Patents

Literature

37results about How to "Improve hydrogen efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

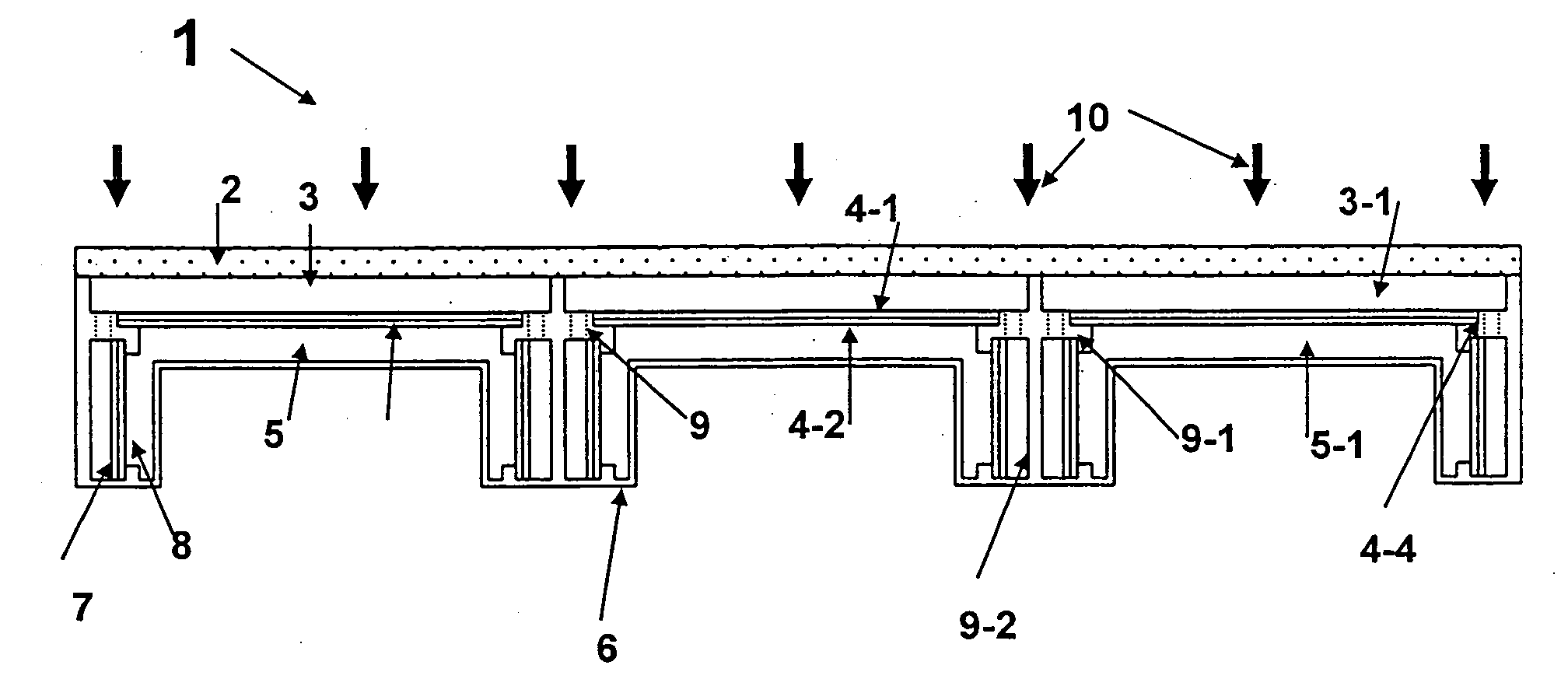

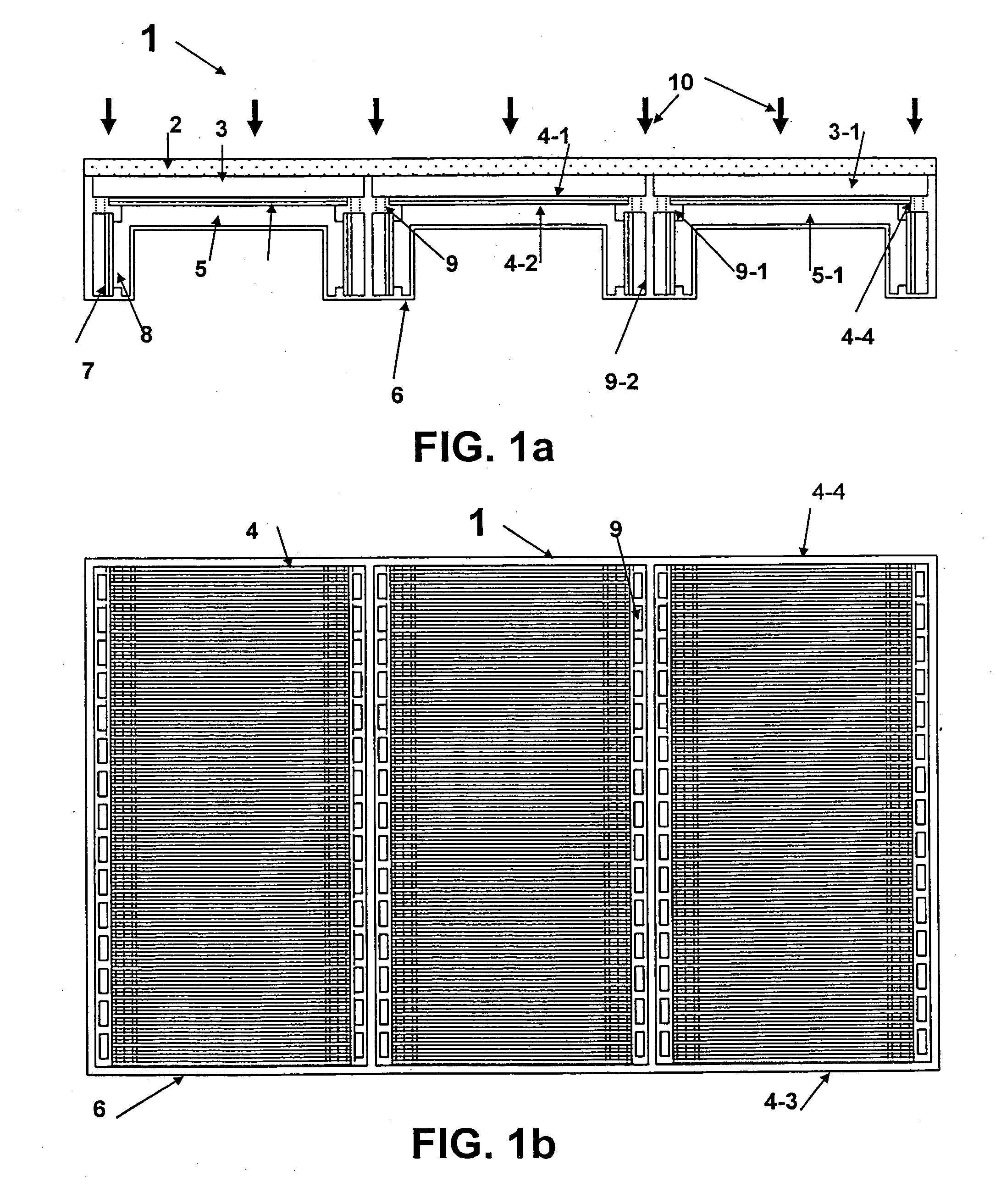

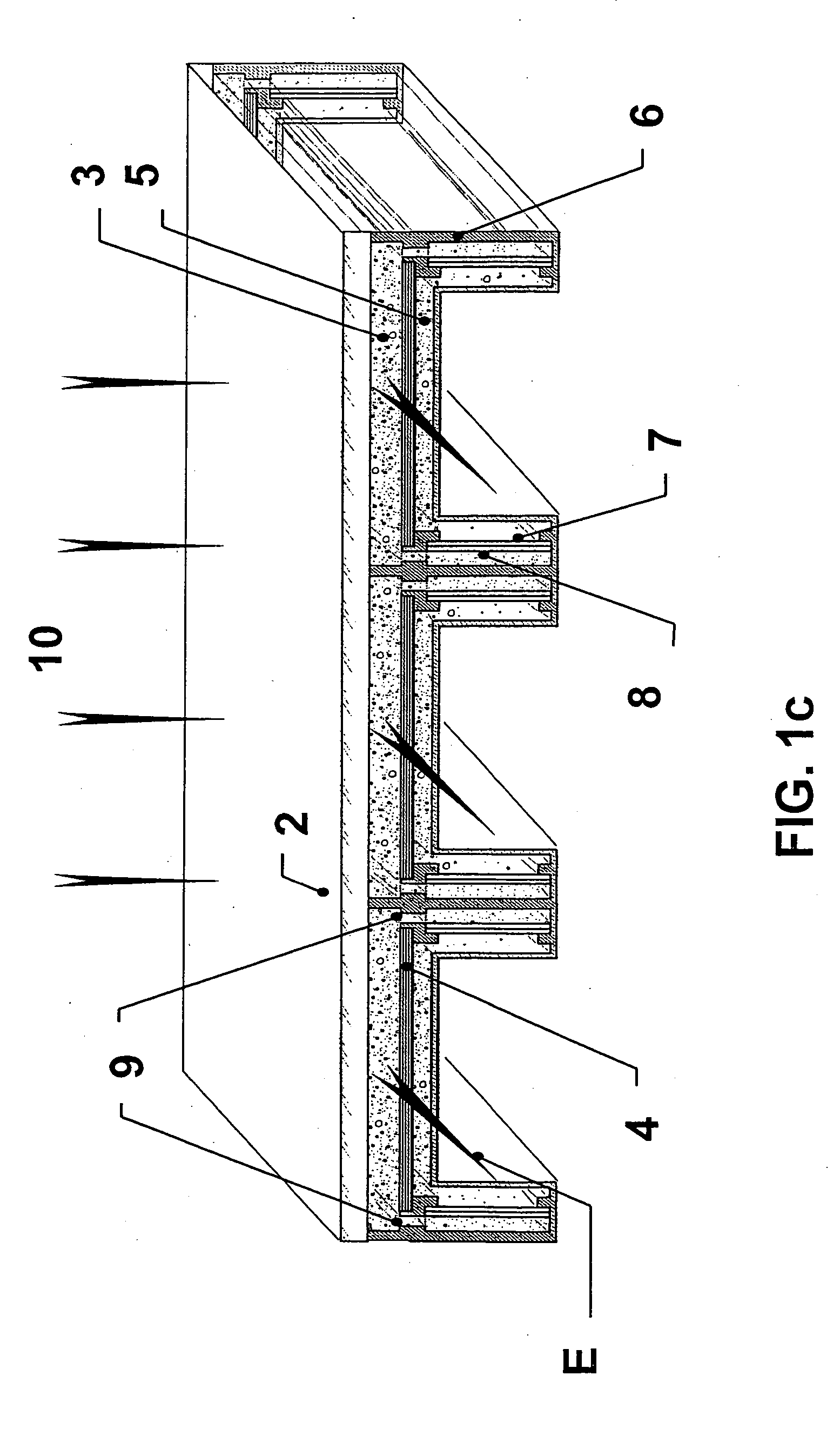

Integrated photoelectrochemical cell and system having a liquid electrolyte

InactiveUS20050211290A1Improve hydrogen efficiencyImprove oxygen production efficiencyCellsLight-sensitive devicesHydrogenPhotoelectrochemical cell

An integrated photoelectrochemical (PEC) cell generates hydrogen and oxygen from water while being illuminated with radiation. The PEC cell employs a liquid electrolyte, a multi-junction photovoltaic electrode, and a thin ion-exchange membrane. A PEC system and a method of making such PEC cell and PEC system are also disclosed.

Owner:UNIVERSITY OF TOLEDO

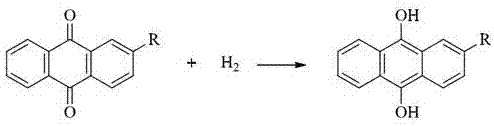

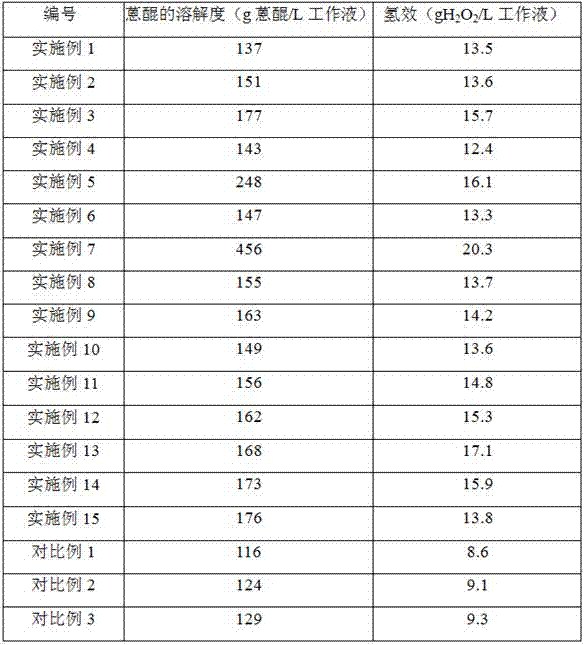

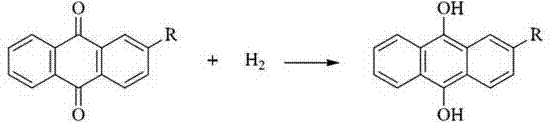

Organic flux system in hydrogen peroxide producing process

ActiveCN1552618AImprove solubilityImprove hydrogen efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolventSolubility

An organic solvent system for preparing H2O2 is prepared from C9-C10 arylhydrocarbon (100 wt portions), trioctyl phosphate (0.5-50), and 2-methylcyclohexyl acetate (0.5-90). Its advantages are high solubility of anthraquinone and hydrogenated anthraquinone in it, low by-effect and high productivity of H2O2.

