Patents

Literature

54results about How to "Reduce invalid decomposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bimetallic catalyst for degrading chlorine substitutional organic pollutant, preparation method and application

InactiveCN1915511ALow priceReduce invalid decompositionMolecular sieve catalystsWater/sewage treatment by reductionTrichloroethyleneReducing agent

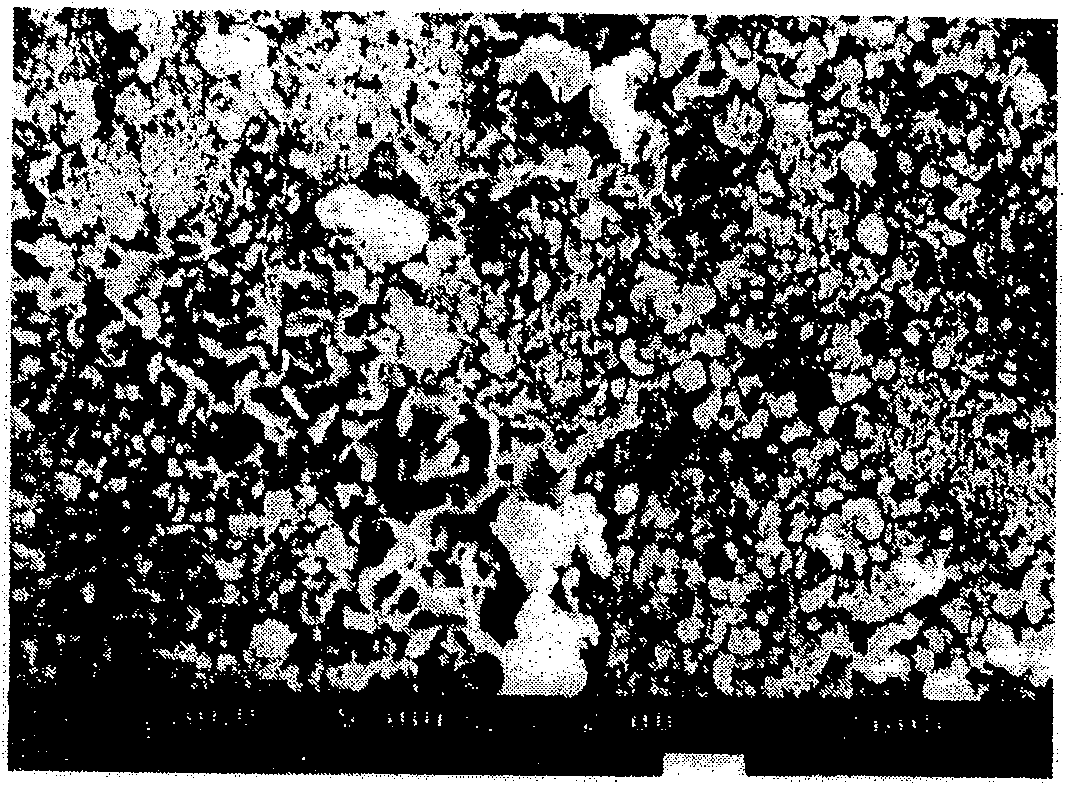

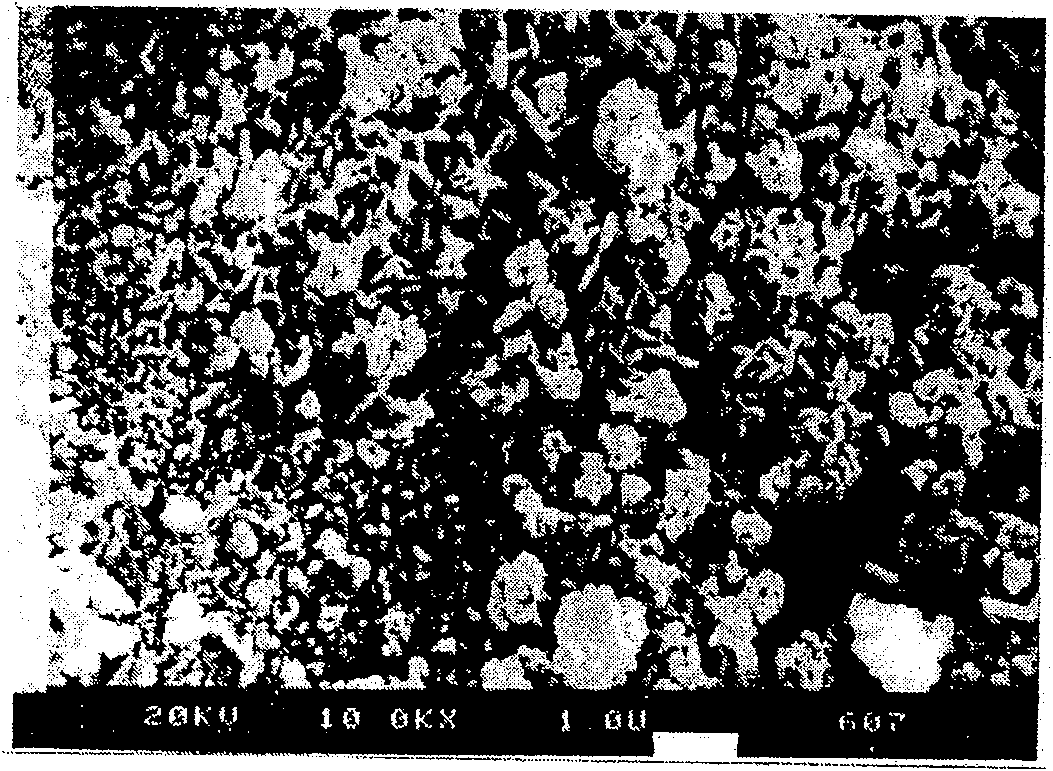

A bimetal catalyst for degradating the CCl4, trichlorothene and tetrachloroethene is sewage within one hour is composed of the modified zeolite as carrier and the bimetal Fe-Ni in the mass ratio of (1-10): 100. Said bimetal Fe-Ni is prepared by using sodium dithionite as reducer to reduce the Ni ions on the surfaces of Fe filings.

Owner:XINYI AGRI CHEM PLANT JIANGSU PROV

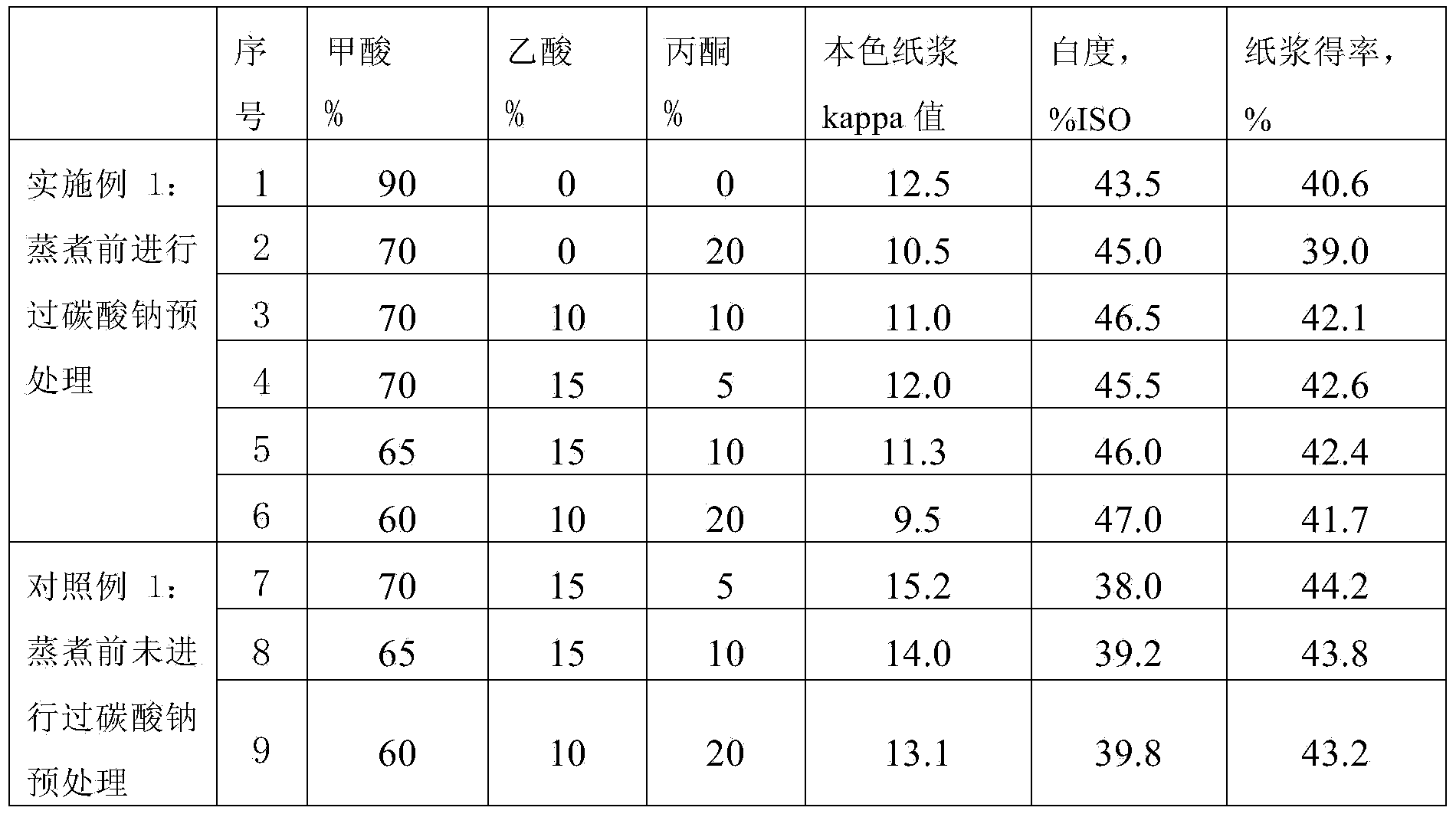

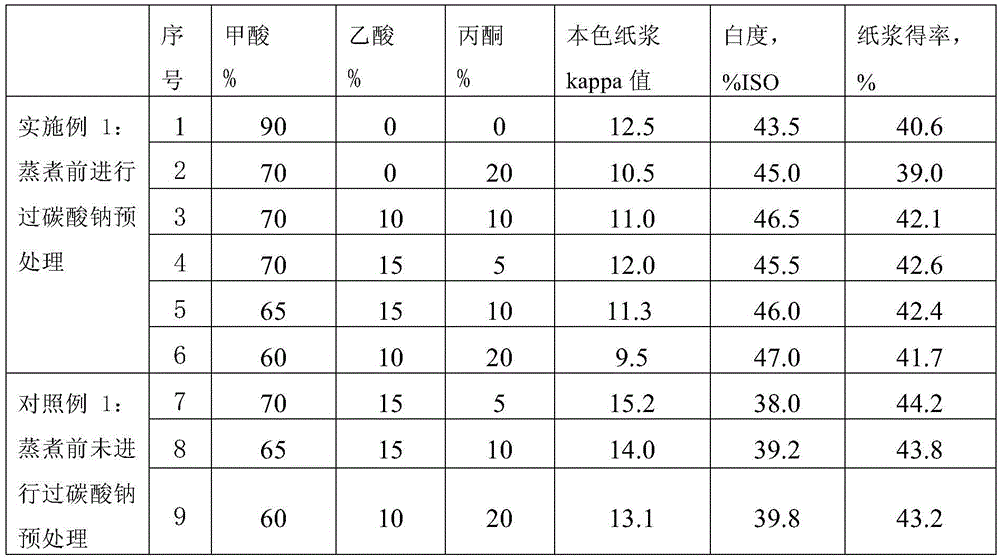

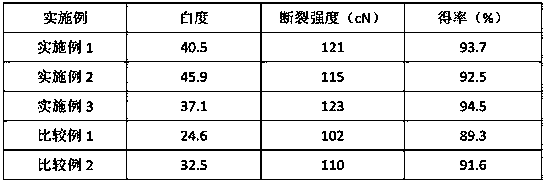

Unbleached pulp production method for increasing whiteness of pulp

ActiveCN103924470ALoose structureImprove permeabilityPulping with acid salts/anhydridesPulping with organic solventsAcetic acidOrganic solvent

The invention relates to an unbleached pulp production method for increasing the whiteness of pulp. The method comprises the following steps: pre-treating a plant fiber material with sodium percarbonate; stewing the pre-treated plant fiber material with a mixed organic solvent of methane acid, acetic acid and acetone; washing the pulp after sewing with the methane acid and hot water; and preparing the unbleached pulp. The method can be used for increasing the whiteness of the unbleached pulp obviously.

