Fluidized bed reactor system having an exhaust gas plenum

A technology of reactor system and ventilation system, applied in fluidized bed boilers, fluidized bed combustion equipment, chemical instruments and methods, etc., can solve problems such as complex structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

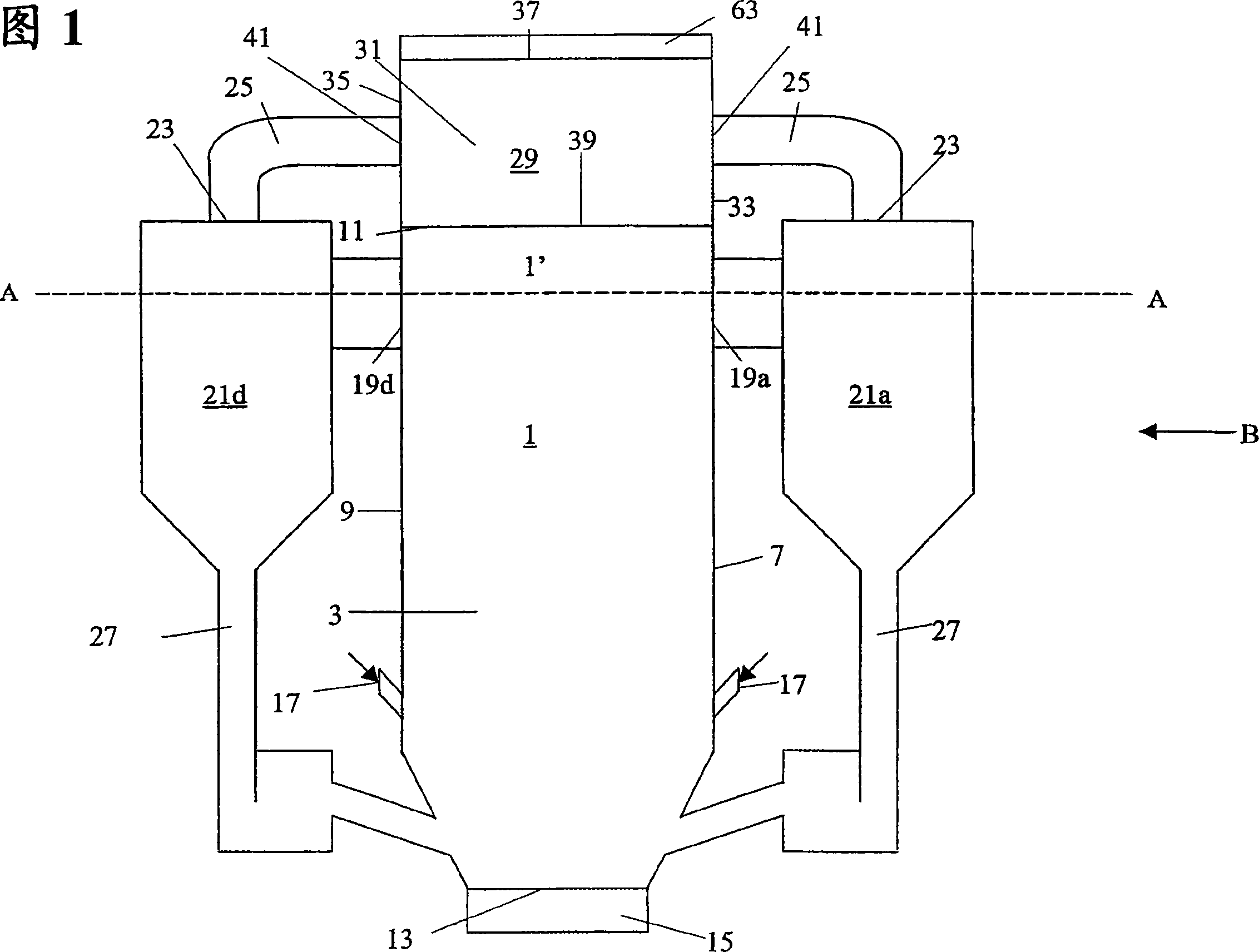

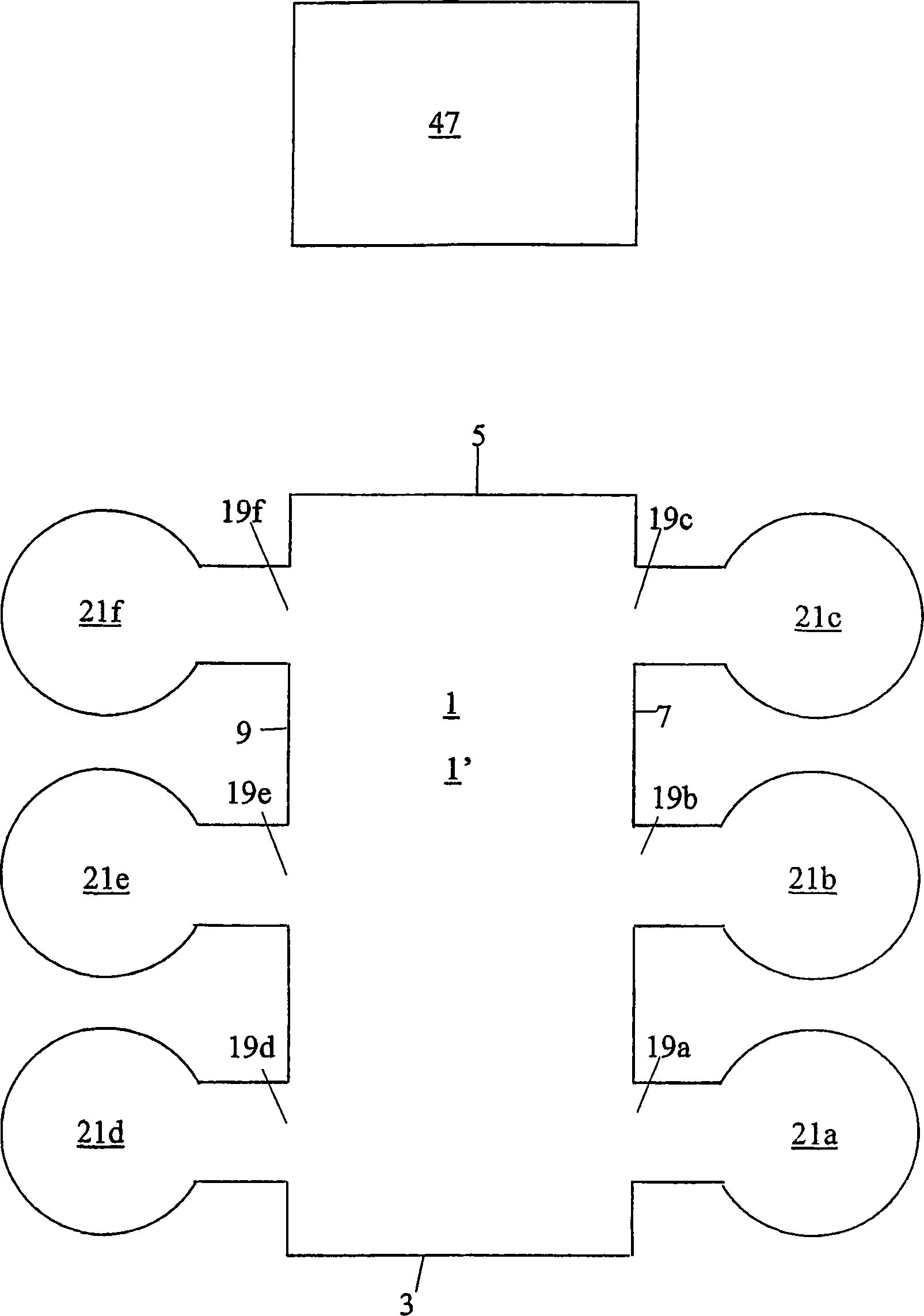

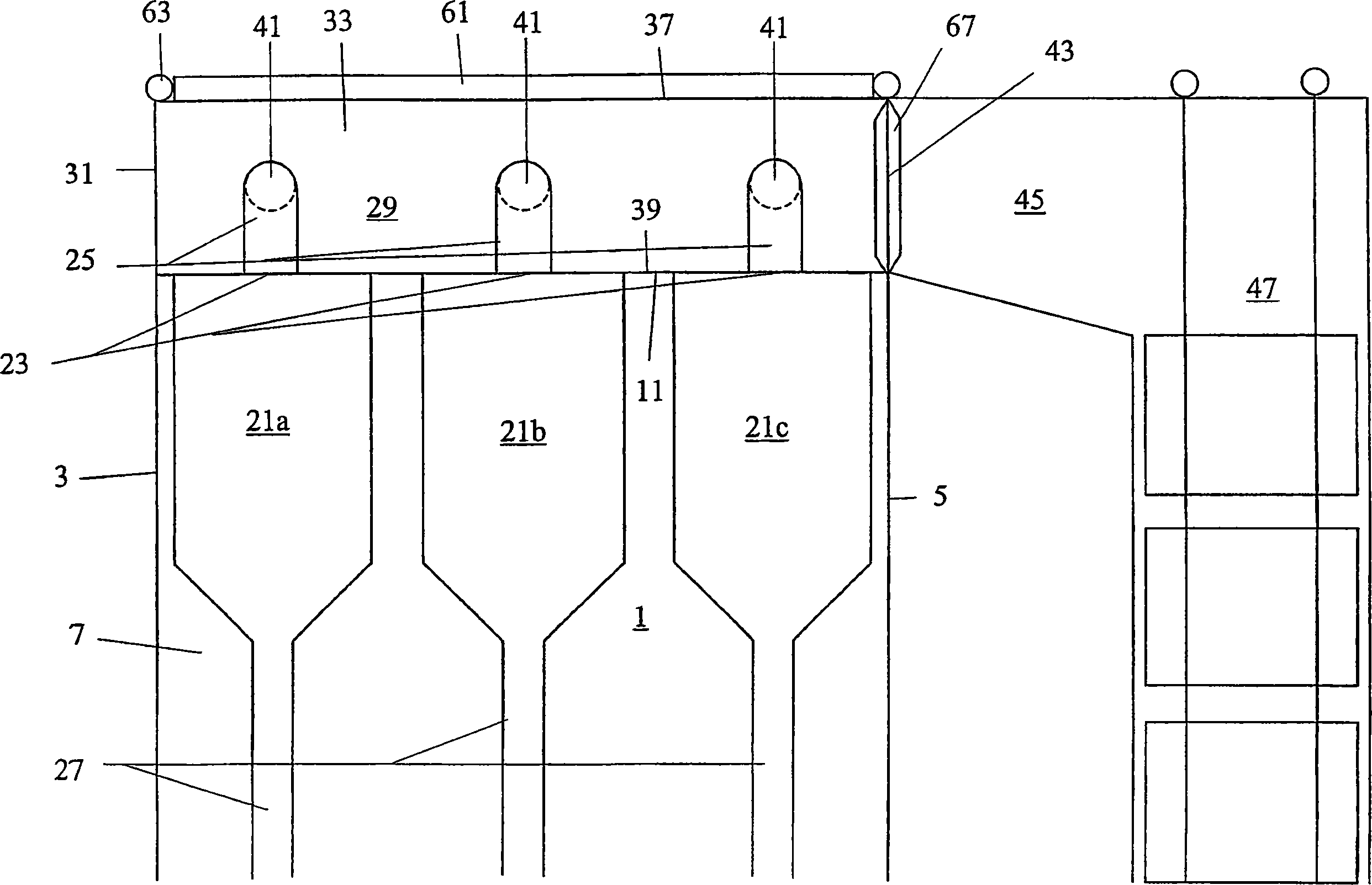

[0038] As shown in Figures 1, 2 and 3, the circulating fluidized bed reactor system includes a reaction chamber 1 in which a fluidized bed of solid particles is arranged. The reaction chamber 1 includes a front wall 3, a rear wall 5, a right side wall 7 and a left side wall 9, a top 11, and a bottom 13, and the chamber is formed by a common water tube plate, which includes water tubes connected by fins. The reaction chamber 1 includes a mechanism 15 for introducing fluidization gas, such as a nozzle or a ventilation pipe; a mechanism 17 for introducing fuel, such as a pneumatic or gravity fuel conveyor. The side walls 7, 9 of the reaction chamber are provided with six discharge ports 19a to 19f, which can discharge the particle suspension of the exhaust gas and the solid particles formed in the reaction chamber 1 through the upper part 1' of the reaction chamber 1. The outlets 19a to 19f of the reaction chamber are respectively provided with six particle separators 21a to 21f ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com