Patents

Literature

96results about "Fluidised bed boilers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air-fired co2 capture ready circulating fluidized bed heat generation with a reactor subsystem

ActiveUS20090211500A1Less expenseImprove efficiencyFluidized bed combustionEmission preventionAir preheaterWorking fluid

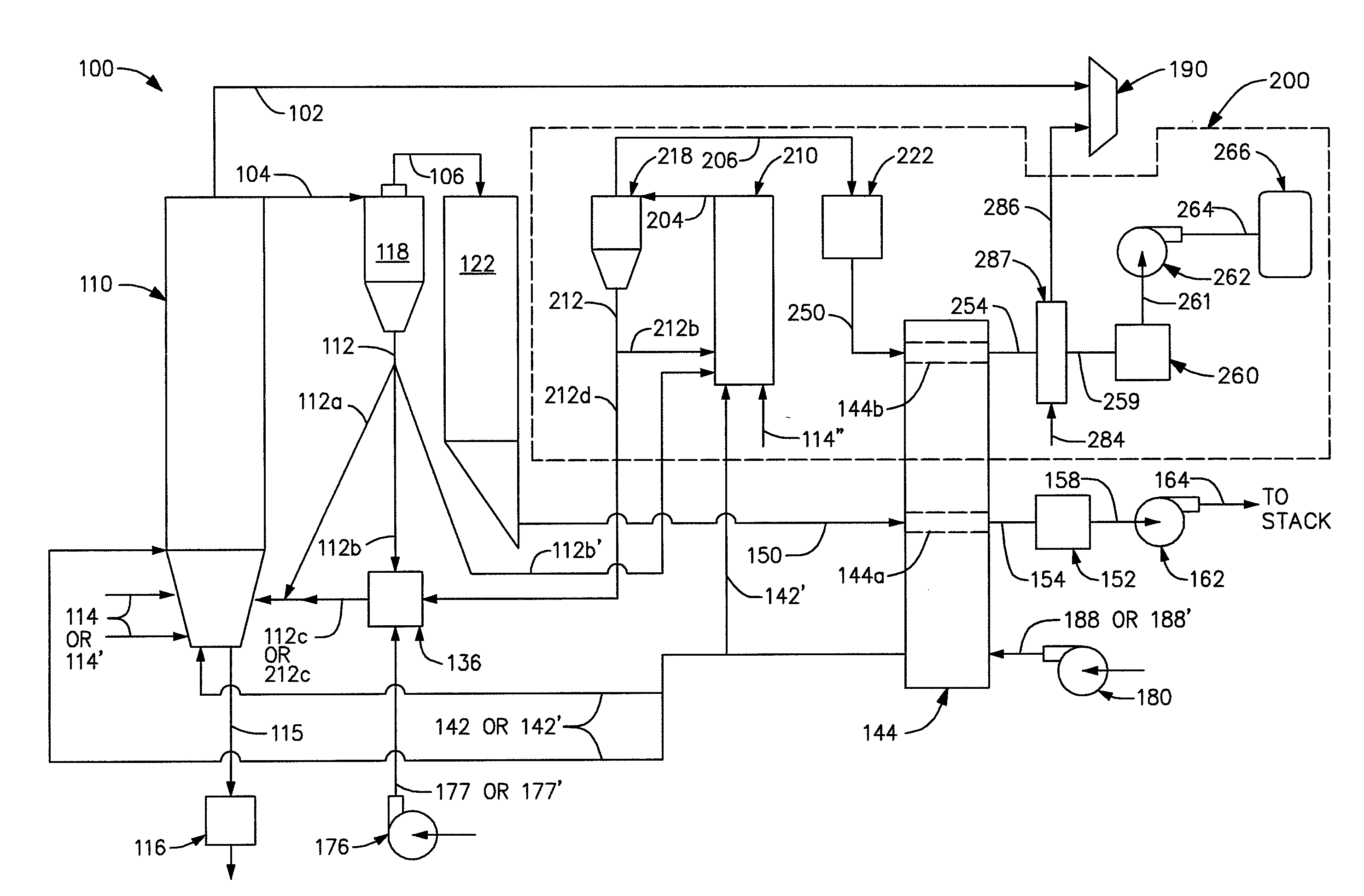

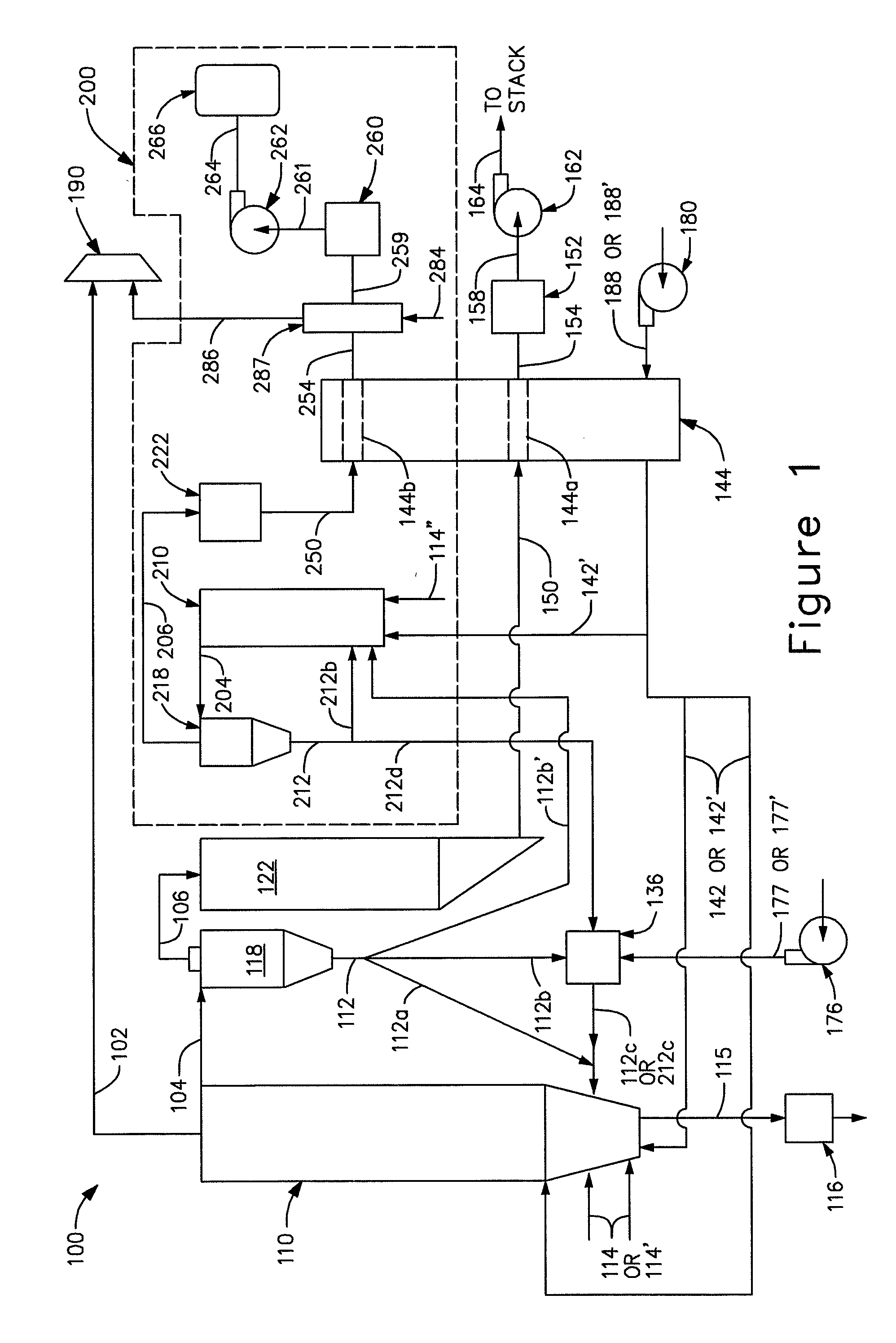

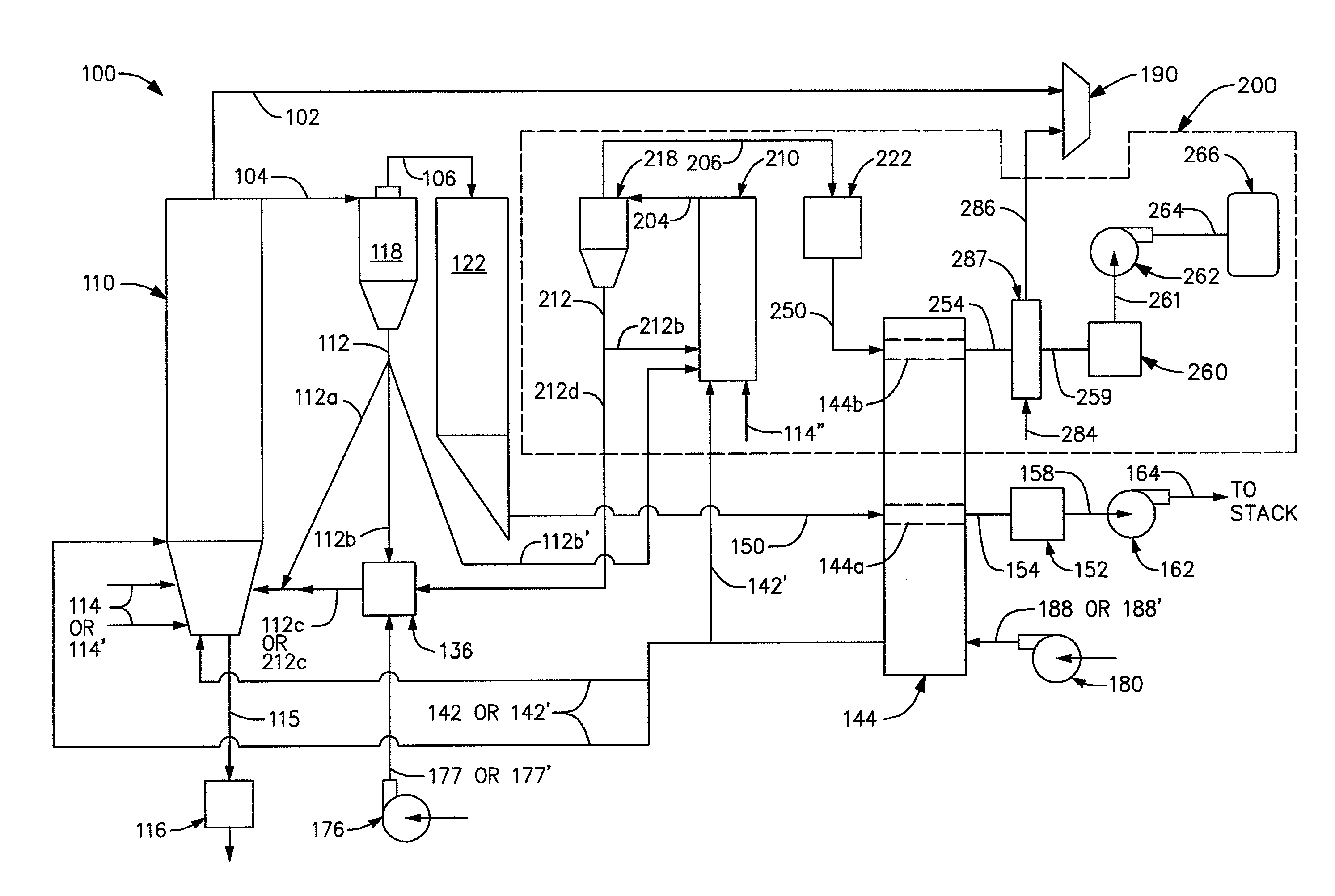

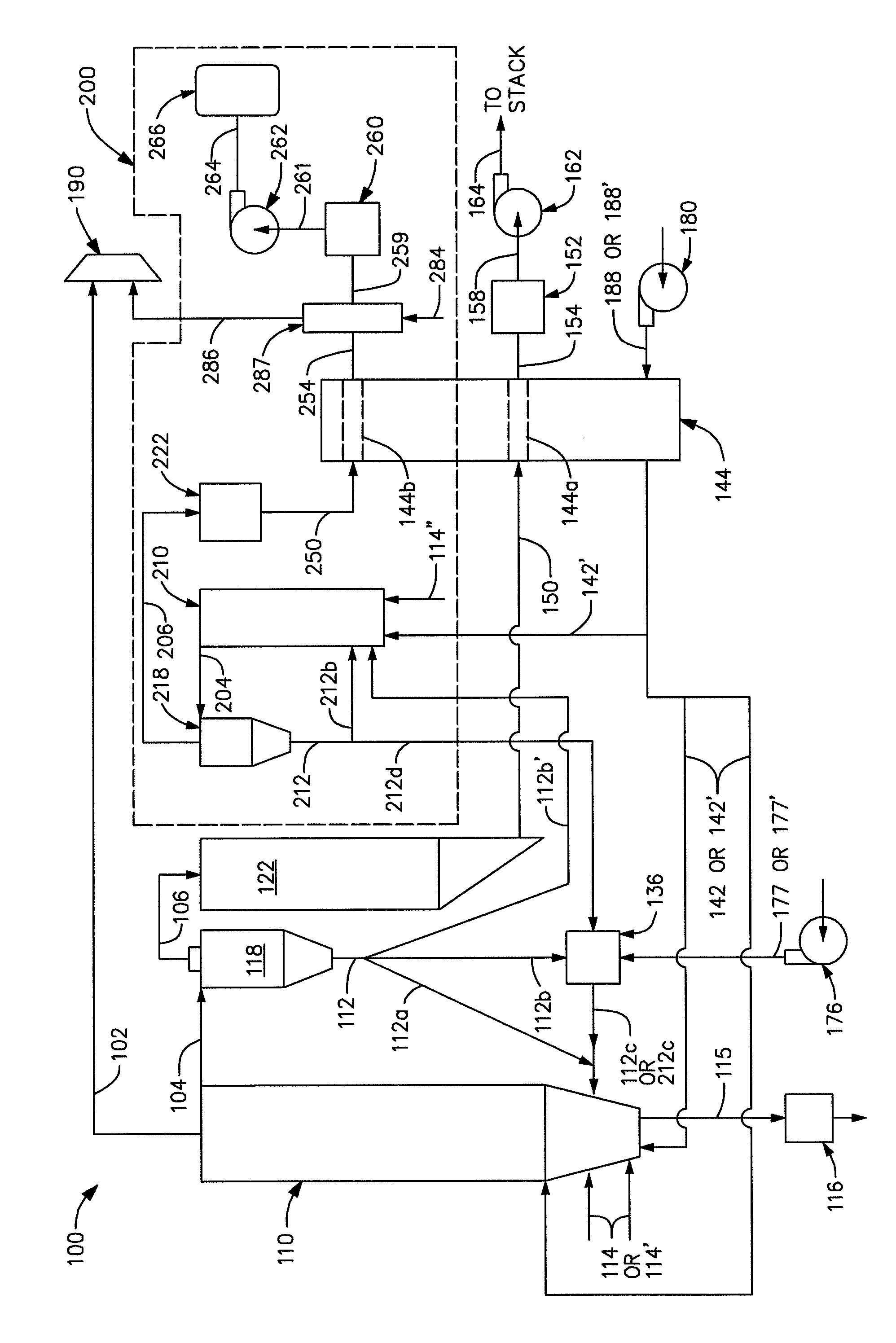

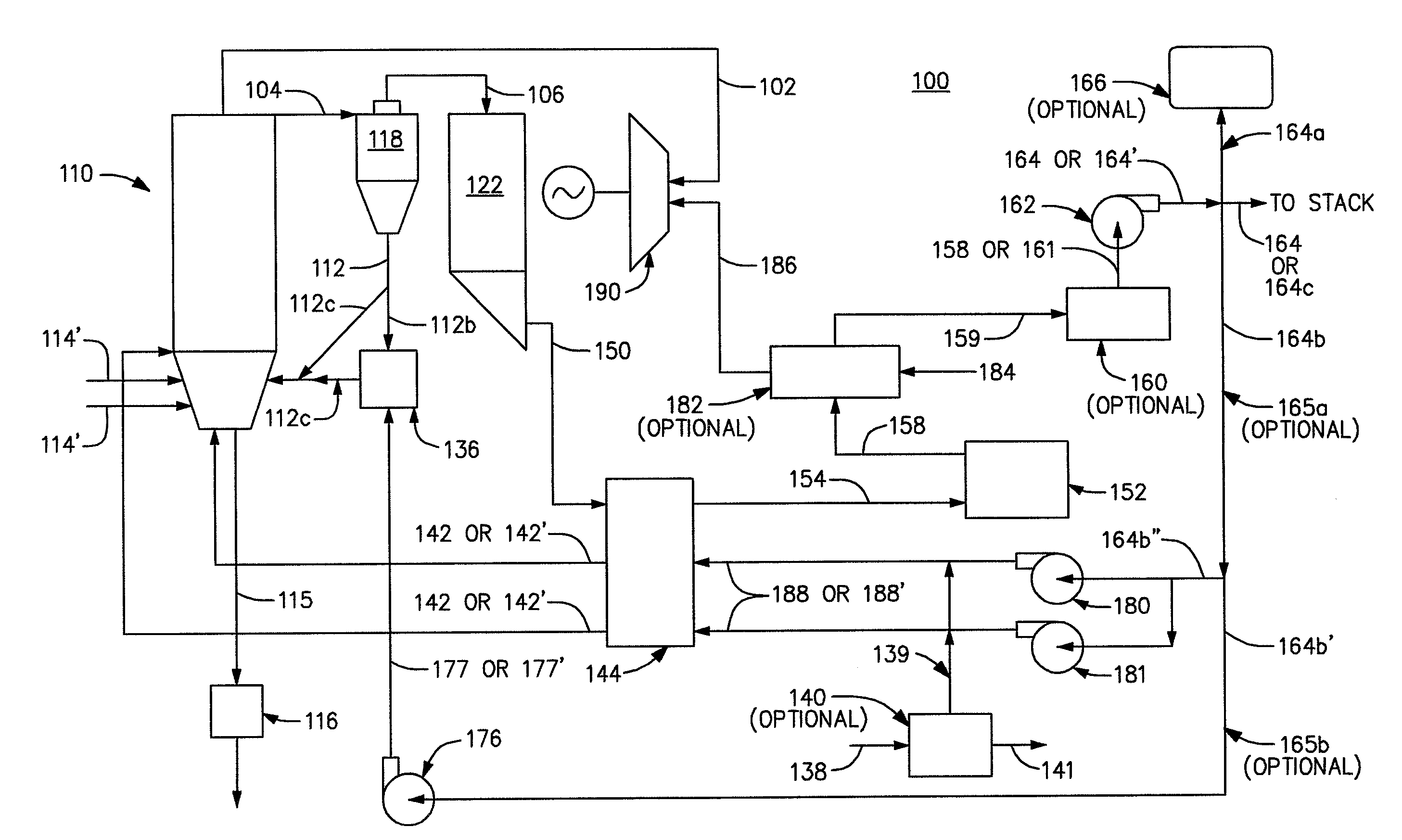

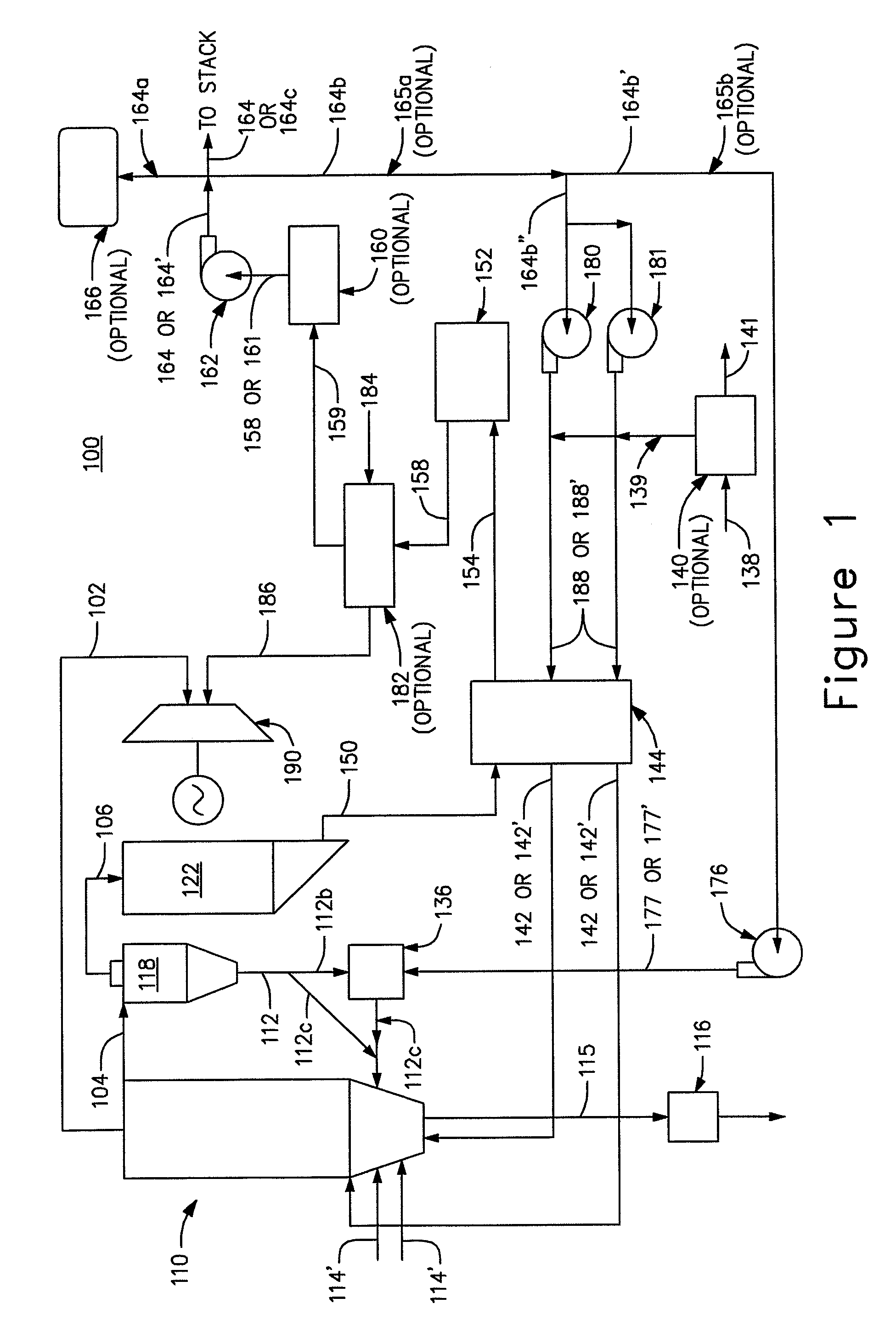

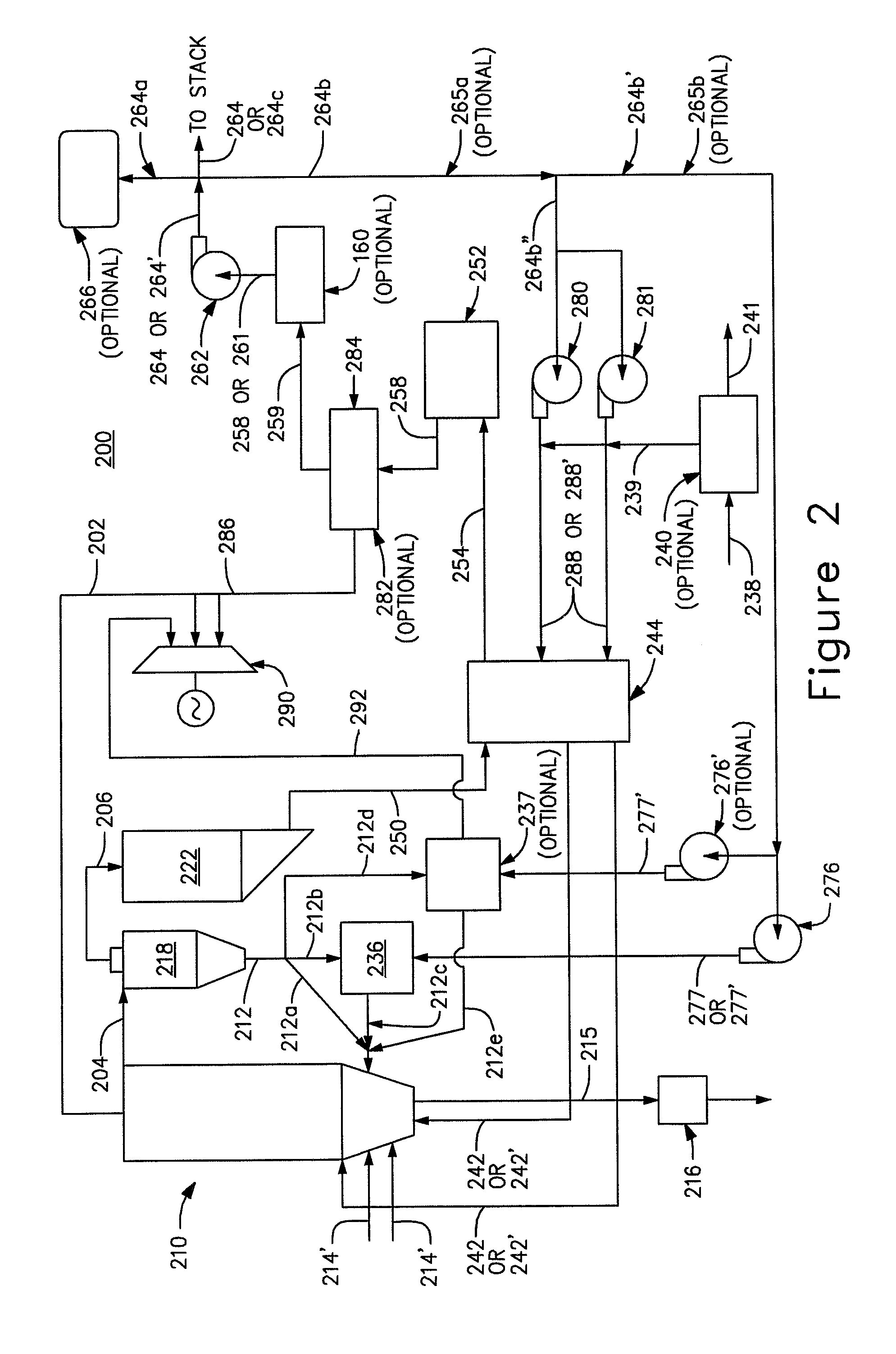

A combustor 110 combust a fluidized bed of fossil fuel 114, 114′ to heat a working fluid 102 and generate flue gas 104. An air preheater 144 has first and second gas passageways 144a, 144b for respectively directing the generated flue gas 150 and another gas 250 with captured CO2 generated by combustion outside of the combustor 110. When operated in a non-CO2 capture, the air preheater 144 receives the flue gas 150, but not the other gas 250, and the first gas passageway 144a directs the flue gas 150 so as to preheat the air 188. However, when operated in the CO2 capture mode, the air preheater 144 receives the flue gas 150 and the other gas 250, and the second gas passageway 144b also directs the other gas 250 so as to preheat the air 188′. In either mode, the preheated air 188, 188′ is applied by the combustor 110 to fluidize a bed of fossil fuel 114, 114′.

Owner:GENERAL ELECTRIC TECH GMBH

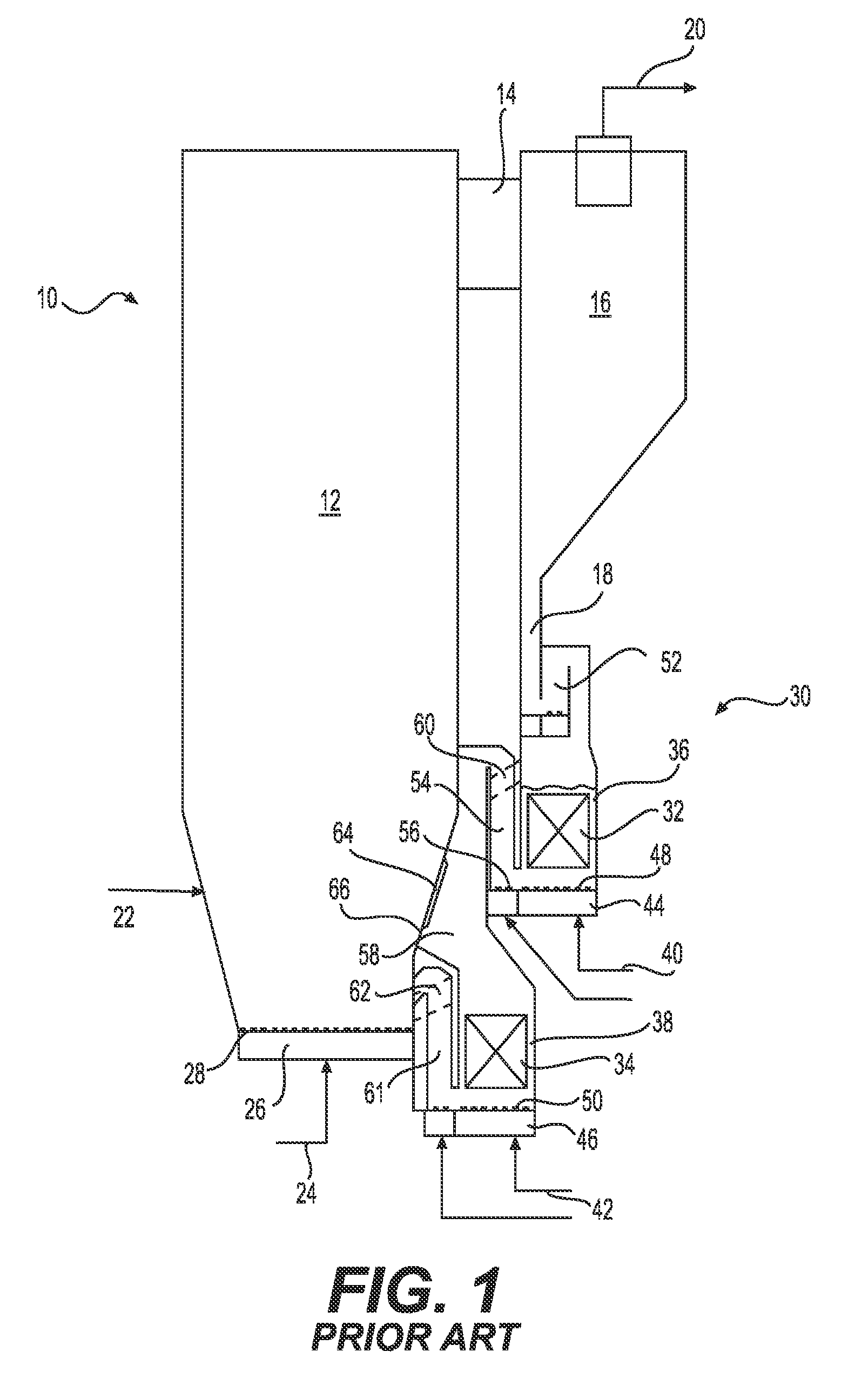

Fluidized bed reactor system having an exhaust gas plenum

InactiveUS7244400B2Simple and feasible mannerWear minimizationFluidized bed combustionFluidised-bed furnacesReactor systemFluidized bed