Owner:山东济清科技服务有限公司

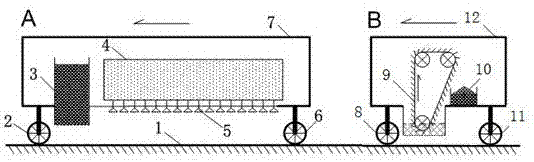

In-situ repair method and system for heavy meal cadmium and polycyclic aromatic hydrocarbon polluted farmland soil

The invention discloses an in-situ repair method and system for heavy meal cadmium and polycyclic aromatic hydrocarbon polluted farmland soil. The method comprises the following steps: (1) spreading a mixture of carbon coated porous foamed iron subparticles, a peroxide and sodium phytate into polluted soil; (2) spraying a hydrogen peroxide solution into the polluted soil, concentrating and removing pollutants such as polycyclic aromatic hydrocarbon and heavy meal cadmium in the soil; and then recycling carbon coated porous foamed iron subparticles. The system comprises a material spreading device and a recycling device, the material spreading device comprises a material spreading moving rack, and the material spreading moving rack is provided with a mixture hopper, a hydrogen peroxide solution storage tank and a hydrogen peroxide solution spray head; the recycling device comprises a recycling moving rack, and the recycling moving rack is provided with a magnet recycling device and a foamed iron recycling tank. The method is simple in process, low in cost and high in continuity, the damage on soil microorganisms and organic matters is avoided, and the risk of secondary pollution does not exist.

Owner:QINGDAO AGRI UNIV

A kind of natural pulp production method for improving pulp whiteness

ActiveCN103924470BLoose structureImprove permeabilityPulping with acid salts/anhydridesPulping with organic solventsAcetic acidOrganic solvent

The invention relates to an unbleached pulp production method for increasing the whiteness of pulp. The method comprises the following steps: pre-treating a plant fiber material with sodium percarbonate; stewing the pre-treated plant fiber material with a mixed organic solvent of methane acid, acetic acid and acetone; washing the pulp after sewing with the methane acid and hot water; and preparing the unbleached pulp. The method can be used for increasing the whiteness of the unbleached pulp obviously.

Owner:山东济清科技服务有限公司

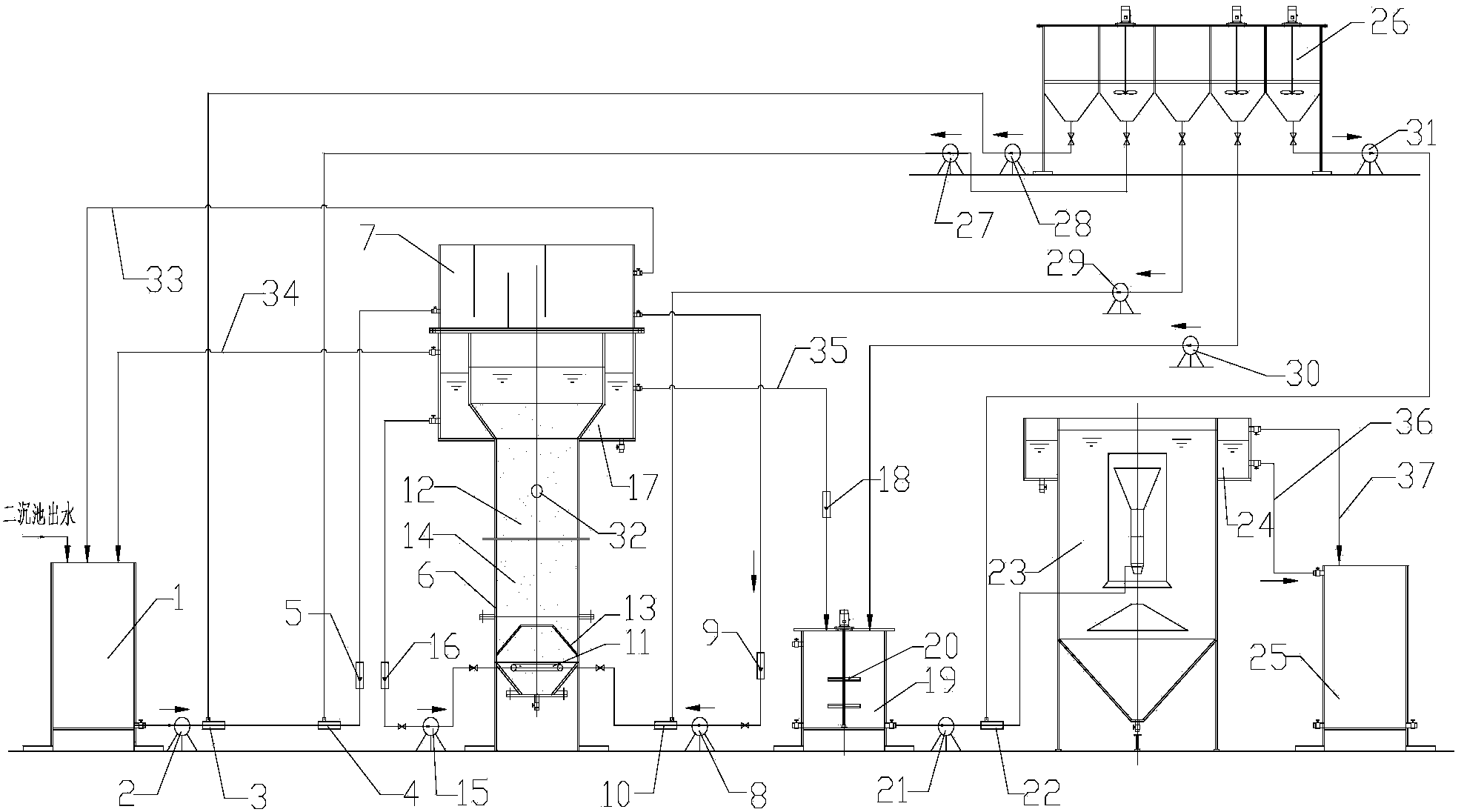

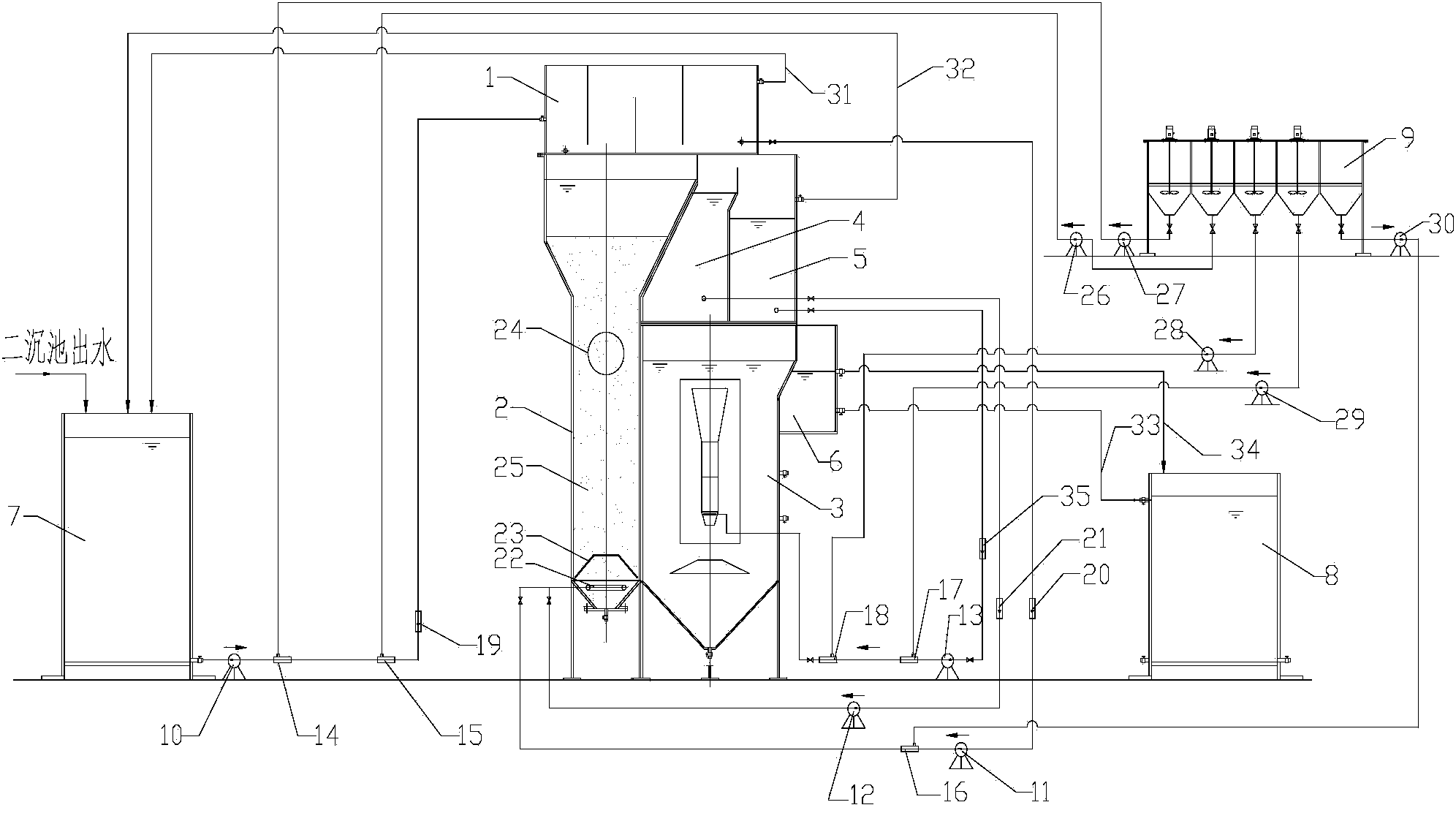

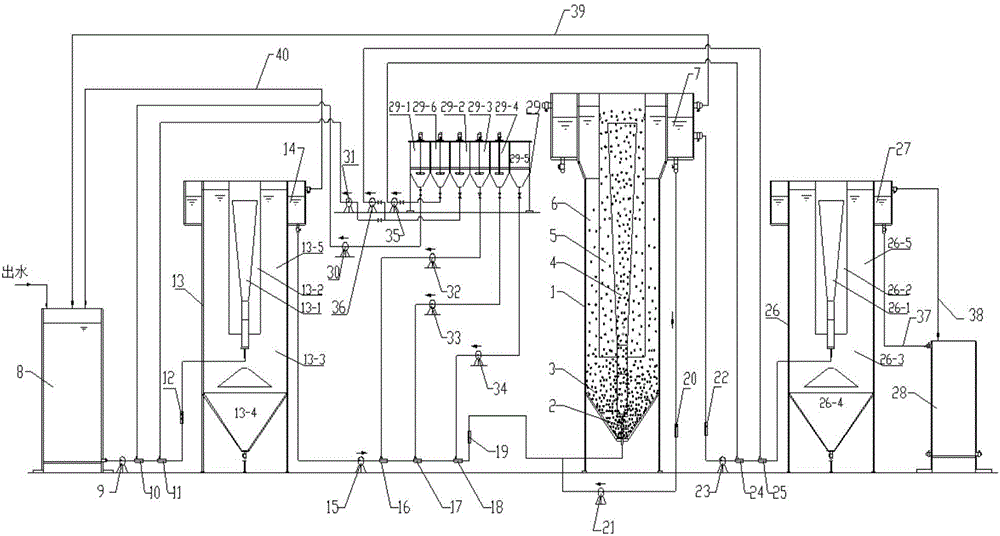

Device and method for treating pulping wastewater by Fenton catalytic oxidation method

