Preparation method and application of nano-limited-range photocatalytic hydrogel

A nano-confinement and hydrogel technology, applied in the field of nano-materials, can solve problems such as uneven structure and disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

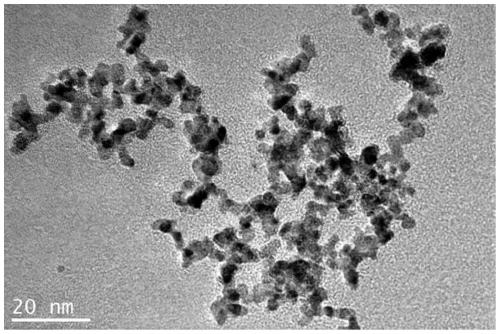

[0039] Embodiment 1: Preparation of metal nanomaterial dispersion liquid

[0040] Add 2.48mL of hexachloroplatinic acid solution with a concentration of 0.25mol / L and 1.028g of polyvinylpyrrolidone into a 250mL round bottom flask, then dilute to 50mL with deionized water, stir and mix evenly; then accurately weigh 352mg of boron Sodium hydride, dissolved in 30mL of water, was slowly added dropwise into the round-bottomed flask under uniform stirring at a uniform speed, and then continued to stir at a constant speed for 1 hour after the dropwise addition, to obtain a metal nanomaterial dispersion with a particle shape.

Embodiment 2

[0042] 1. Surface modification of metal nanomaterials

[0043] To the metal nanomaterial dispersion with a concentration of 0.0078 mol / L and a zero-dimensional particle shape prepared in Step 1 of Example 1, add allylthiol, a functional modifier with a mass of 0.006% of the total mass of the metal nanomaterial dispersion, Thoroughly stir and uniformly ultrasonically mix for 5 minutes at room temperature to obtain a surface-modified noble metal nanomaterial dispersion.

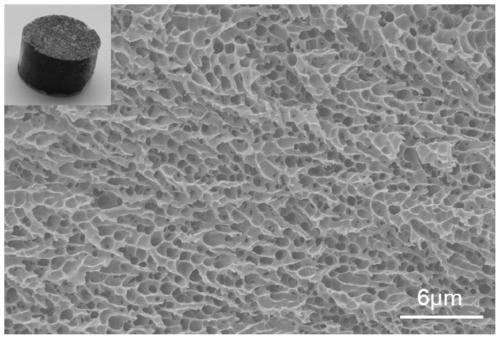

[0044] 2. Dissolution of hydrophilic monomers and initiators and preparation of hydrogels

[0045] To the surface-modified noble metal nanomaterial dispersion obtained in step 1, add hydrophilic monomer acrylamide accounting for 20% of the total mass of the noble metal nanomaterial dispersion and 0.3% of the total mass of the noble metal nanomaterial dispersion Initiator persulfuric acid Ammonium, fully stirred at room temperature and ultrasonically mixed for 20 minutes, nitrogen was introduced for 10 minutes,...

