Bimetallic catalyst for degrading chloro organic pollutant, preparation method and application

A bimetallic catalyst and organic pollutant technology, applied in the field of degrading chlorinated organic pollutants in water, bimetallic catalyst and its preparation, can solve the problems of complex process, small processing capacity, high energy consumption, etc., and achieve continuous and efficient degradation and reduction Moderate activity and the effect of maintaining reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

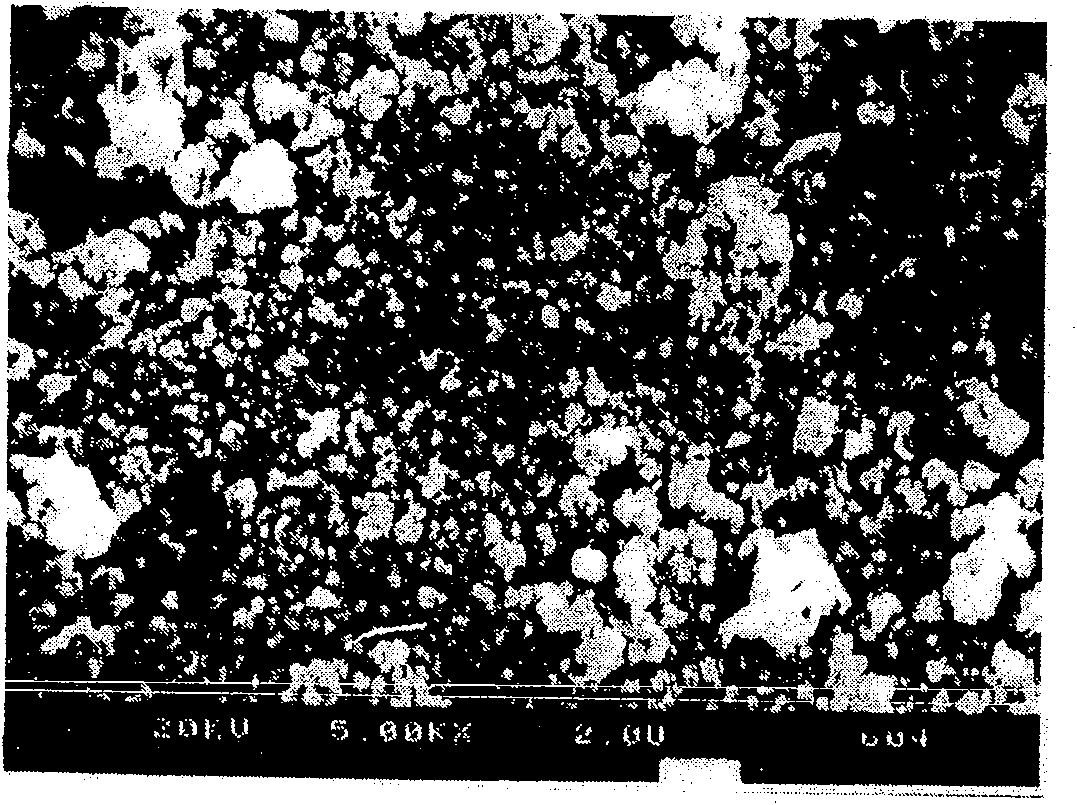

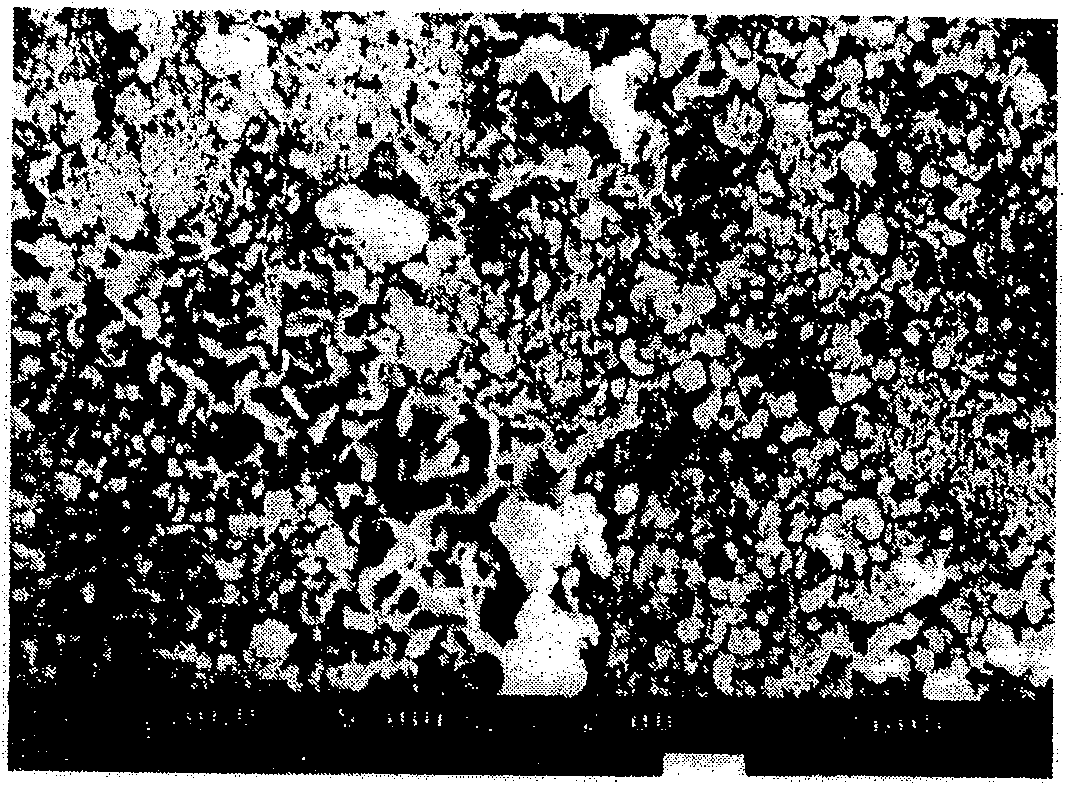

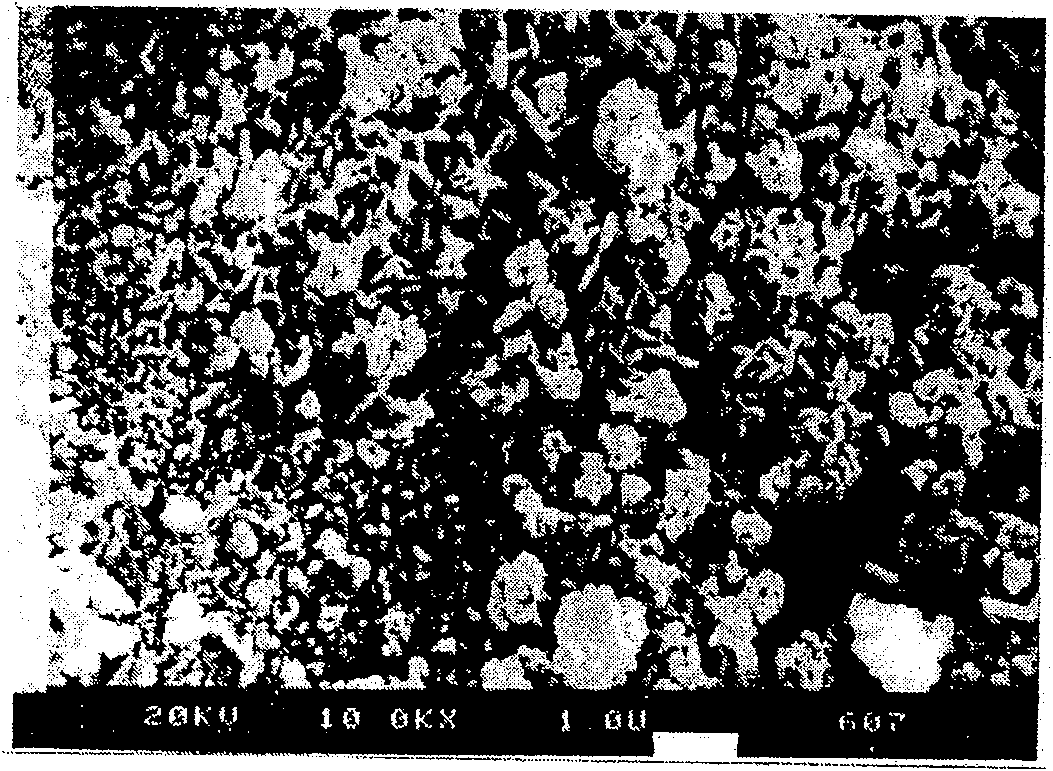

Image

Examples

Embodiment 1

[0036] Comparison of the effect of treating wastewater containing tetrachloroethylene (PCE) with the method of the present invention and the prior art

[0037] (1) Water quality containing PCE wastewater

[0038] PCE concentration 142mg / L

[0039] pH 5.74

[0040] Cl - Concentration <2mg / L

[0041] (2) Weigh three parts of iron filings of the same quality, the first part without catalyst nickel and modified zeolite is pure iron filings, called filler A; the second part adopts ion exchange method to prepare iron-nickel bimetal, sulfuric acid The concentration