Patents

Literature

55results about How to "Improve light oil yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Comprehensive utilization method of oil shale

InactiveCN102031153AImprove light oil yieldSolve the problem of hydrogen sourceThermal non-catalytic crackingHydrogen separationSyngasHydrogenation process

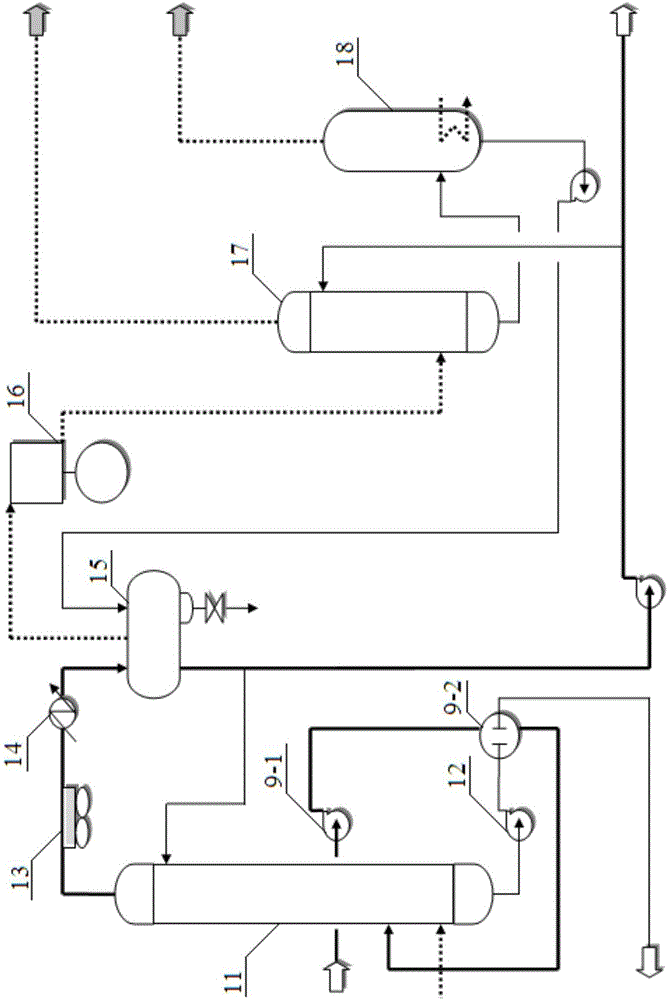

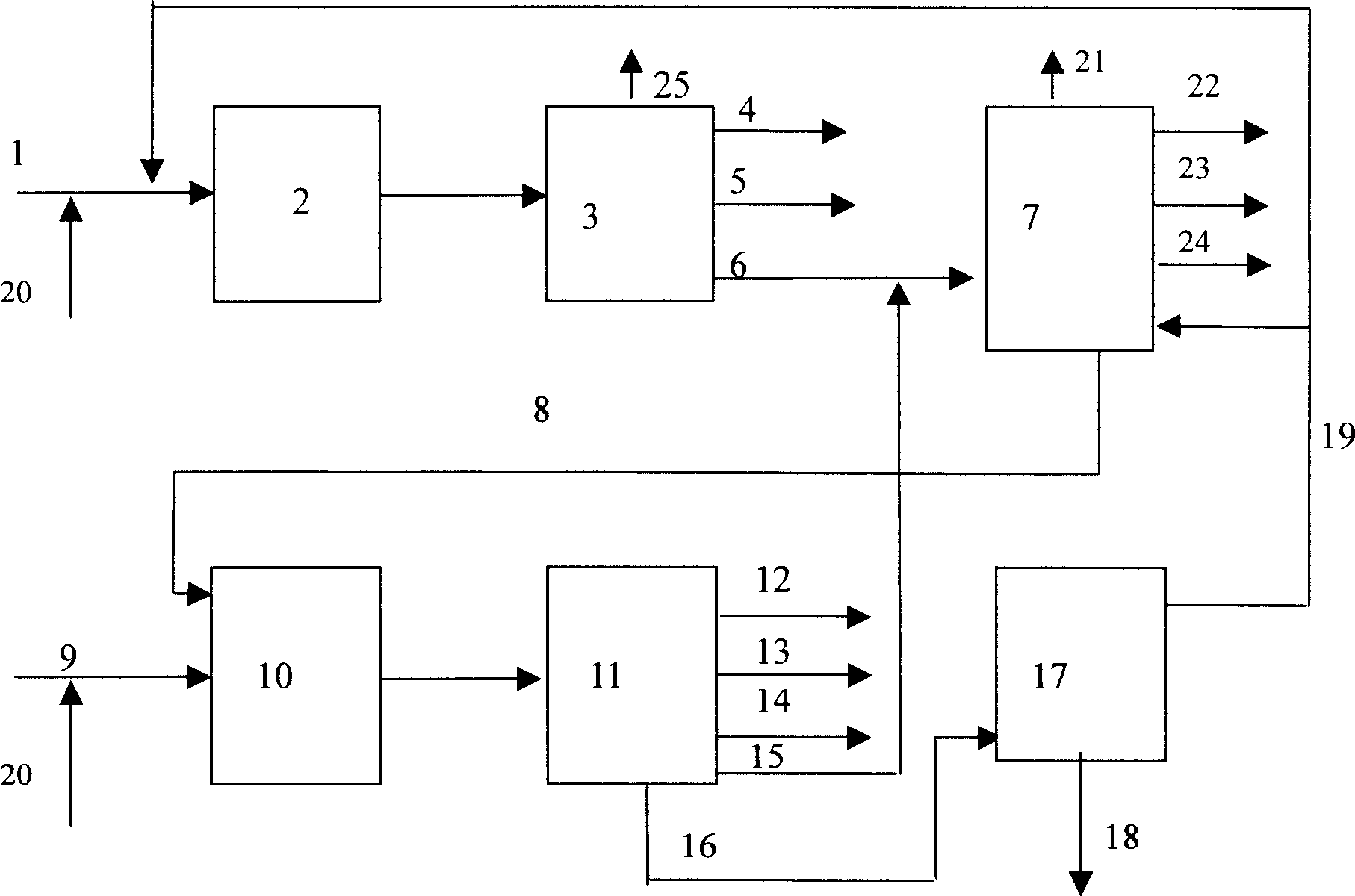

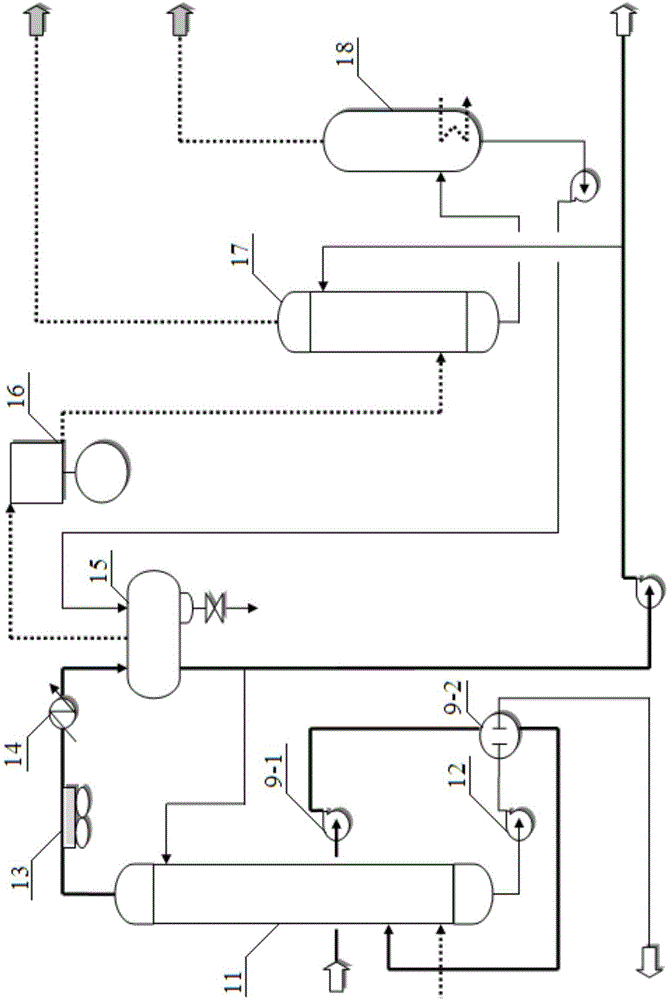

The invention relates to the field of comprehensive utilization of oil shale, and provides a comprehensive utilization method of oil shale. Particularly, in the method, hydrogen production and oil hydrogenation processes of synthesis gas generated by oil shale dry distillation, dry distillation semicoke pre-charking, semicoke gasification after pre-charking, heavy oil recycle and gasification areorganically combined so as to obtain oil products from raw materials to the maximum extent, the oil products are hydrotreated to obtain high-quality clean oil products, the synthesis gas generated bygasification can be used as high-quality and cheap raw material for hydrogen production to provide a hydrogen source for oil product hydrogenation, and oil shale ash products obtained by cooling after gasification and complementary calcination are used as high-quality building materials. The invention provides a comprehensive utilization cleaner production process which can convert raw materials into high-quality products to the maximum extent and can fully utilize semicoke resources and rich production energy.

Owner:WISON ENG

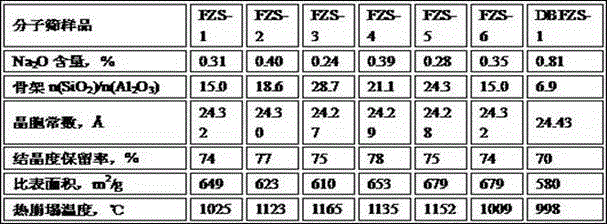

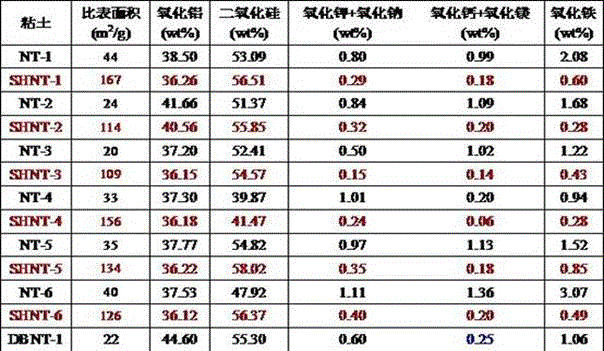

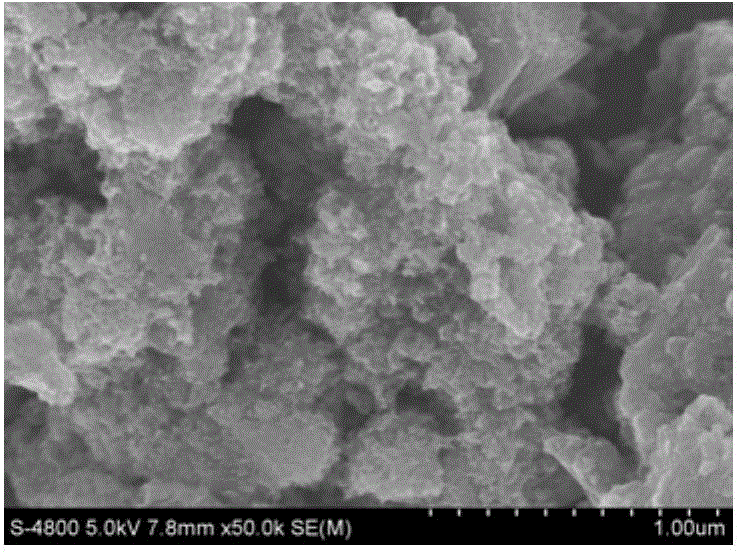

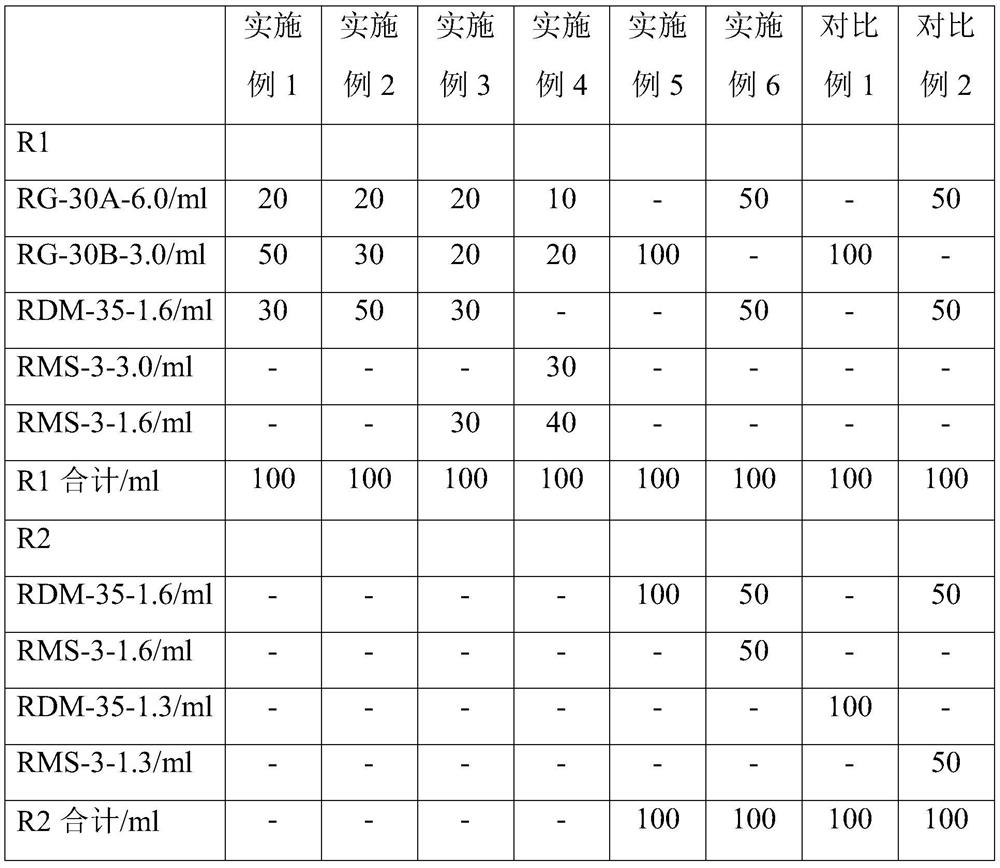

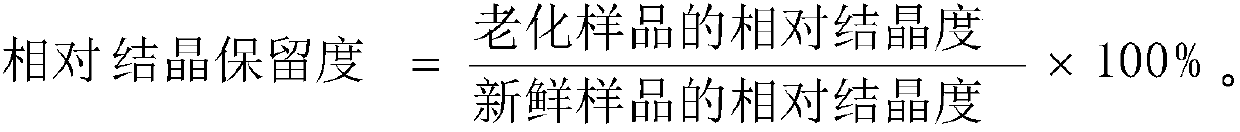

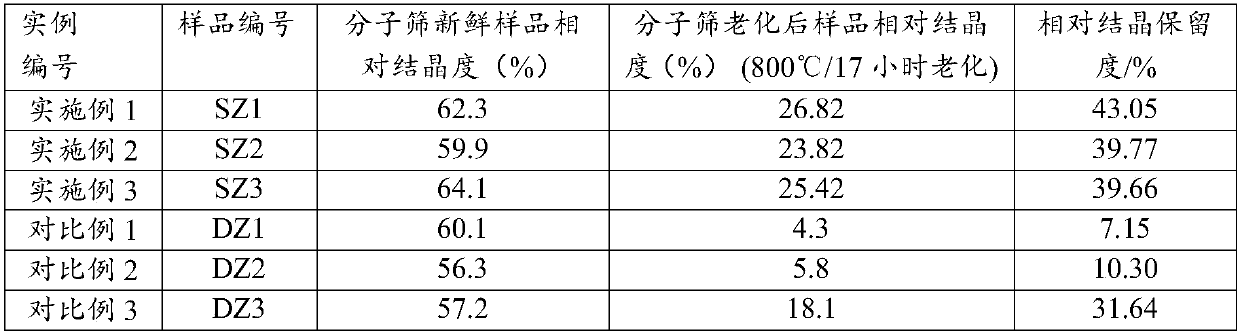

Preparation method of catalytic cracking catalyst

ActiveCN106732745AHigh crystallinity retentionImprove thermal stabilityCatalytic crackingMolecular sieve catalystsHigh concentrationGas phase

The invention relates to a preparation method of a catalytic cracking catalyst. According to the method, the NaY molecular sieve raw powder and halogen-containing gas are contact to perform gas phase ion exchange reaction; the sodium reduction and the ultra-stabilization of the NaY molecular sieve raw powder are completed in one step; the low-sodium high-silica-alumina-ratio molecular sieve is prepared. According to the method, different kinds of clay raw ores are compounded and are treated by high-concentration acid to obtain acid active composite clay; then, the low-sodium high-silica-alumina-ratio molecular sieve, the acid active composite clay, bonding agents, rare earth and decationized water are mixed and pulped; then, spraying granulation is performed; roasting and curing are performed; washing and drying are not needed; a finished product of the catalytic cracking catalyst is obtained. The catalytic cracking catalyst has the advantages that the olefin content in the gasoline can be obviously reduced; the light oil yield is improved; the preparation flow process of the catalyst is short; no ammonia and no nitrogen are discharged.

