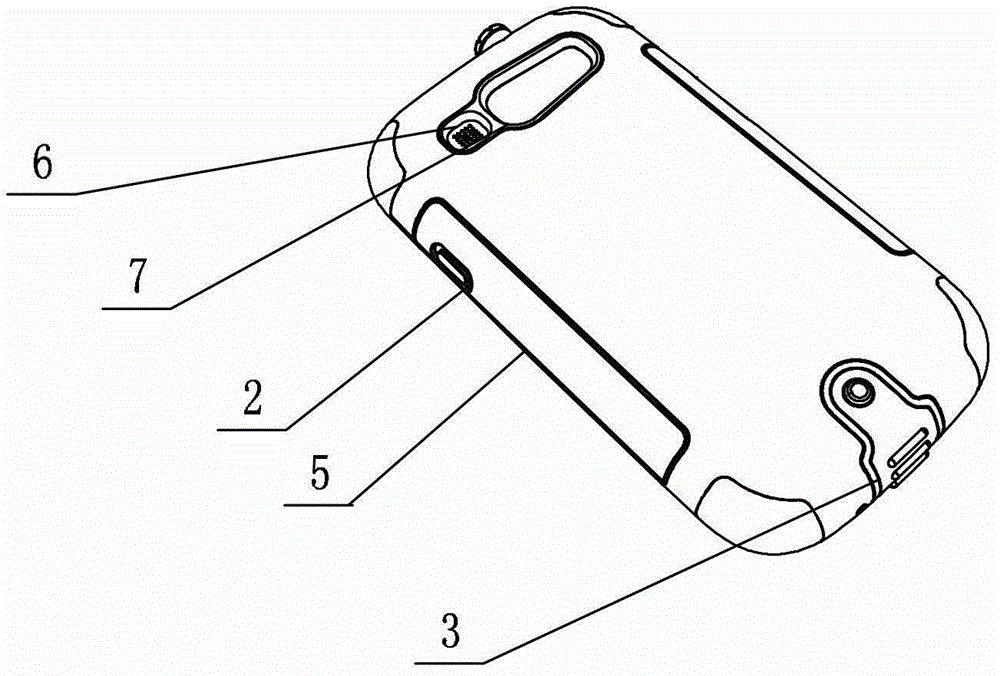

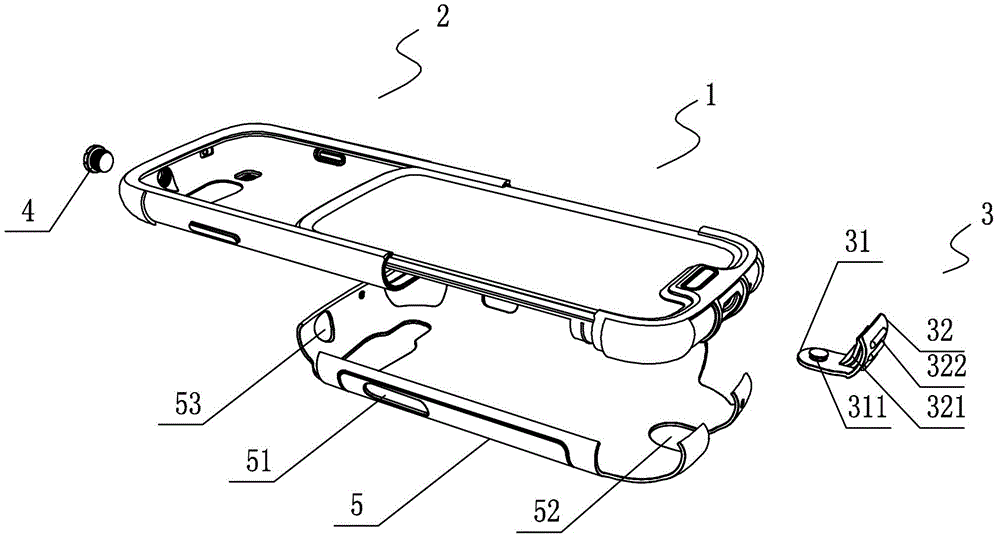

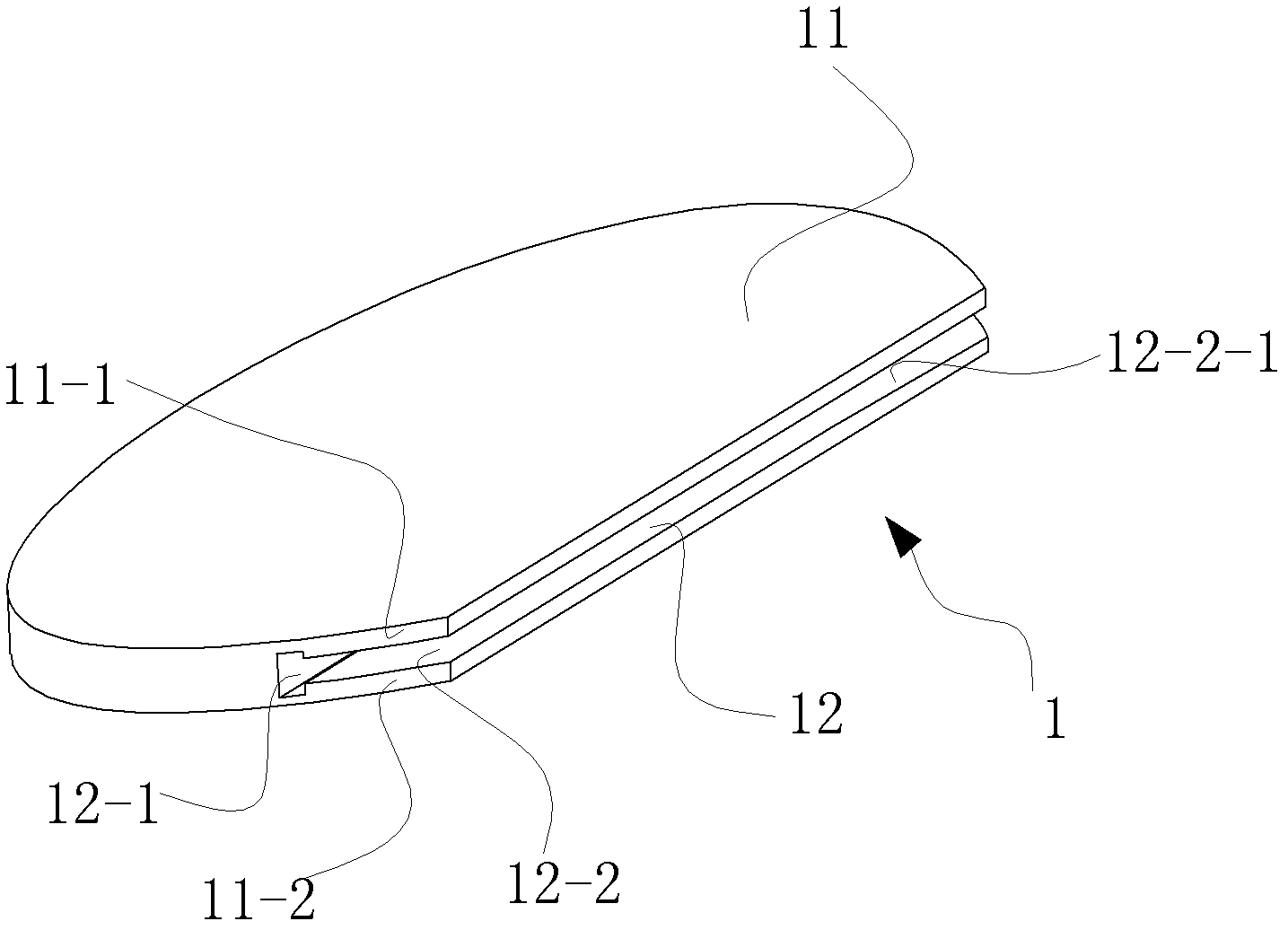

Waterproof protective jacket for electronic equipment

InactiveCN104066294AStrong sealingGood waterproof effectHermetically-sealed casingsMaterial selectionElectric equipment

The invention belongs to the technical field of the protective jacket, and particularly relates to a waterproof protective jacket for electronic equipment. The waterproof protective jacket comprises a protecting sheet, a protective shell, a first sealing plug and a second sealing plug; the protecting sheet comprises a transparent sheet area, a frame part and an enveloping end part; and the protective shell at least comprises an opening end part and a closed end part. According to the waterproof protective jacket provided by the invention, a better sealing structure is formed by the close cooperation between the protective shell and the protecting sheet by a waterproof bulge and a waterproof slot on at least two sides and the cooperation of an outer locking shell. The waterproof protective jacket is strong in air-tightness and good in waterproof effect; in addition, the material selection requirements of the protective shell, the protective shell and the outer locking shell are not high, and the material cost is low.

Owner:林佐伟

A method for improving the denitrification rate of shale oil hydrotreating

ActiveCN105838418BImprove utilization efficiencyImprove the level of comprehensive utilizationTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaFractionation

