In-situ surface-enhanced Raman spectroscopy system and application thereof

A surface-enhanced Raman and spectroscopic system technology, applied in the field of spectroelectrochemistry, can solve the problems of single surface-enhanced Raman substrate and inability to modify electrodes, and achieve good photocatalytic performance, good light transmission performance, and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) TiO 2 Preparation of NTs / Ti electrode: Grind the titanium plate and sonicate for five minutes according to water, ethanol, and water respectively, at V(HCl):V(H 2 (O)=1:1 etch for 10min until the solution turns purple. then in NH 4 F is oxidized at a constant potential (30V) in an ethylene glycol solution, and after cleaning, it is heated in a tube furnace at 500°C for 3 hours to obtain TiO 2 array of nanotubes.

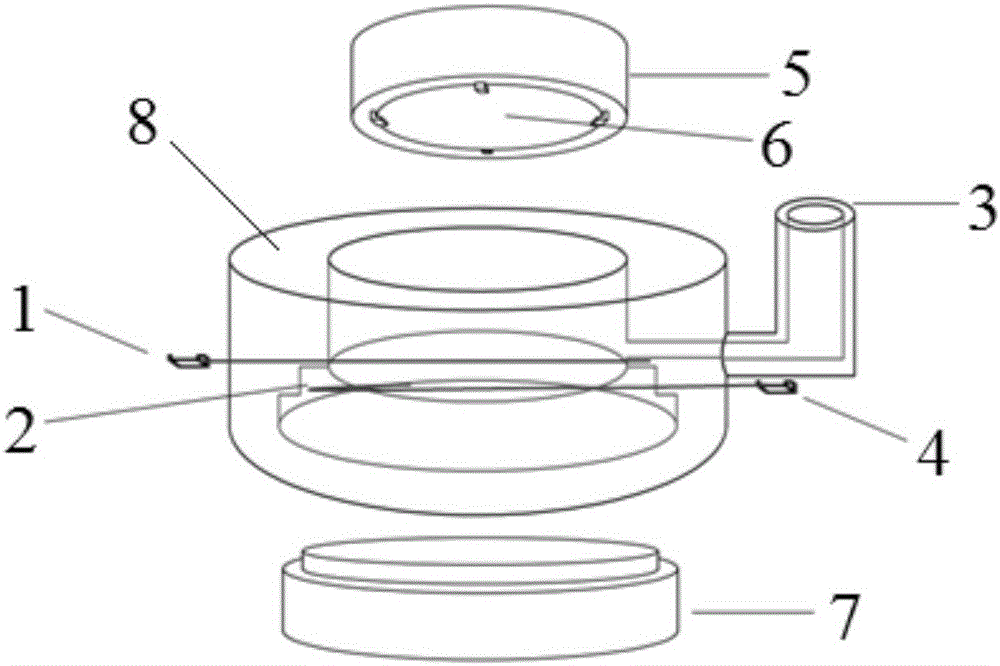

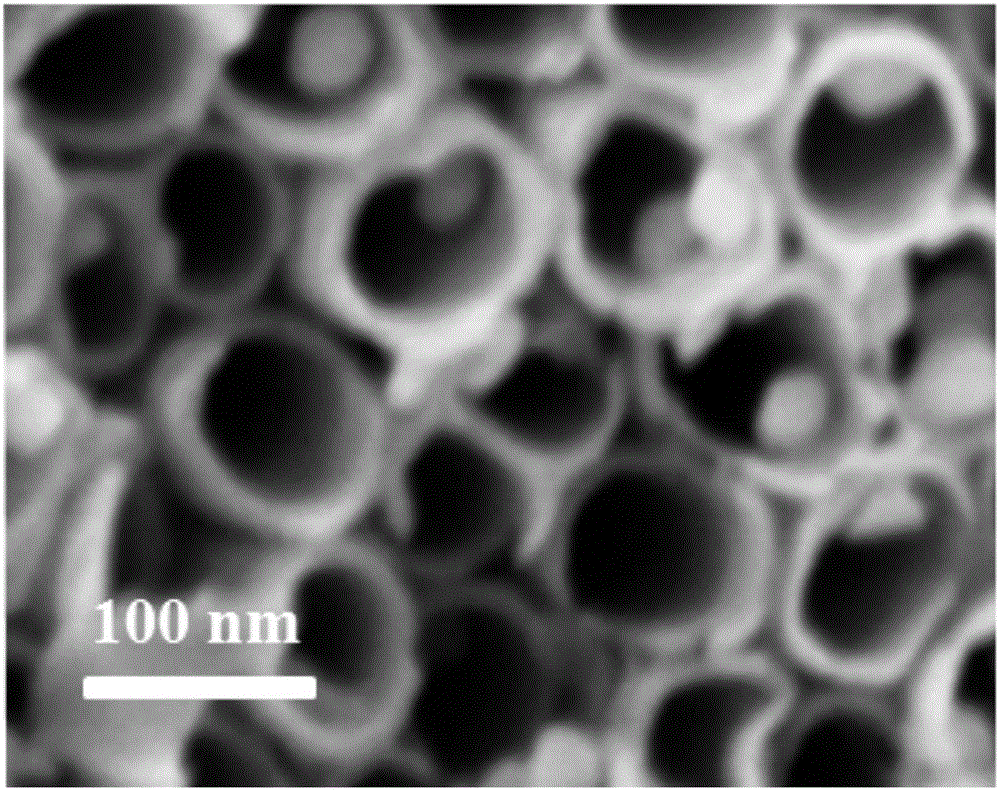

[0037] 2) Preparation of AuNPs / TiO by cyclic voltammetry 2 On NTs / Ti electrode: Potential -0.9V~0V, Pt wire as counter electrode, saturated calomel electrode as reference electrode, AuNPs / TiO 2 NTs / Ti is the working electrode, at 2mmol L -1 HAuCl 4 and 0.1mol L -1 Preparation of AuNPs / TiO by Cycling Different Numbers of Cycles in KCl Solution 2 NTs / Ti electrode, the final cycle of 15 cycles can get the electrode with good photocatalytic performance and surface-enhanced Raman performance. The scanning electron microscope picture is as follows figur...

Embodiment 2

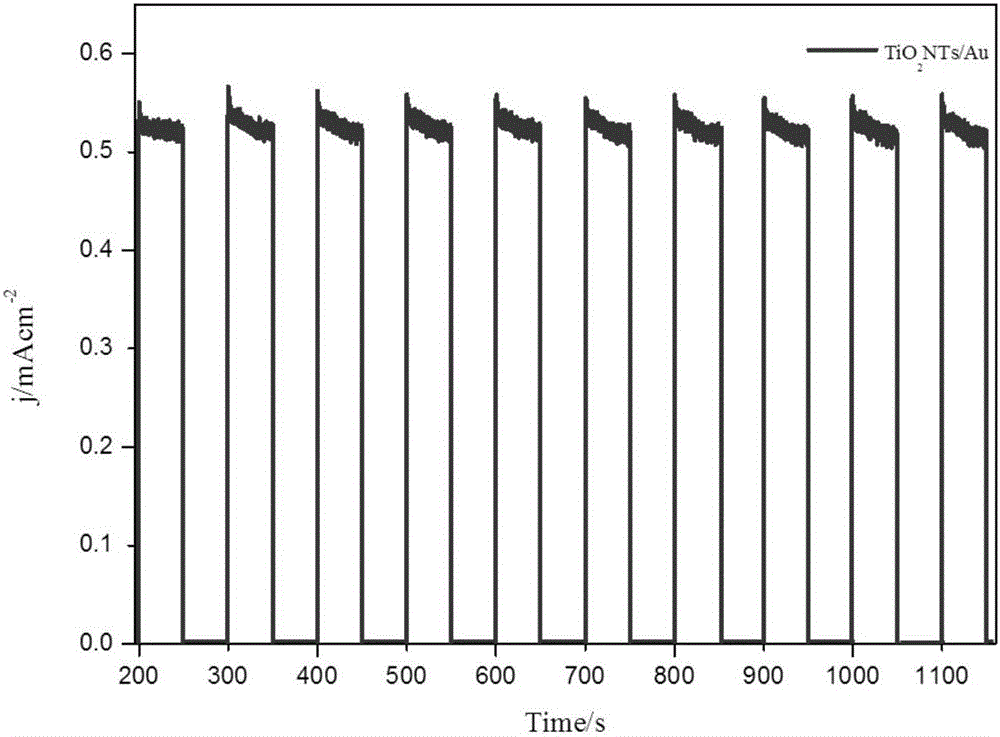