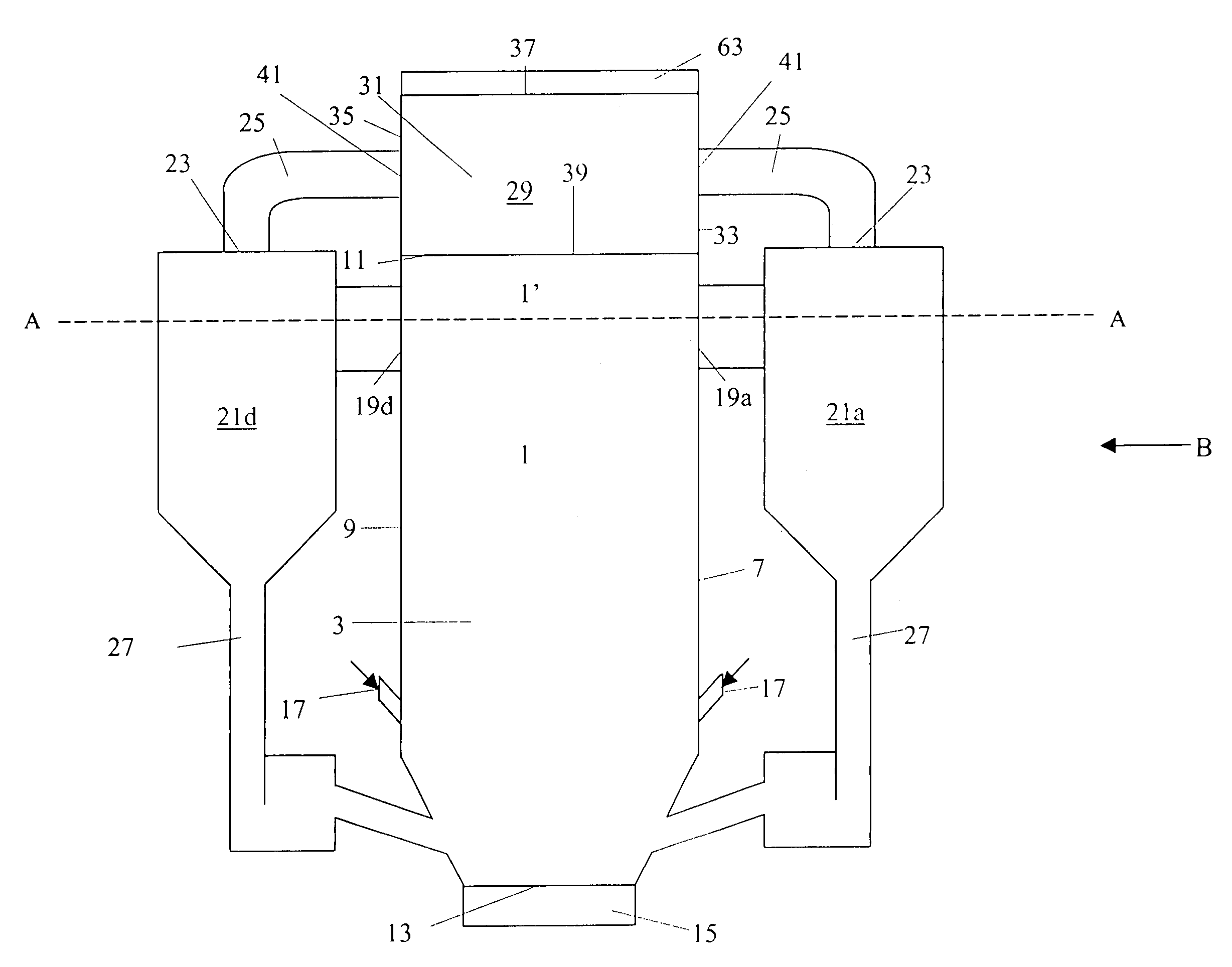

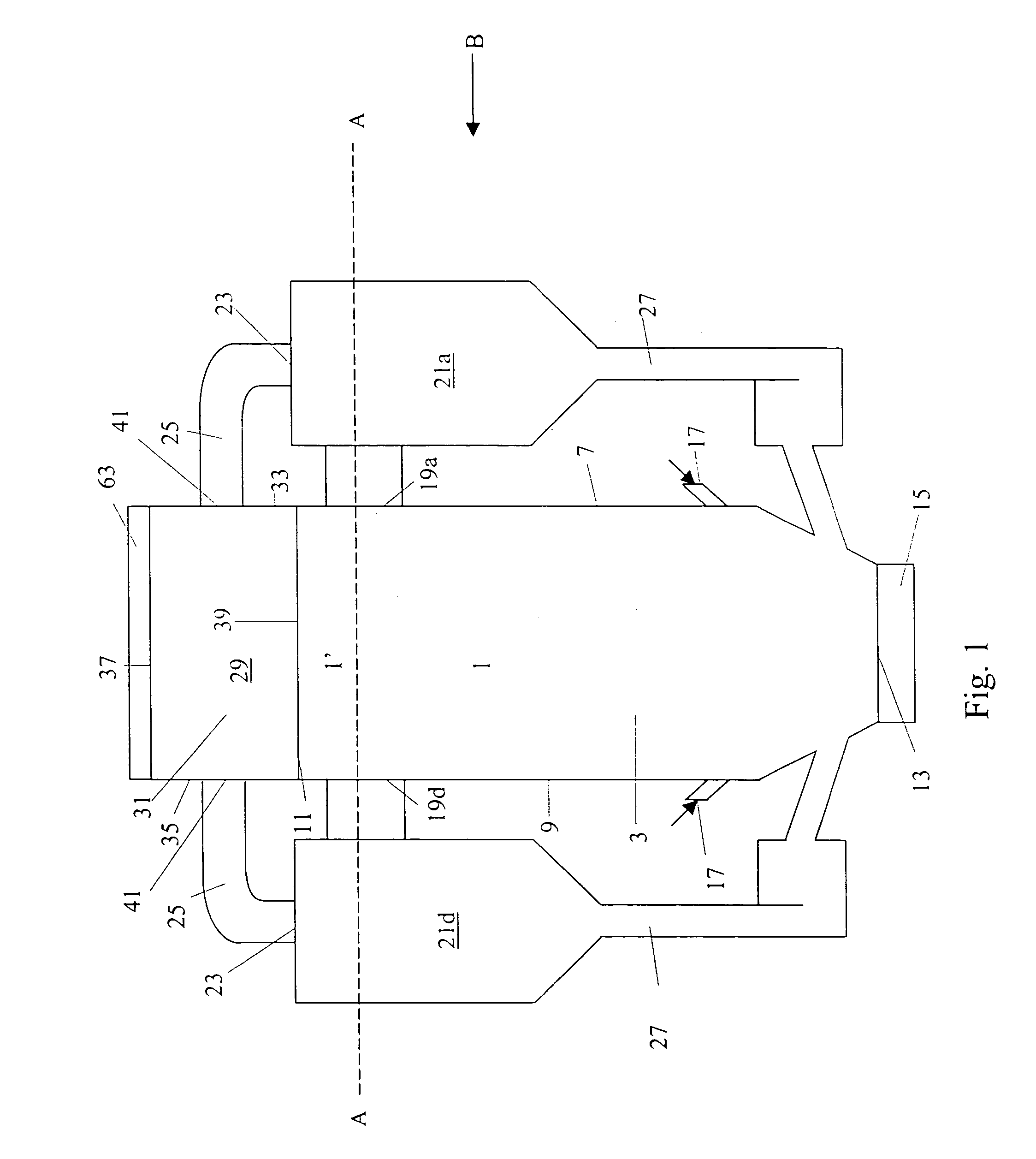

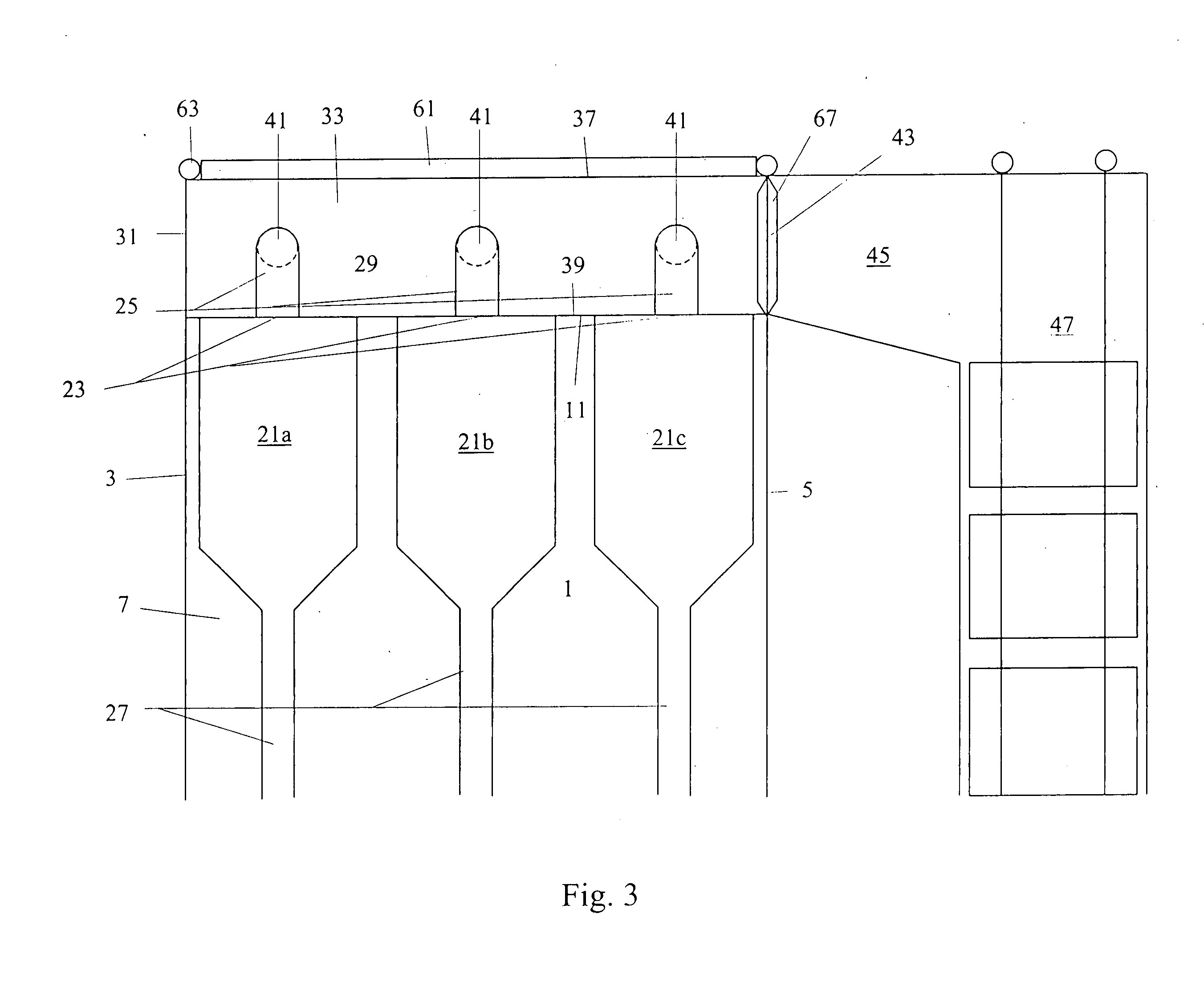

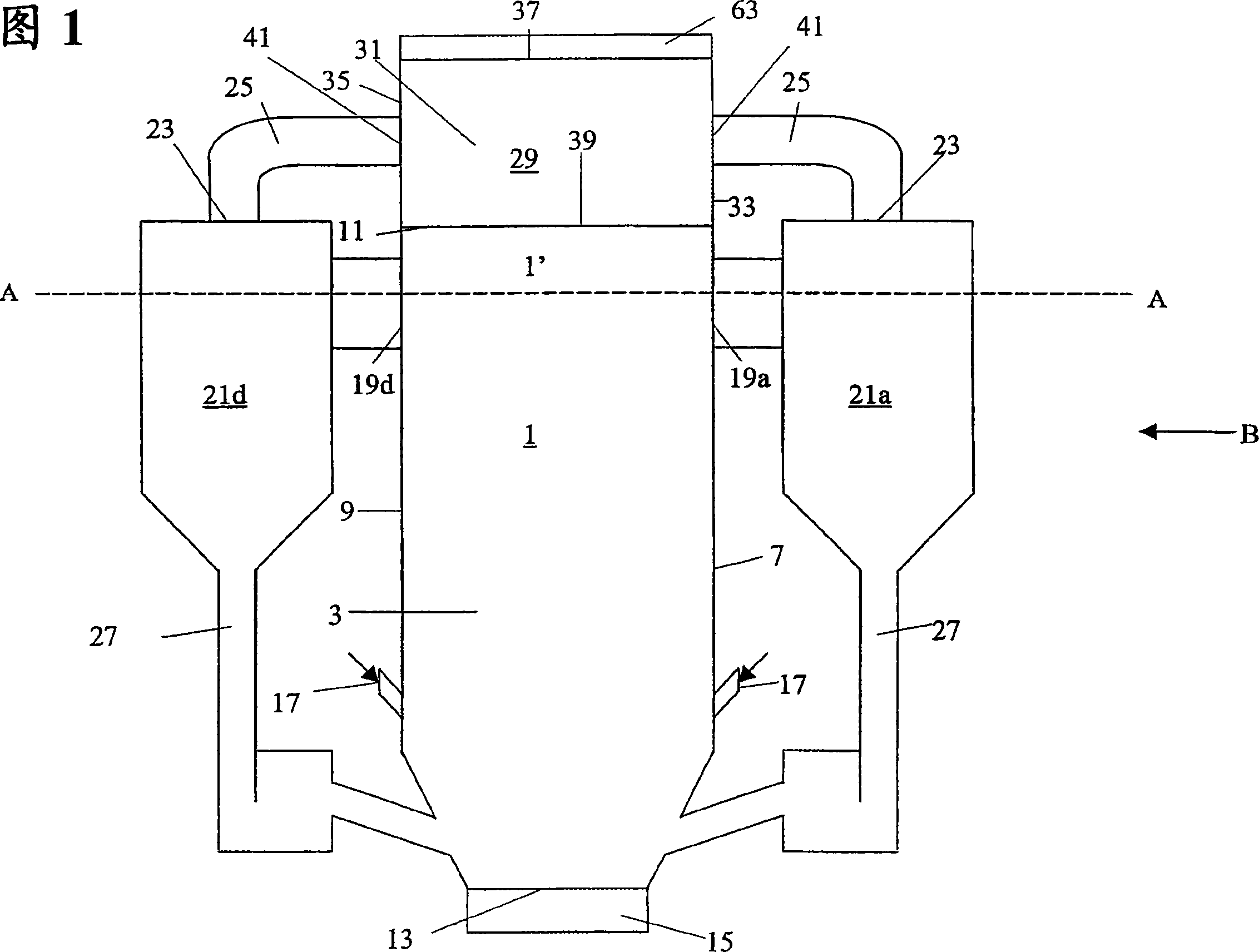

An arrangement for directing exhaust gases from at least one particle separator of a circulating fluidized bed reactor system to a heat recovery section includes a gas plenum located above a reaction chamber, the gas plenum being defined by a ceiling, a bottom, and walls and being integrated with the reaction chamber. The walls of the gas plenum are provided with at least one inlet opening for cleaned exhaust gases, each of which is coupled with a discharge duct connected to one of the particle separators, for directing the cleaned exhaust gases from the particle separators to the gas plenum, from where the cleaned exhaust gases are directed to the heat recovery section downstream of the gas plenum. The reaction chamber is at least partially formed by water tube panels, and the enclosure of the gas plenum is also formed by water tube panels as extensions of water tube panels of the reaction chamber.

Owner:KAUTEX TEXTRON GMBH & CO KG

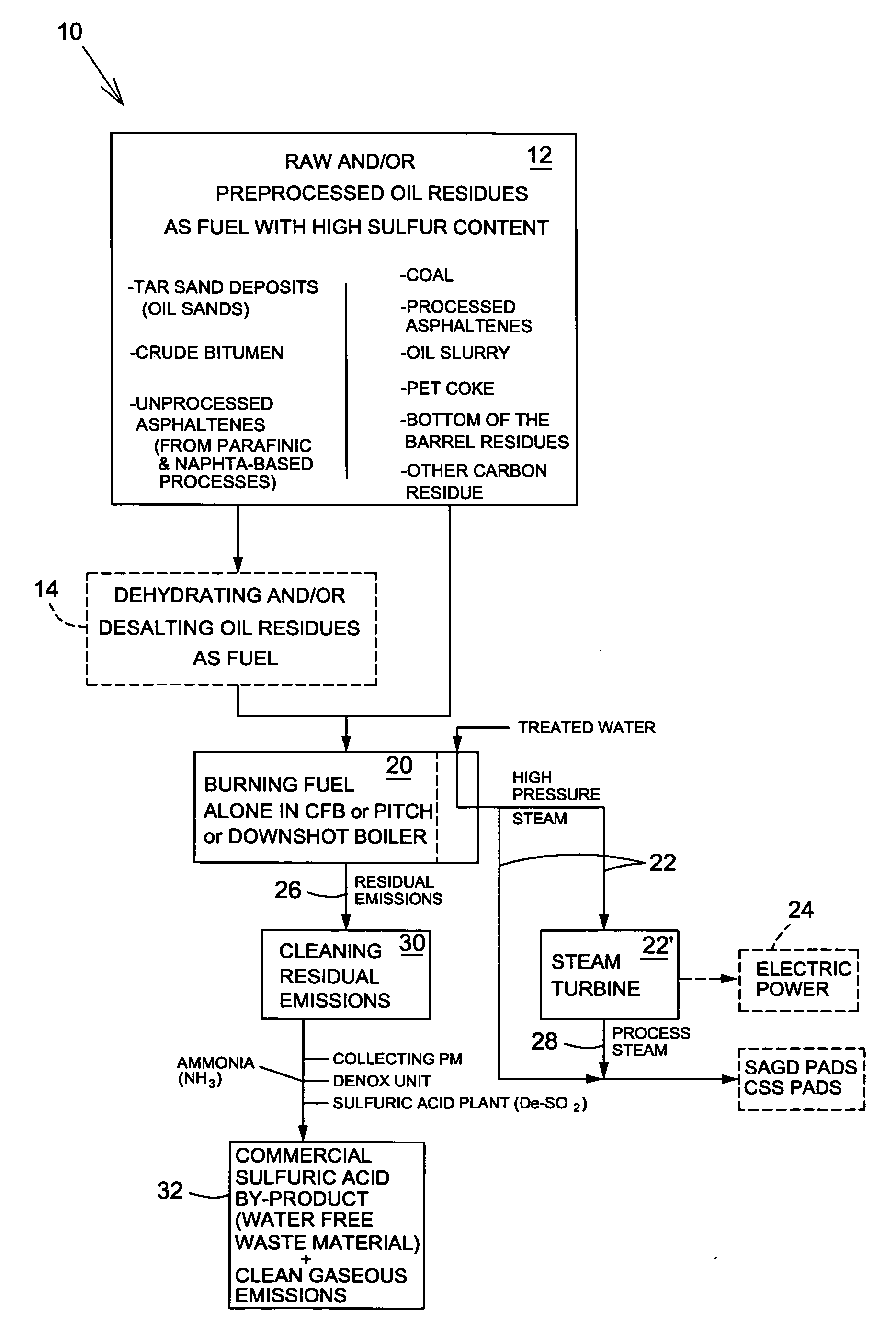

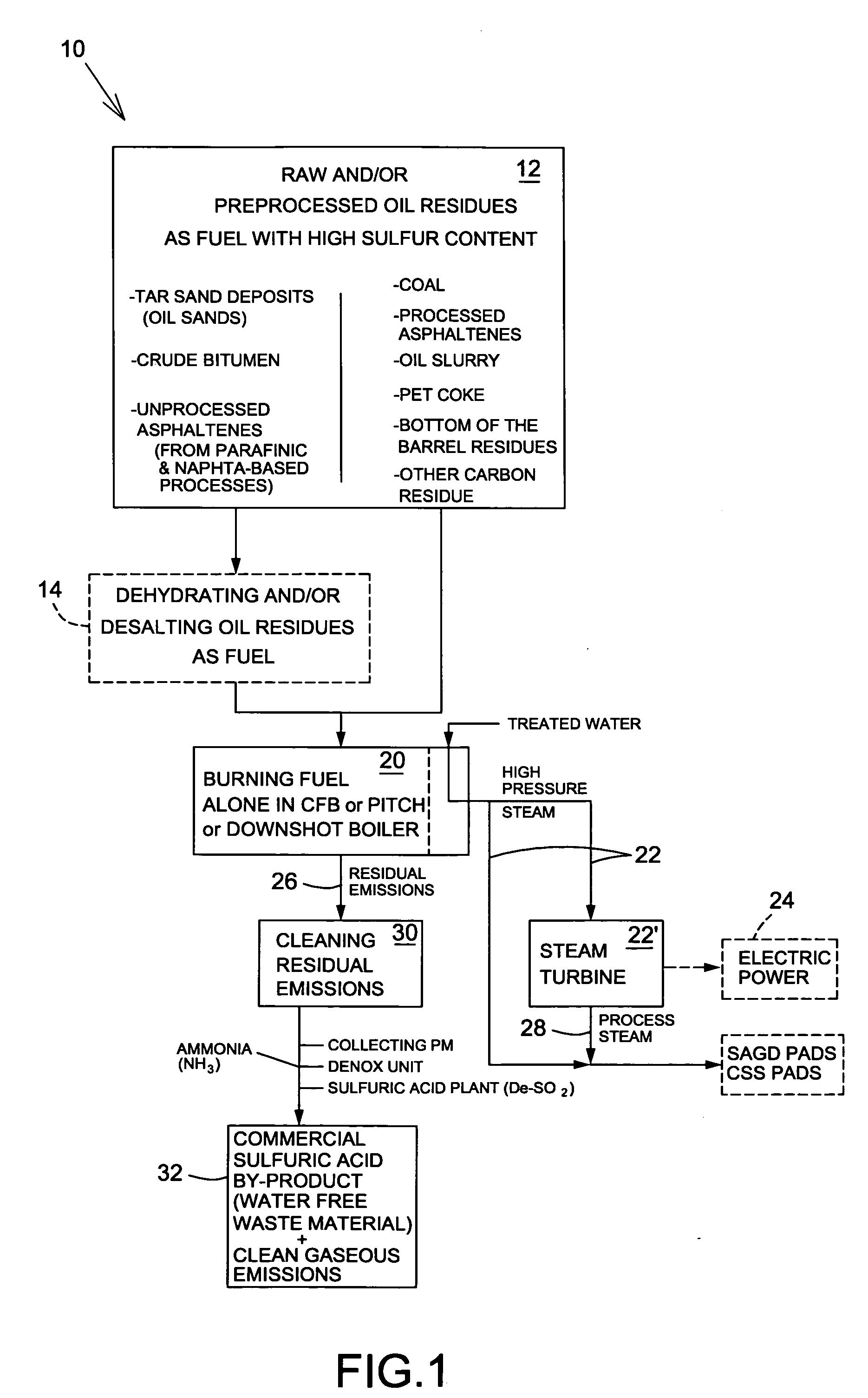

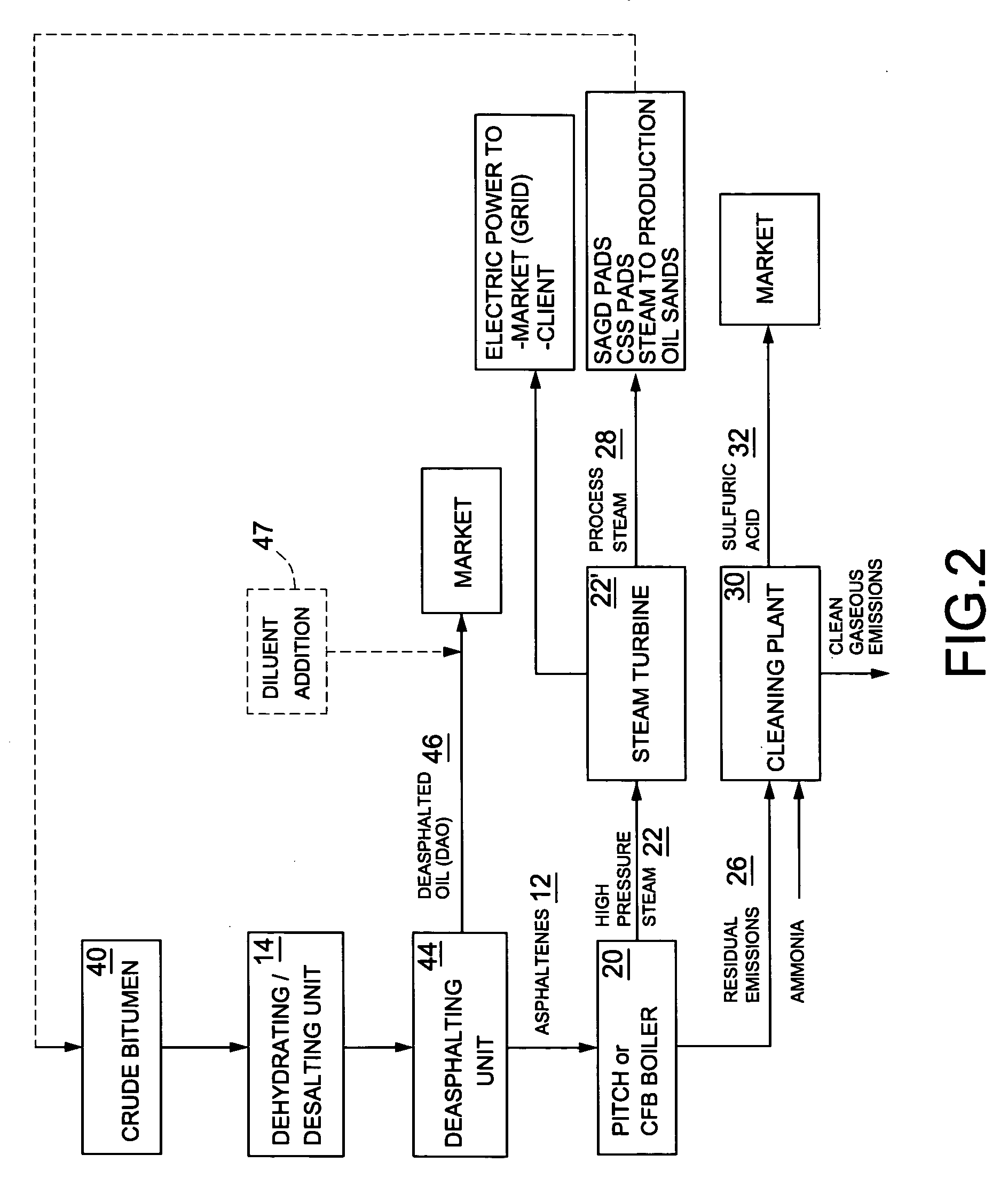

Process for producing steam and/or power from oil residues with high sulfur content

InactiveUS20100126395A1Low costWeaken energyDispersed particle separationSulfur compoundsSorbentDiluent

Power is produced using fuel, preferably with a sulfur content larger than 1% wt, from raw and / or preprocessed oil residues which are burned alone, i.e. without any addition of sorbents, diluents or the like, with a CFB boiler, a pitch boiler or a downshot boiler to generate high pressure steam and / or power and residual emissions. Residual emissions are cleaned to simultaneously remove PM, NOx and SO2 therefrom. The sulfur in emissions can be used to produce sulfuric acid. The process uses a low cost fuel, generates steam, and / or power and sulfuric acid and meets all emission requirements for PM, NOx and SO2.

Owner:GAUTHIER RICHARD

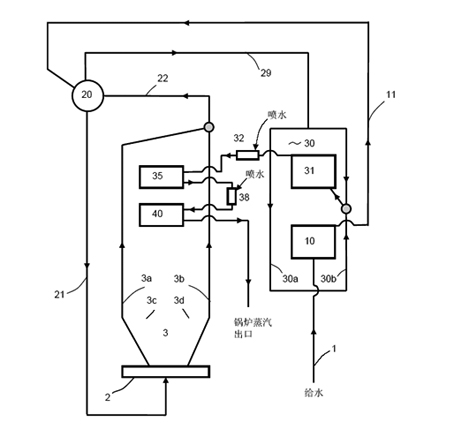

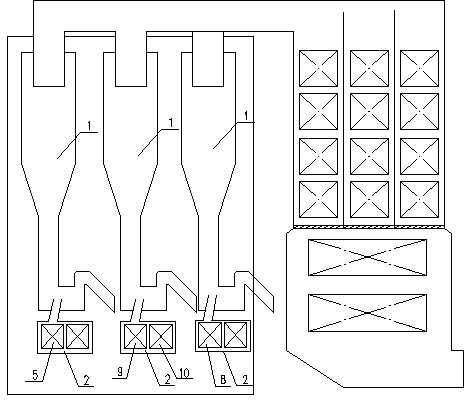

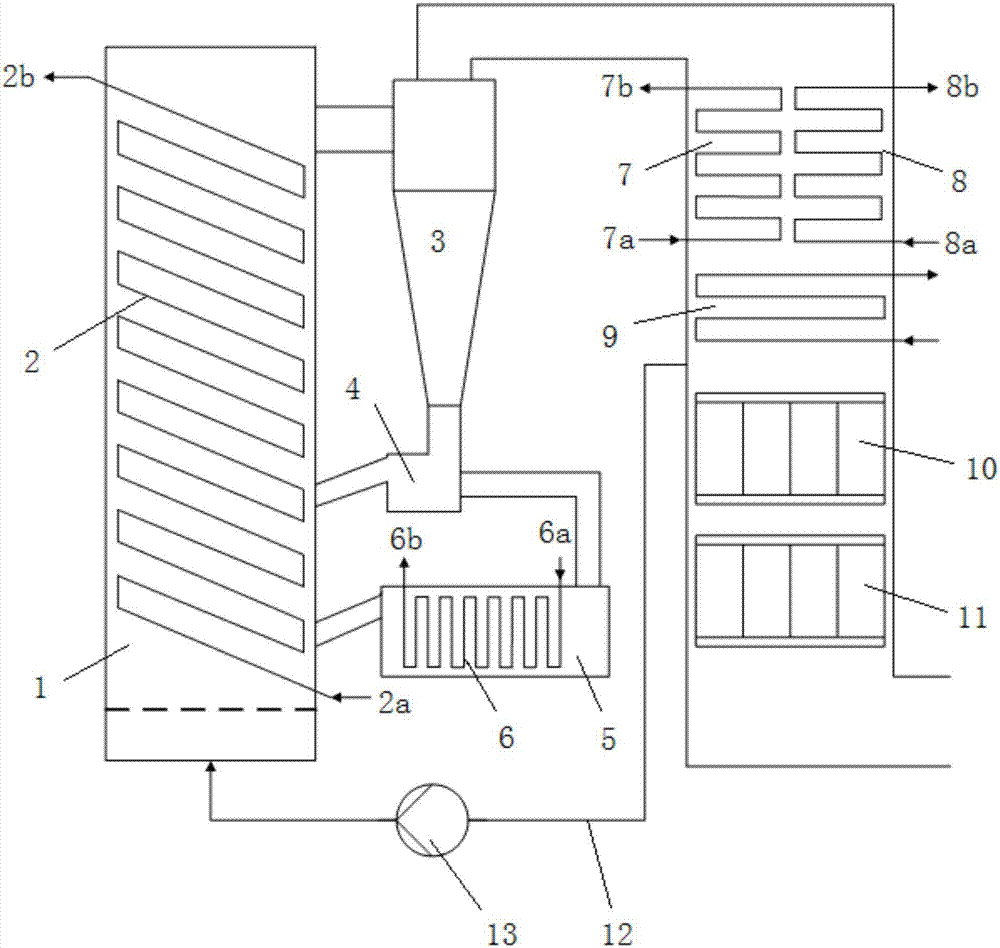

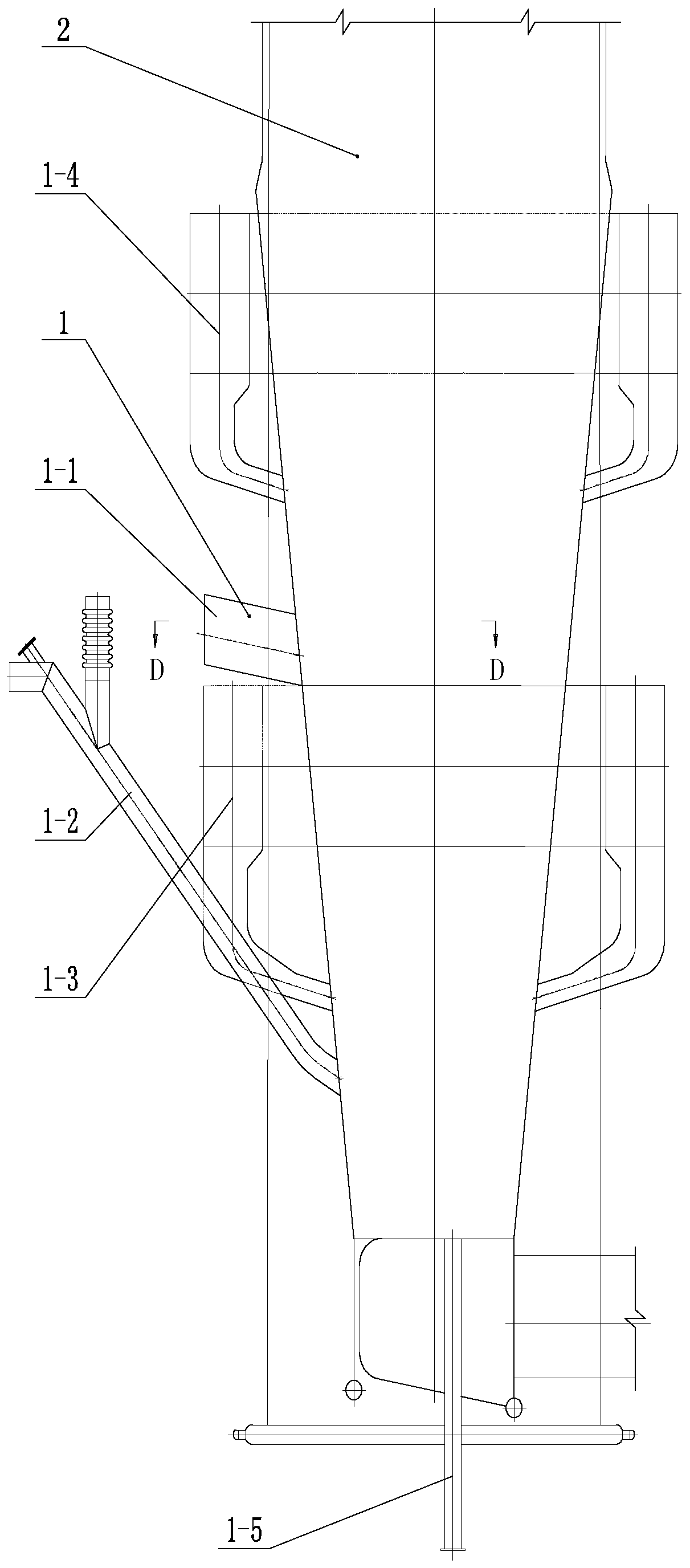

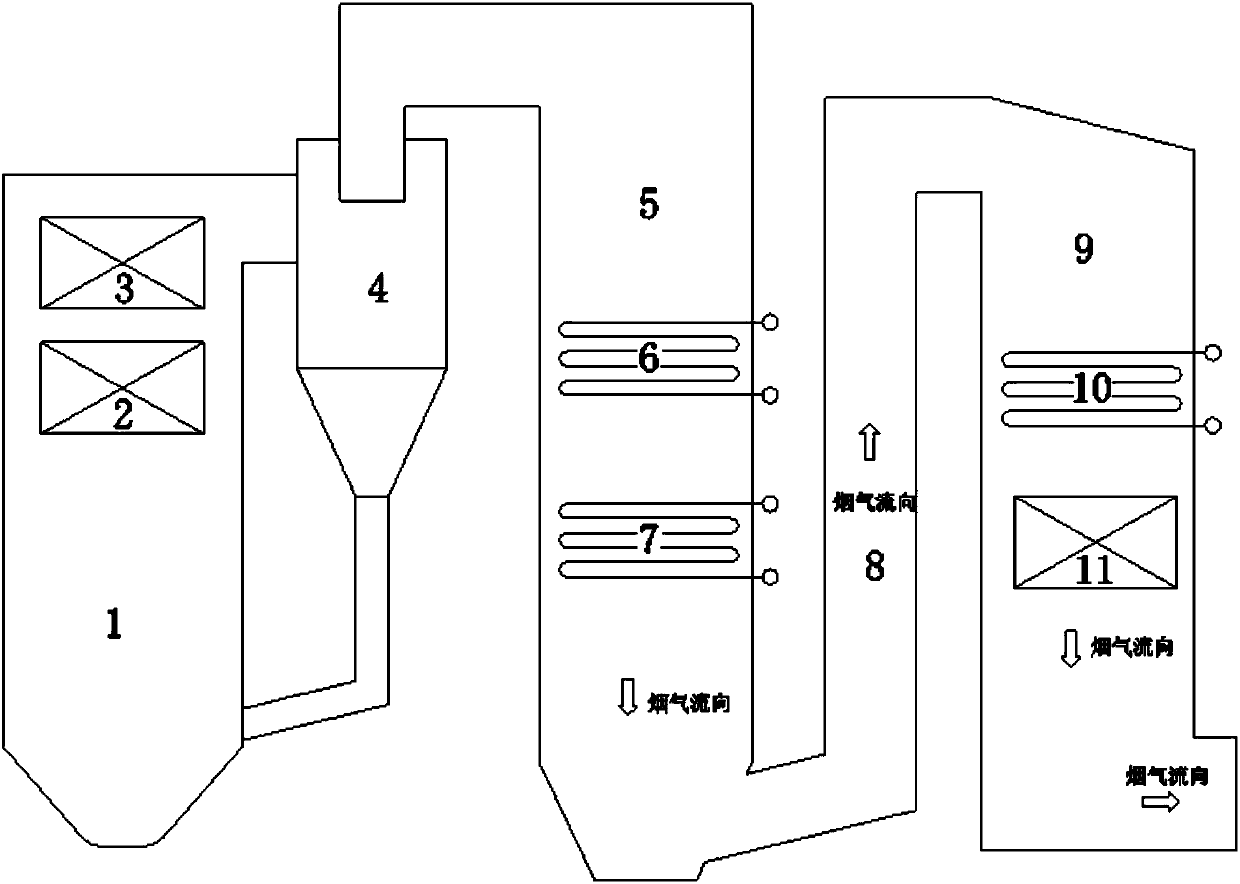

Arrangement structure of all levels of superheaters of circulating fluidized bed boiler

InactiveCN101986024AImprove securityWall temperature improvementSuperheating controlFluidised bed boilersClosed loopSuperheater

The invention relates to an arrangement structure of all levels of superheaters of a circulating fluidized bed boiler. The arrangement structure comprises a coal economizer, a steam pocket, a hearth water cooled wall, and a plurality of tail-cladding superheaters, low-temperature superheaters and high-temperature superheaters, wherein the coal economizer is arranged in a convection flue on the tail part of the boiler; the steam pocket is connected with the coal economizer through a pipeline; the hearth water cooled wall is connected with the steam pocket through a pipeline; the plurality of the tail-cladding superheaters, the low-temperature superheaters and the high-temperature superheaters are connected with one another through pipelines to form a closed loop; the high-temperature superheaters are arranged in the hearth of the boiler; and the heat absorption capacity of the high-temperature superheaters is in an amount of 48 to 58 percent based on the heat absorption capacity of an overall superheater system. By using the arrangement structure, the steam temperature and wall temperature properties of all levels of the superheaters of the boiler under various loads are greatly improved; the operating safety of the boiler is improved; and the service life of the boiler is prolonged.

