Phenolic wastewater and gasified waste coke mixed burning system

A technology for phenol wastewater and gas, which is applied in the field of mixed incineration system of phenol-containing wastewater and gasification waste coke, can solve problems such as the wear of the heating surface of the tail boiler, poor fuel ignition conditions, and large ash content in the flue gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

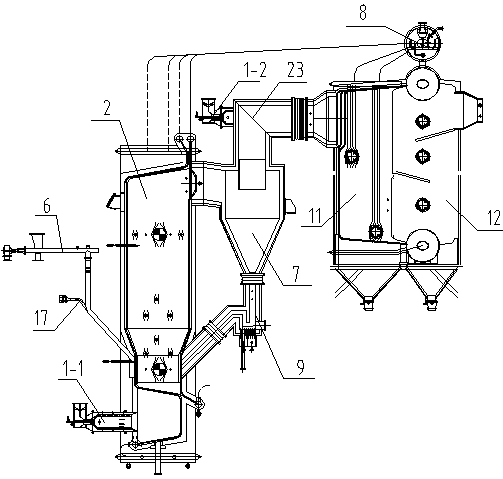

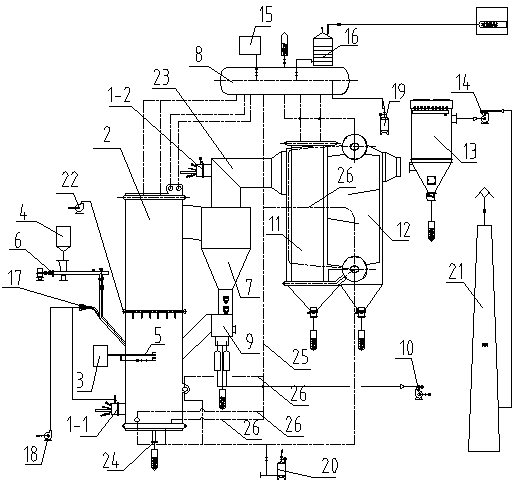

[0018] A mixed incineration system for phenol-containing waste water and gasified waste coke. The burner (1-1) for starting the furnace with gas or oil is installed in one of the primary air distribution chambers under the air distribution plate at the bottom of the circulating fluidized bed incineration boiler (2). On the side, the phenol-containing wastewater storage tank (3) is connected to the phenol-containing wastewater atomizing nozzle (5) through a booster pump and pipeline, and the phenol-containing water atomizing nozzle (5) is installed on the circulating fluidized bed incineration boiler (2) , the gasification waste coke powder storage bin (4) communicates with the circulating fluidized bed incineration boiler (2) through a shaftless screw feeder (6) and pipelines, and a feeder is arranged on the pipeline for gasification waste coke powder transportation The air duct (17), the feeding air duct (17) is connected with the primary fan (18), the secondary air dry pipe a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com