Owner:YICHANG SUPENG TECH CO LTD

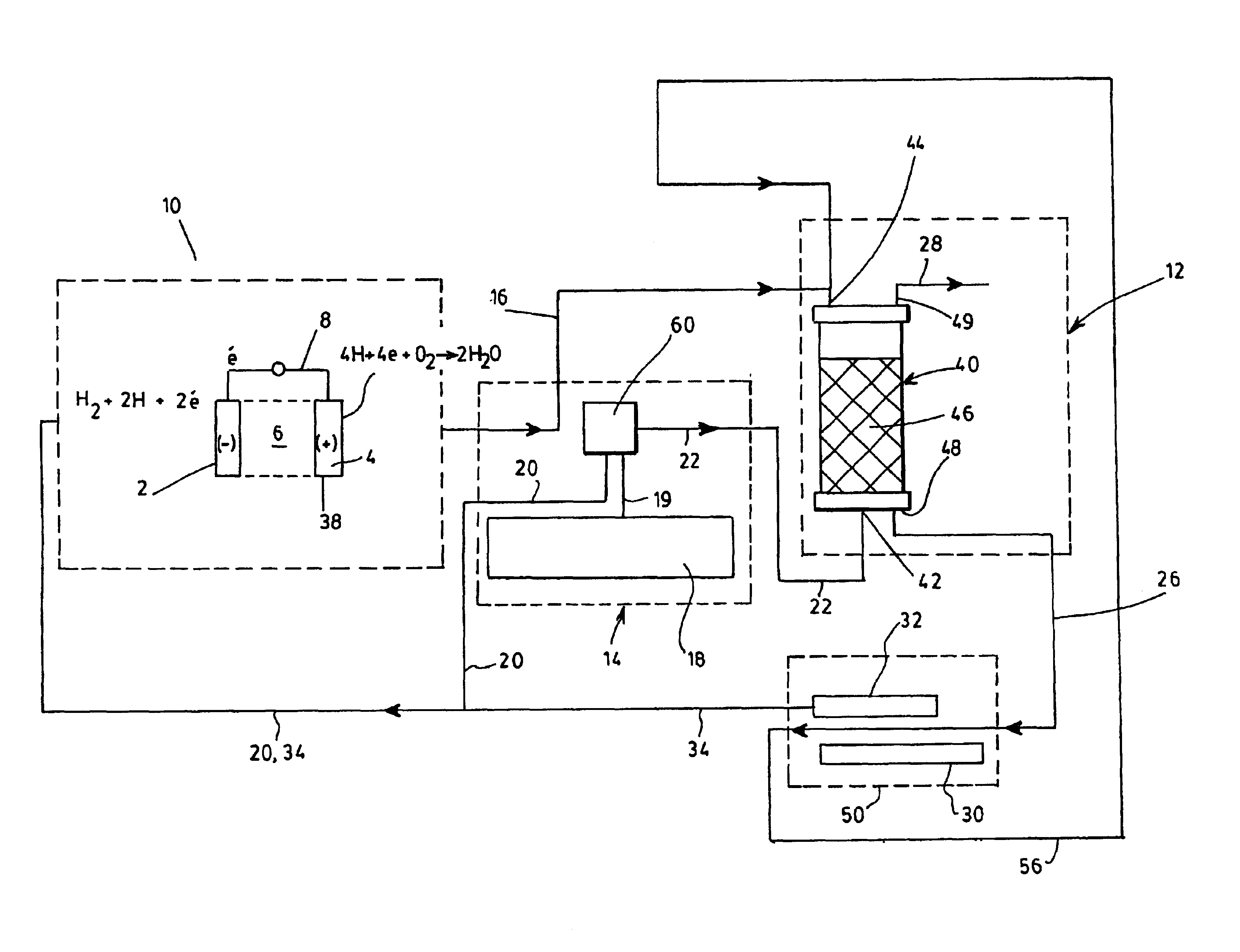

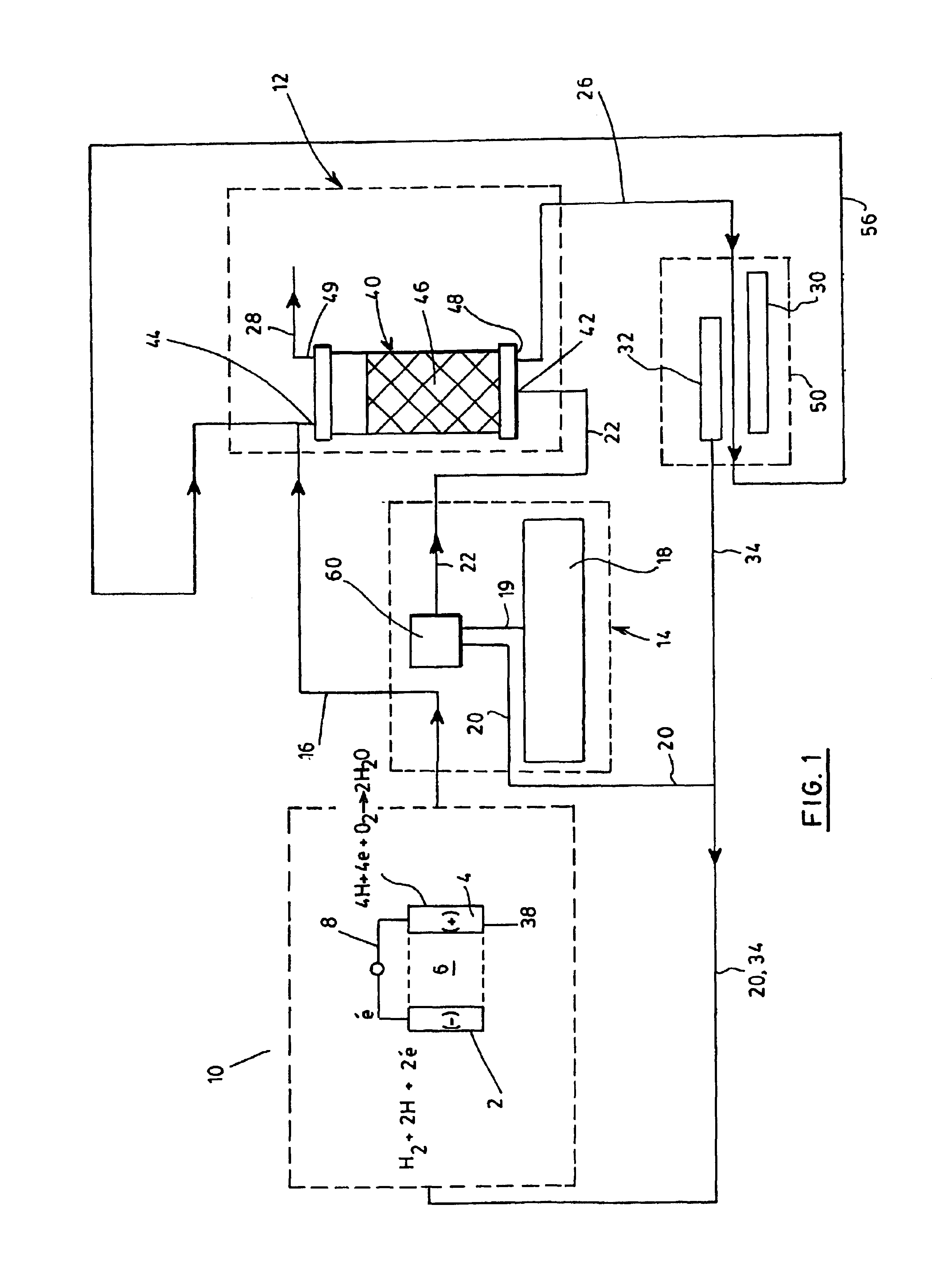

Process for generating electricity with a hydrogen fuel cell

InactiveUS6846584B2Improve hydrogen efficiencySimple and non-pollutingFinal product manufactureRegenerative fuel cellsElectricityCoupling

The object of the invention is the coupling of a hydrogen fuel cell to an enzymatic process for the production of electricity and the transformation and sequestration of CO2. Gaseous CO2 emissions from processes such as hydrocarbon reforming are transformed into carbonate or bicarbonate ions and hydrogen ions by the enzymatic system in order to prevent their contribution to the greenhouse effect. The hydrogen ions resulting from the enzymatic process are recovered and combined in order to supply the hydrogen fuel cell. Finally, water, a by-product of the oxidizing reaction of the hydrogen fuel cell, is recovered and recycled back into the aqueous enzymatic system.

Owner:CO2 SOLUTION

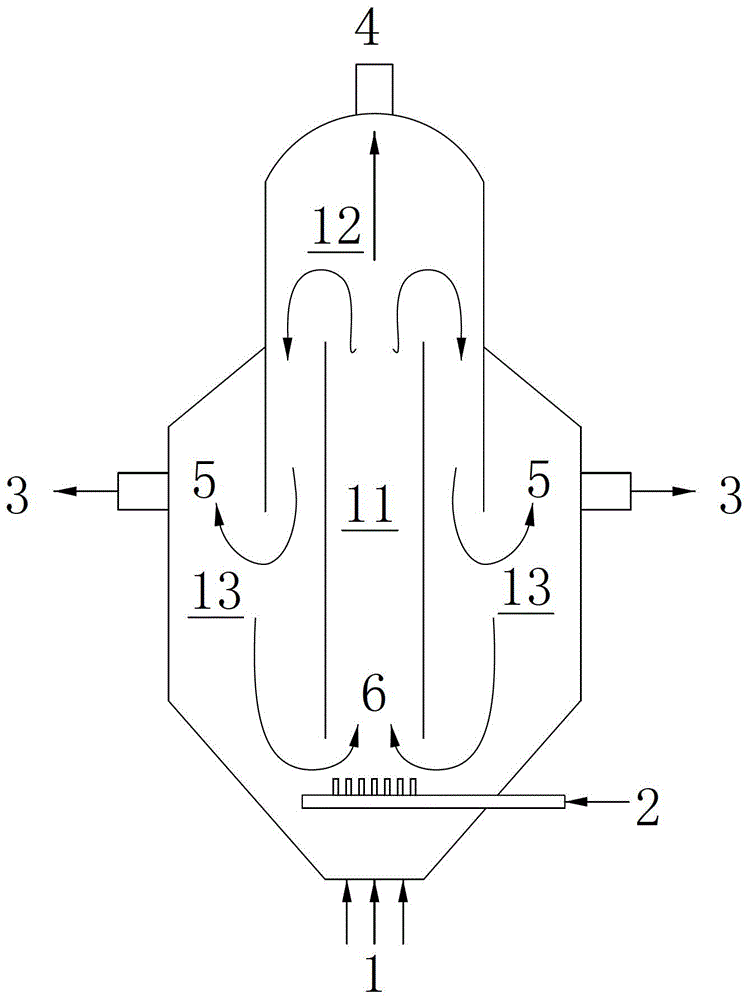

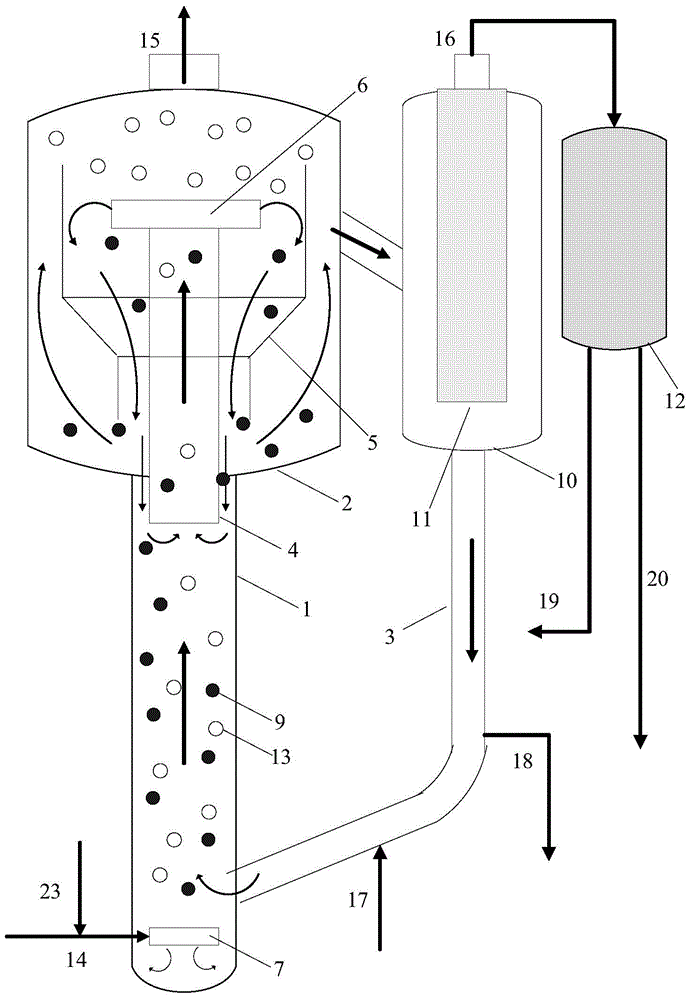

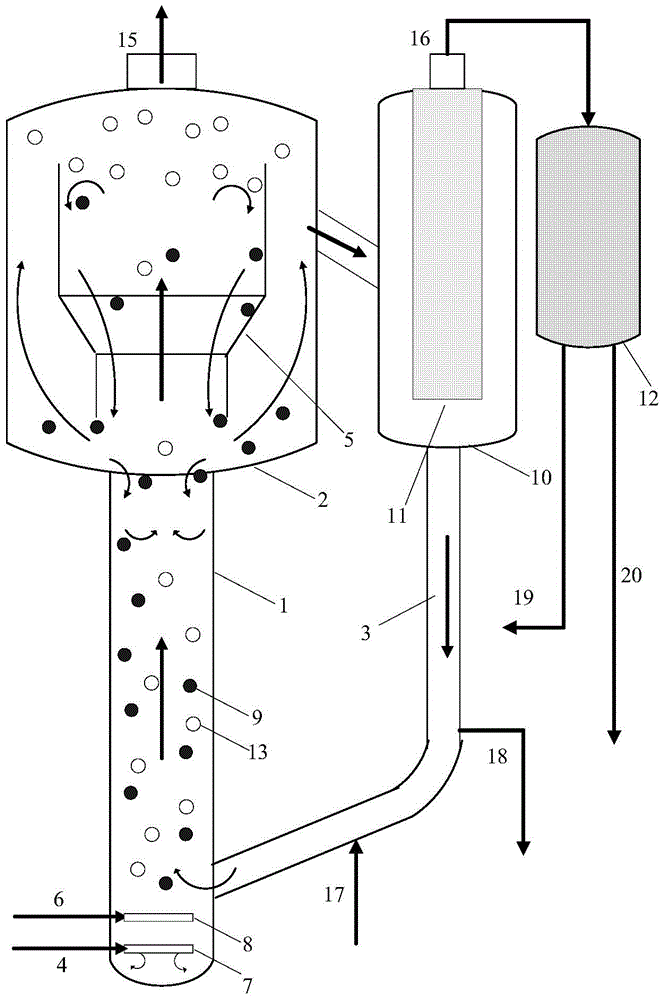

Method for preparing hydrogen peroxide

ActiveCN104418309AImprove hydrogen efficiencyAvoid air lockPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogen peroxide breakdownHydrogen