Owner:SHANGHAI BOILER WORKS

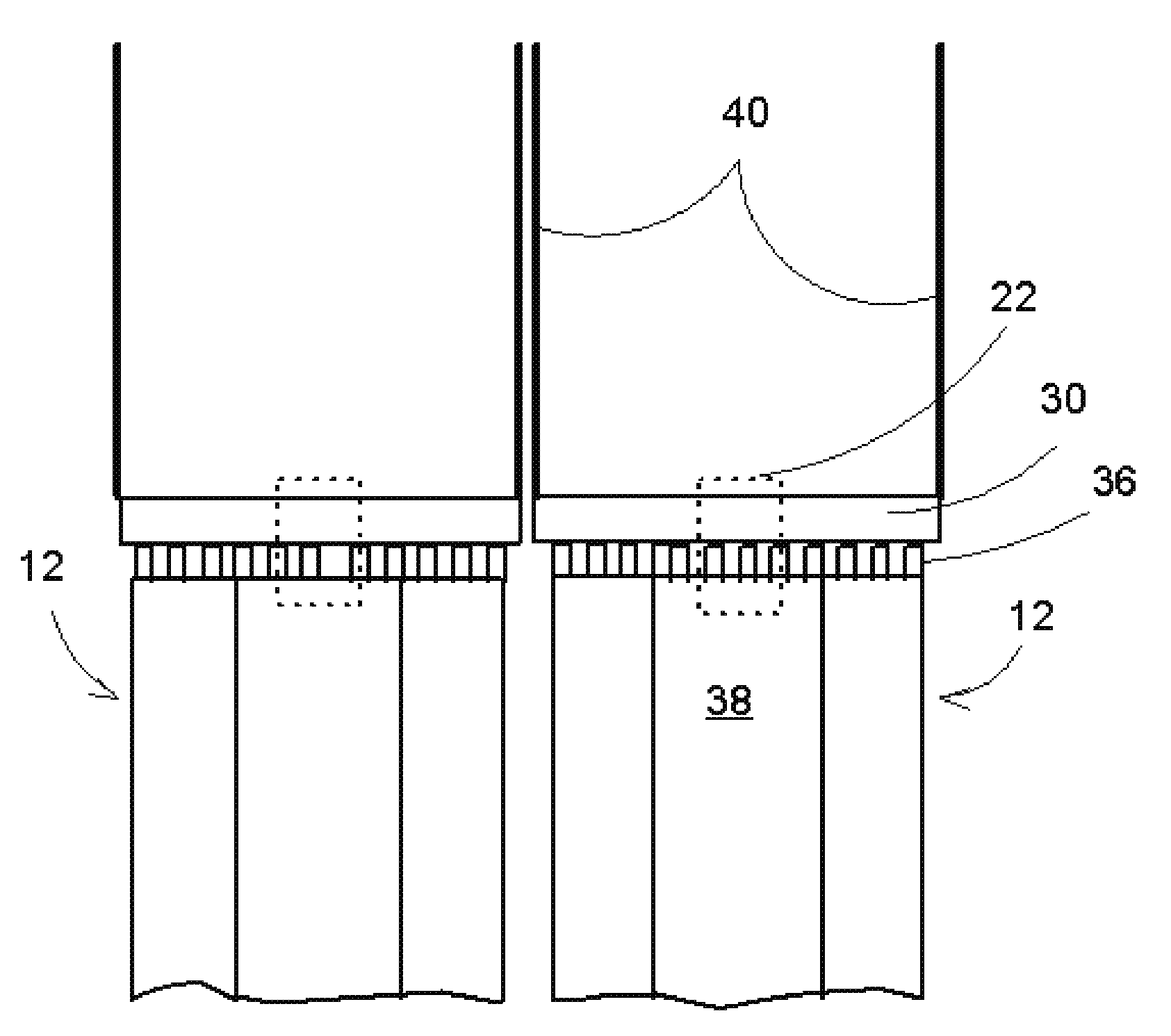

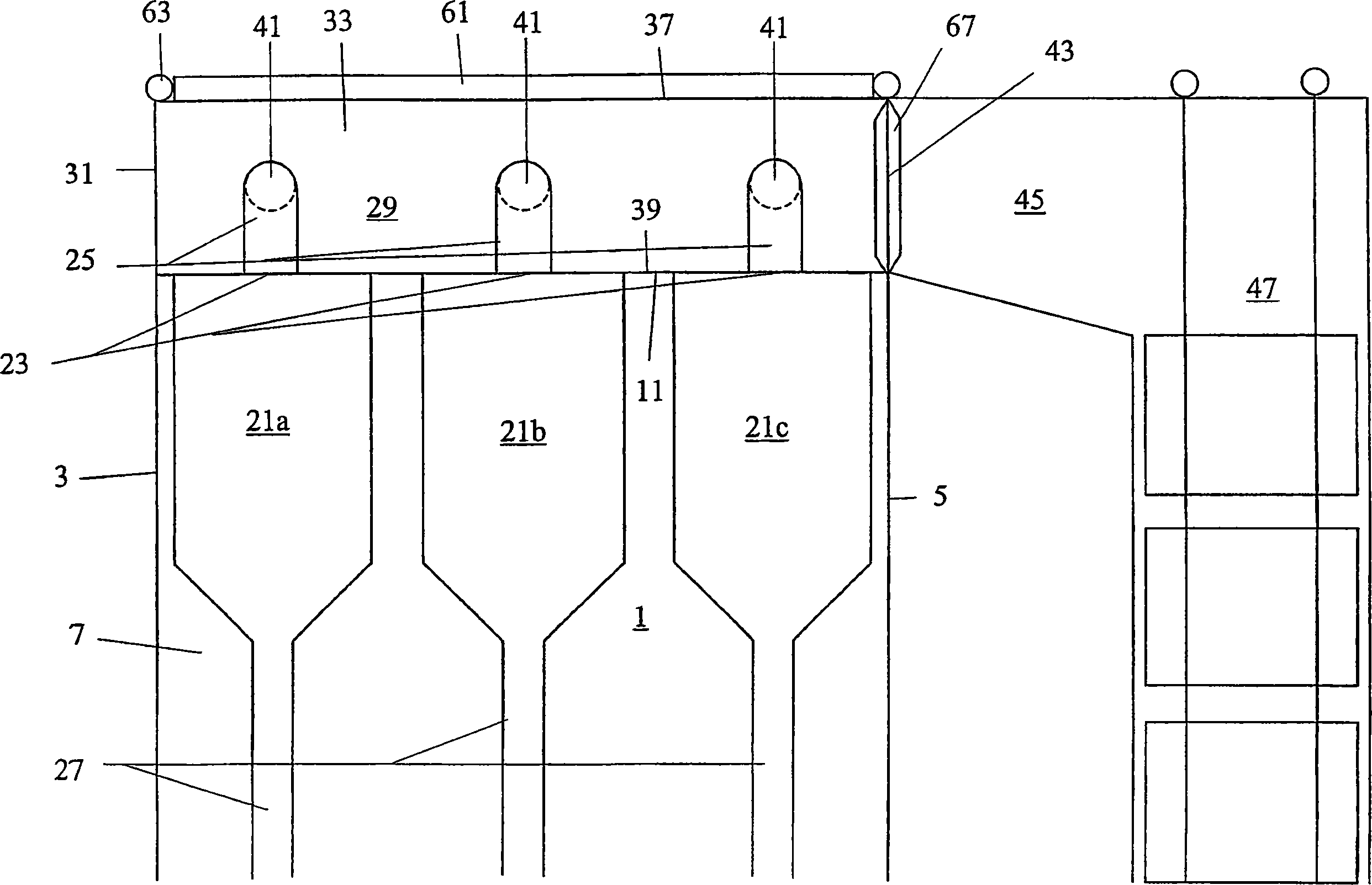

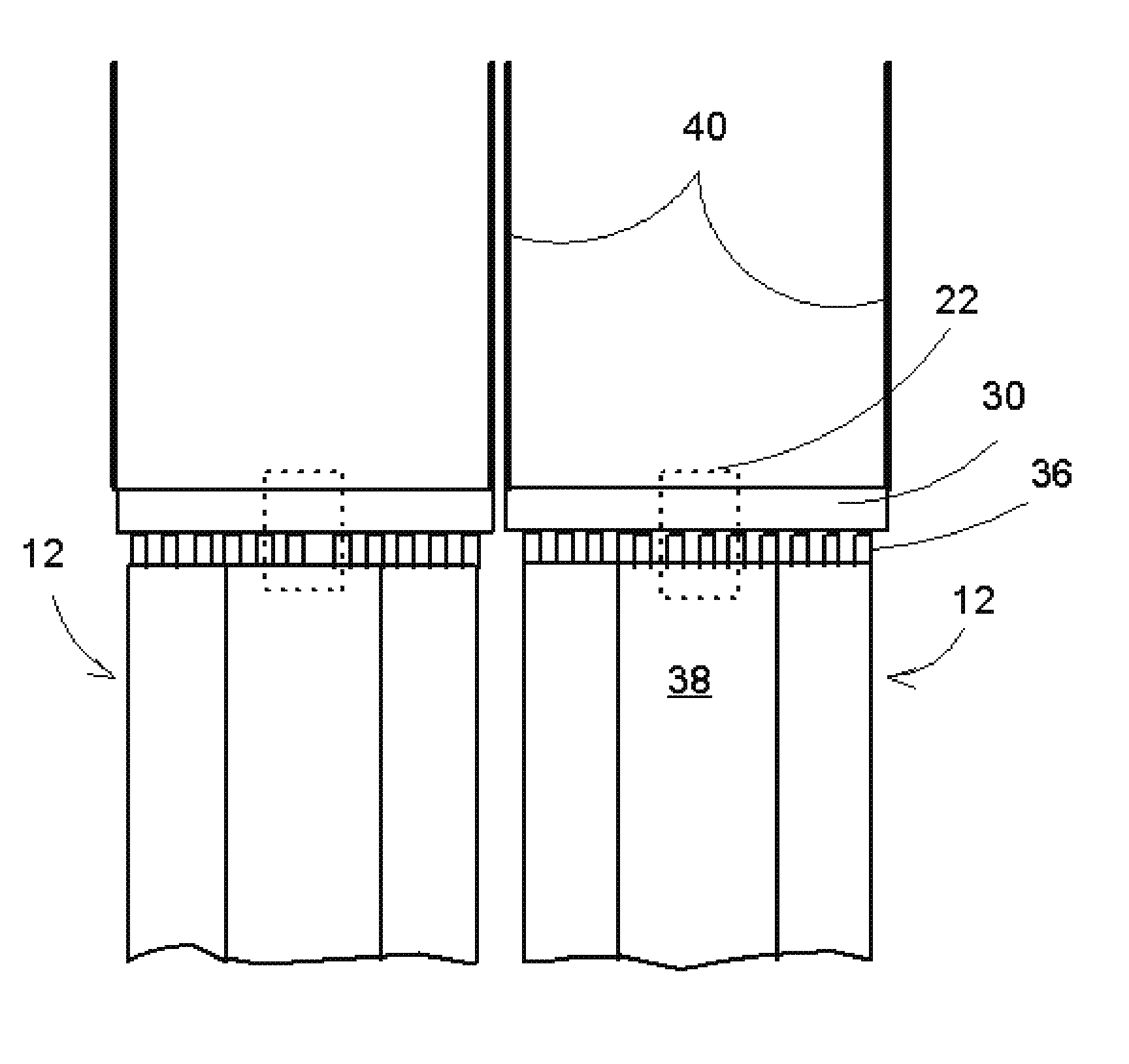

Fluidized bed reactor system having an exhaust gas plenum

InactiveUS20050112037A1Simple and feasible mannerWear minimizationFluidized bed combustionFluidised-bed furnacesReactor systemFluidized bed

An arrangement for directing exhaust gases from at least one particle separator of a circulating fluidized bed reactor system to a heat recovery section includes a gas plenum located above a reaction chamber, the gas plenum being defined by a ceiling, a bottom, and walls and being integrated with the reaction chamber. The walls of the gas plenum are provided with at least one inlet opening for cleaned exhaust gases, each of which is coupled with a discharge duct connected to one of the particle separators, for directing the cleaned exhaust gases from the particle separators to the gas plenum, from where the cleaned exhaust gases are directed to the heat recovery section downstream of the gas plenum. The reaction chamber is at least partially formed by water tube panels, and the enclosure of the gas plenum is also formed by water tube panels as extensions of water tube panels of the reaction chamber.

Owner:FOSTER WHEELER ENERGY CORP

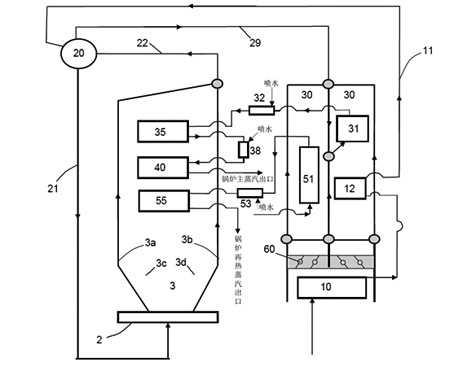

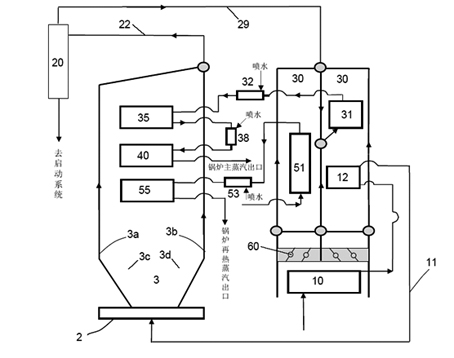

Circulating fluidized bed boiler with second reheaters

ActiveCN103363516ADowngradeLow costFluidized bed combustionSteam engine plantsCombustion chamberSuperheater

The invention discloses a circulating fluidized bed boiler with second reheaters. The boiler comprises an air compartment, an air distributor, a combustion chamber, a primary air system, a second air system, a horizontal flue, a plurality of cyclone separators, a plurality of external heat exchangers and a back-end flue. The contraction ratio of the lower part of the combustion chamber is 0.2-0.49. A flue gas damper is arranged in the back-end flue. The back-end flue contains at least two parallel flues. A low-temperature superheater is arranged in one parallel flue. A primary low-temperature reheater is arranged in the other parallel flue. A medium-temperature superheater is arranged in at least one external heat exchanger. A primary high-temperature reheater is arranged in at least one external heat exchanger. A second low-temperature reheater and a second high-temperature reheater are arranged in at least one external heat exchanger. A high-temperature superheater is arranged at the upper part of the combustion chamber. The boiler can effectively raise the heat-transfer intensity inside the boiler, and cooperates with optimized heating surface arrangement modes to achieve effective combination of second reheaters and a circulating fluidized bed, and therefore the aims of raising power generating efficiency of coal power units and reducing pollutant discharge are achieved, and long and high-efficient running of the device can be guaranteed.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

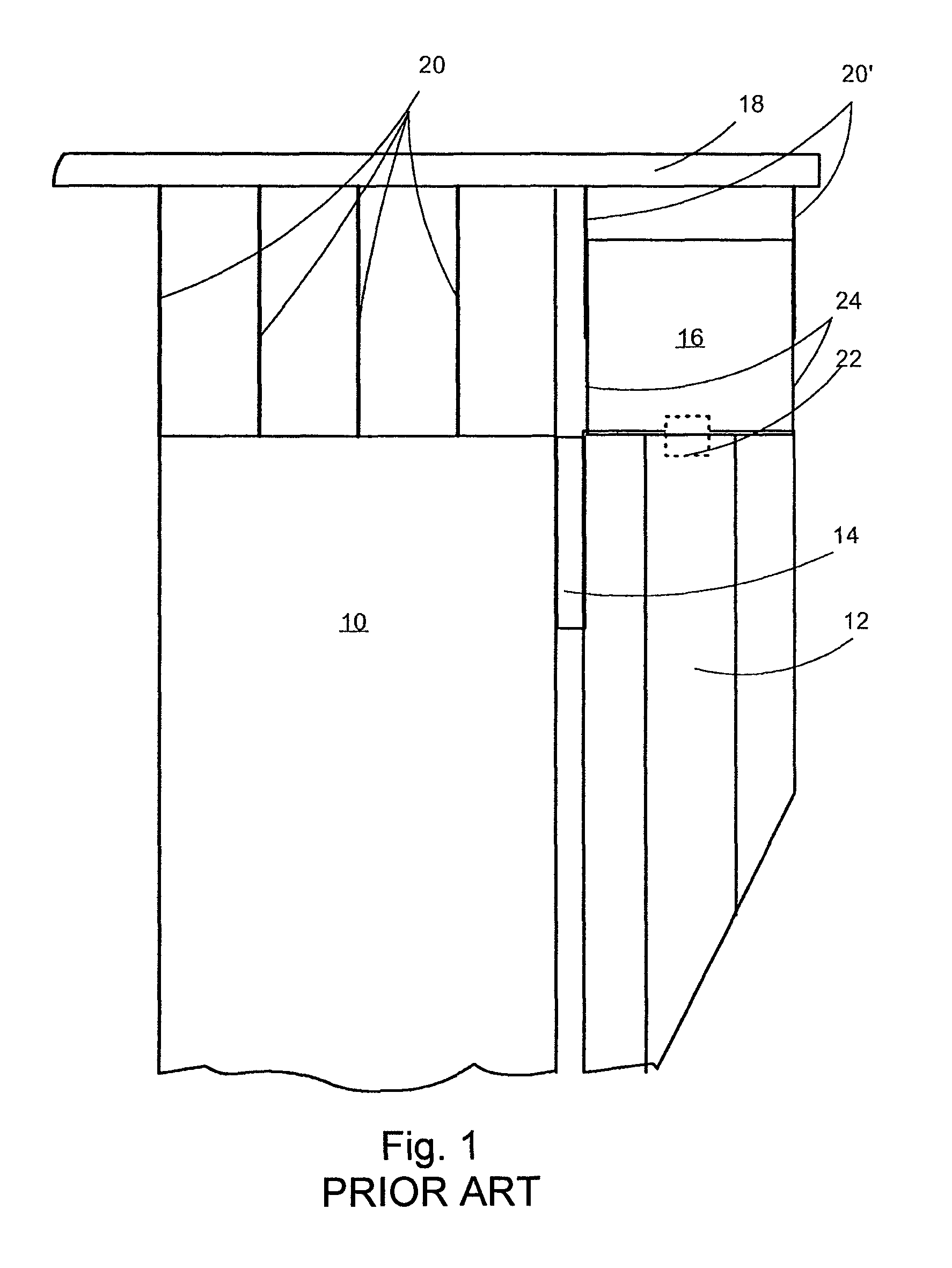

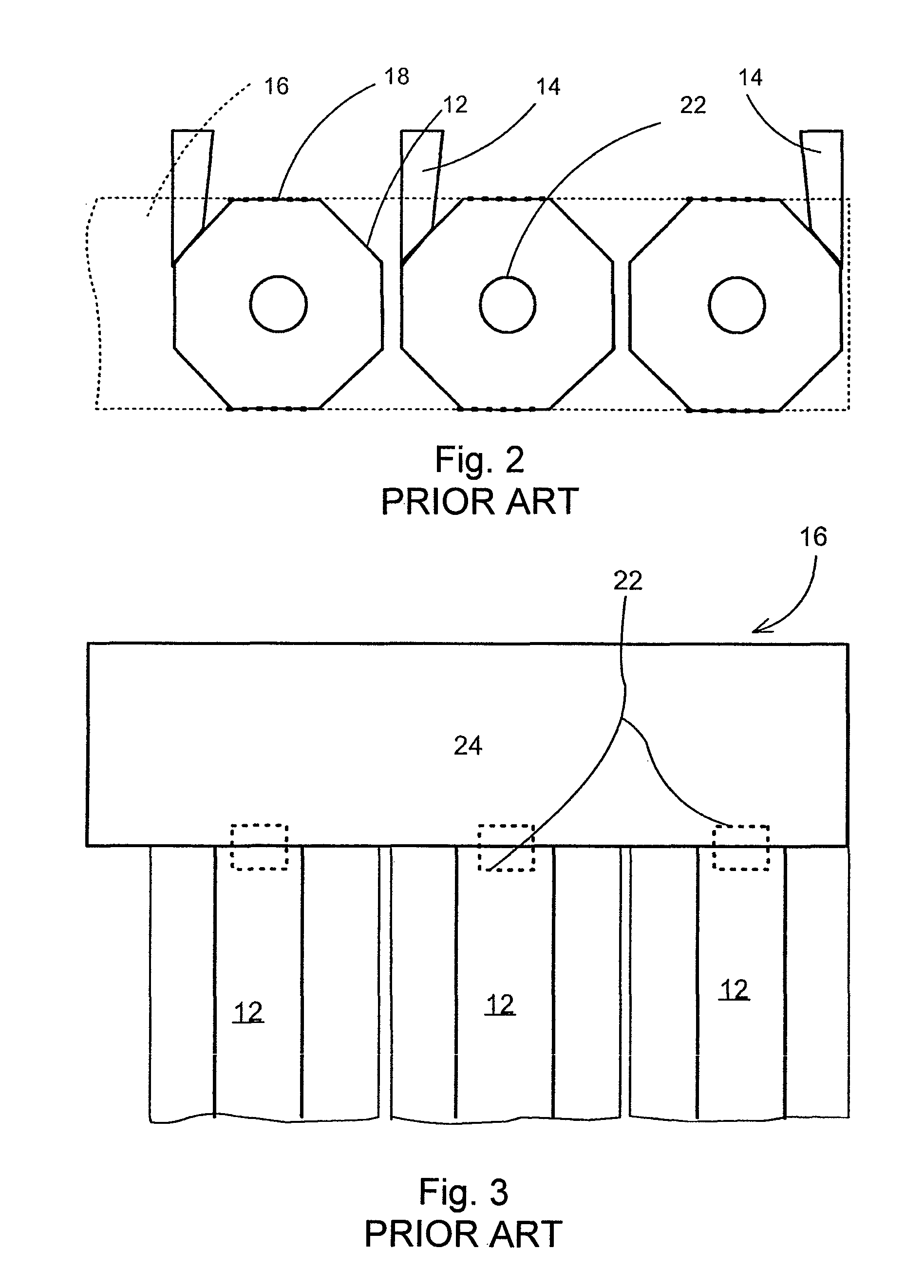

Separator Construction of a Fluidized Bed Boiler

ActiveUS20100024694A1Lose weightIncreased construction costFluidized bed combustionBoiler supporting/setting arrangementsFlue gasOperating energy

A separator construction, connectable to a fluidized bed boiler having a furnace, for circulating bed material and returning the material to the furnace. The separator construction includes walls, a ceiling, an inlet conduit, an outlet conduit in flow communication with a flue gas channel located above the separator, and a suspending device connecting the separator to a supporting structure in a building housing the boiler. The suspending device is formed of a frame arranged between the flue gas channel and the separator in connection with an upper circumference of the wall of the separator, and hanger rods or wires connecting the frame directly to the supporting structure.

Owner:FOSTER WHEELER ENERGIA OY

Air-fired CO2 capture ready circulating fluidized bed heat generation with a reactor subsystem

ActiveUS8196532B2Less expenseImprove efficiencyFluidized bed combustionEmission preventionAir preheaterWorking fluid

A combustor 110 combust a fluidized bed of fossil fuel 114, 114′ to heat a working fluid 102 and generate flue gas 104. An air preheater 144 has first and second gas passageways 144a, 144b for respectively directing the generated flue gas 150 and another gas 250 with captured CO2 generated by combustion outside of the combustor 110. When operated in a non-CO2 capture, the air preheater 144 receives the flue gas 150, but not the other gas 250, and the first gas passageway 144a directs the flue gas 150 so as to preheat the air 188. However, when operated in the CO2 capture mode, the air preheater 144 receives the flue gas 150 and the other gas 250, and the second gas passageway 144b also directs the other gas 250 so as to preheat the air 188′. In either mode, the preheated air 188, 188′ is applied by the combustor 110 to fluidize a bed of fossil fuel 114, 114′.

