Integrated fluidized catalytic oxidation tower and method for deeply treating wastewater by using same

A catalytic oxidation tower and catalytic oxidation technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of large amount of chemicals and high treatment costs, and reduce output , the effect of enhancement, the effect of increasing the efficiency of mass transfer and the rate of chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

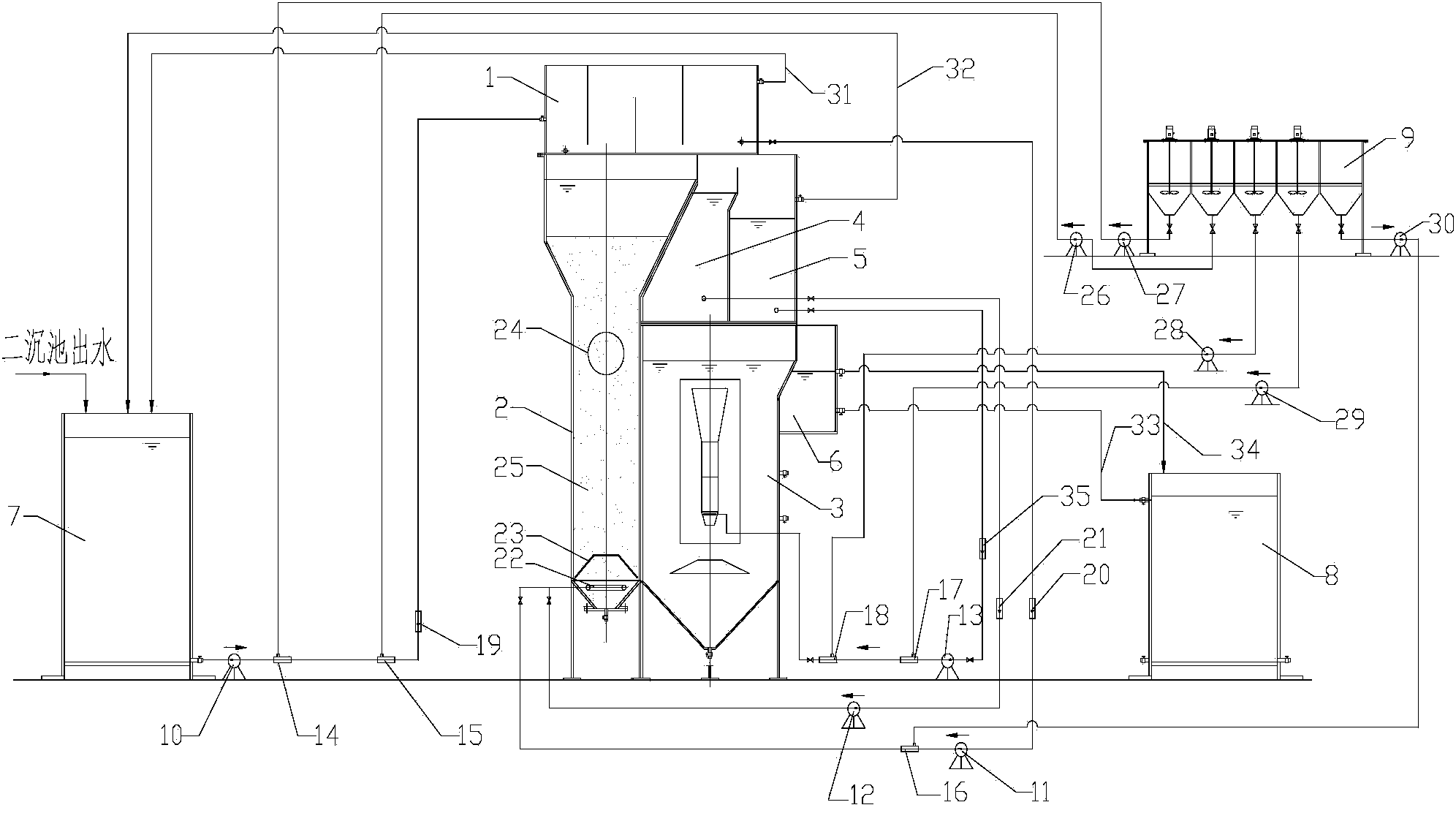

Embodiment 1

[0034] In this example, the integrated fluidized catalytic oxidation tower is used to treat the wastewater from the southern miscellaneous wood pulp D0 / C-(EO)PD1 bleaching wastewater after hydrolytic acidification and activated sludge treatment, and the COD of the wastewater cr 350mg / L, BOD 5 It is 55mg / L, and the color is 490C.U.

[0035] The method for treating waste water with an integrated fluidized catalytic oxidation tower comprises the following steps and process conditions:

[0036] 1) Equilibrium adjustment: the waste water in the sump 7 is transported to the equilibrium adjustment unit 1 at the top of the integrated fluidized catalytic oxidation tower through the first water pump 10, and is added in sequence through the first pipeline mixer 14 and the second pipeline mixer 15 at the same time h 2 SO 4 and FeSO 4 ·7H 2 O, the balance adjustment unit 1 is provided with several partitions separated from each other, and the waste water passes through each partition ...

Embodiment 2

[0043] This example is the same as Example 1 except for the following: the integrated fluidized catalytic oxidation tower is used to treat the wastewater produced by the papermaking process of reconstituted tobacco leaves of a certain tobacco sheet enterprise after being treated by UASB and SBR, and the COD of the wastewater cr It is 550mg / L, and chromaticity is 1900C.U.; In the present embodiment, by volume of waste water, FeSO 4 ·7H 2 The addition amount of O is 1375 mg / L, the addition amount of hydrogen peroxide is 825 mg / L, and the addition amount of polyacrylamide is 2.0 mg / L. After treatment, the COD of wastewater cr It is 190mg / L, and the color is 260C.U. While adopting the conventional Fenton treatment method, the COD of the wastewater after treatment cr Between 230-260mg / L, the chromaticity is 400-480C.U., and the processing cost is relatively high.

Embodiment 3

[0045] This example is the same as Example 1 except for the following: the integrated fluidized catalytic oxidation tower is used to treat the wastewater produced by the papermaking process of reconstituted tobacco leaves of a certain tobacco sheet enterprise after being treated by UASB and SBR, and the COD of the wastewater cr It is 550mg / L, and chromaticity is 1900C.U.; In the present embodiment, by volume of waste water, FeSO 4 ·7H 2 The addition amount of O is 825 mg / L, the addition amount of hydrogen peroxide is 1925 mg / L, and the addition amount of polyacrylamide is 1.0 mg / L. After treatment, the COD of wastewater cr It is 160mg / L, and the color is 220C.U. While adopting the conventional Fenton treatment method, the COD of the wastewater after treatment cr Between 230-260mg / L, the chromaticity is 400-480C.U., and the processing cost is relatively high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com