InactiveCN103771625AHigh speedHigh degree of fluidizationMultistage water/sewage treatmentSludgeCatalytic oxidation

The invention discloses a device and method for treating pulping wastewater by a Fenton catalytic oxidation method. The device comprises a water collecting tank, a catalytic oxidation tower, a neutralization tank, a coagulative precipitation tower, a clean water tank and a medicament preparation system, wherein a balance regulating tank at the top of the catalytic oxidation tower is connected with the water collecting tank through a pipeline; the balance regulating tank is connected with a water distribution pipe at the bottom of a fluidized catalytic reaction column of the catalytic oxidation tower through a pipeline; a circulating water outlet tank is connected with the water distribution pipe through a pipeline; the neutralization tank is connected with a water distribution pipe of the coagulative precipitation tower through a pipeline; an outlet water tank is arranged on the external wall of the upper part of the coagulative precipitation tower, and the top of the coagulative precipitation tower is connected with the outlet water tank through an overflow port. The method comprises the steps of carrying out balance regulating treatment, carrying out fluidized catalytic oxidation treatment, carrying out coagulative precipitation and purifying. According to the device and the method, by using efficient mass transfer efficiency under fluidized conditions, a relatively high wastewater treatment effect is achieved under the condition that the dosage of hydrogen peroxide and ferrous ions is relatively low, so that the wastewater treatment efficiency is increased, and meanwhile, the amount of generated sludge is reduced.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing ramie fibers through oxidation, degumming and repeated multiple-step feeding

ActiveCN103233279AAvoid damageBreak down evenlyFibre treatment to obtain bast fibreDecompositionColloid

The invention provides a method for preparing ramie fibers through oxidation, degumming and repeated multiple-step feeding, which comprises three feeding processes and comprises the following specific steps: in the first feeding process, preparing a degumming solution from surfactant, a fiber expanding agent, peroxide stabilizer, a defoaming agent, sodium hydroxide, peroxide and water, mixing raw hemp of ramie and the degumming solution to form a degumming solution system, and heating to remove part of colloid; in the second feeding process 20-50 minutes later, adding peroxide and sodium hydroxide, and keeping the temperature to further remove the colloid; in the third feeding process 20-50 minutes later, adding peroxide, and further keeping the temperature until the reaction is finished and the colloid is completely removed; and finally, washing refined dried hemp fibers with clear water, oiling, drying, opening, and combing to obtain the prepared ramie fibers. The method provided by the invention overcomes the defects in the existing oxidation and degumming technology; a repeated multiple-step method is used, so that the reaction is uniform and moderate, the damage to the fibers caused by over too high initial concentration of initial concentration is reduced, and the quality of the refined dried hemp product is improved; and meanwhile, the ineffective decomposition of the peroxide and the consumption of the defoaming agent are reduced, thereby saving the cost.

Owner:DONGHUA UNIV

Method for alkaline hydrogen peroxide bleaching of paper pulp

The invention relates to a method for alkaline hydrogen peroxide bleaching of paper pulp. Chitosan with deacetylation degree bigger than 80% is added in the alkaline hydrogen peroxide bleaching process of high yield pulp or deinked pulp to act as the stabilizer of the hydrogen peroxide, and the dosage of the chitosan is 0.5-5kg per ton pulp; and hydrogen peroxide, sodium hydroxide and sodium silicate are added at the same time of bleaching. By adding chitosan in the alkaline hydrogen peroxide bleaching of the paper pulp, the method can improve the bleaching efficiency of the hydrogen peroxide and the whiteness of the paper pulp.

Owner:山东济清科技服务有限公司

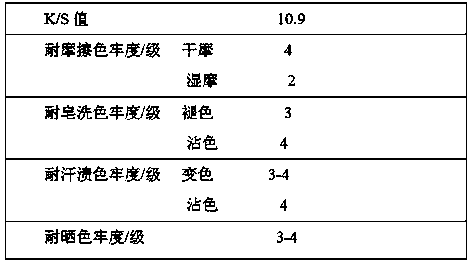

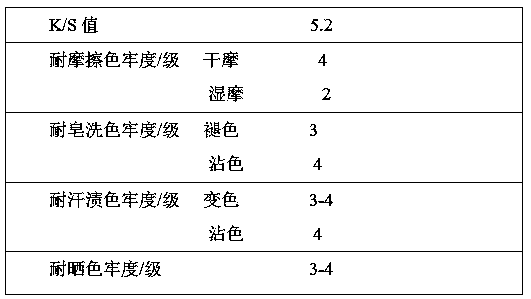

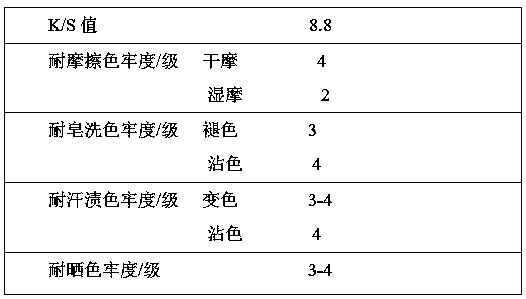

Method for dyeing denim yarn with natural indigo blue

ActiveCN109098011AImprove color vividnessImprove staining reproducibilityDyeing processYarnRoom temperature

The invention discloses a method for dyeing denim yarn with natural indigo blue. The method comprises the following steps: dyeing denim cotton yarns by using a leuco body multi-time padding oxidationmethod, carrying out vatting reduction at 40-50 DEG C, and dyeing denim yarns according to processes of pre-dyeing treatment, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation, dyeing, oxidation and aftertreatmenet with 0.5-2g / L of natural indigo blue, 1.5-4.5g / L of sodium hydroxide, 0.75-1.8g / L of sodium hydrosulfite, 0.25-0.6g / L of a sodium hydrosulfite stabilizer, 10-15g / L of a dyeing acceleration agent sodium chloride or sodium sulfate and 2g / L of a penetrant JFC2. By adopting the dyeing method of multiple times of padding, rolling and oxidation,the dyeing fastness of the denim yarns can be improved, dyeing and oxidation can be both carried out under a room temperature condition, no heating is needed, energy conservation and environment protection can be achieved, reduction is carried out by using a sodium hydrosulfite method, a high reduction velocity can be achieved, and a stable dyeing effect can be achieved.

Owner:鹤壁新歌源丹宁科技有限公司

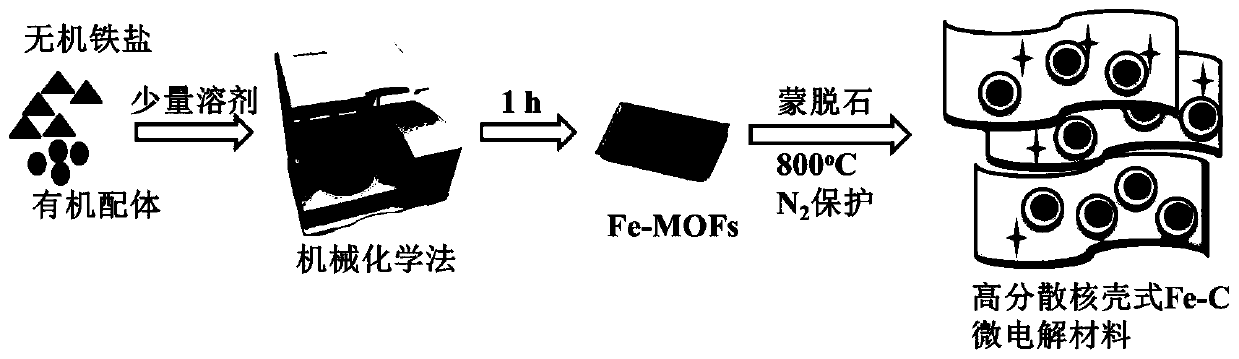

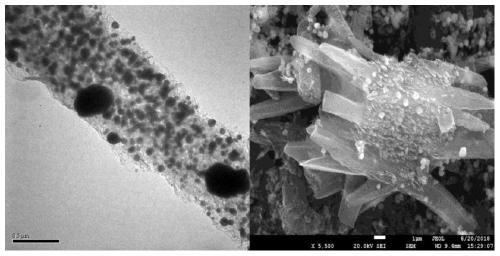

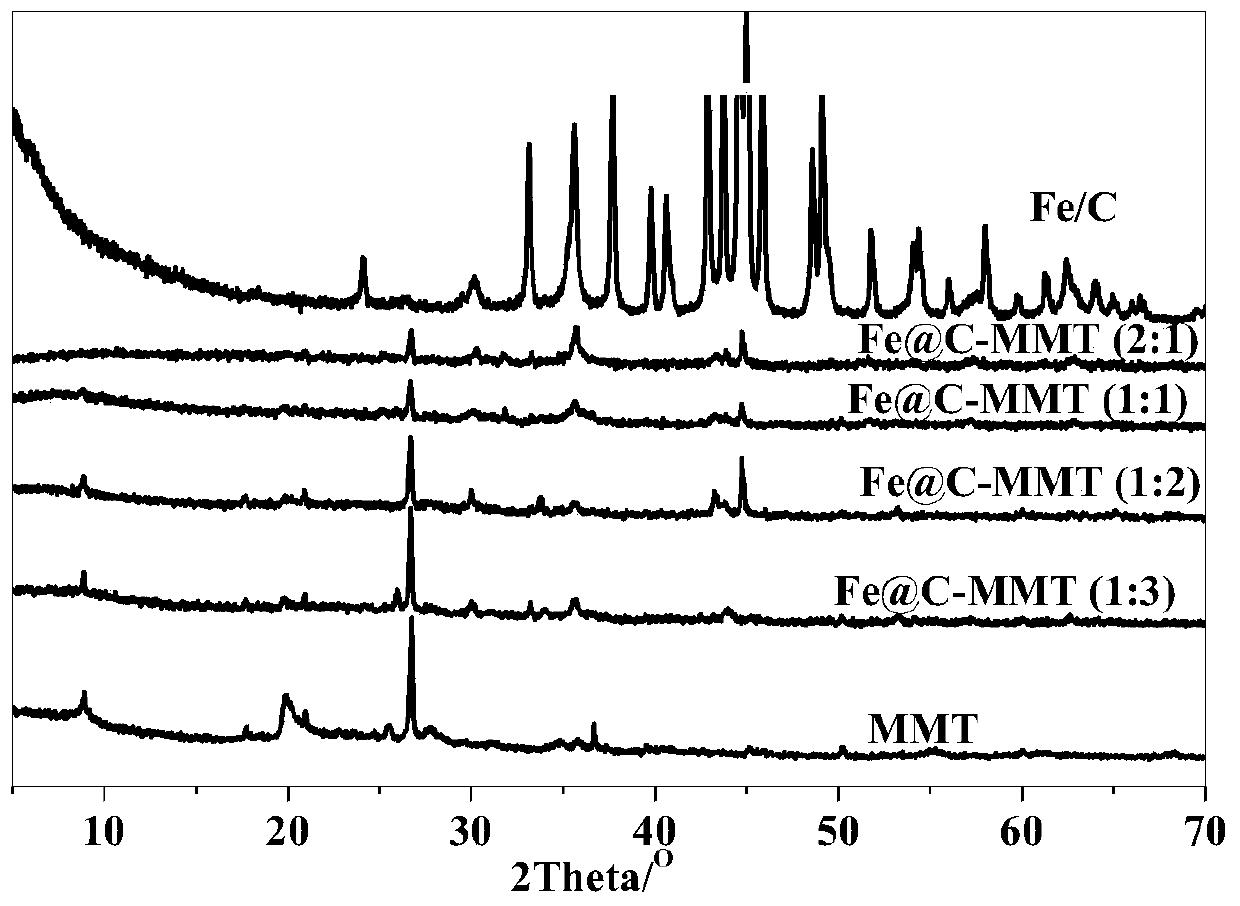

Preparation method and applications of iron-carbon micro-electrolysis material for maintaining long-term catalytic activity of Fenton system

