Method for preparing high molecular fluorescent microballoons

A fluorescent microsphere and polymer technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of changing the properties of fluorescent substances, changing fluorescent substances, difficult chemical reactions, etc., and achieves high repeatability, low price, and high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

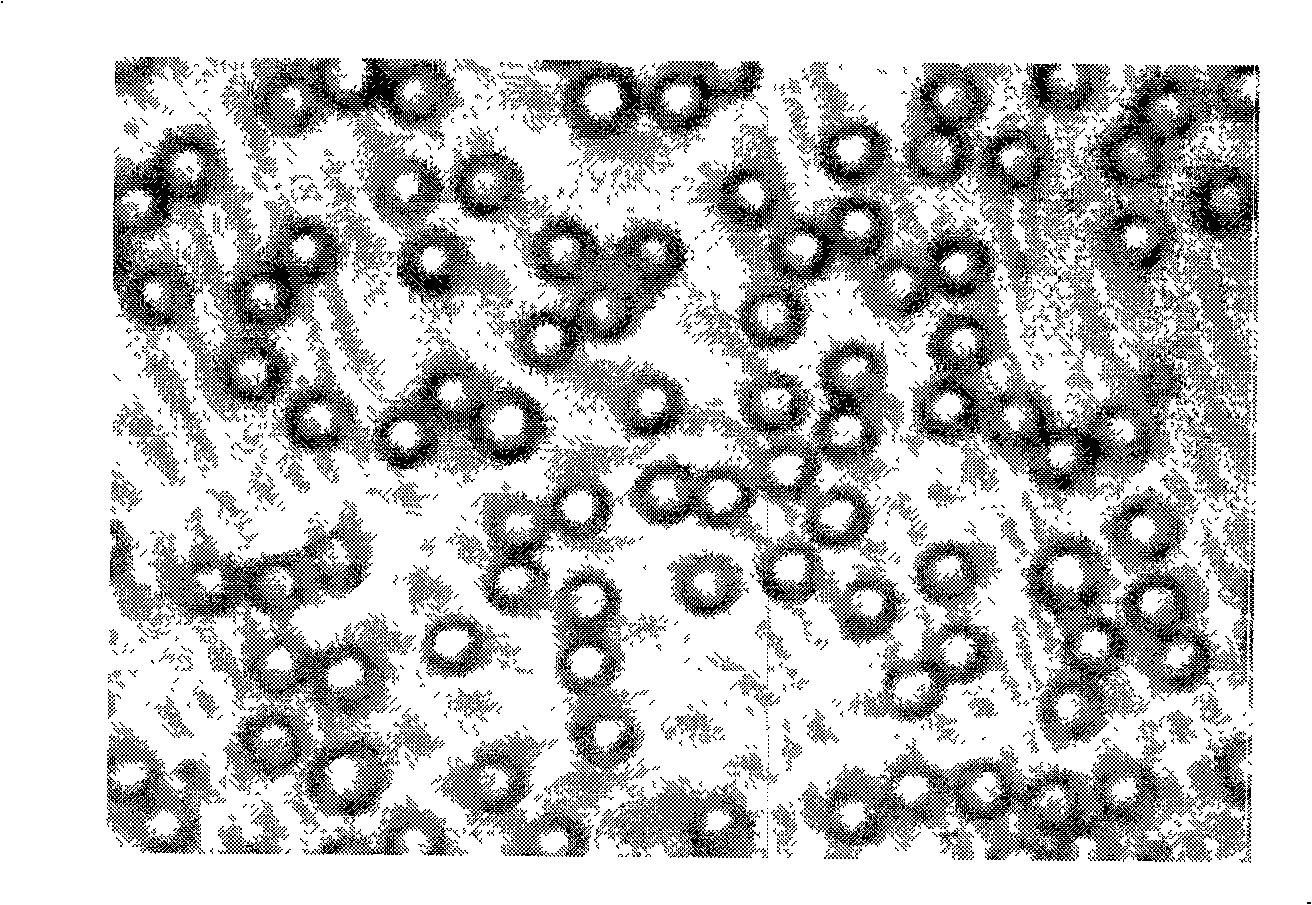

Image

Examples

Embodiment 1

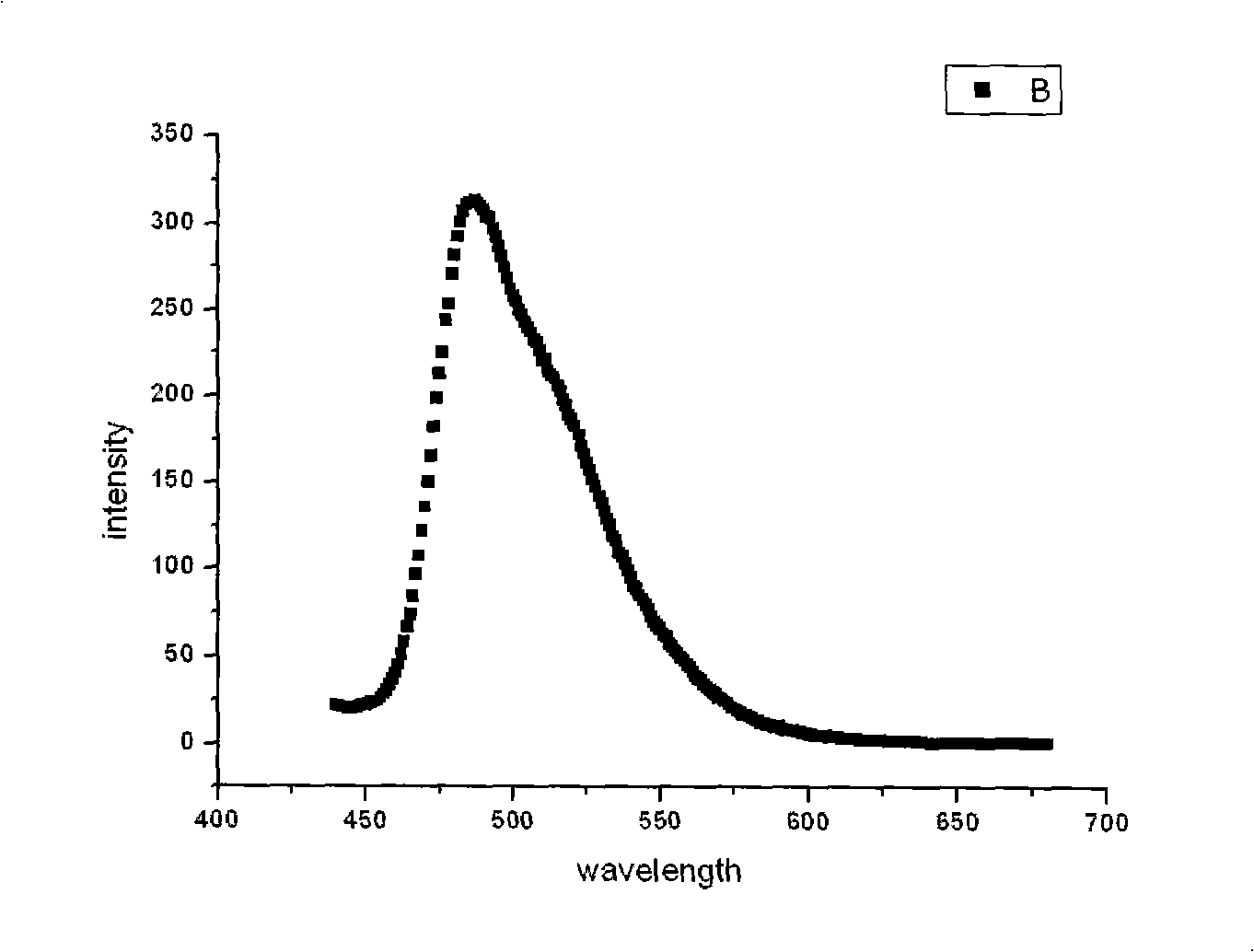

[0034] Embodiment 1: Preparation of polymer fluorescent (coumarin 6) microspheres

[0035] (1) Prepare a stabilizer solution; in an argon atmosphere, add the dispersion stabilizer polyvinylpyrrolidone to the polar medium ethanol, and the mass ratio of the dispersion stabilizer to the polar medium is 1 / 65;

[0036] (2) Prepare the monomer solution; in argon gas, add the initiator azodiethylbutyrocyanide and fluorescein coumarin 6 into the monomer styrene at a temperature of -5°C, and achieve a homogeneous phase by ultrasonic oscillation to obtain In the monomer solution, the mass ratio of the fluorescein to the initiator is 1 / 75, and the mass ratio of the sum of the initiator and the fluorescein to the monomer is 1 / 30;

[0037] (3) Stirring reaction; in an argon atmosphere, the monomer solution is added to the stabilizer solution, the stirring speed is 50 rpm, at a temperature of 70°C, the reaction is for 12 hours, the mass ratio of the monomer solution and the stabilizer solut...

Embodiment 2

[0040]Embodiment 2: Preparation of polymer fluorescent (rhodamine 6G) microspheres

[0041] (1) Prepare a stabilizer solution; in a nitrogen atmosphere, add the dispersion stabilizer polyoxyethylene to the polar medium methanol, and the mass ratio of the dispersion stabilizer to the polar medium is 1 / 130;

