Method for dyeing denim yarn with natural indigo blue

A technology of natural indigo and yarn, applied in dyeing, textile and paper making, etc., can solve the problems of low affinity of leuco indigo to cotton fibers, poor color brightness, tedious manual operation, etc., to improve the utilization rate and Restoring power, dark color, water consumption reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

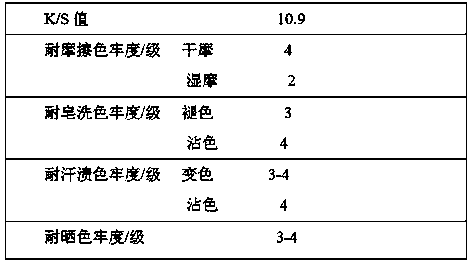

Embodiment 1

[0026] The method of utilizing natural indigo dyed denim yarn of the present embodiment, the steps are as follows:

[0027] (1) Dye pre-reduction: Put the natural indigo into a beaker, add a small amount of alcohol and water and mix thoroughly, then add water and stir to reach 1 / 3 of the total liquid volume. At this time, the concentration of natural indigo is 1.5g / L (equivalent to The concentration in the leuco dye solution is 0.5 g / L), adding sodium hydroxide 3g / L (equivalent to the concentration in the leuco dye solution is 1 g / L), sodium hydrochloride 1.5 g / L (equivalent to The concentration in the leuco dye solution is 0.5 g / L), the hydrosulfite stabilizer is 0.75 g / L (equivalent to the concentration in the leuco dye solution is 0.25 g / L), and it is used at 40°C The dye is fully reduced to obtain a leuco-body mother liquor; wherein the hydrosulfate stabilizer is made of the following components by weight: 40% glucose, 30% sodium hypophosphite, and the balance is anthraqui...

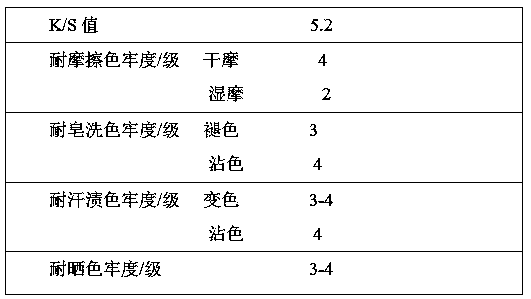

Embodiment 2

[0035] The method of utilizing natural indigo dyed denim yarn of the present embodiment, the steps are as follows:

[0036] (1) Dye pre-reduction: put natural indigo into a beaker, add a small amount of alcohol and water and mix thoroughly, then add water and stir to reach 1 / 3 of the total liquid volume. At this time, the concentration of natural indigo is 6g / L (equivalent to The concentration in the leuco dye solution is 2 g / L), adding sodium hydroxide 9g / L (equivalent to 3 g / L in the leuco dye solution), and 3.6 g / L hydrosulfite (equivalent to The concentration in the leuco dye solution is 1.2 g / L), the hydrosulfite stabilizer is 1.8 g / L (equivalent to the concentration in the leuco dye solution is 0.6 g / L), and the dye is made at 50°C Sufficient reduction to obtain leucosome mother liquor; wherein the hydrosulfate stabilizer is made of the following components by weight: 50% glucose, 40% sodium hypophosphite, and the balance is anthraquinone;

[0037] (2) Preparation of dy...

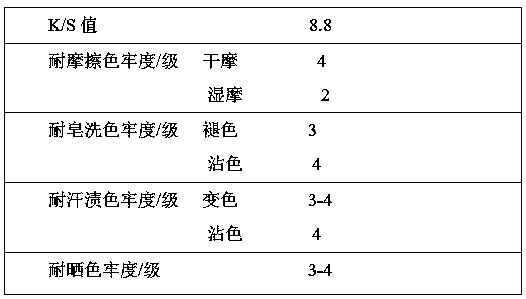

Embodiment 3

[0044] The method of utilizing natural indigo dyed denim yarn of the present embodiment, the steps are as follows:

[0045] (1) Dye pre-reduction: put natural indigo into a beaker, add a small amount of alcohol and water and mix thoroughly, then add water and stir to reach 1 / 3 of the total liquid volume. At this time, the concentration of natural indigo is 3.9g / L (equivalent to The concentration in the leuco dye solution is 1.3 g / L), adding sodium hydroxide 6g / L (equivalent to 2g / L in the leuco dye solution), and 2.4 g / L hydrosulfite (equivalent to The concentration in the leuco dye solution is 0.8 g / L), the hydrosulfite stabilizer is 1.2 g / L (equivalent to the concentration in the leuco dye solution is 0.4 g / L), and the dye is made at 45°C Sufficient reduction to obtain leucosome mother liquor; wherein the hydrosulfate stabilizer is made of the following components by weight ratio: 40% glucose, 40% sodium hypophosphite, and the balance is anthraquinone;

[0046] (2) Preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com