Owner:GENERAL ELECTRIC TECH GMBH

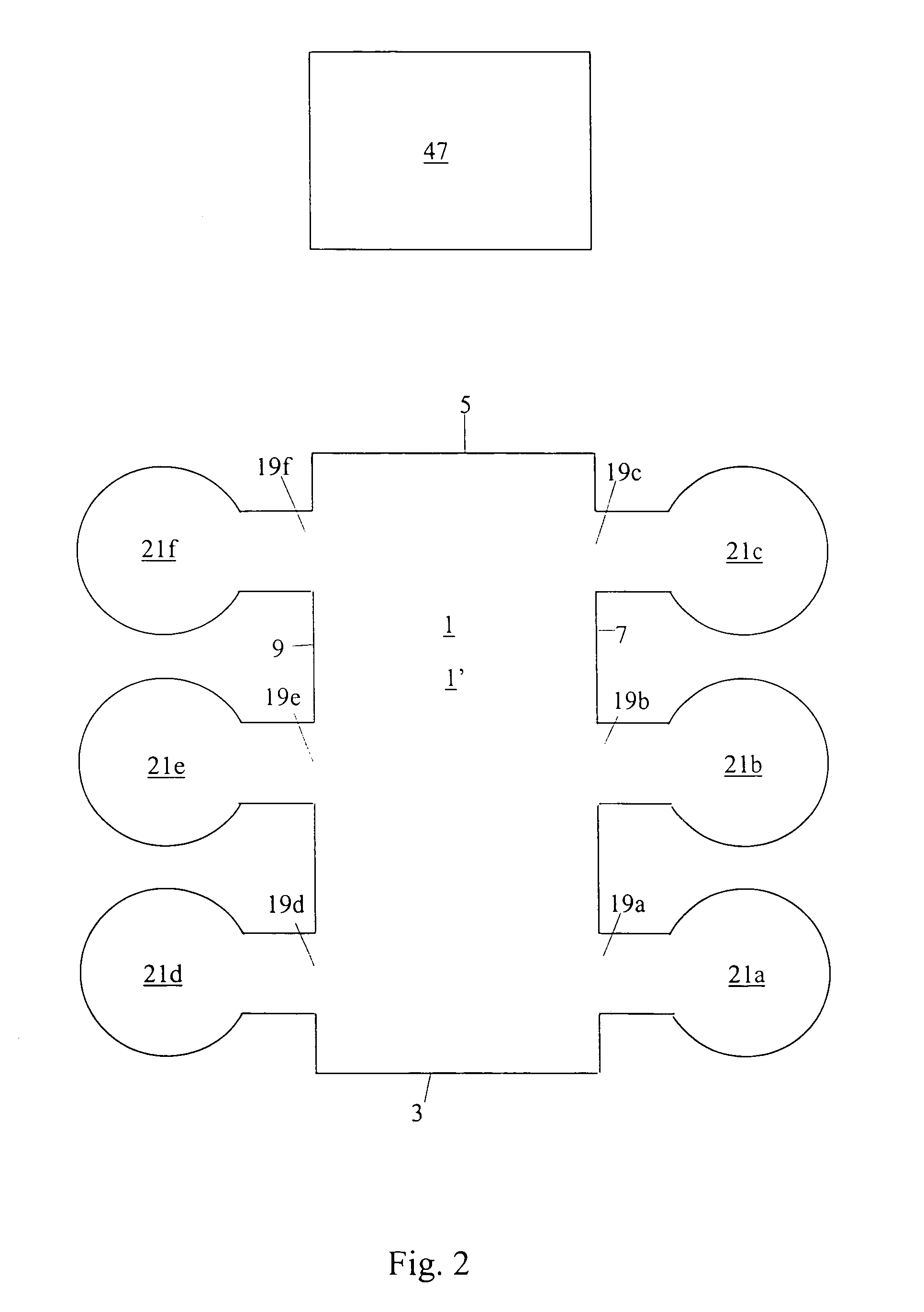

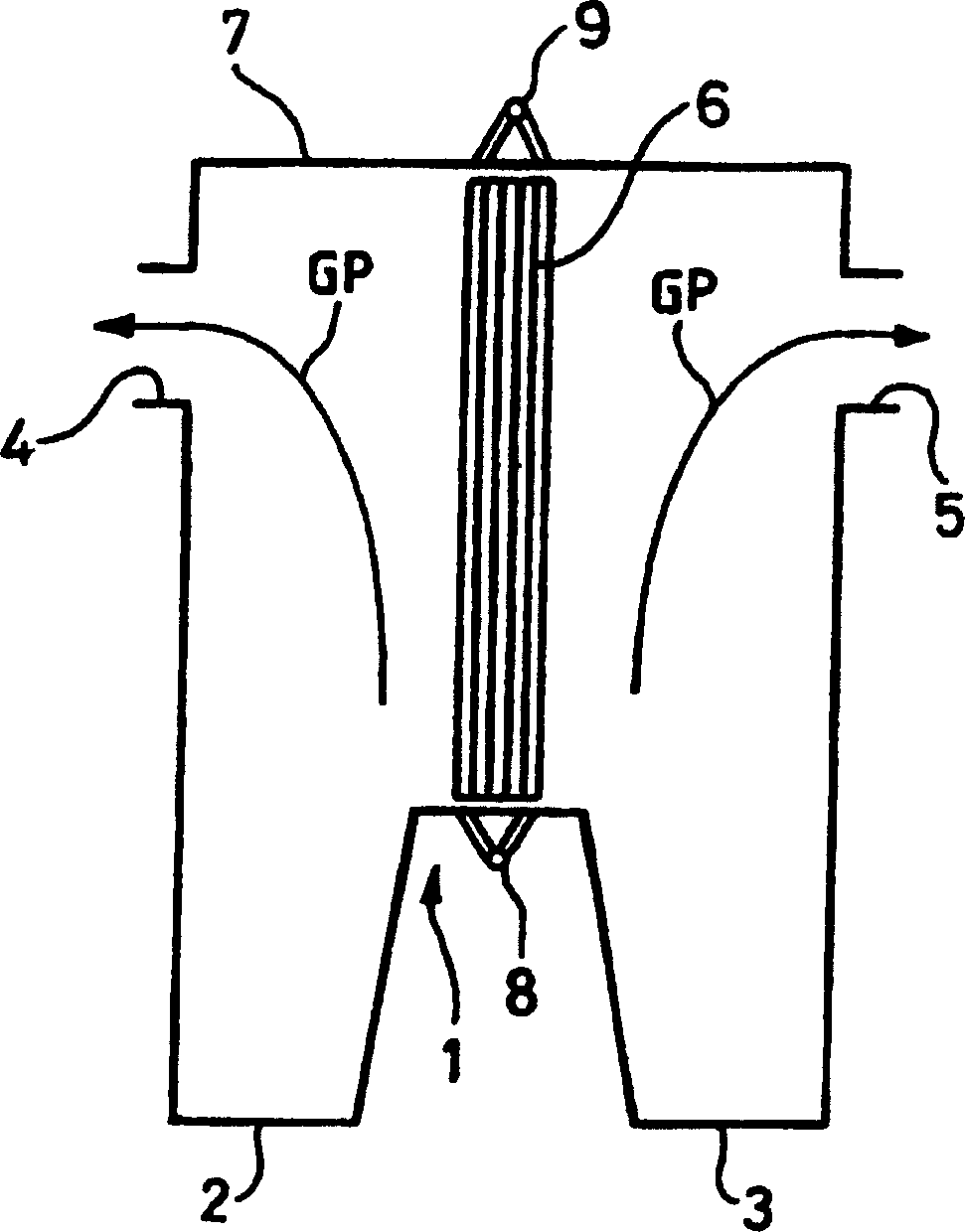

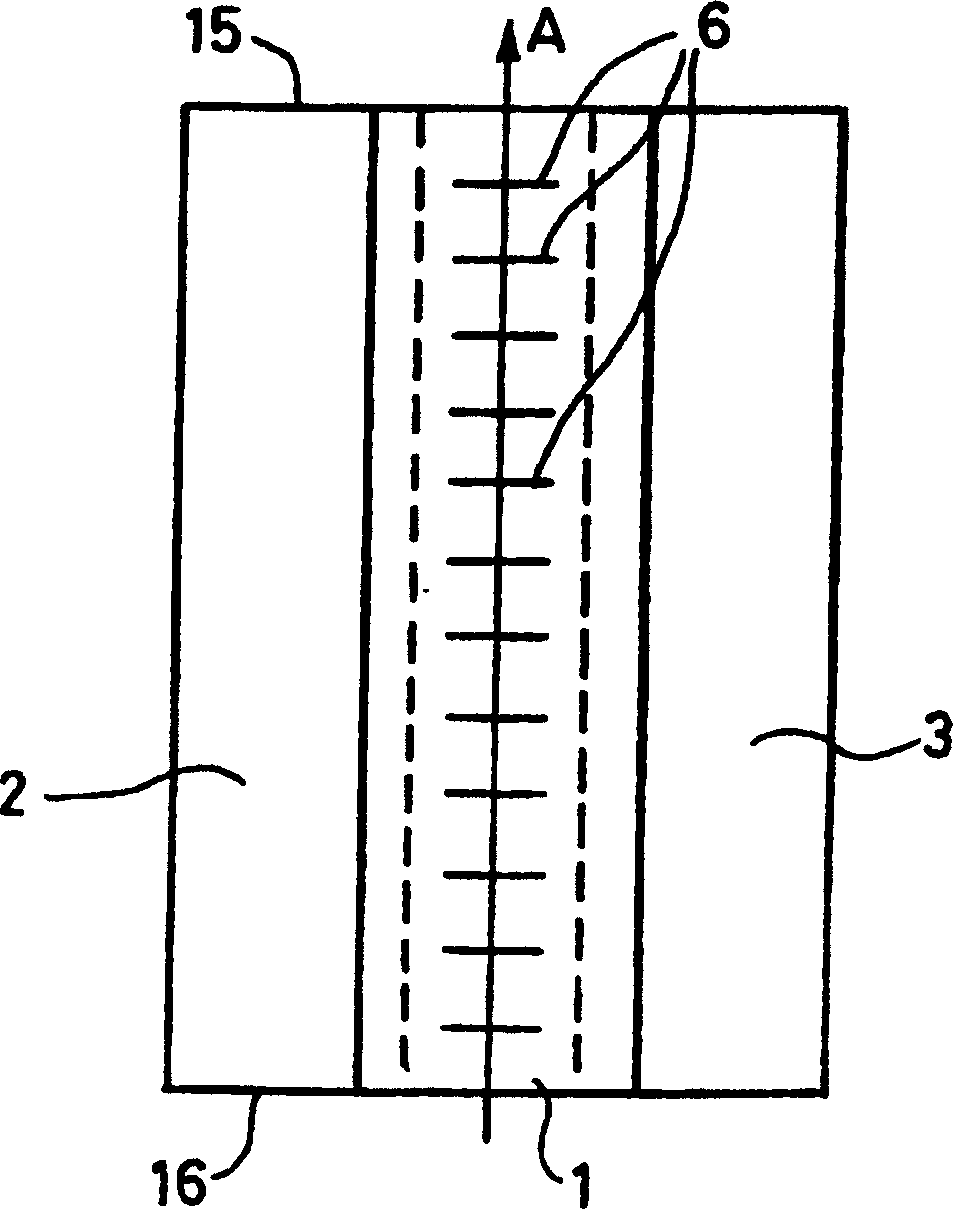

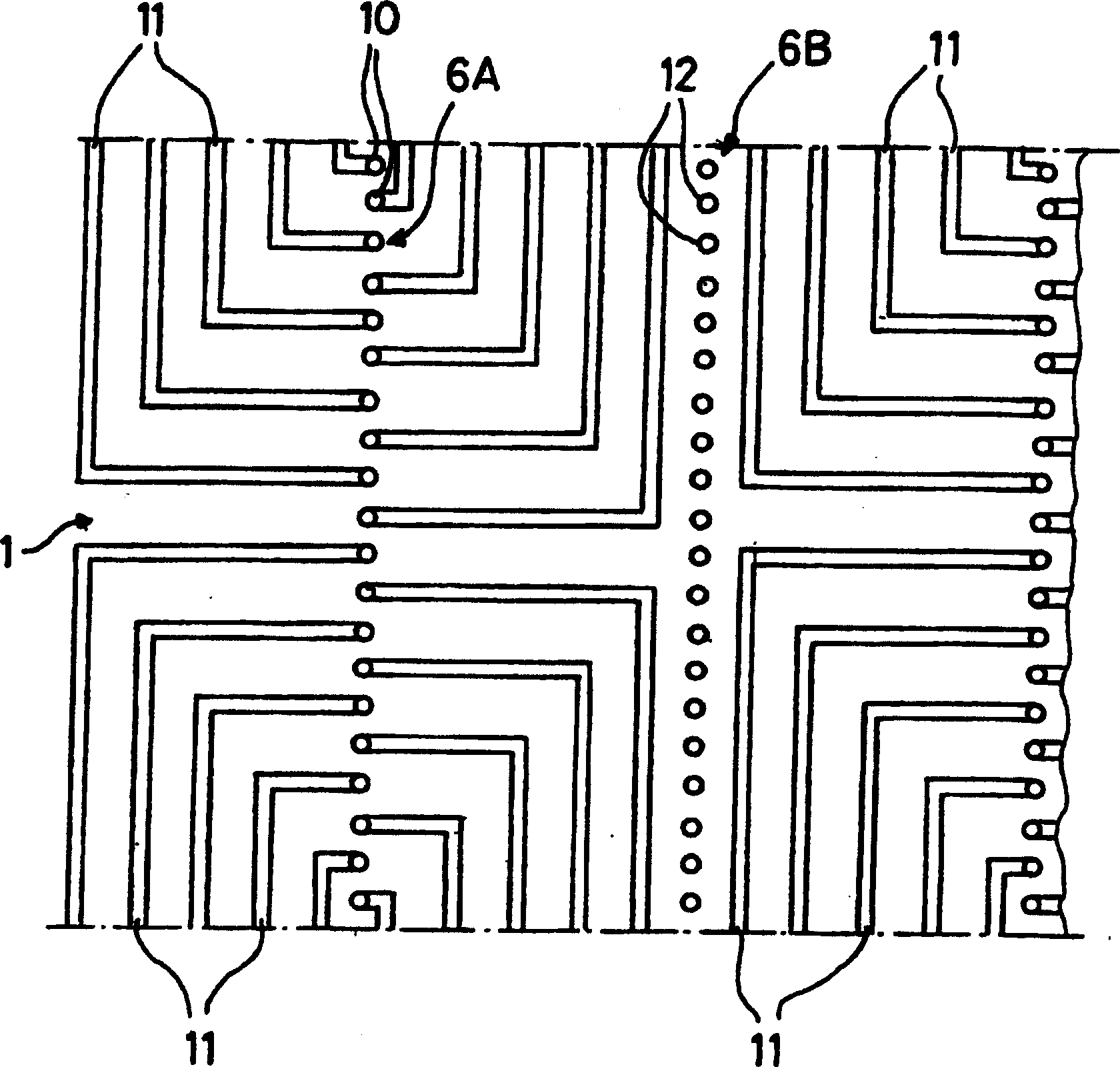

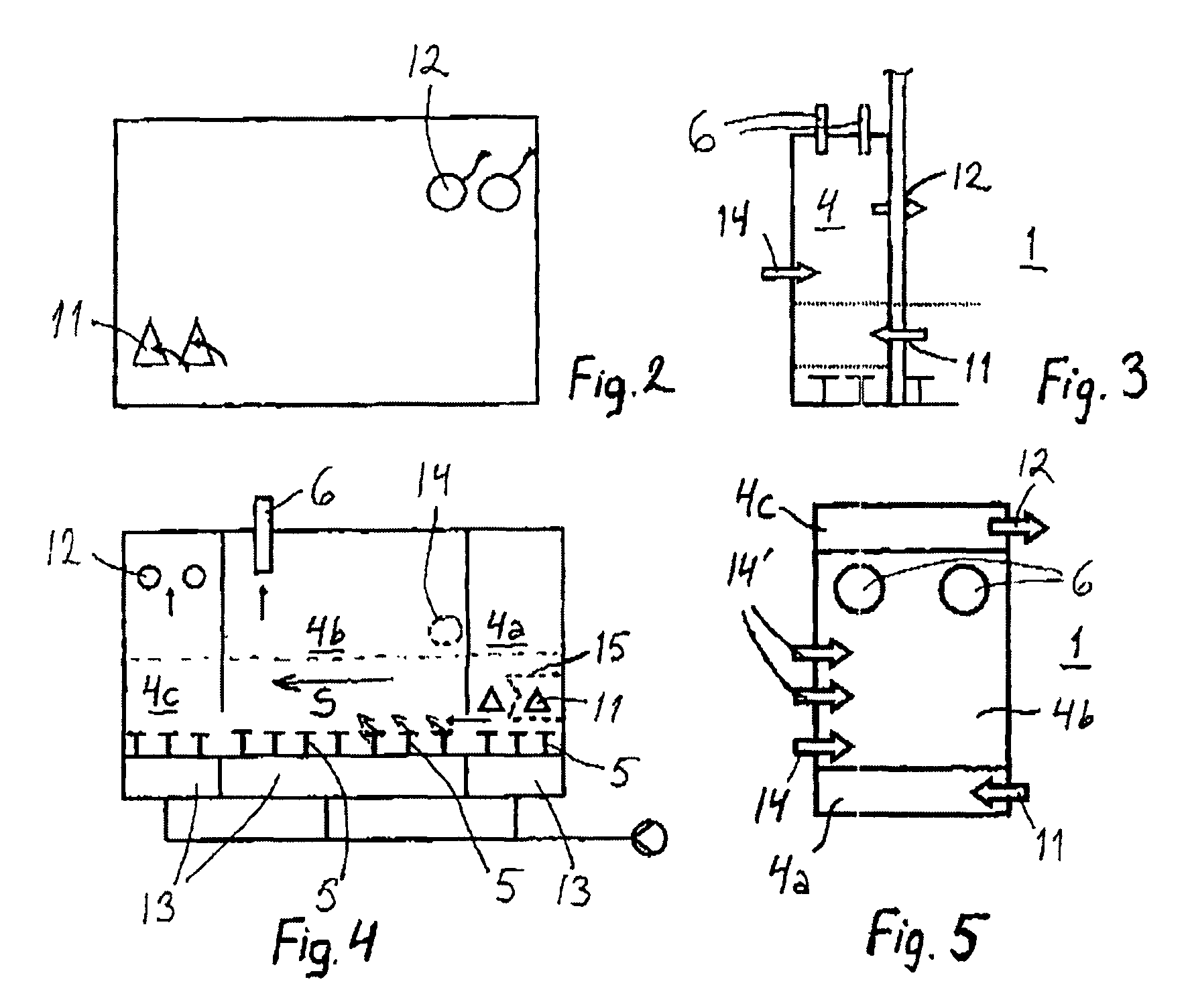

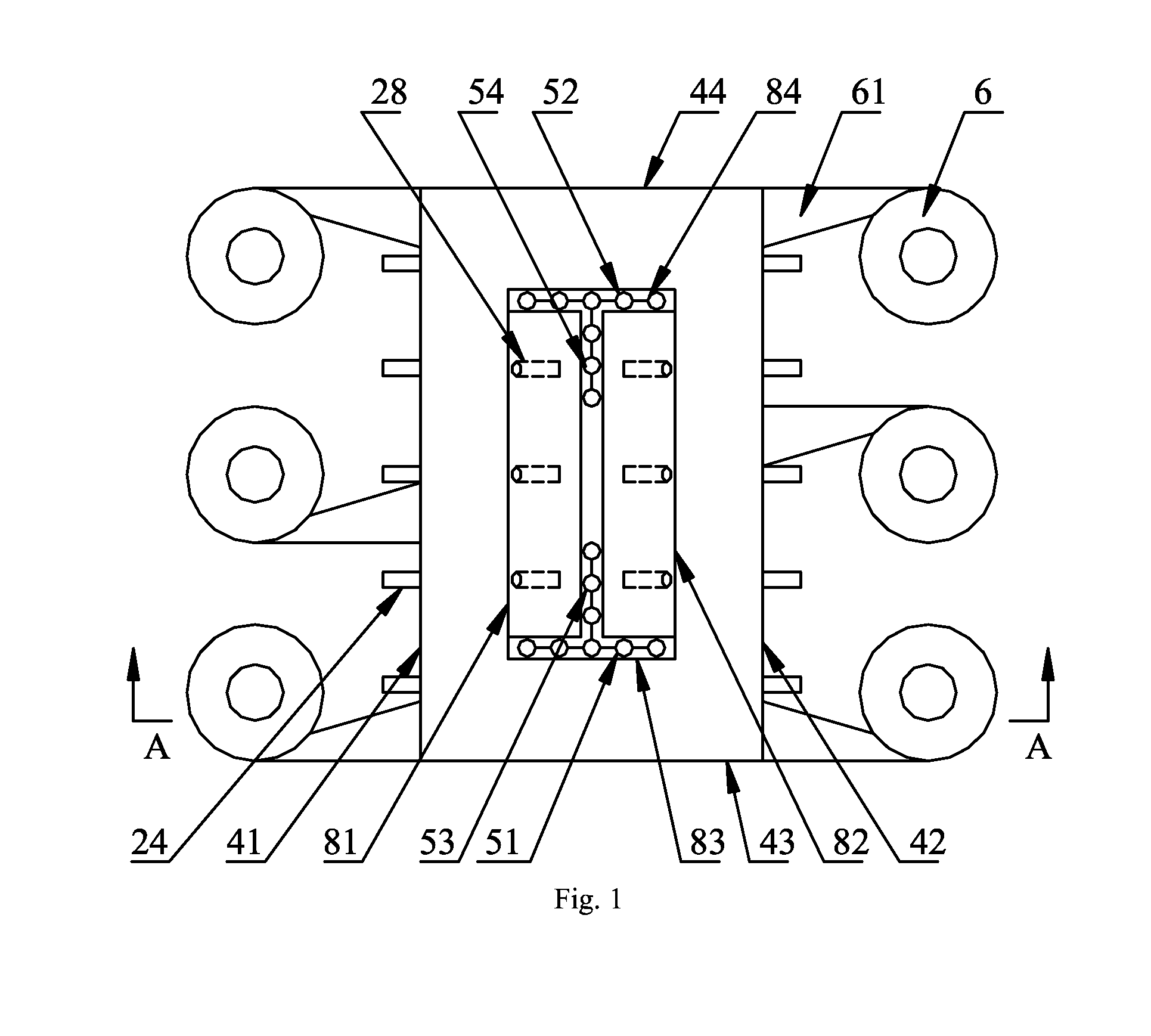

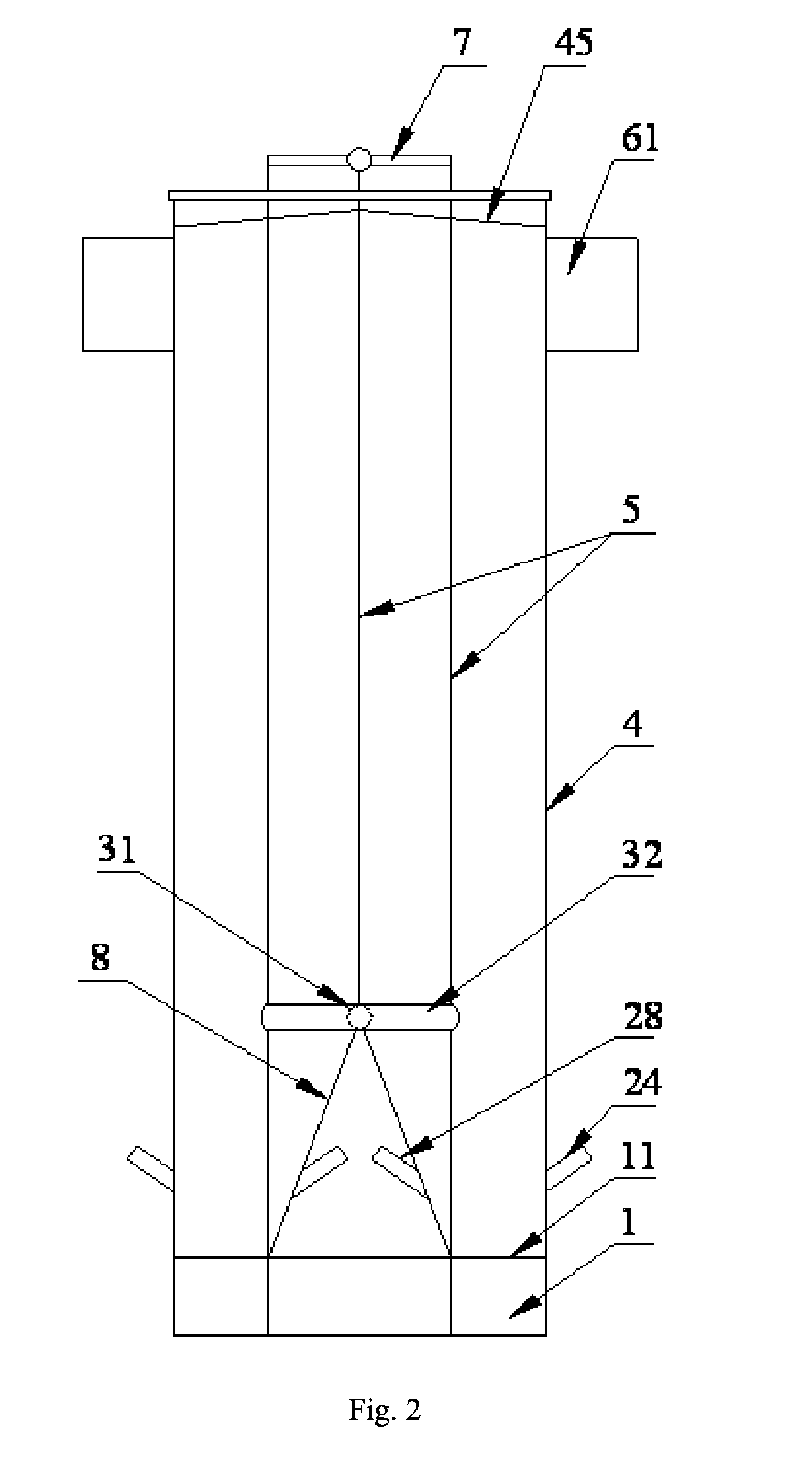

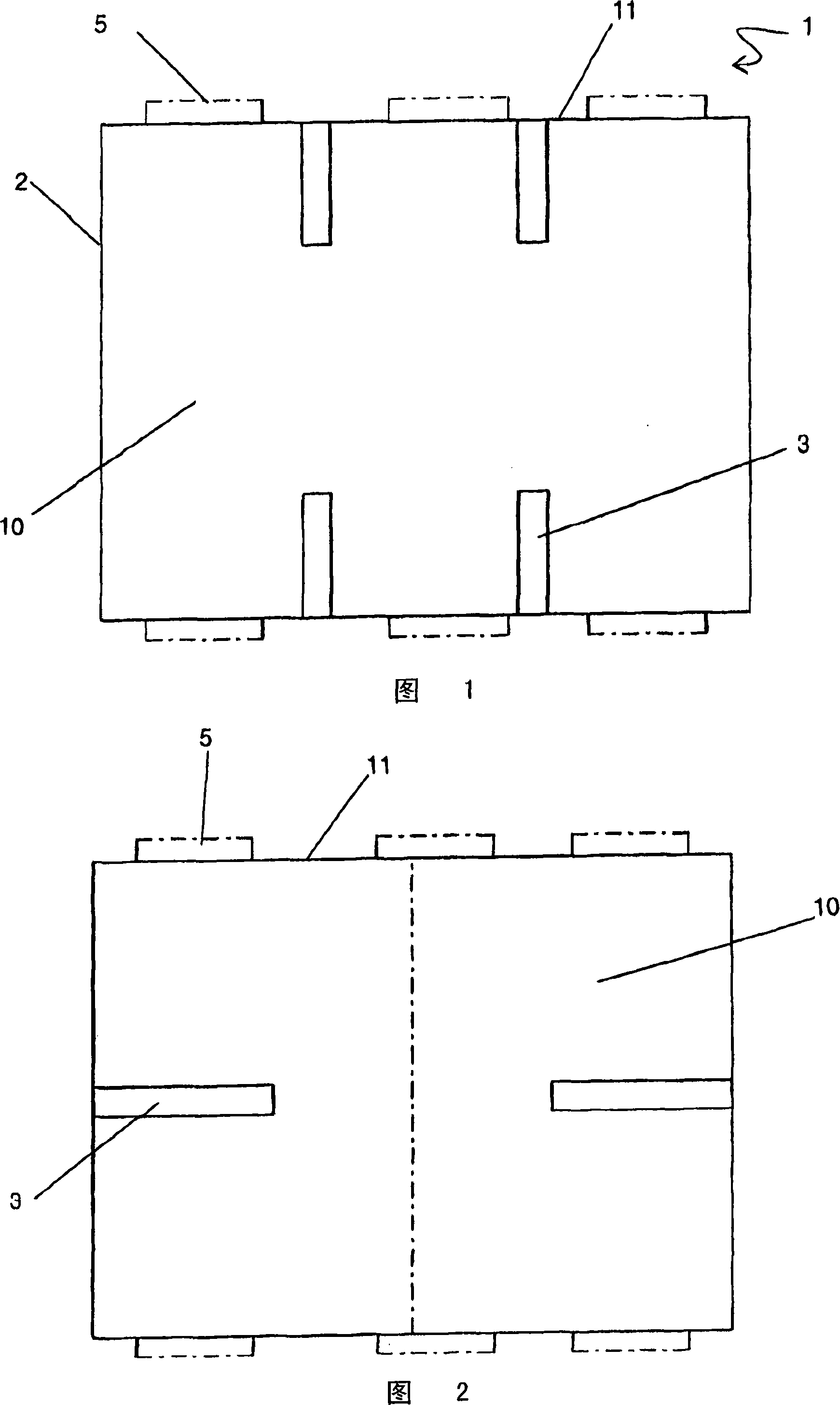

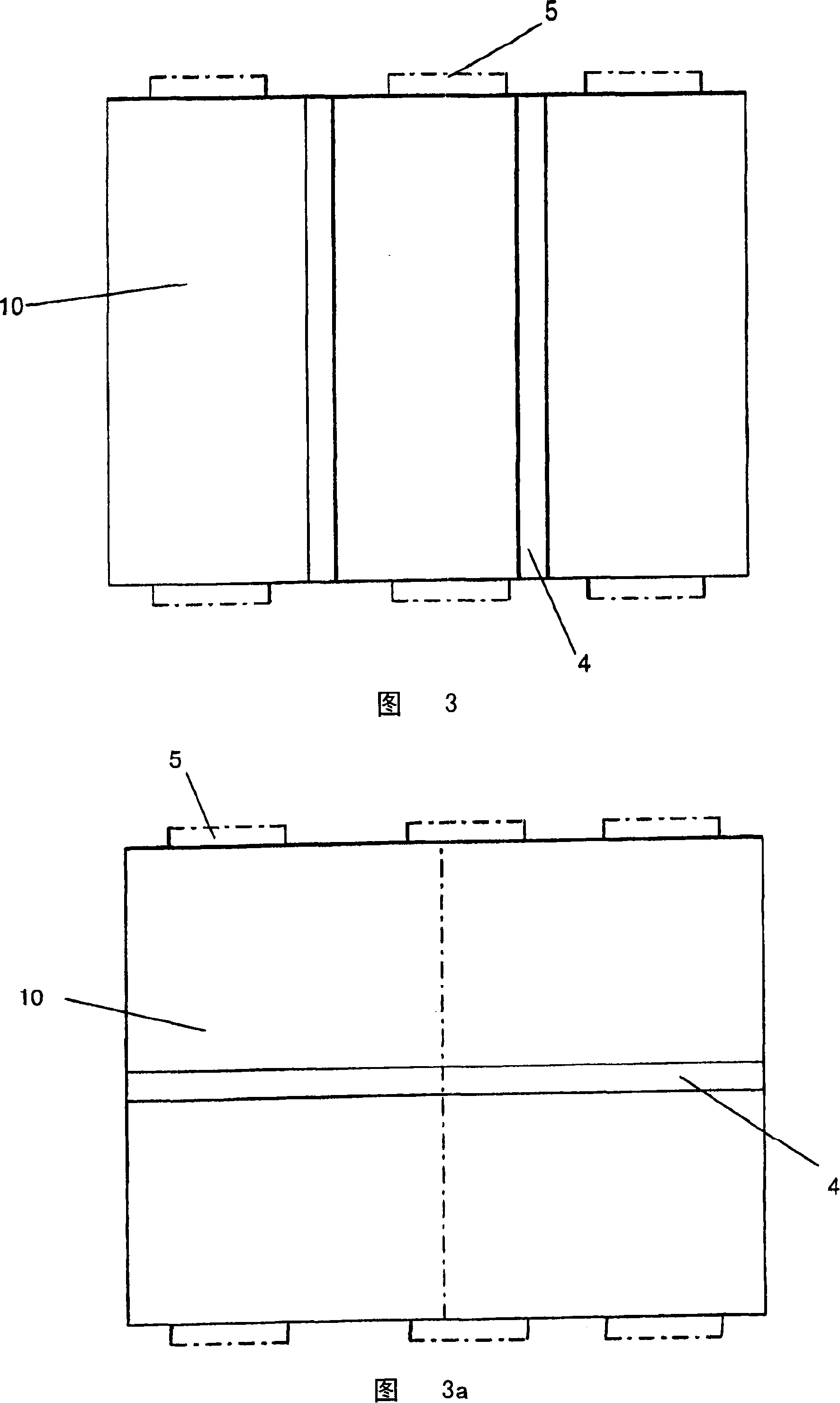

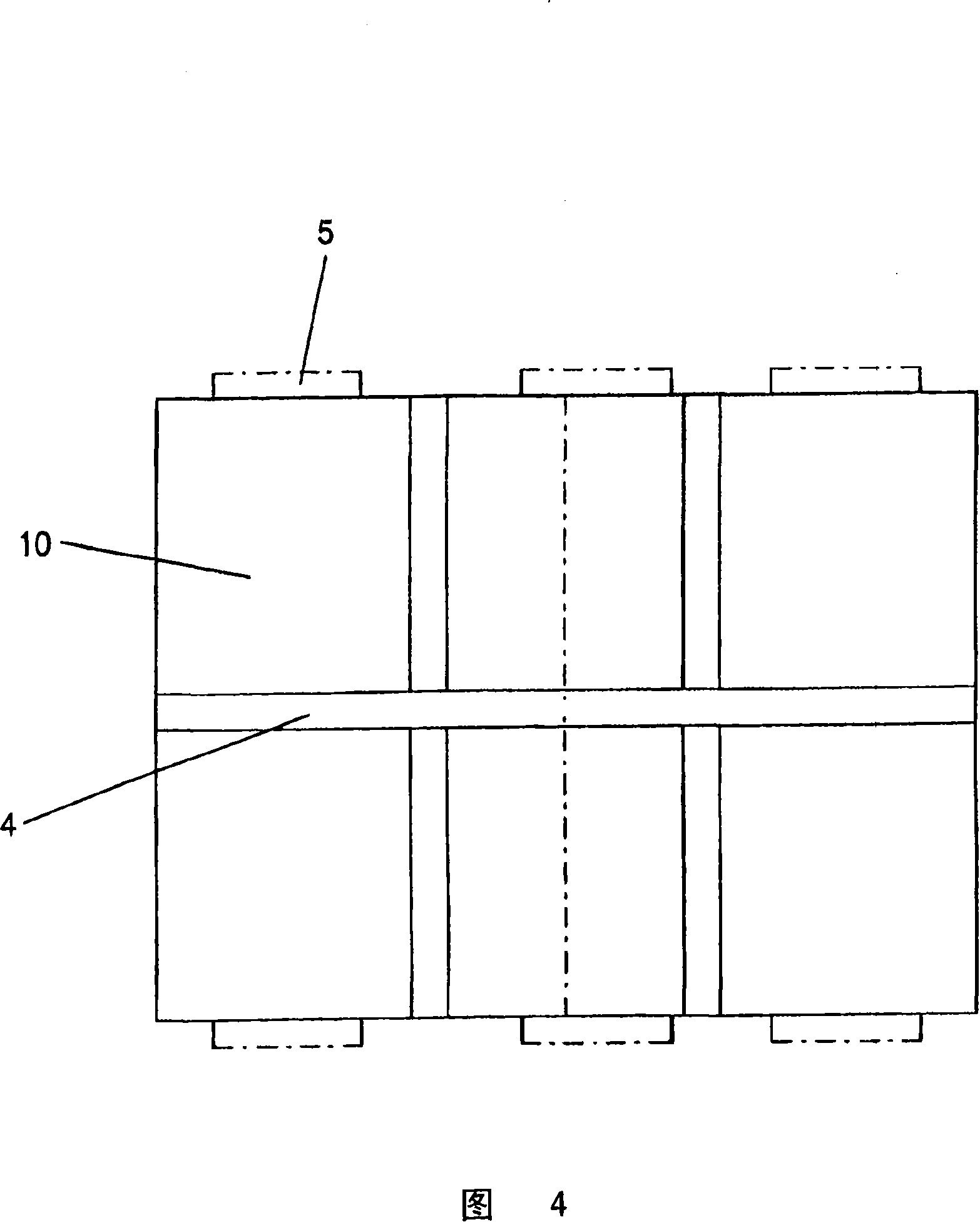

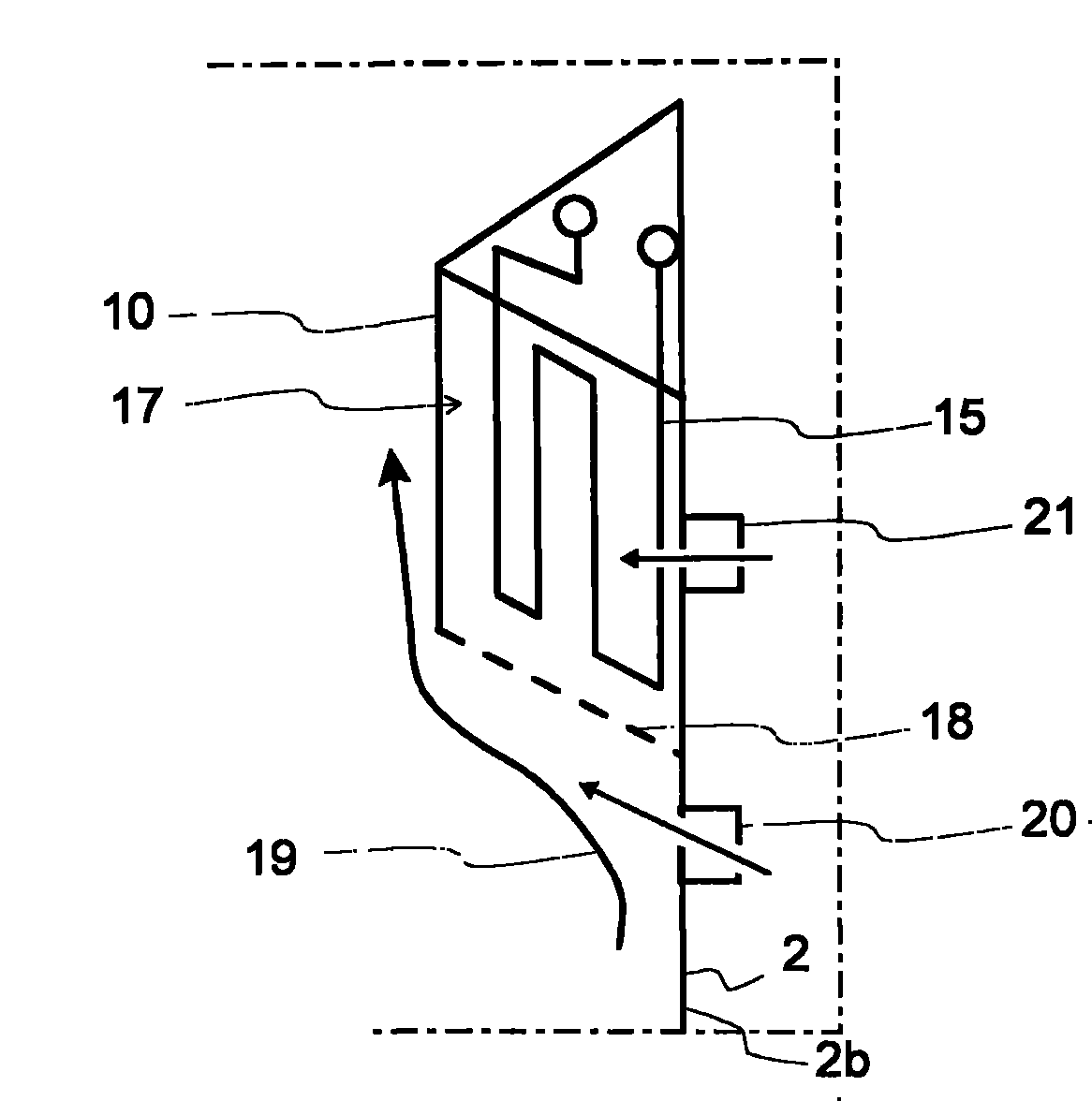

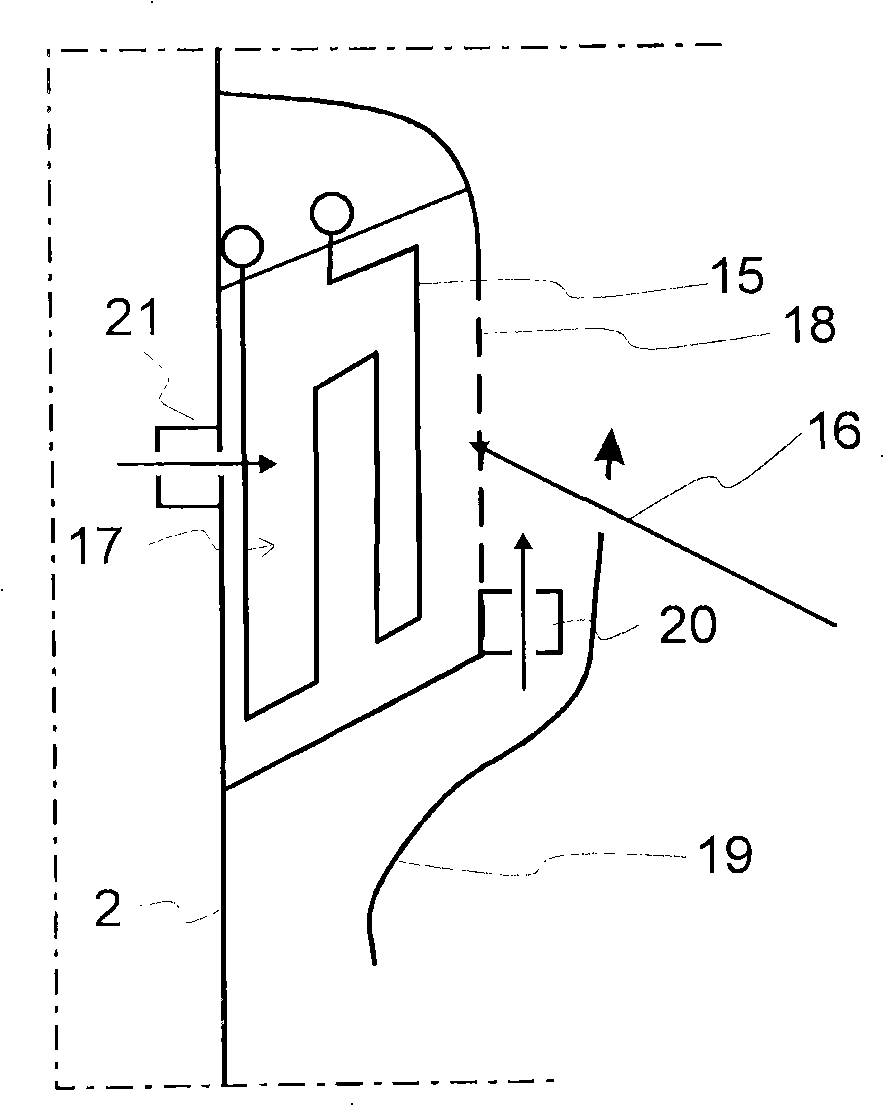

Fluidized bed boiler furnace comprising two hearths separated by an inside leg area

The fluidized bed boiler furnace provided with two hearths (2,3) separated by an inside leg area (1) in the lower part of the furnace comprises one or several panels (6) of heat exchange pipes each of which is disposed vertically above the inside leg area of the furnace and perpendicularly in relation to the longitudinal direction (A) of said hearths.

Owner:GENERAL ELECTRIC TECH GMBH

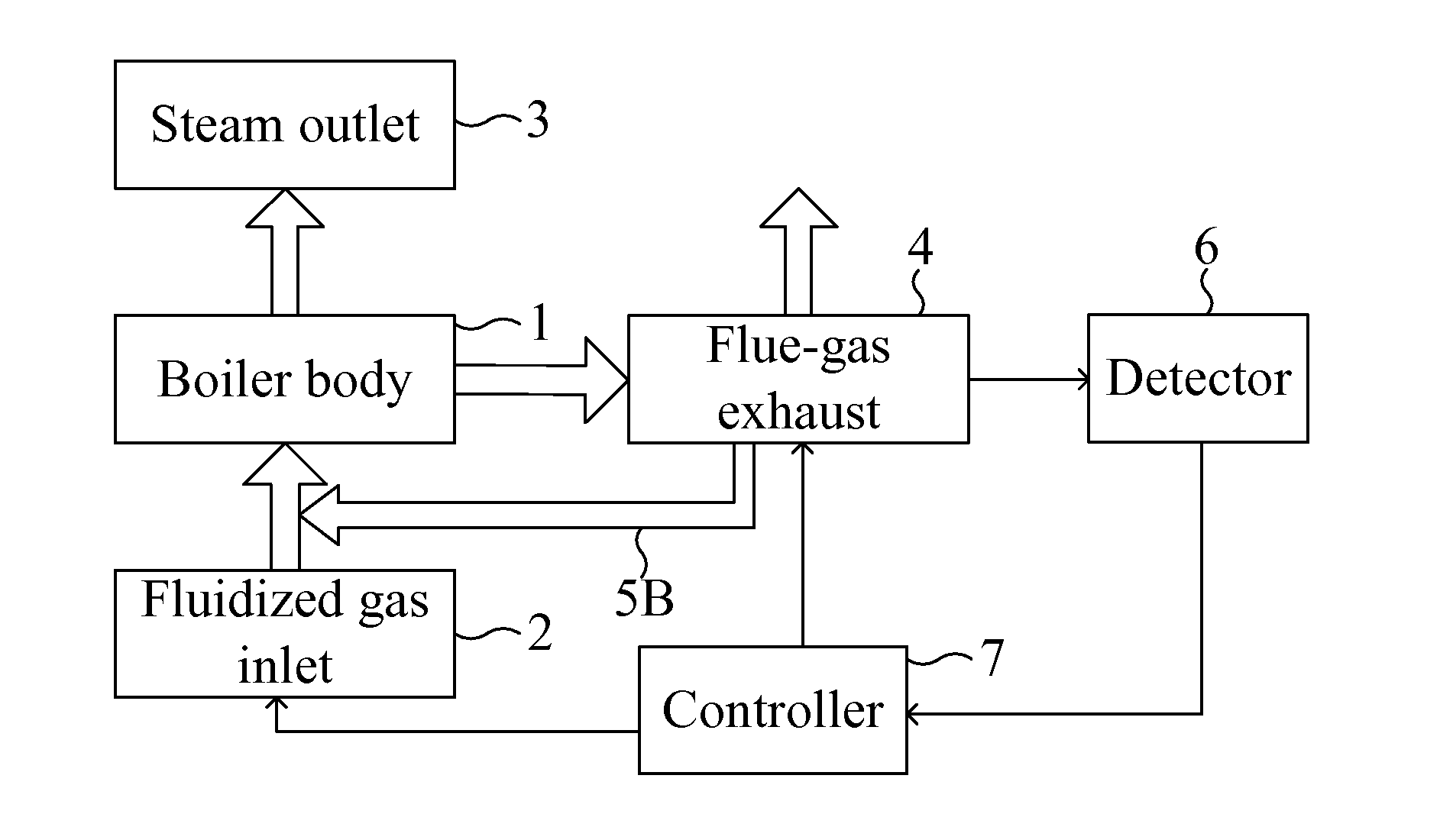

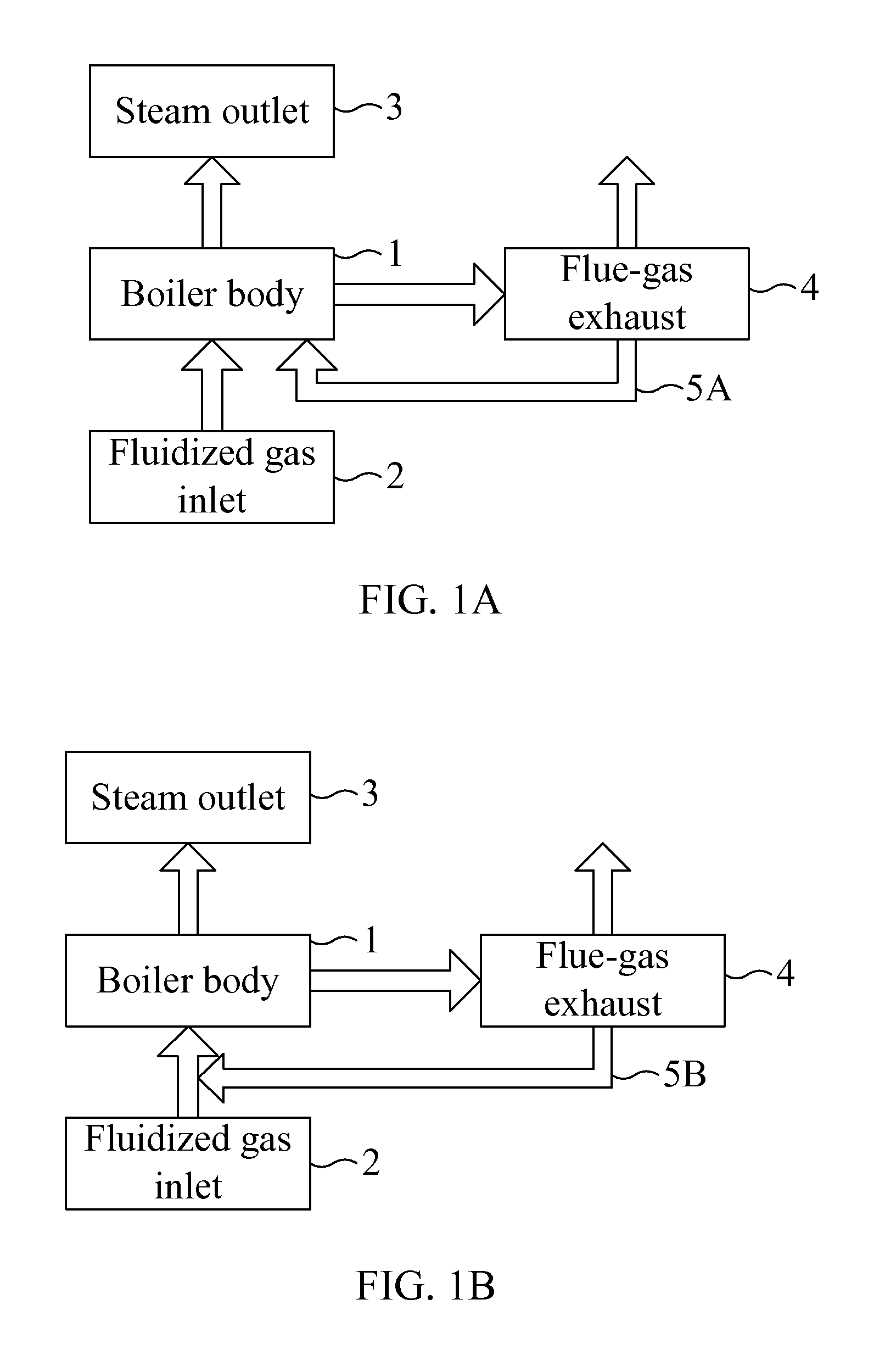

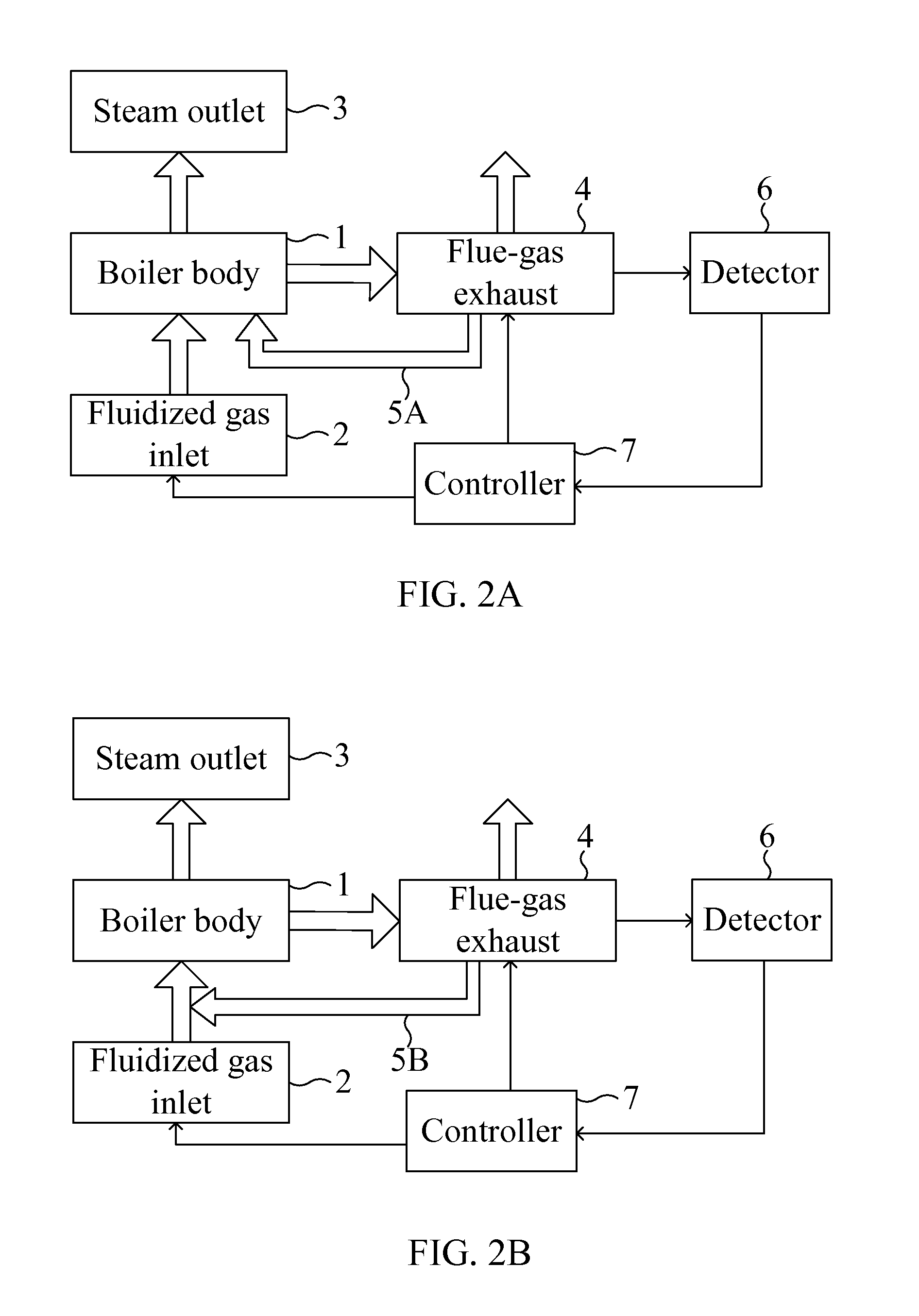

Fluidized bed boiler and method for enhancing furnace efficiency of the same

InactiveUS20150330622A1Improve the efficiency of the furnaceLow oxygenFuel supply regulationFluidized bed combustionCombustionAutomatic control

A method for enhancing furnace efficiency of a fluidized bed boiler is provided. The fluidized bed boiler includes a boiler body for carrying out fuel combustion in a fluidized bed thereof; a fluidized gas inlet for inputting an oxygen-containing fluidized gas into the boiler body to fluidize a boiler bed and facilitate the fuel combustion; a steam outlet for outputting a steam resulting from the fuel combustion from the boiler body; and a flue-gas exhaust for emitting a flue gas resulting from the fuel combustion from the boiler body. The method includes steps of: detecting an oxygen concentration of the flue gas; feeding a portion of the flue gas back to the fluidized gas inlet; and dynamically adjusting a flow rate of the feeding fluidized gas according to oxygen concentrations of the flue gas and the feeding fluidized gas to achieve automatic control of the fluidized bed boiler.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

Air-fired co2 capture ready circulating fluidized bed steam generators

ActiveUS20090211503A1None is suitable for purposeOperation forceFluidized bed combustionDirect carbon-dioxide mitigationAir preheaterCombustor

A combustor 110 is operative to effect therewith the combustion of fossil fuel 114′ in order to thereby both heat to a working fluid 102 and generate a flue gas 104. An air preheater 144 receives the flue gas 104 generated in the combustor 110. A blower 180 causes air 188 to flow to the air preheater 144 when operating in an air fired mode, and causes both O2 and recycled flue gas 188′ to flow when operating in the O2 firing mode. The air preheater 144 is operative to transfer heat from the flue gas 150 received thereby to the air 188 that is received when operating in an air fired mode or to both the received O2 and the recycled flue gas 188′ that is received when operating in the O2 firing mode in order to thereby effect a preheating of the air 188 or of both the O2 and recycled flue gas, 188′ depending upon the specific nature of the mode of operation thereof, and to thereby effect therewith a cooling of the flue gas received thereby. The preheated air 142 or both the preheated O2 and the recycled flue gas 142′, depending upon the specific nature of the mode of operation, is caused to flow from the air preheater 144 to the combustor 110 in order to thereby effect therewith a fluidization of the fossil fuel 114′.