ActiveCN110252305AIncrease profitIncrease loadMaterial nanotechnologyWater treatment compoundsElectrolysisDecomposition

The invention provides a preparation method and applications of an iron-carbon micro-electrolysis material for maintaining the long-term catalytic activity of a Fenton system. According to the present invention, the catalyst is derived from an iron metal organic framework (Fe-MOFs) and montmorillonite; after Fe-MOFs prepared by a mechanochemical method are mixed with montmorillonite, high temperature carbonizing is performed to form a core-shell type iron-carbon filler micro-electrolysis material (Fe@C-MMT) dispersed between the montmorillonite sheet structures; the inefficient decomposition of hydrogen peroxide can be delayed by highly dispersing the Fe@C-MMT material in the water sample, and the hydroxyl radicals are selectively generated, such that the hydrogen peroxide in the system has long-term oxidation ability; the catalyst has a certain pH value adjustment ability, wherein organic pollutants can be efficiently degraded when the initial pH value is 3-6.5; and the catalyst has good stability, can be reused multiple times, and is suitable for removing refractory organic pollutants such as phenol, methyl orange and the like in environmental water samples by advanced oxidation technology Fenton reactions.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Method for improving hydrogen peroxide bleaching efficiency of paper pulp

InactiveCN102363929ALow bleaching efficiencyImprove bleaching efficiencyPulp bleachingChemical/chemomechanical pulpEthylene diamineActive agent

The invention discloses a method for improving hydrogen peroxide bleaching efficiency of paper pulp, and belongs to the technical field of pulp preparation and papermaking. According to the method, a urea active agent and a chelating agent are simultaneously added in the alkali hydrogen peroxide bleaching process of chemical mechanical pulp or waste paper ink removed pulp, the consumption of the urea is 2.0 to 20 kilograms per ton of pulp, the consumption of ethylene diamine tetraacetic acid (EDTA) or diethylenetriamine pentaacetic acid (DTPA) serving as the chelating agent is 1 to 10 kilograms per ton of pulp, and hydrogen peroxide, sodium hydroxide and sodium silicate are simultaneously added during bleaching. In the alkali hydrogen peroxide bleaching process of the paper pulp, the urea serving as the active agent is added at the same time of adding the chelating agent, so that the hydrogen peroxide bleaching efficiency can be improved. Compared with a method without adding the urea serving as the active agent during bleaching, the method has the advantages that: the whiteness of the bleached pulp is obviously improved after the urea is added during bleaching, and the physical strength of the bleached pulp is basically as same as that of the pulp when the urea is not added.