Owner:REZEL CATALYSTS CORP

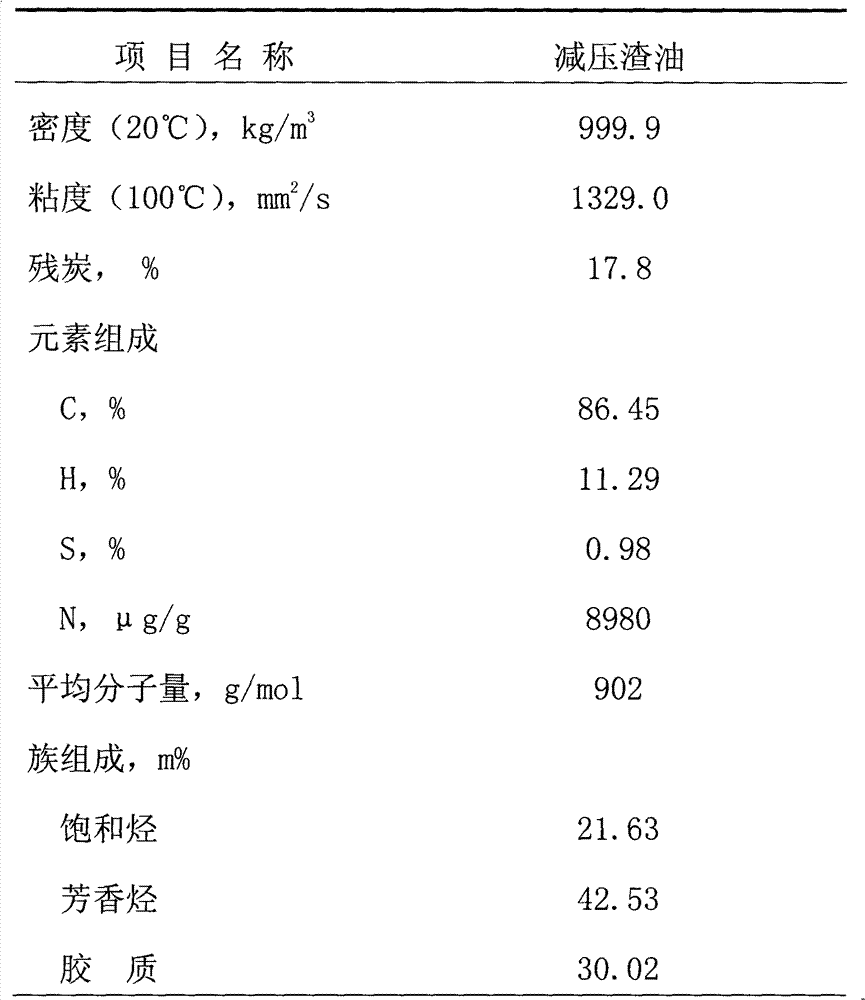

Delayed coking method

InactiveCN103087769ASave operating costsSave processHydrocarbon oils treatmentGas phaseFractionation

The invention aims at solving defects such as low light oil yield, high foam layer, and high coke yield of prior arts, and discloses a delayed coking method. The method is characterized in that: a mixed raw material is heated in a heating furnace; the heated hot material flow enters a primary hydrocyclone, such that a gas phase (1) and a mixed liquid phase (1) are obtained; the gas phase (1) is quenched and is delivered into a fractionation column; high-temperature steam is injected into the mixed liquid phase (1), and the mixture is delivered into a secondary hydrocyclone; the secondary hydrocyclone separates the mixed liquid phase (1) into a gas phase (2) and a mixed liquid phase (2). The gas phase (2) is delivered into a fractionation column; high-temperature steam is injected into the mixed liquid phase (2), and the mixture is delivered into a coke column; coke is discharged from the bottom of the coke column, and reaction oil gas is delivered into the fractionation column.

Owner:CHINA PETROLEUM & CHEM CORP +1

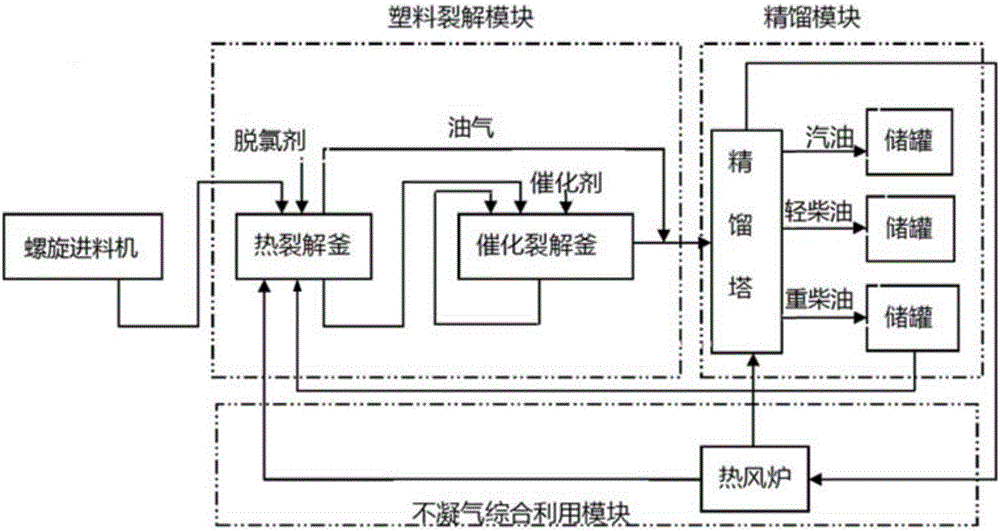

Waste plastic pyrolysis equipment and method

ActiveCN106281396AAnti-cokingContinuous productionChemical industryPlastic recyclingCatalytic pyrolysisDistillation

The invention provides waste plastic pyrolysis equipment and method. The waste plastic pyrolysis equipment comprises a plastic pyrolysis module, an oil product distillation module and a non-condensable gas comprehensive utilization module, wherein the plastic pyrolysis module comprises a thermal pyrolysis reaction kettle, a catalytic pyrolysis reaction kettle, a high-temperature pump, a first filter and a second filter; the oil product distillation module comprises a distillation tower, a condenser and a plurality of storage tanks; the non-condensable gas comprehensive utilization module comprises a hot blast furnace and a high-temperature heat exchanger. The waste plastic pyrolysis equipment and method have the following advantages: the equipment has the characteristics of realizing continuous production, being environment-friendly, anti-coking, high in light oil yield, efficient, energy-saving and the like and can be widely popularized and used.

Owner:BIOLAND ENVIRONMENTAL TECH GRP CORP

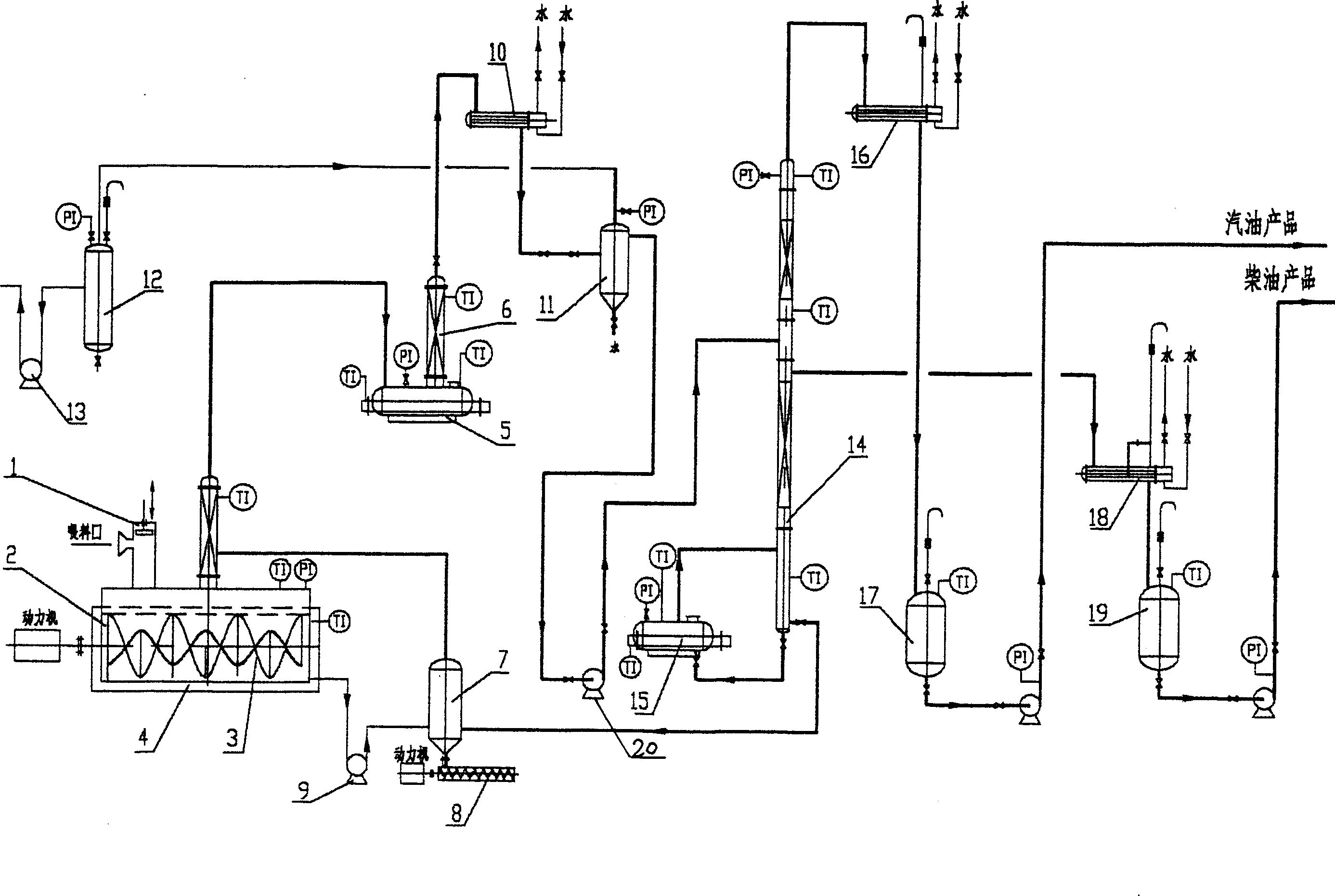

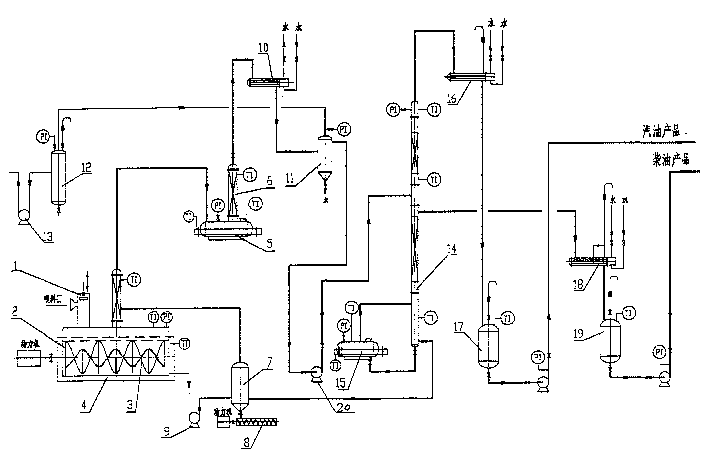

Industrial method of reusing waste plastics to produce gasoline and diesel oil

The present invention is industrial method of reusing waste plastics to produce gasoline and diesel oil. Waste plastics including polyethylene, polypropylene and polystyrene in certain proportion are mixed and heated to liquefy and crack inside one reactor with double-screw stirrer inside it and molten salt inside sandwiched layer as heat conducting medium; the produced material is viscosity reducing cracked and the cracked gas is condensated into liquid fed to rectifying tower; molten plastic liquid is pumped from the reactor into one solid-liquid separator with separating molten salt liquid to separate residue and dirt; clean molten plastic is returned to the reactor while the separated residue and dirt is exhausted via screw extruder in the bottom of the separator; and decompression distillation is performed to produce oil. The present invention can produce oil with high quality in low cost and high conversion rate while tackling white pollution.

