High-activity propylene gas-phase epoxidation catalyst and preparation method thereof

A catalyst, epoxidation reaction technology, applied in physical/chemical process catalysts, molecular sieve catalysts, chemical instruments and methods, etc., can solve the problems of ineffective decomposition of hydrogen peroxide, limit the number of TS-1 molecular sieve Ti active sites, etc., to improve the load efficiency and stability, reducing synthesis costs, and reducing the effect of ineffective decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

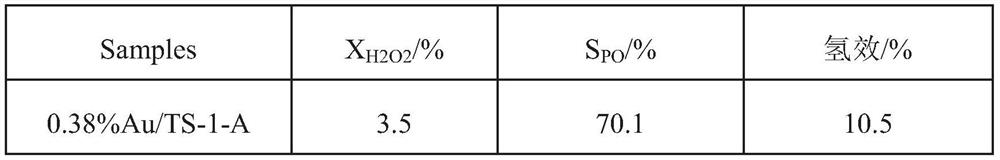

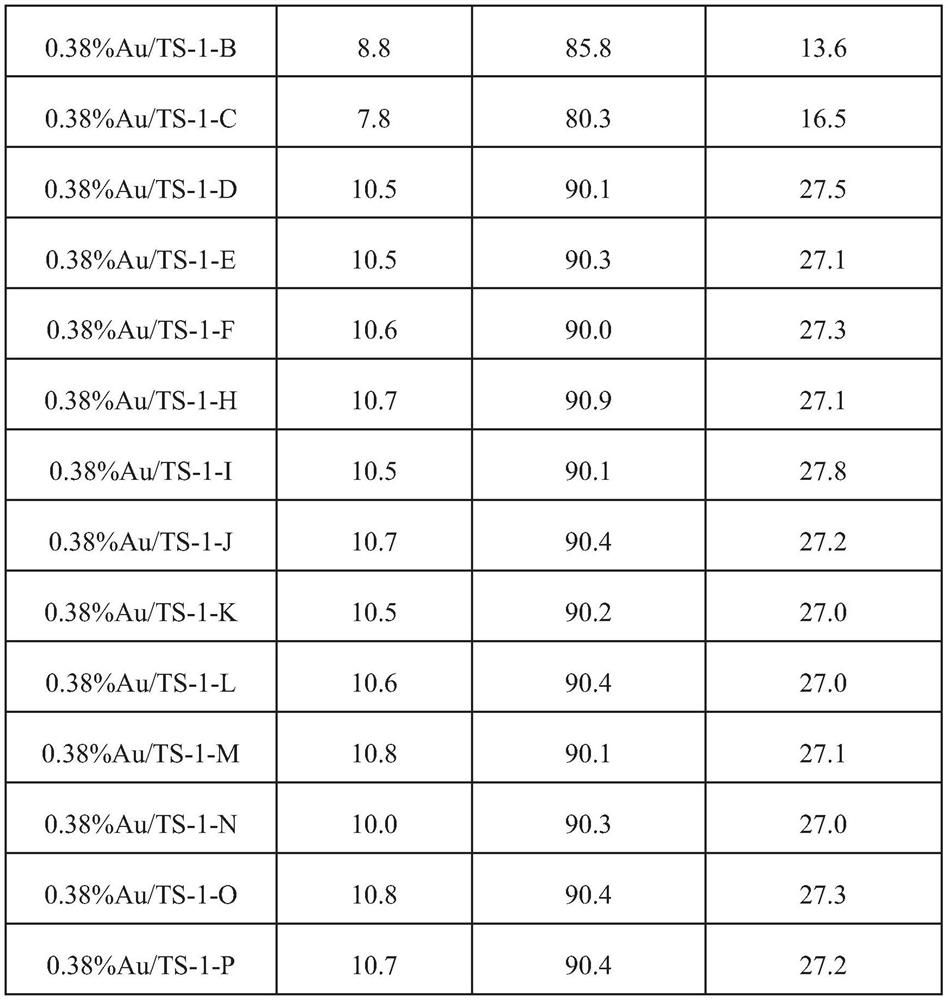

Embodiment 1

[0042] 45gSiO 2 Add 30% silica sol into a jacketed three-necked flask, add 0.05g soluble starch, 44g 25wt% TPAOH aqueous solution and 38g water, and hydrolyze at 40°C for 2h to obtain a silicon source hydrolysis mixture; 3.8g tetrabutyl titanate Dissolve in 18.7g of isopropanol, then stir for 30min to obtain the titanium source hydrolysis mixture; mix the titanium source and the silicon source hydrolysis mixture, remove the alcohol at 80°C for 1.5h, replenish 50.2g of water and stir for 30min, and the obtained Put the transparent glue into a crystallization kettle to crystallize, and crystallize at 170°C for 36 hours. After washing and drying, the crystallized product is washed with 1M HCl aqueous solution (the liquid-solid ratio is 50ml g -1 ), calcined in air at 550°C for 6h, and obtained a TS-1 sample with a Si / Ti ratio of 31.8 after XRF testing. Repeat the Au loading process in Comparative Example 1 to obtain a catalyst of 0.38% Au / TS-1-D.

Embodiment 2

[0044] Repeat Example 1, replace the soluble starch in the defect site auxiliary agent in the preparation process of TS-1 with sodium carboxymethylcellulose, polyacrylamide, polyethyleneimine, the amount of the component substances remains unchanged, after crystallization, Adopt 1M HCl aqueous solution washing after drying (liquid-solid ratio is 50ml g -1 ), calcined in air at 550°C for 6h, and obtained TS-1 samples with Si / Ti ratios of 31.7, 31.9, and 31.8 after XRF testing.

[0045] The loading process of Au in Comparative Example 1 was repeated to obtain catalysts of 0.38% Au / TS-1-E, 0.38% Au / TS-1-F, and 0.38% Au / TS-1-G.

Embodiment 3

[0047] Repeat Example 1, the tetraethyl orthosilicate in the TS-1 preparation process is replaced by tetramethyl orthosilicate, tetrapropyl orthosilicate, the amount of tetrabutyl orthosilicate component material remains unchanged, After crystallization, adopt 1M HCl aqueous solution washing after drying (liquid-solid ratio is 50ml g -1 ), calcined in air at 550°C for 6h, and obtained TS-1 samples with Si / Ti ratios of 32.1, 31.9, and 32.0 through XRF testing.

[0048] The Au loading process in Comparative Example 1 was repeated to obtain catalysts of 0.38% Au / TS-1-H, 0.38% Au / TS-1-I, and 0.38% Au / TS-1-J.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com