Device and method for treating pulping wastewater by Fenton catalytic oxidation method

A technology for catalytic oxidation and pulping wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of large amount of sludge and chemicals, high treatment cost, etc. Achieve high treatment effect, improve efficiency, and high mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

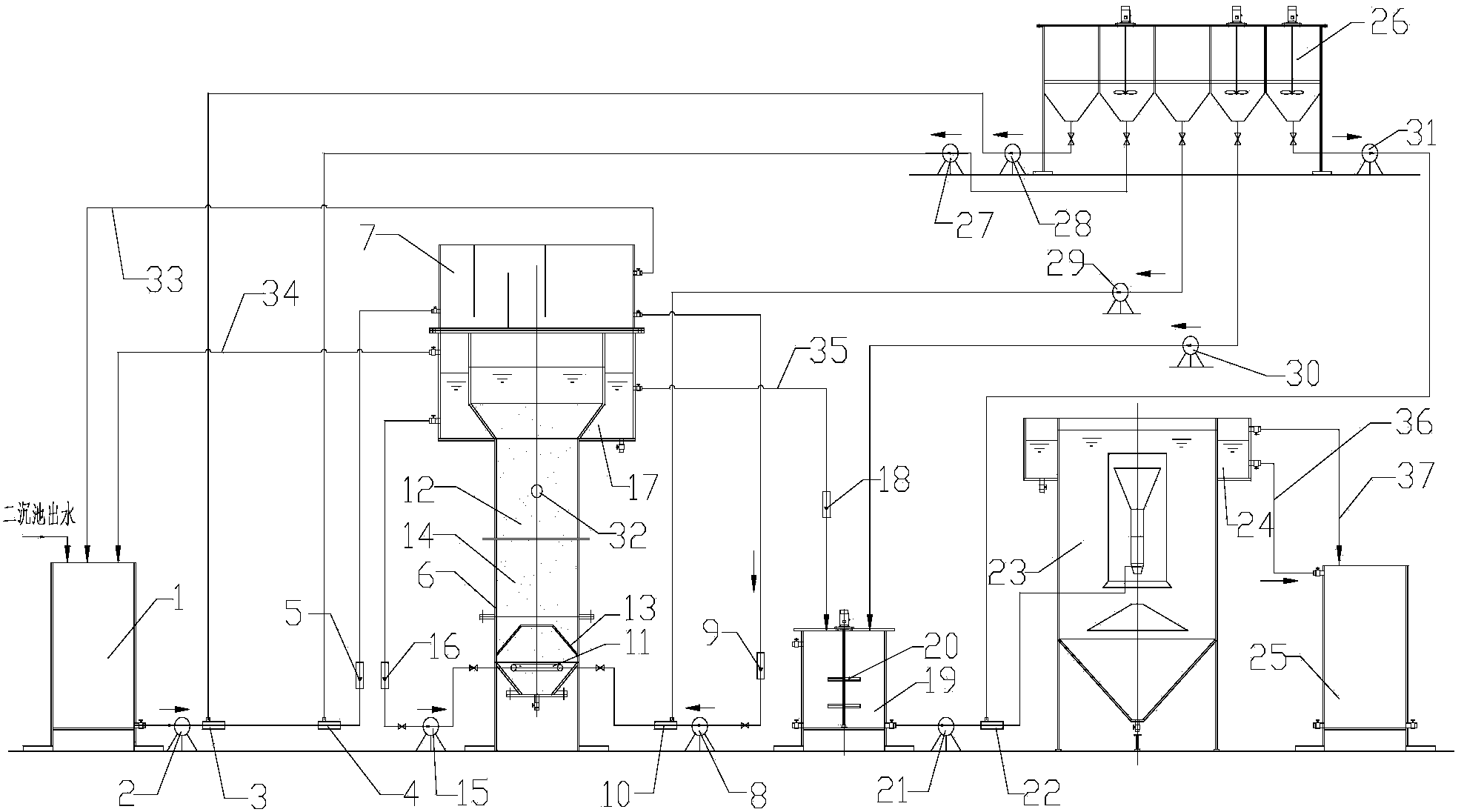

[0048] This example treats the wastewater from the southern miscellaneous wood pulp D0 / C-(EO)PD1 bleaching wastewater after hydrolytic acidification and activated sludge treatment, and the COD of the wastewater cr 350mg / L, BOD 5 It is 55mg / L, and the color is 490C.U.

[0049] The method for processing pulping wastewater by the Fenton catalytic oxidation process of the above-mentioned device comprises the following steps and process conditions:

[0050] 1) Balanced adjustment treatment: the wastewater in the sump 1 is transported to the balanced adjustment tank 7 at the top of the catalytic oxidation tower 6 through the first water pump 2, and H is added through the first pipeline mixer 3 and the second pipeline mixer 4 respectively. 2 SO 4 and FeSO 4 ·7H 2 O. Several partitions separated from each other are arranged in the balance adjustment tank 7, and the waste water passes through each partition successively in a push-flow manner, so that the waste water, H 2 SO 4 an...

Embodiment 2

[0059] This example is the same as Example 1 except for the following: a device for treating pulping wastewater by a Fenton catalytic oxidation method is used to treat southern miscellaneous wood pulp D0 / C-(EO)PD1 bleaching wastewater is treated by hydrolytic acidification and activated sludge method After the wastewater, the COD of the wastewater cr It is 310mg / L, and chromaticity is 530C.U.; In the present embodiment, by volume of waste water, FeSO 4 ·7H 2 The addition amount of O is 465 mg / L, the addition amount of hydrogen peroxide is 930 mg / L, and the addition amount of polyacrylamide is 1.8 mg / L. After treatment, the COD of wastewater cr It is 95mg / L, and the color is 100C.U. While adopting the conventional Fenton treatment method, the COD of the wastewater after treatment cr Between 120-150mg / L, the chromaticity is 120-170C.U., and the processing cost is relatively high.

Embodiment 3

[0061] This example is the same as Example 1 except for the following: a device for treating pulping wastewater by Fenton catalytic oxidation method is used to treat the waste water produced by the papermaking method of reconstituted tobacco leaves of a certain tobacco sheet enterprise after being treated by UASB and SBR, and the COD of the waste water cr It is 550mg / L, and chromaticity is 1900C.U.; In the present embodiment, by volume of waste water, FeSO 4 ·7H2 The addition amount of O is 1100 mg / L, the addition amount of hydrogen peroxide is 825 mg / L, and the addition amount of polyacrylamide is 2.0 mg / L. After treatment, the COD of wastewater cr It is 180mg / L, and the color is 280C.U. While adopting the conventional Fenton treatment method, the COD of the wastewater after treatment cr Between 230-260mg / L, the chromaticity is 400-480C.U., and the processing cost is relatively high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com