Owner:北京斯泰普文投资顾问有限公司

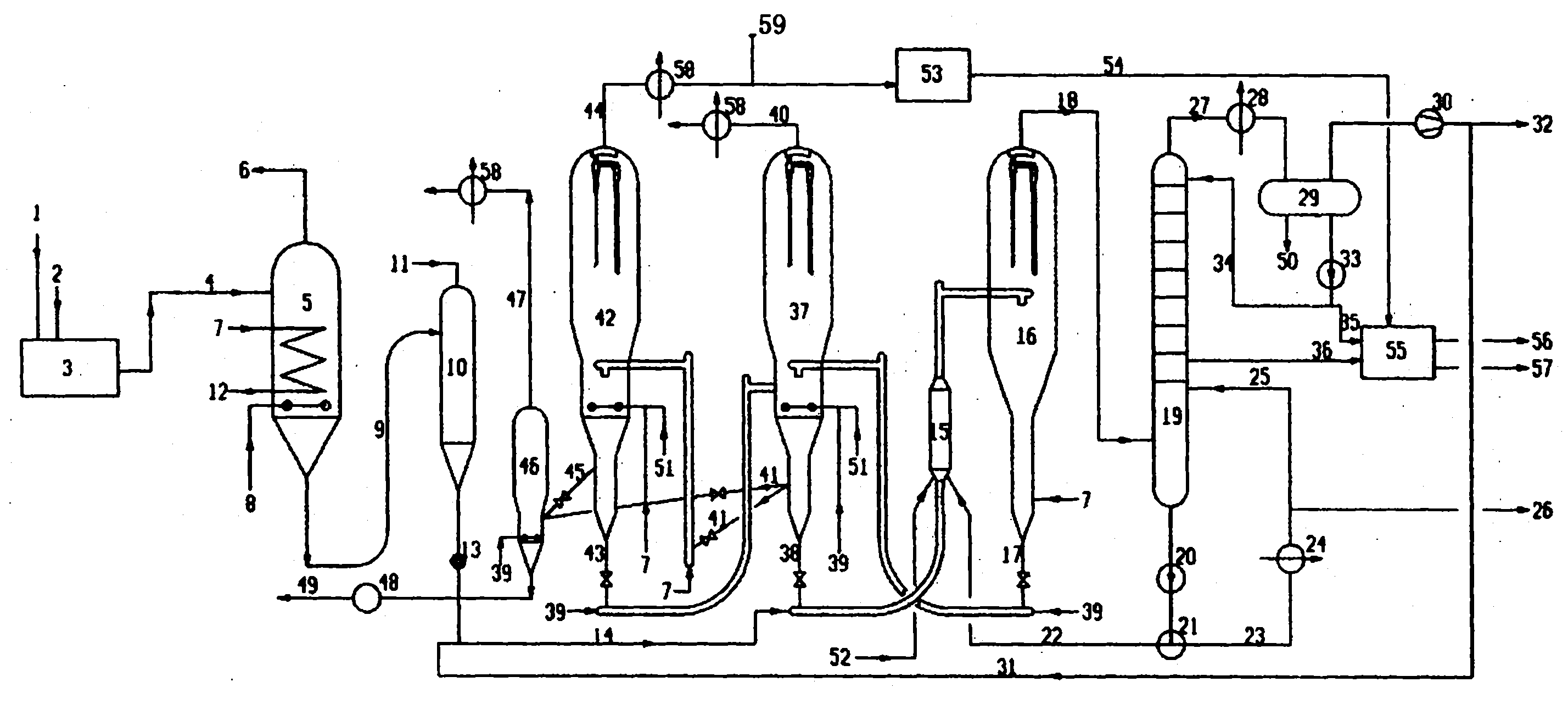

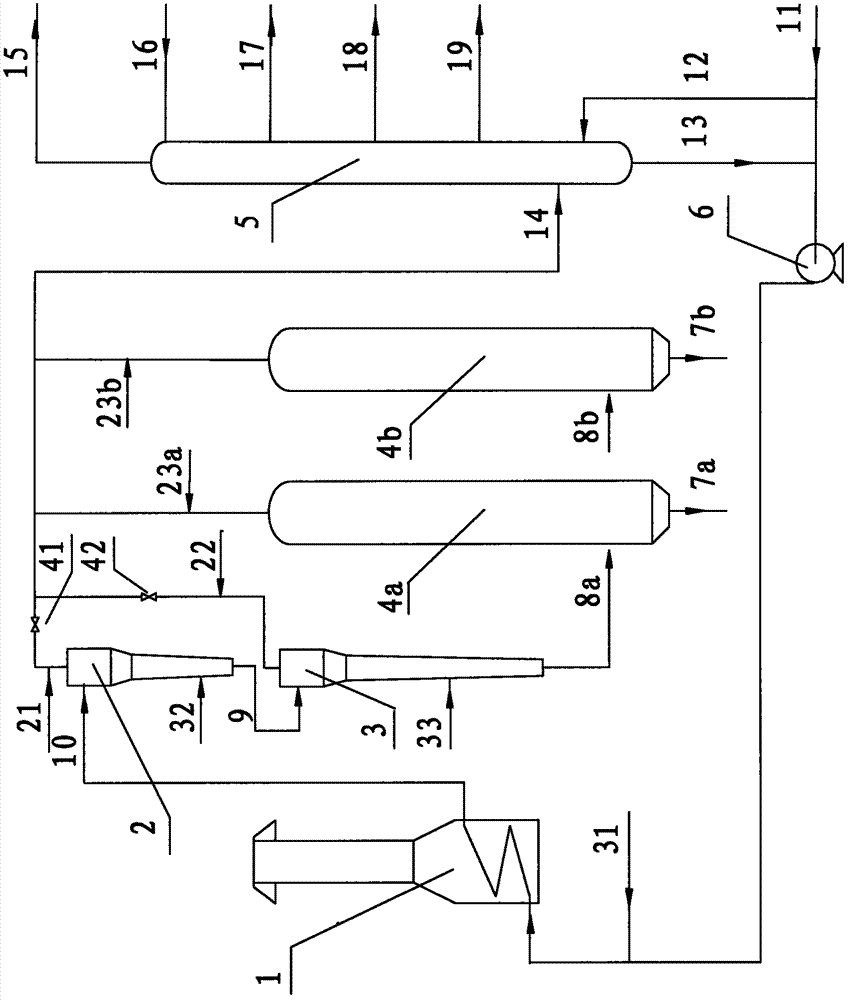

Comprehensive processing and utilizing method for heavy oil

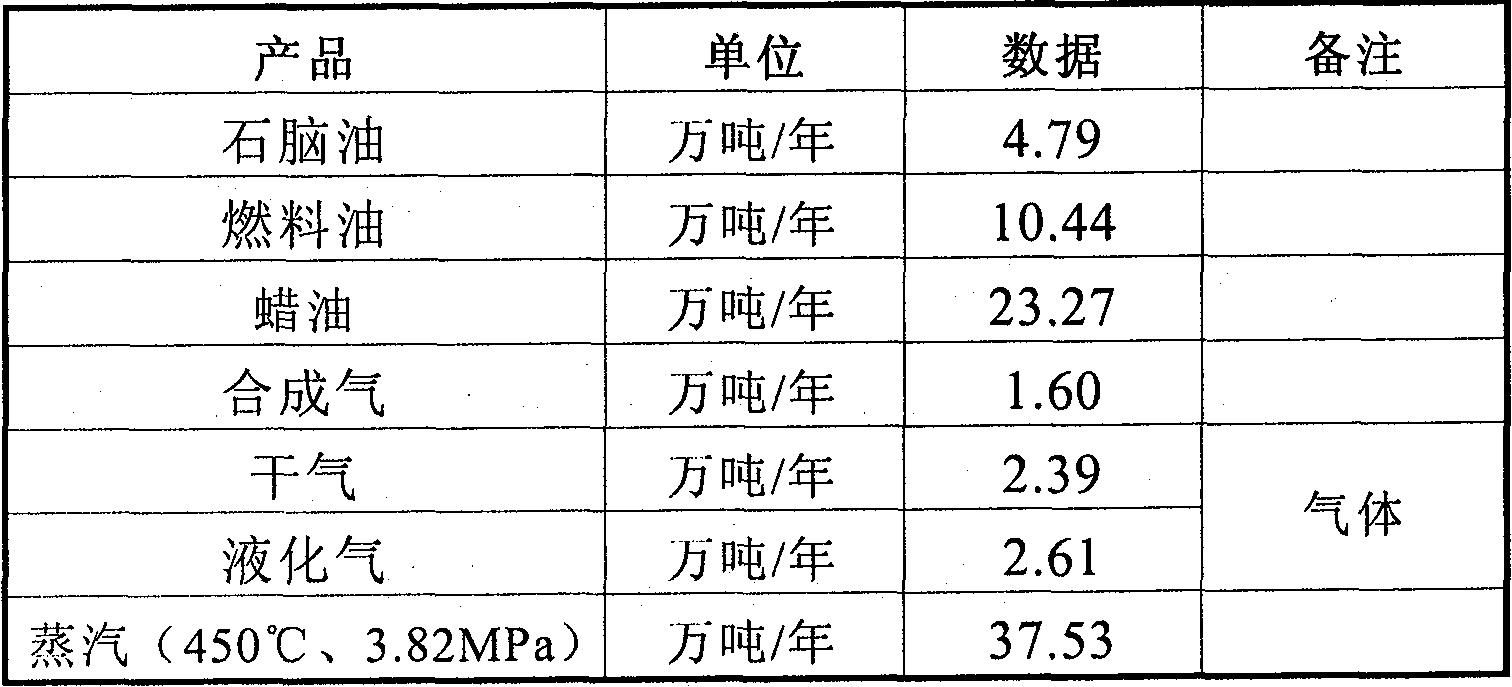

InactiveCN102031135AAchieve rapid lysisImprove light oil yieldThermal non-catalytic crackingHydrogen separationSyngasFuel oil

The invention belongs to the field of petroleum processing and utilization, and relates to a comprehensive processing and utilizing method for heavy oil. By integrating quick cracking of the heavy oil, pre-combustion and gasification of the generated coke, recycling of non-converted heavy oil, hydrogen production by synthetic gas generated through gasification, and a hydrofining process for cracked oil products, light oil can be prepared from the heavy oil to the greatest degree, the light oil is hydrogenated to form high-quality clean oil products, and also can generate the synthetic gas through gasification, and the synthetic gas can serve as a hydrogen production raw material to provide a cheap hydrogen source for oil product hydrofining, and also can serve as fuel gas to provide clean fuel for a refinery. The invention provides a low-cost comprehensive processing and utilizing method for converting the heavy oil into clean light oil products to the greatest degree.

Owner:WISON ENG

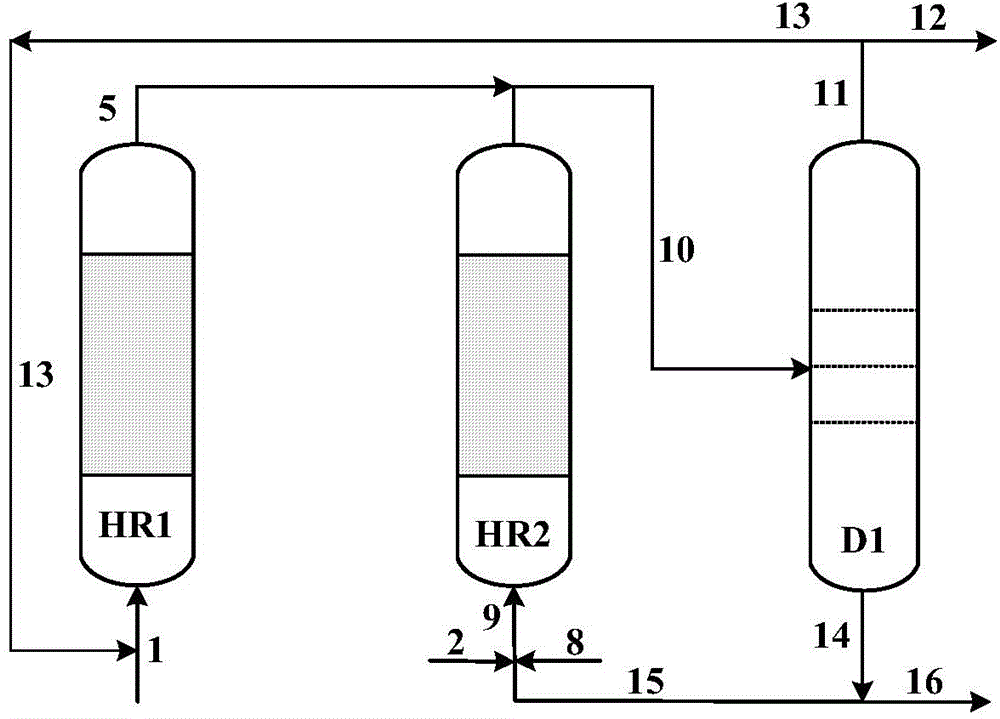

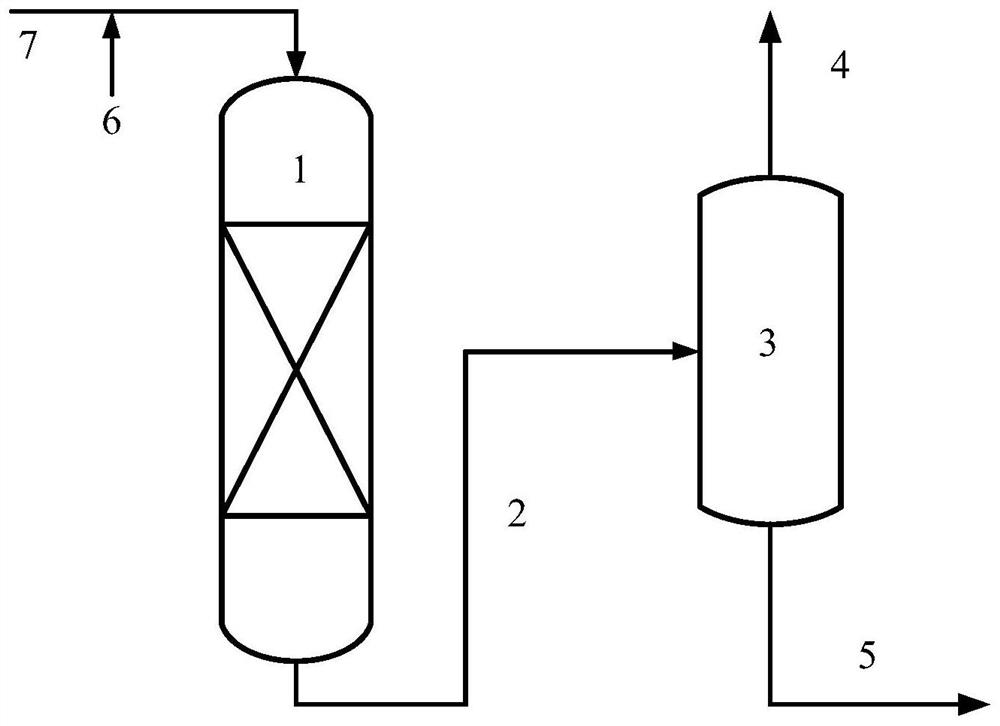

Method for improving shale oil hydrorefining denitrification rate

ActiveCN105838418AImprove utilization efficiencyImprove the level of comprehensive utilizationTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaFractionation

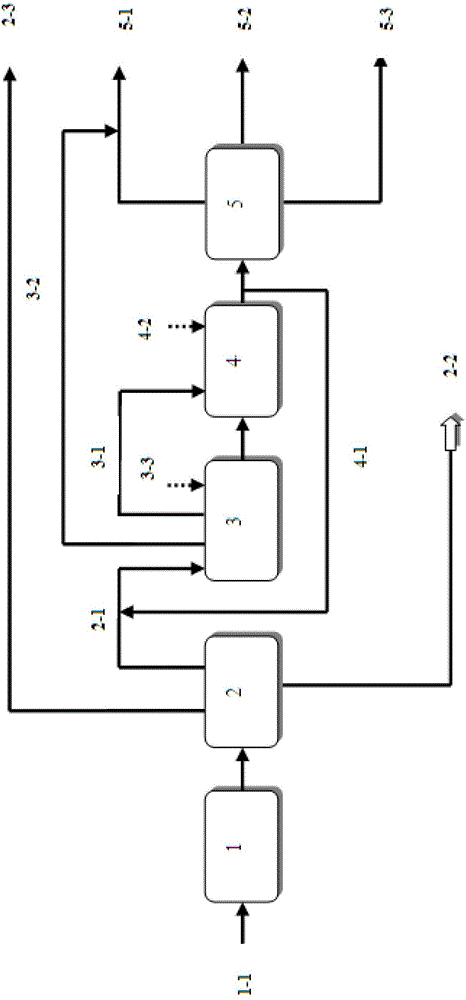

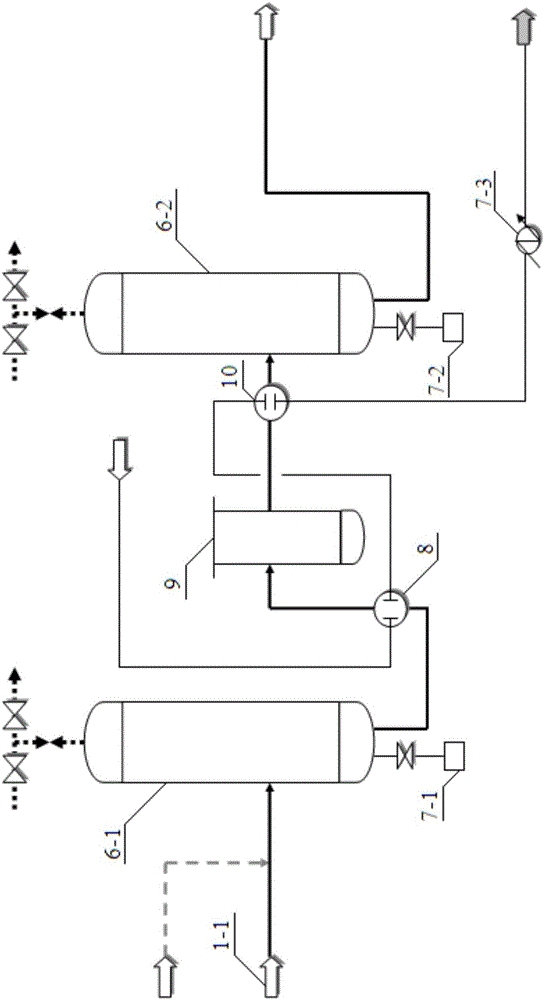

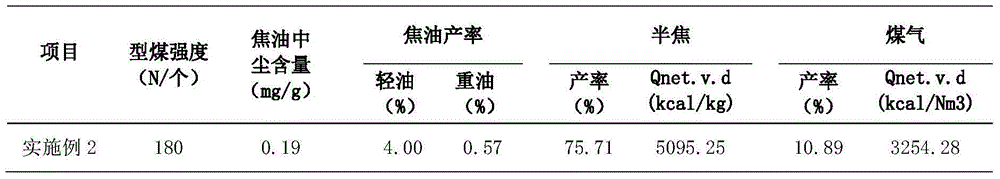

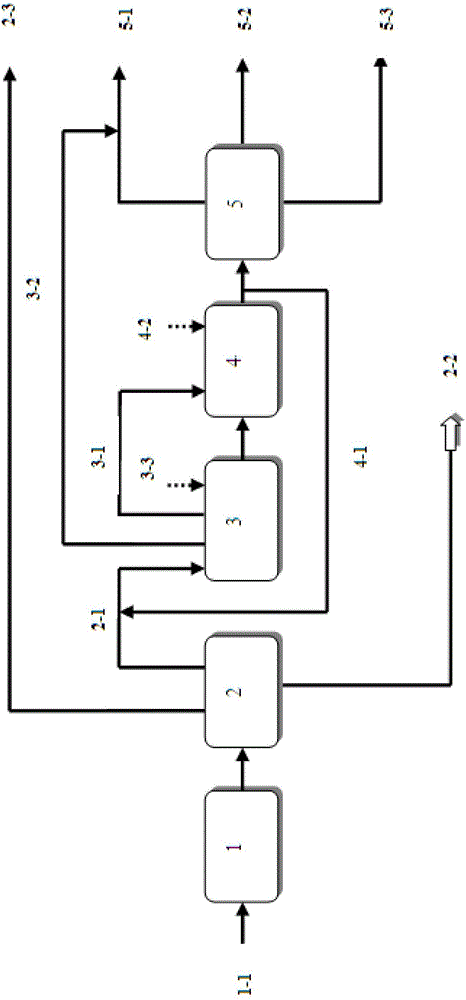

The invention provides a method for improving the shale oil hydrorefining denitrification rate, and relates to a whole fraction shale oil hydro-denitrification process. The method aims at solving the technical problems that in the existing method for producing diesel oil through shale oil hydrorefining, the stability of a diesel oil product is low, and the operation running period of a hydrorefining catalyst is short. According to the method, a raw material pretreatment unit 1, a raw material pre-fractionation unit 2, a primary hydrorefining reaction unit 3, a secondary hydrorefining reaction unit 4 and a product fractionation unit 5 are used. When the method provided by the invention is used for processing shale oil, the light oil yield is high; the nitrogen content of the diesel oil product is low; the chromaticity and the stability conform to national V standard requirements; the goal of light oil product deep denitrification can be achieved; the service life of the hydrorefining catalyst is prolonged; the operation running period of the catalyst is improved. A main product of the method is hydrorefining diesel oil; byproducts are high-value LPG and hydrogenated naphtha; heavy shale oil and hydrogenation tail oil thrown out in the technical process can be further processed and used in a downstream device. The method provided by the invention belongs to the field of whole-fraction shale oil deep processing.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

