Fluidized bed boiler furnace comprising two hearths separated by an inside leg area

A technology for fluidized bed boilers and partitions, which is applied in fluidized bed boilers, fluidized bed combustion equipment, steam boilers, etc., and can solve problems such as limiting panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

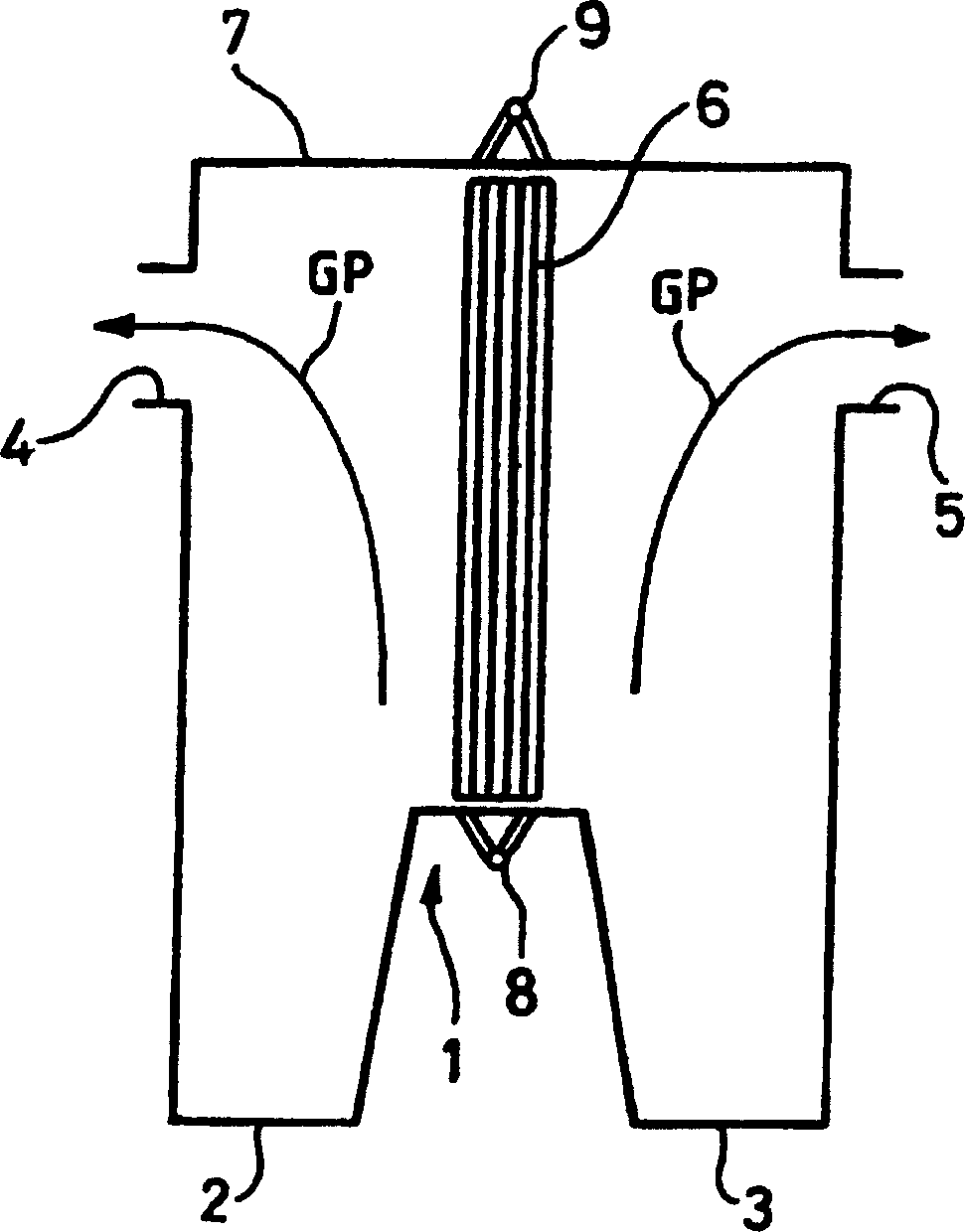

[0011] figure 1 The boiler shown in is a circulating fluidized bed (CFB) boiler in which the bottom forms a partition 1 separating the two furnace chambers 2 and 3 of the boiler. The outlets from the boiler to the cyclone are indicated by reference numerals 4 and 5 . The outlets to the cyclones are usually provided on the side walls of the boiler, and a boiler with a partition may include four or more outlets to the cyclones on either side of the partition.