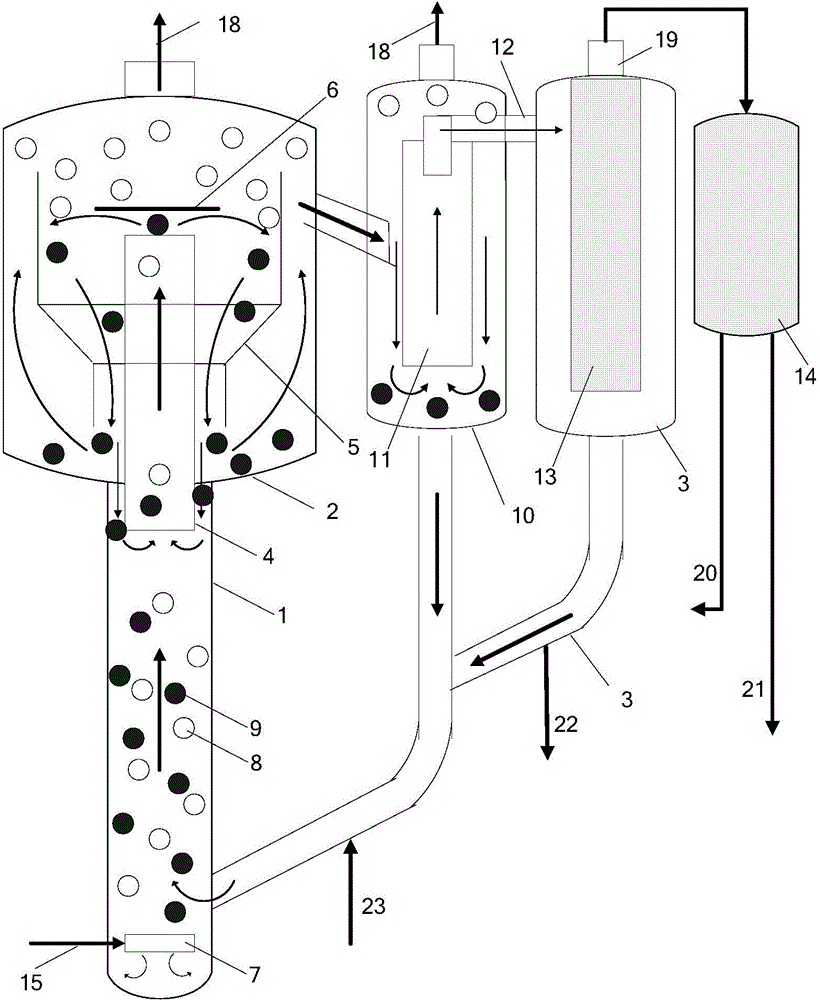

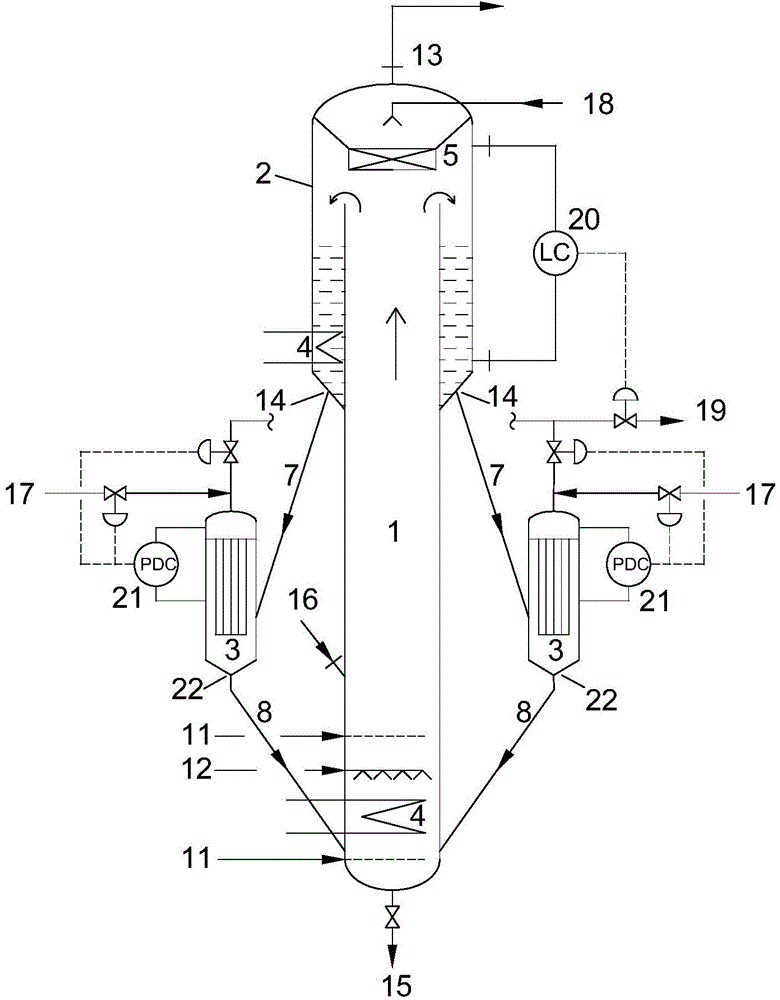

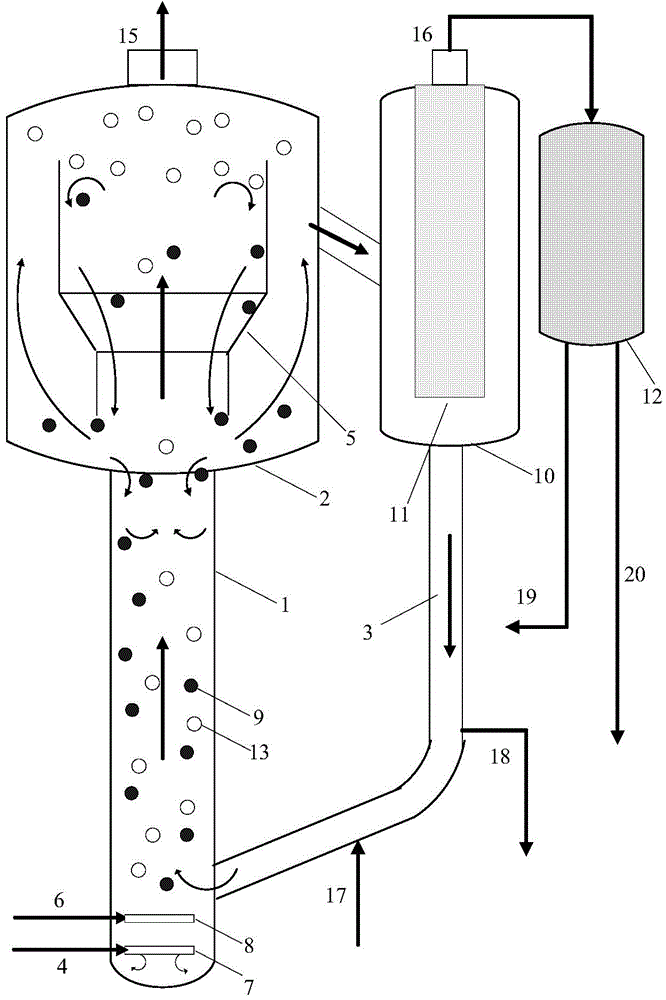

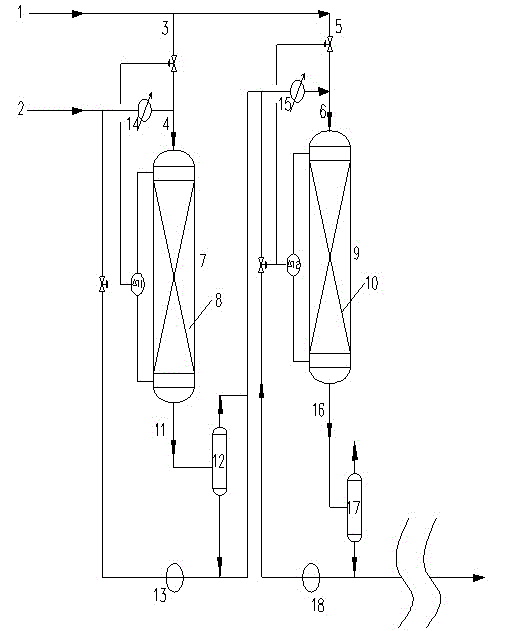

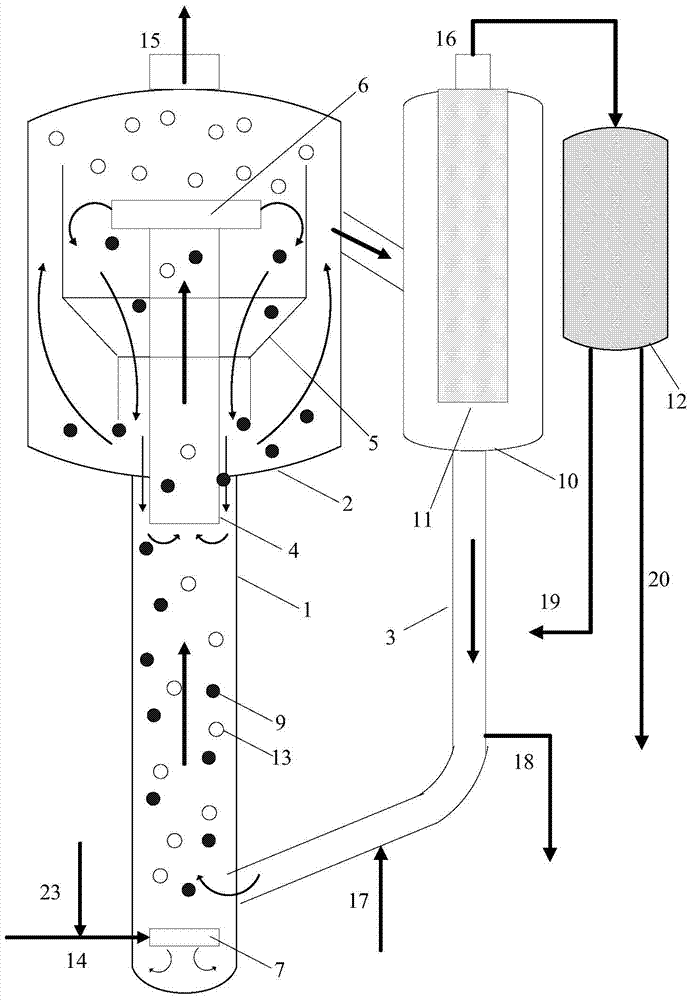

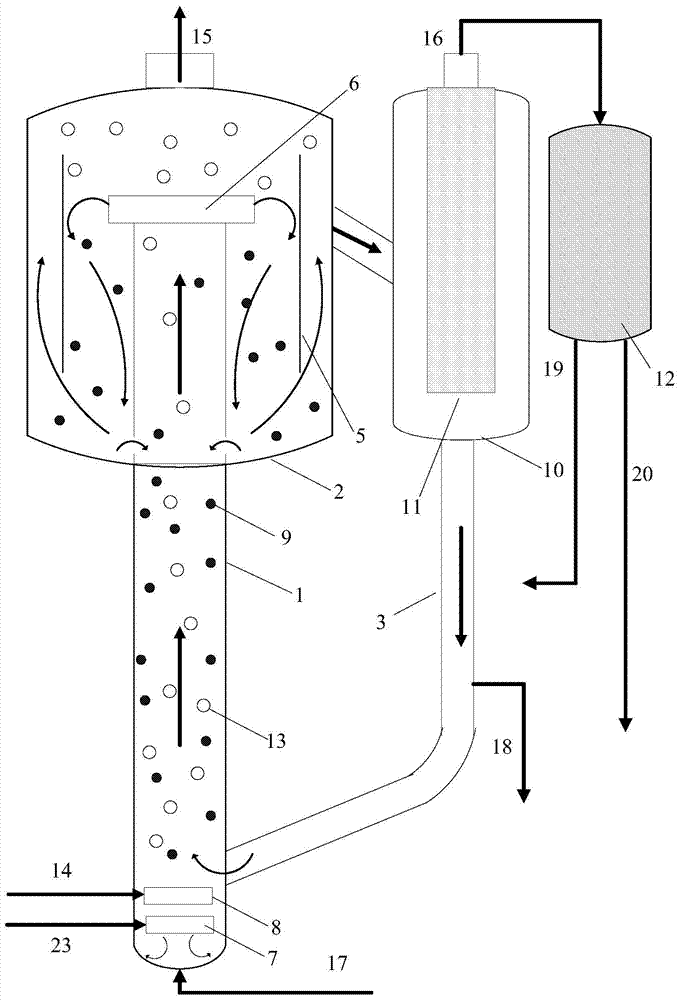

The invention discloses a method for preparing hydrogen peroxide. A working liquid and a hydrogen-containing gas are introduced into a slurry bed reactor; a hydrogenated liquid is obtained by reaction in the existence of a catalyst; the hydrogenated liquid reacts with oxygen to obtain the hydrogenated liquid containing hydrogen peroxide in an oxidation reactor; oxidized liquid is extracted and separated from an extraction tower to obtain a hydrogen peroxide solution and working liquid; the slurry bed reactor comprises a cap (12), an expanding section (13) and a draft tube (11); the expanding section (13) is positioned at the lower part of the cap (12); the pipe diameter of the expanding section (13) is greater than that of the cap; the draft tube (11) is arranged in the expanding section (13); the pipe diameter of the draft tube (11) is smaller than that of the cap (12); a bottom opening of the cap (12) extends into the expanding section (13); the outer wall of the cap (12) is connected with the top of the expanding section (13); an upper opening of the draft tube (11) extends into the cap (12); and an opening is formed in the lower part of the draft tube (11). The method disclosed by the invention is stable to operate, and easy for realization of industrial enlargement; no alkali is introduced in the process of preparing hydrogen peroxide; and the risk of explosion caused by hydrogen peroxide decomposition is avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

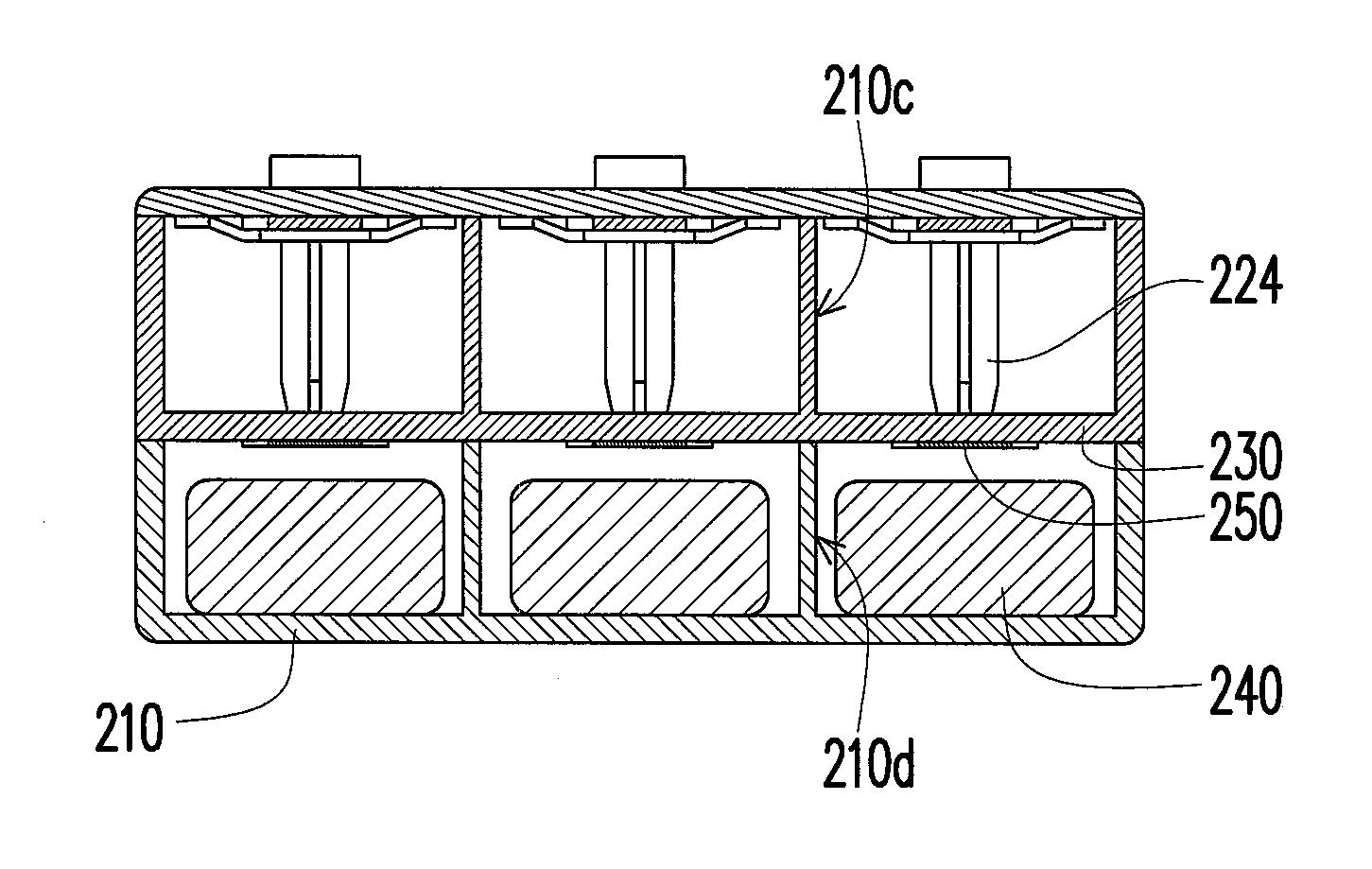

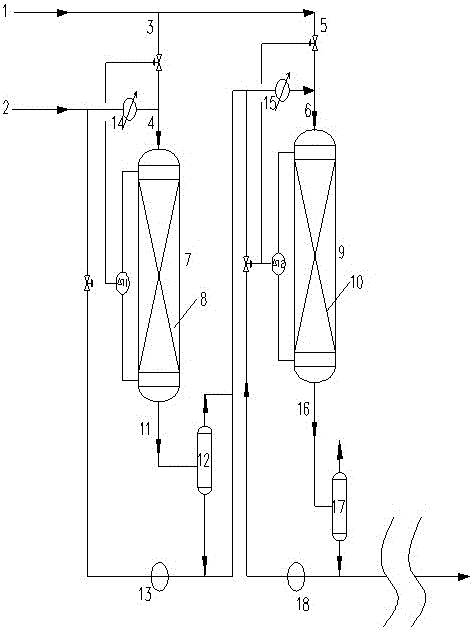

Slurry bed loop reactor, application and method for producing hydrogen peroxide

ActiveCN104549060AExtended operating cycleEasy to separatePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

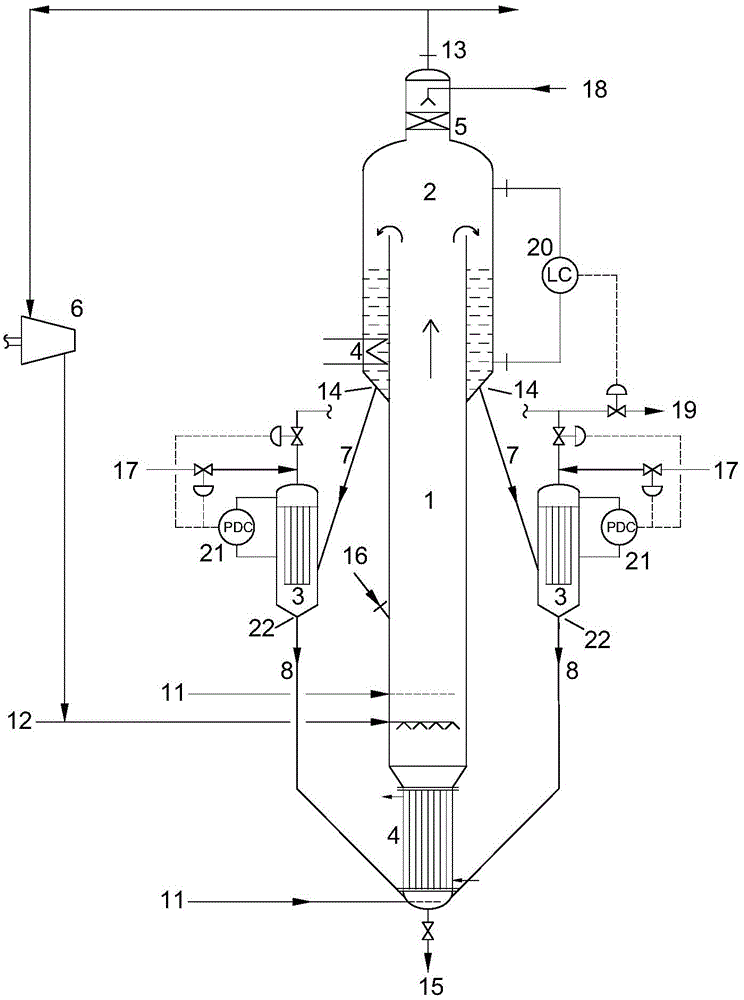

The invention relates to a slurry bed loop reactor, application and a method for producing hydrogen peroxide. The slurry bed loop reactor comprises a riser, a separation tank and a downcomer which are communicated sequentially, wherein an expansion section with expanded pipe diameter is arranged at the upper part of the riser, the upper part of the expansion section is communicated with the separation tank, a liquid phase outlet in the upper part of the separation tank is communicated with the upper part of the downcomer, the bottom of the downcomer is communicated with the bottom of the riser, and the bottom of the separation tank is communicated with the lower part of the downcomer; and a raw material inlet is formed in the bottom of the riser, gas outlets are formed in the top of the expansion section of the riser and in the top of the separation tank, a filtration component is arranged in the downcomer and a clear liquid outlet is formed in the upper part of the downcomer via the filtration component. According to a hydrogenation method for producing hydrogen peroxide by an anthraquinone method with the adoption of the slurry bed loop reactor, the gas-liquid-solid three-phase separation efficiency is high, the excess local liquid holdup of a catalyst is avoided, the possibility of excessive hydrogenation is reduced, the hydrogenation efficiency is further effectively improved and a hydrogen peroxide product with relatively high concentration can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

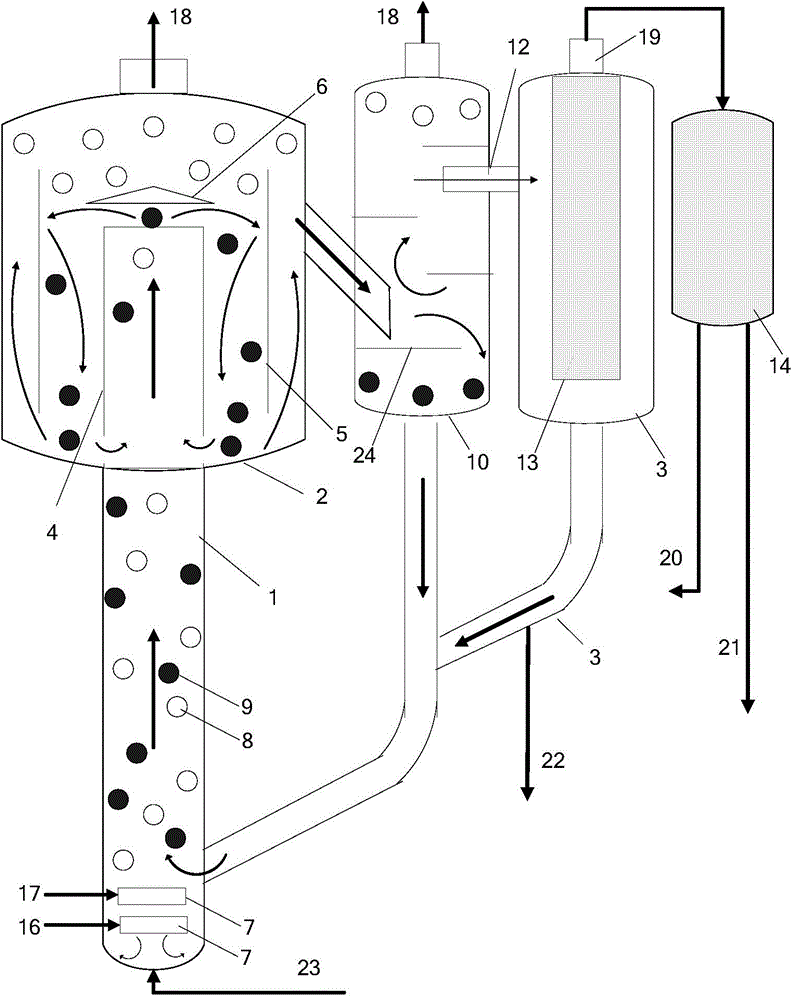

Slurry-bed circulation flow reactor and application and method for producing hydrogen peroxide