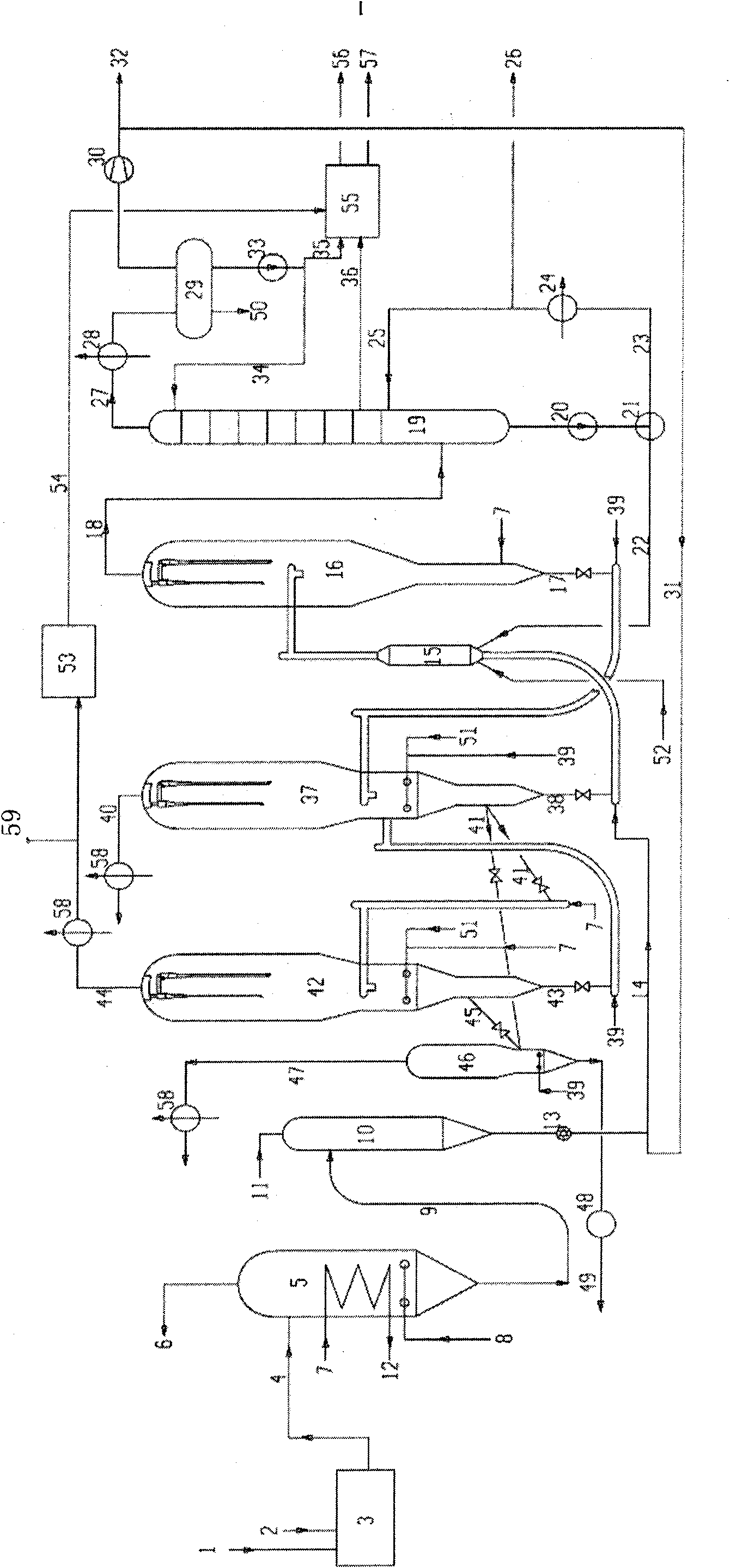

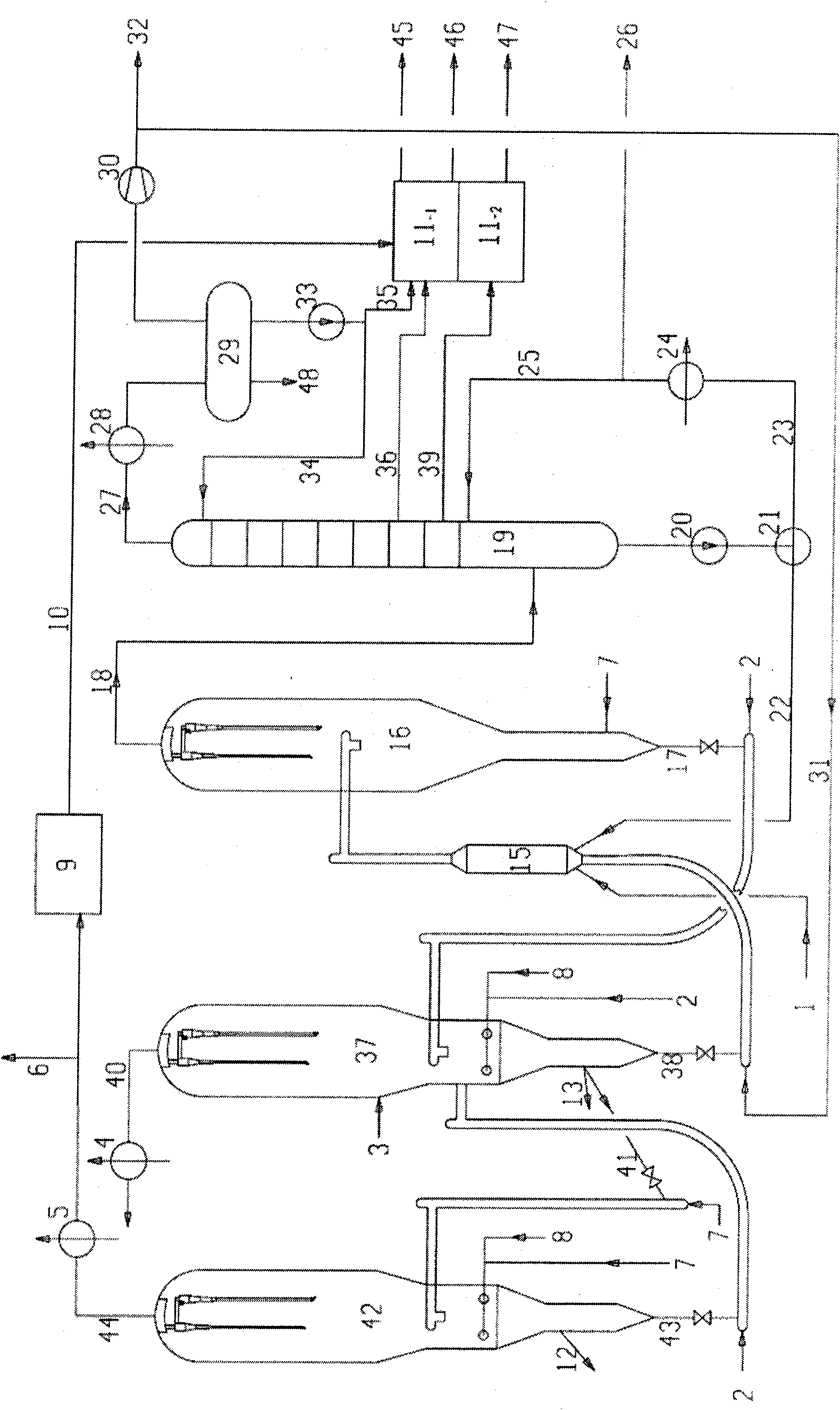

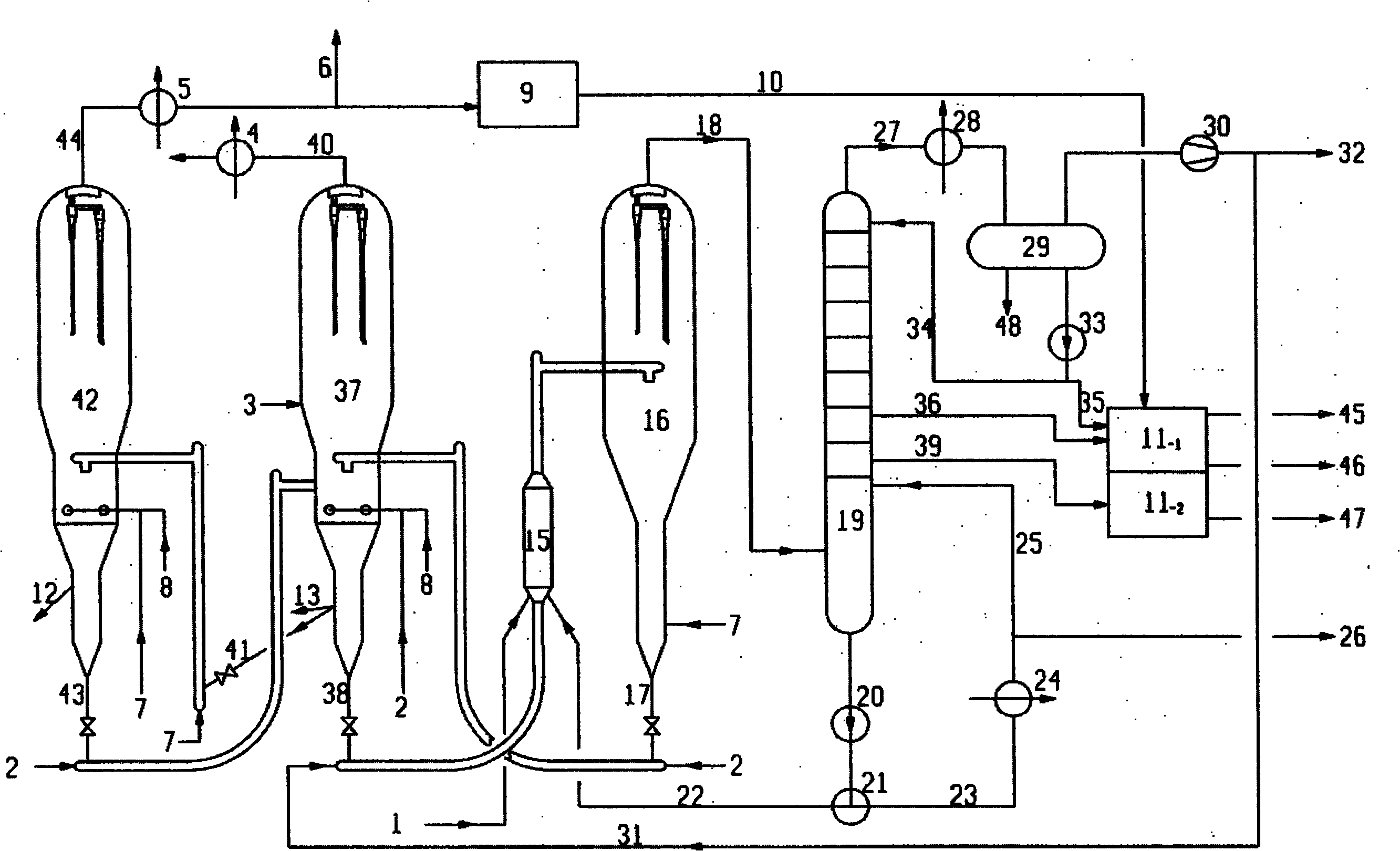

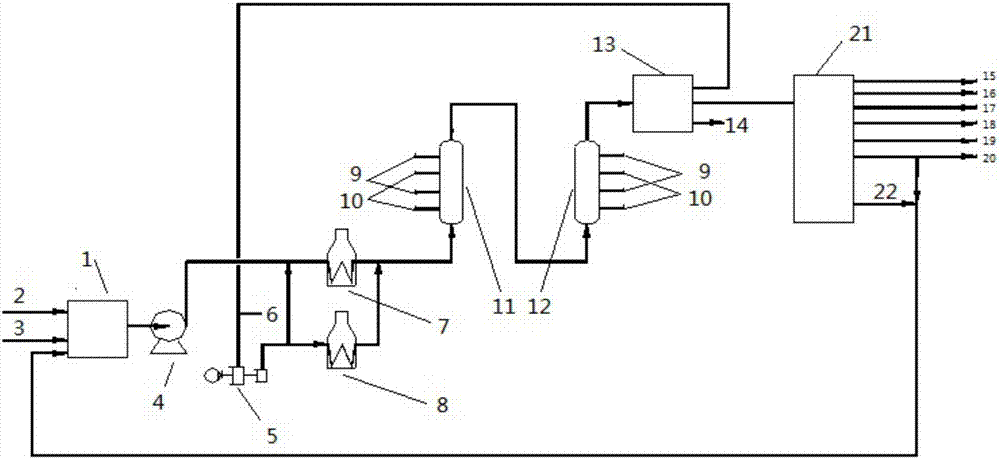

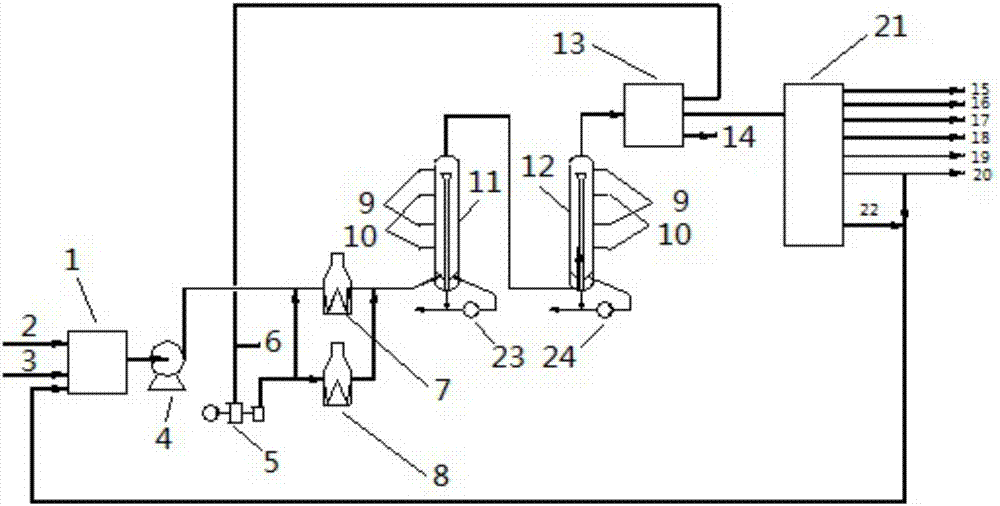

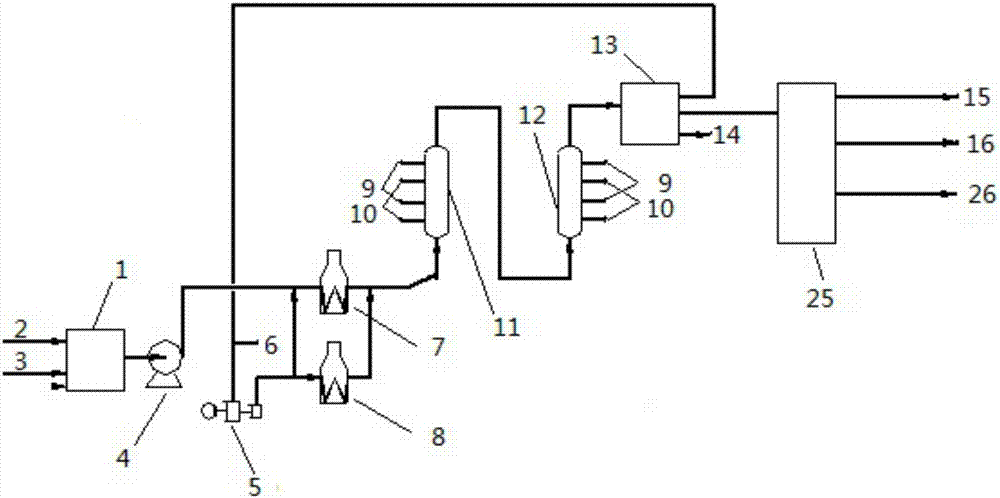

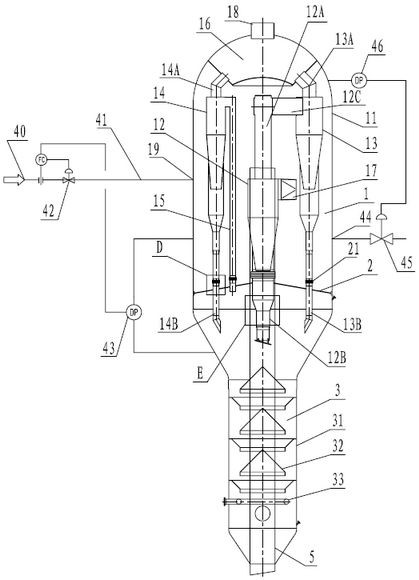

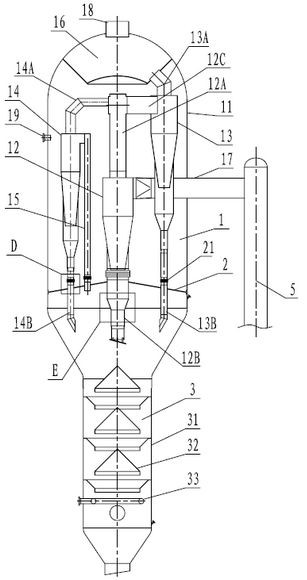

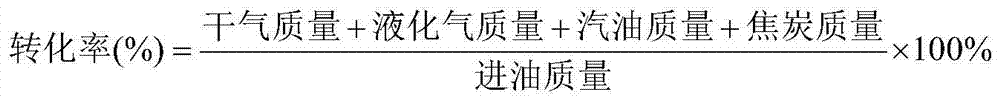

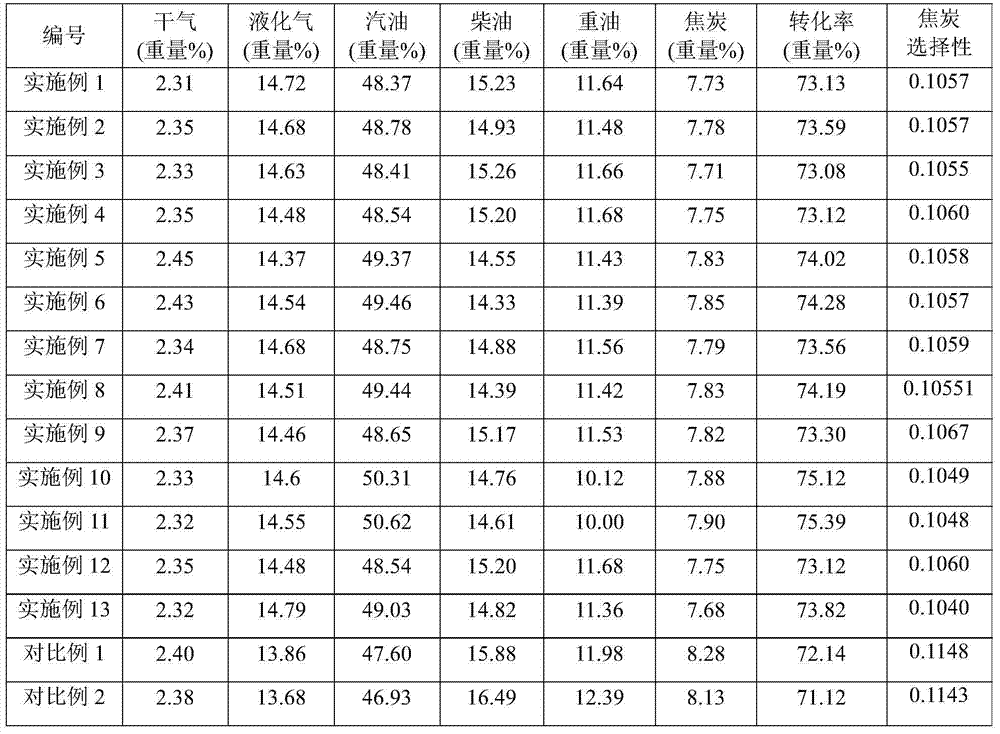

Dual-cycle mode catalytic cracking reaction regenerative system production technology and device

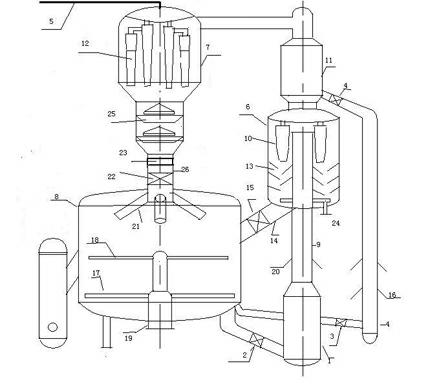

The invention belongs to the technical field of catalytic racking reaction and provides a dual-cycle mode catalytic cracking reaction regenerative system production device which is of a design structure consisting of a riser used for carrying out two-stage catalytic cracking reaction, a two-stage precipitator, a stripper and a high-and-low parallel reaction regenerator (8); a heavy oil riser (1) is of a riser structure used for carrying out the two-stage catalytic cracking reaction, and is provided with a heavy oil riser first reactor (9) and a heavy oil riser second reactor (11); a first precipitator (6) is arranged between the heavy oil riser first reactor (9) and the heavy oil riser second reactor (11), and with the adoption of the first precipitator (6), the reaction of the heavy oil riser is divided into a catalyst first cyclic system and catalytic cracking first reaction stage, and a catalyst second cyclic system and catalytic cracking second reaction stage; and according to the invention, the problems of large light oil yield deviation, high coking rate, coking influence, catalyst regeneration and the like found in the traditional riser production process are solved.

Owner:马俊杰

Cracking catalyst containing laminar clay and its preparation method

InactiveCN1175086CHeavy oil cracking ability is strongImprove light oil yieldCatalytic crackingTitaniumFuel oil

The present invention relates to a cracking catalyst containing laminar clay. It is prepared by adopting the following steps: mixing the expandable clay modifying component, pseudo-thin hydrargillite and water, pulping for 0.1-10 hr. to obtaining a slurry liquor, ageing slurry liquor for 0.1-10 hr. at 50-85 deg.C, drying, forming, washing with water, ageing, finally drying and roasting so as to obtain said catalyst. The described modifying component can be selected from one or several kinds of hydroxyl polymers of silicon, aluminium, zirconium or titanium or one or several kinds of one or several substances containing the described hydroxyl polymer. Said catalyst has higher heavy oil conversion capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for promoting light oil yield of atmospheric and vacuum distillation of petroleum oil

InactiveCN100348695CImprove light oil yieldNo need to change the structureHydrocarbon distillationAcetic acidOrganic solvent

The invention relates the method for improving atmospheric and vacuum distillation light oil productivity. The method comprises the following step: adding the 0.001-0.1wt% addition agent with colophony into crude oil in atmospheric and vacuum distillation tower. The addition agent comprises 50-80% colophony and 50-20% organic solvent. The pH is 7.0-7.5. The organic solvent comprises ethanol or cellosolve or ethyl propyl acetone or acetate cellosolve. The method can be used in oil-extraction plant, and the light oil productivity is improved by 1.5-2.3wt%.

Owner:SHANGHAI JIAO TONG UNIV

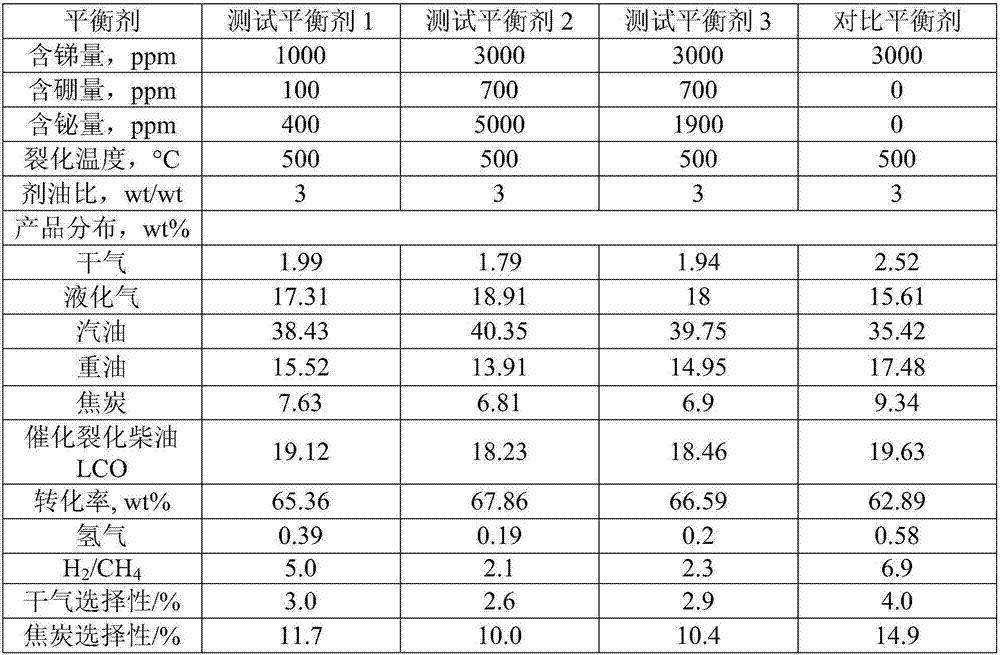

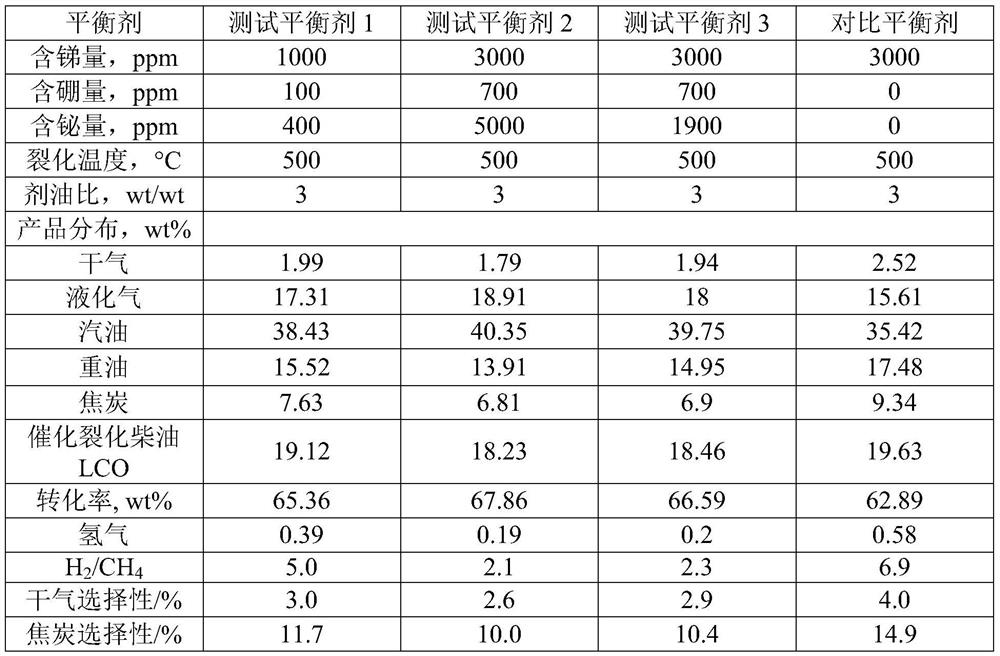

Preparation method for metal deactivator applied to catalytic cracking, and metal deactivator prepared by using same

ActiveCN107971041ASimple preparation processShort reaction timeCatalyst protectionRare earthEconomic benefits

