Air-fired CO2 capture ready circulating fluidized bed heat generation with a reactor subsystem

a technology of air-fired co2 and fluidized bed, which is applied in the direction of lighting and heating apparatus, emission prevention, combustion types, etc., can solve the problems of many quarters adding coal-fired heat-generating system capacity, power availability, and system site itself being insufficient, so as to achieve less expense and greater efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

Common System Components and Associated Operations

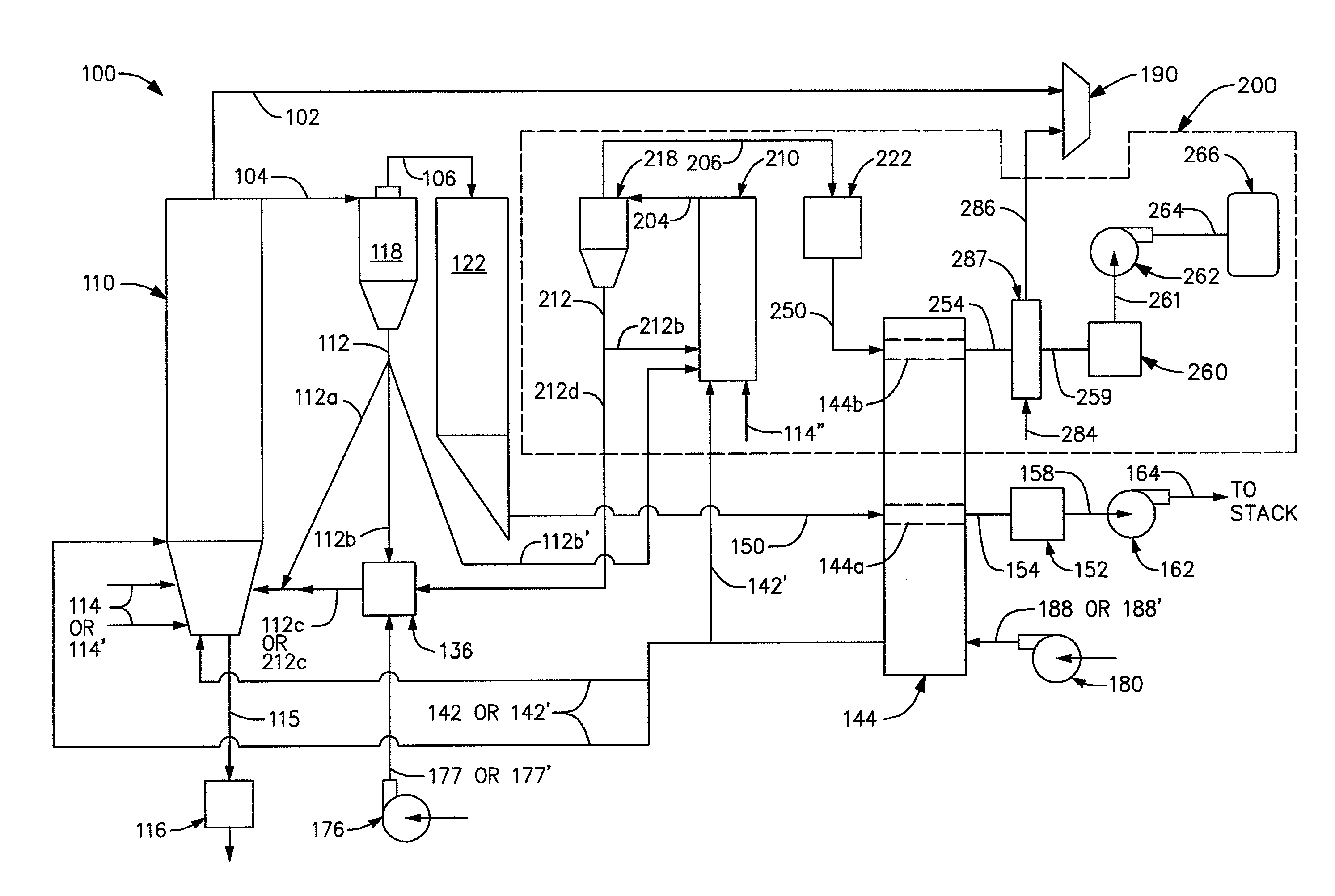

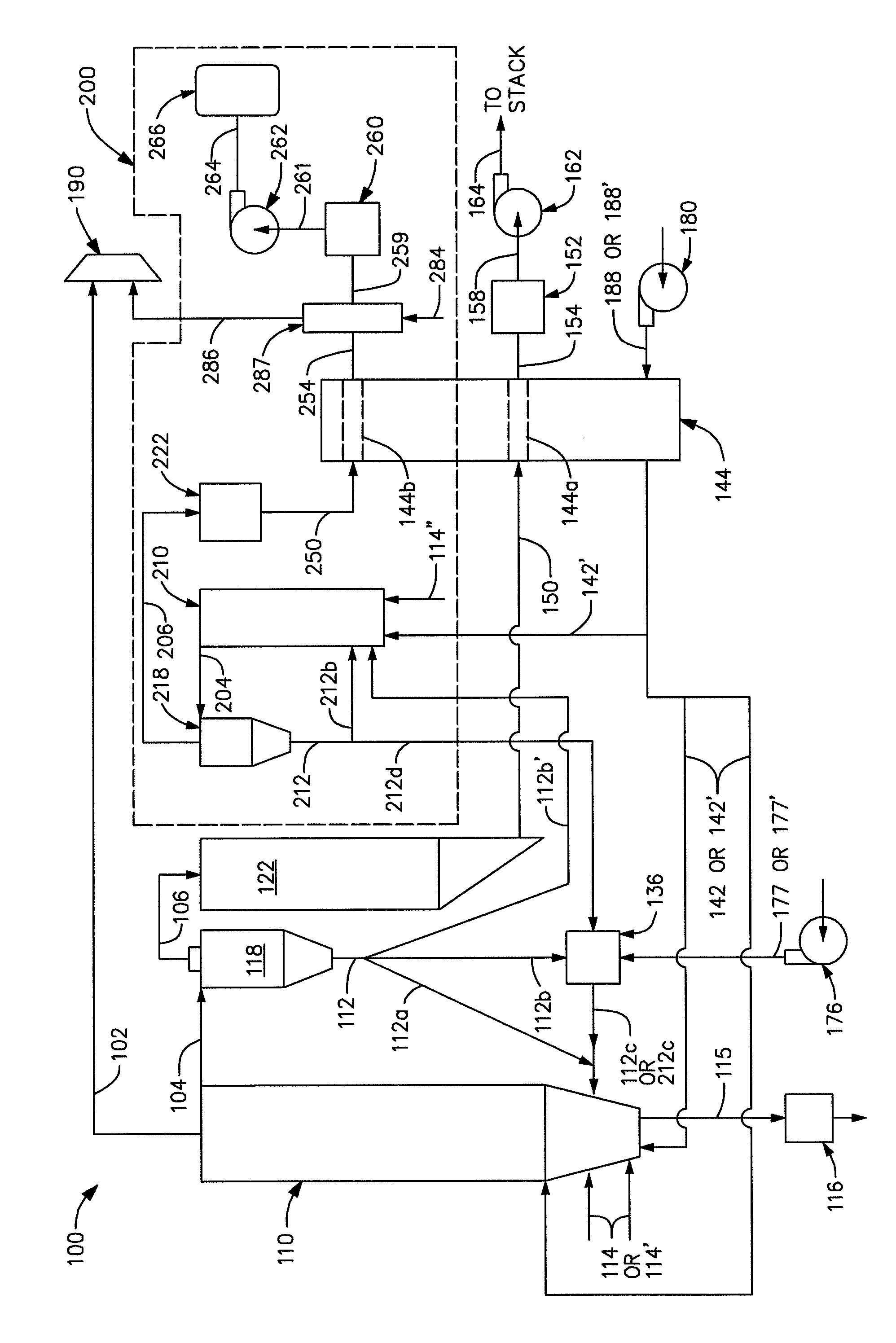

[0031]FIG. 1 depicts a schematic view of an exemplary air fired circulating fluidized bed (CFB) heat generating system 100, in accordance with the present invention. The CFB heat generating system 100, uses air to combust the fossil fuel.

[0032]In the particular exemplary implementation described below, the fossil fuel is pulverized coal. It should be understood that other types of fossil fuels could be utilized in lieu of pulverized coal, however preferably a fossil fuel with a high carbon content such as pulverized coal or petcoke, or a biomass is used. The working fluid is H2O, which may be in a liquid, gaseous or mixed liquid and gaseous state at different points in the process. However, here again it should be understood that other types of working fluids could be utilized in lieu of H2O. Furthermore, it will be understood that the working fluids which flow within various components could be of the same type or different types.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com