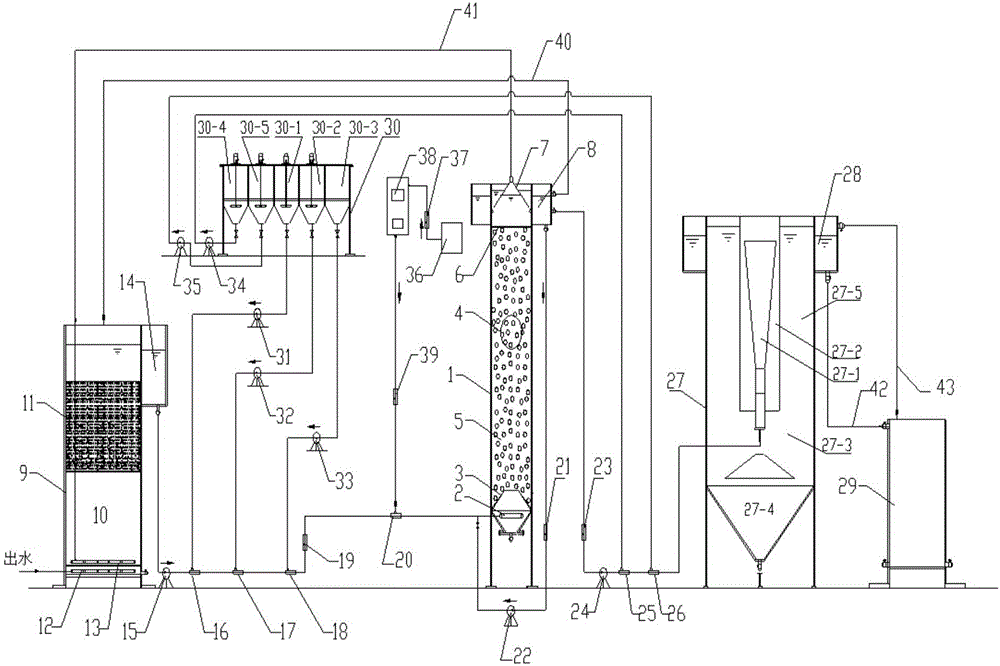

Fenton synergistic ozone wastewater treatment device and wastewater treatment method thereof

A technology for ozone treatment and wastewater treatment, applied in the directions of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of high wastewater cost, low ozone solubility, low ozone utilization rate, etc., to reduce wastewater Pollution load, efficient mass transfer efficiency, the effect of improving the removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In this embodiment, a Fenton cooperative ozone treatment wastewater treatment device is used to treat the waste water of southern hardwood pulp D0 / C-(EO)PD1 bleaching wastewater after hydrolysis acidification and activated sludge treatment, and the COD of the wastewater cr 320 mg / L, BOD 5 It is 60 mg / L and the color is 630 C.U.

[0053] A method for treating southern hardwood pulp bleaching wastewater using a Fenton and ozone treatment wastewater device includes the following steps and process conditions:

[0054] (1) Pretreatment: The effluent from the secondary sedimentation tank is pumped into the pretreatment tower 9 through the water distribution pipe 12 at the bottom of the pretreatment tower 9, and the ozone-oxygen mixed gas tail gas from the gas collection device 7 at the top of the catalytic oxidation tower 1 passes through The air distribution pipe 13 arranged at the bottom of the pretreatment tower 9 enters the pretreatment tower 9; the ozone-oxygen mixed gas and w...

Embodiment 2

[0061] In this embodiment, a Fenton cooperative ozone treatment wastewater device is used to treat waste paper deinking pulping wastewater after IC tower and SBR treatment, and the COD of wastewater cr It is 390 mg / L and the color is 650 C.U.

[0062] A method for treating southern hardwood pulp bleaching wastewater using a Fenton and ozone treatment wastewater device includes the following steps and process conditions:

[0063] (1) Pretreatment: The effluent from the secondary sedimentation tank is pumped into the pretreatment tower 9 through the water distribution pipe 12 at the bottom of the pretreatment tower 9, and the ozone-oxygen mixed gas tail gas from the gas collection device 7 at the top of the catalytic oxidation tower 1 passes through The air distribution pipe 13 arranged at the bottom of the pretreatment tower 9 enters the pretreatment tower 9; the ozone-oxygen mixed gas and wastewater are fully and evenly mixed at the bottom of the pretreatment tower 9 and enter the p...

Embodiment 3

[0070] In this embodiment, a Fenton cooperative ozone treatment wastewater device is used to treat waste paper and papermaking wastewater after hydrolysis acidification and SBR treatment, and the COD of the wastewater cr It is 230 mg / L and the color is 320 C.U.

[0071] A method for treating southern hardwood pulp bleaching wastewater using a Fenton and ozone treatment wastewater device includes the following steps and process conditions:

[0072] (1) Pretreatment: The effluent from the secondary sedimentation tank is pumped into the pretreatment tower 9 through the water distribution pipe 12 at the bottom of the pretreatment tower 9, and the ozone-oxygen mixed gas tail gas from the gas collection device 7 at the top of the catalytic oxidation tower 1 passes through The air distribution pipe 13 arranged at the bottom of the pretreatment tower 9 enters the pretreatment tower 9; the ozone-oxygen mixed gas and wastewater are fully and evenly mixed at the bottom of the pretreatment towe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com