The invention provides a method for improving the shale oil hydrorefining denitrification rate, and relates to a whole fraction shale oil hydro-denitrification process. The method aims at solving the technical problems that in the existing method for producing diesel oil through shale oil hydrorefining, the stability of a diesel oil product is low, and the operation running period of a hydrorefining catalyst is short. According to the method, a raw material pretreatment unit 1, a raw material pre-fractionation unit 2, a primary hydrorefining reaction unit 3, a secondary hydrorefining reaction unit 4 and a product fractionation unit 5 are used. When the method provided by the invention is used for processing shale oil, the light oil yield is high; the nitrogen content of the diesel oil product is low; the chromaticity and the stability conform to national V standard requirements; the goal of light oil product deep denitrification can be achieved; the service life of the hydrorefining catalyst is prolonged; the operation running period of the catalyst is improved. A main product of the method is hydrorefining diesel oil; byproducts are high-value LPG and hydrogenated naphtha; heavy shale oil and hydrogenation tail oil thrown out in the technical process can be further processed and used in a downstream device. The method provided by the invention belongs to the field of whole-fraction shale oil deep processing.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

Installation device for outside rear-view mirrors of automobile

InactiveCN103303201ALow requirements for material selectionReduce manufacturing processOptical viewingWing mirrorEngineering

