A kind of natural pulp production method for improving pulp whiteness

A production method and pulping technology, applied in papermaking, textiles and papermaking, pulping with organic solvents, etc., can solve the problems of low whiteness, low whiteness of natural pulp, environmental pollution of natural pulp, etc., and achieve the effect of improving whiteness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

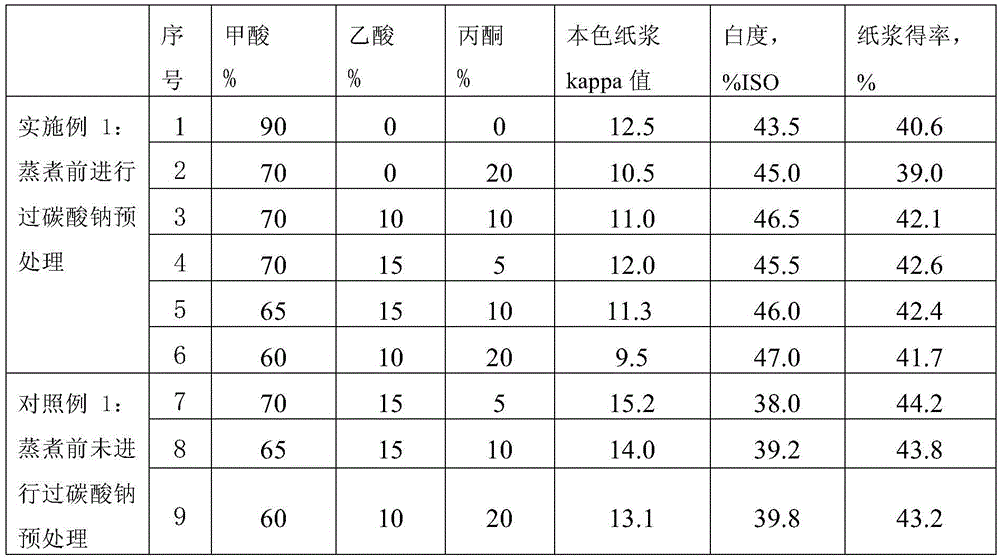

[0042] Embodiment 1, poplar wood raw material system natural color pulp

[0043] Poplar wood is cut into wood chips with a size of about 30mm×4mm×2mm, first pretreated with sodium percarbonate, the pretreatment conditions are: 2.5% sodium percarbonate, 1.0% sodium hydroxide, pentasodium diethyltriaminepentaacetate 0.2%, add water, liquid ratio 1:6, pretreatment temperature 110°C, time 90min. After pretreatment, it is washed with hot water at 60-80° C., and then concentrated to a dryness of 45 wt%. Then carry out organic solvent cooking, the liquid ratio is 1:8, the cooking conditions are: the organic solvent concentration (v / v) in the cooking liquid is 90%, the balance is water; the temperature is 135°C, and the time is 30min. The organic solvent is a combination of formic acid, acetic acid and acetone, wherein the concentration (%, volume ratio) of formic acid, acetic acid and acetone is changed, respectively numbered 1-6. After cooking, the pulp is washed with formic acid ...

Embodiment 2

[0049] Embodiment 2, natural color paper pulp of bamboo raw material system

[0050] Bamboo is cut into bamboo slices with a size of about 25×3.5mm×1.8mm, firstly pretreated with sodium percarbonate, the treatment conditions are: 3.0% sodium percarbonate, 1.0% sodium hydroxide, diethyltriaminepentaacetic acid penta Sodium 0.2%, add water, liquid ratio 1:8, temperature 120°C, time 90min. Carry out washing after pretreatment, then carry out organic solvent cooking, cooking condition is: organic solvent concentration (v / v) 85% in the cooking liquid, wherein, the concentration (v / v) of formic acid, acetic acid and acetone is respectively 65%, 10% % and 10%, liquid ratio 1:8, temperature 140°C, time 40min. After cooking, the pulp is washed with formic acid at 80-85°C and hot water at 80-90°C. The kappa value of the obtained natural color pulp was 16.5, the brightness was 42.2%ISO, and the yield was 42.0%.

Embodiment 3

[0052] Embodiment 3, wheat straw raw material system natural color pulp

[0053] Cut the wheat straw into grass slices with a length of about 25mm, firstly use sodium percarbonate to pretreat, the pretreatment conditions are: 3.0% sodium percarbonate, 0.2% pentasodium diethyltriaminepentaacetate, add water, the liquid ratio is 1:7, The temperature is 125°C, and the pretreatment time is 90 minutes. Carry out washing after pretreatment, then carry out organic solvent cooking, cooking condition is: organic solvent concentration 85% (v / v) in the cooking liquor, wherein, formic acid concentration (v / v) 60%, acetic acid concentration (v / v) 10% %, acetone concentration (v / v) 15%, liquid ratio 1:8, temperature 130°C, time 30min. After cooking, the pulp is washed with formic acid at 80-85°C and hot water at 80-90°C. The kappa value of the obtained natural color pulp was 9.5, the brightness was 44.0%ISO, and the yield was 41.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com