ActiveCN104549065AReduced chance of wear and tearIncrease concentrationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

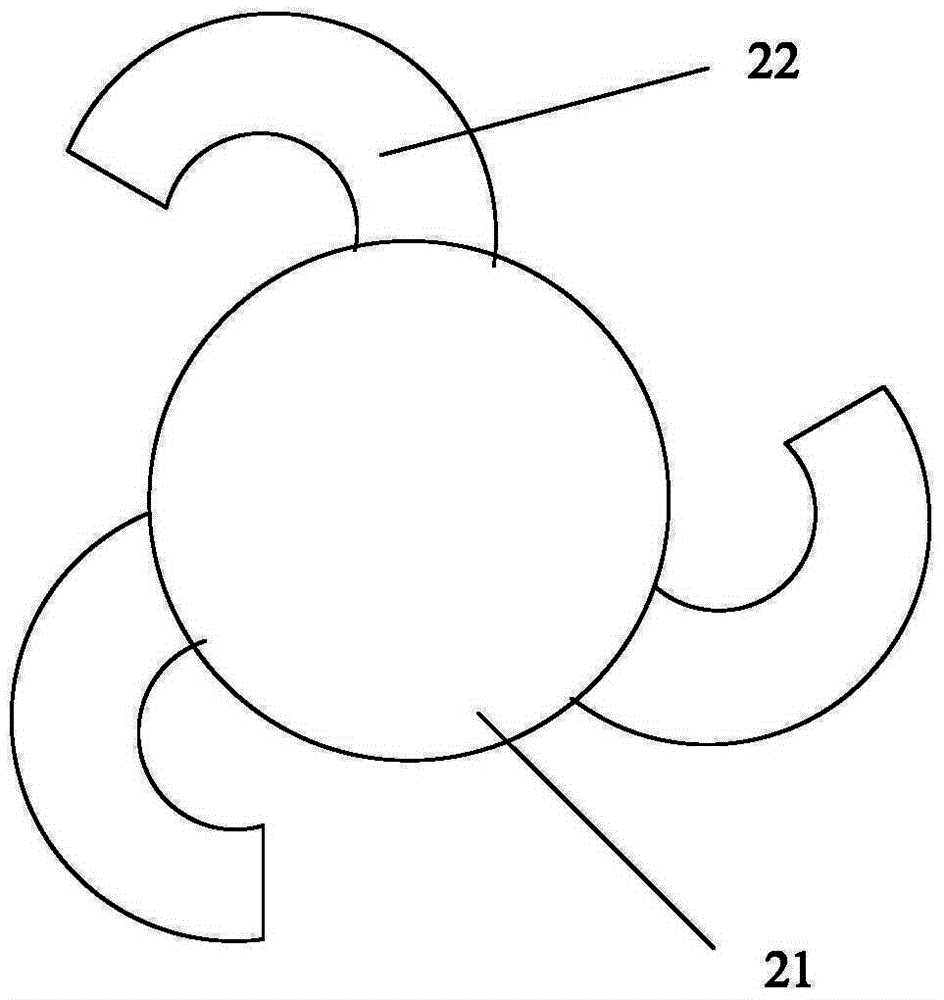

The invention discloses a slurry-bed circulation flow reactor and an application and a method for producing hydrogen peroxide. The slurry-bed circulation flow reactor comprises an ascension pipe, an expanding section used for expanding pipe diameter of the upper part of the ascension pipe and a solid-liquid separator, wherein the expanding section is communicated with the upper part of the solid-liquid separator; the bottom of the solid-liquid separator is communicated with the bottom of the ascension pipe; a three-phase separator of a double sleeve structure is arranged in the expanding section; a raw material inlet is formed in the bottom of the ascension pipe; a gas outlet is formed in the top of the expanding section; a filtration component is arranged in the solid-liquid separator; and a clear liquid outlet is arranged at the upper part of the solid-liquid separator by virtue of the filtration component. According to a method for producing hydrogen peroxide by taking the slurry-bed circulation flow reactor as a hydrogenation reactor, the gas-liquid-solid three-phase separation efficiency is high; the local excessive hydrogenation of the catalyst is avoided; the excessive hydrogenation possibility is reduced; the hydrogenation efficiency is high; and hydrogen peroxide products with high concentration can be produced.

Owner:CHINA PETROLEUM & CHEM CORP +1

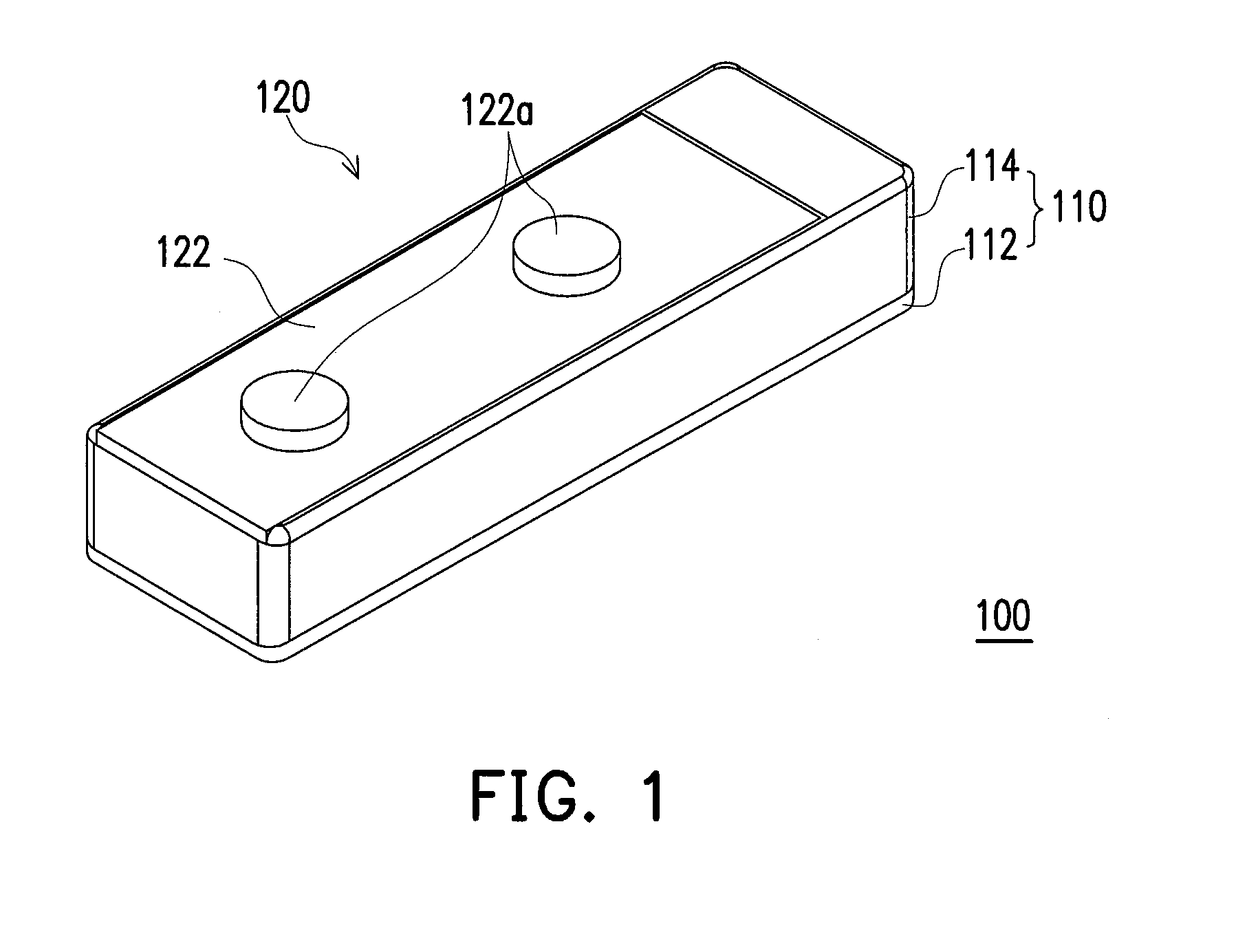

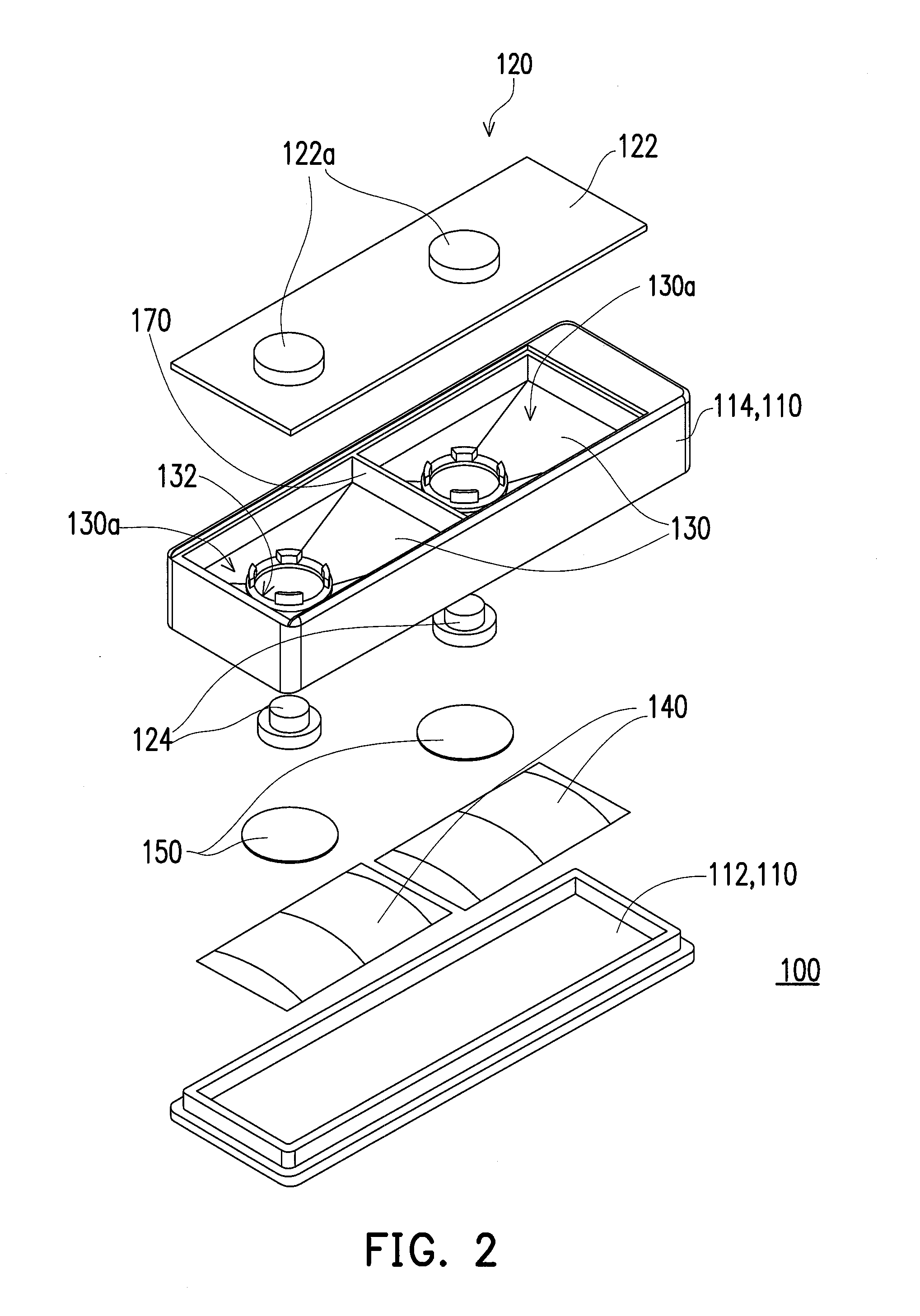

Apparatus for generating hydrogen

InactiveUS20120156103A1Improve hydrogen efficiencyImprove efficiencyHydrogenGaseous chemical processesHydrogenFuel cells

An apparatus for generating hydrogen for fuel cells is provided. The apparatus includes a housing, a button, a first separating plate, a solid state reactant, and a separating membrane. The housing has an opening and a reservoir. The button connected to the housing covers the opening. The first separating plate disposed in the housing divides the reservoir into first and second sub-rooms. The opening communicates with the first sub-room and the first sub-room is suitable for storing a liquid reactant. The first separating plate has a through hole opposite to the button. The solid state reactant is disposed in the second sub-room. The separating membrane disposed on the through hole separates the first sub-room from the second sub-room. When the button is pushed, the button damages the separating membrane. Therefore, the liquid reactant flows to the second sub-room and reacts with the solid state reactant to generate hydrogen.

Owner:YOUNG GREEN ENERGY

Preparation method of hydrogen peroxide

InactiveCN104370276AAvoid Explosion HazardsImprove hydrogen efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesHydrogen peroxide breakdownHydrogen

A preparation method of hydrogen peroxide is as follows: a working liquid and a hydrogen-containing gas are introduced into a slurry bed reactor, in the presence of a catalyst, the working liquid reacts with hydrogen to obtain a hydrogenated liquid, the hydrogenated liquid reacts with oxygen in an oxidation reactor to obtain an oxidizing solution containing hydrogen peroxide; the oxidizing solution is extracted and separated to obtain a hydrogen peroxide solution and a working fluid, the slurry bed reactor comprises a reaction cylinder (1), a separator (2) and a filter (3), a top opening of the reaction cylinder (1) extends into the separator (2), the outer wall of the reaction cylinder (1) is connected with the bottom of the separator (2), the separator (2) is communicated with the filter (3) by a liquid phase outlet (14), and a slurry outlet of the filter (3) is communicated with the bottom of the reaction cylinder (1). The method provided by the invention is stable in operation and easy in industrialization amplification. In the process of preparing of hydrogen peroxide, no alkali is introduced, and the danger of explosion led by hydrogen peroxide decomposition caused by an alkali can be avoided.

Owner:CHINA PETROLEUM & CHEM CORP +1

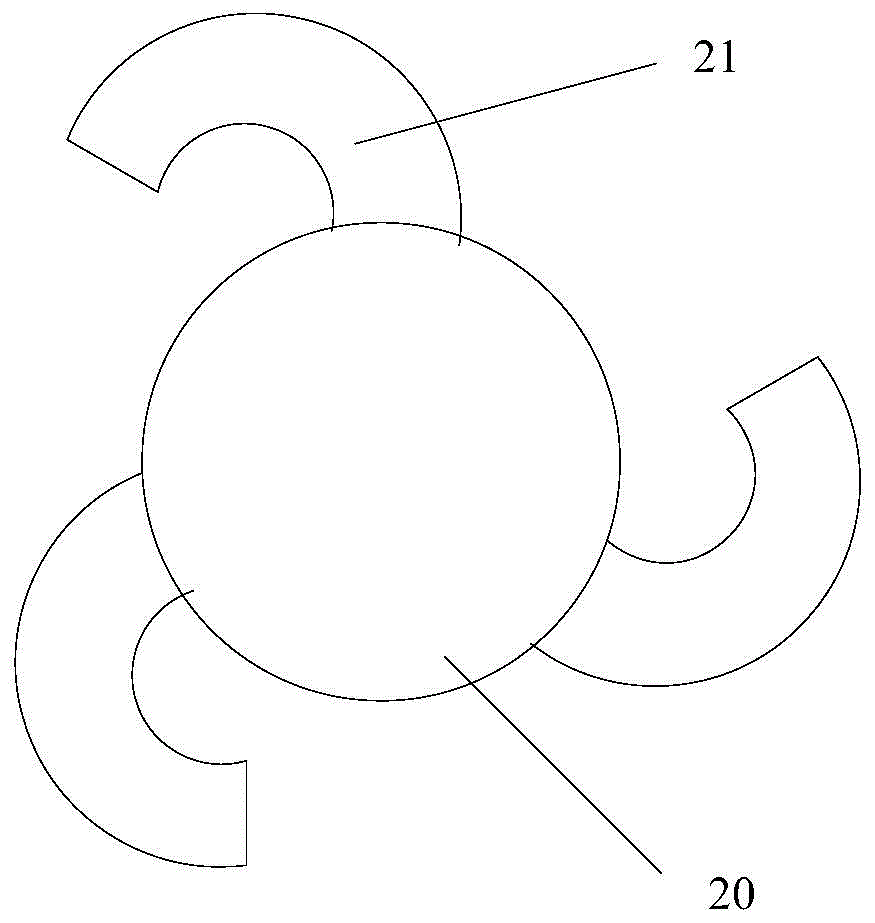

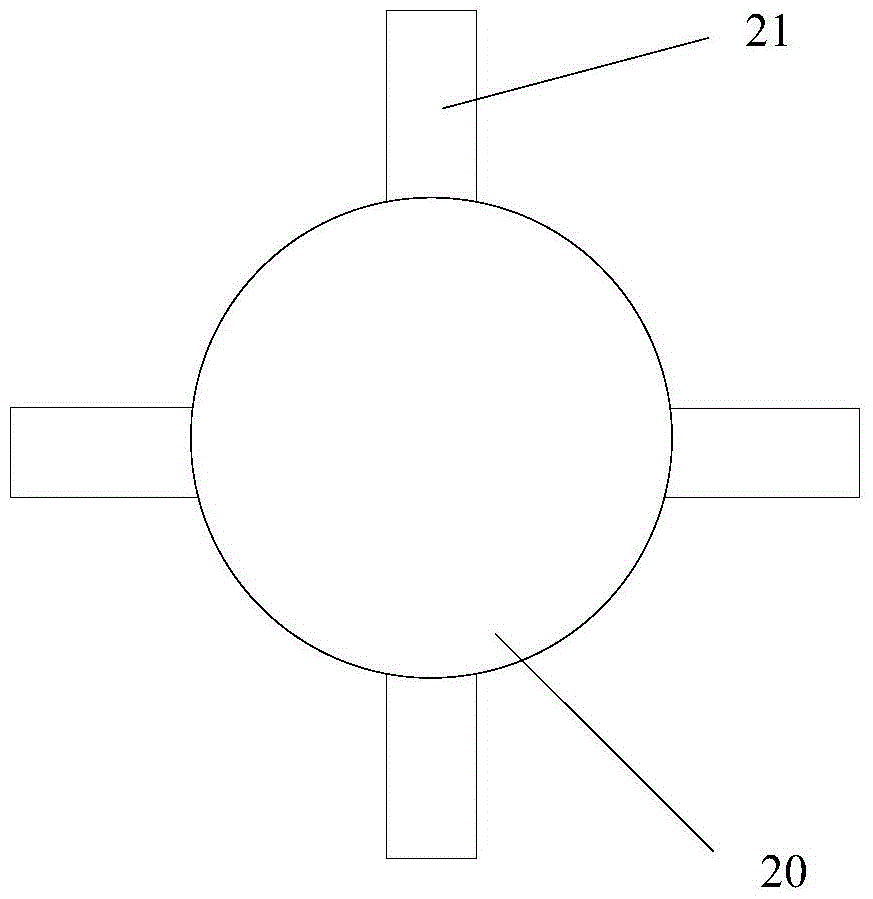

Slurry bed hydrogenation reactor for preparing hydrogen peroxide by adopting anthraquinone process and application of slurry bed hydrogenation reactor