The invention discloses a preparation method for a metal deactivator applied to catalytic cracking and the metal deactivator prepared by using the same. The preparation method comprises the followingsteps: a, mixing antimony trioxide, hydroxycarboxylic acid, a rare-earth salt, a pH value conditioning agent and water and carrying out a reaction at a temperature of 20 to 90 DEG C for 30 to 60 min so as to obtain a first product; and b, mixing an oxidizing agent with the first product obtained in the step a, and carrying out a reaction in an enclosed container at a temperature of 100 to 150 DEGC for 1 to 2 h so as to obtain the metal deactivator applied to catalytic cracking. The preparation method for the metal deactivator applied to catalytic cracking has the advantages of simple process,short reaction time, low cost and reduction in energy consumption, and produces substantial economic benefits. The metal deactivator prepared by using the method has a good nickel and vanadium passivation function when applied to a catalytic cracking reaction and can obviously increasing the yield of light oil and reducing the proportions of coke and dry gas in a product.

Owner:CHINA PETROLEUM & CHEM CORP +1

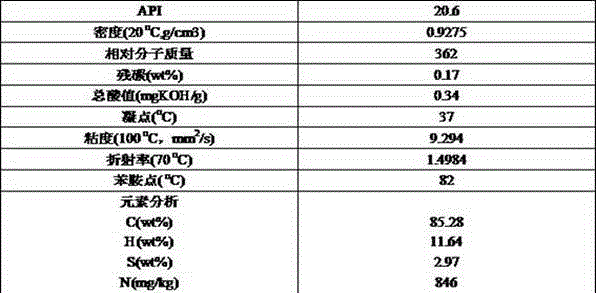

Method for agilely treating inferior heavy oil, residual oil

ActiveCN1769389AImprove raw material adaptabilityImprove light oil yieldTreatment with hydrotreatment processesSolventChemistry

The invention discloses the heavy and ungraded residual oil process method. The method comprises the following steps: hydrotreating the fixed bed and suspended bed, deasphalting and catalytic cracking the dissolvent, and graded treatmenting the heavy and ungraded residual oil raw material. The method comprises many characteristics, as follow: sufficiently utilizing the fixed bed and suspended bed by hydrotreating the two or more than two kinds of feeds respectively, improving the productivity of light oil; through adjusting the proportion of deasphalted oil in the feed of fixed bed hydrotreating, residual oil hydrogenation unit of fixed bed handling more residual oil, effectively decreasing the coke deposit rate on the hydrogenation catalyst, and extending the durability of catalyst; with the said technique, producing the more light end product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Petroleum hydrocarbon cracking catalyst

A cracking catalyst for petroleum hydrocarbon is composed of the Y-type zeolite which consists of super-stable RE Y-type zeolite and high-Si Y-type zeolite, the ZSM-5 zeolite whose mole ratio of silicon oxide to aluminium oxide is 15-200, and the carrier. It can decrease the coke output rate in the catalytic cracking of heavy oil, and increase the octane number of gasoline and the output rate of light oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method of heavy oil in coal tar

ActiveCN103450936AShort processOvercome blockageWorking-up pitch/asphalt/bitumenTreatment with hydrotreatment processesDistillationFuel oil

The invention provides a treatment method of heavy oil in coal tar. The treatment method comprises the following steps of heating heavy oil of light oil extracted in coal tar to 360-380 DEG C, then conveying the heavy oil into an intermittent kneading machine for carrying out negative pressure distillation and separation, returning the light oil obtained by separation to a light oil hydrogenation device, feeding the rest of asphalt, namely modified asphalt with the high additional value and the particle size in the range from 3mm to 5mm into a liquid nitrogen device, cooling to below -15 DEG C to -20 DEG C, then feeding into a high-speed rotary type mill with the rotating speed of 800-1200r / min, and grinding the cooled asphalt particles into 0.0063mm-0.15mm powder when the cooled asphalt particles pass through a gap between a rotor and a stator. The treatment method has the advantages of short technological process and high light oil yield, and is easy to operate.