of the nickel solution is 0.4mol / L, the mass ratio of nickel and iron filings contained in it is 3:100, the preparation time is 2h, and the prepared iron-nickel bimetal without modified zeolite is composed of filler B; the third part The iron-nickel bimetal is prepared by the liquid-phase reduction method. The concentration of the nickel sulfate solution is 0.4mol / L. Alkaline solution, then add iron filings with a par...

Embodiment 2

[0047] Example 2 Treatment of waste water containing trichloroethylene (TCE) with the method of the present invention

[0048] (1) Water quality containing TCE wastewater

[0049] Concentration of TCE 37mg / L

[0050] pH 6.35

[0051] Cl - Concentration <2mg / L

[0052] (2) adopt the liquid phase reduction method to prepare the iron-nickel bimetal, the concentration of the nickel chloride solution is 0.5mol / L, and the sodium hydrosulfite is dissolved in the sodium hydroxide solution of 0.3mol / L and configured to contain sodium hydrosulfite to be 0.75 mol / L mol / L alkaline solution, then add iron filings with a particle size of 1 to 3 mm into the nickel chloride solution and stir rapidly, the mass ratio of nickel and iron filings contained in it is 5:100, and the reaction is carried out at 40 ° C for 1.5 h, then stood for filtration, washed with deionized water until neutral, dehydrated and dried to obtain iron-nickel bimetals; the natural zeolite was soaked and washed with de...

Embodiment 3

[0058] Example 3 Treatment of wastewater containing tetrachloromethane (CT) with the method of the present invention

[0059] (1) Water quality containing CT wastewater

[0060] CT concentration 217mg / L

[0061] pH 6.51

[0062] Cl - Concentration <2mg / L

[0063] (2) The iron-nickel bimetal is prepared by the liquid-phase reduction method, the concentration of the nickel chloride solution is 0.2 mol / L, and the sodium hydrosulfite is dissolved in the sodium hydroxide solution of 0.1 mol / L, and the sodium hydrosulfite is configured to contain 0.3 mol / L of sodium hydrosulfite. mol / L alkaline solution, then add iron filings with a particle size of 1 to 3 mm into the nickel chloride solution and stir rapidly, the mass ratio of nickel and iron filings contained in it is 1:100, and react at 20 ° C for 1 h , then stood for filtration, washed with deionized water until neutral, dehydrated and dried to obtain iron-nickel bimetal; the natural zeolite was soaked and washed with deioni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com