Owner:GENERAL ELECTRIC TECH GMBH

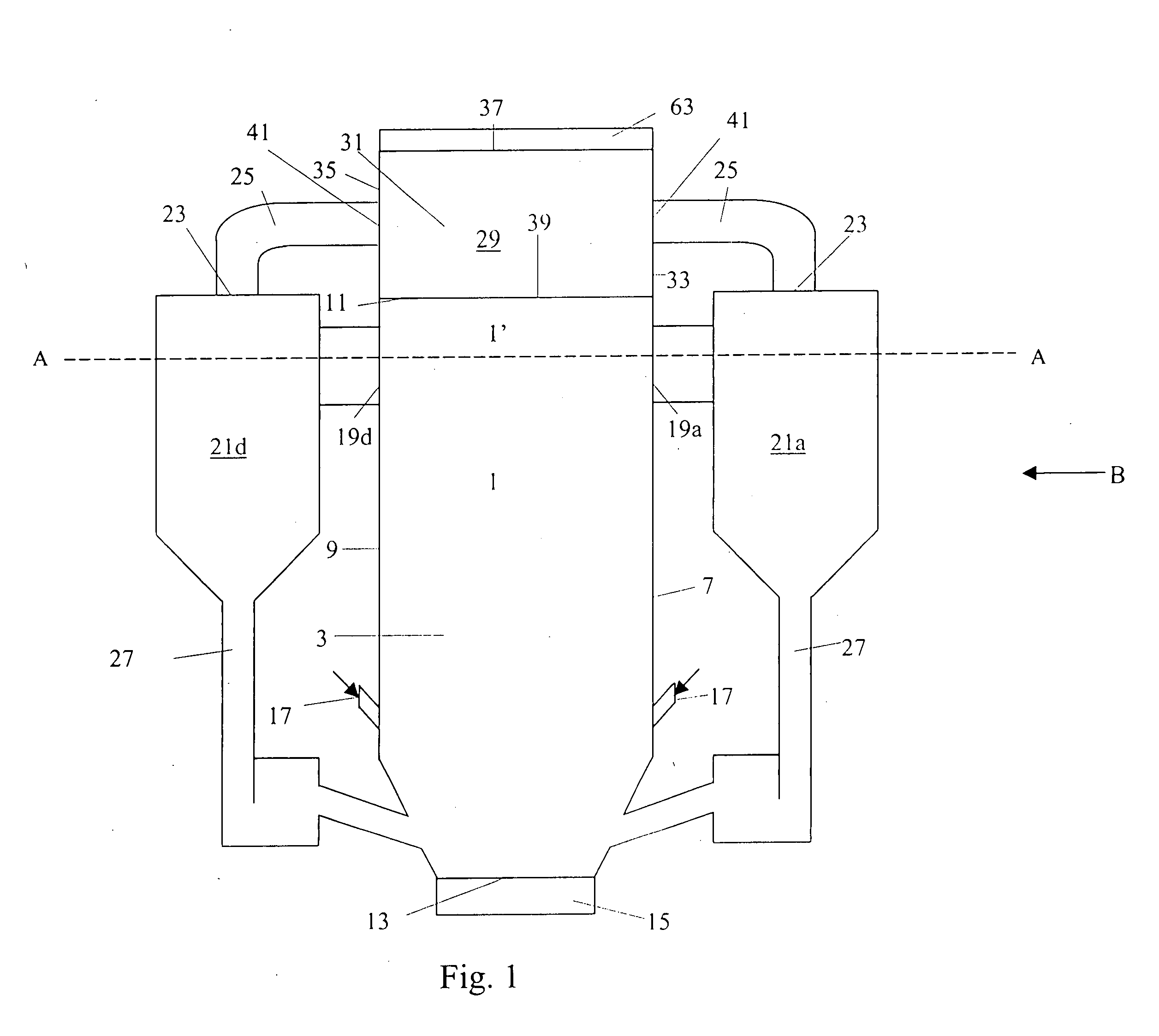

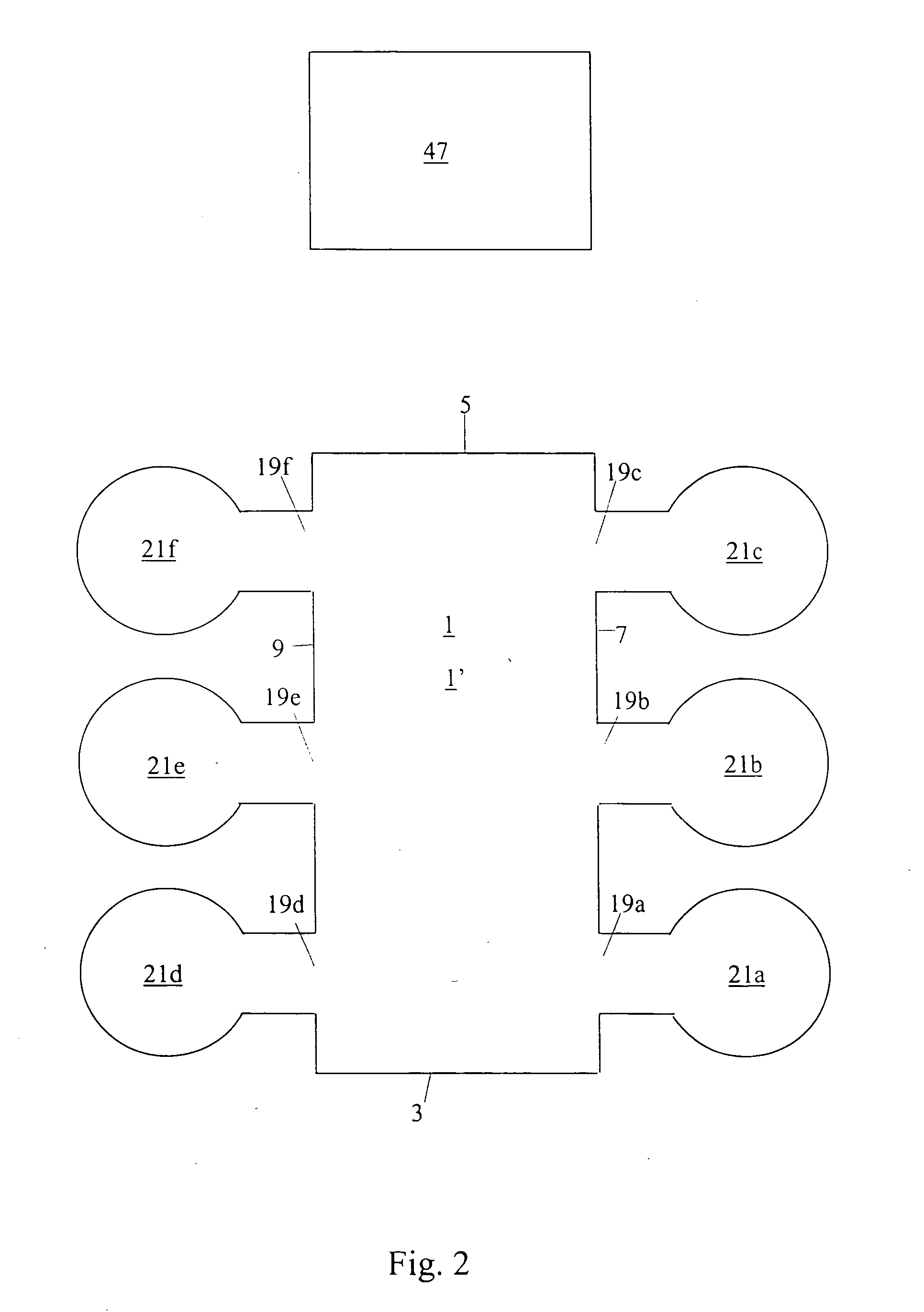

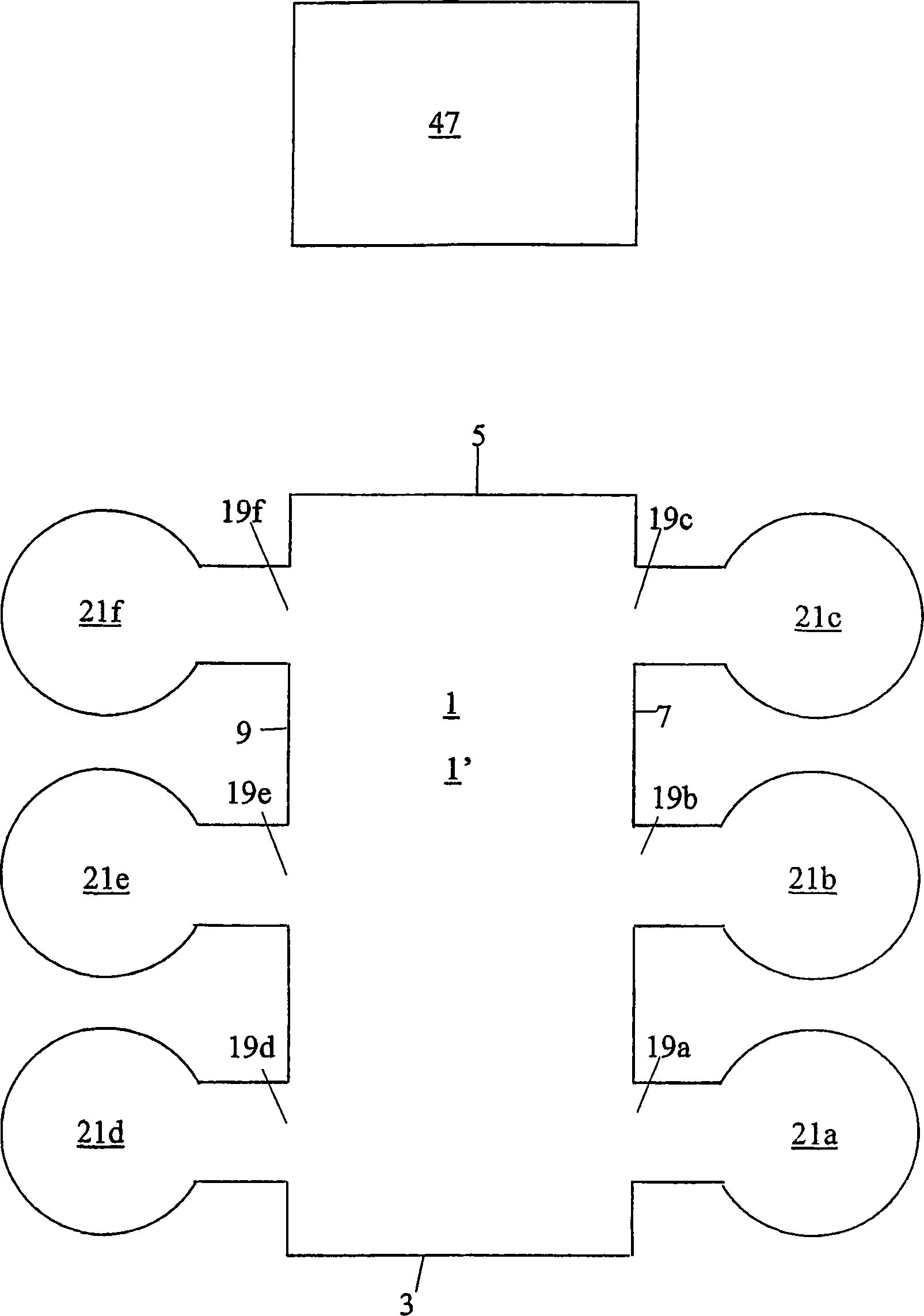

Fluidized bed reactor system having an exhaust gas plenum

An arrangement for directing exhaust gases from at least one particle separator (21a,d) of a circulating fluidized bed reactor system to a heat recovery section includes a gas plenum (29) located above and integrated with a reaction chamber (1). The walls of the gas plenum are provided with at least one inlet opening (41) for cleaned exhaust gases, each of which is coupled with a discharge duct (25) connected to one of the particle separators, for directing the cleaned exhaust gases from the particle separators to the gas plenum, from where the cleaned exhaust gases are directed to the heat recovery section. The reaction chamber is at least partially formed by water tube panels, and the enclosure of the gas plenum is formed by water tube panels as extensions of water tube panels of the reaction chamber.

Owner:KAUTEX TEXTRON GMBH & CO KG

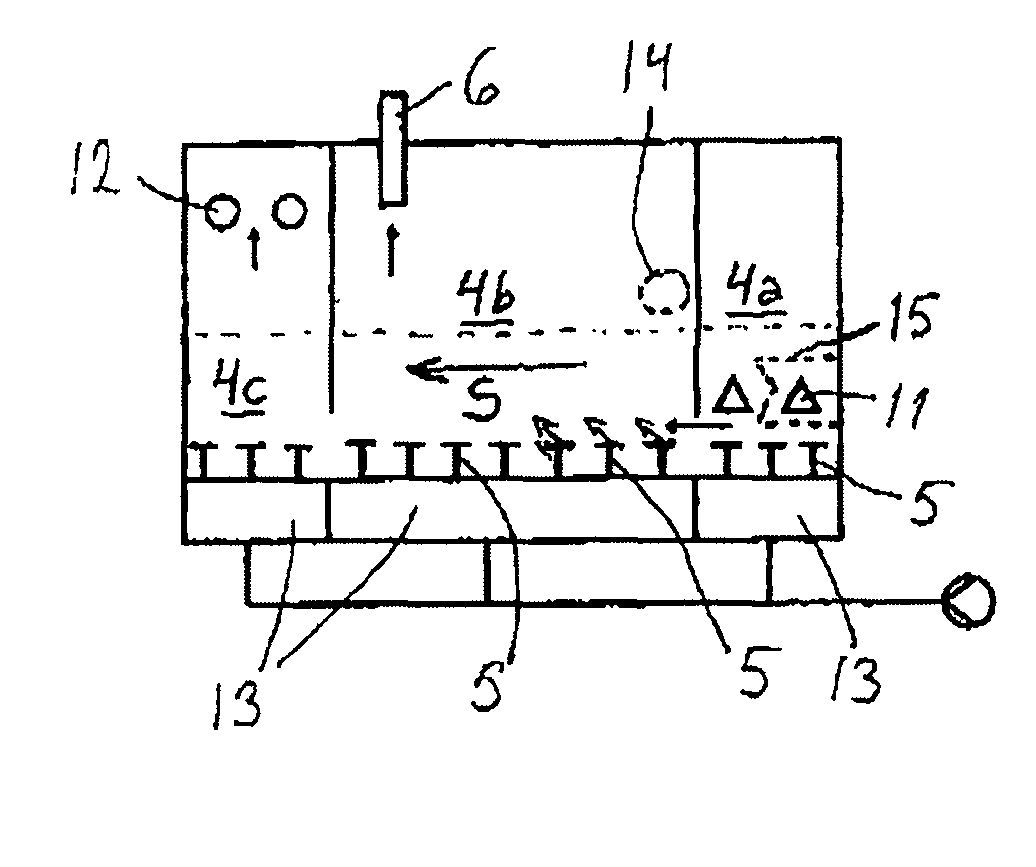

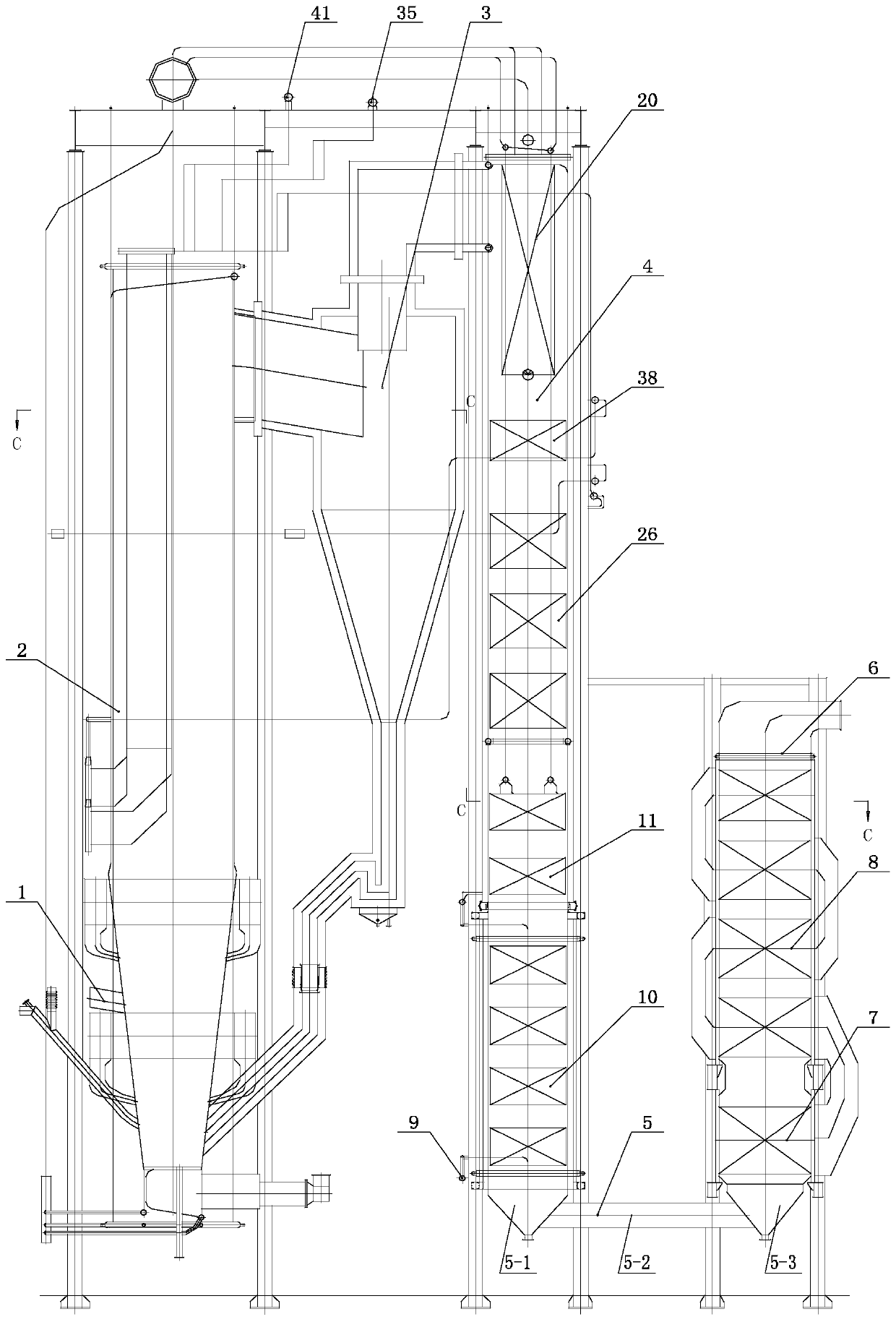

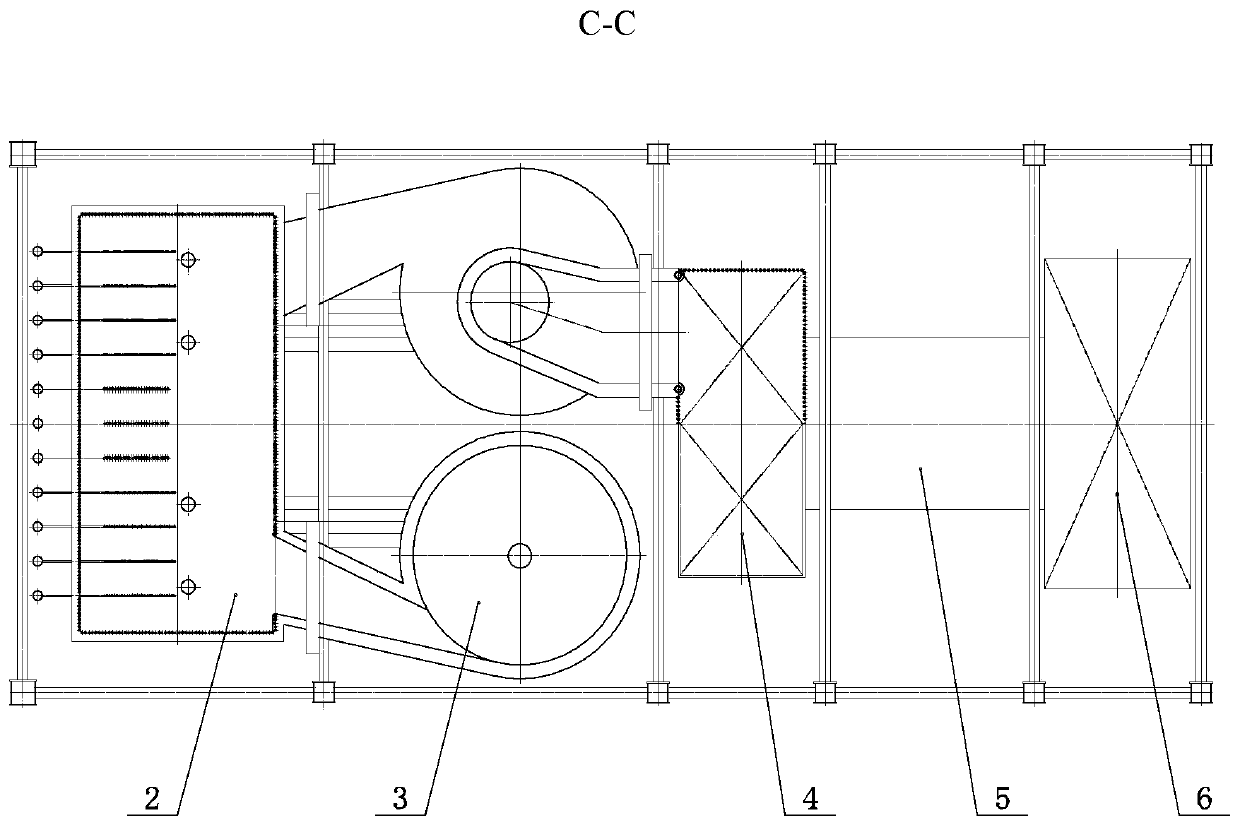

Method for performing pyrolysis and a pyrolysis apparatus

ActiveUS8500959B2Improve efficiencyCompact solutionFluidized bed combustionCombustible gas coke oven heatingProcess engineeringBubbling fluidized bed

A pyrolysis apparatus comprises a substantially closed pyrolyzer (4), a supply inlet for supplying pyrolyzable fuel to the pyrolyzer (4), an outlet for taking hot bed material in particle form out of the pyrolyzer, one or more exit outlets (6) for taking condensible gaseous substances separated from the fuel to be pyrolyzed out of the pyrolyzer, a condenser (8) for condensing the condensible gaseous substances into pyrolysis oil, and a line (7) for transferring the condensible gaseous substances from the exit outlet of the pyrolyzer (4) to the condenser (8). The means for maintaining pyrolysis conditions in the pyrolyzer (4) comprise an inlet for taking hot bed material in particle form into the pyrolyzer and means (5) for supplying fluidizing gas to the pyrolyzer.The pyrolyzer (4) is a chamber bounded directly by a furnace (1) of a bubbling fluidized bed boiler, through which chamber fluidized bed material is arranged to be circulated between the inlet and the outlet. Means (5) for supplying fluidizing gas are divided over an area between the inlet (11) and the outlet (12) in the pyrolyzer (4) so that they create a cross-flow of fluidizing gas in relation to the transfer direction (S) of the bed material and fuel.