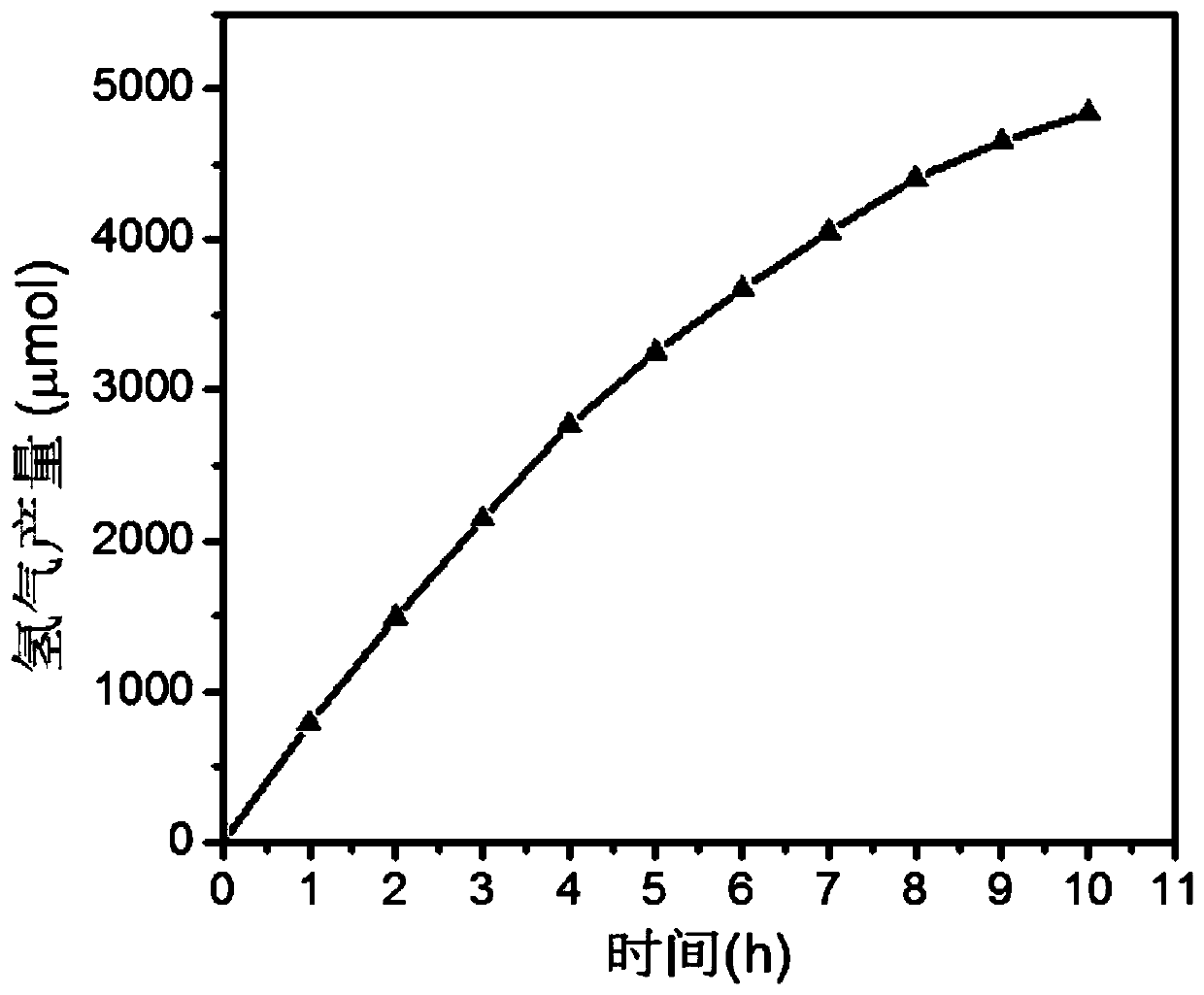

Embodiment 3

[0048] 1. Surface modification of metal nanomaterials

[0049] To the metal nanomaterial dispersion with a concentration of 0.0078 mol / L and a zero-dimensional particle shape prepared in Step 1 of Example 1, add allylthiol, a functional modifier with a mass of 0.006% of the total mass of the metal nanomaterial dispersion, Thoroughly stir and uniformly ultrasonically mix for 5 minutes at room temperature to obtain a surface-modified noble metal nanomaterial dispersion.

[0050] 2. Dissolution of hydrophilic monomers, initiators and accelerators

[0051] To the surface-modified noble metal nanomaterial dispersion obtained in step 1, add hydrophilic monomer acrylamide accounting for 20% of the total mass of the noble metal nanomaterial dispersion, and 0.3% of the initiator persulfuric acid accounting for the total mass of the noble metal nanomaterial dispersion ammonium, fully stirred at room temperature and ultrasonically mixed for 20 minutes, nitrogen gas was introduced for 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com