ActiveCN104549059AReduce operational burdenReduced chance of wear and tearPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesAnthraquinone processHigh concentration

The invention discloses a slurry bed hydrogenation reactor for preparing hydrogen peroxide by adopting an anthraquinone process and application of the slurry bed hydrogenation reactor. The hydrogenation reactor comprises an ascension pipe, an expanding section for expanding the upper pipe diameter of the ascension pipe, and a solid-liquid separator, wherein the expanding section is communicated with the upper part of the solid-liquid separator; the bottom of the solid-liquid separator is connected with the bottom of the ascension pipe; a guide cylinder is arranged in the expanding section; the bottom of the ascension pipe is provided with a raw material inlet; the top of the expanding section is provided with a gas outlet; a filter assembly is arranged in the solid-liquid separator and provided with a purified liquor outlet. The method for preparing the hydrogen peroxide is characterized in that the slurry bed hydrogenation reactor is applied to a hydrogenation unit, the gas-liquid-solid three-phase separation efficiency is high, the catalyst locality cannot be excessively hydrogenated, the excessive hydrogenation possibility is reduced, the hydrogenation efficiency is high, and a hydrogen peroxide product with the relatively high concentration can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

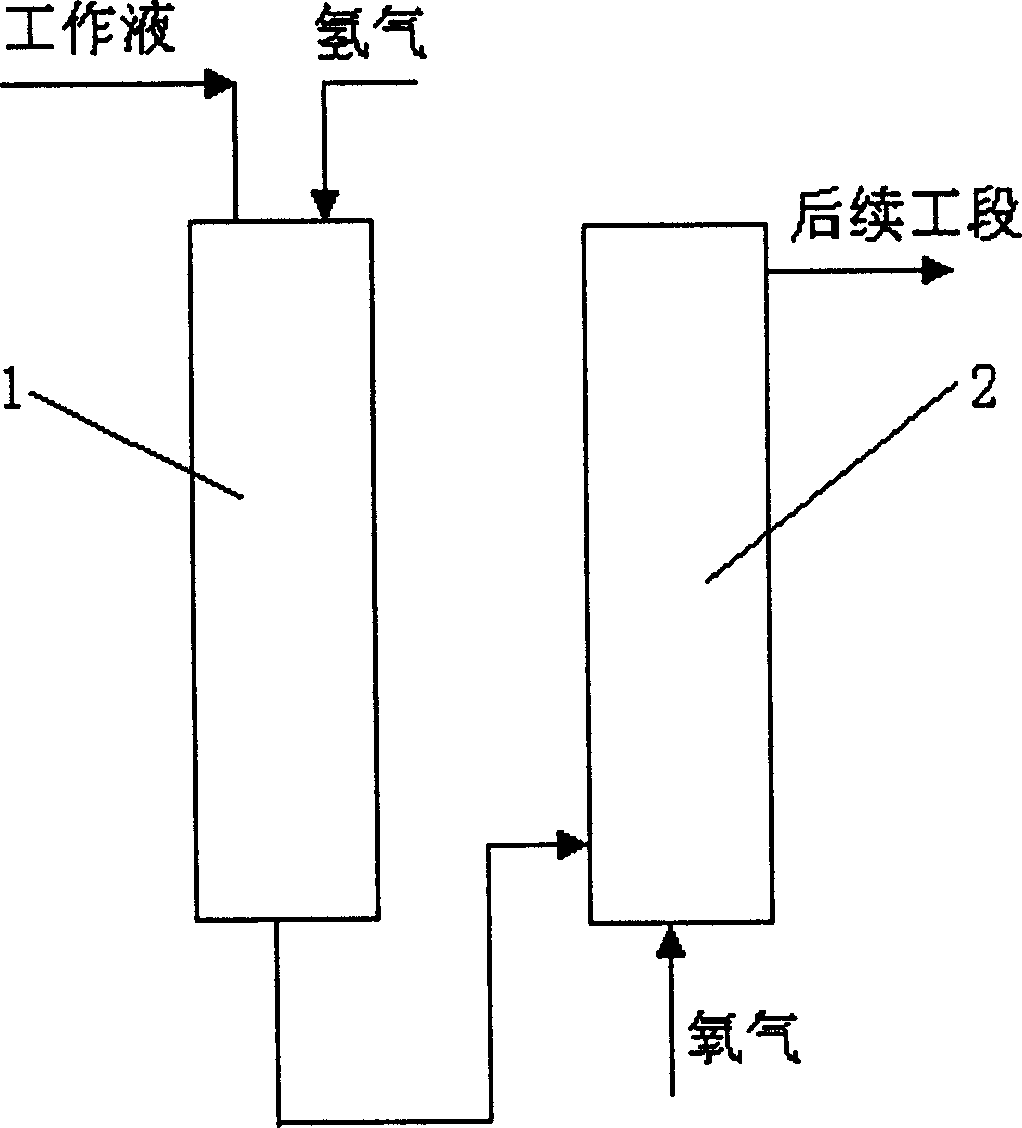

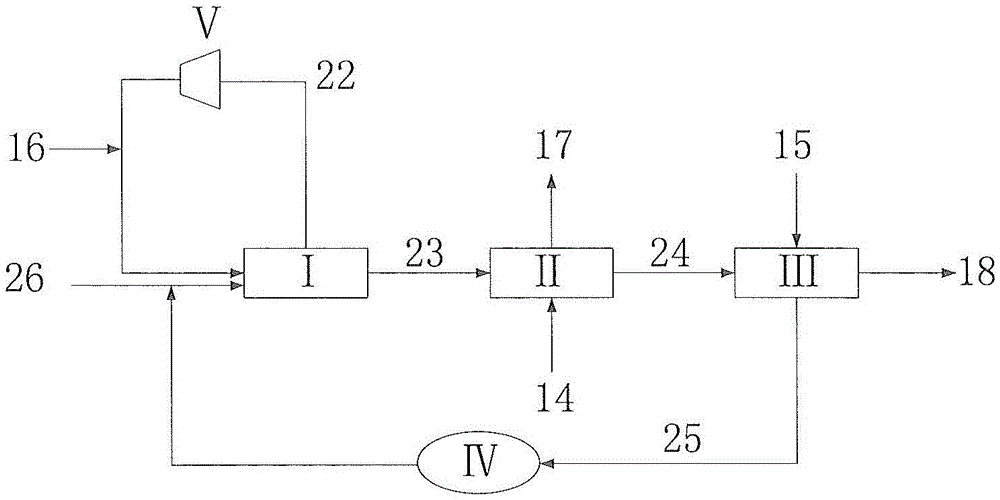

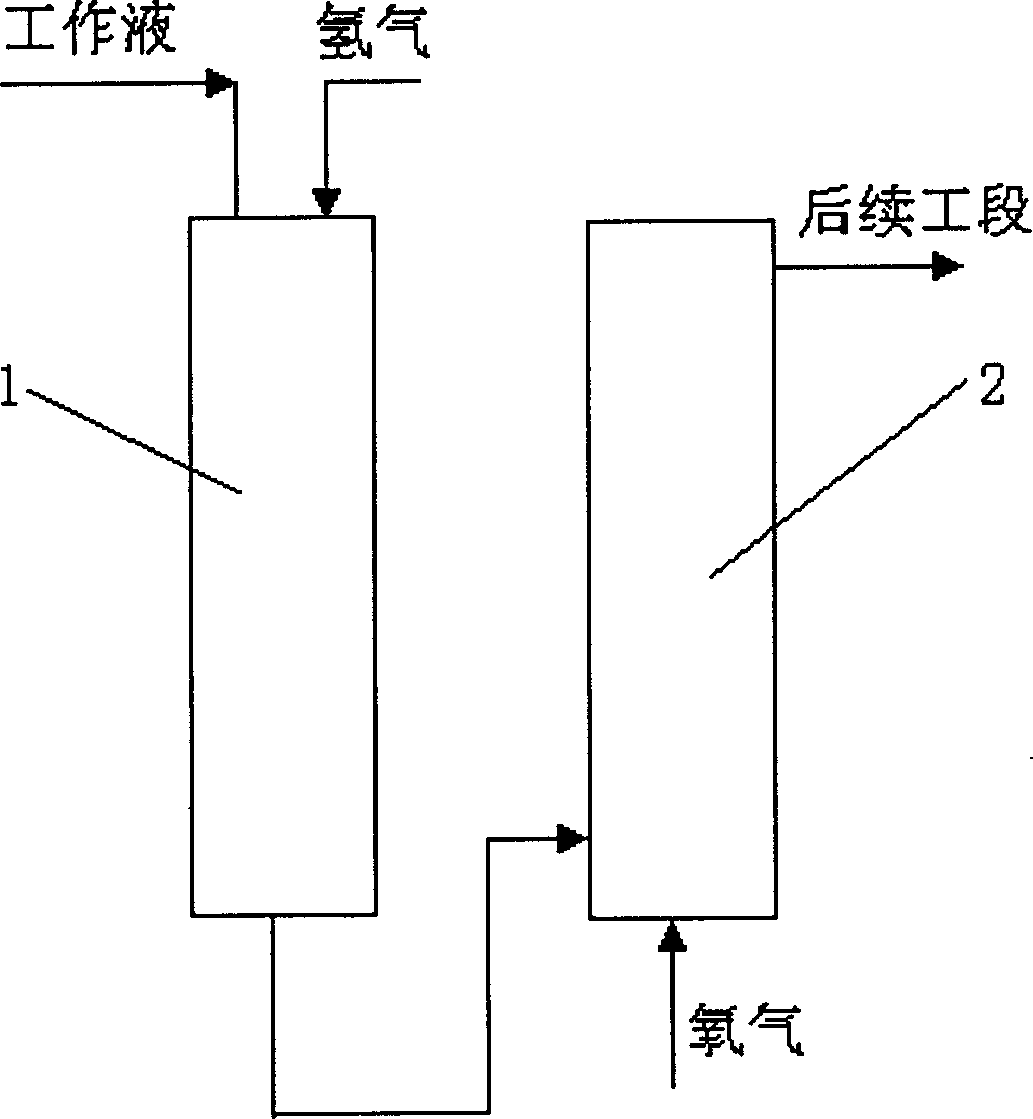

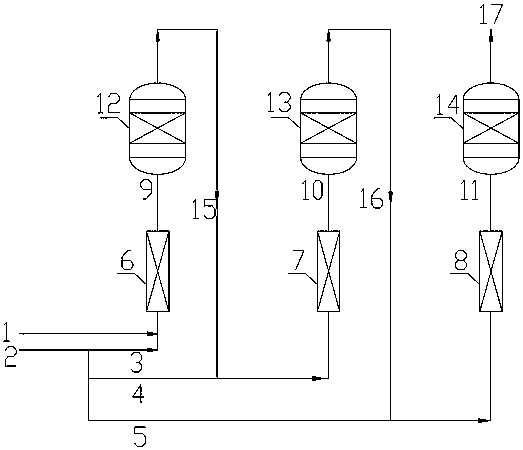

Hydrogenation process for producing hydrogen peroxide by anthraquinone method

ActiveCN104555935APrevent deficienciesAvoid excessive hydrogenation reactionsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesGas phaseHydrogenation process

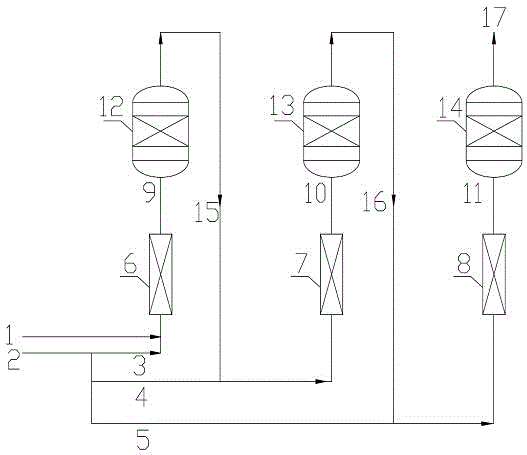

The invention discloses a hydrogenation process for producing a hydrogen peroxide by an anthraquinone method. The hydrogenation process comprises the following steps that: (1) two reactors are arranged in the hydrogenation process for producing the hydrogen peroxide by the anthraquinone method; a first current of fresh hydrogen and a working liquid serve as a feeding material I and perform hydrogenation in the first reactor; the reacted material is subjected to gas-liquid separation to obtain a gas phase and a liquid phase, wherein part of the liquid phase is recycled back to the first reactor; the rest of the liquid phase is reasonably optimized and modulated; the phenomenon that the reaction hydrogen is deficient or excessive is avoided; the hydrogenation completeness is realized; the liquid phase and the gas phase are mixed to serve as feeding material II and enter the second reactor; (2) a second current of fresh hydrogen and the feeding material II perform the hydrogenation in the second reactor; the reacted material is subjected to the gas-liquid separation to obtain a gas phase and a liquid phase, wherein part of the liquid phase is recycled back to the second reactor, and the rest of the liquid phase enters an oxidation process. According to the process disclosed by the invention, a hydrogenation process is optimized, and meanwhile, side effects are reduced, so that the hydrogenation is more uniform, and the service life of a catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

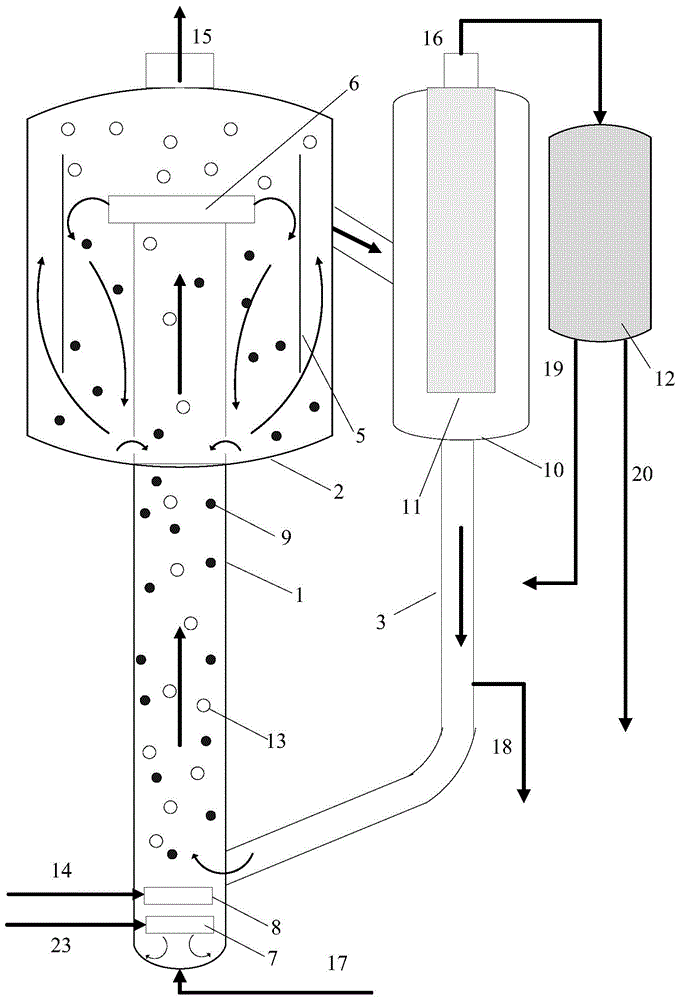

Hydrogenation process for hydrogen peroxide production

ActiveCN105621365AFully dispersedEvenly dispersedPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesWorking fluidHydrogenation reaction