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

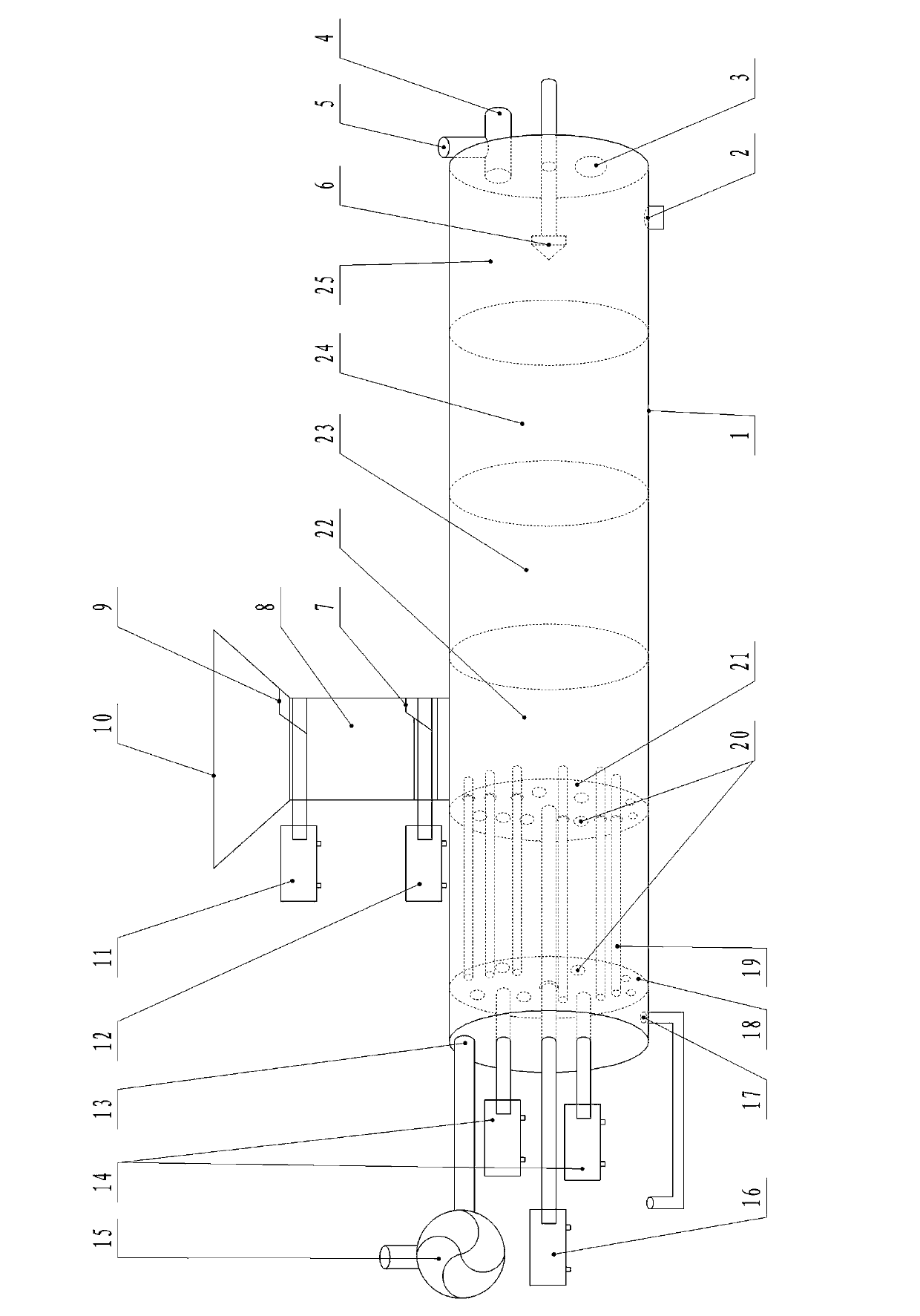

Device for horizontally utilizing biomass fuel to continuously produce combustible gases

InactiveCN103421524AReduce material selection requirementsReduce the impactBiofuelsSpecial form destructive distillationHydraulic cylinderPunching

The invention discloses a device for horizontally utilizing biomass fuel to continuously produce combustible gases. The device comprises a housing, and the housing is columnar and horizontally placed. The upper side of the housing is connected with a storage chamber, and the upper end of the storage chamber is connected with a feed hopper. A combustion head is arranged in a right-side inner cavity of the housing, and an air inlet and a waste outlet are formed in the right end part of the housing. A punching piston and a pushing piston are arranged in a left-end inner cavity of the housing from left to right sequentially, and a plurality of horizontal through rods are arranged on the punching piston. One end of each through rod is connected with the punching piston, and the other end of each through rod can penetrate through the pushing piston. Ventholes are formed in the punching piston and the pushing piston, the punching piston is connected with a second hydraulic cylinder, and the pushing piston is connected with a first hydraulic cylinder. A fuel gas outlet communicated with an exhaust fan is formed in the left-end part of the housing. The device has the advantages of simple structure and low cost, can continuously produce the combustible gases in a high-efficient mode, has a lower requirement on raw materials, can sufficiently combust, and has little influence on environment and a higher conversion rate.

Owner:陈星志

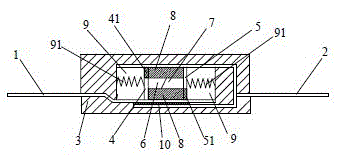

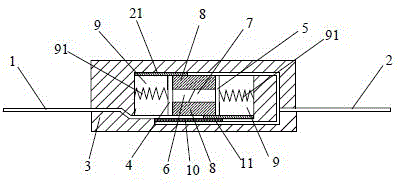

a circuit protector

ActiveCN104078279BRealize opening and closingAvoid misuseHeating/cooling contact switchesElectrothermally operated protective switchesControl switchResistor

