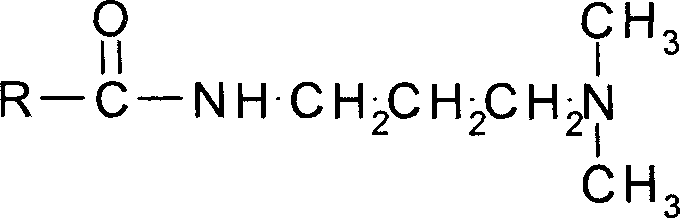

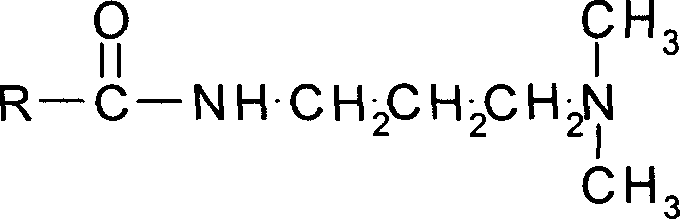

Prepn of alkyl amidopropyldimethyl amine oxide surfactant

A technology of alkylamidopropyl dimethylamine oxide and alkylamidopropyl dimethylamine, which is applied in the directions of surface active detergent compositions, chemical instruments and methods, organic chemistry, etc., can solve the problem of short reaction time, Long reaction time and other problems, to achieve the effect of increasing the effective concentration, reducing the ineffective decomposition, and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

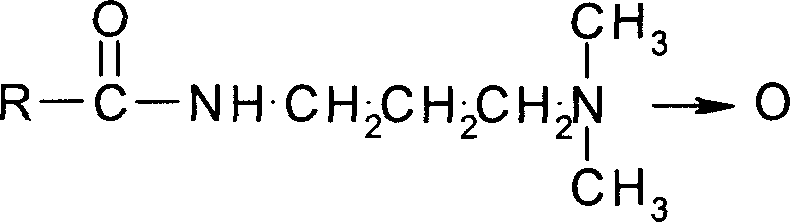

Method used

Image

Examples

Embodiment 1

[0016] Cocamidopropyl dimethylamine 100g, add 215g water, add the catalyst 2.1g of EDTA (52%), citric acid (8%), sodium citrate (16%), sodium bicarbonate (24%). 37g of 35% hydrogen peroxide solution was added dropwise, and reacted for 2.5 hours at 70°C to obtain a 30% alkylamidopropyl dimethyl amine oxide solution with a conversion rate of 99.7%.

Embodiment 2

[0018] Palmimidopropyl dimethylamine 100g, add 218g water, add the catalyst 2.3g of EDTA (62%), citric acid (14%), sodium citrate (10%), sodium bicarbonate (14%). 31 g of 35% hydrogen peroxide solution was added dropwise and reacted for 3 hours at a temperature of 70° C. to obtain a 31% alkylamidopropyl dimethyl amine oxide solution with a conversion rate of 99.8%.

Embodiment 3

[0020] Stearamidopropyl dimethylamine 100g, add 213g water, add the catalyst 2.0g of EDTA (14%), citric acid (6%), sodium citrate (37%), sodium bicarbonate (43%). 33.8 g of 30% hydrogen peroxide solution was added dropwise and reacted for 4 hours at a temperature of 70° C. to obtain a 30% alkylamidopropyl dimethyl amine oxide solution with a conversion rate of 99.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com