Method for improving shale oil hydrorefining denitrification rate

A technology for hydrotreating and shale oil, applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problems of poor stability of diesel products and short operation cycle of hydrotreating catalysts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0073] Specific implementation mode one: a method for improving the denitrification rate of shale oil hydrotreating:

[0074] 1. Raw material pretreatment unit:

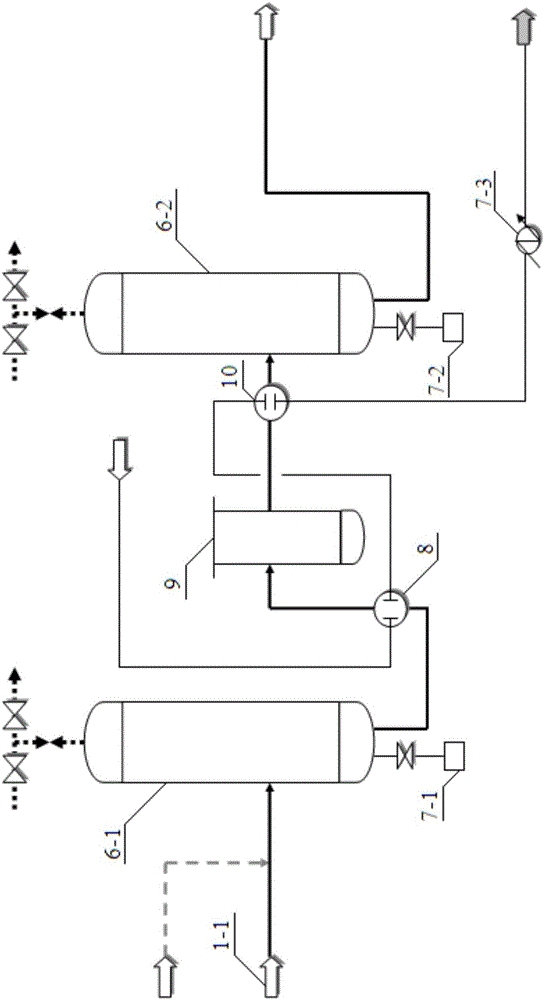

[0075] Send the whole distillate shale oil to the raw material oil buffer tank in turn for buffering, and then enter the raw material pre-fractionation unit for fractionation after buffering;

[0076] The temperature of the raw material oil buffer tank is 60-80° C., and the pressure is 0.1-0.3 MPaG;

[0077] 2. Raw material pre-fractionation unit:

[0078] The whole cut shale oil enters the atmospheric fractionation tower for pre-fractionation of raw materials, and the fractionation products are light shale oil, heavy shale oil and non-condensable gas, and non-condensable gas contains light components and heavy components; The oil and gas at the top of the tower is condensed and cooled and enters the top reflux tank of the atmospheric fractionation tower for gas-liquid separation to separate light shale oil, non-co...