Owner:METSO POWER OY

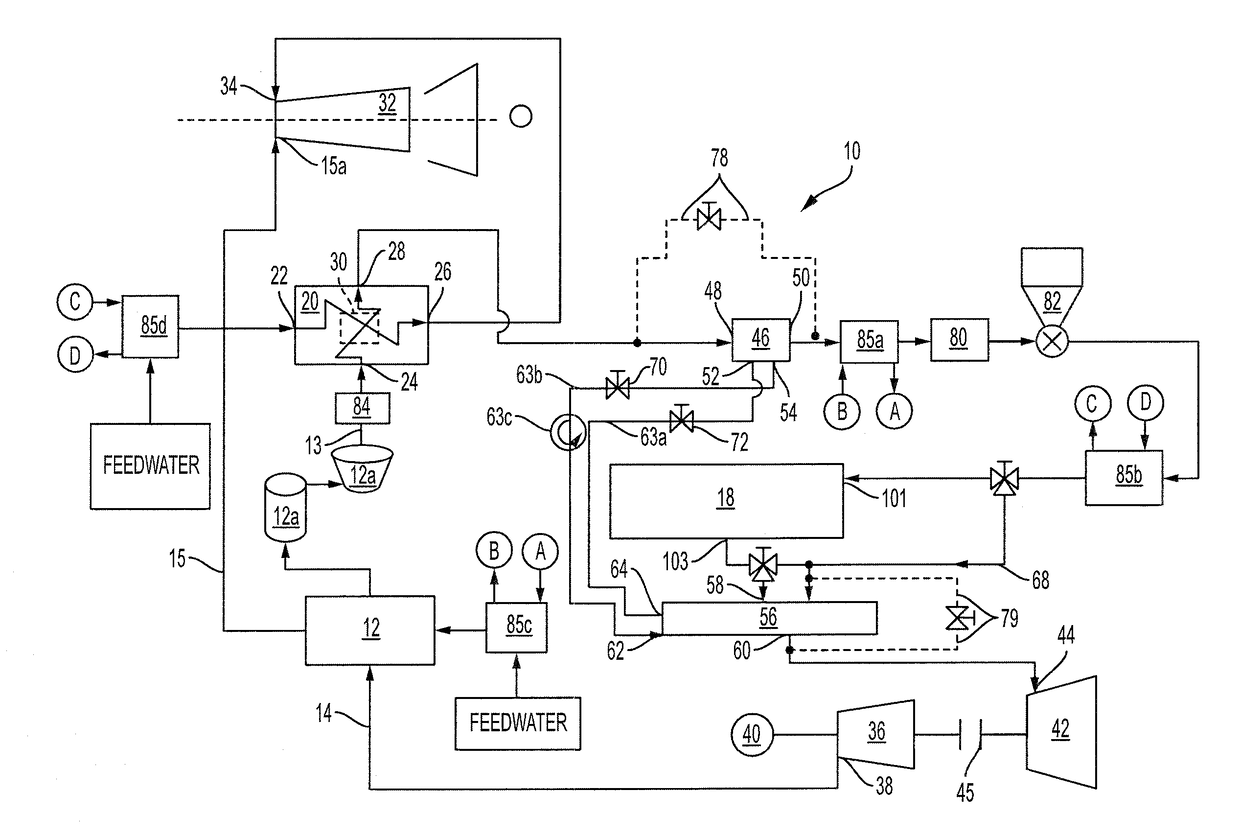

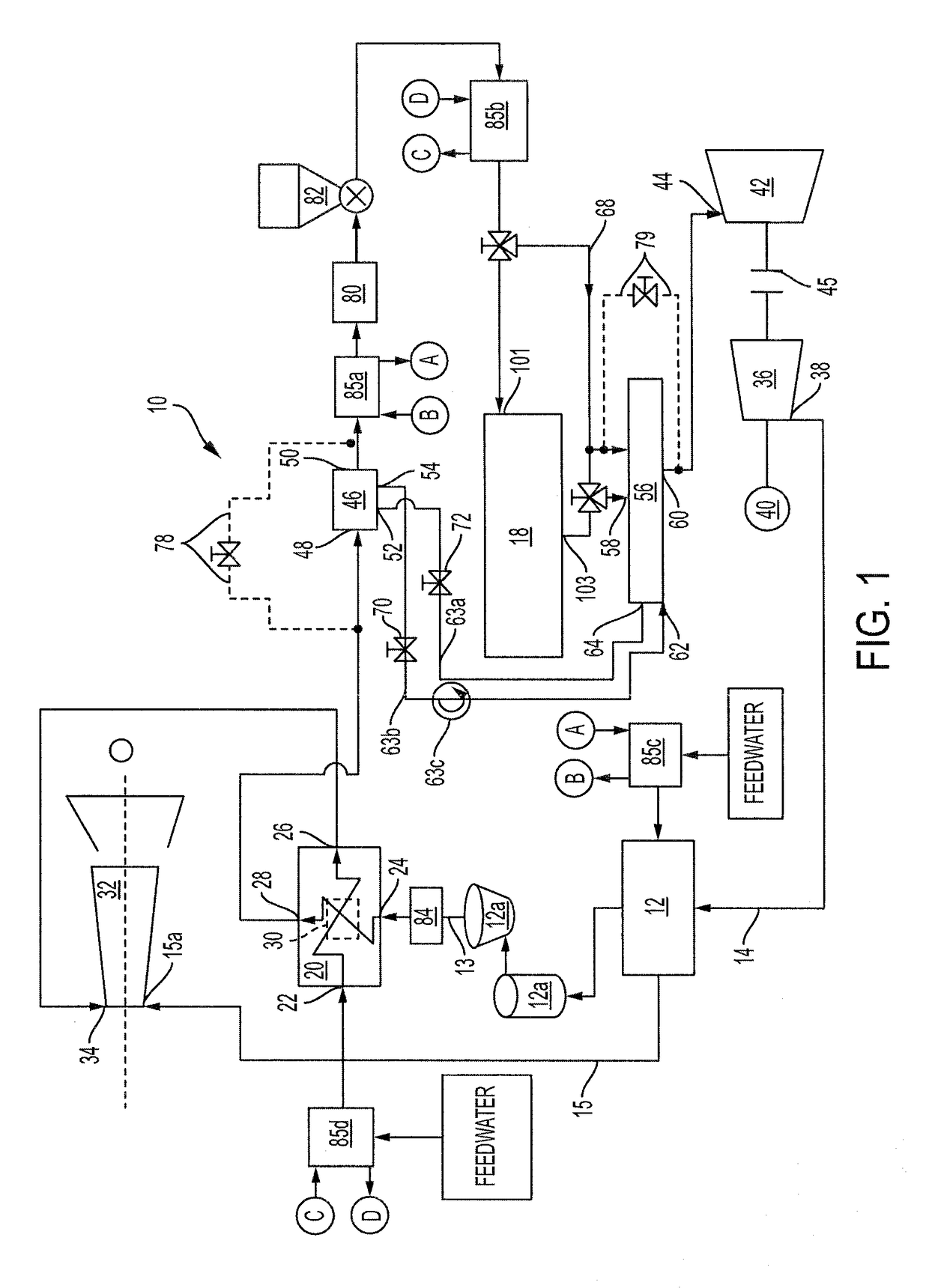

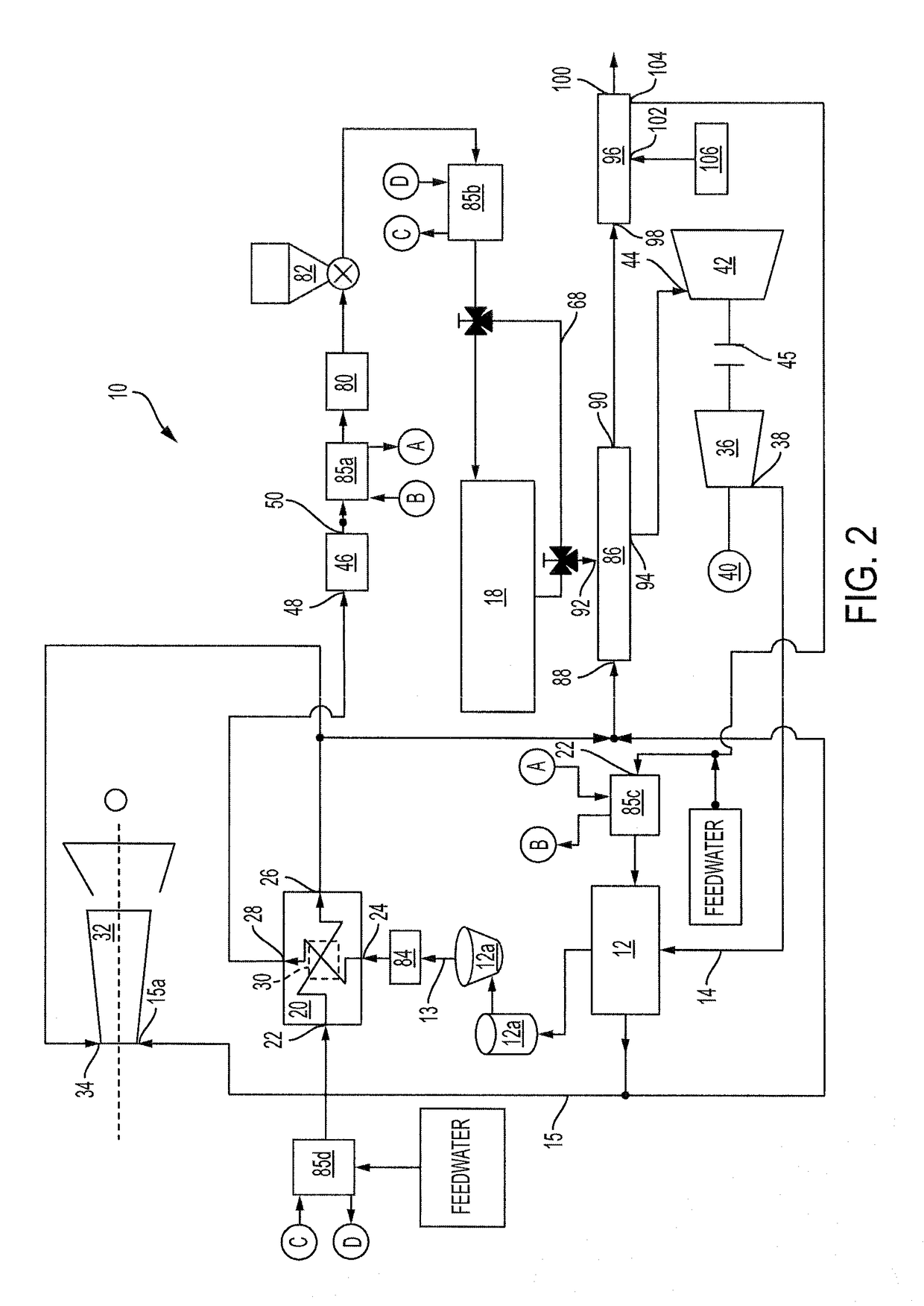

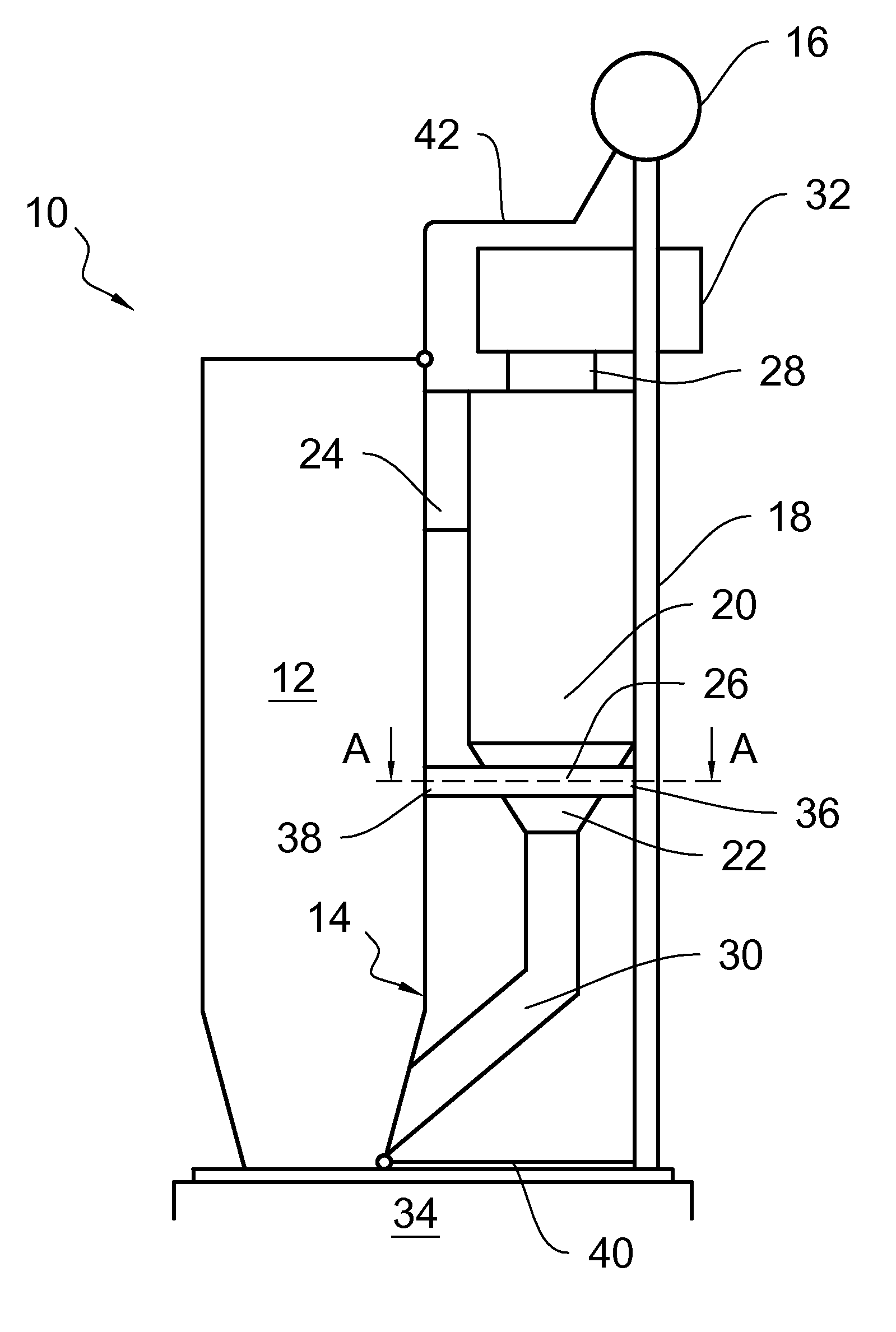

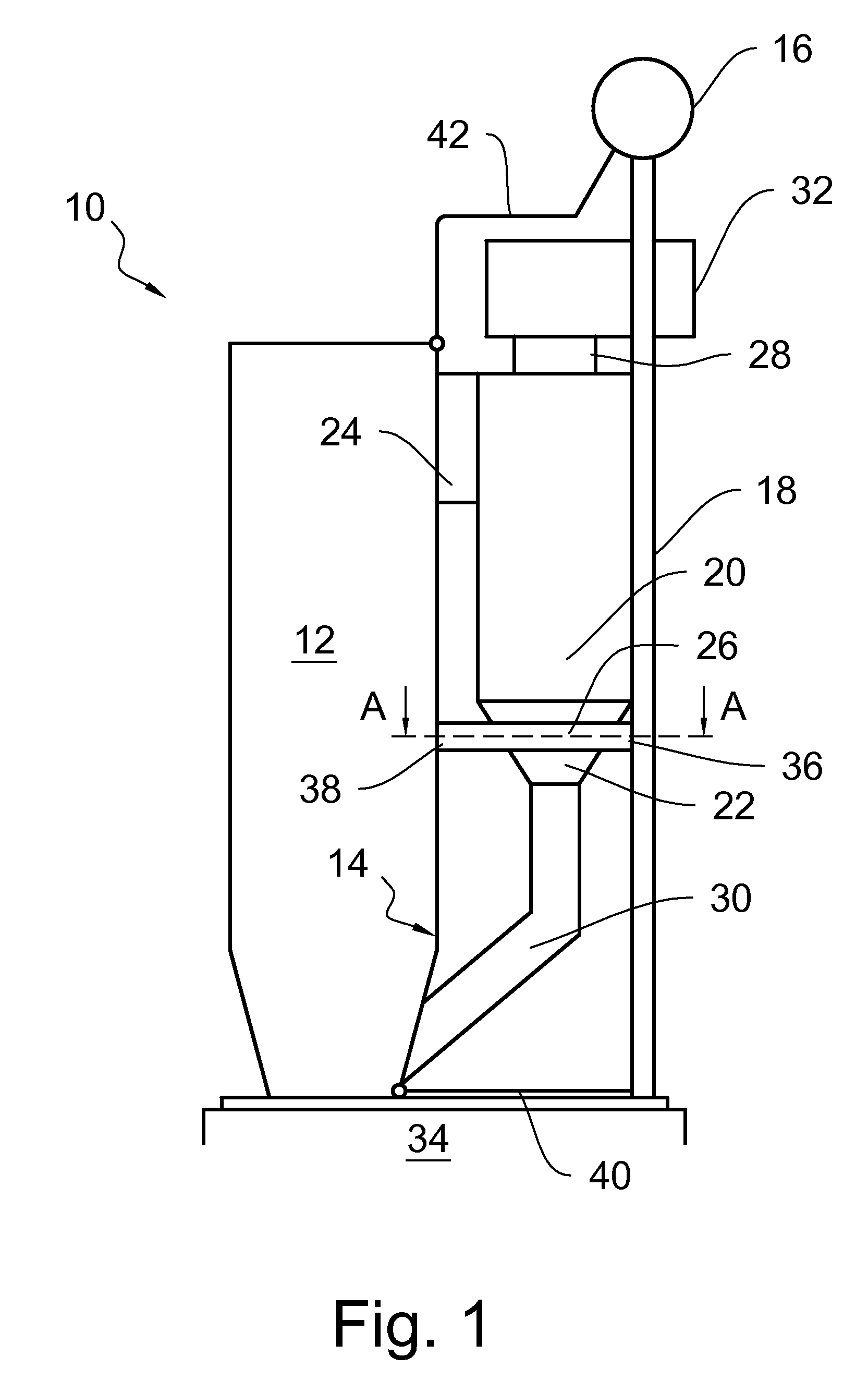

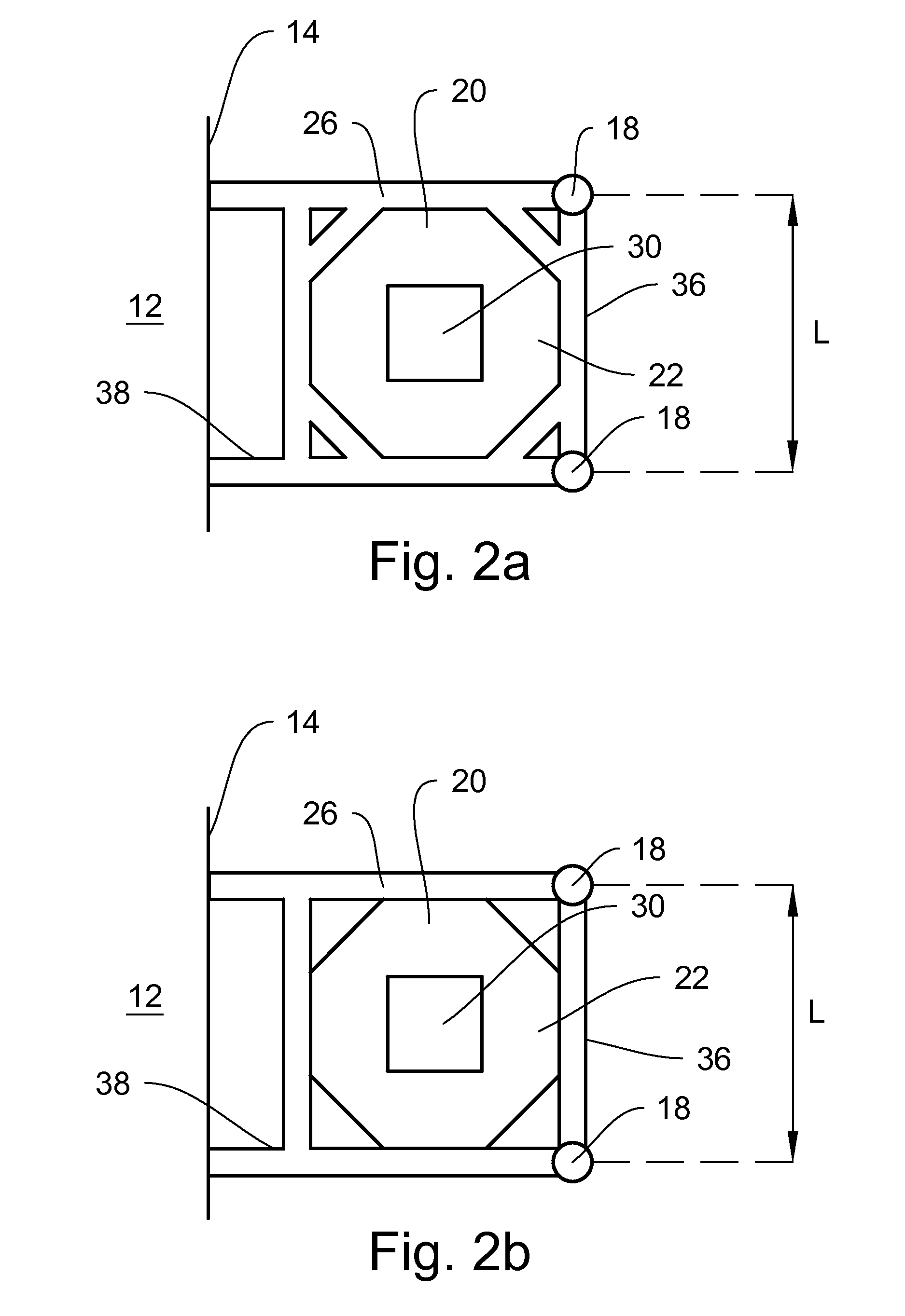

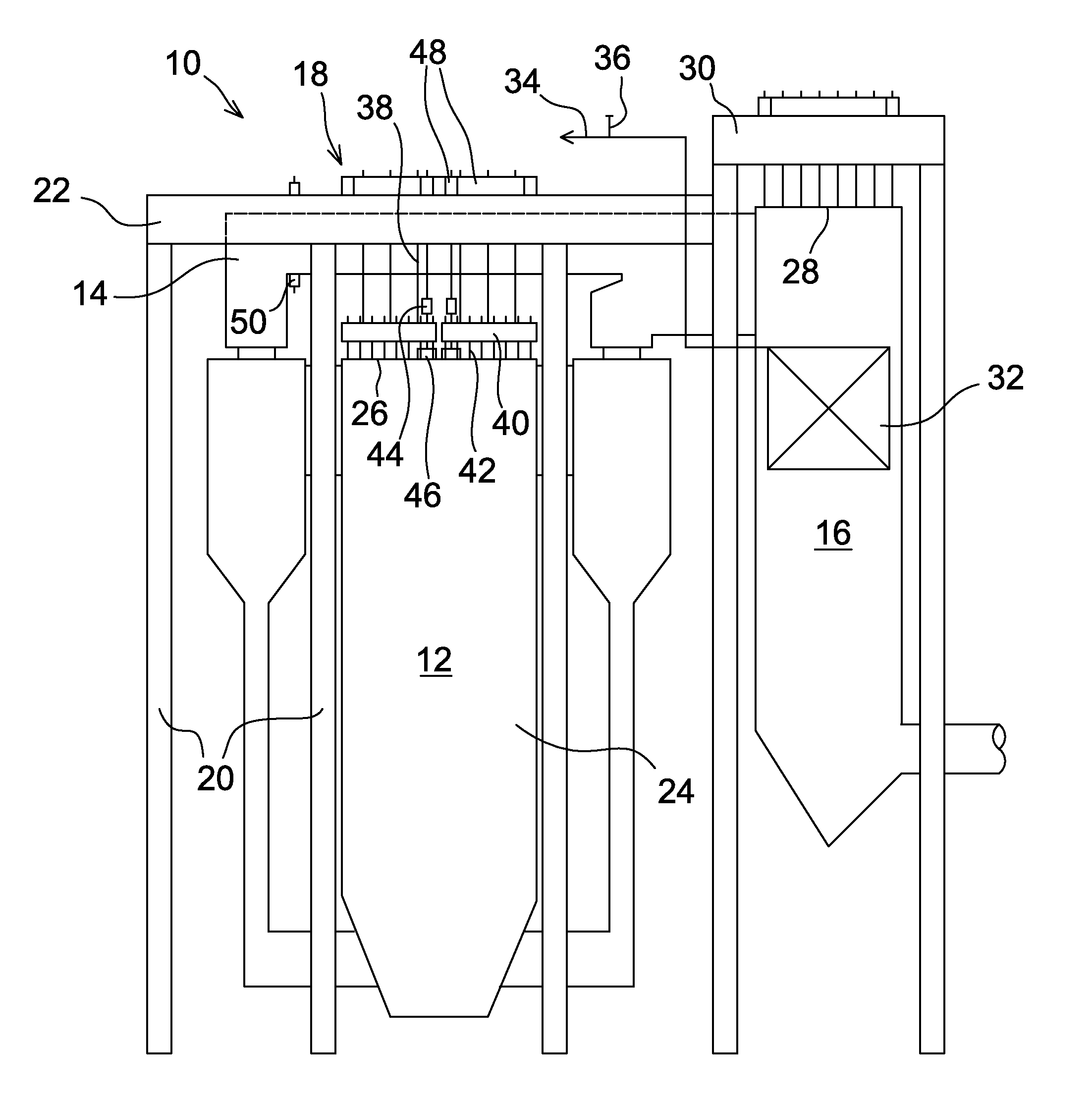

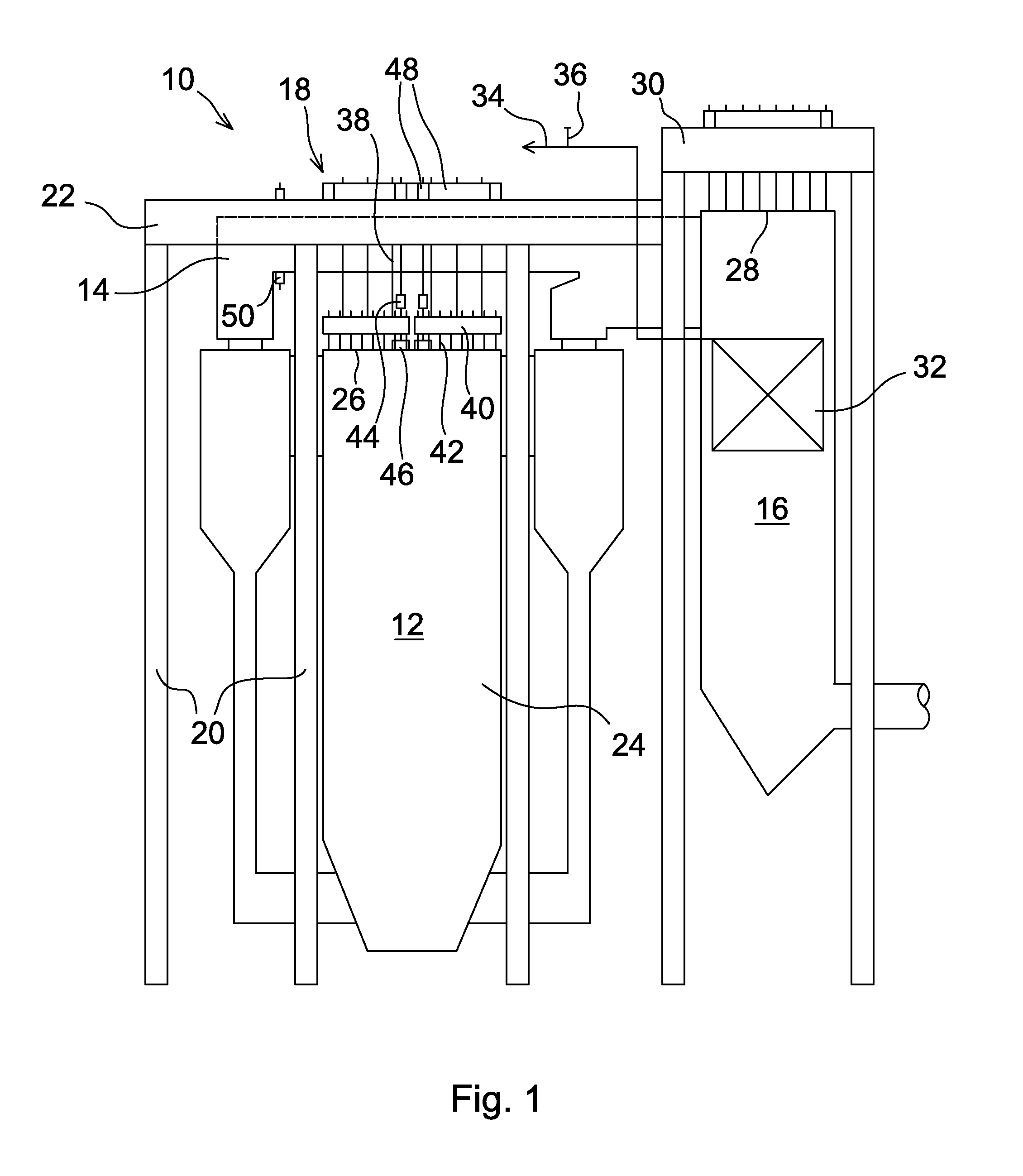

Carbon dioxide capture interface for power generation facilities

ActiveUS20170159502A1Increase temperatureInhibition formationFluidized bed combustionEmission preventionEngineeringAir emission

In a power generation facility (10) wherein a fluidized bed combustion unit (12) produces steam to power a steam turbine generator (32), a heat recovery steam generator (20) produces steam for the steam turbine generator. Electrical power from the steam turbine generator is conducted to a motor (40) that drives and air compressor (36). The air compressor provides pressurized air back to the fluidized bed combustion unit (12) to promote fuel combustion. Flue gas from the heat recovery steam generator is selectively conducted to a CO2 capture unit (18) and then to a gas expander (42) that assists the motor in driving the air compressor (36). A heat exchanger (46) that is upstream of the CO2 Capture Unit and a heat exchanger (56) that is downstream of the CO2 Capture Unit and upstream of the air expander have thermal fluid sides that are connected in a closed circuit. The heat exchangers (46 and 56) convey heat away from the CO2 Capture Unit and provide heat to flue gas flowing to the gas expander to avoid icing conditions in the gas expander and acid condensation in the air emission stack.

Owner:POLVI ESKO OLAVI

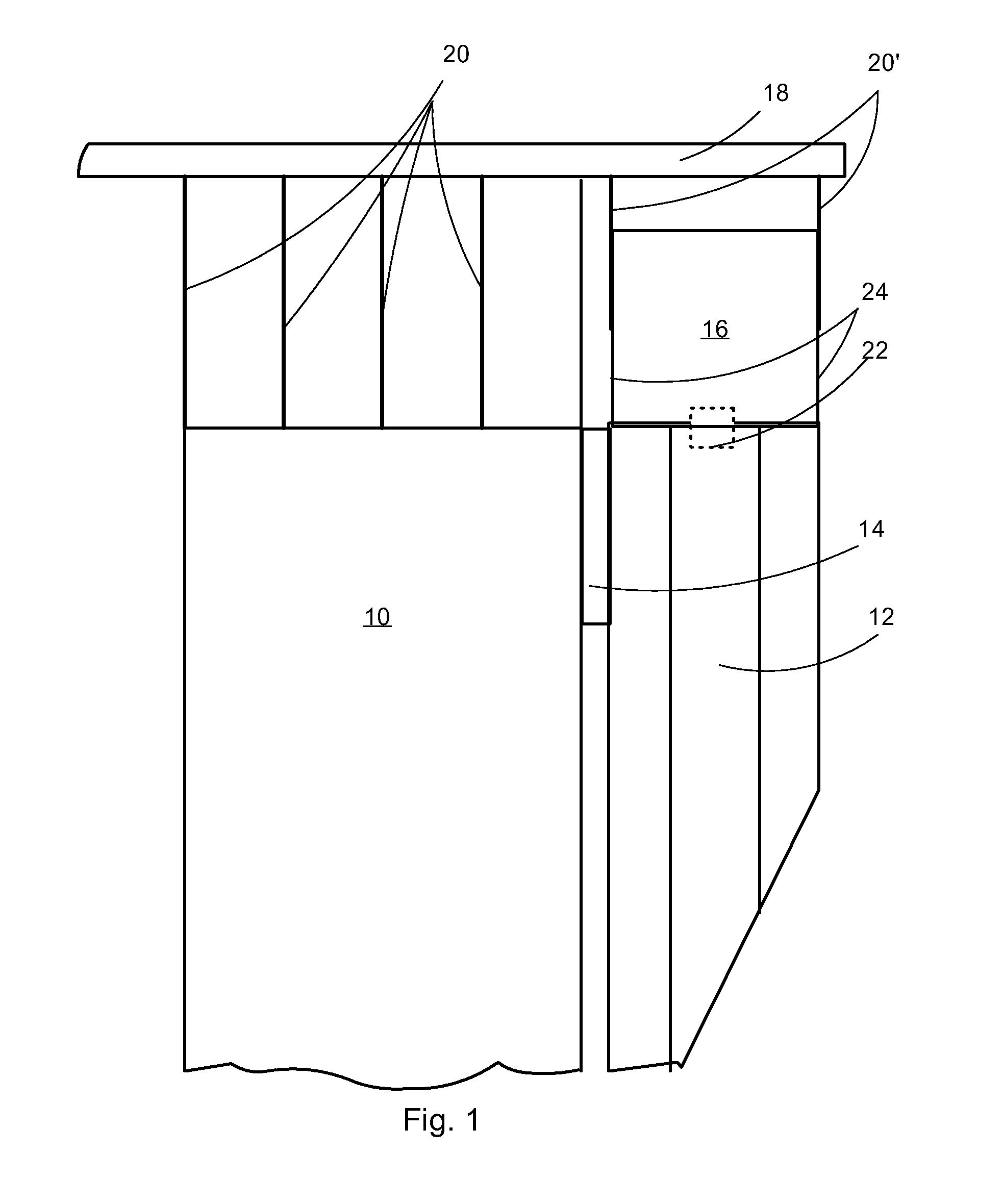

Fluidized bed boiler with a support construction for a particle separator

ActiveUS20160123574A1Stable support systemMinimize impactFluidized bed combustionBoiler supporting/setting arrangementsFluidized bedEngineering

A fluidized bed boiler with a support construction for a particle separator. The fluidized bed boiler includes a bottom-supported furnace in which at least one particle separator with a support construction is in gas flow connection with an upper portion of the furnace and includes a furnace side portion, an outer portion opposite to the furnace side portion, and a conical lower portion. At least two bottom-supported downcomer pipes are in fluid connection with a steam drum and adjacent to the outer portion of the particle separator. The support construction includes a frame-like supporting member surrounding at least a portion of the conical lower portion, and an outboard portion of the supporting member is attached to the at least two downcomer pipes to support the at last one particle separator.

Owner:SUMITOMO SHI FW ENERGIA OY

Thermal Power Plant

ActiveUS20120079996A1Minimize thermal expansionStress minimizationFluidized bed combustionBoiler supporting/setting arrangementsFlue gasEngineering

A thermal power boiler includes a furnace enclosed by two short side walls and two long side walls, flue gas channels arranged above the furnace, a back pass and a supporting structure. The supporting structure includes a stationary bearing structure supported from below. The bearing structure includes multiple vertical pillars and a parallel main supporting beams supported by the vertical pillars, and a suspension structure, so that the furnace hangs from the bearing structure. The main supporting beams and the flue gas channels arranged above the furnace are parallel with each other and parallel with the short side walls. The main supporting beams are preferably arranged at least partially between the flue gas channels extending over the roof of the furnace.

Owner:AMEC FOSTER WHEELER ENERGIA

Supercritical carbon dioxide circulating fluidized bed coal fired boiler and power generation system driven by same

ActiveCN107906498AIncrease energy densitySmall initial economic investmentSteam engine plantsSteam superheatersEngineeringEconomizer

The invention discloses a supercritical carbon dioxide circulating fluidized bed coal fired boiler. Supercritical carbon dioxide is adopted to replace steam in an existing circulating fluidized bed boiler to serve as a working medium for absorbing heat and acting, and the heat absorption process of the working medium comprises the steps of one-time flow division and one-time re-heating. The heating face of the working medium of the supercritical carbon dioxide circulating fluidized bed boiler comprises a carbon dioxide cold wall screen type heater and a high temperature reheater which are arranged in a hearth. An externally arranged a superior economizer treating dust as a heat source is arranged on a material recycling device section between an outlet of a separator and the hearth in parallel. A heating face in a rear smoke channel in the flowing direction of smoke comprises a low temperature reheater and a subordinate economizer. The invention further discloses a power generation system driven by the supercritical carbon dioxide circulating fluidized bed coal fired boiler to generate power. The supercritical carbon dioxide circulating fluidized bed coal fired boiler enhances smoke heat transmission of a high temperature section of the reheater, and meanwhile relieves heat demanded pressure of the rear smoke channel, the emission amount of pollutants can be effectively reduced, the smoke emission temperature can be effectively decreased, and the boiler efficiency is improved.