Owner:内蒙古庆华集团乌斯太精细化工有限公司

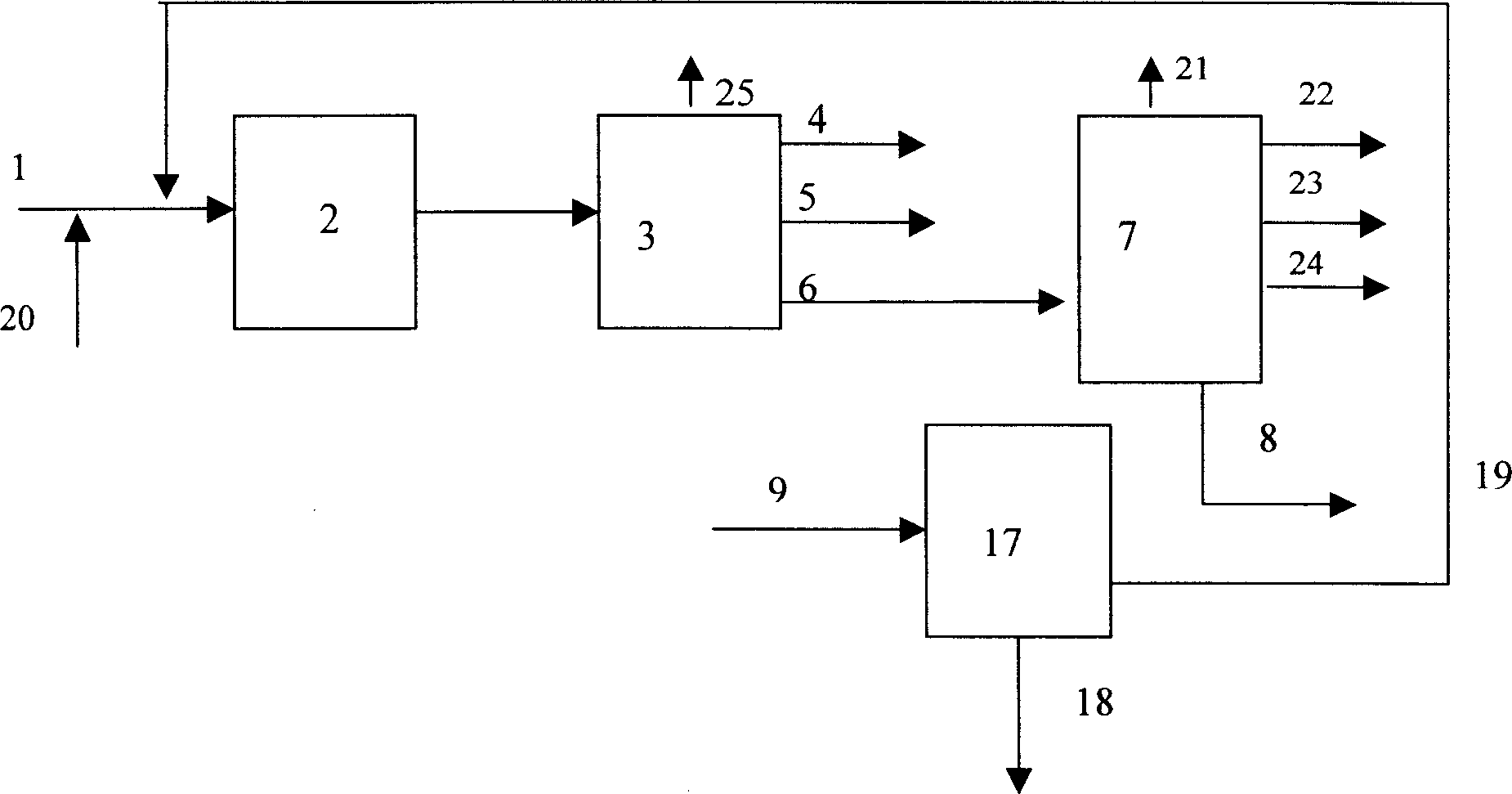

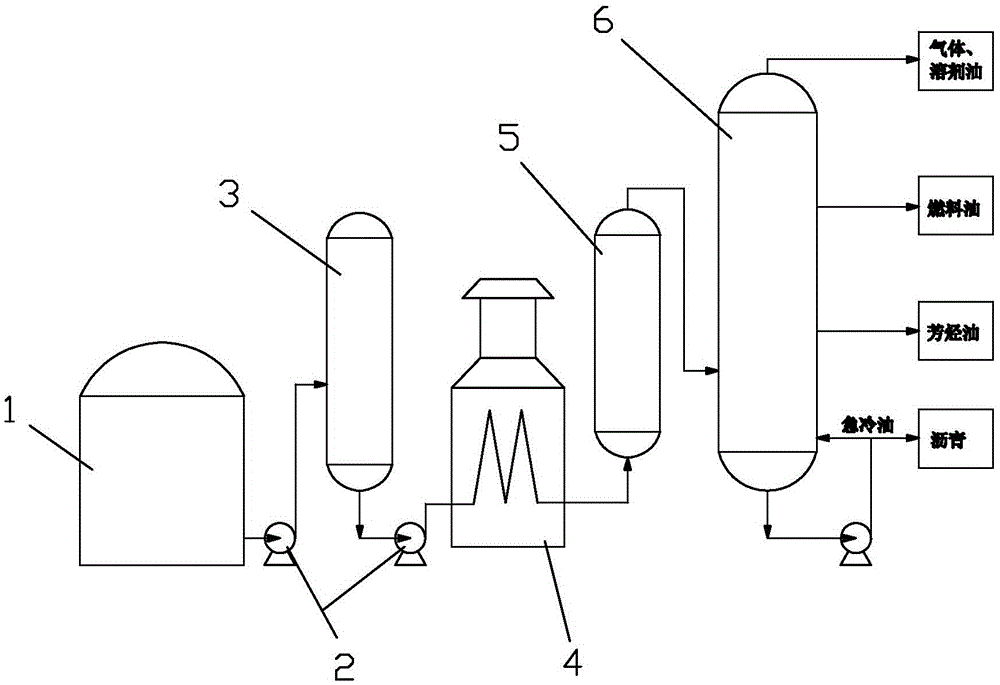

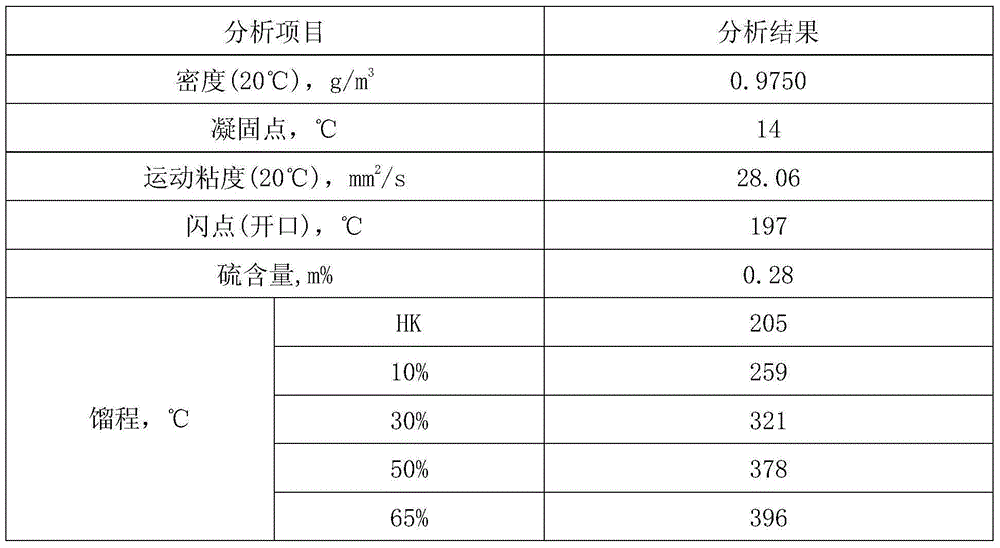

A combined process for producing fuel oil, aromatic oil and asphalt

InactiveCN104327879BHigh aromatic contentImprove utilization efficiencyTreatment with plural serial stages onlyFuel oilSlurry

A fuel oil, aromatic hydrocarbon oil and asphalt combined production process is as follows: catalytic oil slurry or a mixed raw material stored in a raw material tank is conveyed into a buffer tank by a pump, then sent to a heating furnace for heating, and then enters a visbreaking reactor for thermal cracking reaction, after the reaction, reaction products enter into a vacuum distillation tower for separation, solvent oil, and by-product gas, fuel oil, aromatic hydrocarbon oil, and asphalt are successively obtained in the top line, the side line and the tower bottom of the vacuum distillation tower, the solvent oil, the fuel oil, the aromatic hydrocarbon oil and the asphalt with high added value and high market demand can be produced, the comprehensive utilization efficiency of catalytic oil slurry can be improved; at the same time, the light oil yield of the catalytic oil slurry can be significantly increased, content the aromatic hydrocarbon oil can be significantly improved, asphalt product aromaticity can be improved, aromatic hydrocarbon oil and asphalt quality can be improved, the process is simple, the operation condition is easy to control, and large-scale production is easy to realize.

Owner:FOSHAN GAOFU PETROCHINA FUEL ASPHALT

Cracking method for hydrocarbon oil

InactiveCN1428400AHigh hydrocarbon oil conversion and light oil yieldImprove conversion rateCatalytic crackingChemistryAluminium

The present invention relates to a cracking method of hydrocarbon oil, including contact of hydrocarbon oil with catalyst under the cracking condition. Said catalyst is a cracking catalyst containing laminar clay or mixture of said cracking catalyst containing laminar clay and existent cracking catalyst. The described cracking catalyst containing laminar clay is prepared by adopting the following steps: mixing expandable clay, modifying component, pseudo-thin hydrargillite and water, pulping for 0.1-10 hr. to obtain a slurry liquor, ageing for 0.1-10 hr. at 50-85 deg.C, drying, forming, washing with water, ageing, drying and roasting so as to obtain the invented catalyst. The described modifying component can be selected from hydroxyl polymer of silicon, aluminium, zirconium and titanium or substance containing the described hydroxyl polymer.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method for metal deactivator applied to catalytic cracking, and metal deactivator prepared by using same

ActiveCN107971040ASimple preparation processShort reaction timeCatalytic crackingCatalyst protectionBoron containingEconomic benefits

The invention discloses a preparation method for a metal deactivator applied to catalytic cracking and the metal deactivator prepared by using the same. The preparation method comprises the followingsteps: a, mixing antimony trioxide, hydroxycarboxylic acid, a boron-containing compound, a bismuth-containing compound, a pH value conditioning agent and water and carrying out a reaction at a temperature of 20 to 90 DEG C for 30 to 60 min so as to obtain a first product; and b, mixing an oxidizing agent with the first product obtained in the step a, and carrying out a reaction in an enclosed container at a temperature of 100 to 150 DEG C for 1 to 2 h so as to obtain the metal deactivator applied to catalytic cracking. The preparation method for the metal deactivator applied to catalytic cracking has the advantages of simple process, short reaction time, low cost and reduction in energy consumption, and produces substantial economic benefits. The metal deactivator prepared by using the method has a good nickel and vanadium passivation function when applied to a catalytic cracking reaction and can obviously increasing the yield of light oil and reducing the proportions of coke and dry gas in a product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Omnipotent bed hydrogenation technology

InactiveCN107057756AReduce maintenance workloadShort processHydrocarbon oil crackingTreatment with hydrotreatment processesVulcanizationAtmospheric air

The invention provides an omnipotent bed hydrogenation technology. Raw materials comprise atmospheric pressure residual oil, vacuum residual oil, catalytic slurry oil, deoiled asphalt, coal tar or distillate oil, and can further comprise coal dust, firstly, the raw material oil and an oil soluble catalyst are mixed in a raw material / catalyst mixing system, the mixing temperature is 60-350 DEG C, and the mixing time is 20-200 minutes; the vulcanization process is completed in a reactor; the omnipotent bed is a cylindrical reactor excluding a fixed bed layer; the oil soluble catalyst is the combination of one or more of active components of Mo, Ni, Co, W, Fe. According to the omnipotent bed hydrogenation technology, firstly, the oil soluble catalyst and the raw material oil are mutually mixed (after an oil-coal joint hydrogenation technology, coal dust is added to prepare coal-oil slurry, and swelling is conducted), hydrogen is added, the temperature is raised, the pressure is raised, a reaction is conducted, separation is conducted, and fractional distillation is conducted. The omnipotent bed hydrogenation technology has the advantages of being high in raw material adaptability, high in light oil yield, less in atmospheric and solid waste and low in temperature and pressure.

Owner:CATECH TECH

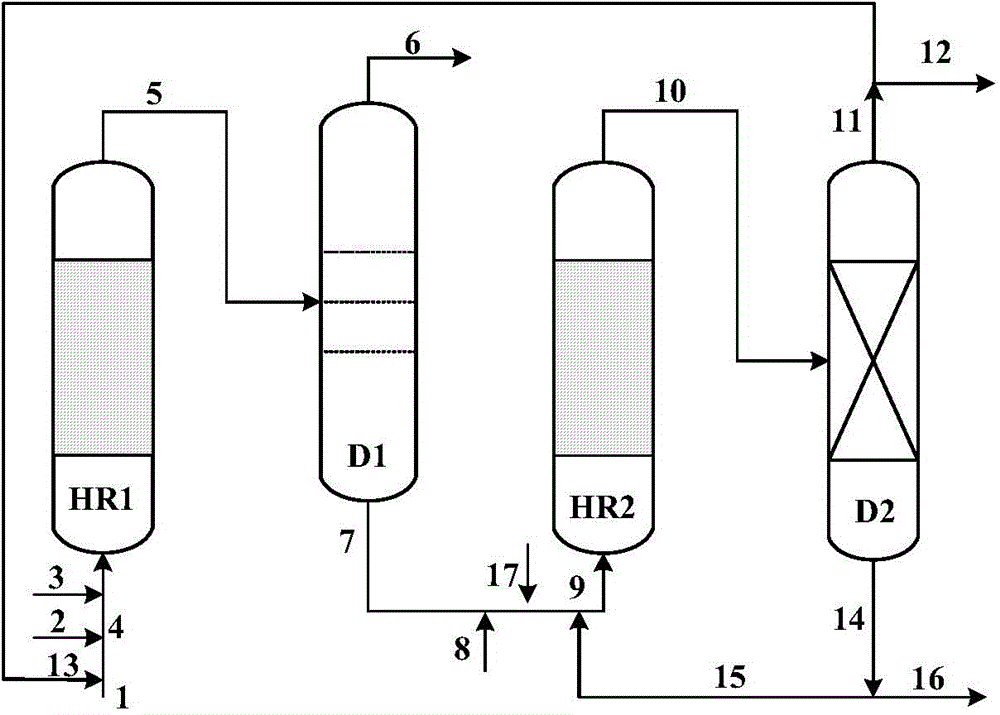

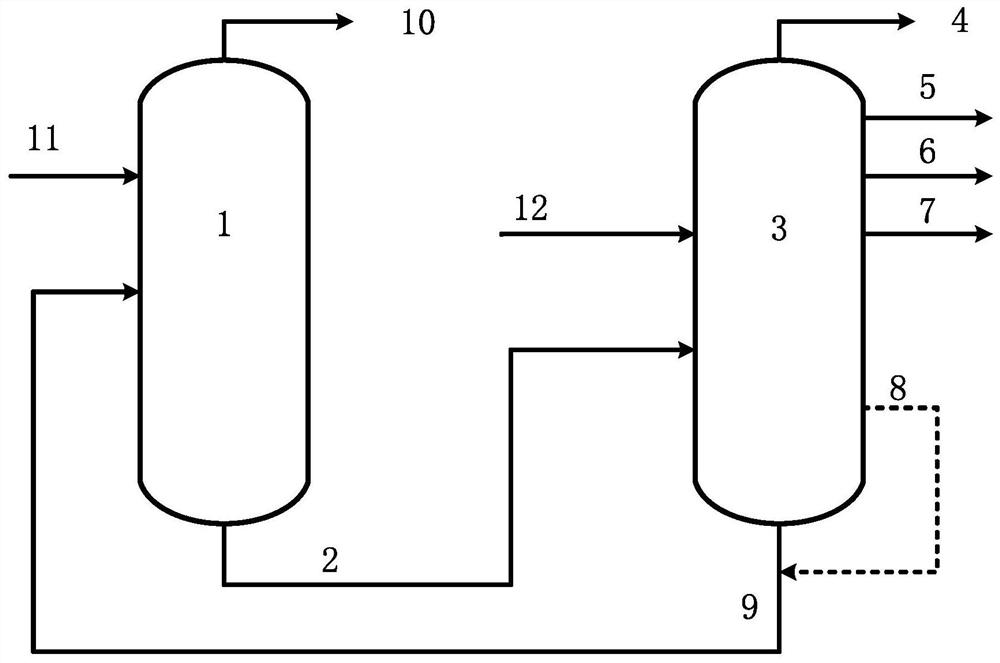

Heavy oil hydro-conversion method

ActiveCN104560163AImprove light oil yieldKeep catalyst activeTreatment with hydrotreatment processesWaxChemistry

The invention provides a heavy oil hydro-conversion method. The method comprises the following steps: (1) a heavy oil raw material and heavy wax oil enter a first reactor in the presence of hydrogen and in the presence or absence of a hydrogen-thermal cracking catalyst to be subjected to a hydrogen-thermal cracking reaction; (2) the reaction product in the first reactor is separated into light distillate, heavy wax oil and residual oil; (3) the residual oil and hydrogen enter a second reactor, and contact with the hydrogen-thermal cracking catalyst to be subjected to a hydrogen-thermal cracking reaction at a relatively low temperature; (4) the reaction product in the second reactor is separated into light distillate, heavy wax oil and residual oil, the separated heavy wax oil is returned to the first reactor, and the separated residual oil part is respectively returned to the two reactors for further reacting according to a proportion; and the reacting temperature in the second reactor is 5-50 DEG C lower than that in the first reactor. Compared with the prior art, the method has the advantages of remarkably improving the heavy oil conversion rate and light oil yield, and improving the light rate of heavy distillate.