[0040] Prepare AuNPs / TiO in Example 1 2 NTs / Ti electrode, in-situ photocatalytic degradation of organic pollutant p-nitroaniline on the electrode surface: Take 2mL containing 0.1mol L -1 Na 2 SO 4 Electrolyte, the concentration is 10 -4 mol L -1 The aqueous solution of p-nitroaniline is injected into the electrolytic cell through the reference adapter. Using Pt wire as the counter electrode, AuNPs / TiO 2 The NTs / Ti electrode is used as the anode, and the Ag / AgCl electrode is used as the reference electrode. The effective photoanode area is 4.5cm 2 , adjust the Raman spectrometer to focus on the electrode surface. Under the irradiation of ultraviolet light with a wavelength of 365nm and a power of 5W, a bias voltage of 0.6V was applied to continuously measure the surface-enhanced Raman spectrum of the degradation process of p-nitroaniline, and analyze its presence in AuNPs / TiO 2 Photocatalytic degradation process on NTs / Ti electrode surface. From Figure 4 It can be se...

Embodiment 3

[0042] Take 2mL concentration as 10 -4 mol L -1 The p-nitroaniline solution is injected into the electrolytic cell through the reference adapter. Using Pt wire as the counter electrode, AuNPs / TiO 2 The NTs / Ti electrode is used as the anode, and the Ag / AgCl electrode is used as the reference electrode. The effective photoanode area is 4.5cm 2 , adjust the Raman spectrometer to focus on the electrode surface. Under the irradiation of ultraviolet light with a wavelength of 365nm and a power of 5W, the surface-enhanced Raman spectrum of the degradation process of p-nitroaniline was continuously measured, and its concentration in AuNPs / TiO 2 Photocatalytic degradation process on NTs / Ti electrode surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com