Papermaking-process reconstituted tobacco wastewater advanced treatment device and wastewater treatment method thereof

A technology of reconstituted tobacco leaves and advanced treatment, applied in water/sewage treatment, biological water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of low ozone solubility, high waste water cost, low ozone utilization rate, etc., to improve Mass transfer efficiency, the effect of improving the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

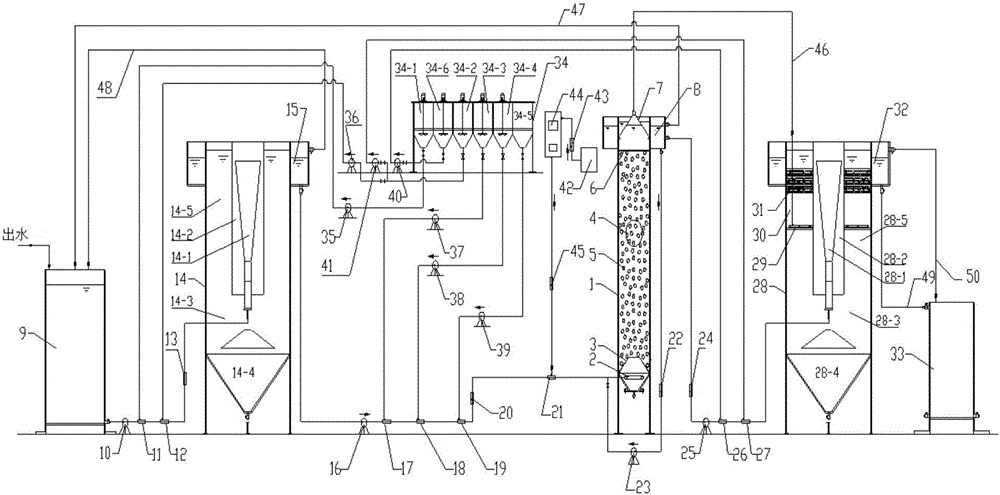

[0061] In this example, a device for advanced treatment of reconstituted tobacco wastewater from papermaking is used to treat wastewater from papermaking reconstituted tobacco wastewater after air flotation and UASB+SBR treatment. The COD of wastewater is cr It is 540 mg / L, the color is 920 C.U., and the SS is 530 mg / L.

[0062] Applying a papermaking process reconstituted tobacco wastewater advanced treatment device of the present invention to treat the papermaking process reconstituted tobacco wastewater secondary biological treatment effluent includes the following steps and process conditions:

[0063] (1) Pre-treatment: The effluent from the secondary settling tank of secondary biological treatment of reconstituted tobacco wastewater from papermaking method enters the sump 9, and is transported by the first water pump 10 through the pipeline to the jet water inlet of the pre-treatment tower 14, and the flow entering the pre-treatment tower 14 State reaction zone 14-1, add...

Embodiment 2

[0071] In this example, a device for advanced treatment of reconstituted tobacco wastewater from papermaking is used to treat wastewater from papermaking reconstituted tobacco wastewater after air flotation and UASB+SBR treatment. The COD of wastewater is cr It is 540 mg / L, the color is 920 C.U., and the SS is 530 mg / L.

[0072] Applying a papermaking process reconstituted tobacco wastewater advanced treatment device of the present invention to treat the papermaking process reconstituted tobacco wastewater secondary biological treatment effluent includes the following steps and process conditions:

[0073] (1) Pre-treatment: The effluent from the secondary settling tank of secondary biological treatment of reconstituted tobacco wastewater from papermaking method enters the sump 9, and is transported by the first water pump 10 through the pipeline to the jet water inlet of the pre-treatment tower 14, and the flow entering the pre-treatment tower 14 In the state reaction zone 14...

Embodiment 3

[0081] In this example, a device for advanced treatment of reconstituted tobacco wastewater from papermaking is used to treat wastewater from papermaking reconstituted tobacco wastewater after air flotation and UASB+SBR treatment. The COD of wastewater is cr It is 540 mg / L, the color is 920 C.U., and the SS is 530 mg / L.

[0082] Applying a papermaking process reconstituted tobacco wastewater advanced treatment device of the present invention to treat the papermaking process reconstituted tobacco wastewater secondary biological treatment effluent includes the following steps and process conditions:

[0083] (1) Pre-treatment: The effluent from the secondary settling tank of secondary biological treatment of reconstituted tobacco wastewater from papermaking method enters the sump 9, and is transported by the first water pump 10 through the pipeline to the jet water inlet of the pre-treatment tower 14, and the flow entering the pre-treatment tower 14 In the state reaction zone 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com