Embodiment approach

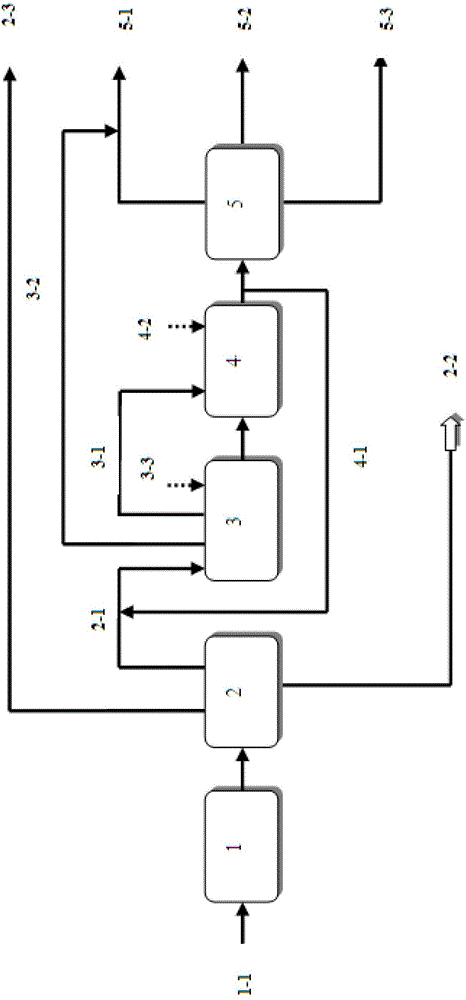

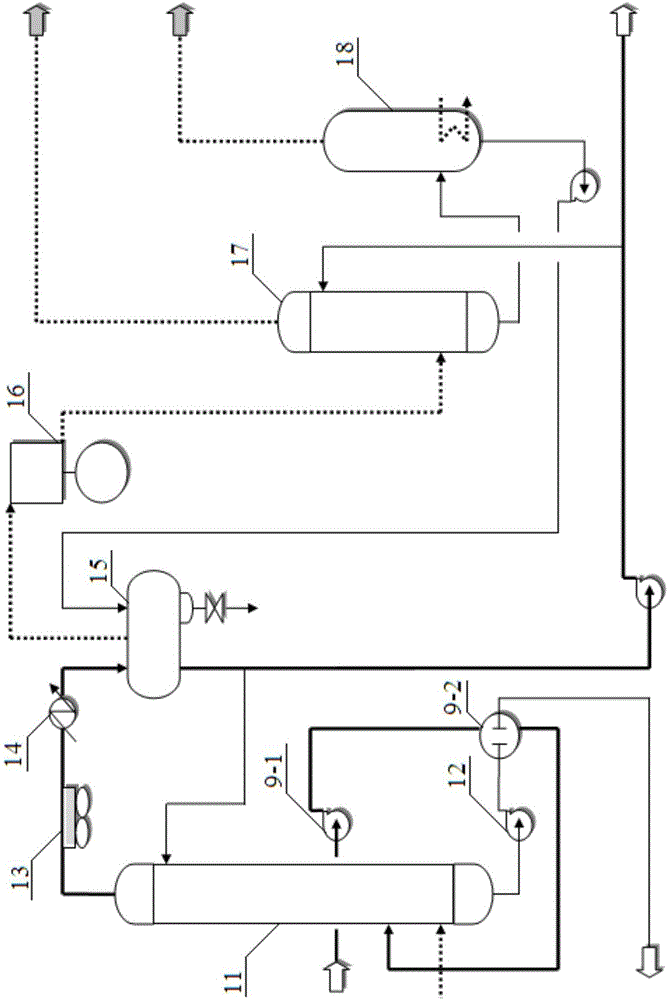

[0109] The full-fraction shale oil from the tank farm (which can be properly blended for secondary processing) enters the raw material pretreatment unit 1 for raw material pretreatment; the pretreated full-fraction shale oil enters the raw material pre-fractionation unit 2 to separate LPG2 -3. Light shale oil 2-1, heavy shale oil 2-2; light shale oil 2-1 enters the first hydrogenation refining reaction unit 3 and hydrogen 3-2 and hydrogenation catalyst in the first hydrogenation Catalytic hydrogenation reaction occurs in the hydrogen reactor, the generated primary hydrogenated naphtha 3-2 is merged into the 5-1 secondary hydrogenated naphtha fraction, and the generated primary hydrogenated diesel oil 3-1 enters the secondary hydrogenation refining Reaction unit 4; in the secondary hydrogenation refining reaction unit 4, the primary hydrogenation diesel oil 3-1, hydrogen 4-2 and hydrogenation catalyst undergo a catalytic hydrogenation reaction in the second hydrogenation reactor...

specific Embodiment approach 2

[0156] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the light shale oil described in step two is a distillate oil of ≤365°C; the heavy shale oil is a distillate oil of >365°C; step two The light component in the noncondensable gas described in is to contain C1 and C2 components, and the heavy component is to contain C3 and C4 components; the analysis gas described in step 2 is to contain C3 and C4 components, as by-product LPG; Analytical oils are ≥C5 components. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com