Boiler equipped with a superheater

A superheater and boiler technology, applied in steam boilers, steam superheating, fluidized bed boilers, etc., can solve impractical problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

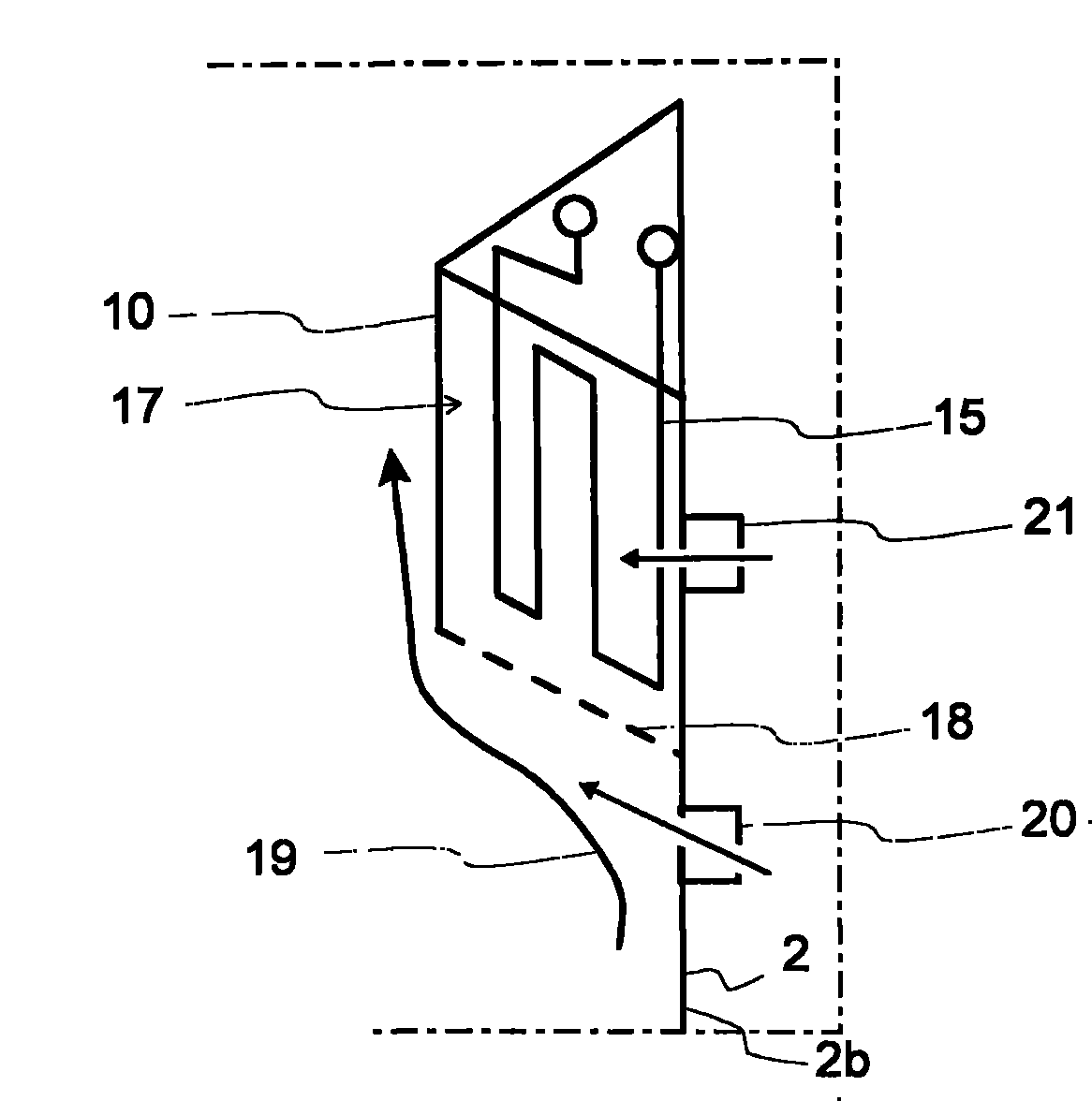

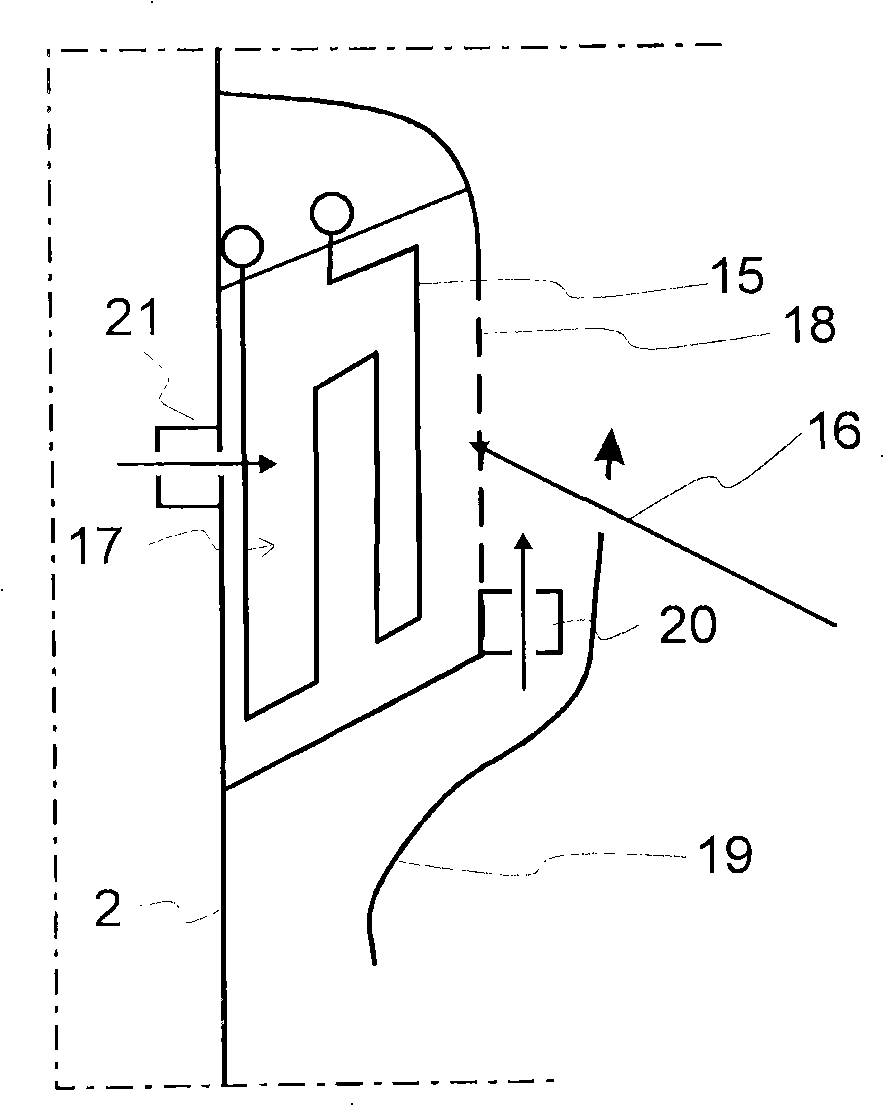

[0034] In the figures, elements with corresponding functions are indicated with the same reference numerals.