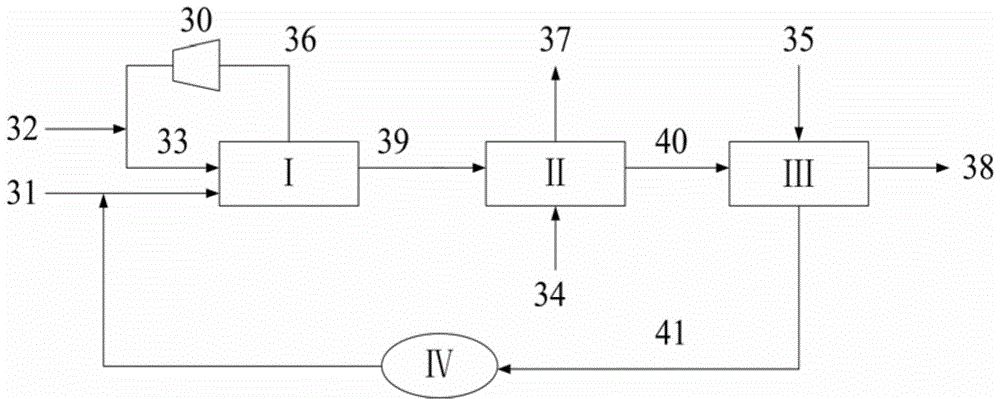

The invention discloses a hydrogenation process for hydrogen peroxide production. The process comprises the following steps: (1) in a hydrogenation process for producing hydrogen peroxide by an anthraquinone process, arranging a hydrogenation tower I, a hydrogenation tower II and a hydrogenation tower III, and feeding hydrogen gas in three channels, i.e., hydrogen gas I, hydrogen gas II and hydrogen gas III; (2) mixing and dissolving working fluid feed and the hydrogen gas I in high-pressure gas dissolving equipment, and then, enabling the solution to enter the hydrogenation tower I for a first-stage hydrogenation reaction; (3) mixing and dissolving effluent of the first-stage hydrogenation reaction and the hydrogen gas II in the high-pressure gas dissolving equipment, and then, enabling the solution to enter the hydrogenation tower II for a second-stage hydrogenation reaction; (4) mixing and dissolving effluent of the second-stage hydrogenation reaction and the hydrogen gas III in the high-pressure gas dissolving equipment, and then, enabling the solution to enter the hydrogenation tower III for a third-stage hydrogenation reaction; and (5) enabling a material obtained after the third-stage hydrogenation reaction to flow out, carrying out gas-liquid separation, and going to next procedure. According to the process, through controlling the proportion of dissolved hydrogen, not only can a relatively high hydrogenation effect be achieved, but also minimal anthraquinone degradation products are obtained, so that the improvement on product concentration and device scale and the lowering of the consumption of a catalyst and anthraquinone are facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Middle distillate hydrocracking catalyst with a base extrudate having a low particle density

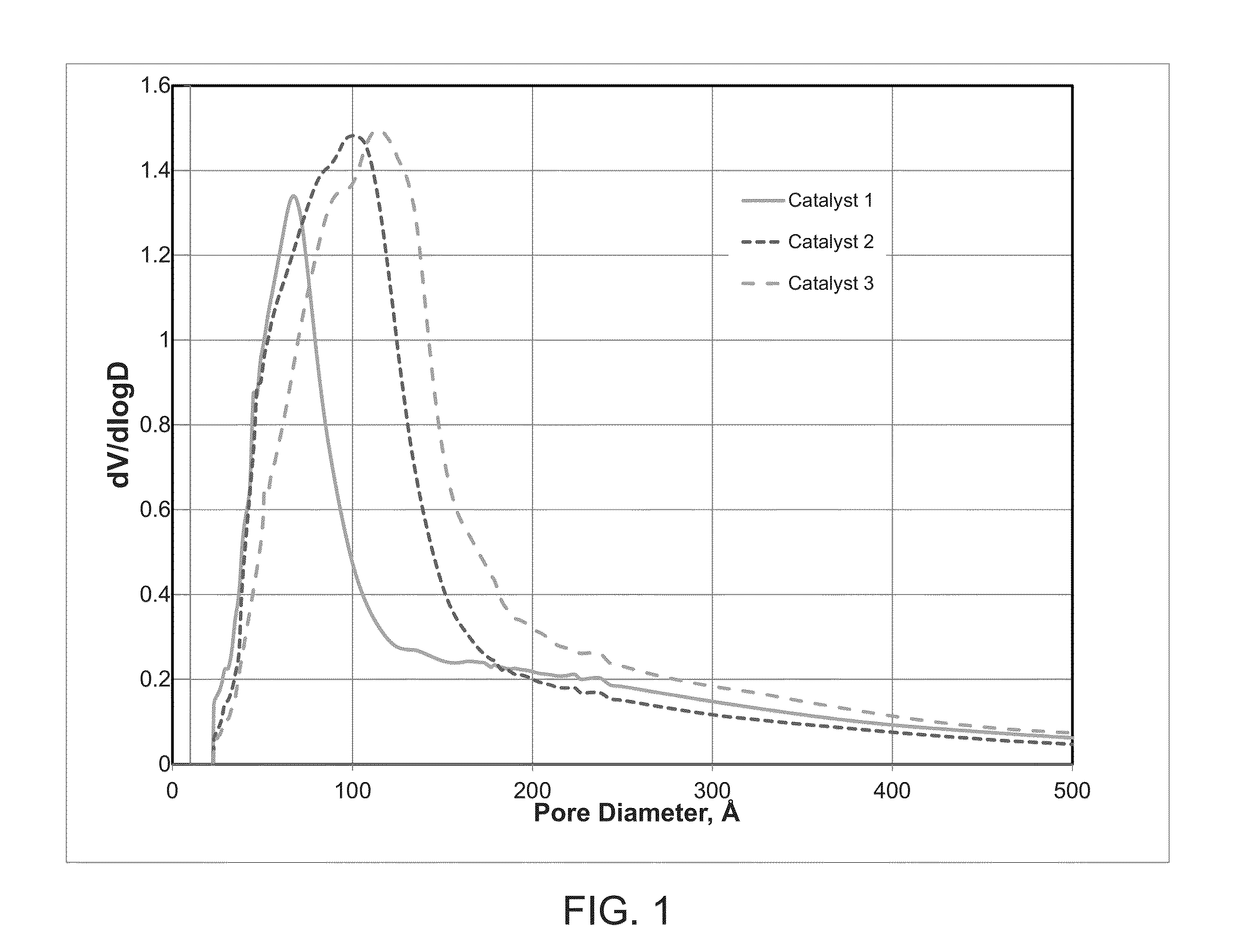

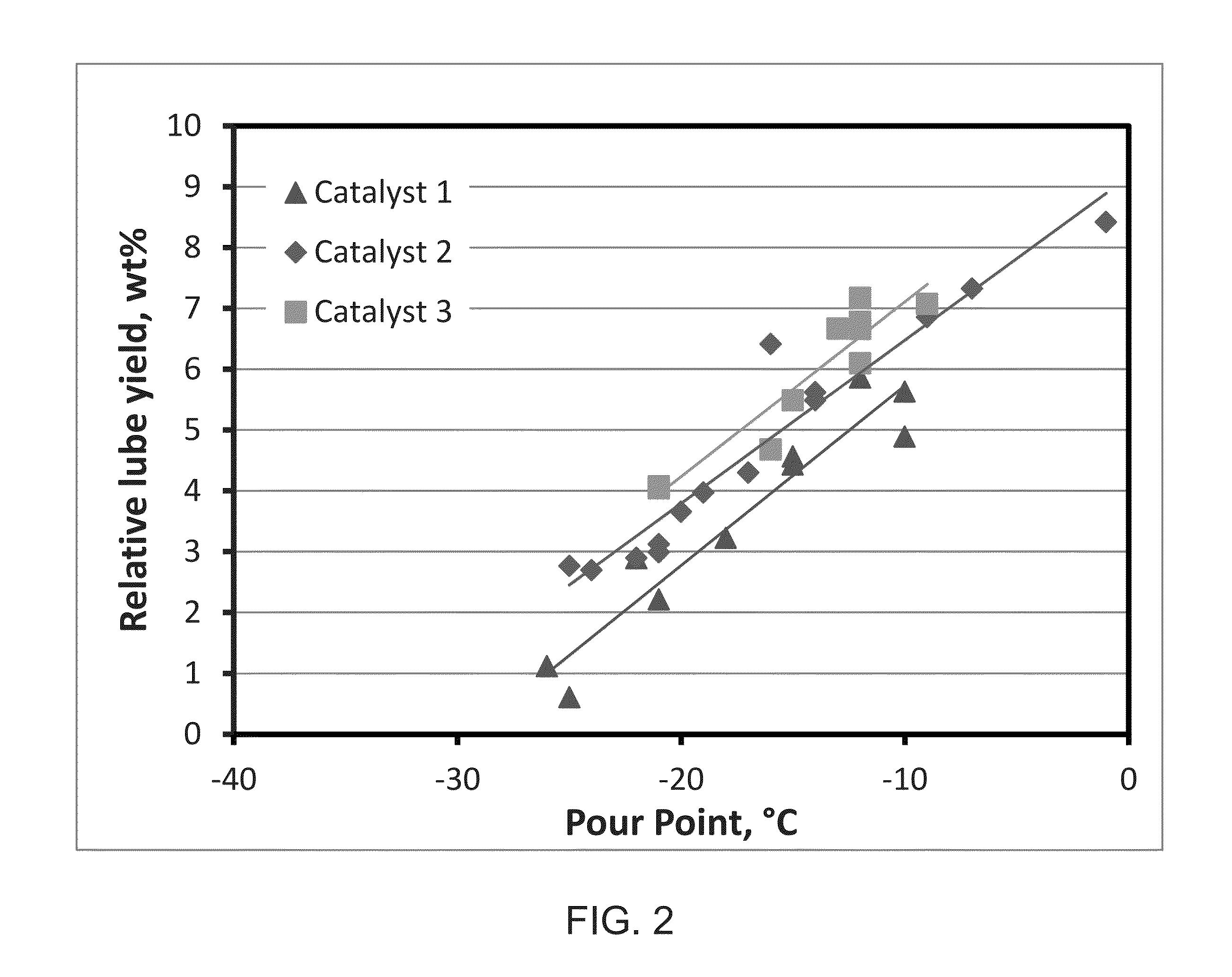

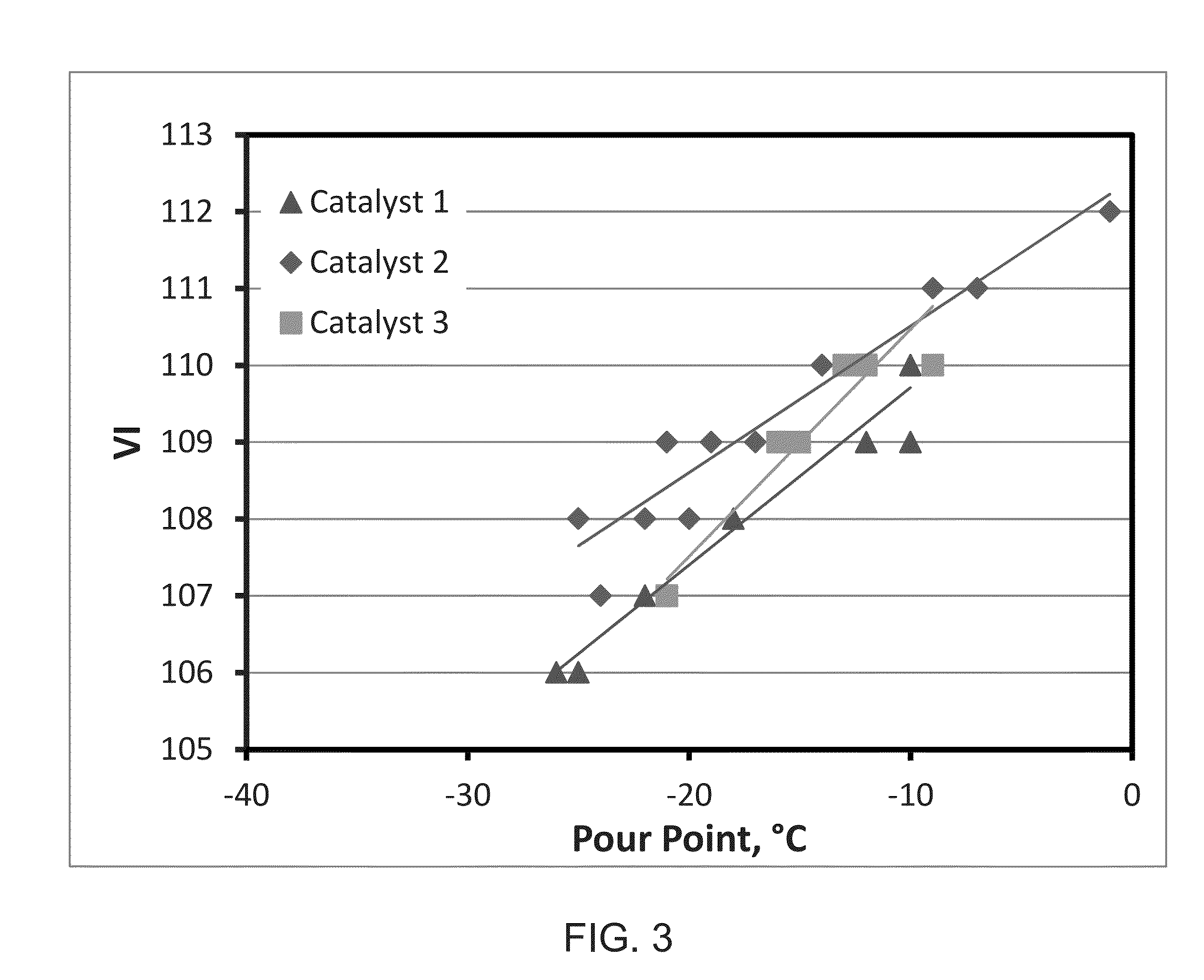

InactiveUS20150306582A1Particle density is loweredIncreased metal loadingMolecular sieve catalystsCatalyst activation/preparationHydrogenVolumetric Mass Density

The present invention is directed to an improved hydrocracking catalyst containing a amorphous silica-alumina (ASA) base and alumina support. The ASA base is characterized as having a high nanopore volume and low particle density. The alumina support is characterized as having a high total nanopore volume. Hydrocracking catalysts employing the combination high nanopore volume ASA base and alumina support exhibit improved hydrogen efficiency, and greater product yield and quality, as compared to hydrocracking catalysts containing conventional ASA base and alumina components.

Owner:CHEVROU USA INC

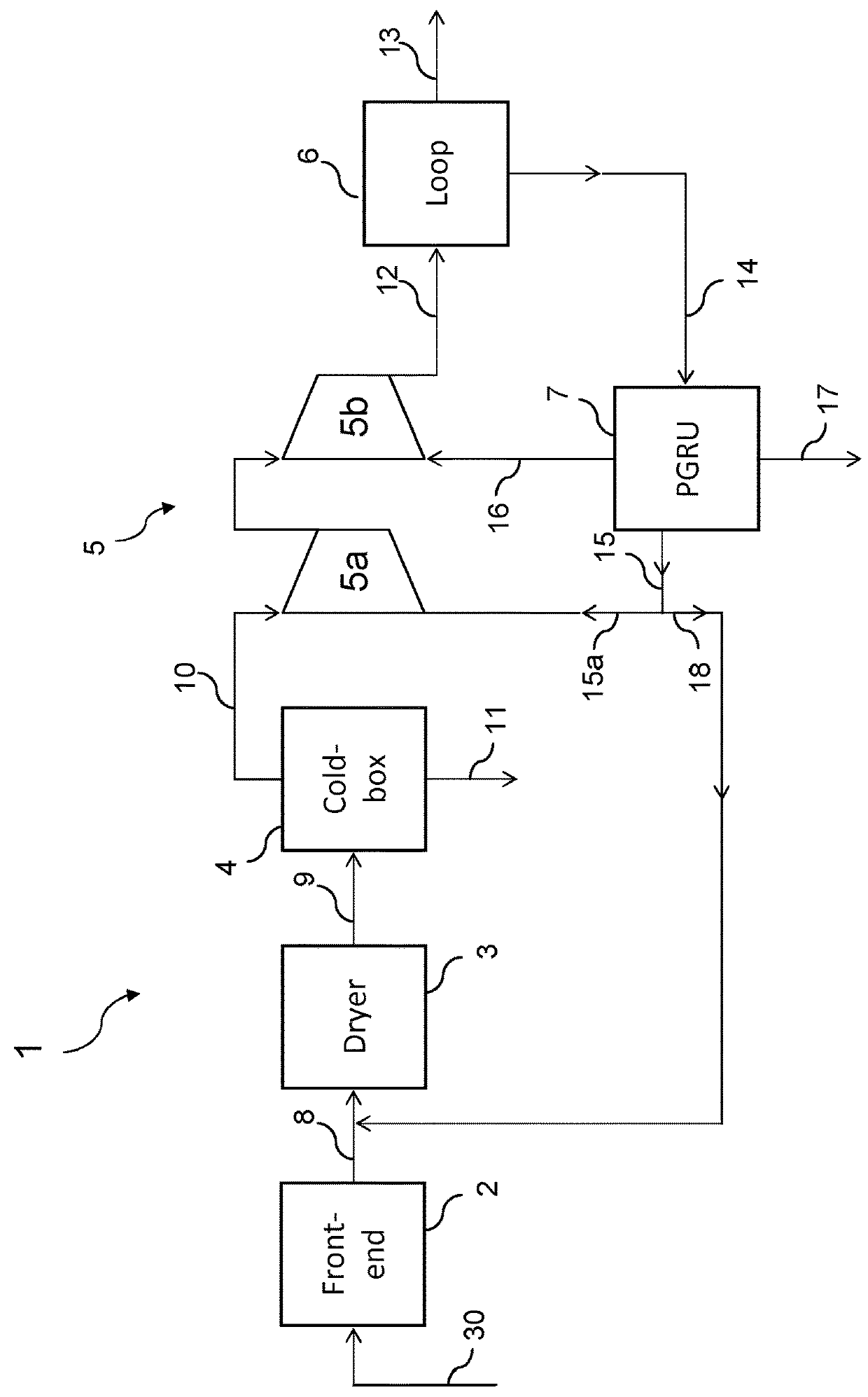

Plant and process for ammonia production with cryogenic purification, and related method of revamping