Owner:MCC PAPER YINHE

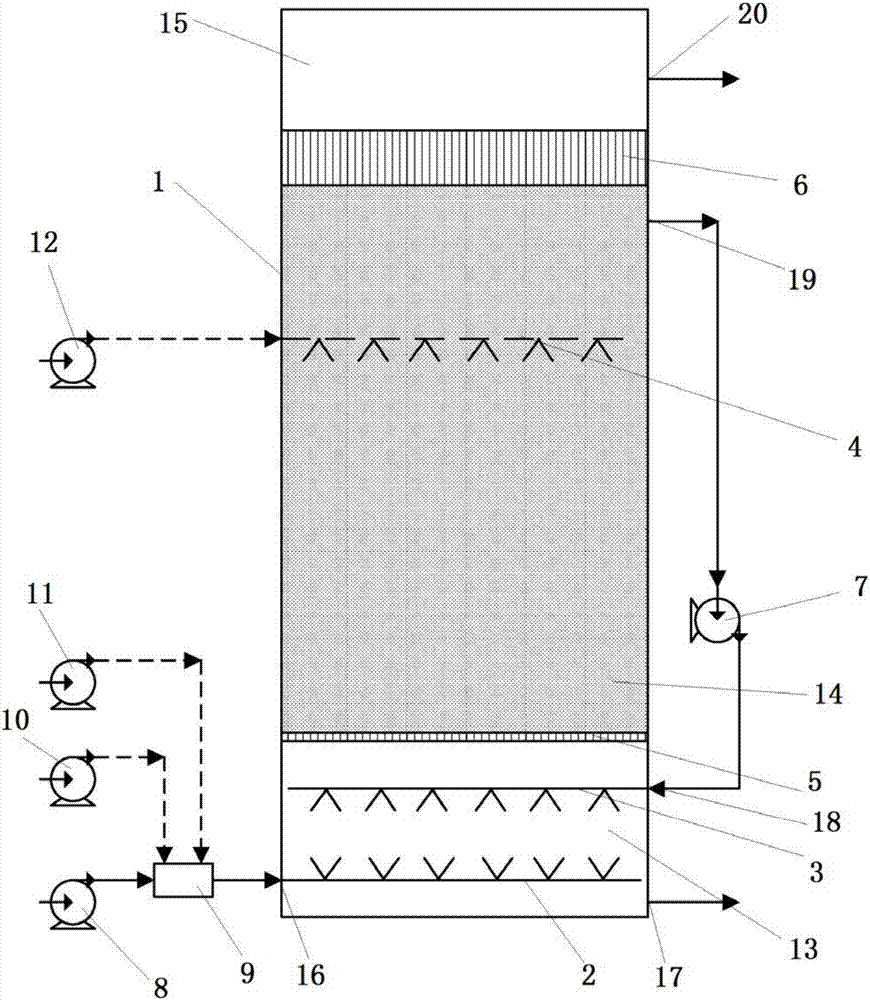

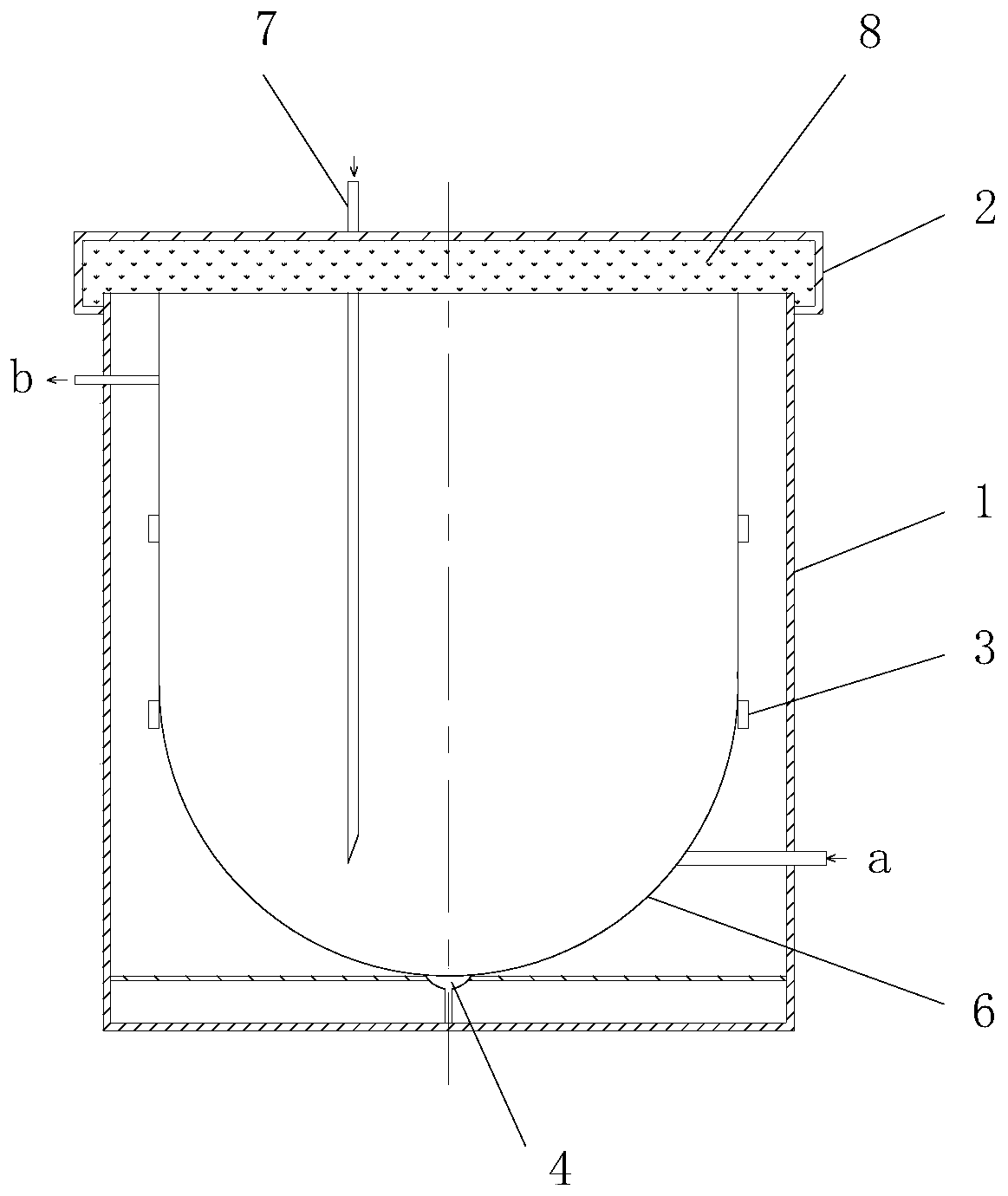

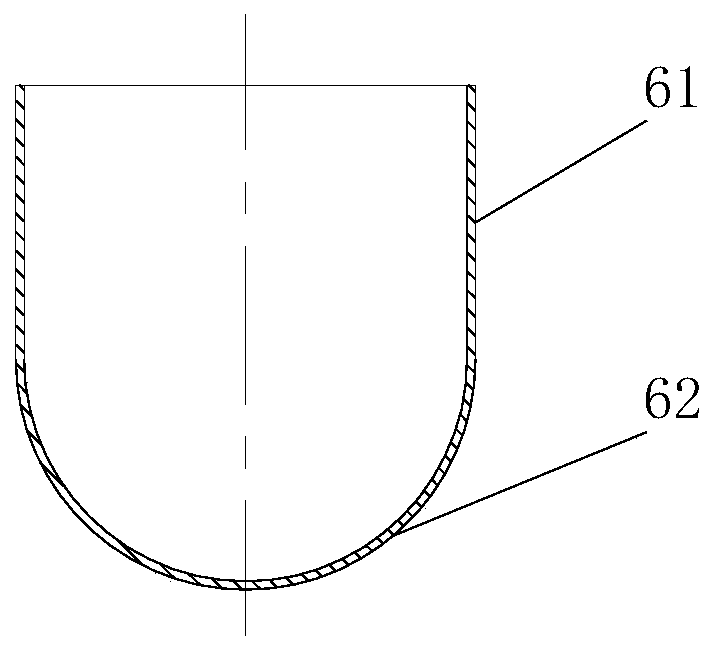

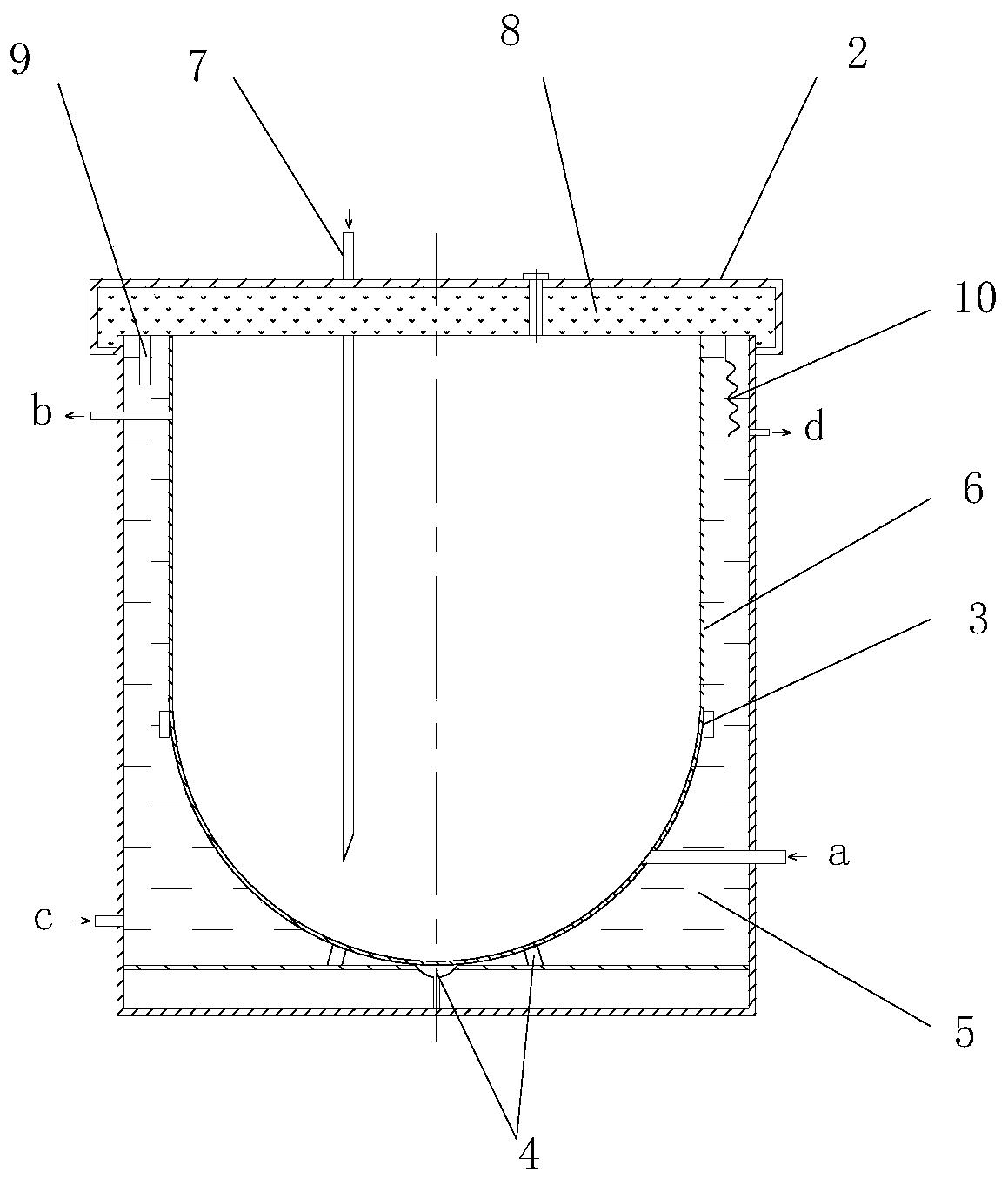

A Fenton fluidized bed reactor and an operation method thereof

ActiveCN107098457AReduce yieldReduce invalid decompositionWater treatment compoundsSustainable biological treatmentFluidized bedDecomposition

A Fenton fluidized bed reactor and an operation method thereof are disclosed. The reactor includes a reactor shell, an inlet flow pattern distributor, a reflux flow pattern distributor, a hydrogen peroxide flow pattern distributor, a separating plate, a three-dimensional filter, a reflux pump, a water feeding pump, a pipeline mixer, an acid adding pump, a ferrous adding pump and a hydrogen peroxide adding pump. The reactor is uniform in water distribution and does not need additionally added power for stirring, thus saving the operation electric charge, reducing ineffective hydrogen peroxide decomposition caused by violent stirring and reducing the using amount of the hydrogen peroxide. The hydrogen peroxide and the ferrous sulphate are added separately, thus reducing ineffective consumption of agents. Active catalytic crystals are formed. The yield of iron-containing sludge is reduced.

Owner:DALIAN MARITIME UNIVERSITY +2

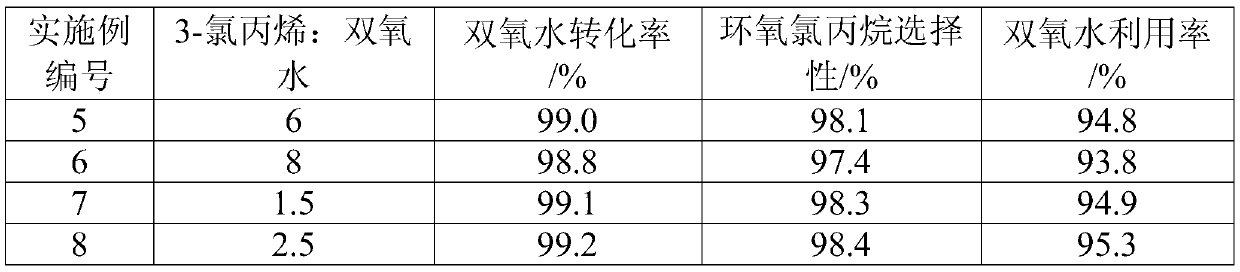

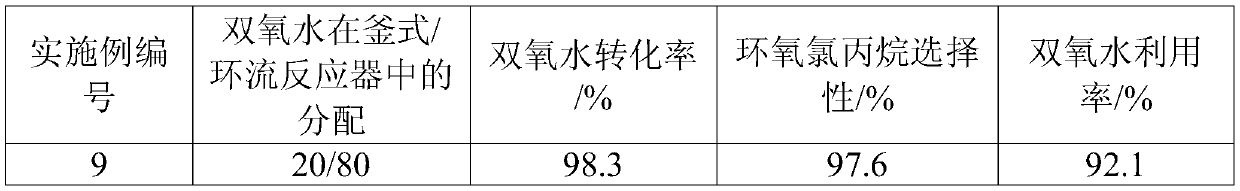

Continuous synthesizing process of epichlorohydrin

ActiveCN110078683AHigh recovery rateFast formingOrganic chemistryChemical recyclingChemistryEpichlorohydrin

The invention relates to a continuous synthesizing process of epichlorohydrin. Specifically, a kettle type reactor and a circulation flow reactor are connected in series; different ratios of hydrogenperoxide are added in stages for reaction; different temperatures and times are controlled; a product directly enters a closed type scraper centrifugal machine to separate out a catalyst and a reaction liquid after the reaction is ended; the reaction liquid is layered to obtain an oil layer and a water layer; chloropropene and the separated catalyst are recycled and pulped to return to a reactionsystem; continuous catalytic operation of the catalyst is realized.

Owner:JIANGSU YANGNONG CHEM GROUP +2

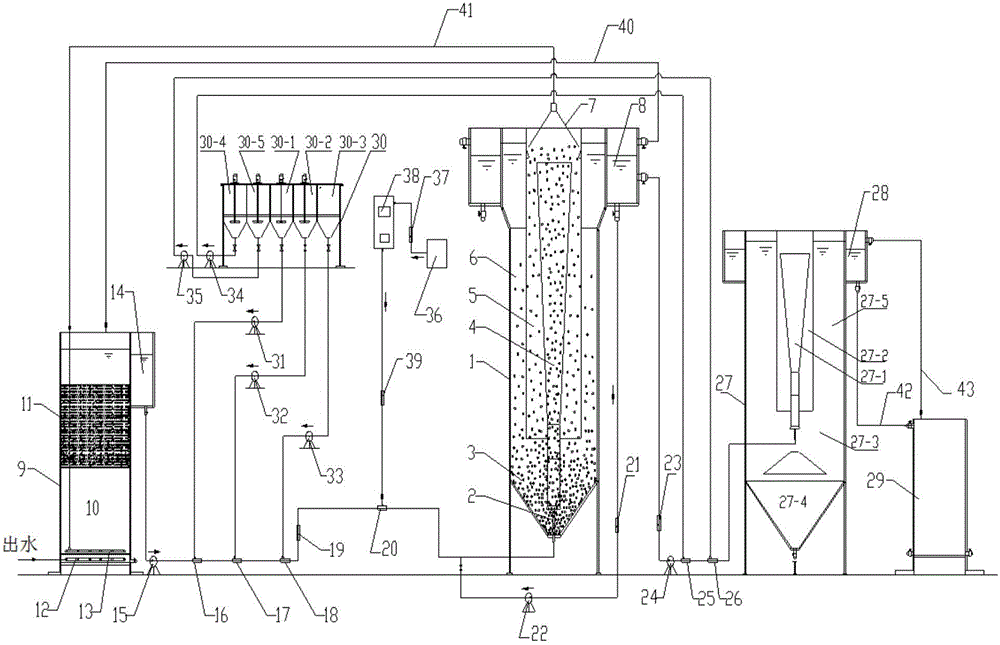

Fenton cooperated ozone fluidized catalytic oxidation waste water treatment device and waste water treatment method thereof

ActiveCN106365348APromote degradationReduce pollution loadMultistage water/sewage treatmentWater/sewage treatment by neutralisationSludgeCatalytic oxidation

The invention discloses a Fenton cooperated ozone fluidized catalytic oxidation waste water treatment device and a waste water treatment method thereof. The device comprises a pretreatment tower (9), a catalytic oxidation tower (1), an aftertreatment tower (27), an agent preparation system (30), an ozone supply system and a clear water pool (29). The waste water treatment method of the device comprises the following steps of 1, pretreatment; 2, catalytic oxidation treatment; 3, aftertreatment. By means of the waste water treatment method of the device, waste water treatment efficiency is improved, the removal effect of COD and chroma of waste water is improved, meanwhile, the use amount of a chemical reagent is reduced, sludge output is reduced, the ozone utilization rate is increased, and the waste water treatment cost is reduced.

