DTY dual-color terylene silk for denim warp thread

A denim and polyester yarn technology, applied in rayon manufacturing, adding pigments to spinning solution, textiles and papermaking, etc., can solve problems such as harsh production environment, large waste of dyestuffs, waste water pollution, etc., and achieve high-grade product quality , to ensure clean and environmentally friendly, no environmental hazards effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

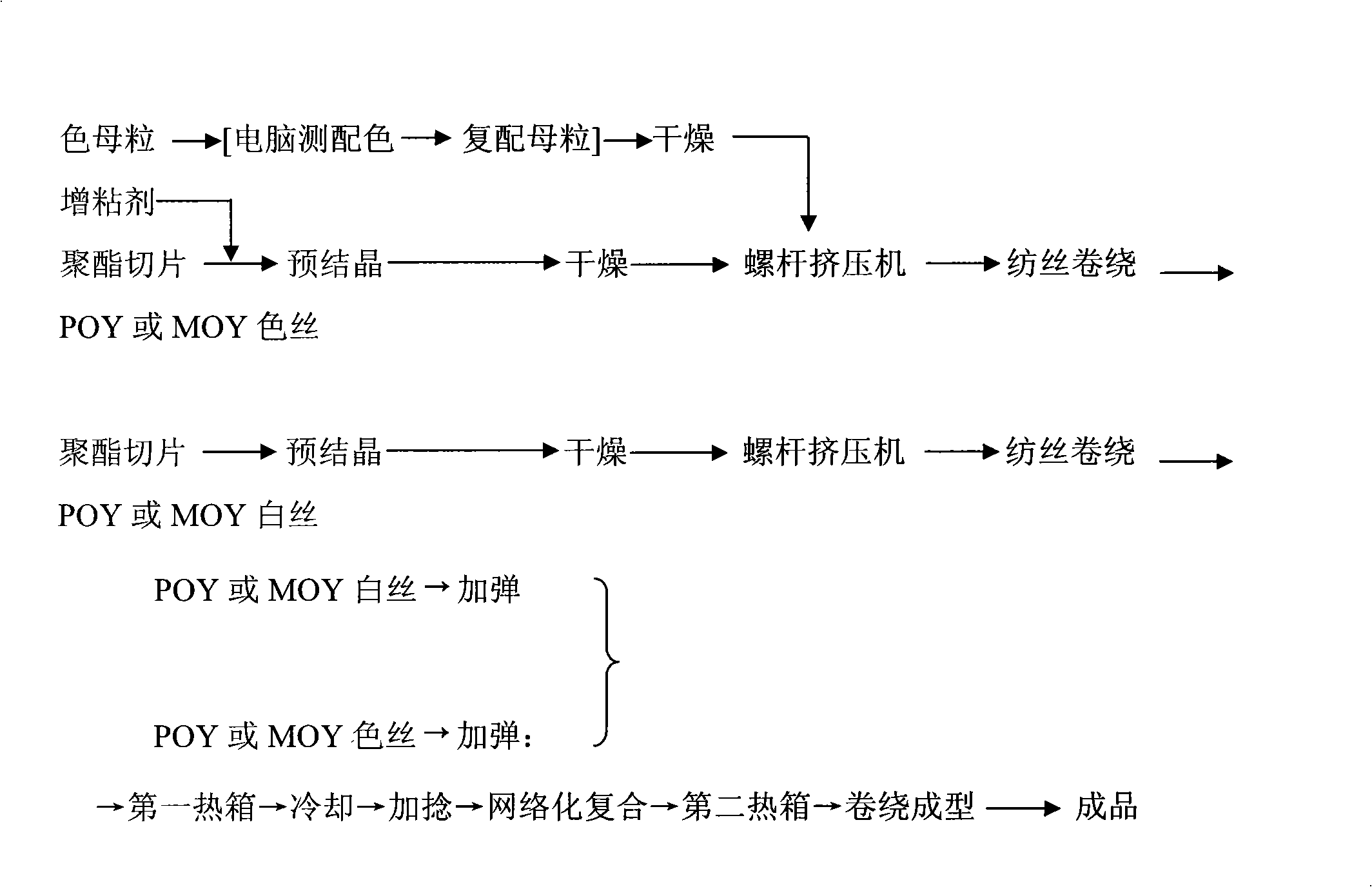

[0019] A kind of DTY two-color polyester yarn for denim warp is prepared by following steps:

[0020] (1) The color masterbatch is measured and matched by computer, and dried to obtain a composite color masterbatch;

[0021] (2) adding a tackifier to the polyester chip, pre-crystallizing, drying, and then adding the compound color masterbatch of step (1) to a screw extruder, spinning and winding to obtain POY or MOY colored yarn;

[0022] (3) The polyester chip is pre-crystallized, dried, and then enters the screw extruder for spinning and winding to obtain POY or MOY white silk;

[0023] (4) POY or MOY colored yarn and POY or MOY white yarn are processed through differential tension control, frequency conversion, overfeeding and texturing, and networked two-color composite processing to obtain DTY two-color polyester yarn for denim warp.

[0024] In step (2): the added amount of the tackifier is controlled at 20%-25% of the weight of the polyester chip; the dried polyester c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com