A kind of preparation method of molecular sieve photocatalyst for ceramic ink

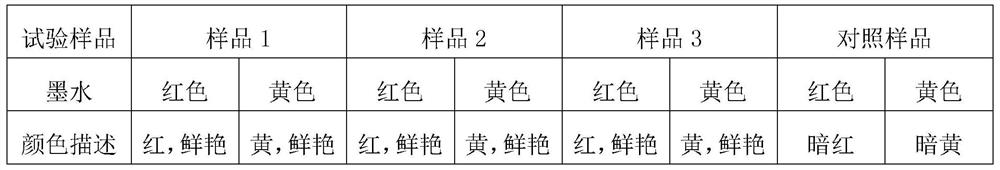

The technology of photocatalyst and ceramic ink is applied in the field of preparation of molecular sieve photocatalyst, which can solve the problems of darkening of colorant, no color development, photocatalytic performance to be improved, etc., and achieve the effect of improving color brightness and stable color development.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation of the molecular sieve photocatalyst for ceramic ink provided by the present embodiment is described as follows:

[0028] A preparation method for a molecular sieve photocatalyst for ceramic ink, comprising the following steps:

[0029] (1) Take lanthanum source, vanadium source and solvent respectively according to the mass volume ratio of lanthanum source, vanadium source and solvent in the ratio of 3g:4g:5ml, and mix the above materials to obtain system I, wherein the lanthanum source is Lanthanum nitrate, the vanadium source is vanadium tetrachloride, and the solvent is water; under vigorous stirring at a stirring speed of 1700r / min, the obtained system I is slowly added dropwise to nitric acid with a pH of 4 and a temperature of 50°C Hydrolysis in the solution to obtain system II, keeping the volume ratio of the total mass of lanthanum source and vanadium source to water in system II at 1:15, and hydrothermally reacting in an autoclave at 120°C for ...

Embodiment 2

[0035] The preparation of the molecular sieve photocatalyst for ceramic ink provided by the present embodiment is described as follows:

[0036] A preparation method for a molecular sieve photocatalyst for ceramic ink, comprising the following steps:

[0037] (1) Take lanthanum source, vanadium source and solvent respectively according to the mass volume ratio of lanthanum source, vanadium source and solvent in the ratio of 4g:5g:7ml, and mix the above materials to obtain system I, wherein the lanthanum source is A mixture of lanthanum chloride and lanthanum acetate mixed in any proportion, the vanadium source is vanadium oxalate, and the solvent is an aqueous organic acid solution; under vigorous stirring at a stirring speed of 1800r / min, the obtained system I is slowly added dropwise Hydrolyze in a nitric acid solution with a pH of 5 and a temperature of 65°C to obtain System II, keep the volume ratio of the total mass of lanthanum source and vanadium source to the water in ...

Embodiment 3

[0043] The preparation of the molecular sieve photocatalyst for ceramic ink provided by the present embodiment is described as follows:

[0044] A preparation method for a molecular sieve photocatalyst for ceramic ink, comprising the following steps:

[0045] (1) Take lanthanum source, vanadium source and solvent respectively according to the mass volume ratio of lanthanum source, vanadium source and solvent in the ratio of 5g:6g:8ml, and mix the above materials to obtain system I, wherein the lanthanum source is A mixture of lanthanum nitrate, lanthanum chloride and lanthanum acetate mixed in any proportion, the vanadium source is a mixture of vanadium tetrachloride and vanadium oxalate mixed in any proportion, and the solvent is an aqueous organic acid solution; the stirring speed is 1900r / min Under vigorous stirring, the obtained system I was slowly added dropwise to a nitric acid solution with a pH of 6 and a temperature of 80°C for hydrolysis to obtain a system II, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com