Owner:SOUTH CHINA UNIV OF TECH

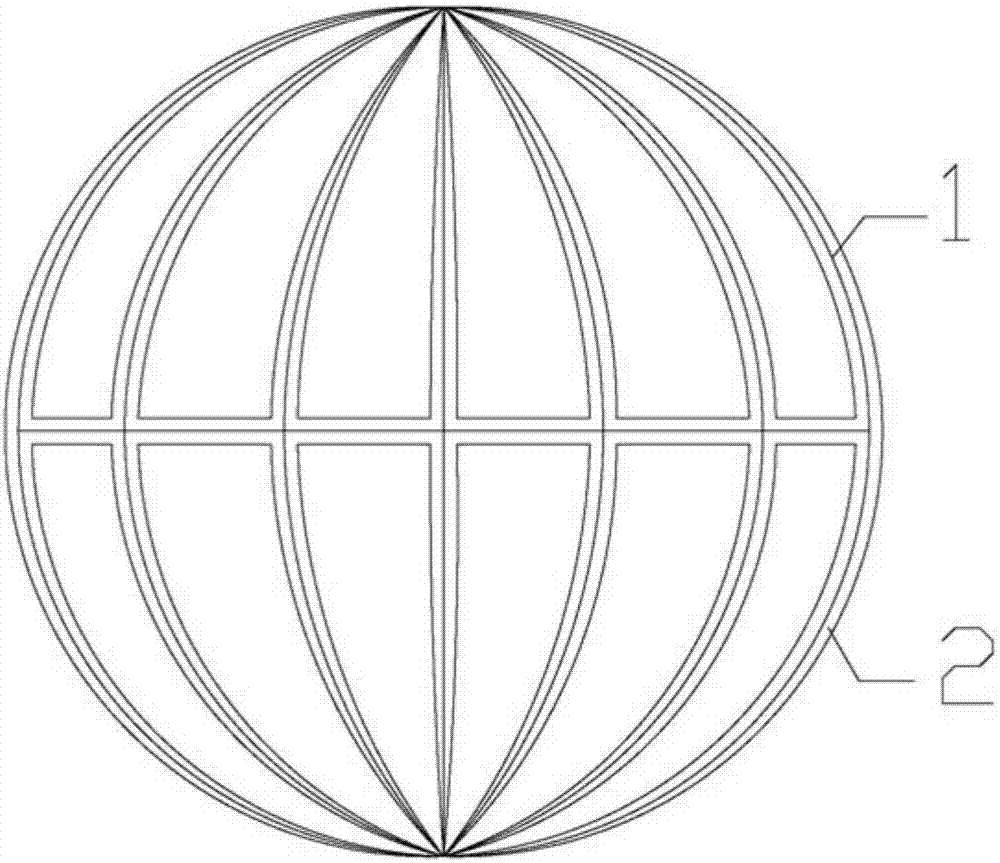

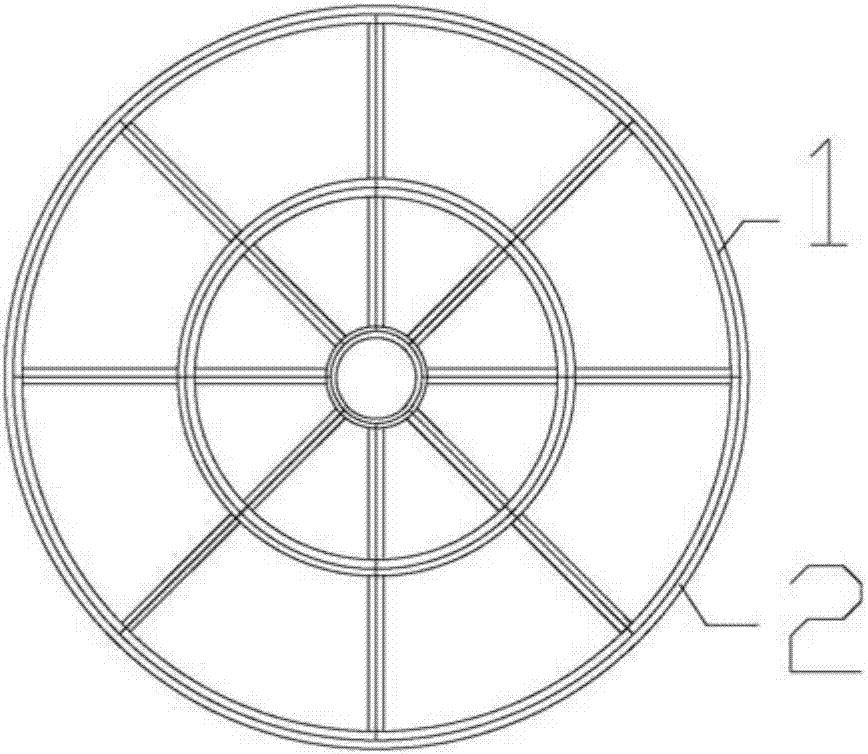

Catalytic type packing for Fenton fluidized bed and preparation method of catalytic type packing

ActiveCN107473364AImprove oxidation efficiencyIncrease profitWater treatment compoundsWaste water treatment from textile industryActivated carbonFenton reaction

The invention relates to catalytic type packing for a Fenton fluidized bed and a preparation method of the catalytic type packing and belongs to the field of wastewater treatment. The catalytic type packing for the Fenton fluidized bed comprises porous suspended packing and a catalyst layer, wherein the porous suspended packing is covered with the catalyst layer; the catalyst layer comprises components as follows: metal salt with Fenton reaction catalytic activity, activated carbon and a binder, a weight ratio of the metal salt, activated carbon and the binder is (0.3-1.2):6:(1.0-1.5), and the metal salt loaded on activated carbon is 5%-20%. The catalytic type packing for the Fenton fluidized bed has a huge catalytic area, can effectively increase oxidation efficiency and utilization rate of hydrogen peroxide, can reduce invalid decomposition of hydrogen peroxide and reduce output of iron-containing sludge, so that sewage treatment effect is improved, and the added amount of chemical and operating cost are reduced.

Owner:DALIAN MARITIME UNIVERSITY +2

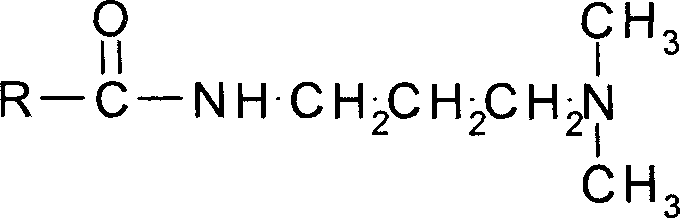

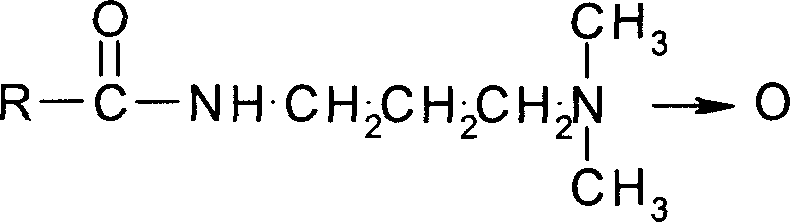

Prepn of alkyl amidopropyldimethyl amine oxide surfactant

InactiveCN1887861AReduce invalid decompositionIncrease the effective concentrationOrganic chemistrySurface-active detergent compositionsChemistrySodium bicarbonate

The present invention relates to preparation process of alkyl amidopropyldimethyl amine oxide as surfactant. The preparation process includes the reaction between alkyl amidopropyldimethyl amine and hydrogen peroxide solution of 20-90 % concentration at 60-90 deg.c and in the presence of EDTA, citric acid, sodium citrate and sodium bicarbonate as catalyst for 2-4 hr to obtain alkyl amidopropyldimethyl amine oxide solution of 30 % or higher concentration in the conversion rate over 99.5 %. The prepared alkyl amidopropyldimethyl amine oxide may be used as surfactant widely used in detergent, cosmetics, textile assistant, medicine and other fields.

Owner:上海高维化学有限公司

Reducing and bleaching composition for pulp from decoloured waste paper and its bleaching method

InactiveCN1351211AReduce invalid decompositionImprove bleaching efficiencyPulp bleachingSodium carbonateSolvent

A reducing and bleaching composition for decoloured waste pulp is prepared from sodium dithionite (5-15 wt.%), chelating agent (1.25-15), sodium carbonate or sodium hydroxide or their mixture (0.25-3) and water (79.5-93.5) through uniform mixing. Its bleaching method features that the stabilizer and said composition are cooperated, and the oil or solvent not dissolved in water is added to isolate air, so improving the stability of bleaching liquid, reducing consumption of sodium dithionite and improving bleaching effect. Its advantages include less damage to strength and opaqueness of paper fibres, less corrosion to pipeline, less pollution and low cost.

Owner:SOUTH CHINA UNIV OF TECH

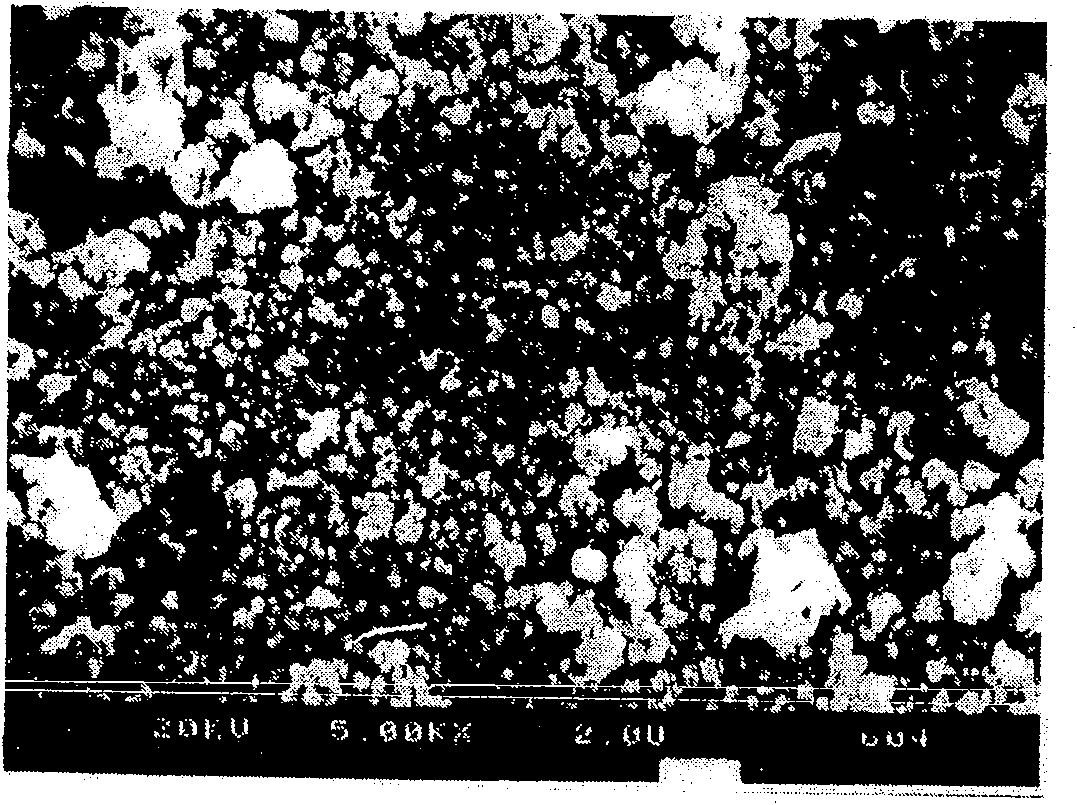

Bimetallic catalyst for degrading chloro organic pollutant, preparation method and application

InactiveCN100553776CLow priceReduce invalid decompositionMolecular sieve catalystsWater/sewage treatment by reductionTetrachloroethyleneDithionous acid

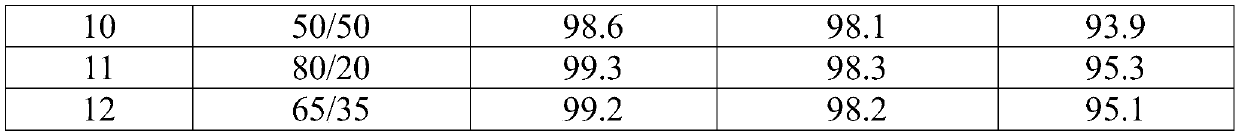

The invention relates to a bimetallic catalyst for degrading chlorinated organic pollutants in water, a preparation method and application thereof. The component of this catalyst is iron-nickel bimetal and carrier, and the mass ratio of iron-nickel bimetal and carrier is 100: (1-10), and wherein the mass ratio of iron-nickel in the iron-nickel bimetal is 100: (1-10) 5), the carrier is a modified zeolite. The iron-nickel bimetal is prepared by reducing nickel ions on the surface of iron filings with sodium dithionite as the reducing agent. The iron-nickel bimetal has a good degradation and dechlorination effect on carbon tetrachloride, trichlorethylene and tetrachlorethylene in wastewater, and the removal effect of carbon tetrachloride, trichlorethylene and tetrachlorethylene can reach 95% within one hour. % or more, and the dechlorination efficiency is above 90%.