Owner:BYD CO LTD

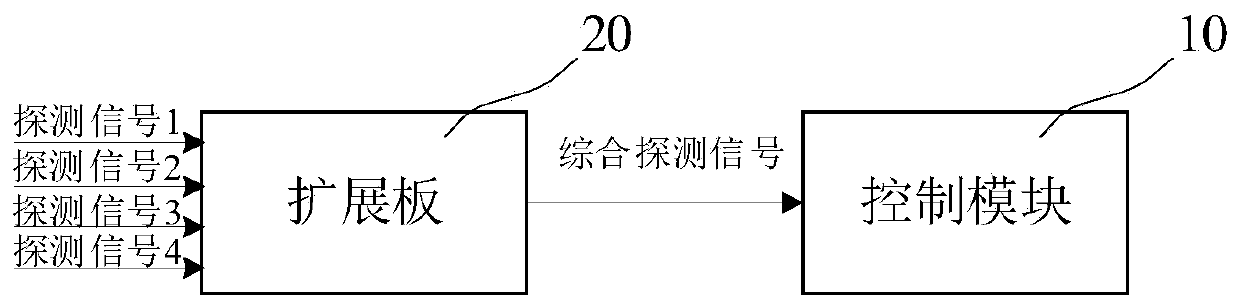

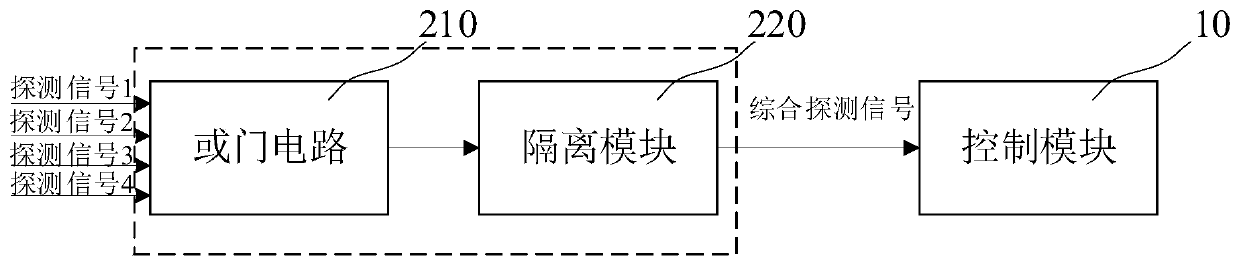

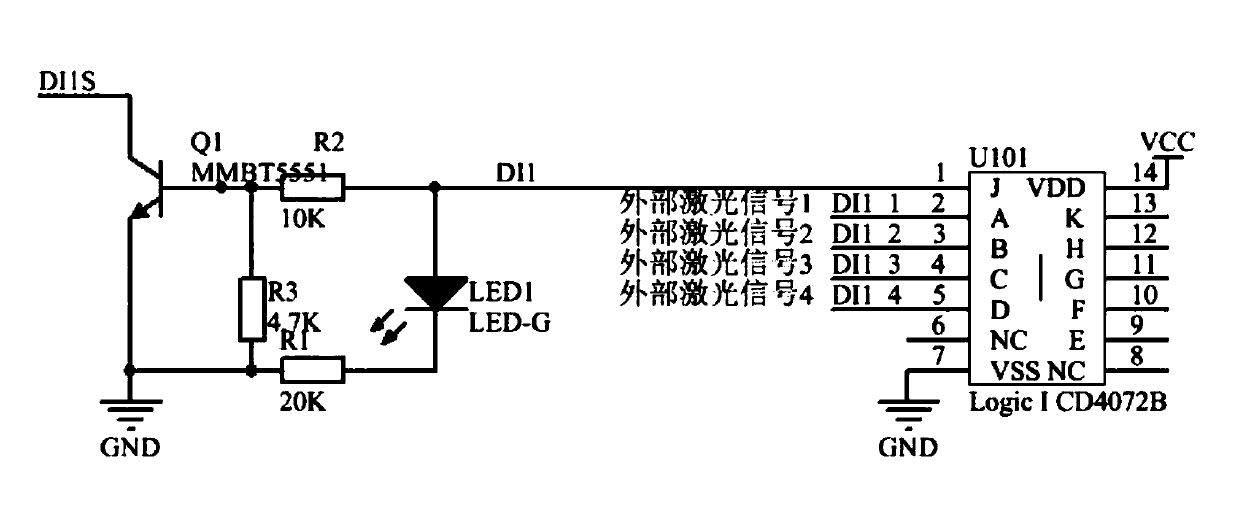

Mainboard expansion device and method applied to unmanned forklift

PendingCN111077966AReduce areaReduce complexityLifting devicesDigital processing power distributionProbe signalReliability engineering

The invention relates to a mainboard expansion device and method applied to an unmanned forklift. A mainboard comprises a control module, the expansion device comprises an expansion board, the expansion board comprises at least one group of detection signal input interfaces, and the expansion board is used for carrying out comprehensive operation on detection signals received by each group of detection signal input interfaces and then outputting a path of comprehensive detection signals; the input end of the control module is connected with the output end of the expansion board, and the control module is used for judging whether a detection signal is triggered or not according to the comprehensive detection signal and determining which detection signal is triggered when the detection signal is triggered. On one hand, the number of input interfaces of the unmanned forklift main board can be reduced, the area and complexity of the main board and the material selection requirement for themain board can be reduced, on the other hand, it can be guaranteed that the main board can accurately distinguish trigger sources of detection signals, and therefore the unmanned forklift can be controlled to conduct corresponding movement according to the detection signals.

