Flexible transformation system for low-load operation of coal-fired power plant boiler

A coal-fired power station, low-load technology, applied in the direction of combustible gas purification/retrofit, steam boiler, fluidized bed boiler, etc., can solve the problems of high tar output, poor adaptability of boiler raw materials, complex process, etc., to reduce emissions, Facilitate large-scale application and promotion, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

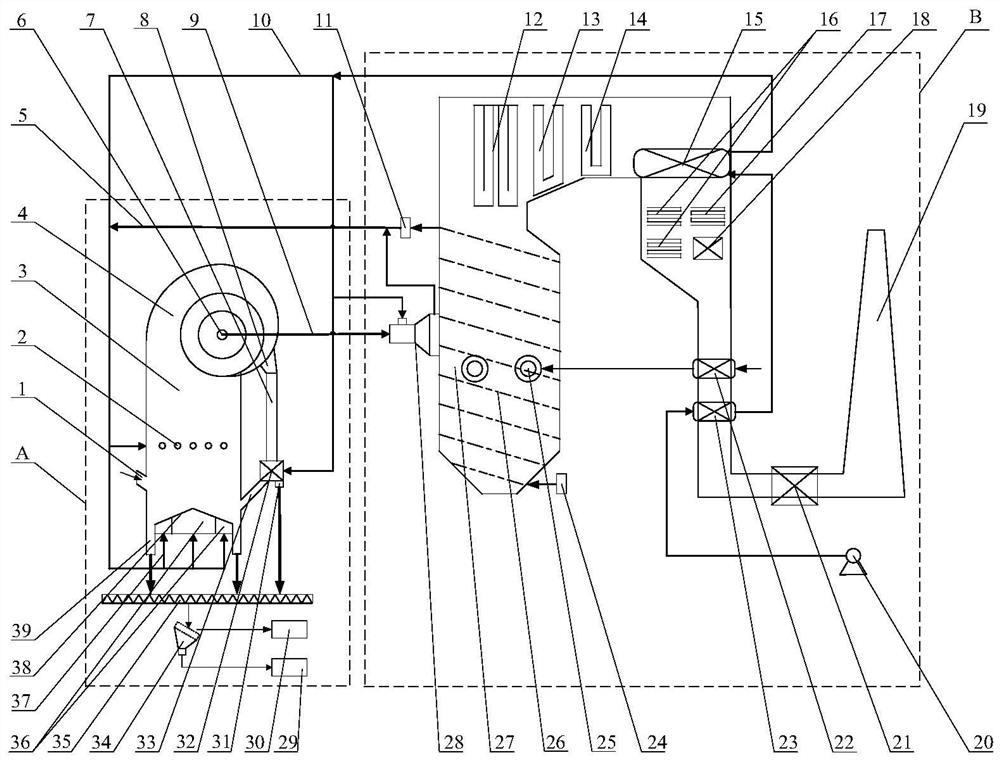

[0052] Referring to Fig. 1(a), when the system is running, firstly, the wood pellets with a particle size of not more than 10 mm will be transported from the feed port to the gasification reactor 3 through the crushing and drying process, wherein the gasification reactor 3 is the positive In the high-pressure operation state, the high-temperature air that has been preheated in two stages enters the gasification reaction furnace 3 through the primary air inlet 37 and the secondary air inlet 2 respectively, to provide the required energy and gasification agent for the gasification reaction process, and the high-temperature air The temperature is 650°C. The high-temperature air preheated in two stages is also passed into the fully premixed water-cooled burner 28 to provide air for the combustion of the combustible gas. In addition, the high-temperature air that has undergone two-stage preheating is also passed into the carbon ash separation device 32 to provide high-temperature a...

Embodiment 2

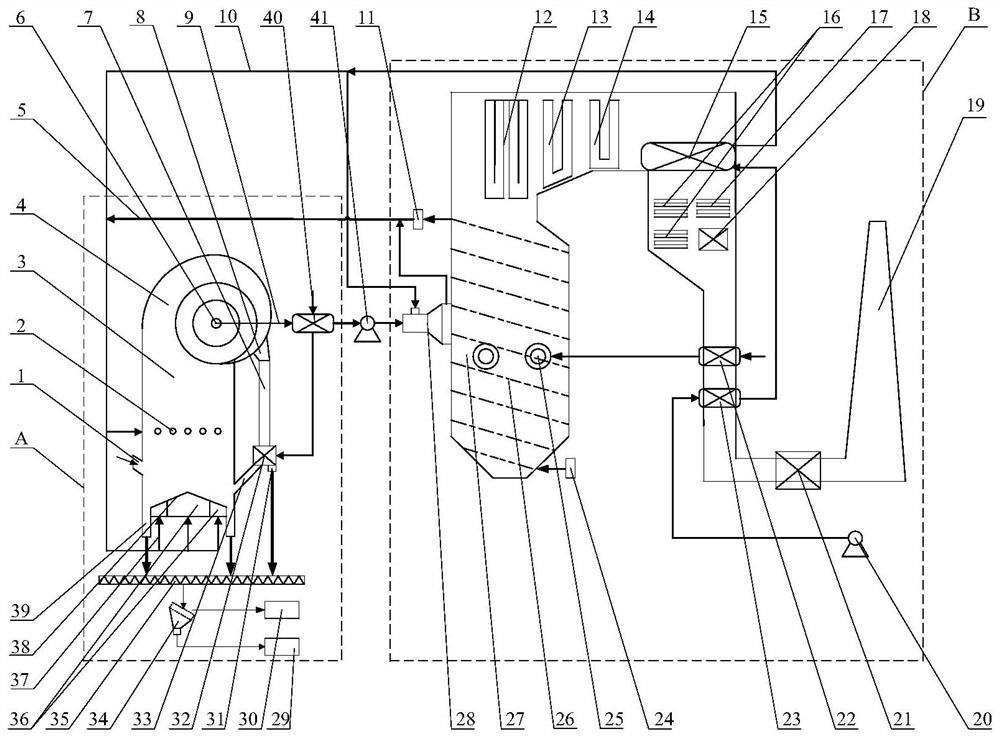

[0054] Referring to Fig. 1(b), the difference from Example 1 is that the gasification reactor in this example operates under normal pressure or negative pressure. Therefore, in order to introduce the high-temperature combustible gas generated in the gasification reactor into the In a coal power plant boiler, an air preheater 22 and an induced draft fan 41 need to be arranged in sequence after the gaseous product outlet 6. The air preheater 22 can reduce the temperature of the combustible gas to 420~450°C. The outlet of the air preheater 22 is connected with the air inlet of the carbon ash separation device 32 through a pipeline, so as to provide high-temperature air flow for the carbon ash separation process of the carbon ash separation device 32, and the high-temperature air through two-stage preheating does not need into the carbon ash separation device. Others are the same as in Example 1.

[0055] By pyrolyzing and gasifying various biomass raw materials, combustible gase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com