Pneumatic dust cleaning device of boiler

A soot cleaning device and boiler technology, which is applied in the field of boiler soot cleaning devices and pneumatic ash cleaning devices, can solve the problems of ineffective removal of soot deposits in refraction angles and horizontal flues, limited soot blowing energy of sonic waves, and soot blowing by steam. There are problems such as dead angles, so that the device is simple and effective, the device has high reliability, and the effect of ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

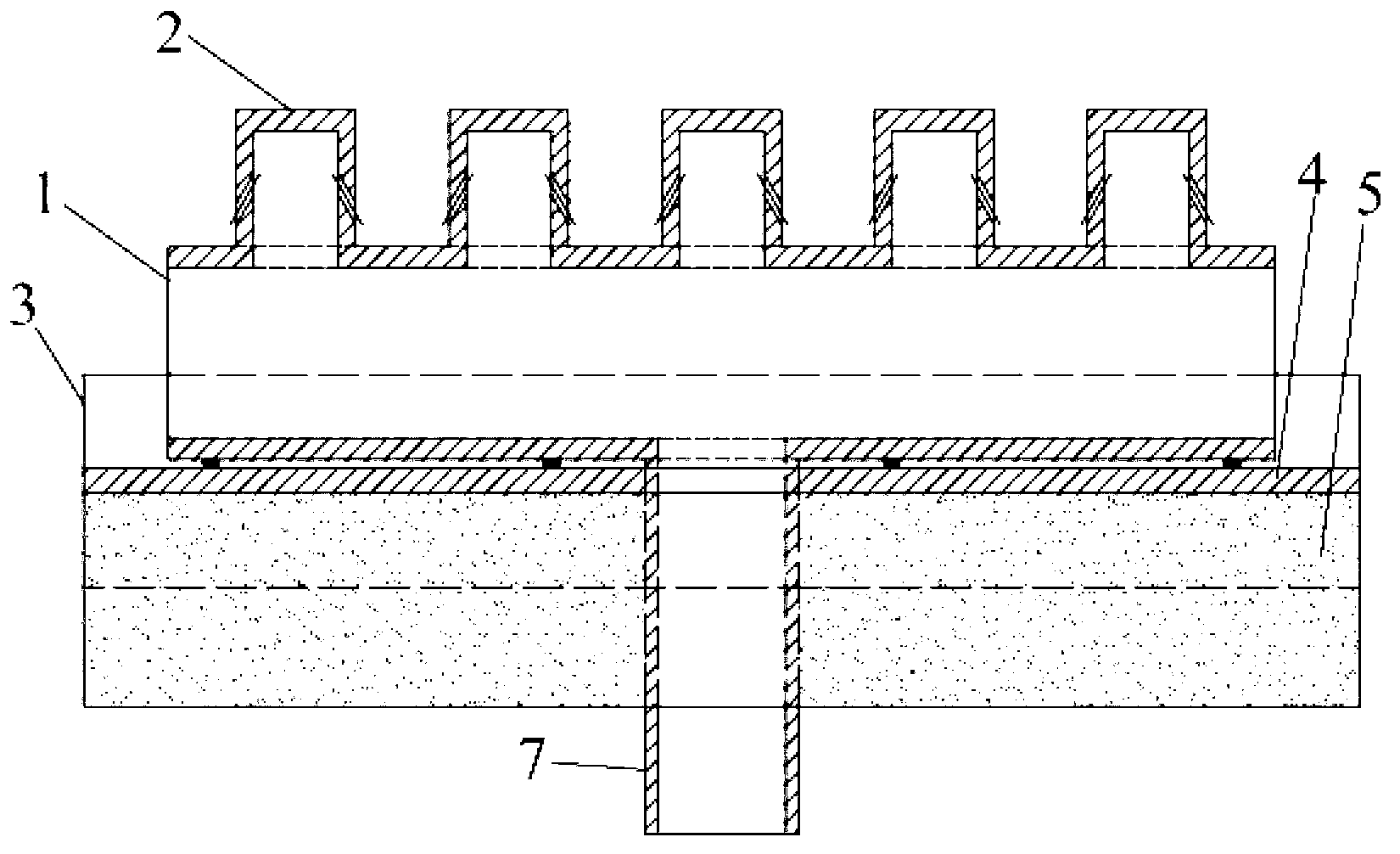

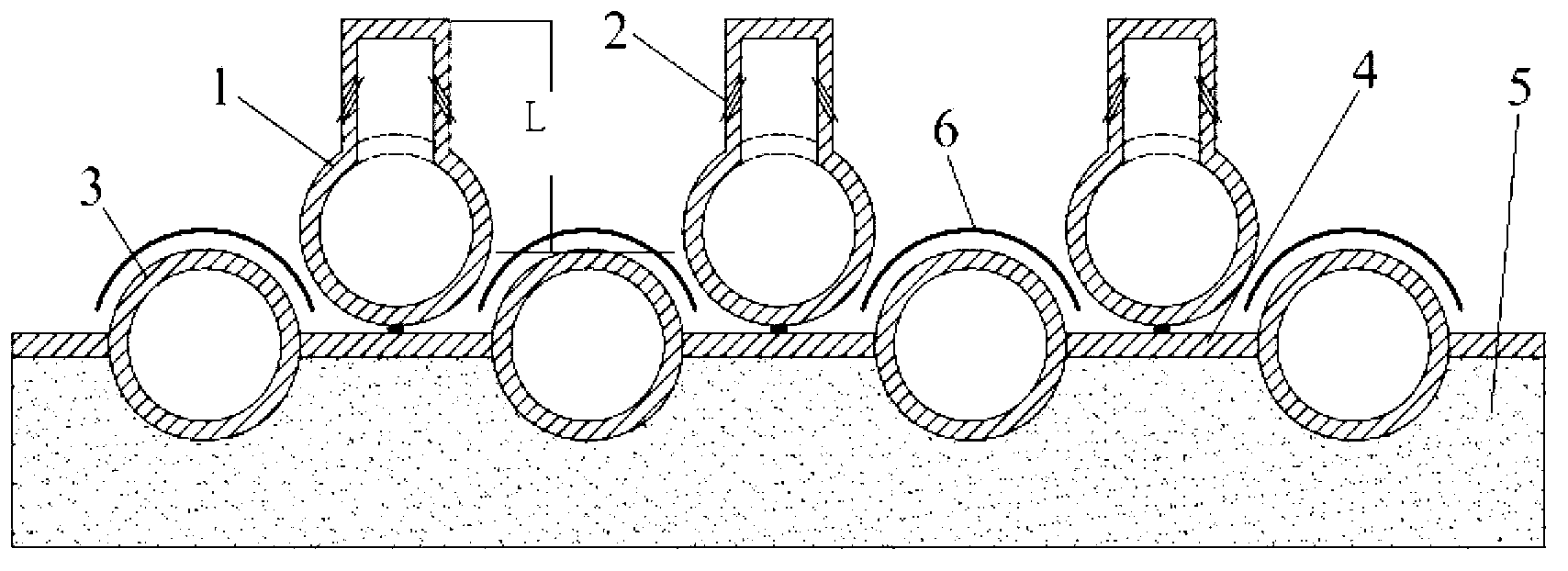

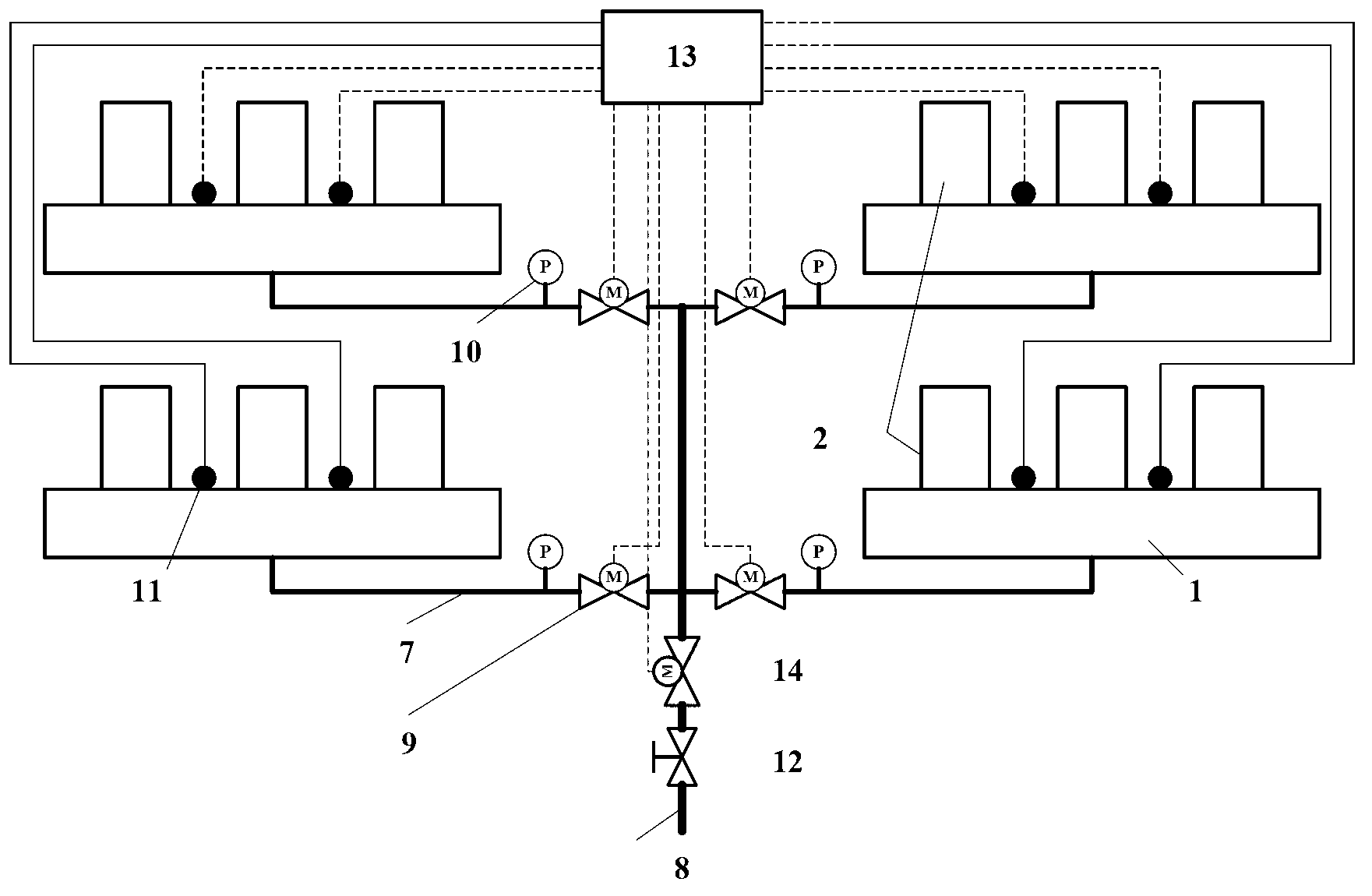

[0022] see figure 1 , 2, the present invention includes several groups of soot blowing tubes 1 installed on the diaphragm 4 between the boiler flame angle or the horizontal flue bottom wall tube 3, and several groups of soot blowing tubes 1 that are connected to each other and pass through the insulation insulation. The soot blowing medium conveying pipeline 7 of the hot layer 5, each group of soot blowing pipes 1 is arranged in sections along the flue gas flow direction, and is arranged in regions along the width direction of the flue. A soot blowing nozzle 2, in order to prevent the blowing damage of the lower wall pipe, the wear plate 6 made of heat-resistant and wear-resistant material is provided on the wall pipe.

[0023] In order to achieve independent and flexible control of soot blowing in different areas, the length of the soot blowing pipe along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com