Owner:VN ROBOTICS LTD FOSHAN

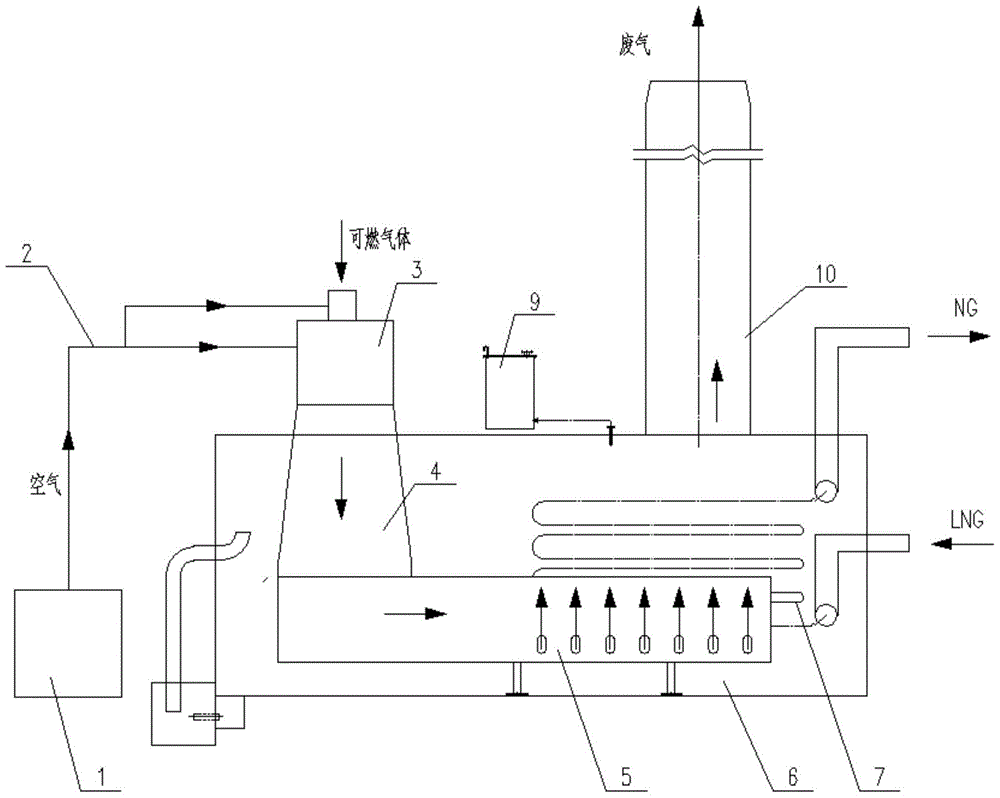

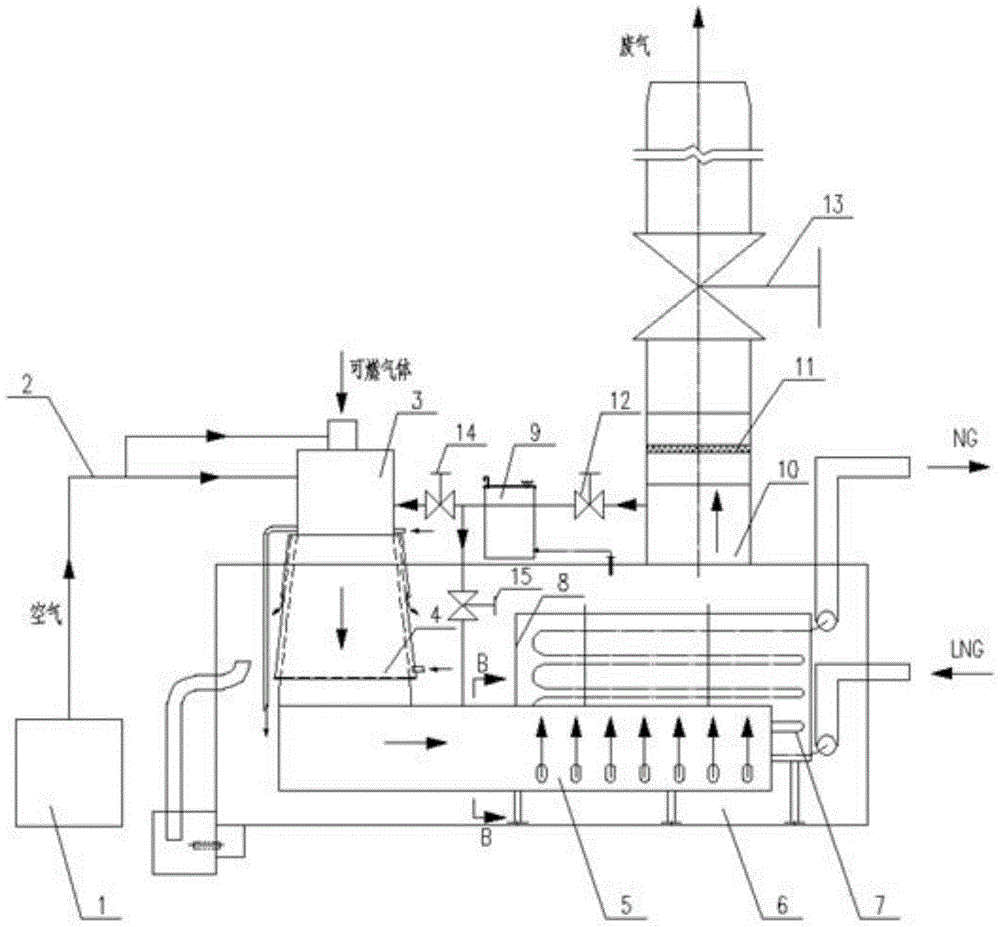

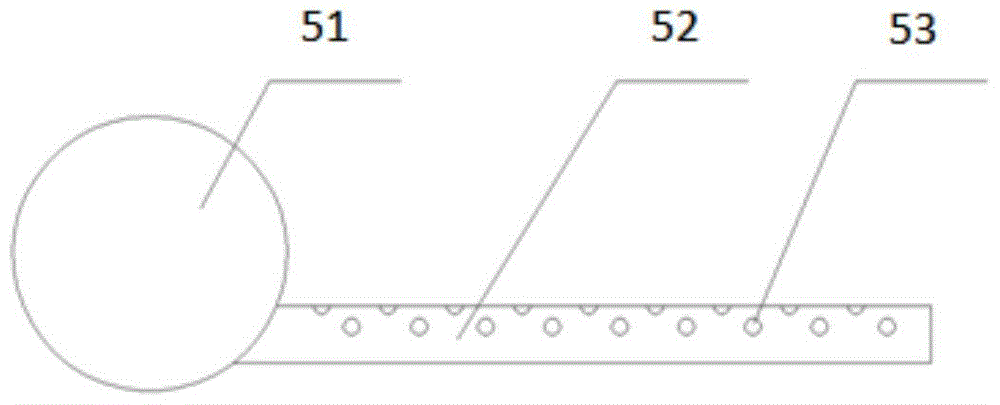

Energy-saving submerged combustion gasifier

ActiveCN105156882BCompact structureSmall footprintStorage heatersPressure vesselsWater bathsCombustion chamber