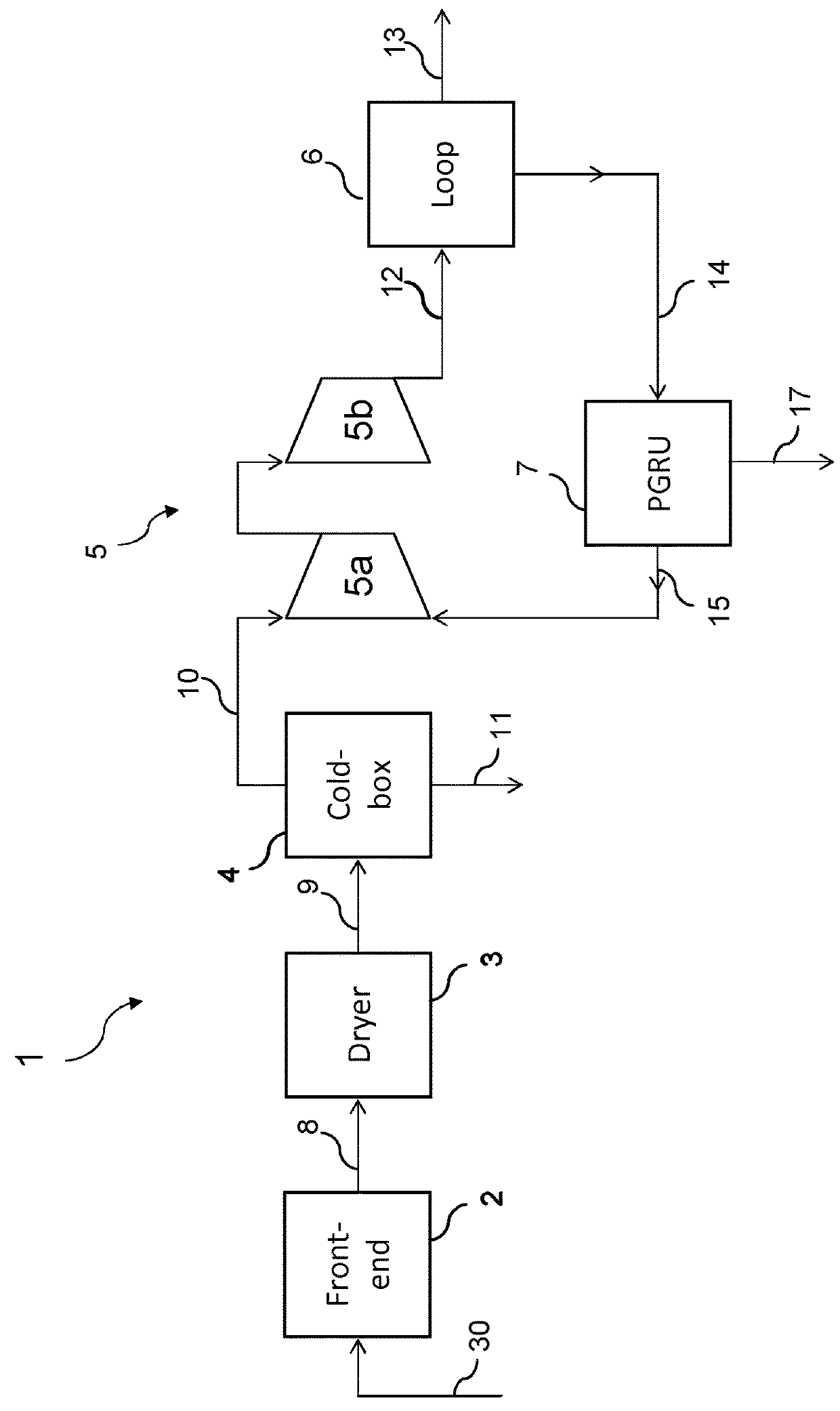

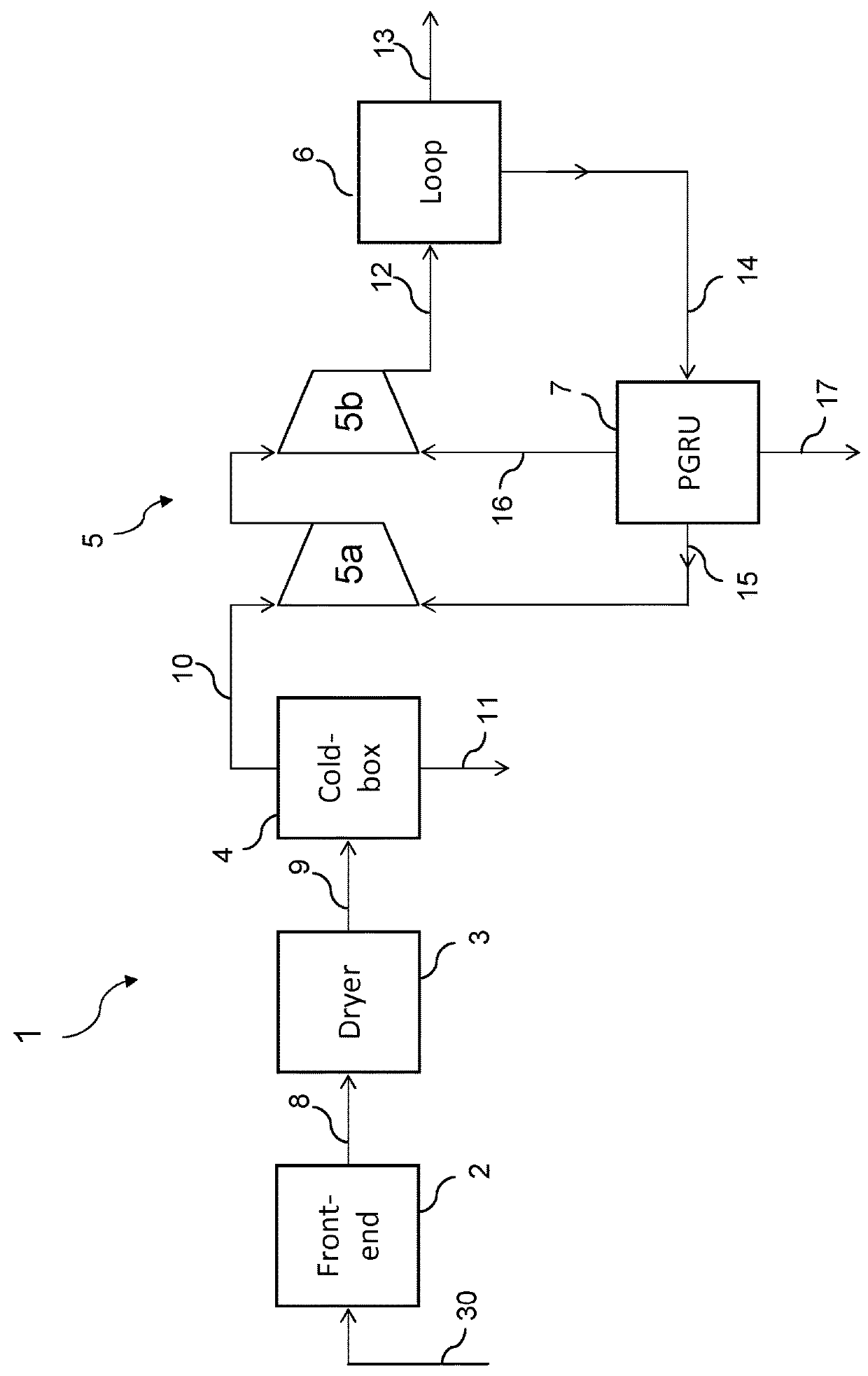

ActiveUS20180266758A1Small pressure lossHigh suction pressureSolidificationLiquefactionHydrogenAmmonia production

Process for the synthesis of ammonia from a make-up gas containing hydrogen and nitrogen, said process comprising: generation of a synthesis gas (8) containing hydrogen and nitrogen in a molar ratio lower than 3, inside a front-end section (2); a first cryogenic purification, designed to remove nitrogen and raise said molar ratio; conversion of the synthesis gas into ammonia (13) inside a high-pressure synthesis loop (6), with extraction from said loop of a purge stream (14) containing hydrogen and inert gases; wherein at least a portion of said purge stream (14) undergoes a further purification in order to recover at least part of the hydrogen contained therein, obtaining at least one stream (15, 15a, 16, 18) containing recovered hydrogen which is recycled to the process.

Owner:CASALE SA

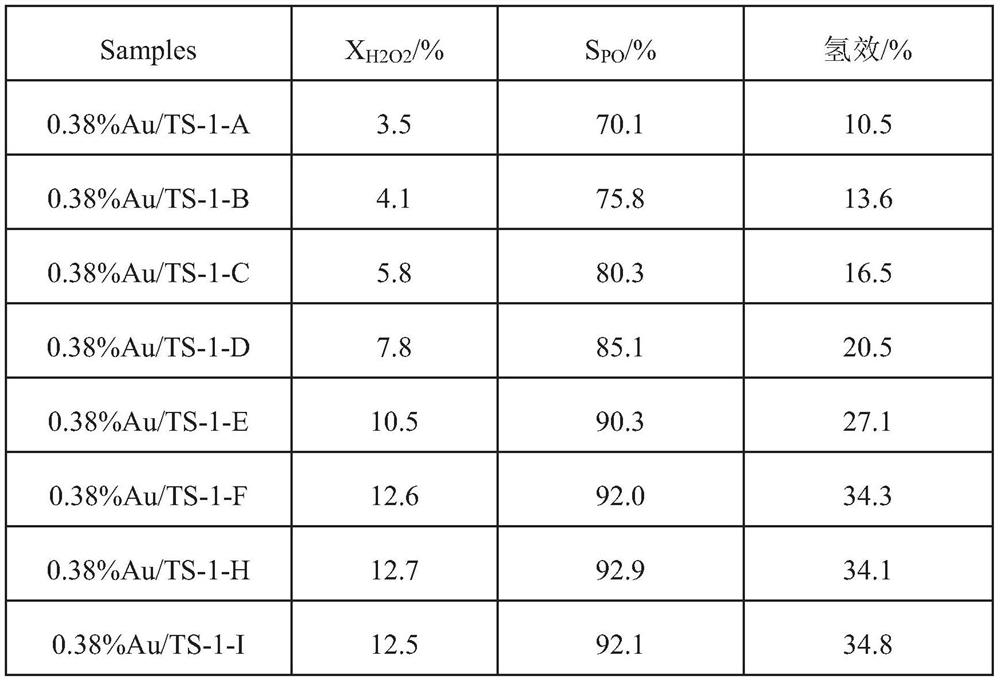

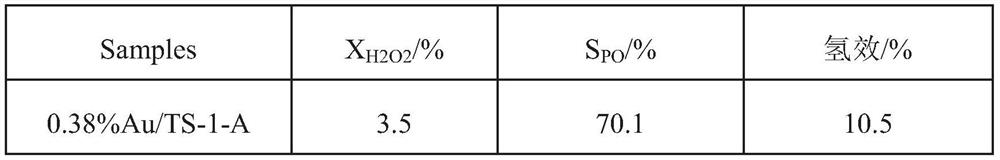

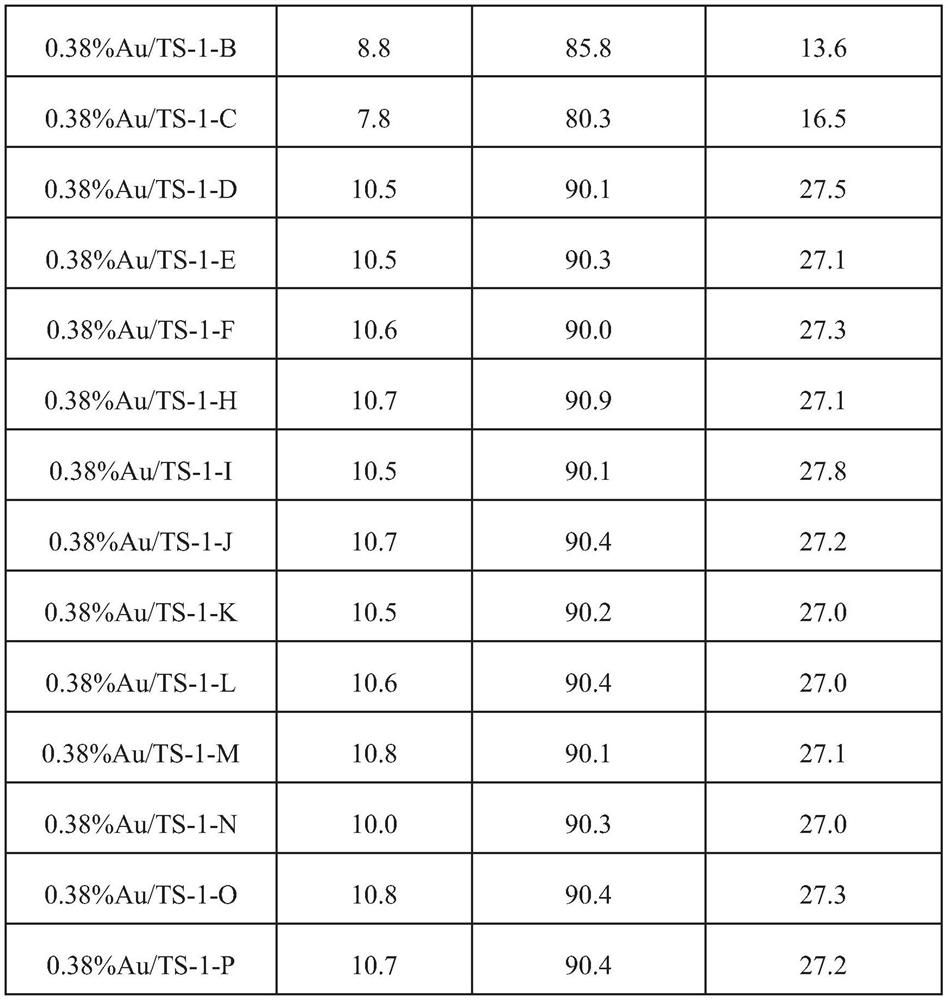

Preparation method of high-activity low-byproduct propylene gas-phase epoxidation catalyst

InactiveCN112871205AHigh titanium contentLower pHOrganic chemistryMolecular sieve catalystsPtru catalystHigh activity

The invention discloses a preparation method of a high-activity low-byproduct propylene gas phase epoxidation catalyst. In the preparation process of the catalyst, a defect site auxiliary agent and an S auxiliary agent are added, titanium-rich defect sites suitable for Au loading are obtained, amorphous species on the catalyst are stabilized by S, then the high-activity propylene gas phase epoxidation catalyst is obtained, and alkali metal ions introduced at the same time with the S auxiliary agent can reduce the production probability of by-products, so that the conversion rate of propylene, the selectivity of PO and the hydrogen efficiency are greatly improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Solvent system in working liquid for hydrogen peroxide production with anthraquinone method, and applications thereof

ActiveCN106629617AImprove solubilityRaw materials are easy to getPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAcetic acidPhosphate

The invention relates to a solvent system in a working liquid for hydrogen peroxide production with an anthraquinone method, wherein the solvent system comprises, by volume, 40-70% of heavy aromatic hydrocarbon, 5-30% of trioctyl phosphate, 10-20% of 2-phenylethanol, 10-20% of diethanol dimethyl ether, and 0.5-5% of acetic acid. According to the present invention, the raw material components of the solvent system are easy to obtain; with the application of the solvent system to prepare the working liquid, compared to the working liquid prepared from the heavy aromatic hydrocarbon and trioctyl phosphate two-component solvent system in the prior art, the working liquid prepared from the solvent system of the present invention has the good hydrogen efficiency under the production condition.

Owner:CHINA PETROLEUM & CHEM CORP +1

Working solution for producing hydrogen peroxide through anthraquinone process

InactiveCN105565277AImprove solubilityImprove hydrogen efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolubilityAnthraquinone process

The invention discloses a working solution for producing hydrogen peroxide through an anthraquinone process. The working solution comprises a solvent and a working solution carrier, wherein the solvent comprises the following components in percentage by volume: 50-80% of heavy aromatics, preferably 70-75 percent, and 20-50% of N-octyl pyrrolidone, preferably 25-30 percent; the working solution carrier refers to alkyl anthraquinone. The working solution adopts a two-component solvent system, the anthraquinone solubility is improved, and the hydrogenation efficiency is improved. Compared with a three-component system, the two-component solvent system has the advantages that the composition is simplified, and the production cost is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Middle distillate hydrocracking catalyst with a base extrudate having a high total nanopore volume

InactiveUS20150306581A1Particle density is loweredIncreased metal loadingMolecular sieve catalystsCatalyst activation/preparationHydrogenVolumetric Mass Density

The present invention is directed to an improved hydrocracking catalyst containing a amorphous silica-alumina (ASA) base and alumina support. The ASA base is characterized as having a high nanopore volume and low particle density. The alumina support is characterized as having a high total nanopore volume. Hydrocracking catalysts employing the combination high nanopore volume ASA base and alumina support exhibit improved hydrogen efficiency, and greater product yield and quality, as compared to hydrocracking catalysts containing conventional ASA base and alumina components.

