A Fenton fluidized bed reactor and an operation method thereof

A technology of fluidized bed reactor and reactor shell, which is applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc. It can solve the problem of affecting the operation effect of Fenton fluidized bed and the low utilization rate of chemicals , long residence time and other issues, to achieve the effect of reducing the yield of iron-containing sludge, improving the utilization rate of chemicals, and saving operating electricity costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

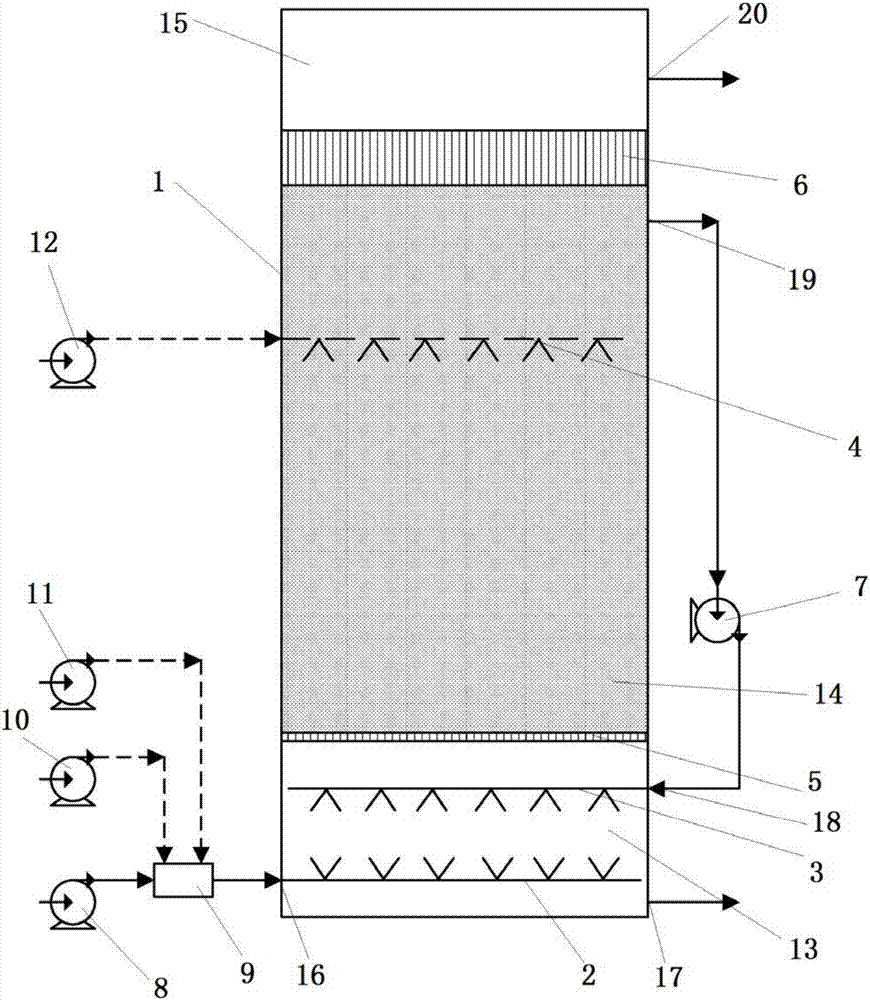

[0040] Such as figure 1 As shown, a Fenton fluidized bed reactor includes a reactor shell 1, an inflow flow distributor 2, a reflux flow distributor 3, a hydrogen peroxide flow distributor 4, a partition 5, a three-dimensional filter 6, Return pump 7, water inlet pump 8, pipeline mixer 9, acid dosing pump 10, ferrous dosing pump 11 and hydrogen peroxide dosing pump 12;

[0041] The reactor shell 1 includes a water distribution area 13, a packing area 14 and a drainage area 15 arranged in sequence from bottom to top. The reactor shell 1 is provided with a water inlet 16, a slag discharge port 17, a return inlet 18, Return outlet 19 and drain outlet 20;

[0042] The inlet water flow distributor 2 and the return flow distributor 3 are located in the water distribution area 13, the inlet water distributor 2 communicates with the water inlet 16, and the water inlet 16 is located in the water distribution area 13. On the side wall of the water distribution area 13, the return flow...

Embodiment 2

[0058] A kind of operation method of a kind of Fenton fluidized bed reactor as described in embodiment 1, has the following steps,

[0059] S1, adding catalytic filler particles in the filler zone 14;

[0060] S2. Turn on the water inlet pump 8, the acid dosing pump 10, and the ferrous dosing pump 11, and control the pH in the reactor to be 2 to 7;

[0061] S3. Turn on the hydrogen peroxide dosing pump 12 and the reflux pump 7, adjust the reflux ratio, control the rising flow rate in the reactor to 100-500m / h, and ensure that the packing area 14 is in a fluidized state;

[0062] S4, according to the characteristics of water quality, adopt orthogonal experiment, optimize and adjust the dosage of hydrogen peroxide and ferrous sulfate to be 0.035% and 0.1% (mass ratio) of the total amount of influent.

[0063] Adopting the technology of the present invention, for the printing and dyeing wastewater of the garden factory, the COD before and after treatment is 200 and 30 respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com