Owner:XINYI AGRI CHEM PLANT JIANGSU PROV

Reducing and bleaching composition for pulp from decoloured waste paper and its bleaching method

Owner:SOUTH CHINA UNIV OF TECH

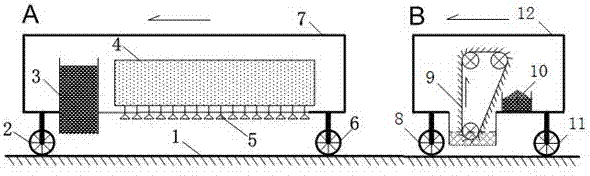

In-situ remediation method and system for farmland soil contaminated by plasticizer and heavy metal lead

InactiveCN107470338ASimple processLow costContaminated soil reclamationContaminated soilsPlasticizer

The invention discloses an in-situ remediation method and system for farmland soil contaminated by a plasticizer and heavy metal lead. The method comprises the following steps that (1) fine carbon-coated porous foam iron particles modified by ethylenediamine tetraacetic acid and a mixture of peroxide and sodium phytate are spread into the contaminated soil; and (2) a hydrogen peroxide solution is sprayed into the contaminated soil, the plasticizer, the heavy metal lead and other pollutants in the soil are enriched and removed, and the fine carbon-coated porous foam iron particles modified by the ethylenediamine tetraacetic acid are recycled. The system comprises a material spreading device and a recycling device. The material spreading device comprises a material spreading moving frame which is provided with a mixture hopper, a hydrogen peroxide solution storage tank and a hydrogen peroxide solution spray head. The recycling device comprises a recycling moving frame which is provided with a magnet recycling device and a foam iron recycling tank. According to the in-situ remediation method and system, the process is simple, the cost is low, the sustainability is high, microorganisms and organic matter in the soil are avoided from being damaged, and secondary pollution risks are avoided.

Owner:QINGDAO AGRI UNIV

Integrated fluidized catalytic oxidation tower and method for deeply treating wastewater by using same

InactiveCN103771624AEasy to handleImprove processing efficiencyMultistage water/sewage treatmentChemical reactionFenton reagent

The invention discloses an integrated fluidized catalytic oxidation tower and a method for deeply treating wastewater by using the same. A balance adjusting unit of the catalytic oxidation tower is connected with a water distribution pipe at the bottom of a catalytic oxidation unit through a pipeline; the outer side of the upper part of the catalytic oxidation unit is provided with a circulating water tank, the outer side of the circulating water tank is provided with an intermediate water tank, and the top of the circulating water tank is connected with the intermediate water tank through an overflow port; the intermediate water tank is connected with a water distribution pipe of a coagulation sedimentation unit through a pipeline, and a water collecting basin is connected with the balance adjusting unit through a pipeline; the balance adjusting unit is connected with the water collecting basin through a first overflow pipe, and the intermediate water tank is connected with the water collecting basin through a second overflow pipe; a water outlet of a water outlet tank is connected with a clean water basin through a water outlet pipe. By using the integrated fluidized catalytic oxidation tower, the mass transfer efficiency and the chemical reaction speed are effectively increased, the oxidative degradation effect for organic pollutants in wastewater is improved, the dosage of a Fenton reagent can be reduced, and the yield of chemical sludge in the later coagulation process can be reduced.

Owner:SOUTH CHINA UNIV OF TECH

High-white-degree bagasse paper pulp and environment-friendly pulp preparation process thereof

InactiveCN106868907ALow viscosityReduce concentrationPretreatment with water/steamWashing/displacing pulp-treating liquorsSlagDistilled water

The invention discloses an environment-friendly pulp preparation process of high-white-degree bagasse paper pulp. The process comprises the following steps of S1, performing dust removal and devitalization on air dried bagasse; adding distilled water accounting for 6 to 10 times of the weight of the absolutely dried bagasse; raising the temperature to 120 to 150 DEG C; performing heat insulation for 30 to 50min; performing filtering; taking filter slag to obtain pre-extraction bagasse; S2, charging the pre-extraction bagasse into a steaming and boiling device; adding hydrogen sulfide, alkali and modified zeolite as the steaming and boiling agents; heating the materials to 150 to 170 DEG C; performing heat insulation to obtain steaming and boiling materials; S3, cooling the steaming and boiling materials; adding alkali; performing heat insulation at the temperature being 60 to 80 DEG C to obtain coarse pulp; S4, diluting the coarse pulp; repeatedly performing washing and purification; then, raising the pulp concentration to be higher than 20 percent to obtain the high-white-degree bagasse paper pulp. The invention also discloses the high-white-degree bagasse paper pulp. The bagasse is used as the raw material; the hot water extraction process is used; the zeolite is added, so that the bleaching efficiency is improved; the production cost is reduced; the paper pulp white degree is improved; the preparation process is reasonable; the efficiency is high.

Owner:芜湖市哈贝纸业有限公司

Method for bleaching complexing catalysis human hair fibers

The invention provides a method for bleaching complexing catalysis human hair fibers. The method is characterized by comprising the following steps that 1) compound amino acid and ferrous sulfate areadded into water, so that the concentration of the compound amino acid is 1-5 g / L, the concentration of the ferrous sulfate is 3-10 g / L, and a stirring reaction is carried out for 10-30 minutes; 2) the temperature rises to 40-60 DEG C, and the human hair fibers are added into the solution prepared in step 1), so that the mass ratio of the human hair fibers to water is 1:(5-30), and soaking is carried out for 10-30 minutes; 3) hydrogen peroxide is added, so that the mass ratio of the hydrogen peroxide to the human hair fibers is (0.3-2):1, bleaching treatment is carried out for 30-100 minutes,and the human hair fibers are taken out and washed. The compound amino acid is prepared by hydrolyzing keratin. According to the provided technical scheme, the method has the advantages of high bleaching efficiency and small damage to the human hair fibers.

Owner:SHAOYANG SUNSHINE HAIR PROD

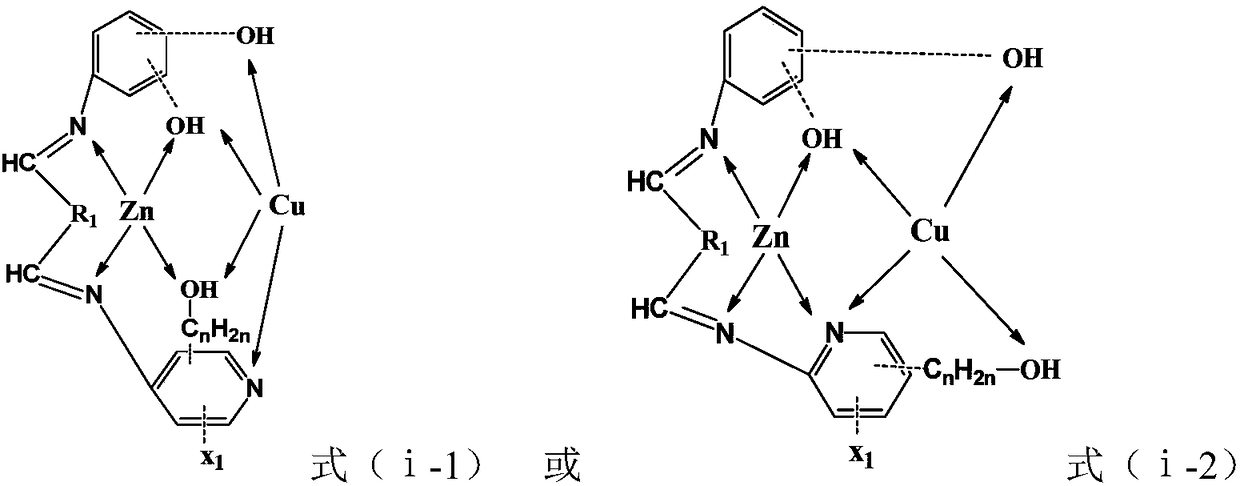

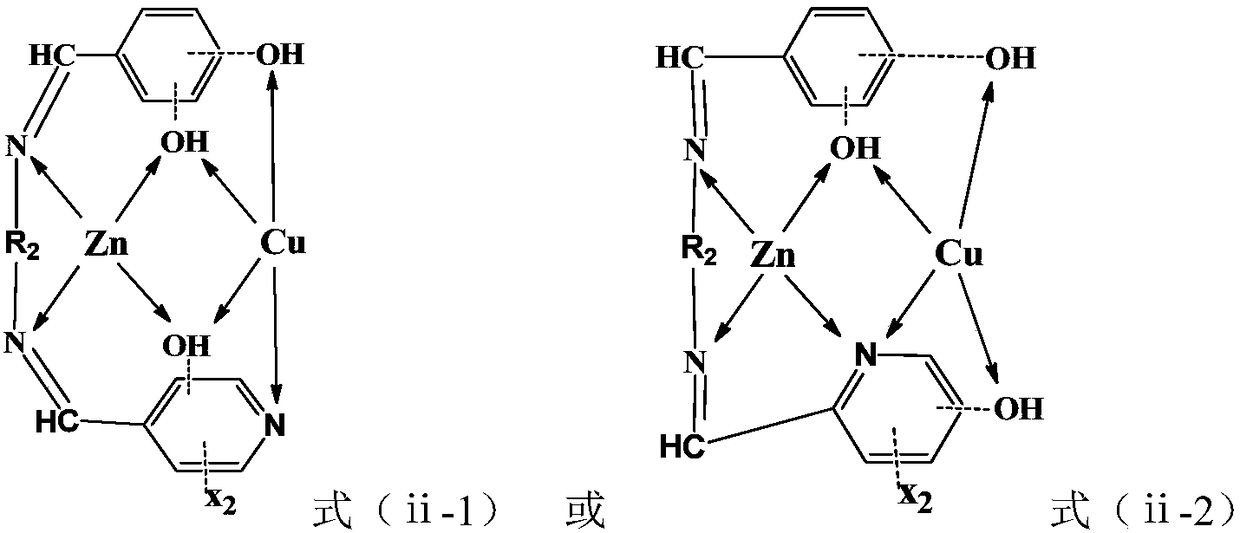

Novel low-temperature oxygen bleaching catalyst and preparation method and application thereof

The invention discloses a novel low-temperature oxygen bleaching catalyst and a preparation method and application thereof. The low-temperature oxygen bleaching catalyst includes clay and a hetero-binuclear Schiff base complex loaded on the clay. The low-temperature oxygen bleaching catalyst is used for bleaching cotton-type fabric and is low in consumption and great in bleaching effect. Comparedwith a traditional 98 DEG C process, the catalyst has the advantage that the whiteness of the bleached fabric is slightly higher, energy consumption is significantly reduced at the low temperature of60-80 DEG C, the strength drop rate of the fabric is not higher than 10%, and fiber damage is smaller; a working raffinate after bleaching is neutral, thus there is no need to carry out acid neutralization and water washing, and the process flow is decreased. The catalyst is stable in structure, and it is proved by a same process for testing the performance of the catalyst after the catalyst is placed for six months that the bleaching effect of the catalyst has no obvious decline.

Owner:TAICANG BAONI IND CO LTD

Method for preparing ramie fibers through oxidation, degumming and repeated multiple-step feeding

ActiveCN103233279BAvoid damageBreak down evenlyFibre treatment to obtain bast fibreDecompositionColloid

The invention provides a method for preparing ramie fibers through oxidation, degumming and repeated multiple-step feeding, which comprises three feeding processes and comprises the following specific steps: in the first feeding process, preparing a degumming solution from surfactant, a fiber expanding agent, peroxide stabilizer, a defoaming agent, sodium hydroxide, peroxide and water, mixing raw hemp of ramie and the degumming solution to form a degumming solution system, and heating to remove part of colloid; in the second feeding process 20-50 minutes later, adding peroxide and sodium hydroxide, and keeping the temperature to further remove the colloid; in the third feeding process 20-50 minutes later, adding peroxide, and further keeping the temperature until the reaction is finished and the colloid is completely removed; and finally, washing refined dried hemp fibers with clear water, oiling, drying, opening, and combing to obtain the prepared ramie fibers. The method provided by the invention overcomes the defects in the existing oxidation and degumming technology; a repeated multiple-step method is used, so that the reaction is uniform and moderate, the damage to the fibers caused by over too high initial concentration of initial concentration is reduced, and the quality of the refined dried hemp product is improved; and meanwhile, the ineffective decomposition of the peroxide and the consumption of the defoaming agent are reduced, thereby saving the cost.