Owner:SOUTHEAST UNIV

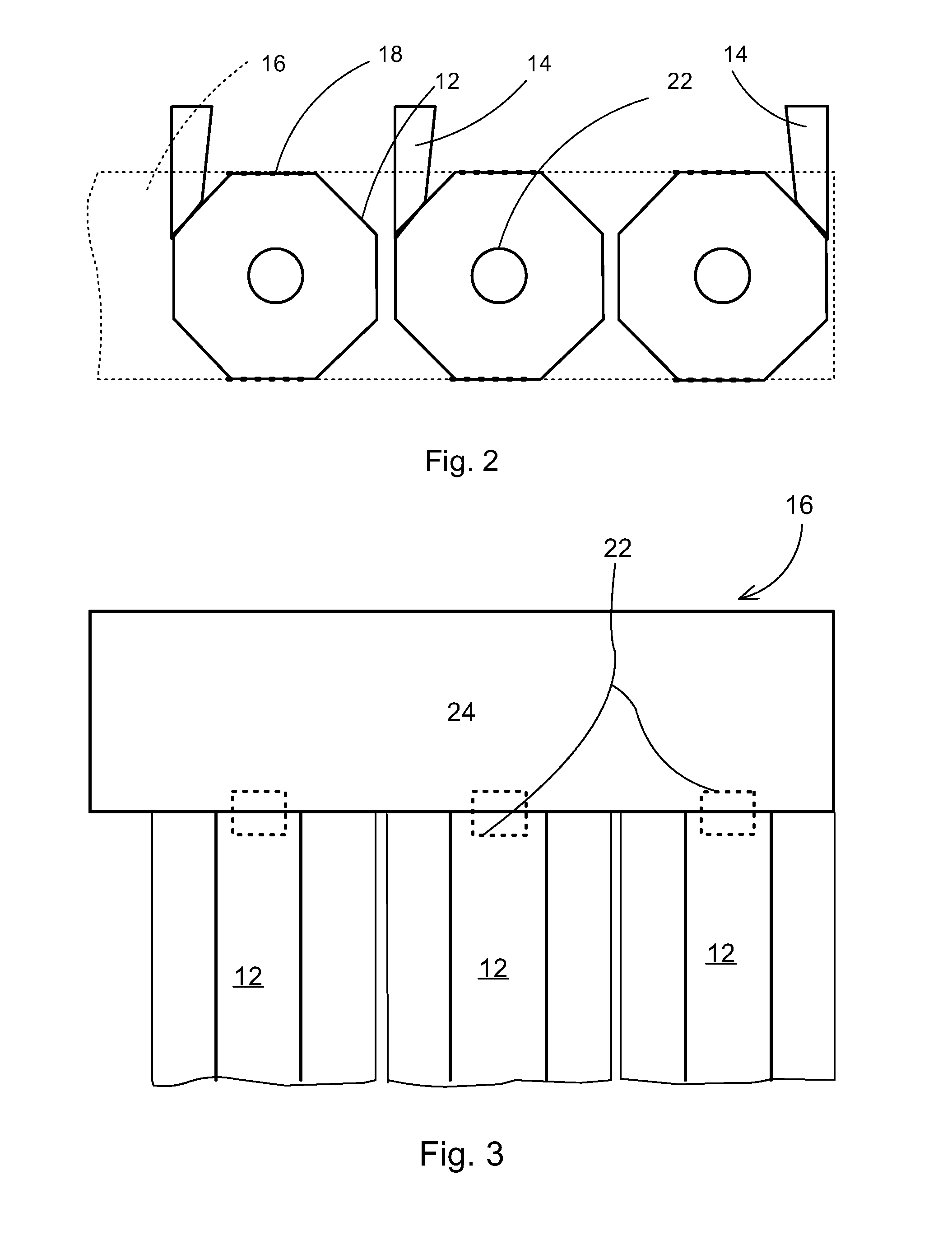

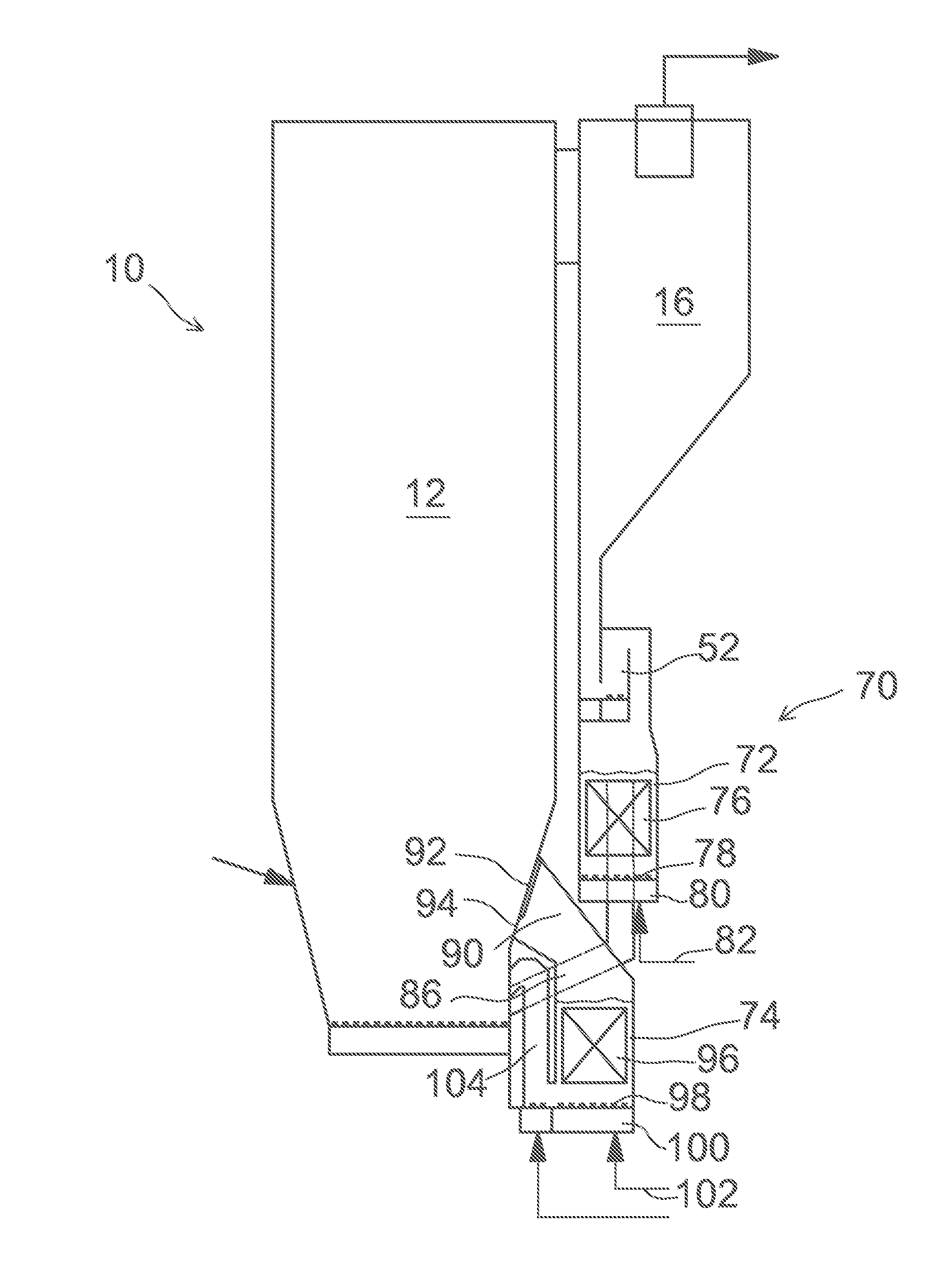

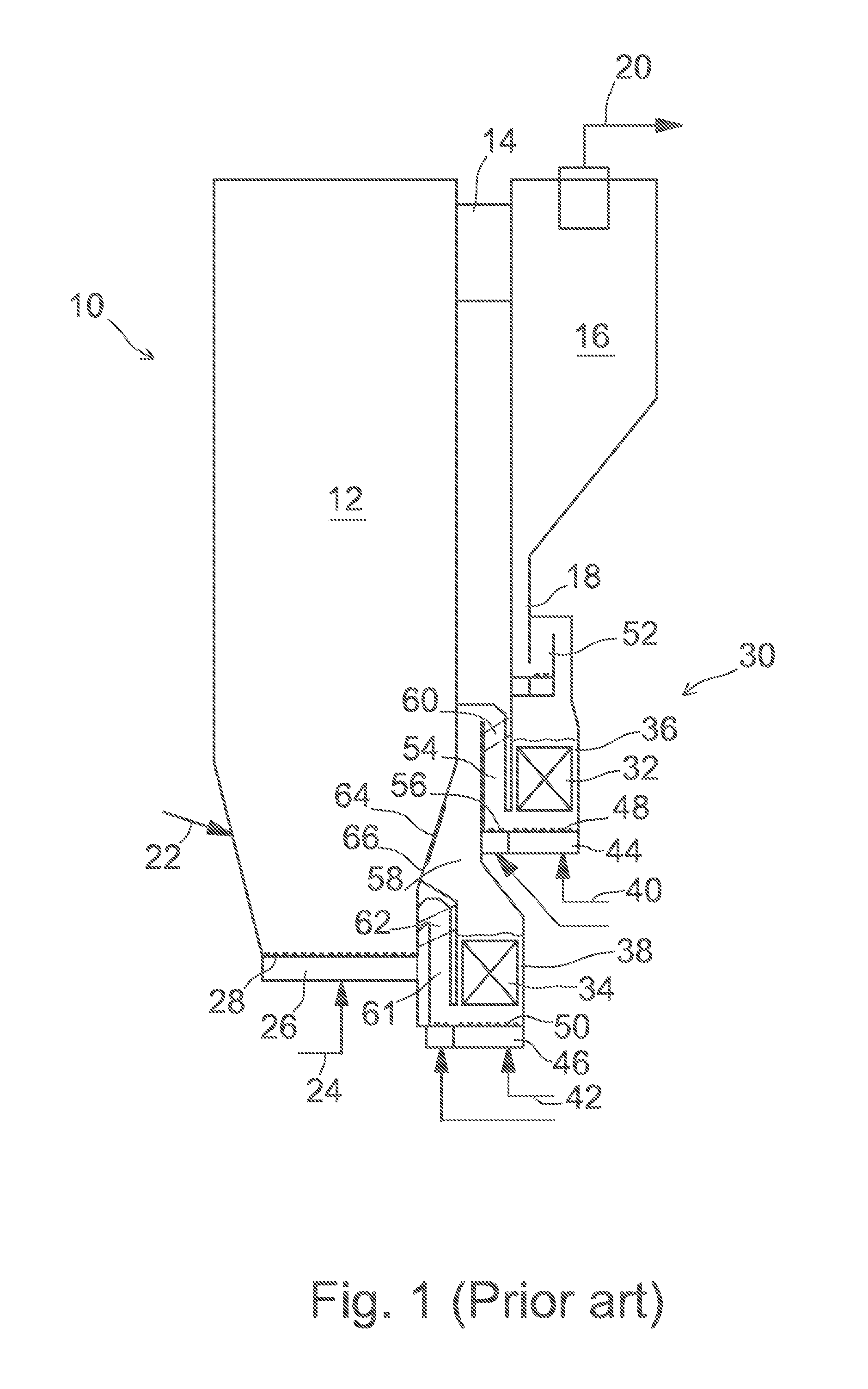

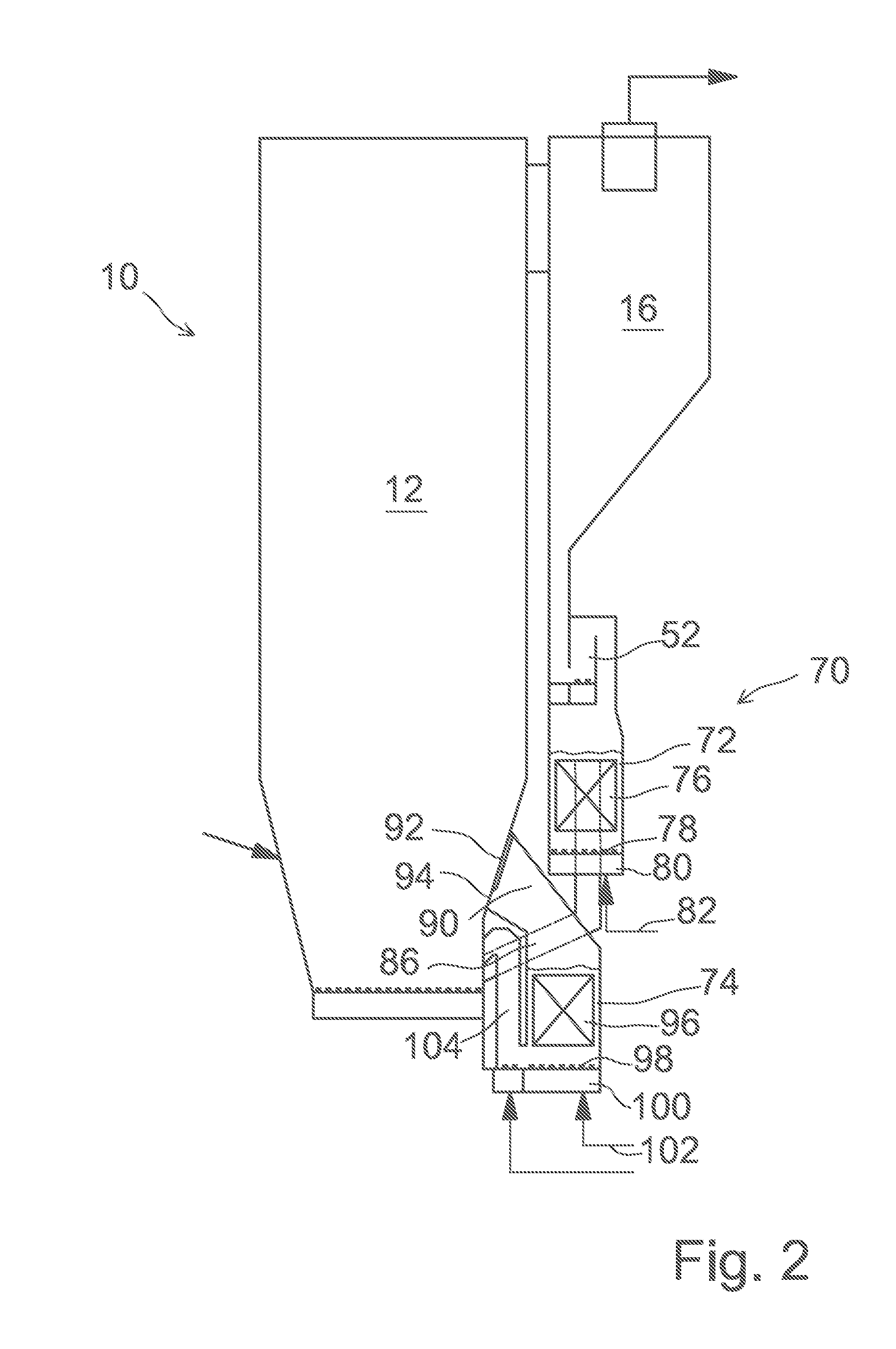

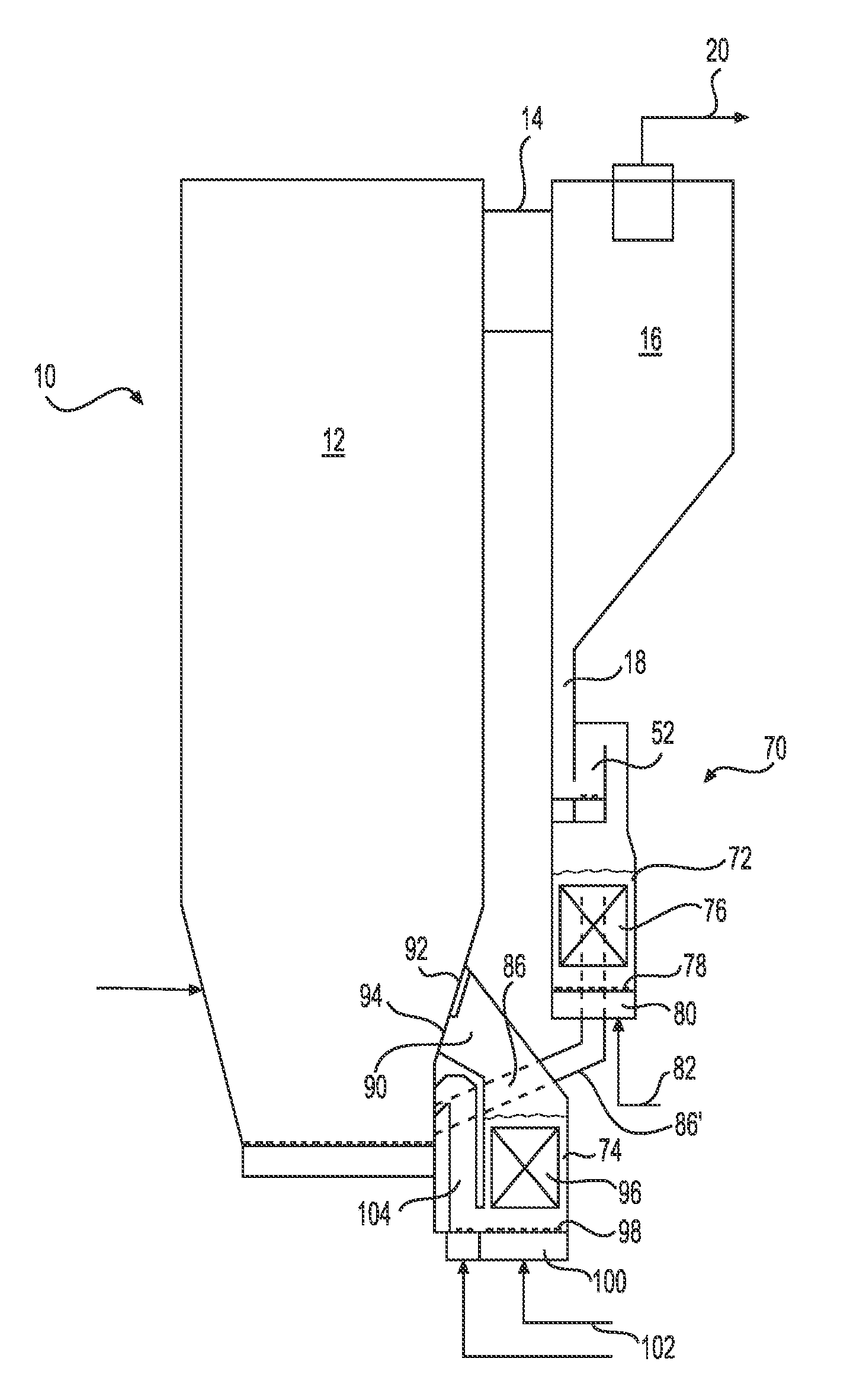

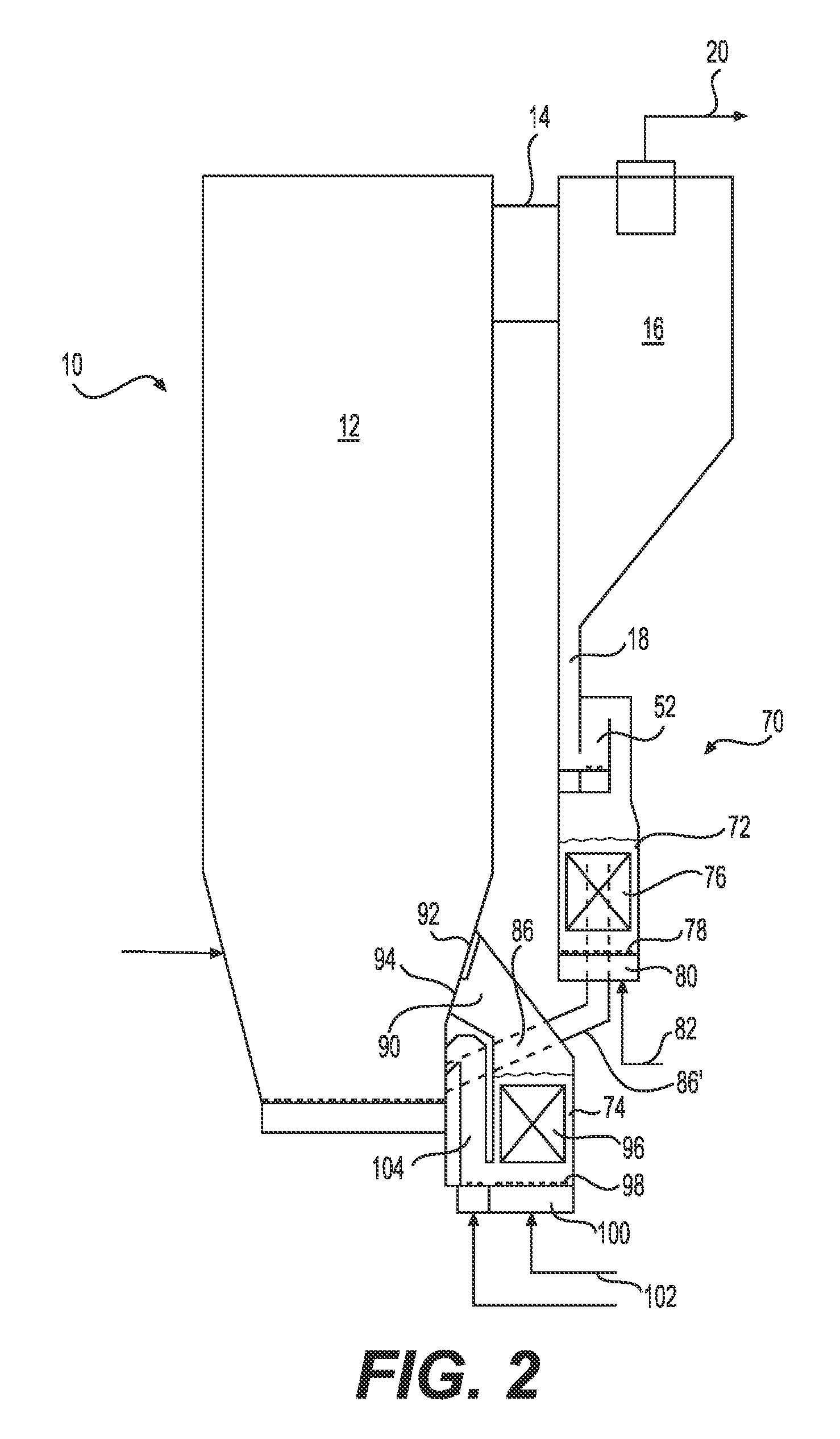

Circulating Fluidized Bed Boiler Having Two External Heat Exchangers for Hot Solids Flow

ActiveUS20130284120A1Minimizes problemConvenient ArrangementFluidized bed combustionFurnace componentsInlet channelFluidized bed

A circulating fluidized bed boiler including a furnace for combusting solid carbonaceous fuel in a fast fluidized bed, the furnace having walls made of water / steam tube panels and used for evaporating water fed therein. A solids separator arranged adjacent to a sidewall of the furnace separates solids entrained with exhaust gas discharged via an outlet channel from an upper portion of the furnace. A gas seal conveys at least a portion of the separated solids to a first fluidized bed heat exchange changer arranged downstream of the gas seal and has internal heat exchange surfaces. A first lift channel has a lower end connected to a bottom portion of the first fluidized bed heat exchanger chamber and an upper end connected to an upper end of a first return channel for discharging solids from the first fluidized bed heat exchange chamber and for taking the cooled solids to a lower portion of the furnace. A second fluidized bed heat exchange chamber is arranged adjacent to a lower sidewall of the furnace and has internal heat exchange surfaces, an inlet channel arranged between the second fluidized bed heat exchange chamber and the furnace for introducing hot solids from the furnace to the second heat exchange chamber, a second lilt channel having a lower end connected to a bottom portion of the second fluidized bed heat exchange chamber and an upper end connected to discharge the solids to the lower portion of the furnace. The first fluidized bed heat exchanger chamber is positioned above the second.

Owner:AMEC FOSTER WHEELER ENERGIA

Circulating fluidized bed boiler having two external heat exchangers for hot solids flow

ActiveUS9423122B2Convenient ArrangementMany alternativesFluidized bed combustionFurnace componentsFluidized bedProcess engineering

A circulating fluidized bed boiler includes a furnace for combusting solid carbonaceous fuel in a fast fluidized bed. A solids separator is adjacent to a sidewall of the furnace and separates solids entrained with exhaust gas discharged via an outlet channel. A gas seal conveys at least a portion of the separated solids to a first fluidized bed heat exchange chamber that is arranged downstream of the gas seal and has internal heat exchange surfaces. A first lift channel has a lower end connected to a bottom portion of the first fluidized bed heat exchange chamber and an upper end connected to an upper end of a first return channel for discharging solids from the first fluidized bed heat exchange chamber and taking the cooled solids to a lower portion of the furnace. A second fluidized bed heat exchange chamber is arranged adjacent to a lower sidewall of the furnace.

Owner:AMEC FOSTER WHEELER ENERGIA

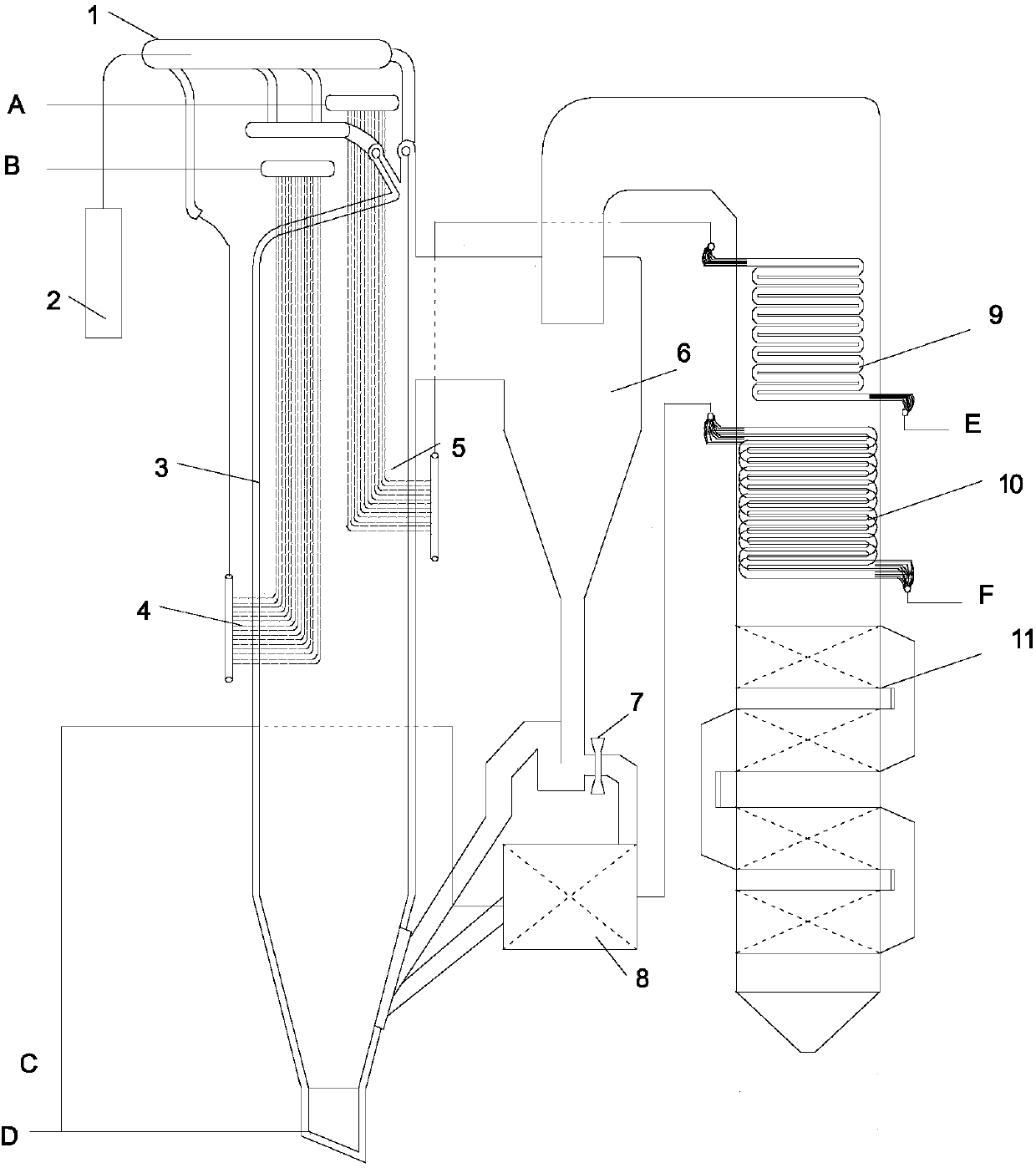

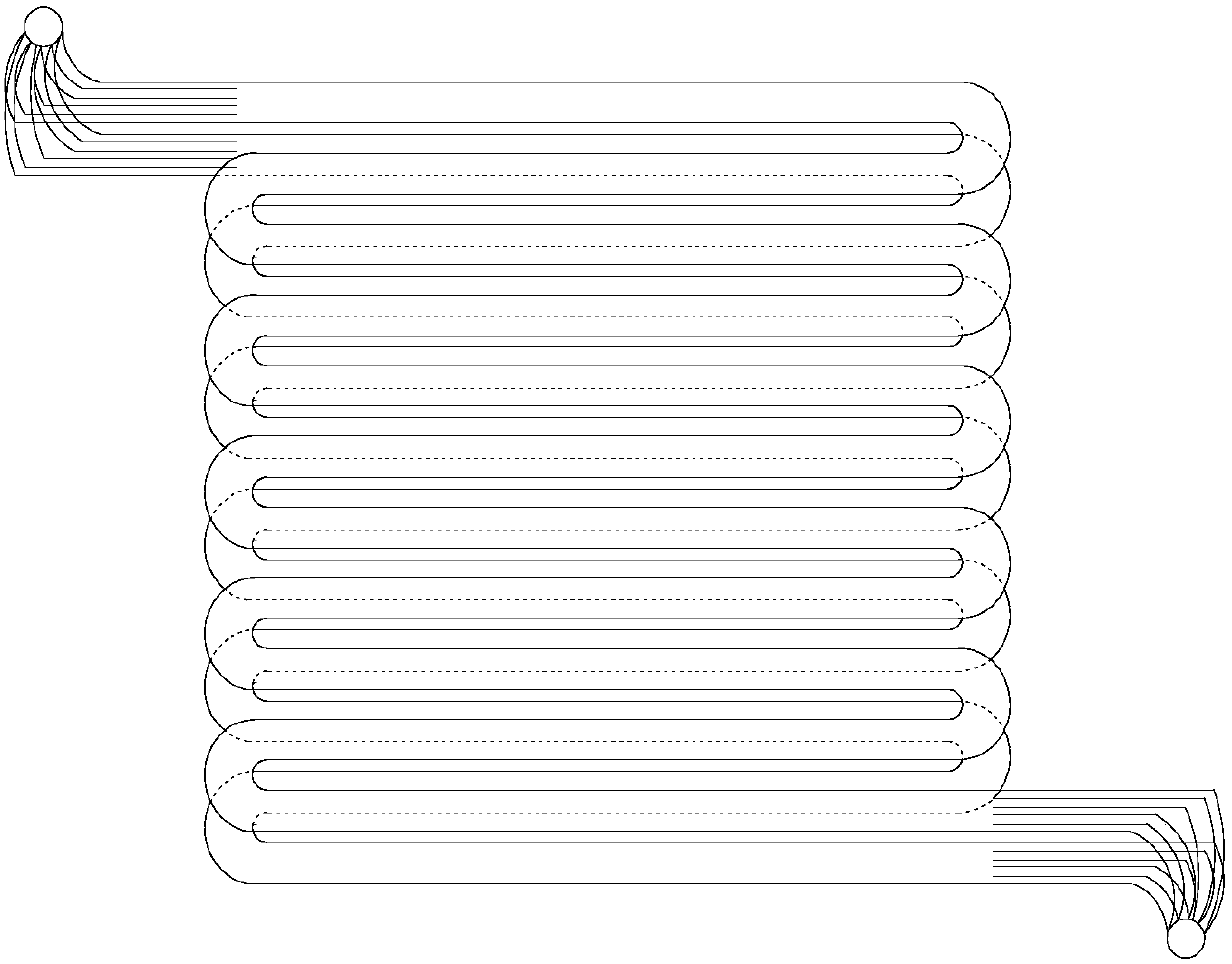

Supercritical carbon dioxide boiler heating system and heating method

ActiveCN107101187AAvoid Overheating ProblemsSolve the lack of layout spaceIndirect carbon-dioxide mitigationSteam superheatersFlue gasEngineering

The invention discloses a supercritical carbon dioxide boiler heating system and a heating method. The supercritical carbon dioxide boiler heating system comprises a boiler, a spiral tube coil superheater, a separator, an external heat exchanger, an external reheater, a flue, a convection superheater and a convection reheater. The spiral tube coil superheater is installed inside a hearth of the boiler and is of a spiral tube coil structure, and a spiral tube coil provides a supercritical carbon dioxide circulating channel. The external reheater is installed inside the external heat exchanger. The convection superheater and the convection reheater are installed inside the flue. The upper end of the hearth communicates with an inlet of the separator. A flue gas outlet of the separator communicates with one end of the flue. A solid particle outlet of the separator communicates with an inlet of the external heat exchanger, and an outlet of the external heat exchanger communicates with the hearth of the boiler. The spiral tube coil superheater and the convection superheater are arranged in parallel. The external reheater and the convection reheater are arranged in parallel.

Owner:SHANDONG UNIV

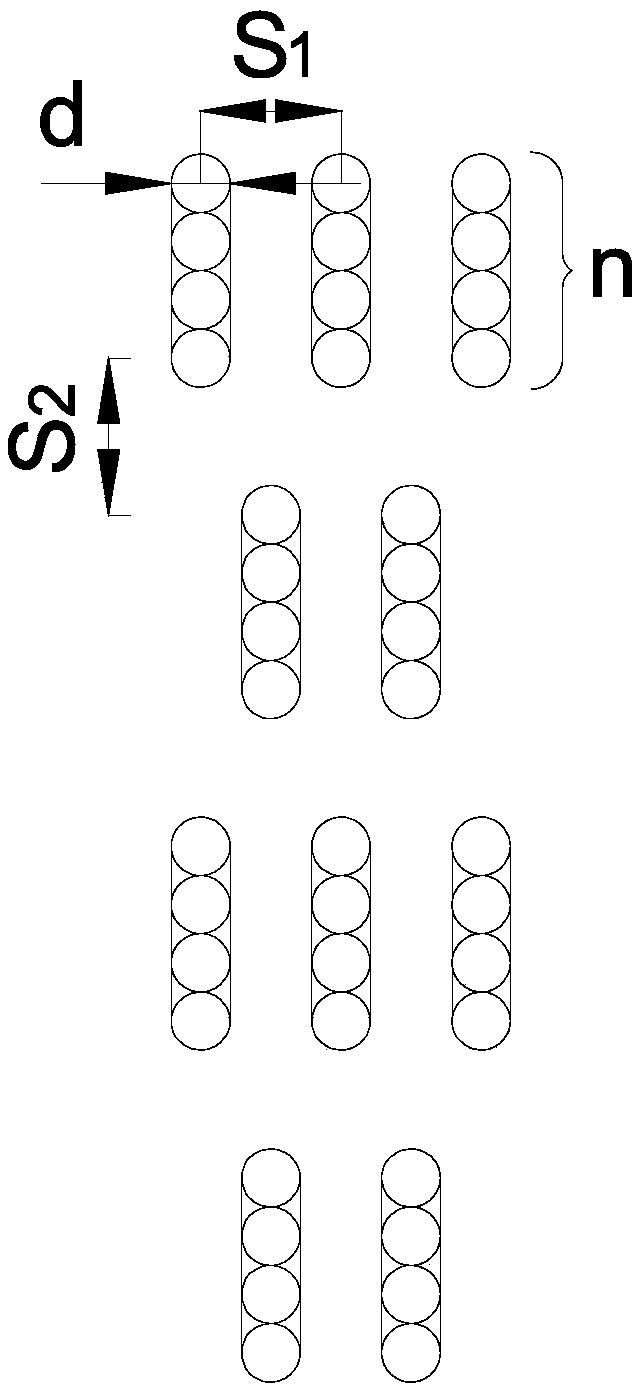

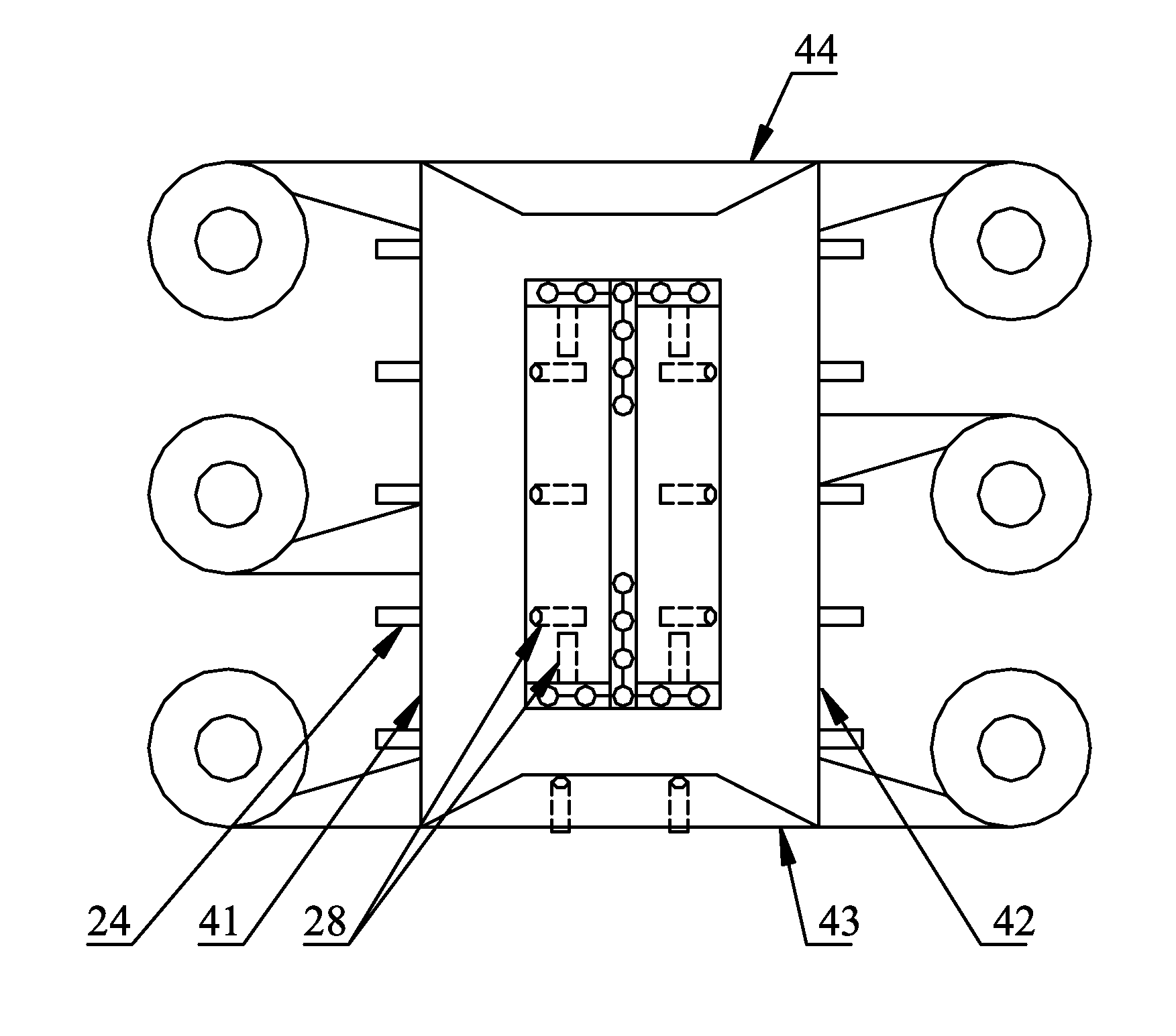

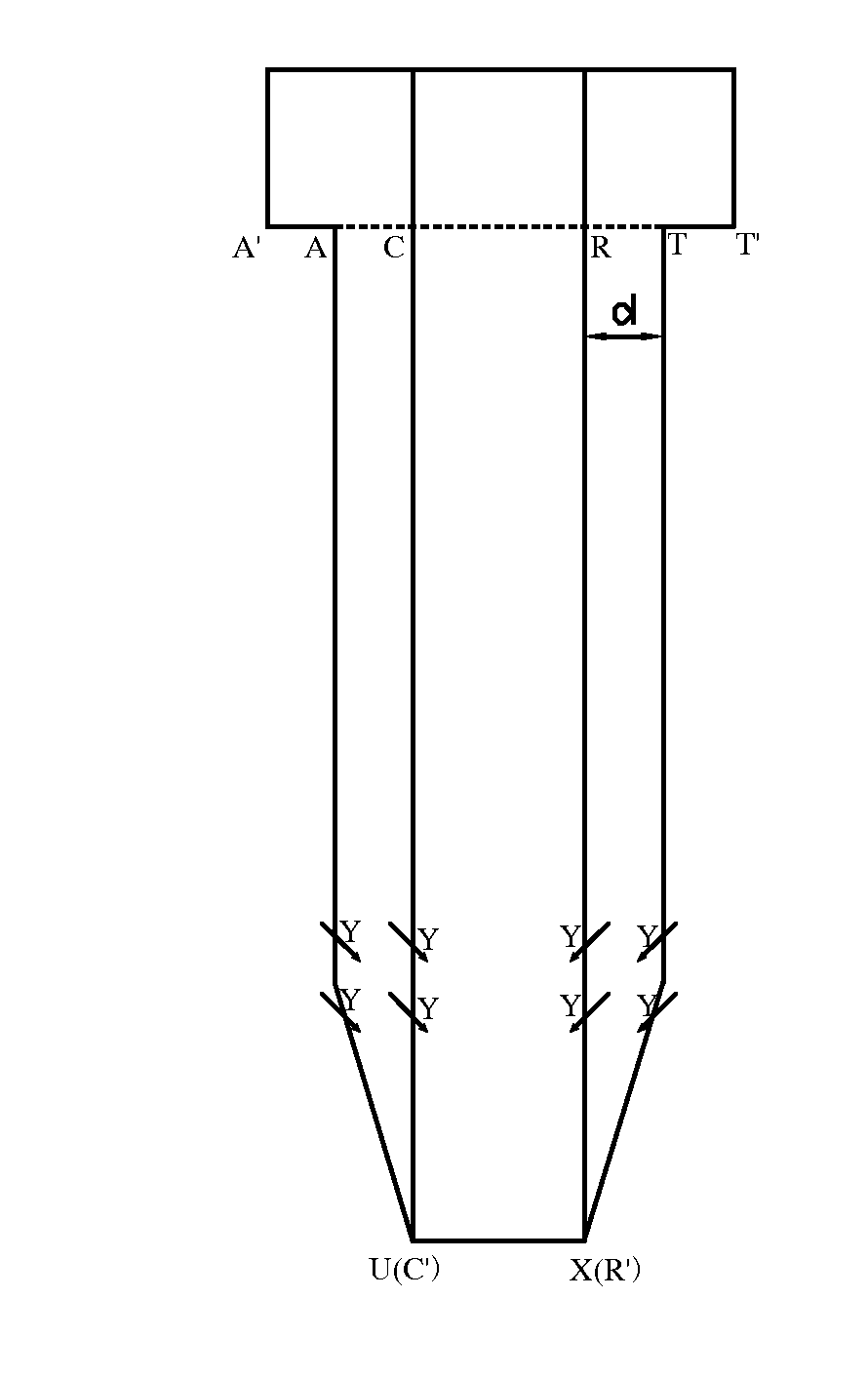

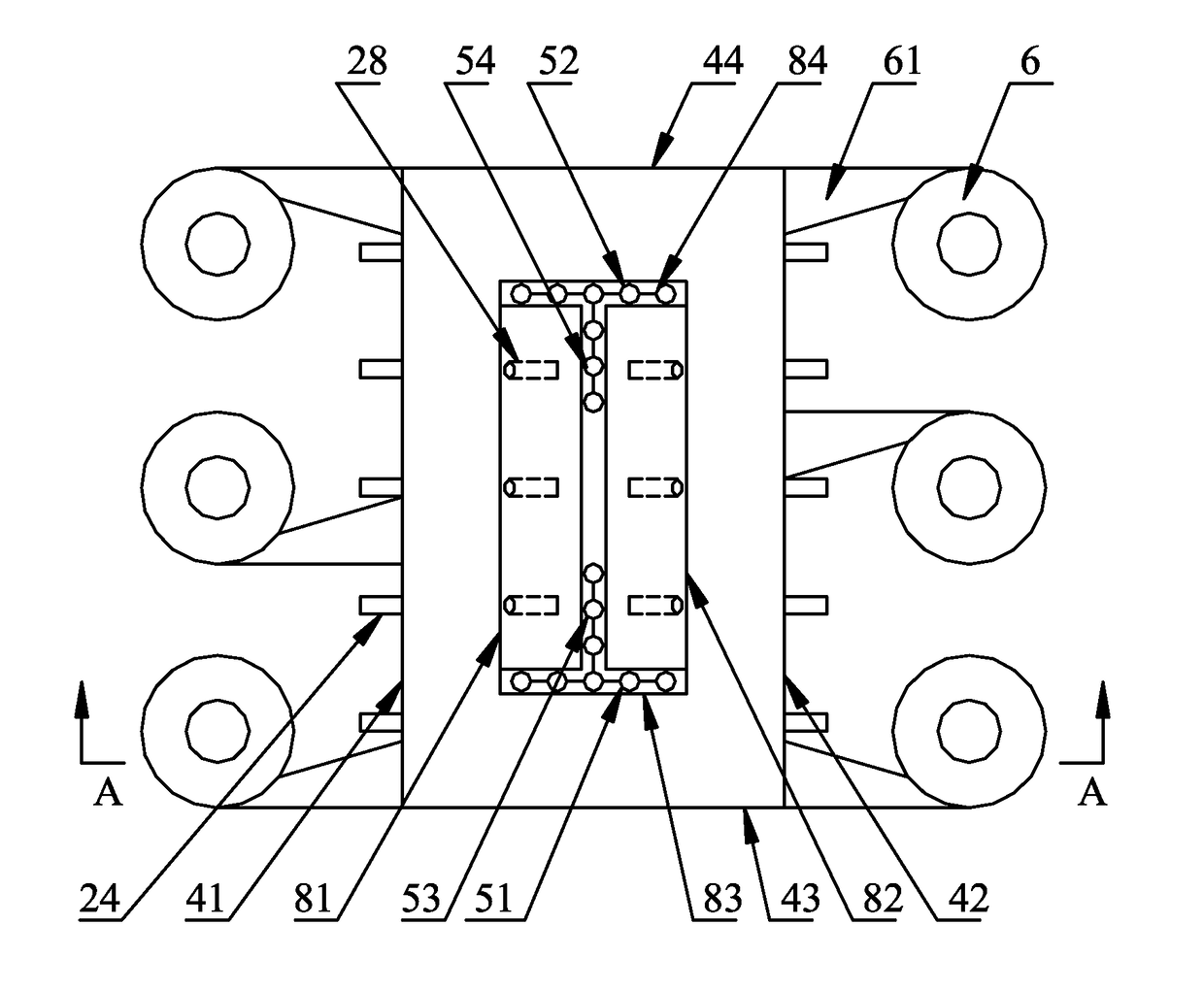

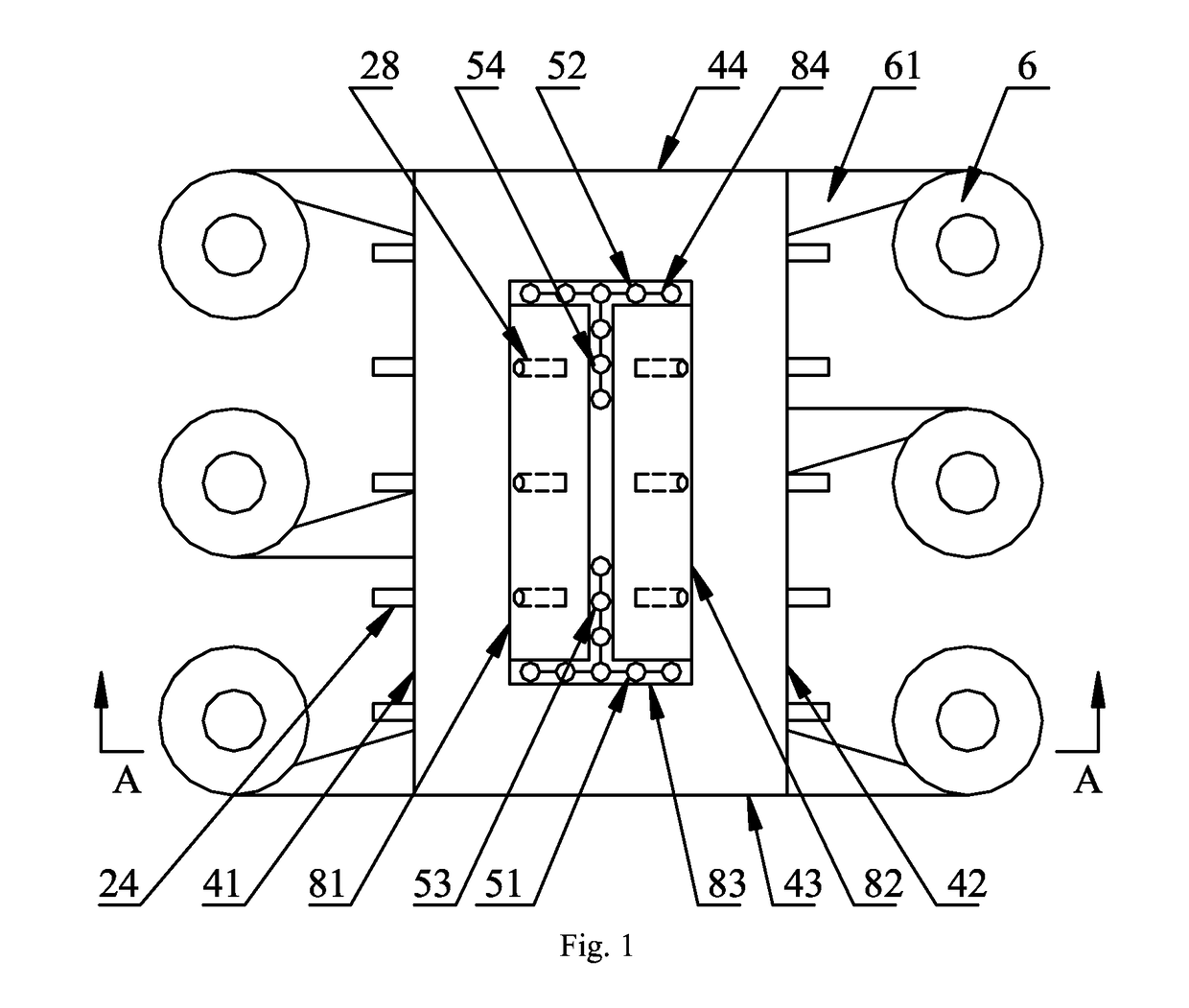

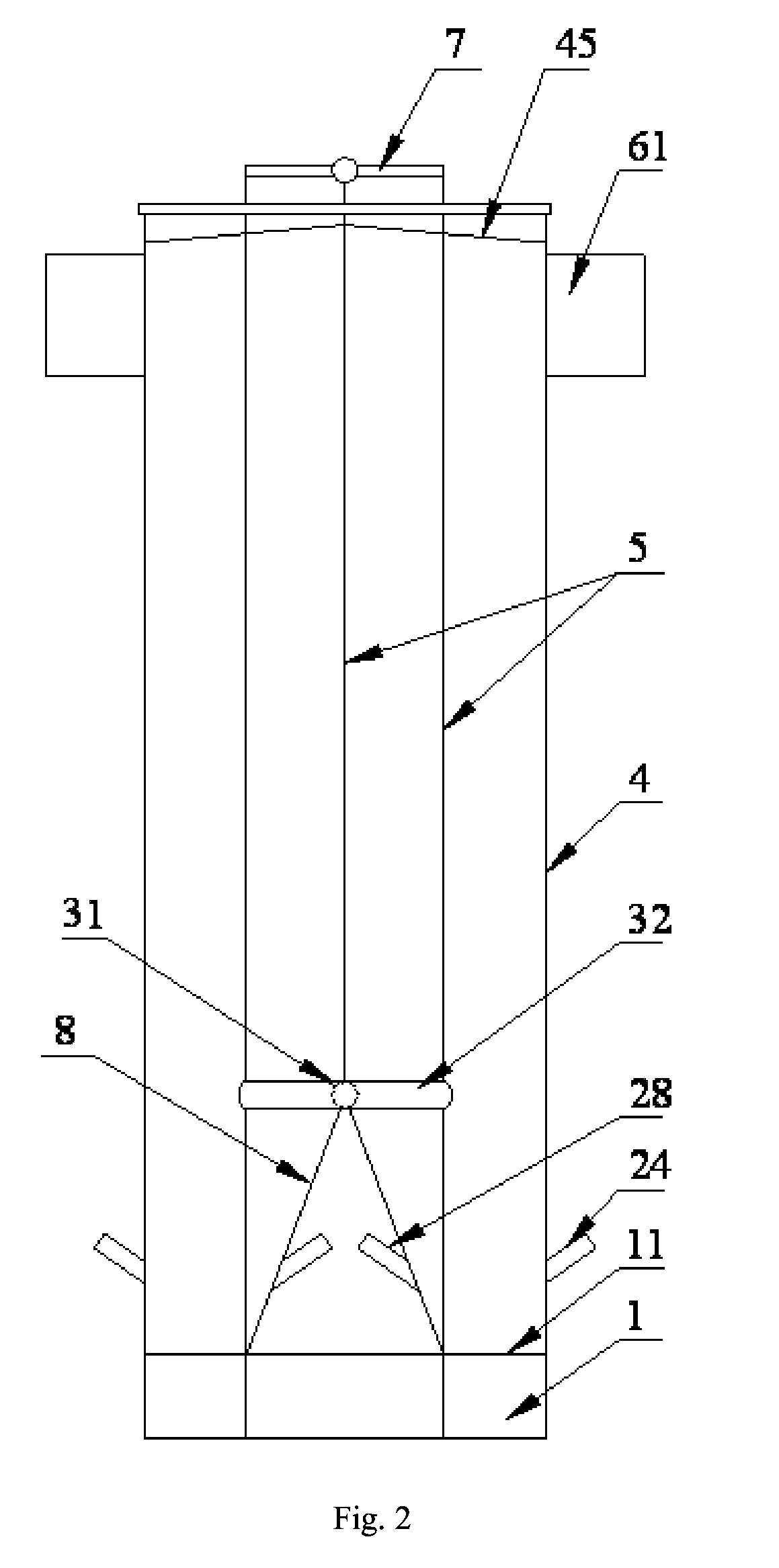

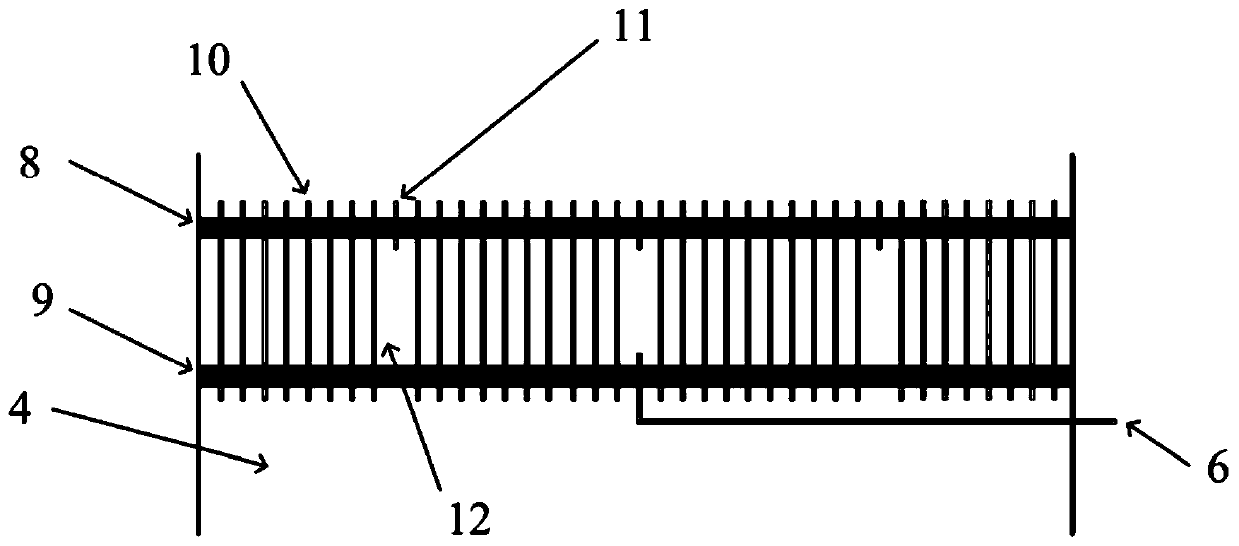

Large-size Circulating Fluidized Bed Boiler, Air Distributor and Air Distributor Assembly

