Method for agilely treating inferior heavy oil, residual oil

A technology for residual oil and low-quality oil, which is applied in the treatment of hydrocarbon oil, hydrotreating process, petroleum industry, etc. It can solve the problems of low quality, heavy processing cost, and increased operation difficulty, so as to reduce the amount of coke deposition and prolong the service life , the effect of increasing light oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

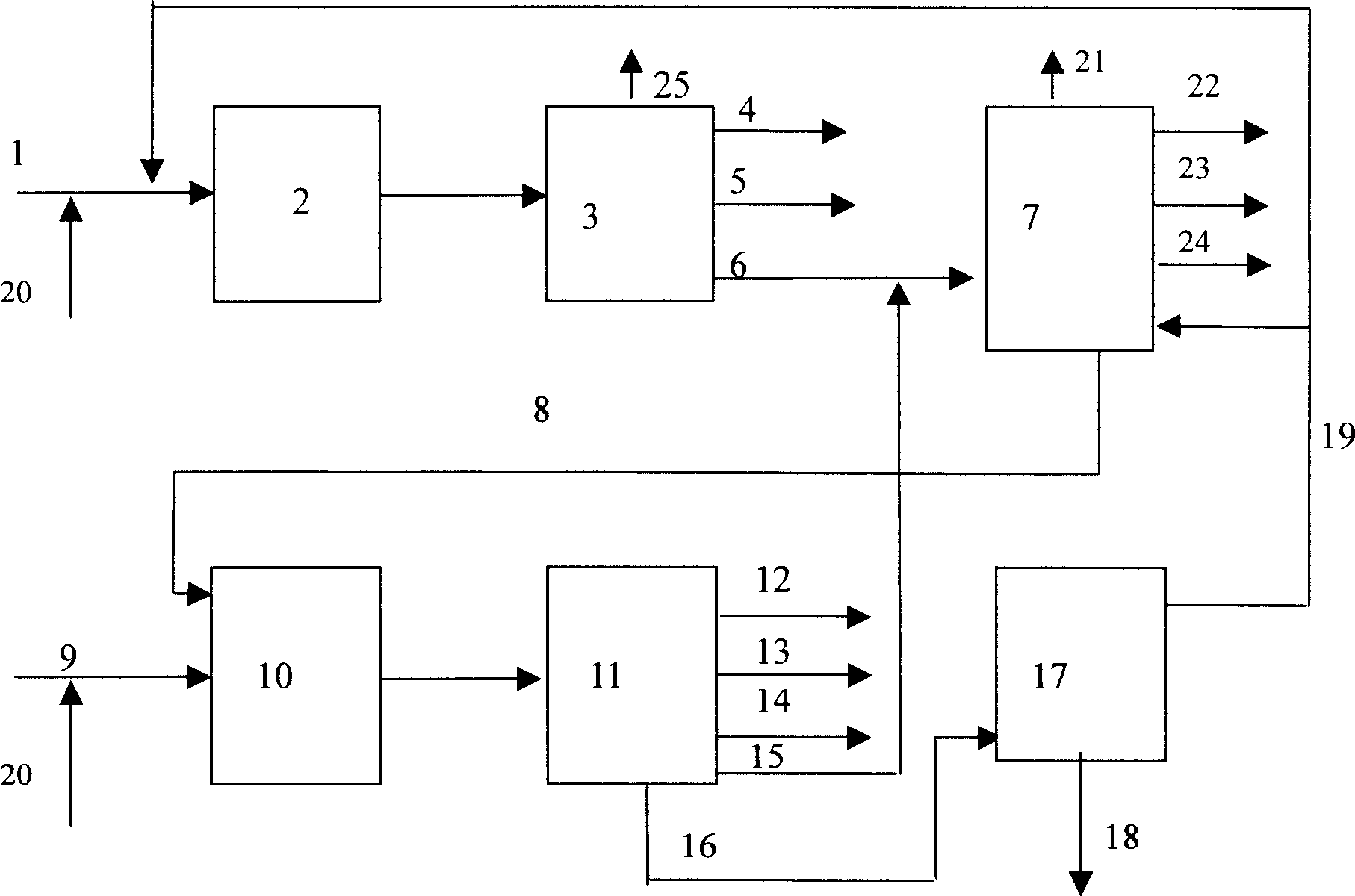

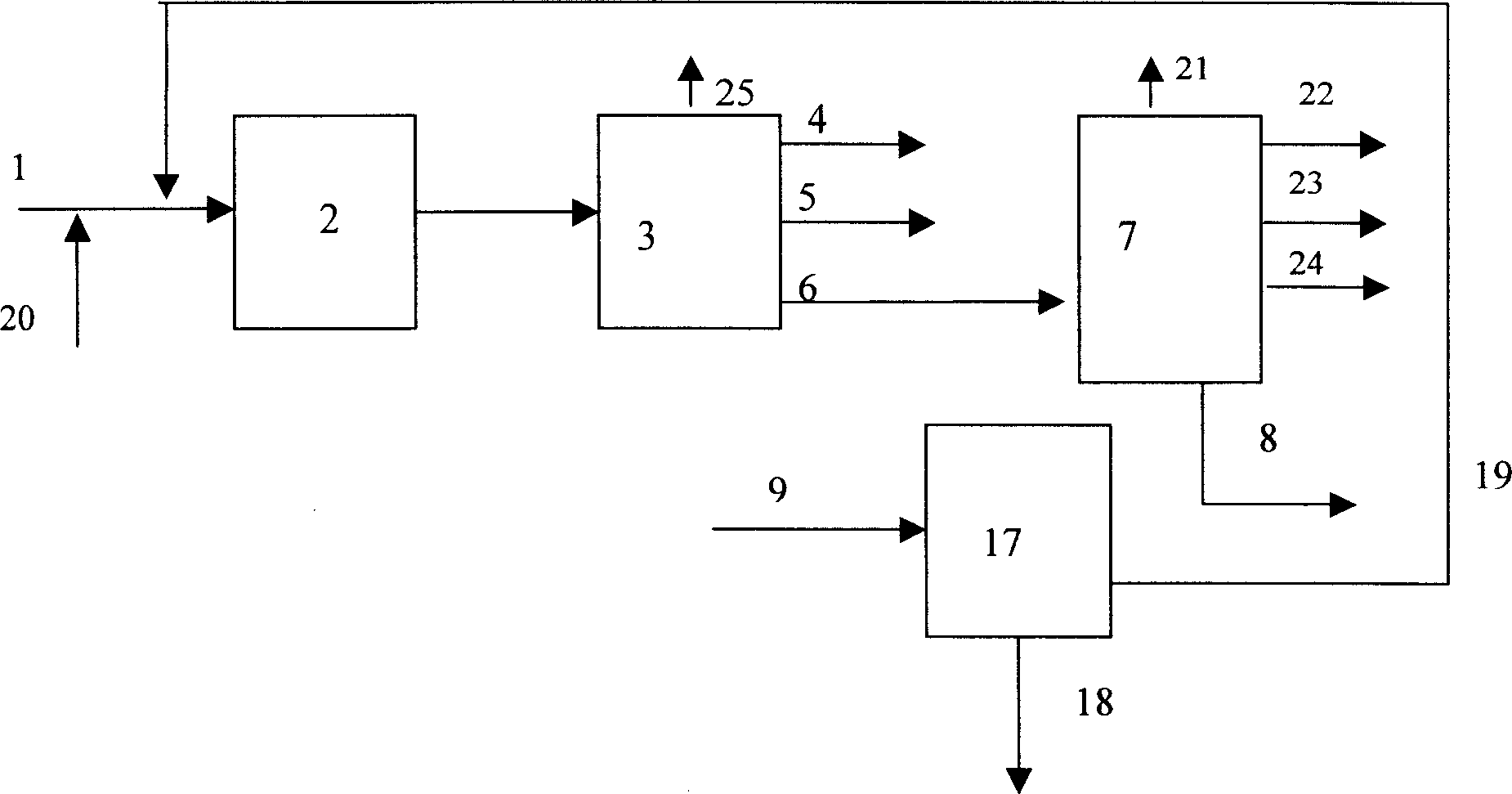

Method used

Image

Examples

Embodiment

[0030] On the riser type catalytic cracking test device, it is equipped with a fixed bed residual oil hydrogenation test device, a suspended bed residual oil hydrogenation test device, a solvent extraction device and an atmospheric and vacuum device for testing. The residual oil fixed bed hydrogenation catalyst used in the fixed bed hydroprocessing test is CEN, FZC series heavy and residual oil hydrogenation demetallization catalyst produced by the pilot base of Fushun Petrochemical Research Institute, and the first chemical fertilizer of Qilu Petrochemical Company The ZTN and ZTS series heavy and residual oil hydrogenation denitrogenation and desulfurization catalysts produced by the factory. The sequence of catalyst loading is hydrodemetallization, hydrodesulfurization and hydrodenitrogenation catalysts. The hydrodemetallization catalysts used in this test are CEN-5, CEN-6; the protective agents are CEN-2, CEN-4, FZC-16 (transitional protective agent); the hydrodesulfurizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com