Owner:江苏中圣压力容器装备制造有限公司

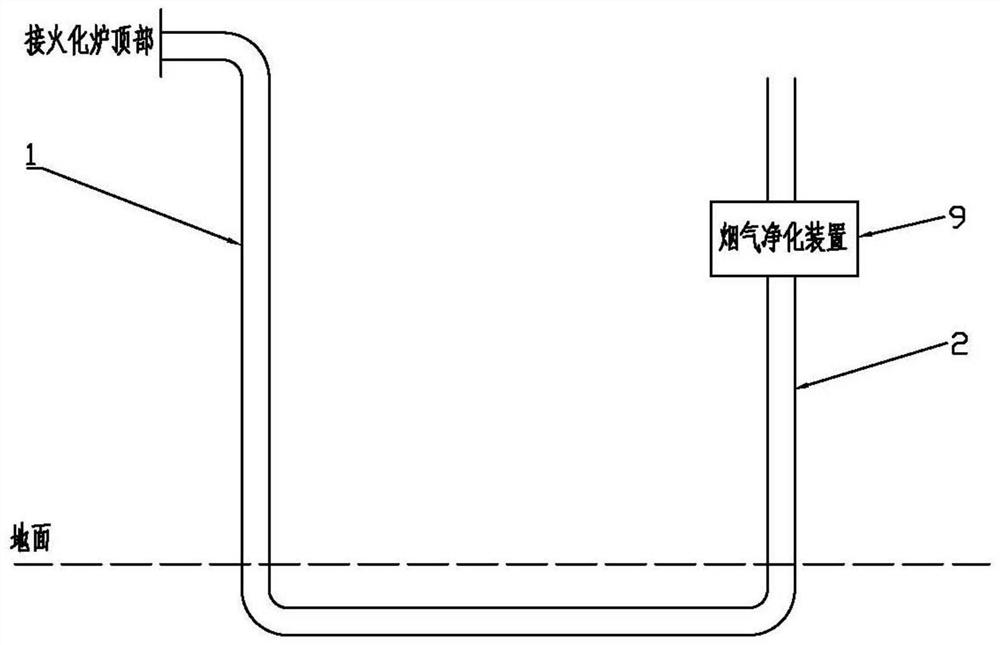

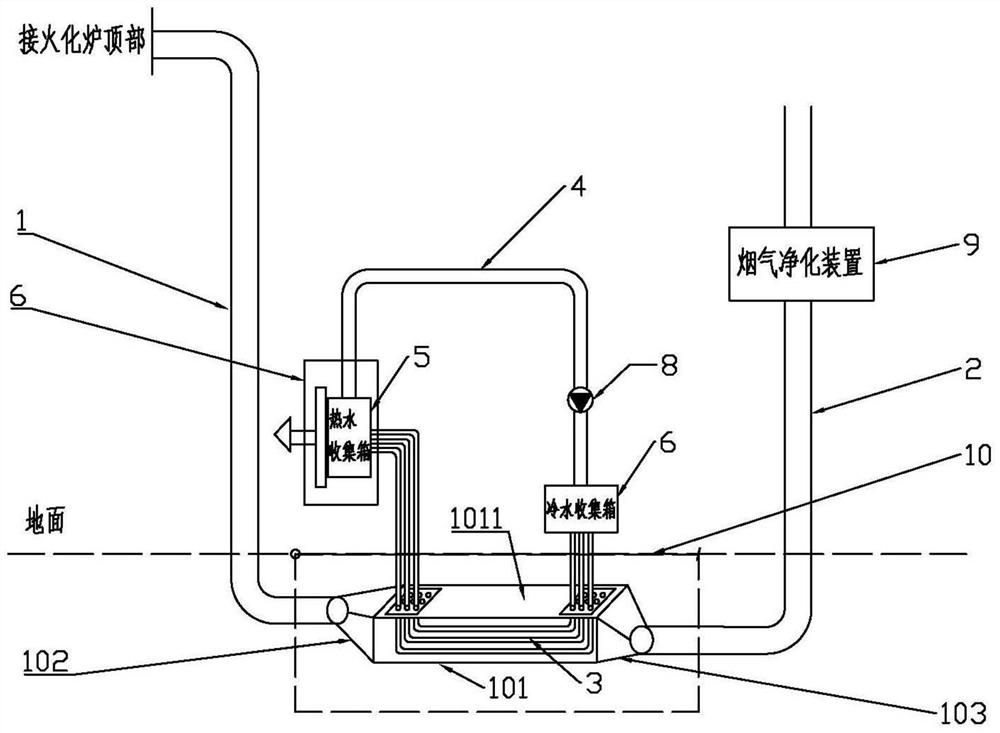

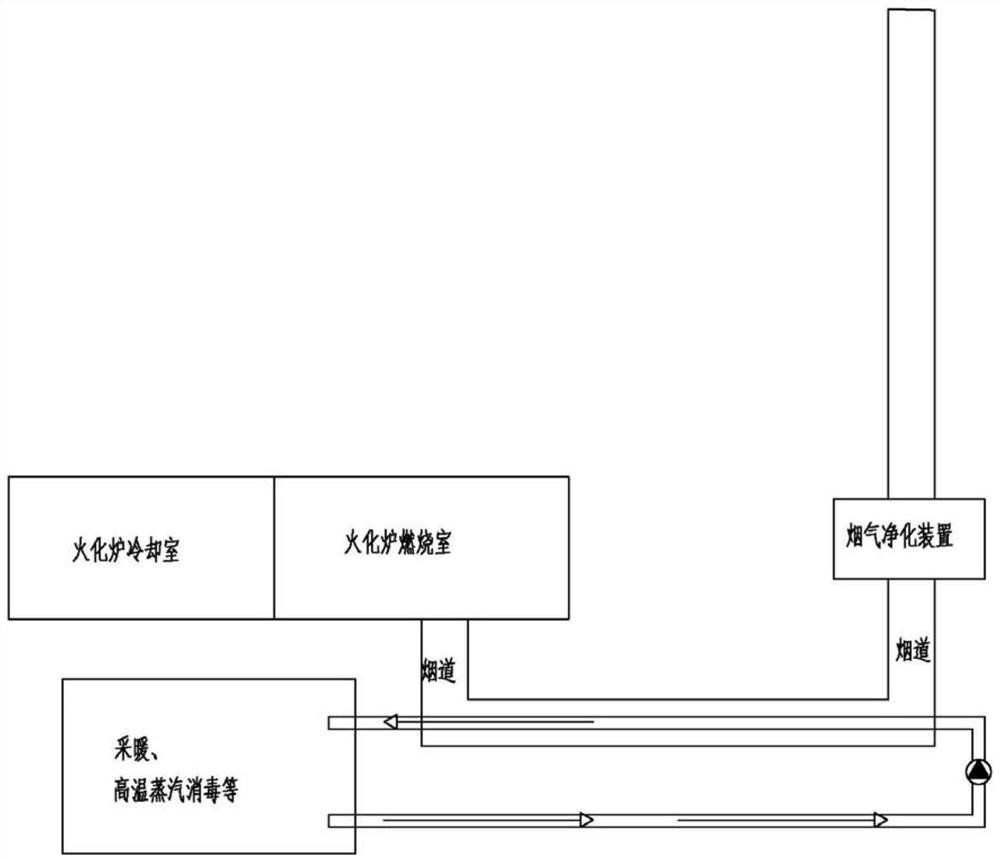

Cremator flue gas pipeline system

PendingCN113294782AImprove economyEfficient reuseCremation furnacesCombustion technology mitigationThermodynamicsFlue gas

The invention discloses a cremator flue gas pipeline system. The problem that in the prior art, waste heat of high-temperature flue gas generated by cremators is insufficiently utilized is solved. In the cremator flue gas pipeline system, a horizontal flue is sequentially divided into a front-end bent pipe, an integrated flue and a rear-end bent pipe, wherein the integrated flue is a body part of the horizontal flue. Integrated heat exchange pipes (a constituent part of heat exchange medium circulating pipelines) are installed at the integrated flue to absorb heat of the flue gas generated by the cremators, the front ends and the rear ends of the integrated heat exchange pipes upwards extend out of the ground correspondingly to communicate with the two ends of water return pipes, hot water collecting boxes and cold water collecting boxes are arranged at the communicating positions correspondingly, and circulating water pumps are arranged on the water return pipes to realize circulating heat exchange. The high-temperature flue gas of the cremators is efficiently recycled, the economical efficiency of the cremators is improved, the transformation and construction cost is low, the overall layout is more reasonable, and meanwhile the requirement for material selection of devices of flue gas purification devices is lowered.

Owner:杨万明

A method for rapidly preparing magnesium alloy fine-grained wire and ultra-fine magnesium alloy wire based on drawing process

The invention discloses a method for quickly preparing a magnesium alloy fine crystalline wire and a superfine magnesium alloy wire based on a drawing process, belongs to the field of nonferrous metalplastic forming, and aims to solve the technical problem that an existing magnesium alloy drawing process is liable to have wire breakage, and is not ideal in crystalline grain size. The method for preparing the magnesium alloy fine crystalline wire comprises the following steps: thermally extruding magnesium alloy cast ingots into bars with diameters Phi being 6mm-10mm, and annealing the bars; II, performing thermal drawing on the bars, and immediately water-cooling the bars to the room temperature after each-pass thermal drawing; III, performing continuous cold-drawing on the bars, and air-cooling the bars to the room temperature; and IV, repeating operations of steps II to III until the diameters Phi of the bars are 1.0mm-1.5mm. The method for preparing the superfine magnesium alloy wire comprises the following steps: step 1, performing continuous cold-drawing on the magnesium alloy fine crystalline wire until the diameter Phi of the wire is lower than 1.0 mm, and air-cooling the wire to the room temperature after annealing; and step 2, repeating the operation of step 1 until the diameter Phi of the wire is 0.10mm. The Phi 0.10mm wire prepared by the method has an average crystalline grain size of 1[mu]m.