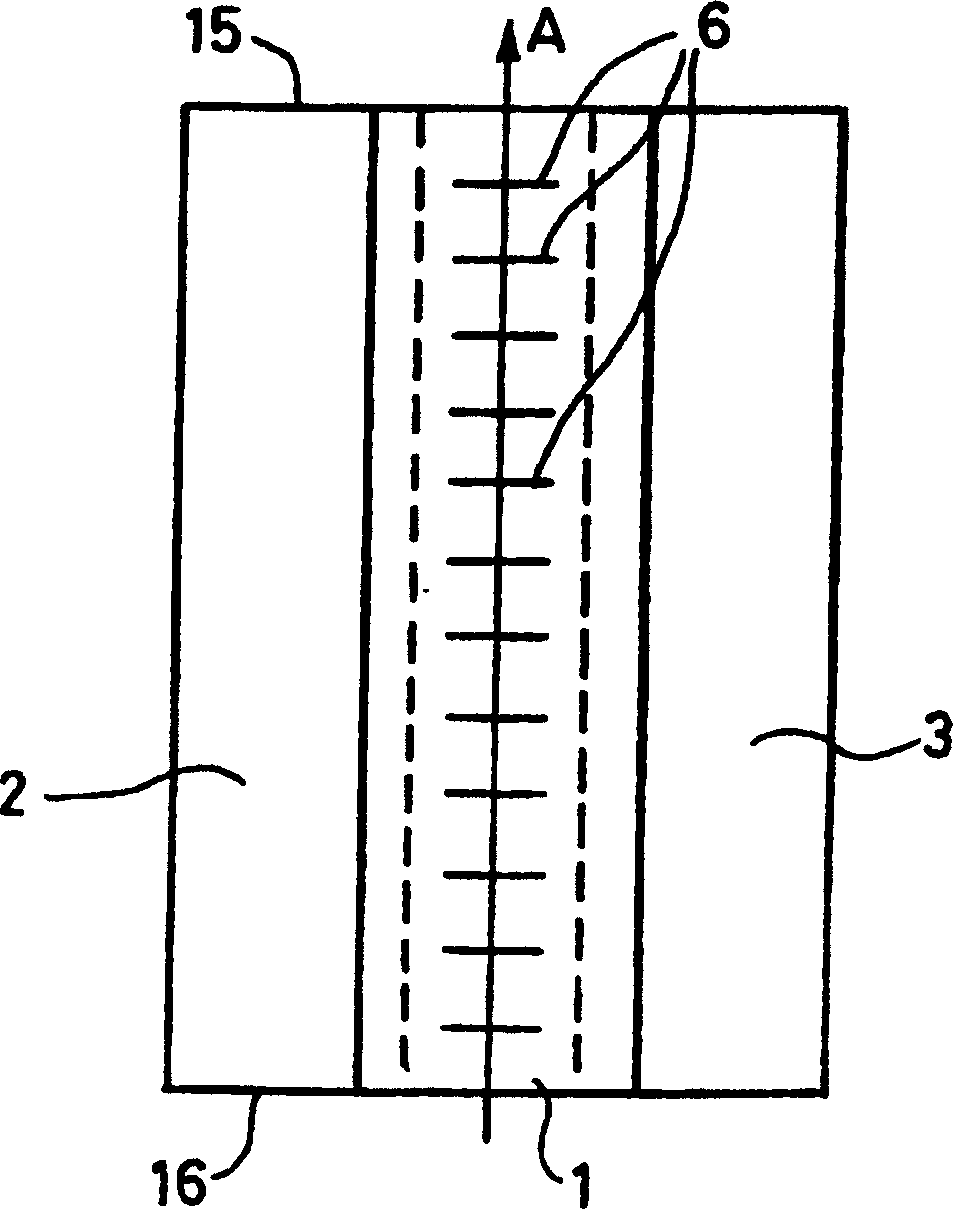

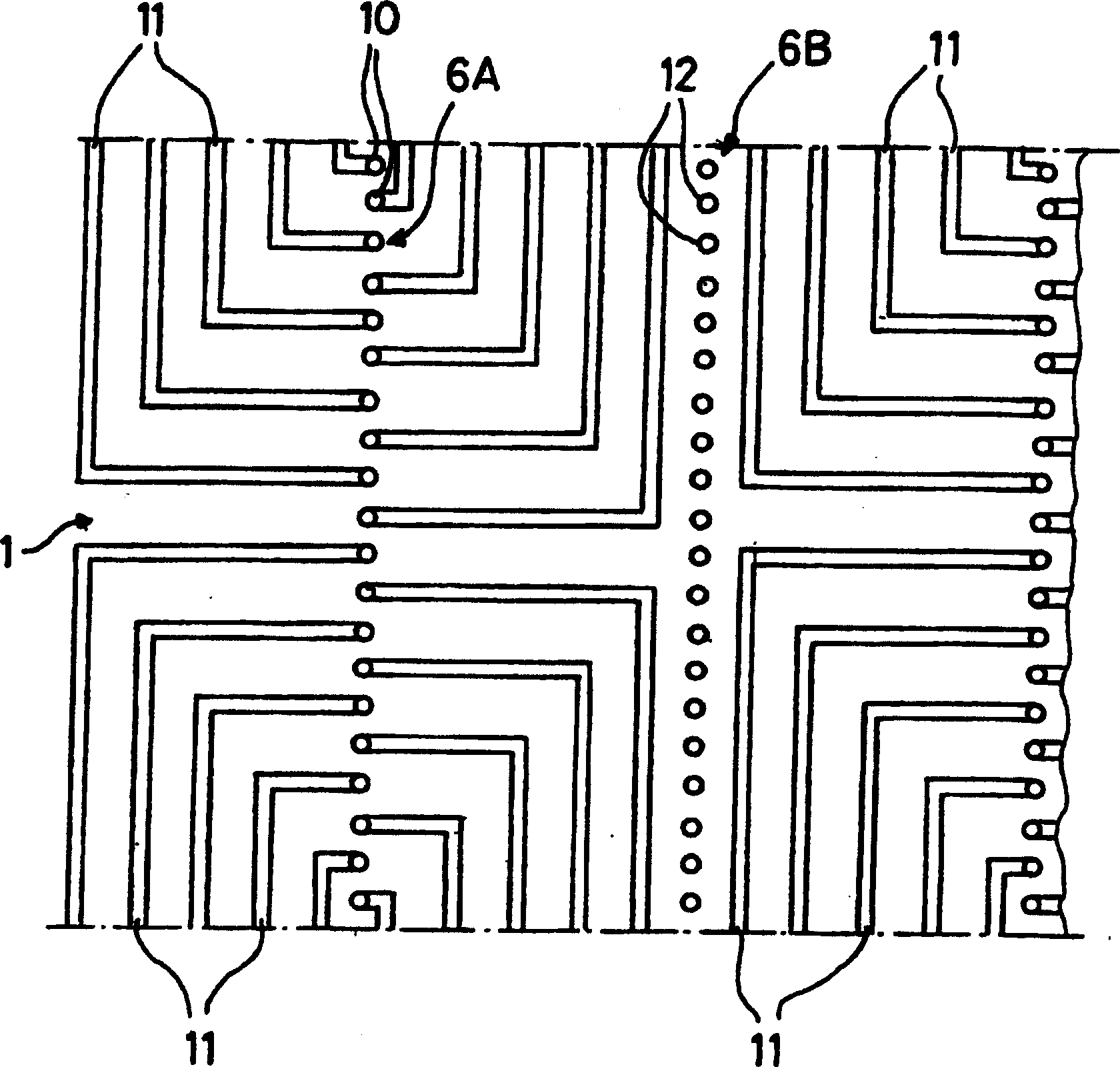

[0012] The boiler of the present invention is equipped with at least one heat exchange tube panel 6 arranged vertically on top of the partition 1 and perpendicular to the longitudinal direction A of the furnaces 2 and 3 so as not to hinder the circulation of gases and particles indicated by arrows GP , and thereby avoid pressure imbalances in the boiler. Each heat exchange tube panel 6 is fixed to the roof 7 of the boiler and is drawn between the roof and the partition to avoid unintentional vibration of the tubes in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com