[0042] (2) Prepare the monomer solution; in nitrogen gas, add the initiator benzoyl peroxide and fluorescein rhodamine 6G into the monomer methyl methacrylate at a temperature of 10°C, and achieve a homogeneous phase by ultrasonic oscillation to obtain a single Body solution, the mass ratio of fluorescein and initiator is 7 / 50, and the mass ratio of the sum of initiator and fluorescein to the monomer is 1 / 90;

[0043] (3) stirring reaction; in nitrogen atmosphere, monomer solution is joined in the stabilizer solution, stirring speed is 500 rev / mins, at 40 ℃ of temperature, reaction 24 hours, the mass ratio of monomer solution and stabilizer solution is 1 / 9;

[0044] (4) c...

Embodiment 3

[0046] Example 3: Preparation of polymer fluorescent (coumarin 6 / rhodamine 6G=1 / 2) microspheres

[0047] (1) Prepare a stabilizer solution; in a mixed atmosphere of argon and nitrogen, the dispersion stabilizer polyethylene glycol is added to the mixed solution of polar medium ethanol and water, the mass ratio of ethanol to water is 25 / 1, and the dispersion is stable The mass ratio of agent and polar medium is 1 / 85;

[0048] (2) Prepare the monomer solution; in the mixed gas of argon and nitrogen, add the mixture of initiator azodiethylbutyronitrile and fluorescein coumarin 6 and rhodamine 6G in the monomer methacrylic acid, coumarin The mass ratio of 6 and rhodamine 6G is 1 / 2, the temperature is 5°C, and the homogeneous phase is obtained by ultrasonic oscillation, and the monomer solution is obtained. The mass ratio of fluorescein and initiator is 1 / 50, and the two kinds of initiator and fluorescein The mass ratio of the sum of substances to the monomer is 1 / 30;

[0049] (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com