Owner:DONGHUA UNIV

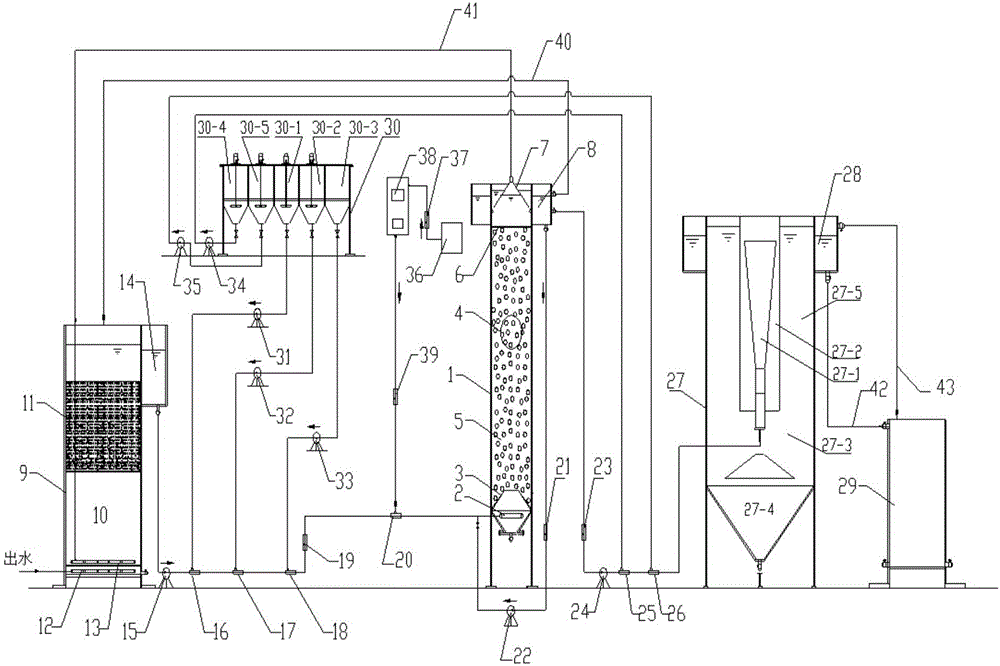

Fenton fluidization wastewater treatment device and wastewater treatment method thereof

PendingCN106336040AEasy to handleMix well and evenlyMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationEngineeringTherapeutic effect

The invention discloses a Fenton fluidization wastewater treatment device and a wastewater treatment method thereof. The device includes a water collection pond (8), a pretreatment tower (13), a fluidization reaction tower (1), a post-treatment tower (26), a reagent preparation system (29) and a clear water pond (28). The wastewater treatment method includes the following steps of 1 pretreatment, 2 Fenton fluidization treatment and 3 post-treatment. The wastewater treatment method can reduce the consumption of chemical reagents, the costs can be reduced, and a treatment effect can be improved.

Owner:SOUTH CHINA UNIV OF TECH

Fenton synergistic ozone wastewater treatment device and wastewater treatment method thereof

ActiveCN106348536APromote degradationReduce pollution loadMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationCatalytic oxidationReagent

The invention discloses a Fenton synergistic ozone wastewater treatment device and a wastewater treatment method thereof. The device comprises a pretreatment tower (9), a catalytic oxidation tower (1), an aftertreatment tower (27), a chemical reagent preparation system (30), an ozone supply system and a clear water tank (29). The wastewater treatment method of the device comprises the following steps: (1) pretreatment; (2) catalytic oxidation treatment; and (3) aftertreatment. By adopting the device for wastewater treatment, the wastewater treatment efficiency can be raised, the removal effect of COD and chroma of the wastewater is improved, the dosage of chemical reagent is reduced, and the ozone utilization rate is high.

Owner:SOUTH CHINA UNIV OF TECH

Organic coated denitration agent and preparation method thereof

PendingCN114272752AImprove denitrification effectReduce invalid decompositionDispersed particle separationPtru catalystPolyol

The invention provides an organic coated denitration agent and a preparation method thereof, and the preparation method comprises the following steps: melting urea, mixing with a catalyst, and carrying out granulation molding to obtain spherical particles; and putting the obtained spherical particles into coating equipment, uniformly rotating the spherical particles, and spraying isocyanate and polyhydric alcohol for coating to obtain the organic coated denitration agent. According to the method, the catalyst is added in the forming process of the urea denitration agent, it is guaranteed that the catalyst is distributed in all local areas when the denitration agent is used, the denitration effect is improved, and the denitration efficiency is improved; according to the method, the surfaces of formed particles are subjected to surface modification in a coating mode, a polyurethane polymeric membrane is formed, the polyurethane polymeric membrane has a slow release effect, invalid decomposition of urea in the denitration process is reduced, the polyurethane polymeric membrane is fully used for reduction of nitric oxide, and the urea utilization rate is increased; the method is simple in operation steps, wide in raw material source, low in equipment investment and production cost and easy to industrially implement.

Owner:JIANGSU YANGNONG CHEM GROUP

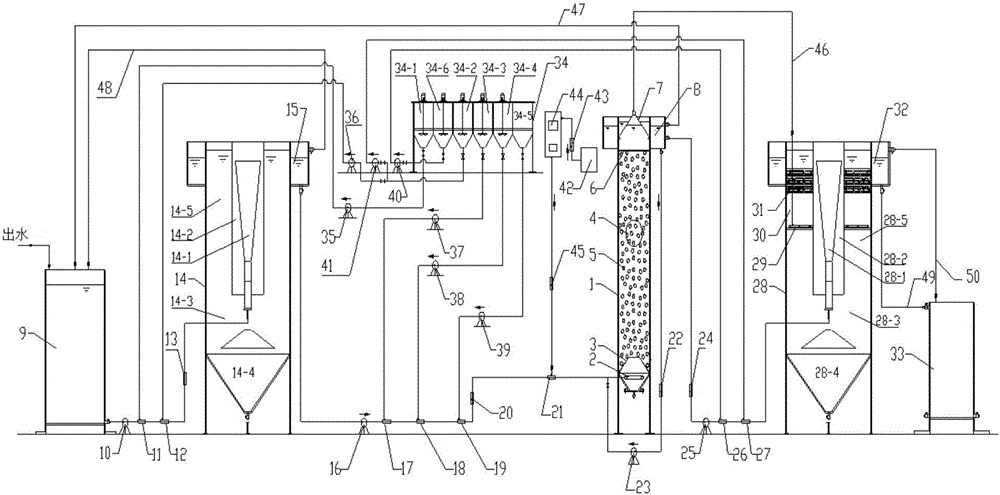

Papermaking-process reconstituted tobacco wastewater advanced treatment device and wastewater treatment method thereof

ActiveCN106315992AReduce consumptionReduce processing costsMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationCatalytic oxidationTower

The invention discloses a papermaking-process reconstituted tobacco wastewater advanced treatment device and a wastewater treatment method thereof. The device comprises a water collecting tank (9), a pretreatment tower (14), a catalytic oxidation tower (1), an aftertreatment tower (28), a medicament preparation system (34), an ozone supply system and a clean water tank (33). The wastewater treatment method of the device comprises the following steps: (1) carrying out pretreatment; (2) carrying out catalytic oxidation treatment; and (3) carrying out aftertreatment. The wastewater treatment method of the device has the advantages that the consumption of a chemical agent can be reduced, wastewater treatment efficiency is improved, wastewater COD and chromaticity removal effect is improved, and the ozone utilization rate is increased.

Owner:SOUTH CHINA UNIV OF TECH

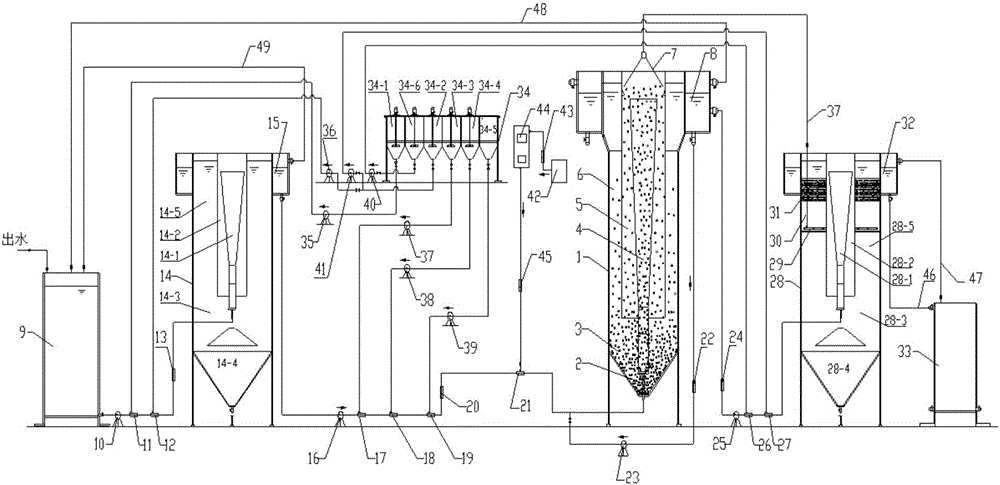

Efficient wastewater treatment device for papermaking process tobacco leaf regeneration and wastewater treatment method thereof

PendingCN106430826AGuaranteed flow rateEasy to handleMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationCatalytic oxidationEngineering

The invention discloses an efficient wastewater treatment device for papermaking process tobacco leaf regeneration and a wastewater treatment method thereof. The device comprises a water-collecting pool (9), a pretreatment tower (14), a catalytic oxidation tower (1), an aftertreatment tower (28), an agent preparation system (34), an ozone supply system and a clear water pool (33). The wastewater treatment method includes the following steps that (1), pretreatment is carried out; (2), catalytic oxidation treatment is carried out; (3), aftertreatment is carried out. By the utilization of the wastewater treatment method, wastewater treatment efficiency is improved, the quantity of consumed chemical agents is reduced, the removal effect of the wastewater COD and color degree is improved, the utilization rate of ozone is increased, and wastewater treatment cost is lowered.

Owner:SOUTH CHINA UNIV OF TECH

A low-noise multi-frequency sonochemical reactor and its application

ActiveCN108706682BIncreased degradation rateReduce processing timeWater/sewage treatment with mechanical oscillationsSound producing devicesIndustrial waste waterChemical reaction

The invention provides a low-noise multi-frequency ultrasonic chemical reactor, and belongs to the field of degradation-resistant industrial wastewater treatment. According to the low-noise multi-frequency ultrasonic chemical reactor, mainly, multiple kinds of ultrasonic generators with different frequencies are used for generating three kinds of ultrasonic waves with different frequencies in horizontal and vertical directions to form an ultrasonic irradiation net, and through arc surface-shaped focusing, the three kinds of ultrasonic waves with the different frequencies are subjected to a compounding superposition action to achieve a cavitation effect and mechanical strength more significant than those of unidirectional single-frequency ultrasonic wave irradiation. The low-noise multi-frequency ultrasonic chemical reactor is even in ultrasonic irradiation, low in noise, high in organic matter degradation rate and high in wastewater treatment efficiency.

Owner:SHAANXI NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com