ActiveUS20150184847A1Reduce vibrationReduce deformationFluidized bed combustionFurnace componentsCombustionFluidized bed

The present invention provides a circulating fluidized bed boiler, comprising: furnace side walls; a ceiling; an air distribution plate provided at a bottom of a furnace; and at least one air distribution cone provided on the air distribution plate, wherein each air distribution cone extends upwards from the air distribution plate into an interior of the furnace and has a shape gradually tapered in an extending direction, cone side walls which form the air distribution cone are provided with secondary air ports, the cone side walls are separated from the furnace side walls, and a furnace combustion space is formed and surrounded by the ceiling, the furnace side walls, the air distribution plate, and the cone side walls. The present invention further relates to an air distributor for a circulating fluidized bed boiler, the air distributor being provided on an air distribution plate of the boiler, wherein the air distributor is in a form of an air distribution cone, which extends upwards from the air distribution plate into an interior of a furnace to form a shape gradually tapered in an extending direction, and secondary air ports are formed in air distribution cone side walls forming the air distribution cone. The present invention also relates to an air distributor assembly for a circulating fluidized bed boiler.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

High-temperature and ultrahigh-pressure reheat steam boiler of biomass direct combination energy-conservation circulating fluidized bed

PendingCN110220182AImprove efficiencyEasy dischargeFluidized bed combustionSteam superheatersFailure rateUltra high pressure

The invention discloses a high-temperature and ultrahigh-pressure reheat steam boiler of a biomass direct combination energy-conservation circulating fluidized bed, relates to the high-temperature andultrahigh-pressure reheat steam boiler, in particular to the high-temperature and ultrahigh-pressure reheat steam boiler of the biomass direct combination energy-conservation circulating fluidized bed, and solves the problems of difficult direct combustion of yellow straw biomasses, shorter continuous operation time, low boiler unit efficiency, more pollution discharge, blocked feeding, weak reliability, higher boiler failure rate and difficult biomass formation. A biomass direct combustion system is mounted at the lower part of a hearth; the upper part of the hearth is connected with the upper part of a separation and return system; the lower part of the hearth is connected with the lower part of the separation and return system; a smoke inlet of a first tail flue is connected with the upper part of the separation and return system; and the lower part of the first tail flue is connected with the lower part of a second tail flue through a connecting flue. The high-temperature and ultrahigh-pressure reheat steam boiler of the biomass direct combination energy-conservation circulating fluidized bed belongs to the field of power generation and combined heat and power generation.

Owner:哈尔滨红光锅炉总厂有限责任公司

Separator construction of a fluidized bed boiler

ActiveUS8316783B2Designing can be facilitatedEasy to measureFluidized bed combustionBoiler supporting/setting arrangementsOperating energyFluidized bed

A separator construction, connectable to a fluidized bed boiler having a furnace, for circulating bed material and returning the material to the furnace. The separator construction includes walls, a ceiling, an inlet conduit, an outlet conduit in flow communication with a flue gas channel located above the separator, and a suspending device connecting the separator to a supporting structure in a building housing the boiler. The suspending device is formed of a frame arranged between the flue gas channel and the separator in connection with an upper circumference of the wall of the separator, and hanger rods or wires connecting the frame directly to the supporting structure.

Owner:FOSTER WHEELER ENERGIA OY

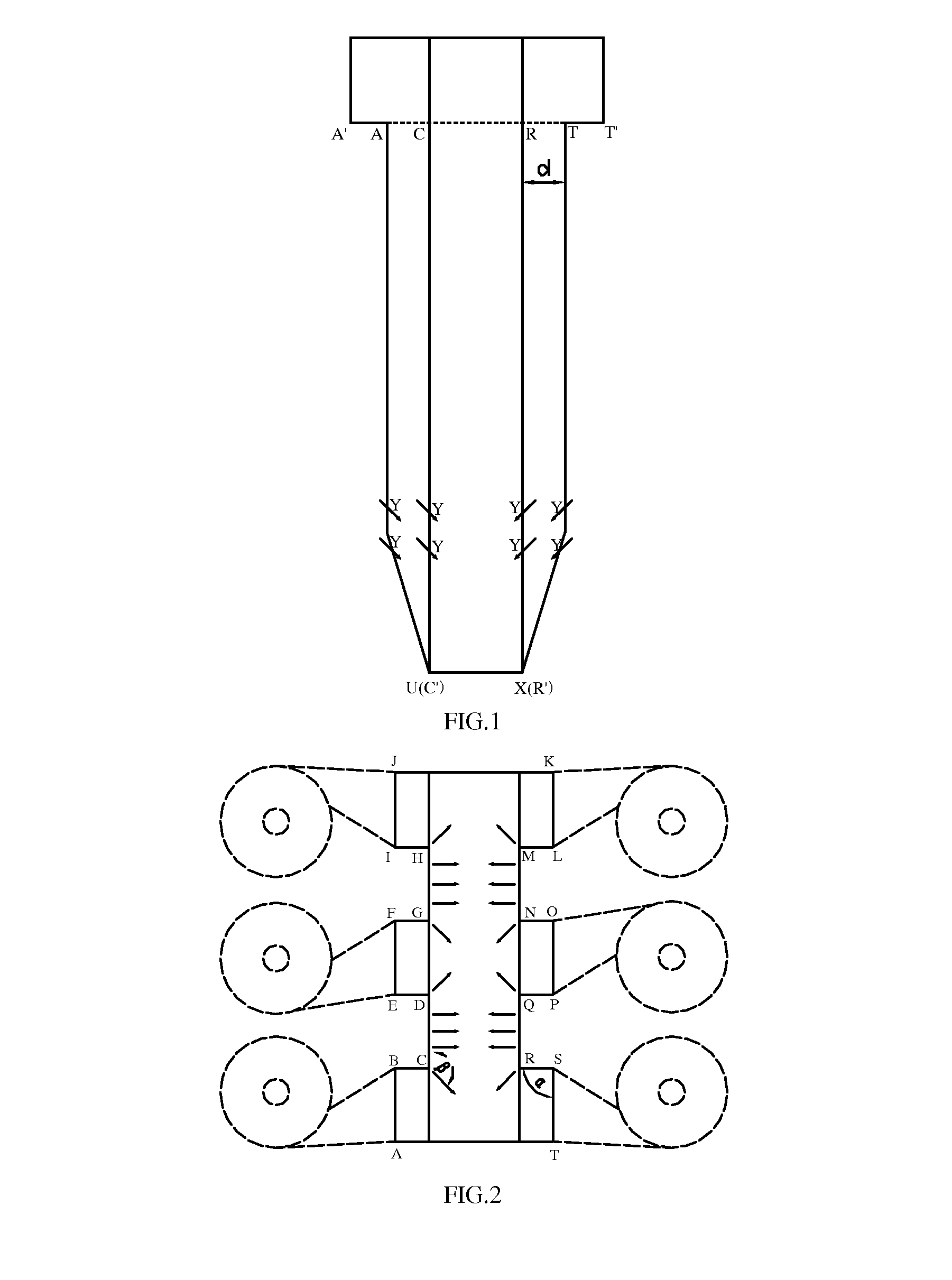

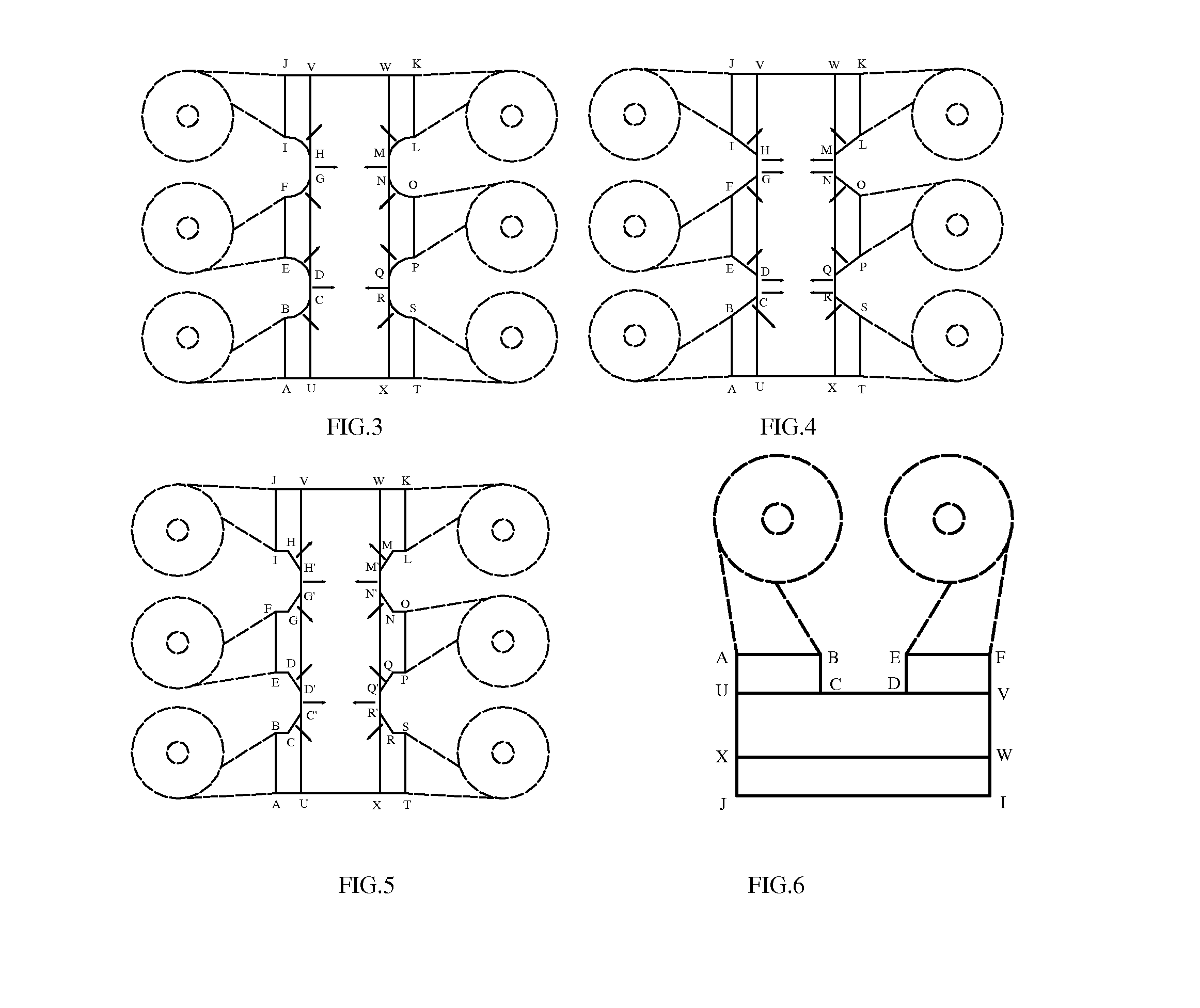

Circulating fluidized bed boiler

ActiveUS20130284119A1Improve combustion performanceImprove discharge performanceFluidized bed combustionIndirect heat exchangersCycloneFlue gas

A circulating fluidized bed boiler is disclosed. The circulating fluidized bed boiler comprising: a furnace defined and enclosed by water walls, a ceiling and an air distributor, the water walls comprising front and rear walls and left and right side walls (AJ, TK) formed by water cooling tubes, and the water walls are provided with secondary air ports (Y) in the lower part thereof, and furnace flue gas outlets (AB, EF, IJ, KL, OP, ST) being provided in an upper part of the furnace; at least two cyclones connected with the furnace flue gas outlets (AB, EF, IJ, KL, OP, ST); a loop-seal is connected with solid outlets of the cyclones and the lower part of the furnace, respectively; and a flue gas duct connected with flue gas outlets of the cyclones wherein the water cooling wall tubes of the water wall form at least one vertical columnar recessed segment (BCDE, FGHI, SRQP, ONML) recessed toward the inside of the furnace, and the at least one columnar recessed segment (BCDE, FGHI, SRQP, ONML) extends at least 15% of the furnace height in a vertical direction.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

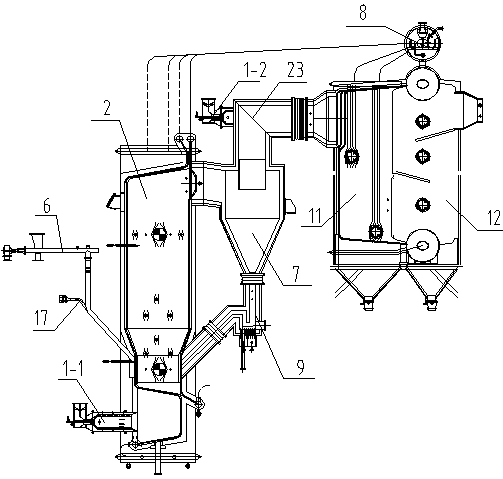

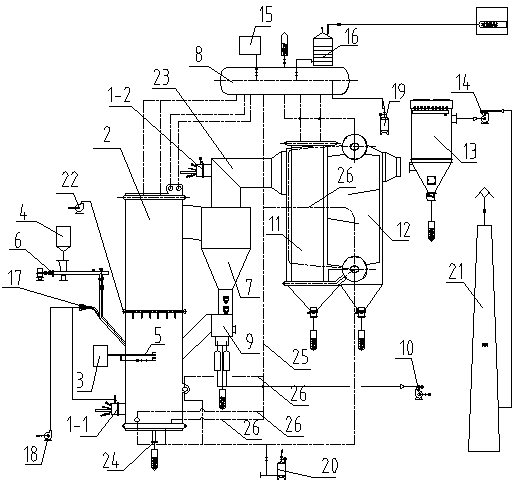

Phenolic wastewater and gasified waste coke mixed burning system

PendingCN108469019AFully consider the physical characteristicsFully consider chemical propertiesFluidized bed combustionCombustion using liquid and pulverulent fuelCombustion chamberResource utilization

The invention discloses a phenolic wastewater and gasified waste coke mixed burning system, and belongs to the technical field of environment science and technology three wastes treatment and comprehensive utilization. A smoke outlet of a circulating fluidized bed incineration boiler is communicated with a cyclone separator, the upper end of the cyclone separator is communicated with a secondary combustion chamber, the lower end of the cyclone separator is communicated with a return feeder, the return feeder is connected with a material loosening and feeding draught fan, and communicates withthe circulating fluidized bed incineration boiler, the secondary combustion chamber is communicated with a high-temperature smoke cooling chamber, the side end of the high-temperature smoke cooling chamber is communicated with a boiler body convection bank, the boiler body convection bank is communicated with a cloth bag dust remover through a pipeline, and the cloth bag dust remover is communicated with a chimney through an induced draft fan and a pipeline. Phenolic wastewater and gasified waste coke powder physical and chemical properties are sufficiently considered, pulverized coal and phenolic wastewater are sufficiently decomposed and combusted in an incinerator, harmless, weight reduction and resource treatment of waste can be sufficiently achieved, and the system is an environment-friendly, energy-saving and resource utilization system.

Owner:DALIAN HANGHUA ENERGY EQUIP CO LTD

Large-size circulating fluidized bed boiler, air distributor and air distributor assembly

ActiveUS9772104B2Reducing vibration and deformationReduce riskFluidized bed combustionFluidised bed boilersCombustionFluidized bed

The present invention provides a circulating fluidized bed boiler, comprising: furnace side walls; a ceiling; an air distribution plate provided at a bottom of a furnace; and at least one air distribution cone provided on the air distribution plate, wherein each air distribution cone extends upwards from the air distribution plate into an interior of the furnace and has a shape gradually tapered in an extending direction, cone side walls which form the air distribution cone are provided with secondary air ports, the cone side walls are separated from the furnace side walls, and a furnace combustion space is formed and surrounded by the ceiling, the furnace side walls, the air distribution plate, and the cone side walls. The present invention further relates to an air distributor for a circulating fluidized bed boiler, the air distributor being provided on an air distribution plate of the boiler, wherein the air distributor is in a form of an air distribution cone, which extends upwards from the air distribution plate into an interior of a furnace to form a shape gradually tapered in an extending direction, and secondary air ports are formed in air distribution cone side walls forming the air distribution cone. The present invention also relates to an air distributor assembly for a circulating fluidized bed boiler.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Heat conduction oil and water vapor double-medium co-production circulating fluidized bed boiler

The invention discloses a heat conduction oil and water vapor double-medium co-production circulating fluidized bed boiler. According to a traditional circulating fluidized bed boiler, on the basis ofarranging a water actuating medium radiant heating surface, a cyclone separator, a water actuating medium convection heating surface and an air pre-heater, a heat conduction oil radiant heating surface is additionally arranged in a hearth of the circulating fluidized bed boiler, and a heat conduction oil convection heating surface is additionally arranged in a tail flue. According to the heat conduction oil and water vapor double-medium co-production circulating fluidized bed boiler, the heat conduction oil heating surfaces are additionally arranged in the circulating fluidized bed boiler, sothat heat conduction oil heating and vapor producing are conducted simultaneously, the temperature of exhaust smoke of the boiler is reduced, the thermal efficiency of the boiler is improved, and theheat load of the single boiler is improved.

Owner:HANGZHOU BOILER GRP CO LTD

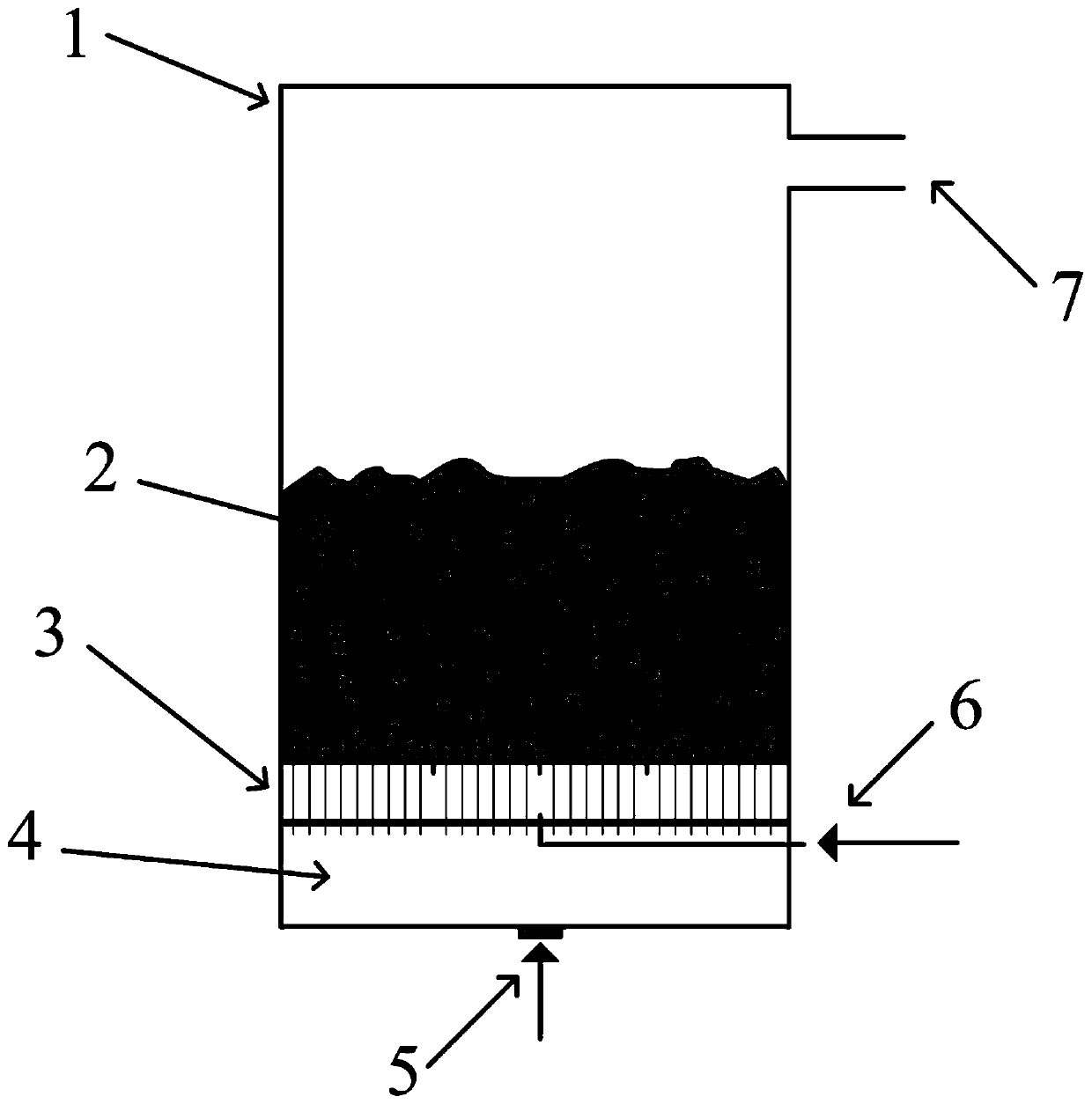

Fluidized bed combustion device for ammonia gas, power generation system and combustion method of ammonia gas

InactiveCN111322610AFire stableUniform temperatureFluidized bed combustionGas turbine plantsFlame propagationFlue gas

The invention relates to the technical field of combustion devices for ammonia gas, and provides a fluidized bed combustion device for ammonia gas, a power generation system and a combustion method ofthe ammonia gas. The combustion device comprises fluidized bed combustor shell, a fluidized bed layer, an air distributing plate, a pumping chamber, a combustion-supporting gas inlet, a fuel gas inlet pipe and a flue gas exhaust port; the air distributing plate is wholly mounted at the lower part of the fluidized bed combustor shell, and the fluidized bed layer is arranged on the upper surface ofthe air distributing plate; the pumping chamber is located below the air distributing plate; the combustion-supporting gas inlet is formed in the pumping chamber; the fuel gas inlet pipe is fixed onthe air distributing plate and communicates with an inner cavity of the air distributing plate; and the flue gas exhaust port is formed in the upper part of the fluidized bed combustor shell. According to the designed fluidized bed combustion device, the problems of has high firing energy, high flame propagation velocity, narrow firing concentration range and unstability of ammonia gas combustionare solved thoroughly. Therefore, the power generation system can successfully use the ammonia gas as fuel, and the remarkable carbon dioxide emission reducing effect is realized.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

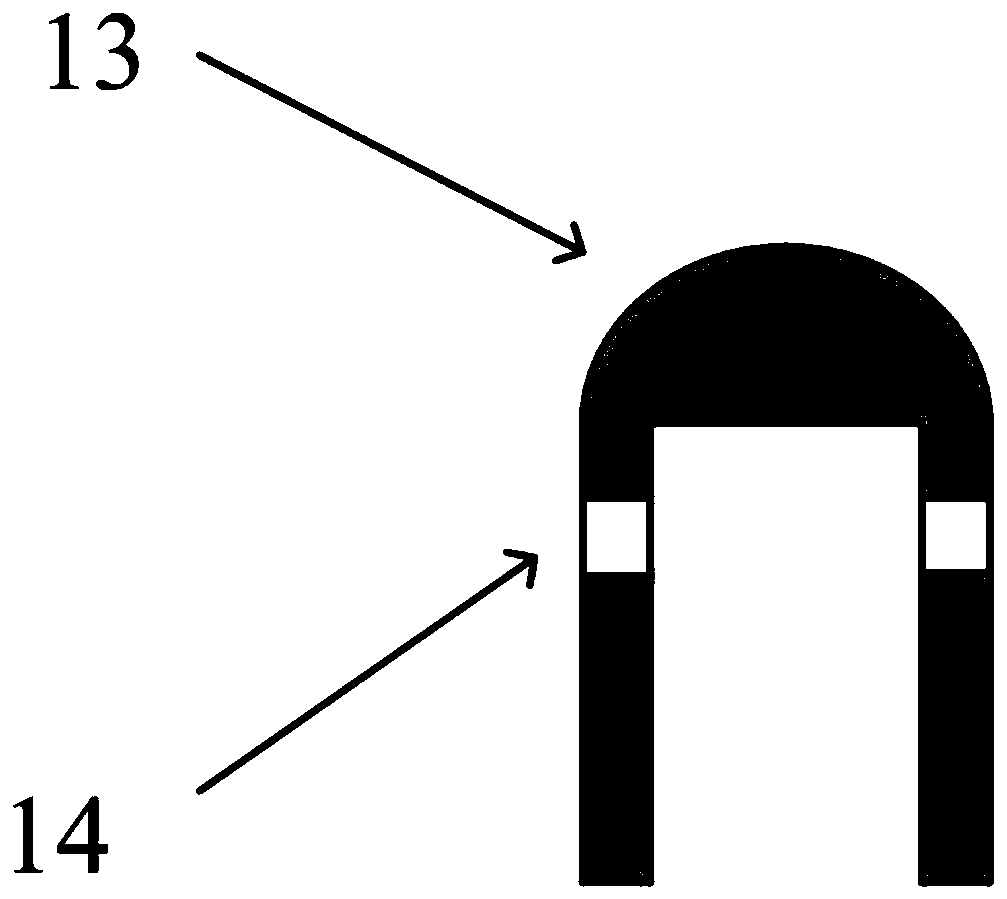

Double wall extension

The invention relates to a fluidised bed reactor (1) consisting of tube walls (2) with membranes cooled by a coolant, said walls surrounding a firebox (10) and comprising tube extension panels (3) through which a coolant flows by means of single-passage forced circulation. According to the invention, the extension panels (3) are paired.

Owner:GENERAL ELECTRIC TECH GMBH

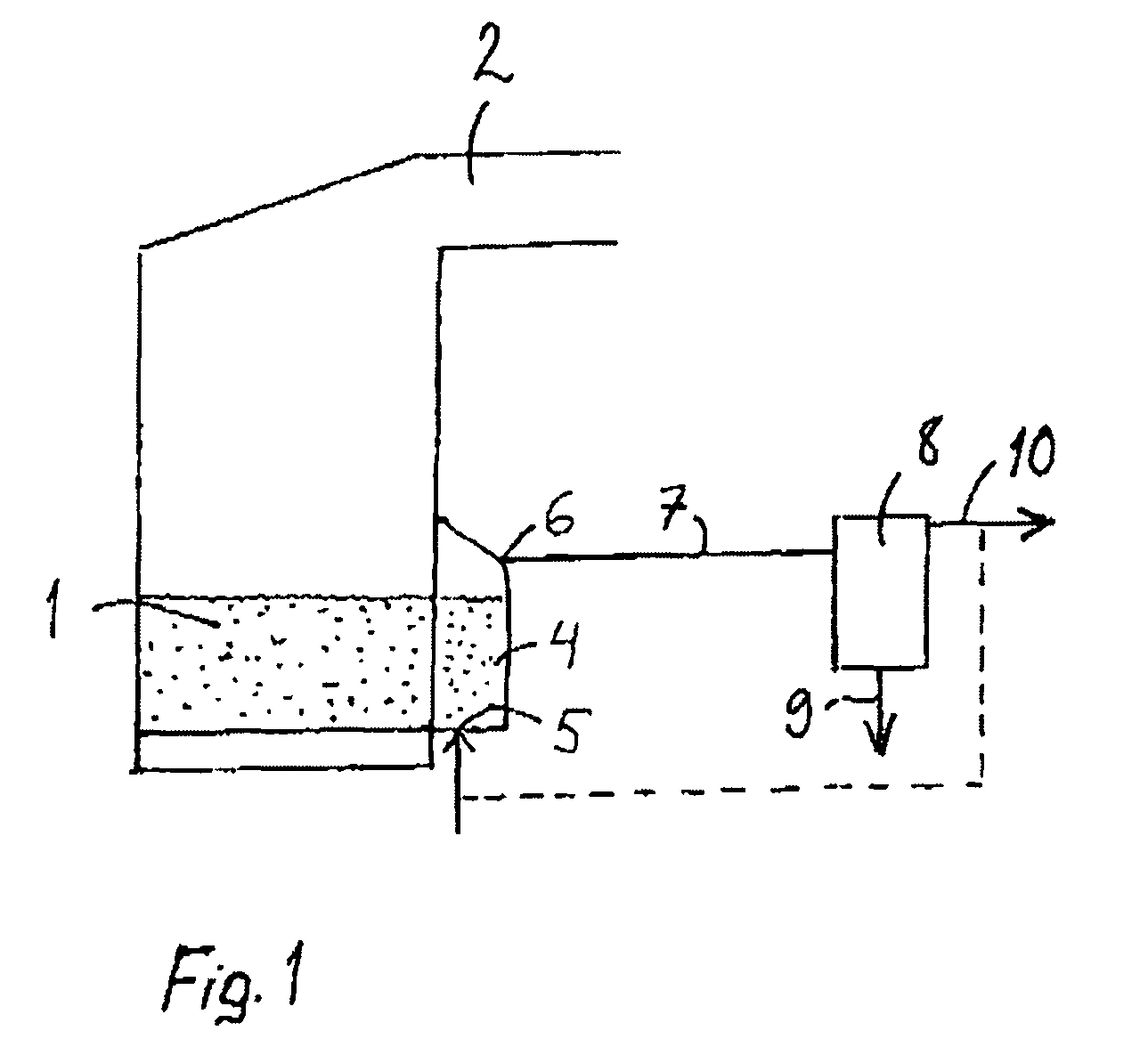

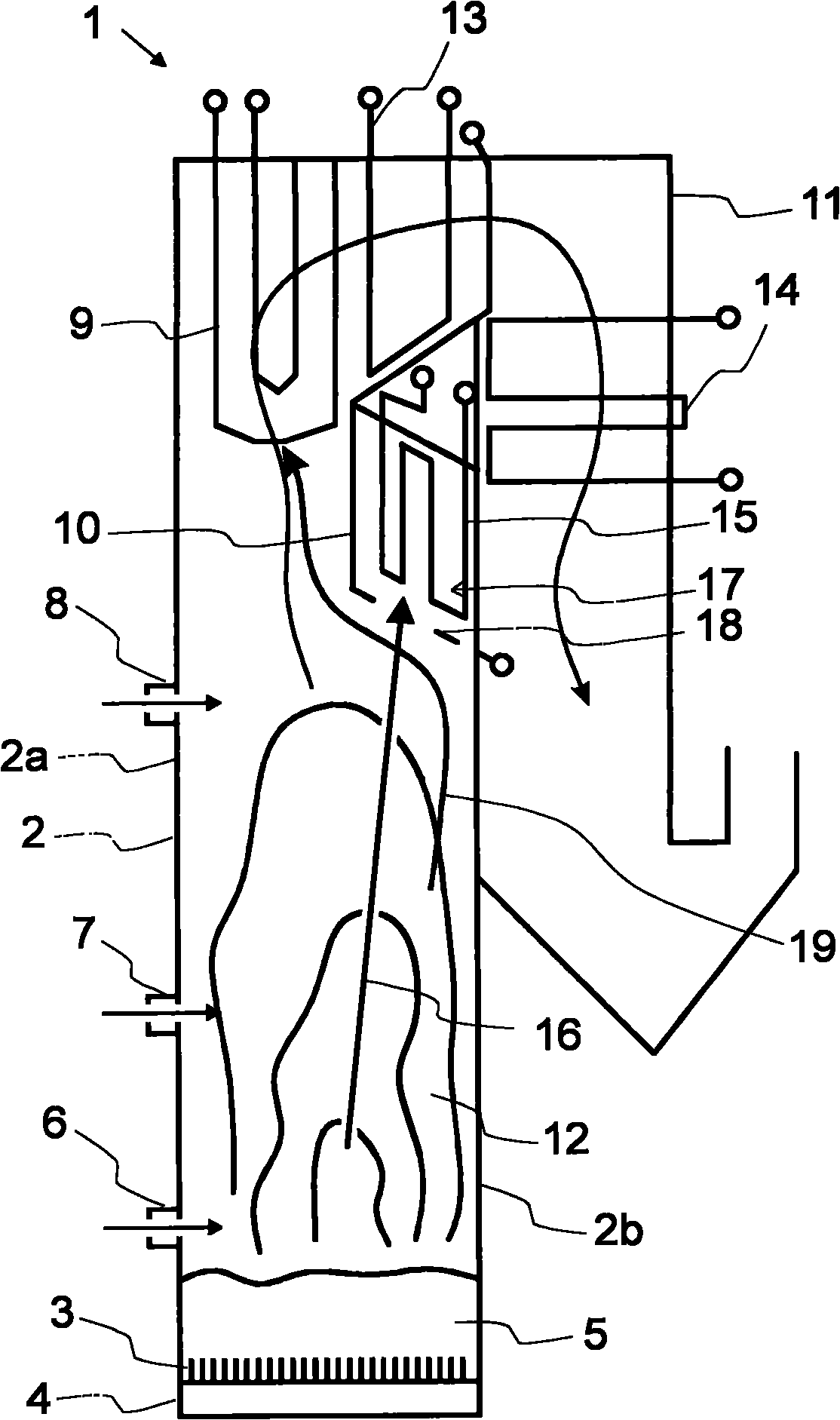

Boiler equipped with a superheater

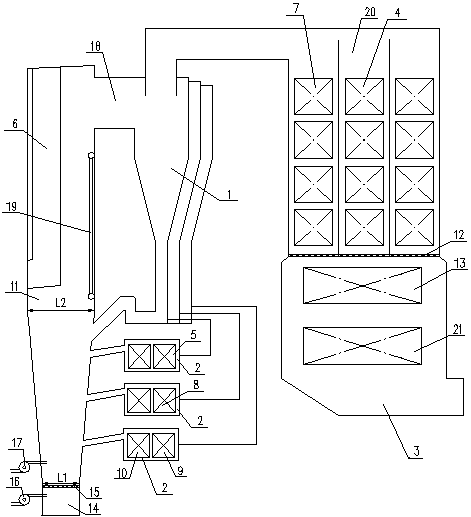

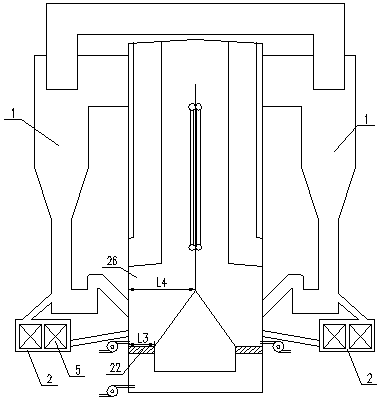

InactiveCN102242922AAvoid corrosionPulp liquors combustionSteam superheatersThermal energyCombustion

The invention relates to a boiler equipped with a superheater. The boiler (1) comprising at least: a furnace (2), in whose lower part the combustion used as the primary source of thermal energy of the boiler is configured to take place; devices (6) for supplying fuel into the furnace; devices (3, 7, 8, 26) for supplying combustion air into the furnace; one or more flue gas ducts (11); at least one chamber (17) accommodating at least one steam superheater (15) for recovering thermal energy. Said chamber is configured to allow a direct line of sight (16) between said superheater and said primary source, to enable the reception of thermal energy by means of thermal radiation. Said chamber is further configured to prevent the entry of said flue gases (19) to said superheater either totally or almost totally, to avoid the reception of thermal energy by convection.

Owner:VALMET POWER OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com