Owner:HARBIN UNIV OF SCI & TECH

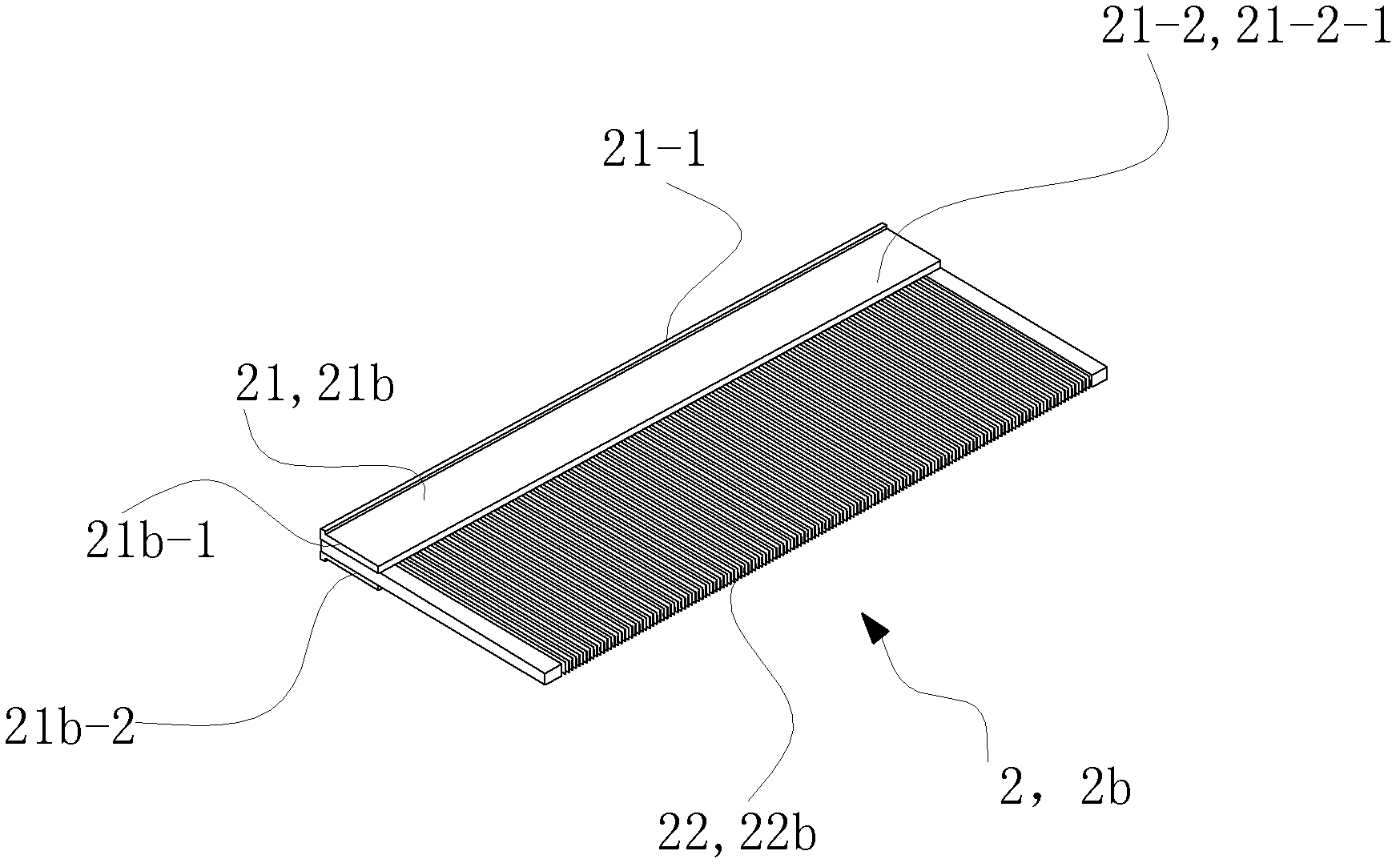

Combined comb

The invention discloses a combined comb, which comprises a handle and a tooth component; the handle comprises a handle main body and a splicing groove, wherein the splicing groove is formed in the handle main body, and forward-opened; the tooth component is a comb tooth component or a fine tooth component; and the tooth component comprises a root board piece and a group of comb teeth connected to the root board piece, the root board piece of the tooth component is mutually spliced with the splicing groove of the handle, the root board piece of the tooth component is in interference fit with the splicing groove of the handle, and the upper and lower lateral surfaces of the root board piece of the tooth component are in contact with the corresponding walls of an installation groove. The handle is matched with the comb tooth part simply and effectively; and when the comb teeth are damaged, the tooth component can be timely changed, so that the service life of the comb is prolonged.