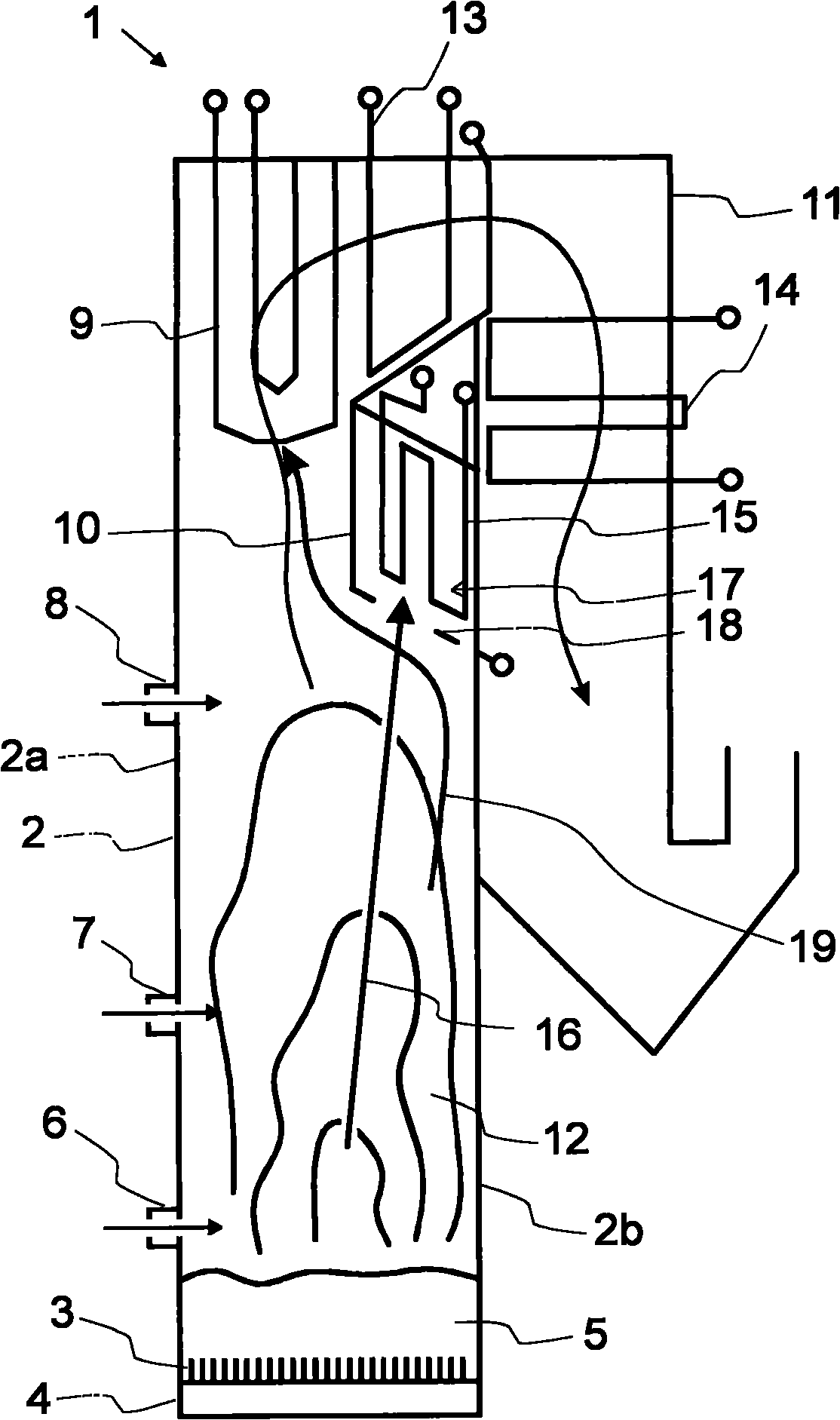

[0035] figure 1 An example of a steam boiler employing the chamber and superheater configuration described above is shown. Due to the location of the steam boiler and the configuration of the chamber and the superheater, boilers based on fluidized bed combustion, especially bubbling fluidized bed boilers (BFB), can be used, such as figure 1 Shown, or circulating fluidized bed boiler (circulating fluidized bed boiler, CFB), such as Figure 5 shown. In a bubbling fluidized bed boiler, a fluidized bed is created by a gas flow. The application location can also be an alkali recovery boiler, which is Image 6 is shown in and is based on black liquor combustion, or a boiler where the fuel is fired on the grate, or another type of steam boiler.

[0036] figure 1 Shown is a boiler 1 , which in this example is a bubbling fluidized bed boiler, comprising a furnace 2 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com