Owner:CHINA PETROLEUM & CHEM CORP +1

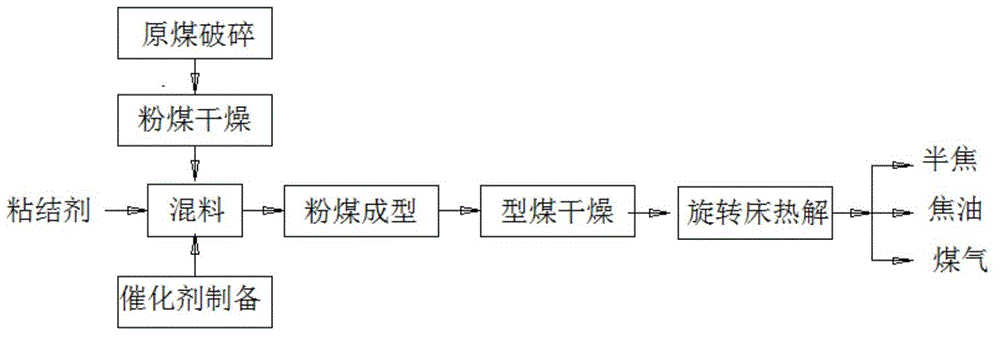

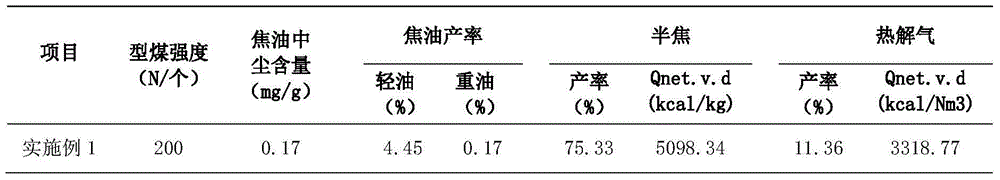

Revolving bed coal catalytic pyrolysis method

ActiveCN104910942AReduce intensityReduced strength requirementsIndirect heating destructive distillationSpecial form destructive distillationCatalytic pyrolysisTitanium

The invention provides a revolving bed coal catalytic pyrolysis method. The method comprises steps of raw coal pretreatment, catalyst preparation, powdered coal shaping with addition of the catalyst, catalyst briquette coal drying, and pyrolysis in a revolving bed thermal decomposition furnace, and the catalyst is one or some selected from vanadium titanium magnetite and Fe3O4. The method solves the problems that after powdered coal shaping with addition of the catalyst, the briquette coal is low in intensity, and is easy to pulverize during the pyrolysis process. The dust content in tar can be lowered, the tar yield is raised, and the tar quality is improved.

Owner:SHENWU TECH GRP CO LTD

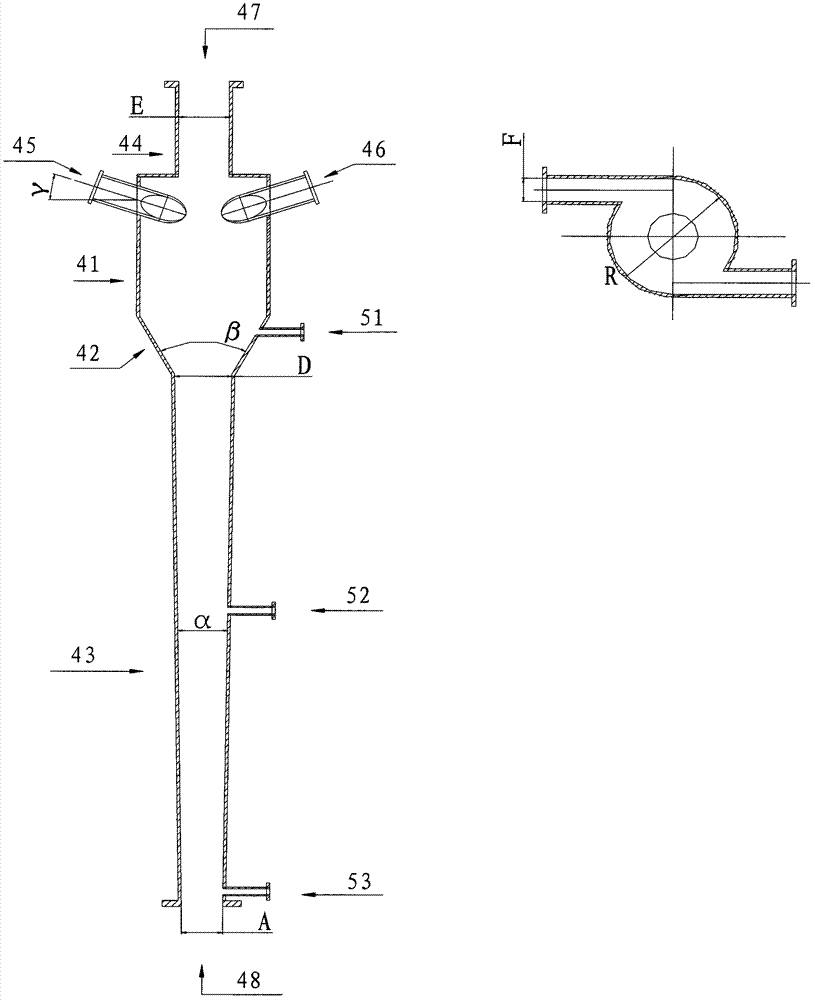

A method for improving the denitrification rate of shale oil hydrotreating

ActiveCN105838418BImprove utilization efficiencyImprove the level of comprehensive utilizationTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaFractionation

The invention provides a method for improving the shale oil hydrorefining denitrification rate, and relates to a whole fraction shale oil hydro-denitrification process. The method aims at solving the technical problems that in the existing method for producing diesel oil through shale oil hydrorefining, the stability of a diesel oil product is low, and the operation running period of a hydrorefining catalyst is short. According to the method, a raw material pretreatment unit 1, a raw material pre-fractionation unit 2, a primary hydrorefining reaction unit 3, a secondary hydrorefining reaction unit 4 and a product fractionation unit 5 are used. When the method provided by the invention is used for processing shale oil, the light oil yield is high; the nitrogen content of the diesel oil product is low; the chromaticity and the stability conform to national V standard requirements; the goal of light oil product deep denitrification can be achieved; the service life of the hydrorefining catalyst is prolonged; the operation running period of the catalyst is improved. A main product of the method is hydrorefining diesel oil; byproducts are high-value LPG and hydrogenated naphtha; heavy shale oil and hydrogenation tail oil thrown out in the technical process can be further processed and used in a downstream device. The method provided by the invention belongs to the field of whole-fraction shale oil deep processing.

Owner:ENERGY & ENVIRONMENT RES INST OF HEILONGJIANG PROVINCE

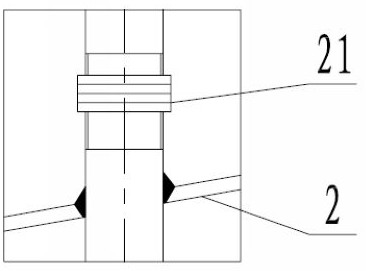

Reactor internal-part with high light oil yield, low back-mixing and long-term operation and technological method thereof

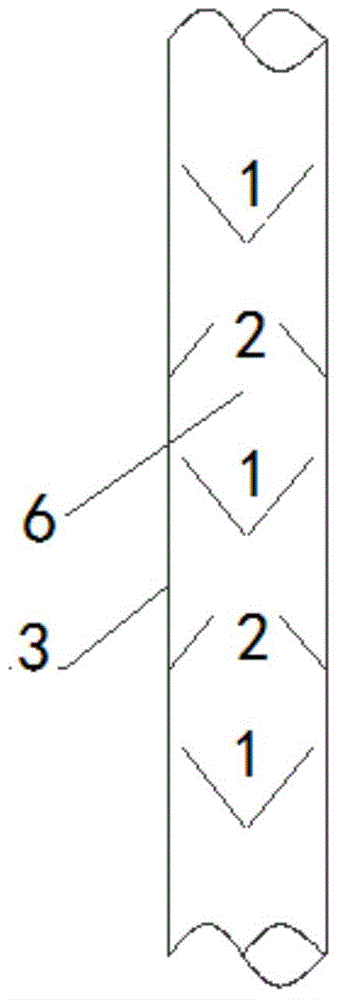

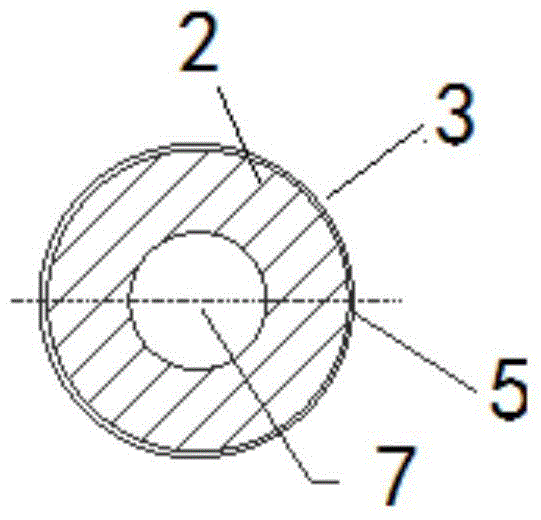

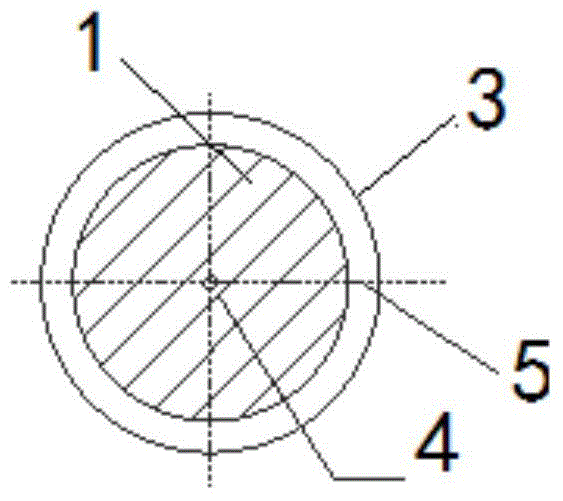

ActiveCN104650955AReduce lossEasy to remove oilThermal non-catalytic crackingShortest distanceEngineering

A reactor internal-part with high light oil yield, low back-mixing and long-term operation and a technological method thereof belong to the technical field of oil refining equipment. Odd-number trays and even-number trays are all inclined a certain degree. The odd-number trays are V-shaped plates with small holes at the center, and there is a long distance between the external edge and a visbreaking tower body; and the even-number trays are inverted V-shaped plates with large holes at the center, and there is a shorter distance between the external edge and the visbreaking tower body. When reaction materials pass through two sides of the odd-number trays, speed will be gradually raised such that the reaction materials pass through intervals between the tower plates and the reactor wall at a high speed. When speed reaches the maximum, the reaction materials leave the even-number trays from the center. Through the gradually-narrowing intervals between the odd-number trays and the tower body, flow velocity of a fluid continuously increases, thus scouring the side wall of the tower body to the maximum so as to avoid back-mixing caused by low flow velocity at the side wall. Reaction raw oil passes through the odd-number trays and the even-number trays in order, successively speeds up at the side wall and center of the reactor, and finally passes through all the trays to go out of the reactor.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Catalytic cracking oil slurry treatment method and system thereof

ActiveCN112342058AReduce deposition rateExtended operating cycleTreatment with hydrotreatment processesHydrocarbon oils treatment productsPtru catalystFluid phase

The present invention relates to a catalytic cracking oil slurry treatment method and a system thereof. The method comprises steps: enabling the catalytic cracking oil slurry and optional catalytic cracking recycle oil to enter a hydrotreating unit to contact with a catalyst in a hydrogenation reaction zone to react, and enabling a reaction effluent to enter a gas-liquid separation zone to be separated to obtain a hydrogen-rich gas and a liquid phase material flow, enabling the liquid-phase material flow and a catalytic cracking raw material to enter a riser reactor of a catalytic cracking unit together to be in contact with a catalytic cracking catalyst for reaction, and separating a reaction effluent to obtain catalytic cracking dry gas, liquefied gas, catalytic cracking gasoline, catalytic cracking diesel oil, catalytic cracking recycle oil and catalytic cracking oil slurry, and returning the catalytic cracking oil slurry to the hydrogenation reaction zone for reaction. According tothe invention, the operation period of the hydrotreating unit is prolonged, and the light oil yield of the catalytic cracking unit is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

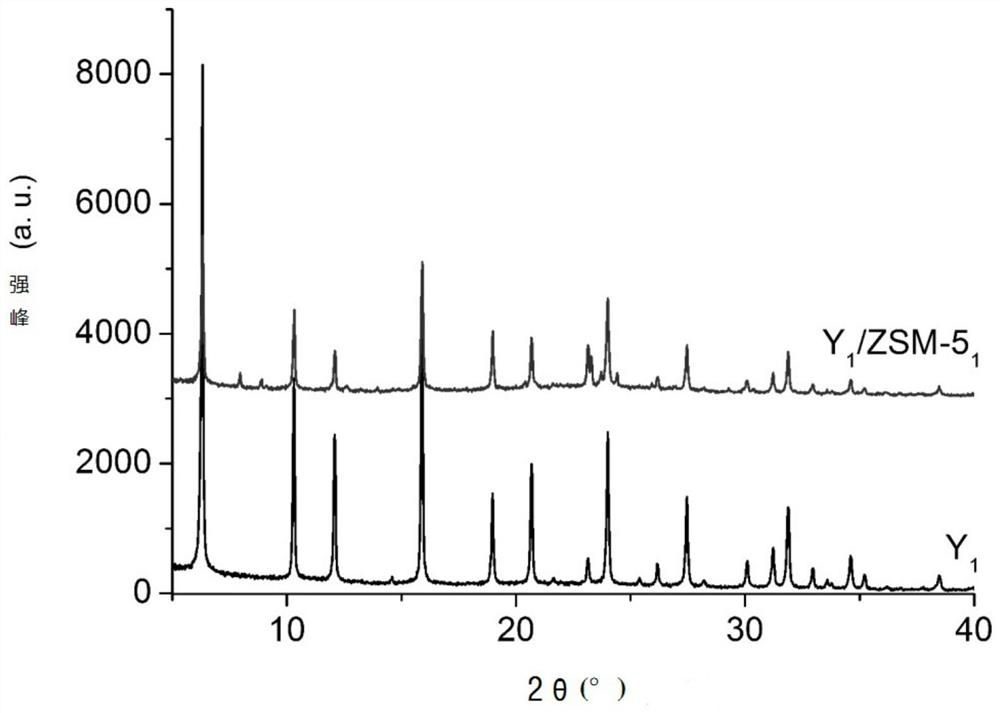

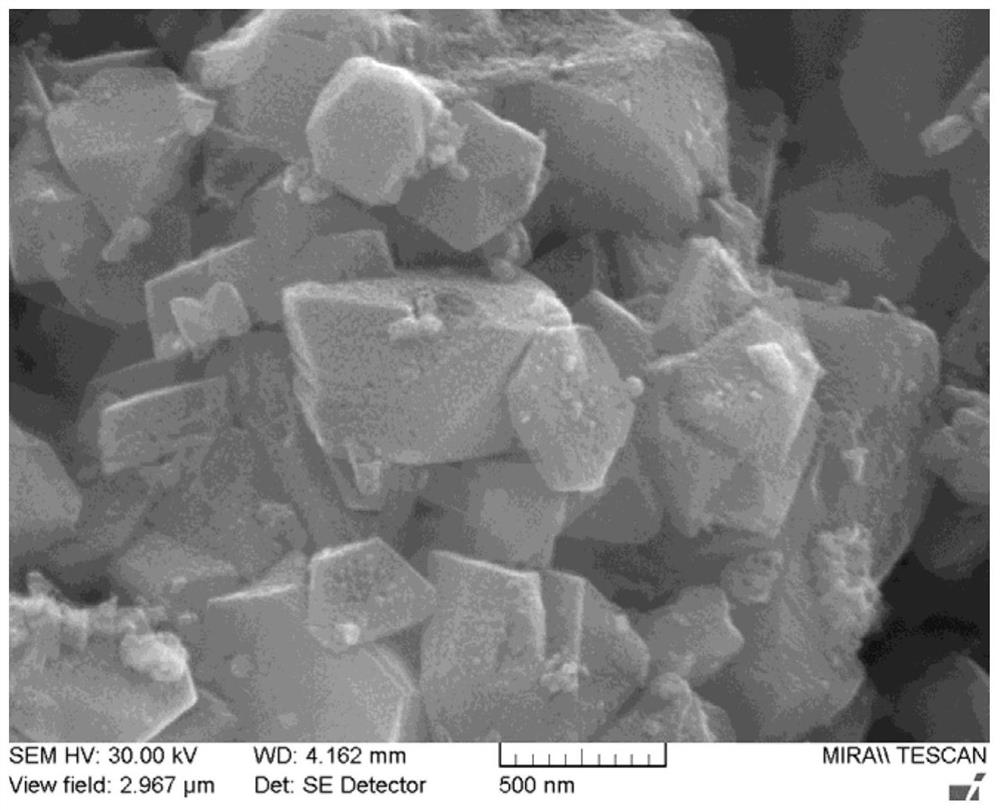

High-stability modified Y-type molecular sieve for high production of isomerized C4 and preparation method of high-stability modified Y-type molecular sieve