Owner:CHEVROU USA INC

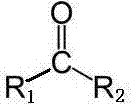

Solvent system and bidirectional working solution for producing hydrogen peroxide through anthraquinone method, and applications of bidirectional working solution

ActiveCN107539955AImprove hydrogen efficiencyReduce solubilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolubilityHydrogen

The invention relates to a solvent system and a bidirectional working solution for producing hydrogen peroxide through an anthraquinone method, and applications of the bidirectional working solution.The solvent system comprises, by volume, 50-70% of tetrahydronaphthalene and 30-50% of ketone, wherein the ketone has a structure represented by a general formula I, R1 is phenyl, and R2 is selected from phenyl or C1-4 alkyl. The bidirectional working solution comprises alkyl anthraquinone and the solvent system, wherein the weight content of the alkyl anthraquinone in the working solution is 80-500 g / L. According to the present invention, the bidirectional working solution can be used for producing hydrogen peroxide through an anthraquinone method, wherein the ketone participates in the reaction so as to generate hydrogen peroxide, and the solubility of the reactant in the solvent and the solubility of the product in the solvent can be respectively increased through the change of the ketone before and after the reaction so as to substantially improve the hydrogen efficiency; and with the working solution system, the hydrogen efficiency can achieve 12-16 g / L and is increased by more than 30% compared to the prior art. The general formula I is defined in the specification.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solvent system and its application in the working solution of hydrogen peroxide produced by anthraquinone method

ActiveCN106629617BHigh selectivityExcellent co-solubilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAcetic acidWorking fluid

The invention relates to a solvent system in a working liquid for hydrogen peroxide production with an anthraquinone method, wherein the solvent system comprises, by volume, 40-70% of heavy aromatic hydrocarbon, 5-30% of trioctyl phosphate, 10-20% of 2-phenylethanol, 10-20% of diethanol dimethyl ether, and 0.5-5% of acetic acid. According to the present invention, the raw material components of the solvent system are easy to obtain; with the application of the solvent system to prepare the working liquid, compared to the working liquid prepared from the heavy aromatic hydrocarbon and trioctyl phosphate two-component solvent system in the prior art, the working liquid prepared from the solvent system of the present invention has the good hydrogen efficiency under the production condition.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solvent system and method of producing hydrogen peroxide through anthraquinone process

ActiveCN109896503AImprove solubilityLow costPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolubilityCatalytic efficiency

The invention discloses a solvent system and method of producing hydrogen peroxide through anthraquinone process. The solvent system is prepared from the following components in volume percentage: 50-80 percent of heavy aromatics, and 20-50 percent of N,N'-diethylethanediamide. The hydrogen peroxide is prepared through the anthraquinone process by dissolving alkyl anthraquinone in the solvent system to serve as a working solution. The solvent system used in the prior art is generally bi-component or tri-component, the bi-component solvent system has low solubility on alkyl anthraquinone, thereby lowering hydrogenation efficiency; although the tri-component or more components solvent system can improve the solubility on alkyl anthraquinone to a certain degree, and improve catalytic efficiency, the system is made to be more complex, and the production cost of hydrogen peroxide is increased. According to the bi-component solvent system adopted by the invention as the solvent system of producing hydrogen peroxide through the anthraquinone process, the composition is simple, the cost is low, the solubility on alkyl anthraquinone is improved, and therefore the hydrogenation efficiency isimproved.

Owner:CHINA PETROLEUM & CHEM CORP +1

Solvent system and variable working solution for producing hydrogen peroxide through anthraquinone method, and applications of variable working solution

ActiveCN107539957AImprove hydrogen efficiencyReduce solubilityPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolubilityHydrogen

The invention relates to a solvent system and a variable working solution for producing hydrogen peroxide through an anthraquinone method, and applications of the variable working solution. The solvent system comprises, by volume, 40-60% of C9-C10 aromatic hydrocarbon, 10-30% of tetrabutyl urea, and 20-40% of ketone, wherein the ketone has a structure represented by a general formula I, R1 is phenyl, and R2 is selected from phenyl or C1-4 alkyl. The variable working solution comprises alkyl anthraquinone and the solvent system, wherein the weight content of the alkyl anthraquinone in the working solution is 80-500 g / L. According to the present invention, the variable working solution can be used for producing hydrogen peroxide through an anthraquinone method, wherein the ketone participates in the reaction so as to generate hydrogen peroxide, and the solubility of the reactant in the solvent and the solubility of the product in the solvent can be respectively increased through the change of the ketone before and after the reaction so as to substantially improve the hydrogen efficiency; and with the working solution system, the hydrogen efficiency can achieve 12-16 g / L and is increased by more than 30% compared to the prior art. The general formula I is defined in the specification.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydroisomerization catalyst manufactured using a high nanopore volume alumina supports

ActiveUS20160089666A1Improve hydrogen efficiencyImprove production yieldMolecular sieve catalystsCatalytic naphtha reformingFull width at half maximumPore diameter

The present invention is directed to an improved finished hydroisomerization catalyst manufactured from a first high nanopore volume (HNPV) alumina and a pore size distribution characterized by a full width at half-maximum, normalized to pore volume, of 15 to 25 nm·g / cc, and a second HNPV alumina having a pore size distribution characterized by a full width at half-maximum, normalized to pore volume, of 5 to 15 nm·g / cc. Their combination yields a HNPV base extrudate having a low particle density as compared to a conventional base extrudates.

Owner:CHEVROU USA INC

Organic flux system in hydrogen peroxide producing process

InactiveCN1216797CImprove solubilityImprove hydrogen efficiencyPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesSolubilityOrganic solvent

Owner:YICHANG SUPENG TECH CO LTD

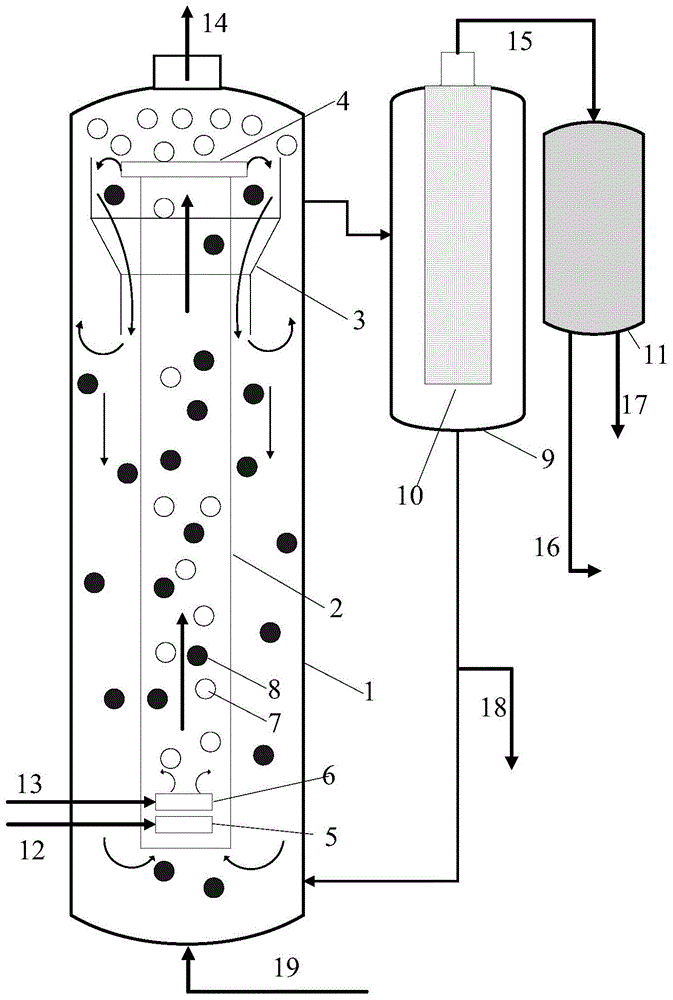

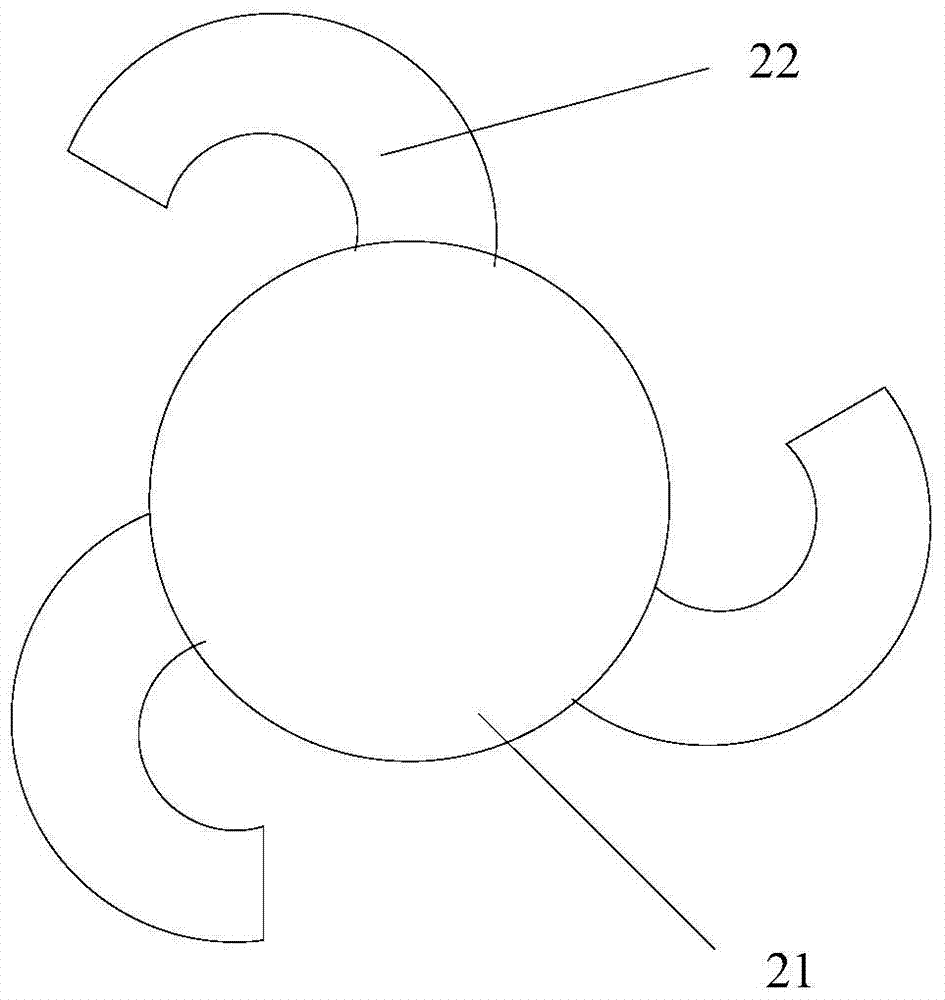

A slurry bed internal circulation reaction device and its application and method for producing hydrogen peroxide

ActiveCN104549066BExtended operating cycleIncrease profitPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

The invention relates to a loop reaction device in a slurry bed, application and a method for producing hydrogen peroxide. The loop reaction device comprises a slurry bed reactor and a solid-liquid separator, wherein the upper part of the slurry bed reactor is communicated with the upper part of the solid-liquid separator, and the bottom of the slurry bed reactor is communicated with the bottom of the solid-liquid separator; and a coaxial inner sleeve is arranged in the slurry bed reactor, an outer sleeve is arranged between the inner sleeve and the outer wall of the slurry bed reactor at the upper part of the slurry bed reactor, a raw material inlet and a fluid distributor are arranged in the inner sleeve and at the bottom, a gas outlet is formed in the top of the slurry bed reactor, a filtration component is arranged in the solid-liquid separator, and a clear liquid outlet is formed in the wall of the solid-liquid separator via the filtration component. According to a hydrogenation method for producing hydrogen peroxide by an anthraquinone method with the adoption of the slurry bed loop reactor, the gas-liquid-solid three-phase separation efficiency is high, the excess local liquid holdup of a catalyst is avoided, the possibility of excessive hydrogenation is reduced, the hydrogenation efficiency is further effectively improved and a hydrogen peroxide product with relatively high concentration can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of solvent system and method for producing hydrogen peroxide by anthraquinone method

ActiveCN109896503BImprove solubilityLow costPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesAnthraquinonesEthyl group

A solvent system and method for producing hydrogen peroxide by anthraquinone method, the solvent system includes the following components in terms of volume percentage: heavy aromatics: 50%~80%, N,N′-diethyloxalamide : 20%~50%. Alkyl anthraquinone is dissolved in the above solvent system as a working solution, and hydrogen peroxide is prepared by anthraquinone method. The solvent system used in the prior art is generally two-component or three-component, and the two-component has low solubility for alkyl anthraquinone, thereby reducing the problem of hydrogenation efficiency. Although the three-component or even more components are to a certain extent It can improve the solubility of alkyl anthraquinone and improve the catalytic efficiency, but it will complicate the system and increase the production cost of hydrogen peroxide. The two-component system of the present invention is used as a solvent system for producing hydrogen peroxide by an anthraquinone method, has simple composition and low cost, and can increase the solubility of alkyl anthraquinone, thereby improving the hydrogen efficiency of the reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

A hydrogenation process in the production of hydrogen peroxide

ActiveCN105621365BFully dispersedEvenly dispersedPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesWorking fluidHydrogenation reaction

The invention discloses a hydrogenation process for hydrogen peroxide production. The process comprises the following steps: (1) in a hydrogenation process for producing hydrogen peroxide by an anthraquinone process, arranging a hydrogenation tower I, a hydrogenation tower II and a hydrogenation tower III, and feeding hydrogen gas in three channels, i.e., hydrogen gas I, hydrogen gas II and hydrogen gas III; (2) mixing and dissolving working fluid feed and the hydrogen gas I in high-pressure gas dissolving equipment, and then, enabling the solution to enter the hydrogenation tower I for a first-stage hydrogenation reaction; (3) mixing and dissolving effluent of the first-stage hydrogenation reaction and the hydrogen gas II in the high-pressure gas dissolving equipment, and then, enabling the solution to enter the hydrogenation tower II for a second-stage hydrogenation reaction; (4) mixing and dissolving effluent of the second-stage hydrogenation reaction and the hydrogen gas III in the high-pressure gas dissolving equipment, and then, enabling the solution to enter the hydrogenation tower III for a third-stage hydrogenation reaction; and (5) enabling a material obtained after the third-stage hydrogenation reaction to flow out, carrying out gas-liquid separation, and going to next procedure. According to the process, through controlling the proportion of dissolved hydrogen, not only can a relatively high hydrogenation effect be achieved, but also minimal anthraquinone degradation products are obtained, so that the improvement on product concentration and device scale and the lowering of the consumption of a catalyst and anthraquinone are facilitated.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of hydrogenation process of producing hydrogen peroxide by anthraquinone method

ActiveCN104555935BPrevent deficienciesAvoid excessive hydrogenation reactionsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesGas phaseHydrogenation process

The invention discloses a hydrogenation process for producing a hydrogen peroxide by an anthraquinone method. The hydrogenation process comprises the following steps that: (1) two reactors are arranged in the hydrogenation process for producing the hydrogen peroxide by the anthraquinone method; a first current of fresh hydrogen and a working liquid serve as a feeding material I and perform hydrogenation in the first reactor; the reacted material is subjected to gas-liquid separation to obtain a gas phase and a liquid phase, wherein part of the liquid phase is recycled back to the first reactor; the rest of the liquid phase is reasonably optimized and modulated; the phenomenon that the reaction hydrogen is deficient or excessive is avoided; the hydrogenation completeness is realized; the liquid phase and the gas phase are mixed to serve as feeding material II and enter the second reactor; (2) a second current of fresh hydrogen and the feeding material II perform the hydrogenation in the second reactor; the reacted material is subjected to the gas-liquid separation to obtain a gas phase and a liquid phase, wherein part of the liquid phase is recycled back to the second reactor, and the rest of the liquid phase enters an oxidation process. According to the process disclosed by the invention, a hydrogenation process is optimized, and meanwhile, side effects are reduced, so that the hydrogenation is more uniform, and the service life of a catalyst is prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

Slurry bed hydrogenation reactor for hydrogen peroxide production by anthraquinone method and its application

ActiveCN104549059BReduced chance of wear and tearIncrease concentrationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationHydrogenation reaction

The invention discloses a slurry bed hydrogenation reactor for preparing hydrogen peroxide by adopting an anthraquinone process and application of the slurry bed hydrogenation reactor. The hydrogenation reactor comprises an ascension pipe, an expanding section for expanding the upper pipe diameter of the ascension pipe, and a solid-liquid separator, wherein the expanding section is communicated with the upper part of the solid-liquid separator; the bottom of the solid-liquid separator is connected with the bottom of the ascension pipe; a guide cylinder is arranged in the expanding section; the bottom of the ascension pipe is provided with a raw material inlet; the top of the expanding section is provided with a gas outlet; a filter assembly is arranged in the solid-liquid separator and provided with a purified liquor outlet. The method for preparing the hydrogen peroxide is characterized in that the slurry bed hydrogenation reactor is applied to a hydrogenation unit, the gas-liquid-solid three-phase separation efficiency is high, the catalyst locality cannot be excessively hydrogenated, the excessive hydrogenation possibility is reduced, the hydrogenation efficiency is high, and a hydrogen peroxide product with the relatively high concentration can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-activity propylene gas-phase epoxidation catalyst and preparation method thereof

InactiveCN112871204ALarge specific surface areaIncrease contentOrganic chemistryMolecular sieve catalystsPtru catalystHigh activity

The invention discloses a high-activity propylene gas-phase epoxidation catalyst and a preparation method thereof. In the preparation process of the catalyst, a defect site auxiliary agent and an S auxiliary agent are added, a large number of defect sites which are rich in titanium and suitable for Au loading are obtained, amorphous species on the catalyst are stabilized by S, the high-activity propylene gas-phase epoxidation catalyst is obtained, and the conversion rate of propylene, the selectivity of PO and the hydrogen efficiency are greatly improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A slurry bed loop reactor and its application and a method for producing hydrogen peroxide

ActiveCN104549065BReduced chance of wear and tearIncrease concentrationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical processesHigh concentrationFiltration

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com