Owner:JIANGSU UNIV OF TECH

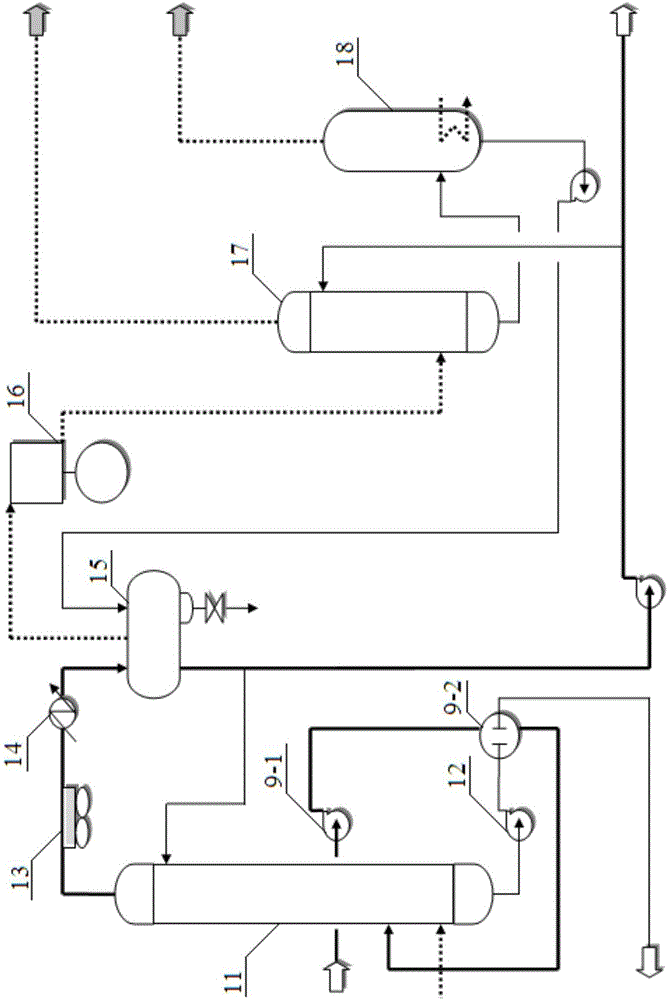

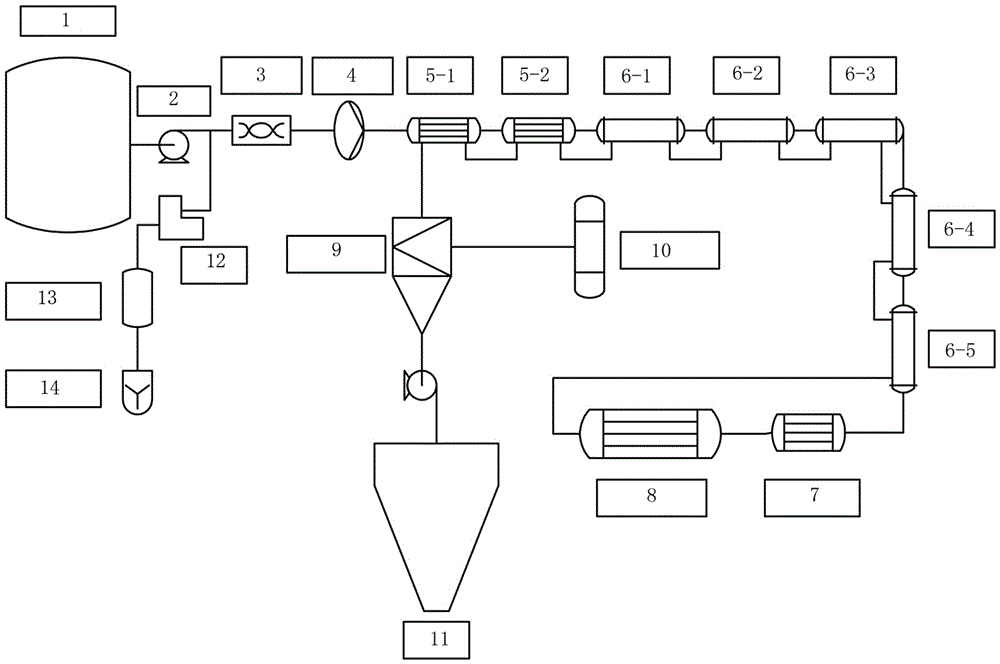

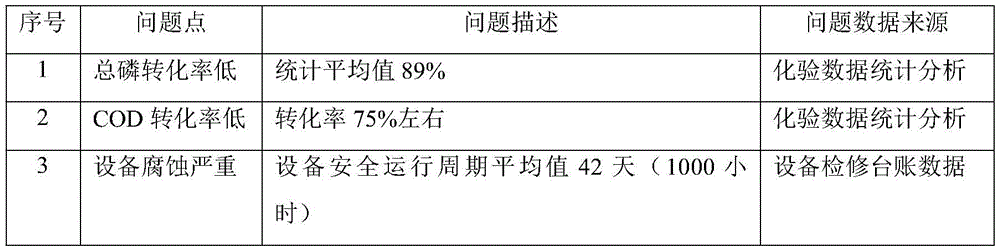

A kind of glyphosate mother liquor catalytic oxidation treatment equipment and process

ActiveCN104556343BDoes not affect product qualitySmall footprintPhosphorus compoundsWater/sewage treatment by oxidationProcess equipmentReaction rate

The invention relates to glyphosate mother liquor catalytic oxidation treating equipment and process. The glyphosate mother liquor catalytic oxidation treating process comprises the following steps: after mixing a copper nitrate.gibbsite solution serving as a catalyst, and a glyphosate mother liquor by virtue of a static mixer, carrying out a catalytic reaction under an oxidation system with the temperature of 210+ / -5 DEG C and the pressure of 4MPa, wherein the oxidation system is a circulation loop comprsing a tubular heat exchanger, a tube heat exchanger, a medium-pressure heat exchanger, a coil heat exchanger and a tube heat exchanger. With the adoption of the glyphosate mother liquor catalytic oxidation treating equipment and process, the realistic problems of incomplete oxidation reaction, high temperature and pressure of the oxidation reaction, large risk, large corrosion of the reaction to the equipment and the like of the glyphosate mother liquor oxidation reaction are solved; after a homogeneous catalyst is added, the reaction rate is greatly increased, the oxidation reaction is complete, the temperature and the pressure of the device system are lowered, the equipment corrosion condition is improved, and a novel perfect and reliable process is provided for ECO treatment of the glyphosate mother liquor.

Owner:内蒙古兴发科技有限公司

A special lined polyurethane knife gate valve for acid and alkali corrosion resistance and its manufacturing process

ActiveCN107351423BEasy to operateShorten the timeSlide valveValve housingsPhysical chemistryEngineering

The invention discloses a special lining polyurethane knife gate valve for anti-acid and alkali corrosion and its manufacturing process. It comprises a knife gate valve body. The two ends of the core are respectively fixed with the setting die 1 and the setting die 2 by bolts. The connection between the setting die 1 and the knife gate valve body and the connection between the setting die 2 and the knife gate valve body are equipped with polyurethane linings, and the polyurethane lining A sealing surface is arranged on the core-pulling of the middle ram at the joint between the parts and the core-pulling of the middle ram. The present invention saves cost in technology, satisfies the performance of acid and alkali corrosion resistance, and at the same time can reduce the requirements for material selection on the gate valve body. If stainless steel is traditionally used, carbon steel or aluminum alloy after heat treatment can be used. It can also save or reduce costs. The gate and seal are lined with two different materials, soft and hard, and the seal is more precise and tight, which can prolong the service life of the product.

Owner:WENZHOU CHISUN VALVE MFG CO LTD

Circuit protector

ActiveCN104078279ARealize opening and closingAvoid misuseHeating/cooling contact switchesElectrothermally operated protective switchesEngineeringControl switch

The invention provides a circuit protector, which comprises a case, a first lead-out end, a second lead-out end, a switch assembly, a protection body and a heating body, wherein the first lead-out end and the second lead-out end are respectively led out from the case; the switch assembly, the protection body and the heating body are positioned in the case; the switch assembly and the heating body are connected in parallel with the first lead-out end and the second lead-out end; the protection body controls the on-off state of the switch assembly; and the protection body is a high-expansion filling object. The circuit protector provided by the invention can be used for protection for many times, and in addition, the resistance in the protector is stable.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com