ActiveCN110652999AHigh thermal and hydrothermal stabilityHigh selectivityCatalytic crackingMolecular sieve catalystsMolecular sievePhysical chemistry

The invention discloses a high-stability modified Y-type molecular sieve for high production of isomerized C4 and a preparation method of the high-stability modified Y-type molecular sieve. The CaO content of the modified Y-type molecular sieve is 0.3-4 wt%, the RE2O3 content is 2 to 7 wt%; the content of Na2O is 0.1 to 0.5 wt%; the total pore volume is 0.33 mL / g to 0.39 mL / g; the pore volume of the secondary pores of 2-100nm accounts for 10-25% of the total pore volume; the lattice constant is 2.440-2.455 nm, the content of non-framework aluminum accounts for not more than 20% of the total aluminum content, the lattice collapse temperature is not lower than 1050 DEG C, and the ratio of the amount of acid B to the amount of acid L measured by a pyridine adsorption infrared method at 200 DEG C is not lower than 2.30. The preparation method comprises the steps of ion exchange, modification treatment under certain temperature and water vapor conditions and reaction with silicon tetrachloride. The modified Y-type molecular sieve has higher heavy oil conversion activity, lower coke selectivity, higher gasoline yield and isomeric C4 yield, and higher isomeric hydrocarbon content in gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

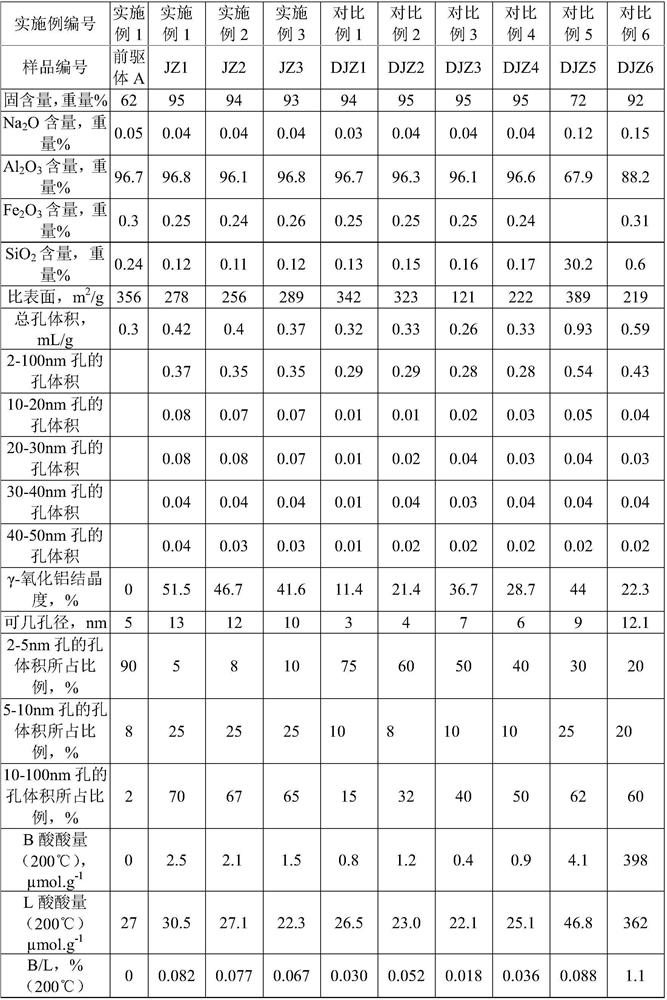

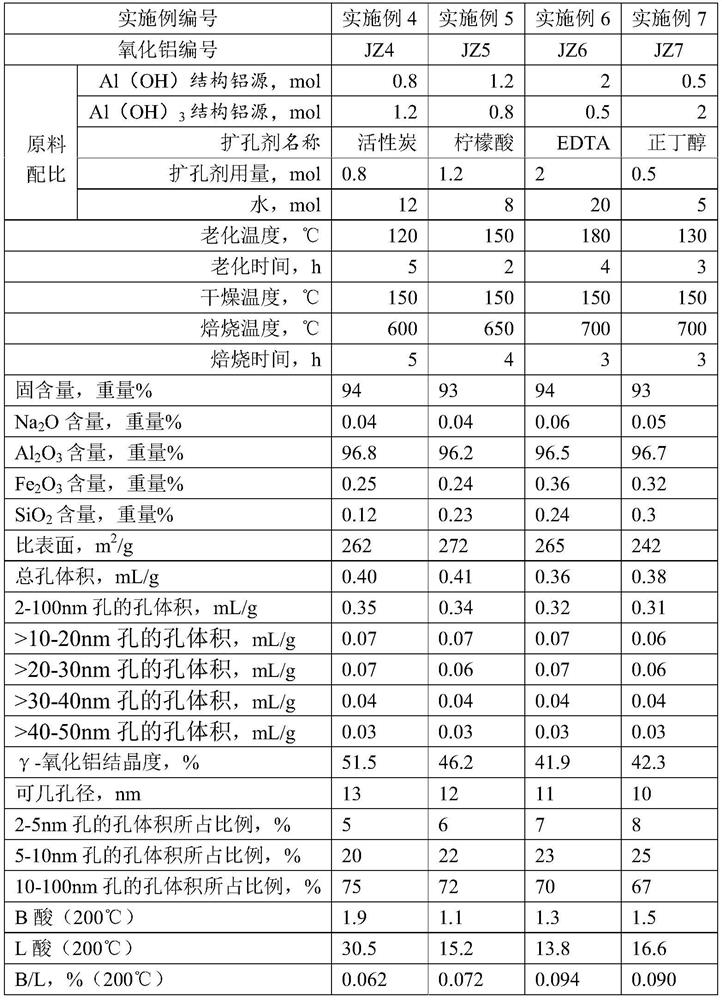

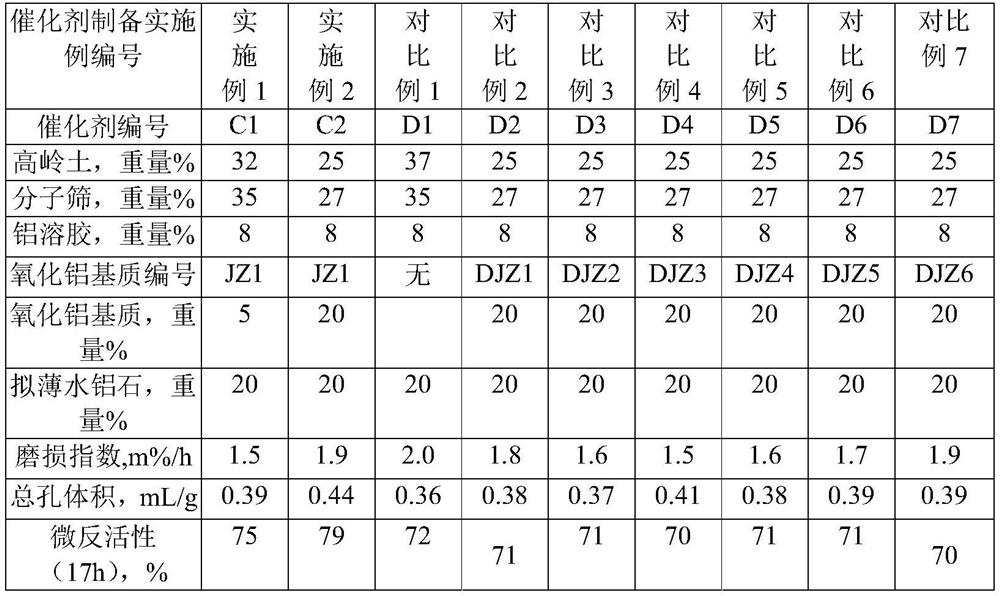

Aluminum oxide as well as preparation method and application thereof

ActiveCN111744483AImprove performanceHigh activityCatalytic crackingMolecular sieve catalystsPtru catalystGasoline

The invention relates to aluminum oxide and a preparation method and application thereof. The aluminum oxide has a crystal phase structure of gamma-aluminum oxide, and the crystallinity of the gamma-aluminum oxide is 40-60%; based on the volume of the pores of 2-100 nm, the pore volume of the pores of 2-5 nm accounts for 0-10%, the pore volume of the pores greater than 5-10 nm accounts for 10-25%,the pore volume of the pores of greater than 10-100 nm accounts for 65-90%, and the probable pore diameter is 10-25 nm; and the ratio of the acid B to the acid L is 0.06-0.1. The preparation method comprises the following steps: treating a mixture containing two aluminum oxide sources and a pore-enlarging agent in a certain proportion in a water vapor atmosphere, and roasting. The aluminum oxideis used for preparing a catalytic cracking catalyst, has a better inferior oil conversion effect, and can have higher gasoline yield and lower coke yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

A preparation method of catalytic cracking metal passivator and metal passivator prepared by the method

ActiveCN107971040BSimple preparation processShort reaction timeCatalytic crackingCatalyst protectionBismuth compoundCarboxylic acid

Owner:CHINA PETROLEUM & CHEM CORP +1

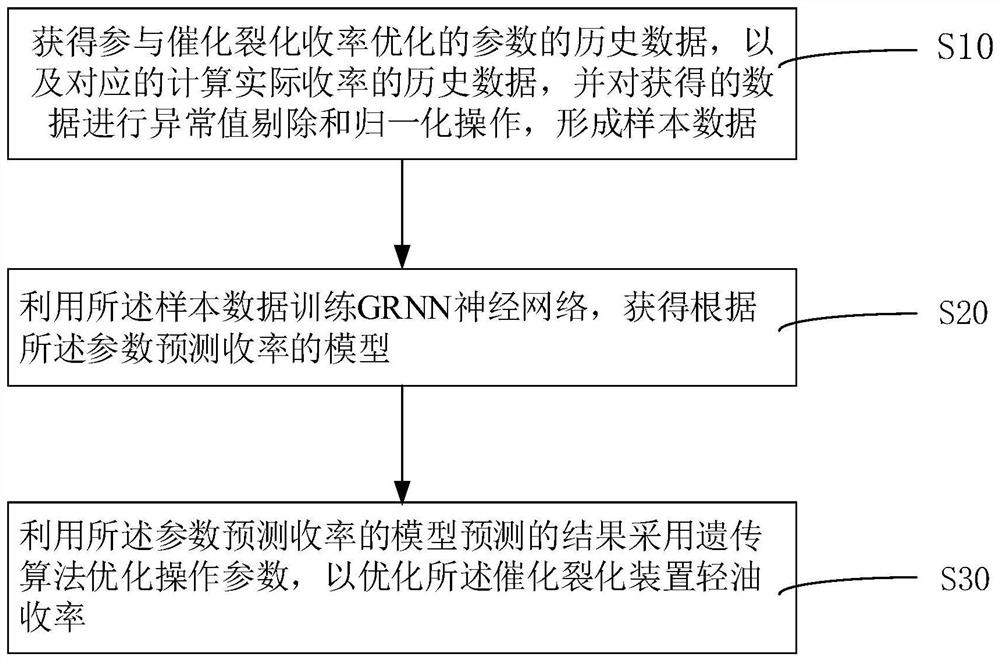

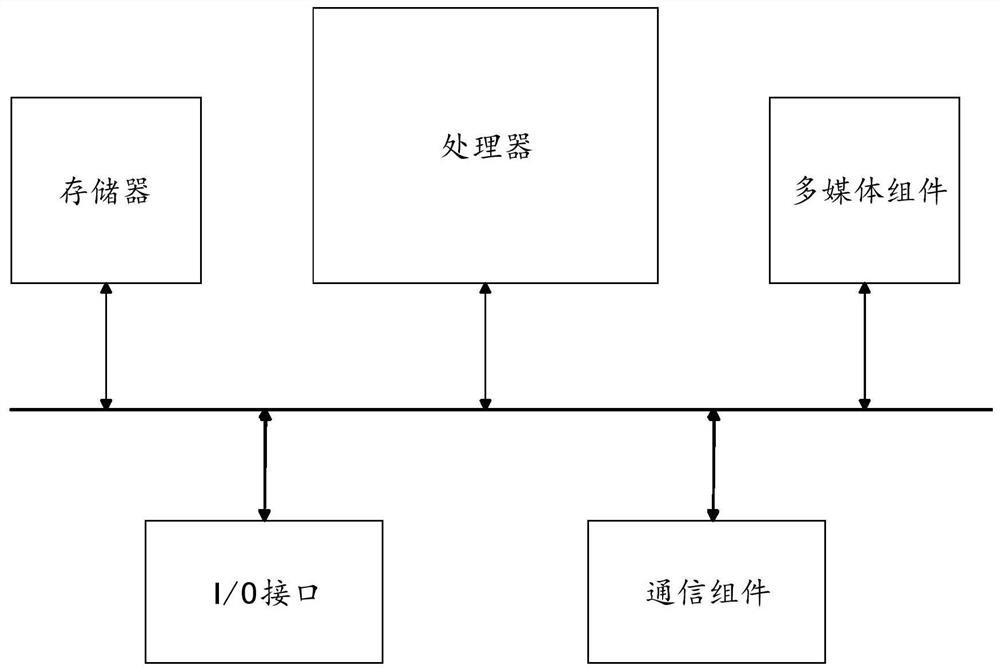

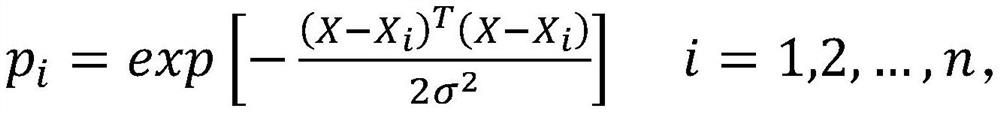

A method, device and storage medium for optimizing light oil yield of catalytic cracking unit

ActiveCN112342050BHigh precisionAccurate descriptionCatalytic crackingNeural architecturesGenetics algorithmsProcess engineering

The invention discloses a method for optimizing the light oil yield of a catalytic cracking unit, comprising the steps of: obtaining historical data of parameters participating in the optimization of catalytic cracking yield, and actual yield values corresponding to the parameters, and analyzing the obtained The historical data of the above parameters and the actual value of the yield are carried out outlier removal and normalization operations to form sample data; the GRNN model is trained using the sample data to obtain a GRNN model that predicts the yield according to the parameters; a genetic algorithm is used Optimizing the model prediction results of the parameter prediction yield to optimize the light oil yield of the catalytic cracking unit. In this way, the method for optimizing the light oil yield of the catalytic cracking unit of the present invention can greatly increase the light oil yield, and can accurately describe the reaction process from the mechanism, and improve the accuracy of data.

Owner:CHINA PETROLEUM & CHEM CORP

A kind of method for preparing compound molecular sieve

InactiveCN109437230BFull basic scientific valueIncreased secondary pore contentFaujasite aluminosilicate zeolitePentasil aluminosilicate zeoliteMolecular sieveDry basis

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Settling steam stripping method

ActiveCN111676050AAvoid cokingAvoid problems such as cloggingCatalytic crackingDispersed particle separationThermodynamicsPetroleum engineering

The invention relates to a settlement steam stripping method; a partition plate is arranged in a settler, and the settler and a steam stripping section at the lower part are divided into two spaces through the partition plate; a reaction oil-gas cyclone separator, a steam stripping outflow medium cyclone separator and a steam stripping outflow medium conveying pipe are arranged above the partitionplate in the settler; a steam stripping outflow medium enters the steam stripping outflow medium cyclone separator through the steam stripping outflow medium conveying pipe to be further separated, the steam stripping outflow medium is prevented from entering the settler, and coking of the settler is prevented.

Owner:QINGDAO JINGRUN PETROCHEM DESIGN INST CO LTD

A kind of catalytic cracking catalyst and its preparation method and application

ActiveCN105268469BOvercome the disadvantage of high selectivityImprove light oil yieldCatalytic crackingMolecular sieve catalystsMolecular sieveRare earth

The invention discloses a catalytic cracking catalyst, and a preparation method and application thereof. The catalytic cracking catalyst contains a cracking active composition, a mesoporous silicon aluminium material, clay and a binder, wherein the cracking active composition contains 70-100 wt% of a first Y type molecular sieve, and the first Y type molecular sieve is a rare earth Y type molecular sieve; the binder is a modified aluminium sol containing Cl and Si, and by taking the total weight of the modified aluminium sol as a reference, Al content is 8-13 wt%, Cl content is 4-9 wt%, the Al-to-Cl weight ratio is 1.2-2.2:1, the Si content is 0.1-1 wt%, and the pH value of the modified aluminium sol is 2.2-5.2. The catalytic cracking catalyst possesses relatively low coke selectivity and relatively high catalytic cracking activity during catalytic cracking of heavy oil, and also helps to obtain relatively high light oil yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com