Double wall extension

A technology of extended plate and fluidized bed reactor, which is applied in the direction of combustion method, water tube steam boiler, fluidized bed boiler, etc. It can solve the problems of insufficient exchange surface and low cost, and achieve simplified manufacturing, large size, and simplified manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

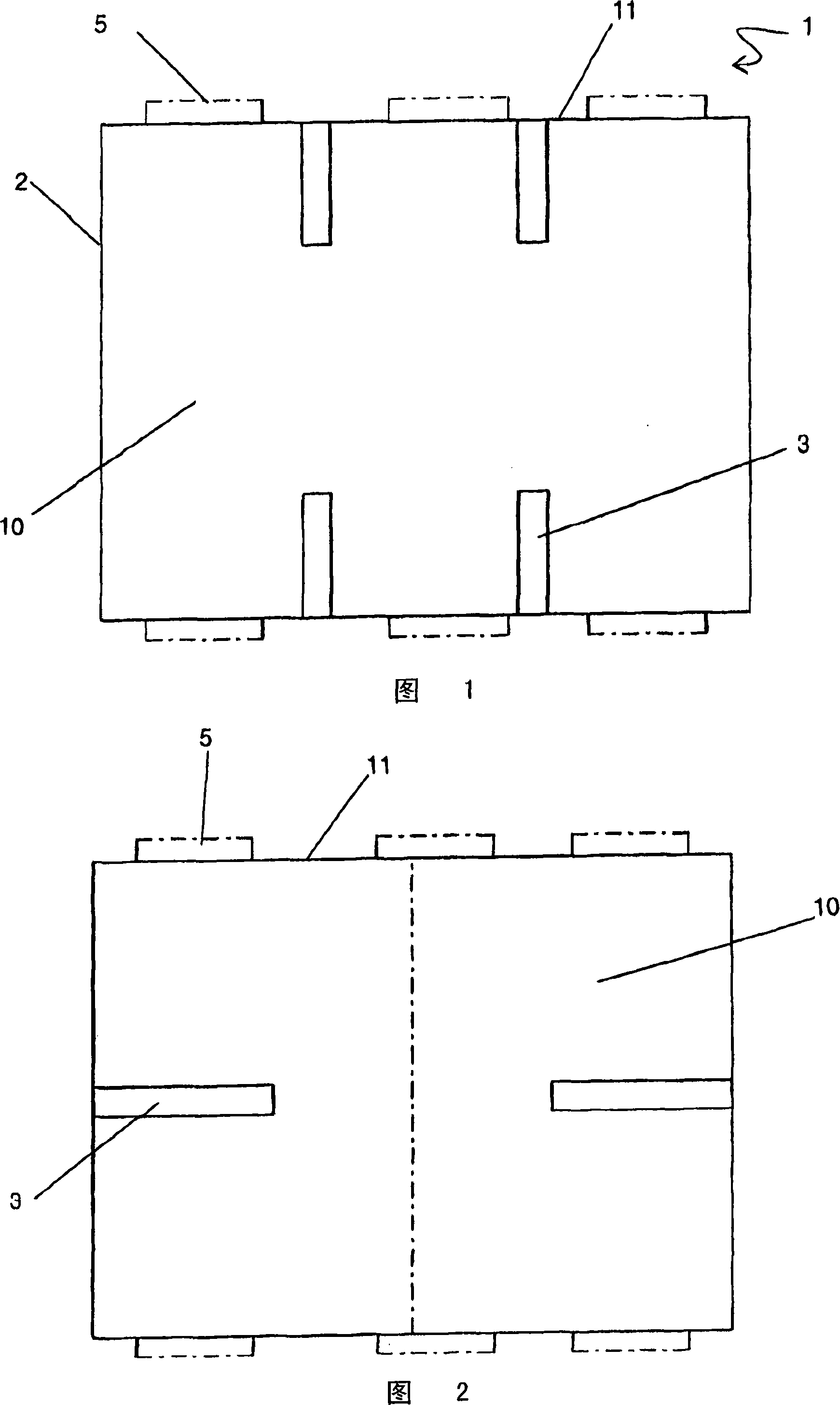

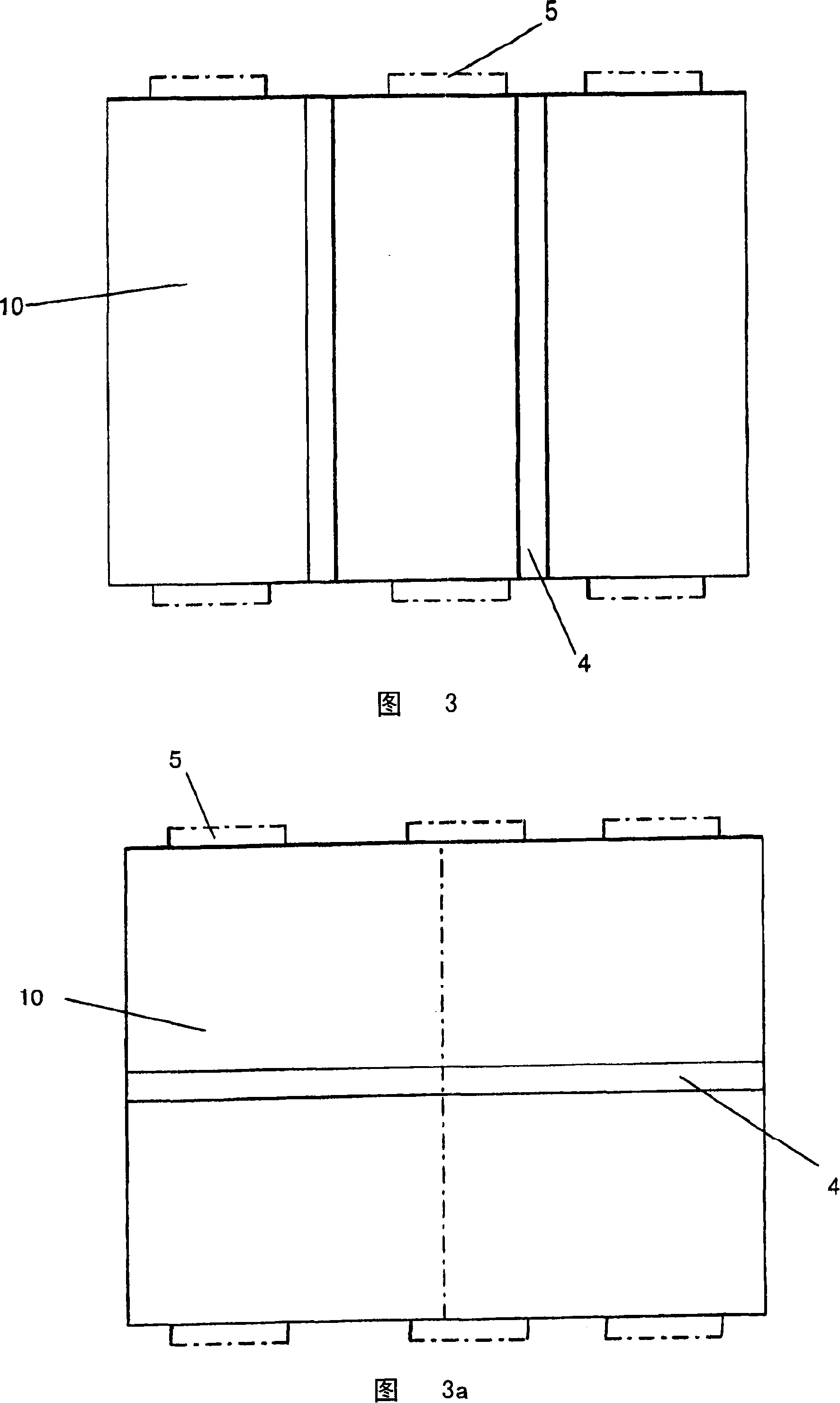

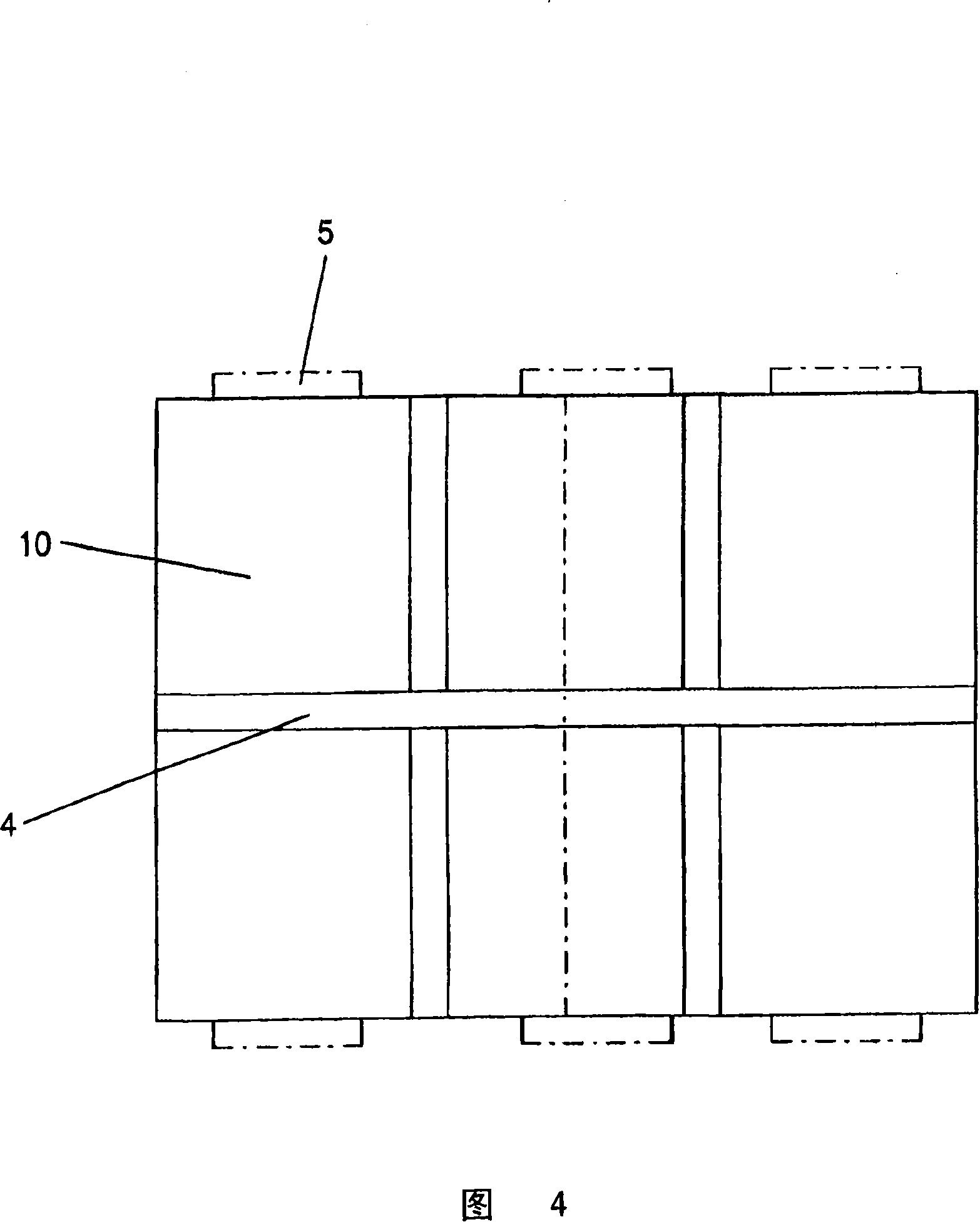

[0038] 1 to 4 show a fluidized bed reactor 1 comprising a membraned, piped wall 2 which encloses a combustion chamber 10 and is cooled by a heat transfer fluid. This wall 2 comprises an extension 3 provided with a pipe. This wall 11 includes an opening 5 communicating with a centrifugal fan (not shown). These extensions can be arranged perpendicular to the wall 11 as shown in FIG. 1, or arranged parallel to the wall 11 as shown in FIG. 2, or as shown in FIG. is divided into three parts, and in Fig. 3a the combustion chamber is divided into two parts. In Fig. 4 the combustion chamber is divided into 6 parts.

[0039] Figure 5 shows possible different types of extensions. These figures generally show possible different configurations depending on the required performance criteria of the exchange surfaces and thermodynamics, which themselves vary with the conditions of the air flow or water vapor fluid circulation. In particular, Figures 5a to 5t include only one end tube for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com